YAMAHA TDR 125 2000 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2000, Model line: TDR 125, Model: YAMAHA TDR 125 2000Pages: 104, PDF Size: 4.88 MB

Page 51 of 104

6-6

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

1

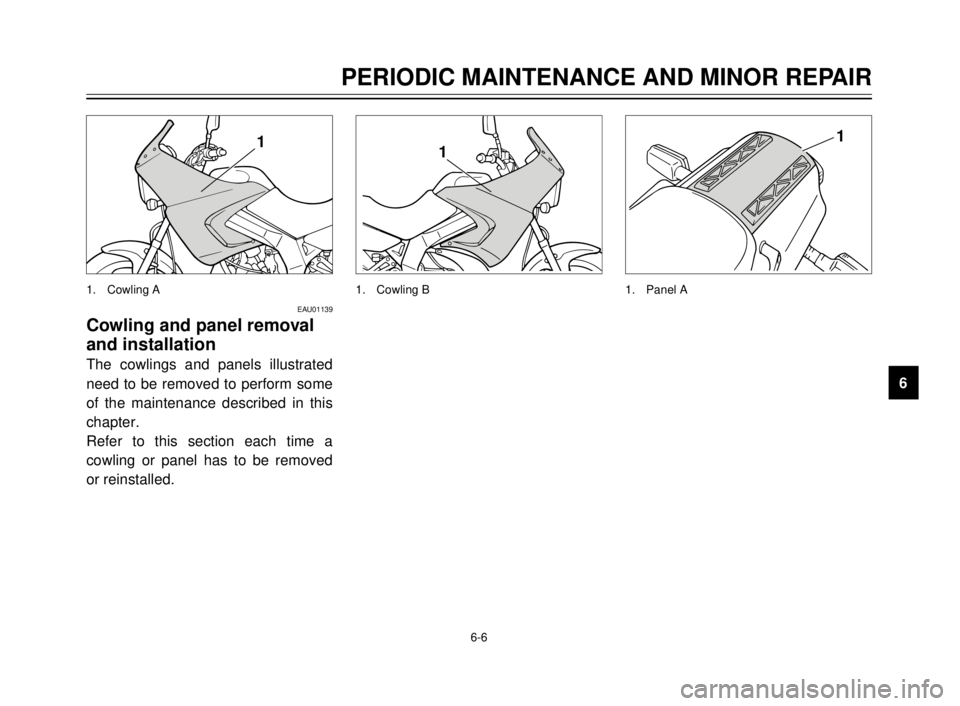

1. Cowling B

1

1. Panel A

EAU01139

Cowling and panel removal

and installation

The cowlings and panels illustrated

need to be removed to perform some

of the maintenance described in this

chapter.

Refer to this section each time a

cowling or panel has to be removed

or reinstalled.

1

1. Cowling A

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 49

Page 52 of 104

6-7

2

1

1

12

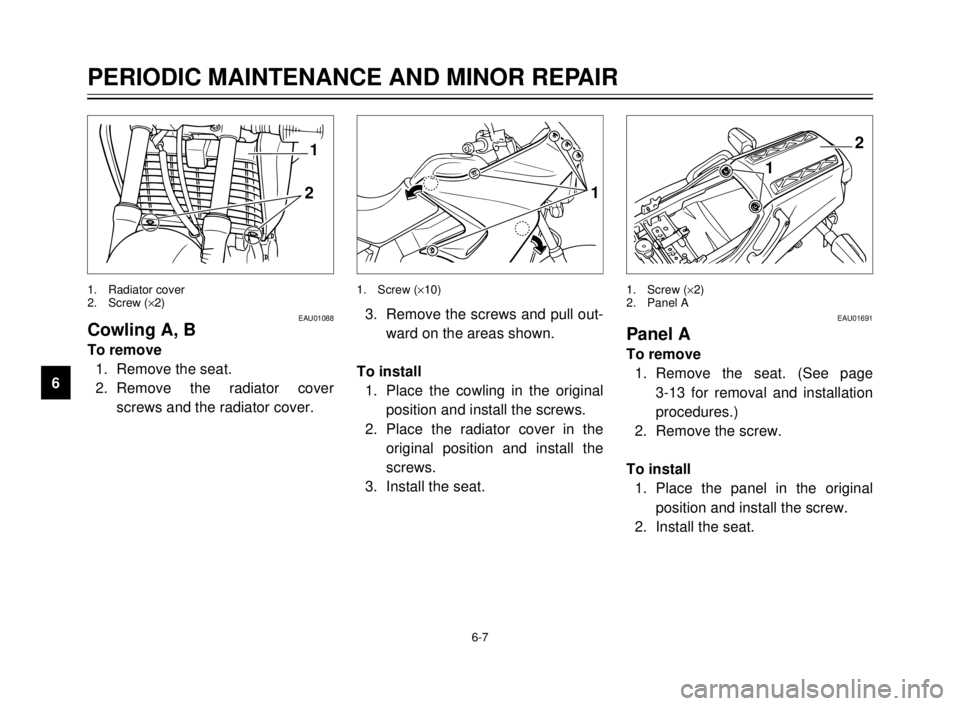

EAU01088Cowling A, B

To remove

1. Remove the seat.

2. Remove the radiator cover

screws and the radiator cover.

1. Radiator cover

2. Screw (´2)1. Screw (´10) 1. Screw (´2)

2. Panel A

3. Remove the screws and pull out-

ward on the areas shown.

To install

1. Place the cowling in the original

position and install the screws.

2. Place the radiator cover in the

original position and install the

screws.

3. Install the seat.EAU01691

Panel A

To remove

1. Remove the seat. (See page

3-13 for removal and installation

procedures.)

2. Remove the screw.

To install

1. Place the panel in the original

position and install the screw.

2. Install the seat.

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 50

Page 53 of 104

6-8

1

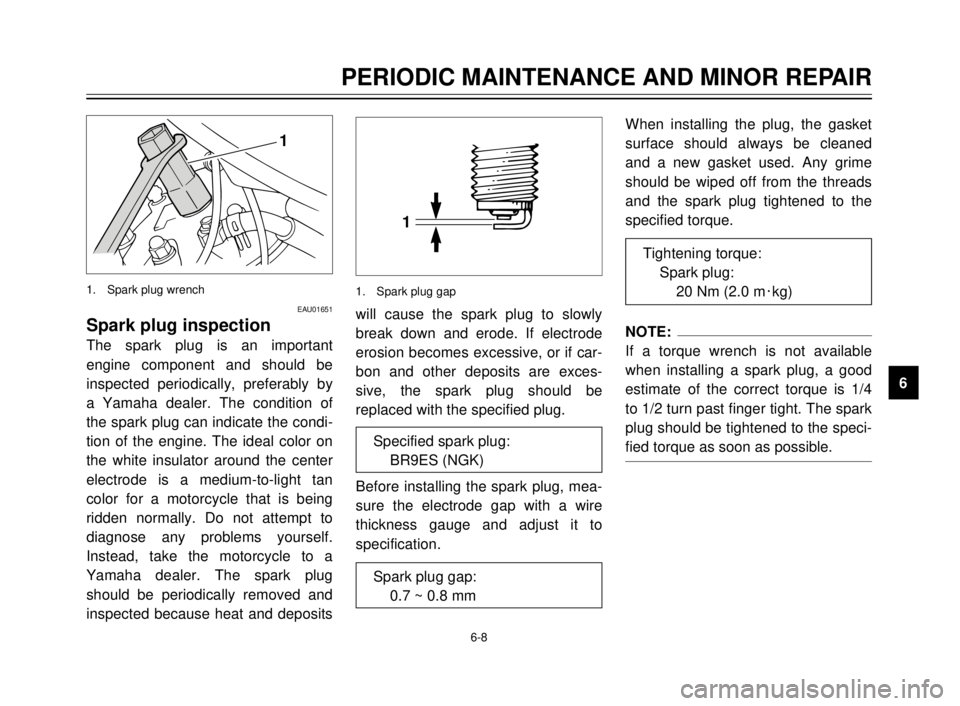

EAU01651

Spark plug inspection

The spark plug is an important

engine component and should be

inspected periodically, preferably by

a Yamaha dealer. The condition of

the spark plug can indicate the condi-

tion of the engine. The ideal color on

the white insulator around the center

electrode is a medium-to-light tan

color for a motorcycle that is being

ridden normally. Do not attempt to

diagnose any problems yourself.

Instead, take the motorcycle to a

Yamaha dealer. The spark plug

should be periodically removed and

inspected because heat and depositswill cause the spark plug to slowly

break down and erode. If electrode

erosion becomes excessive, or if car-

bon and other deposits are exces-

sive, the spark plug should be

replaced with the specified plug.

Before installing the spark plug, mea-

sure the electrode gap with a wire

thickness gauge and adjust it to

specification.When installing the plug, the gasket

surface should always be cleaned

and a new gasket used. Any grime

should be wiped off from the threads

and the spark plug tightened to the

specified torque.NOTE:

If a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4

to 1/2 turn past finger tight. The spark

plug should be tightened to the speci-

fied torque as soon as possible.

1. Spark plug wrench

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9 Specified spark plug:

BR9ES (NGK)

Spark plug gap:

0.7 ~ 0.8 mm

Tightening torque:

Spark plug:

20 Nm (2.0 m0kg)

1

1. Spark plug gap

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 51

Page 54 of 104

6-9

1

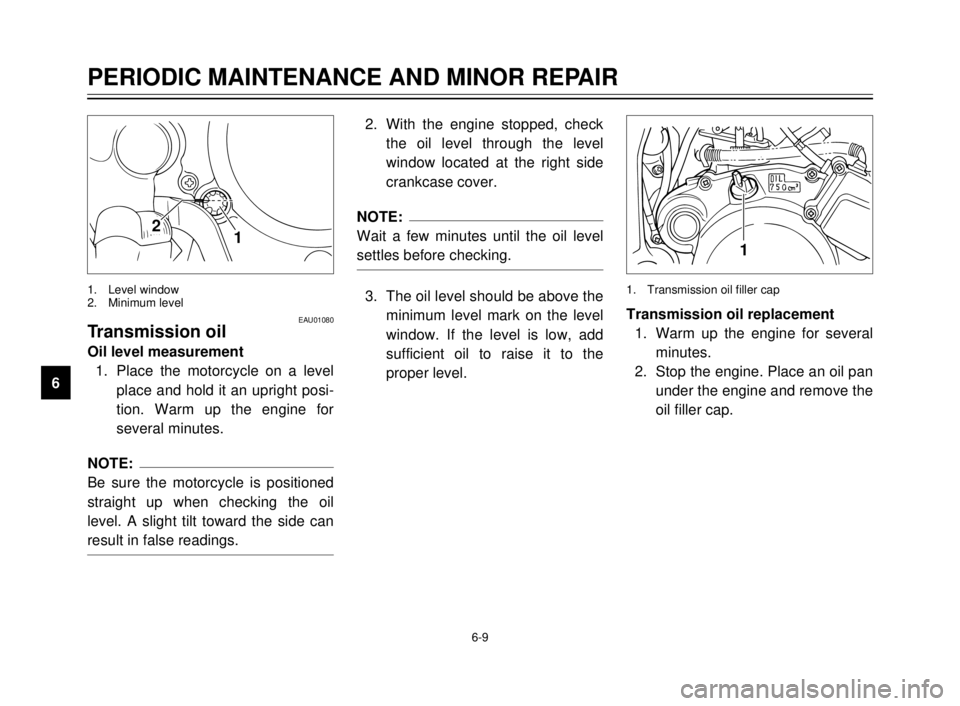

1. Transmission oil filler cap

2. With the engine stopped, check

the oil level through the level

window located at the right side

crankcase cover.

NOTE:

Wait a few minutes until the oil level

settles before checking.

3. The oil level should be above the

minimum level mark on the level

window. If the level is low, add

sufficient oil to raise it to the

proper level.Transmission oil replacement

1. Warm up the engine for several

minutes.

2. Stop the engine. Place an oil pan

under the engine and remove the

oil filler cap.

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

12

EAU01080Transmission oil

Oil level measurement

1. Place the motorcycle on a level

place and hold it an upright posi-

tion. Warm up the engine for

several minutes.

NOTE:

Be sure the motorcycle is positioned

straight up when checking the oil

level. A slight tilt toward the side can

result in false readings.

1. Level window

2. Minimum level

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 52

Page 55 of 104

6-10

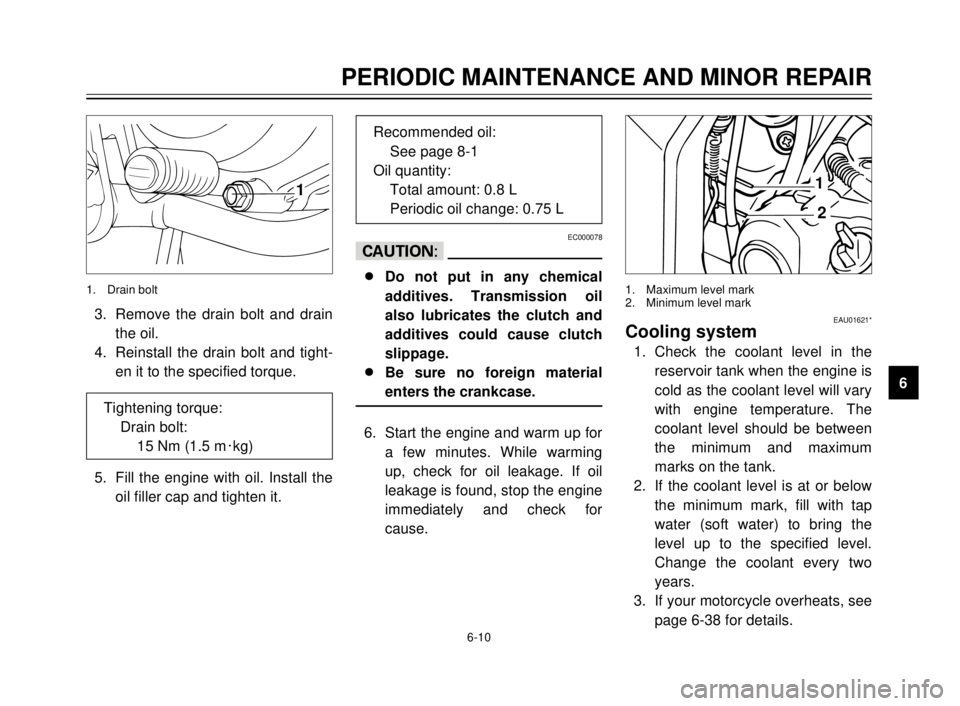

1

3. Remove the drain bolt and drain

the oil.

4. Reinstall the drain bolt and tight-

en it to the specified torque.

5. Fill the engine with oil. Install the

oil filler cap and tighten it.

EC000078

cC

8

8

Do not put in any chemical

additives. Transmission oil

also lubricates the clutch and

additives could cause clutch

slippage.

8 8

Be sure no foreign material

enters the crankcase.

6. Start the engine and warm up for

a few minutes. While warming

up, check for oil leakage. If oil

leakage is found, stop the engine

immediately and check for

cause.

1. Drain bolt

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9 Tightening torque:

Drain bolt:

15 Nm (1.5 m0kg)

Recommended oil:

See page 8-1

Oil quantity:

Total amount: 0.8 L

Periodic oil change: 0.75 L

1

2

1. Maximum level mark

2. Minimum level mark

EAU01621*Cooling system

1. Check the coolant level in the

reservoir tank when the engine is

cold as the coolant level will vary

with engine temperature. The

coolant level should be between

the minimum and maximum

marks on the tank.

2. If the coolant level is at or below

the minimum mark, fill with tap

water (soft water) to bring the

level up to the specified level.

Change the coolant every two

years.

3. If your motorcycle overheats, see

page 6-38 for details.

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 53

Page 56 of 104

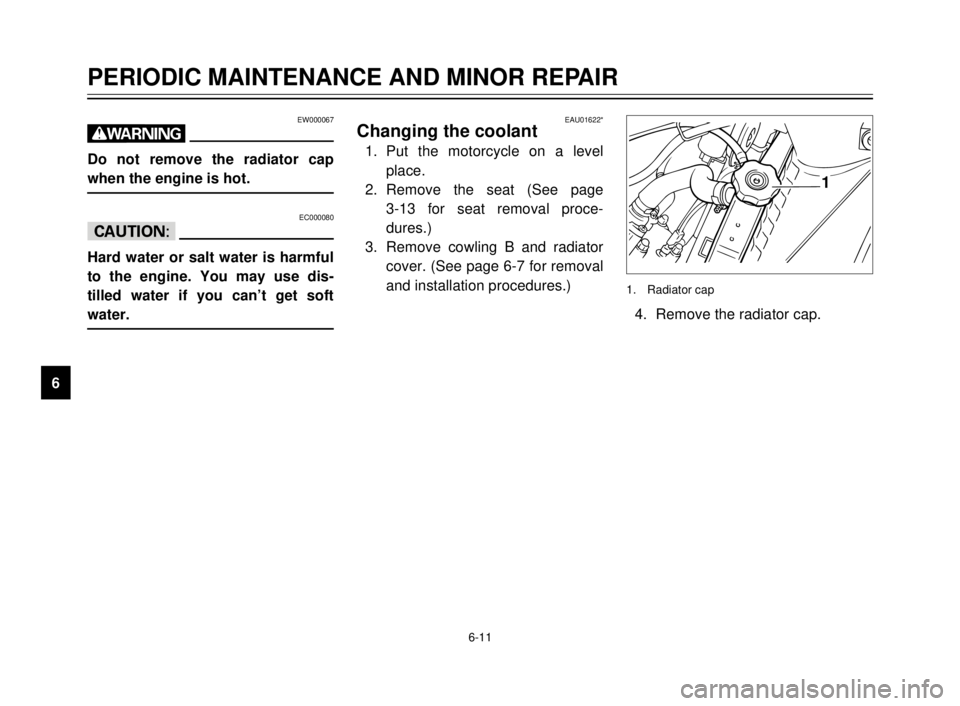

EAU01622*Changing the coolant

1. Put the motorcycle on a level

place.

2. Remove the seat (See page

3-13 for seat removal proce-

dures.)

3. Remove cowling B and radiator

cover. (See page 6-7 for removal

and installation procedures.)

6-11

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

94. Remove the radiator cap.

EW000067

w

Do not remove the radiator cap

when the engine is hot.

EC000080

cC

Hard water or salt water is harmful

to the engine. You may use dis-

tilled water if you can’t get soft

water.

1

1. Radiator cap

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 54

Page 57 of 104

6-12

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

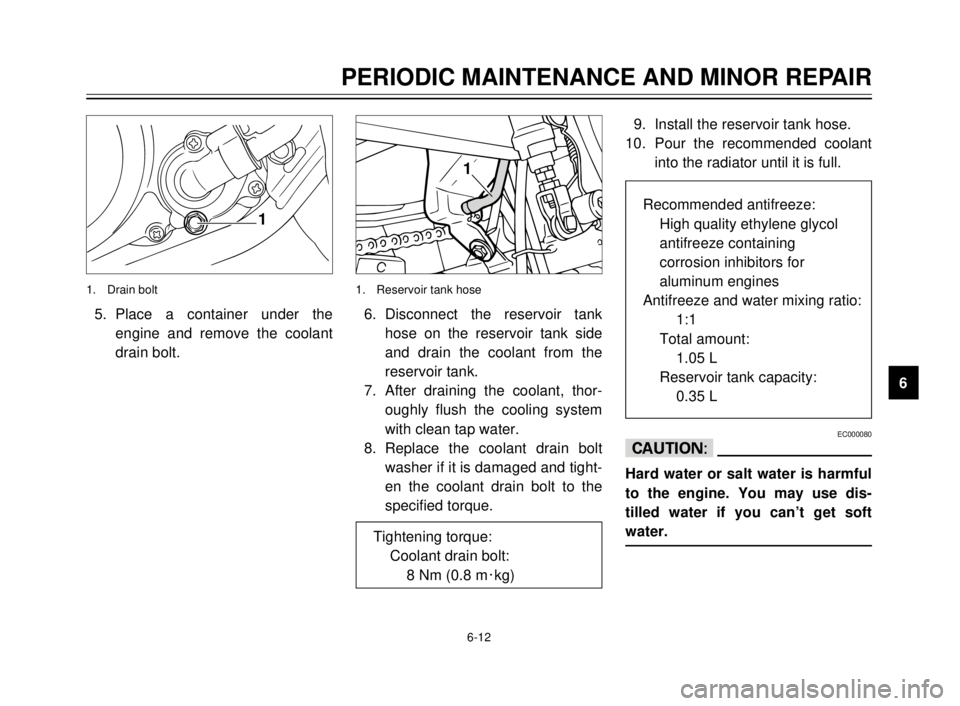

1

5. Place a container under the

engine and remove the coolant

drain bolt.

1. Drain bolt

1

6. Disconnect the reservoir tank

hose on the reservoir tank side

and drain the coolant from the

reservoir tank.

7. After draining the coolant, thor-

oughly flush the cooling system

with clean tap water.

8. Replace the coolant drain bolt

washer if it is damaged and tight-

en the coolant drain bolt to the

specified torque.

1. Reservoir tank hose

Tightening torque:

Coolant drain bolt:

8 Nm (0.8 m0kg)

9. Install the reservoir tank hose.

10. Pour the recommended coolant

into the radiator until it is full.

EC000080

cC

Hard water or salt water is harmful

to the engine. You may use dis-

tilled water if you can’t get soft

water.

Recommended antifreeze:

High quality ethylene glycol

antifreeze containing

corrosion inhibitors for

aluminum engines

Antifreeze and water mixing ratio:

1:1

Total amount:

1.05 L

Reservoir tank capacity:

0.35 L

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 55

Page 58 of 104

6-13

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

2

1

4

5

3

1. Reservoir tank cap

2. Stopper

3. Stopper bolt

4. Maximum level mark

5. Minimum level mark

11. Install the radiator cap.

12. Run the engine several minutes.

Stop the engine and recheck the

coolant level in the radiator. If it

is low, add more coolant until it

reaches the top of the radiator.

13. Fill the reservoir tank with

coolant up to specified level.

14. Install the reservoir tank cap and

check for coolant leakage.

NOTE:

If any leakage is found, ask a

Yamaha dealer to inspect the cooling

sytem.

15. Install the cowling, radiator cover

and the seat.

1

EAU01476*Air filter

The air filter should be cleaned at the

specified intervals. It should be

cleaned more frequently if you are

riding in unusually wet or dusty

areas.

1. Remove the seat.

2. Remove cowling A and B. (See

page 6-7 for cowling removal

and installation steps.)

3. Remove the fuel tank bolt.

4. Lift the front of the fuel tank

upward and position it away from

the air filter case. (Do not

remove the fuel hoses.)

1. Bolt

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 56

Page 59 of 104

6-14

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

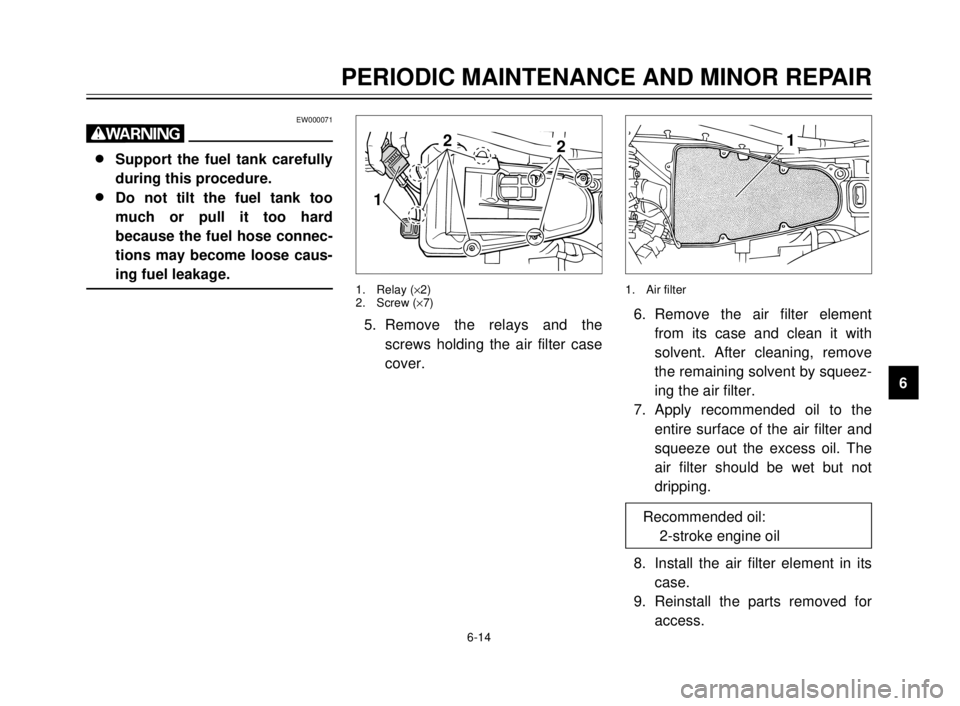

EW000071

w

8 8

Support the fuel tank carefully

during this procedure.

8 8

Do not tilt the fuel tank too

much or pull it too hard

because the fuel hose connec-

tions may become loose caus-

ing fuel leakage.

1

2

2

1. Relay (´2)

2. Screw (´7)

5. Remove the relays and the

screws holding the air filter case

cover.

1

1. Air filter

6. Remove the air filter element

from its case and clean it with

solvent. After cleaning, remove

the remaining solvent by squeez-

ing the air filter.

7. Apply recommended oil to the

entire surface of the air filter and

squeeze out the excess oil. The

air filter should be wet but not

dripping.

8. Install the air filter element in its

case.

9. Reinstall the parts removed for

access. Recommended oil:

2-stroke engine oil

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 57

Page 60 of 104

6-15

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

EC000082

cC

8

8

Make sure the air filter is prop-

erly seated in the air filter

case.

8 8

The engine should never be

run without the air filter

installed. Excessive piston

and/or cylinder wear may

result.

EW000131

w

Make sure that the fuel hoses and

vacuum hose are properly con-

nected, in place and not pinched. If

a hose is damaged, be sure to

replace it.

EAU00629Carburetor adjustment

The carburetor is a vital part of the

engine and requires very sophisticat-

ed adjustment. Most adjustments

should be left to a Yamaha dealer

who has the professional knowledge

and experience to do so. However,

the following may be serviced by the

owner as part of routine mainte-

nance.

EC000094

cC

The carburetor was set at the

Yamaha factory after many tests. If

the settings are changed, poor

engine performance and damage

may result.

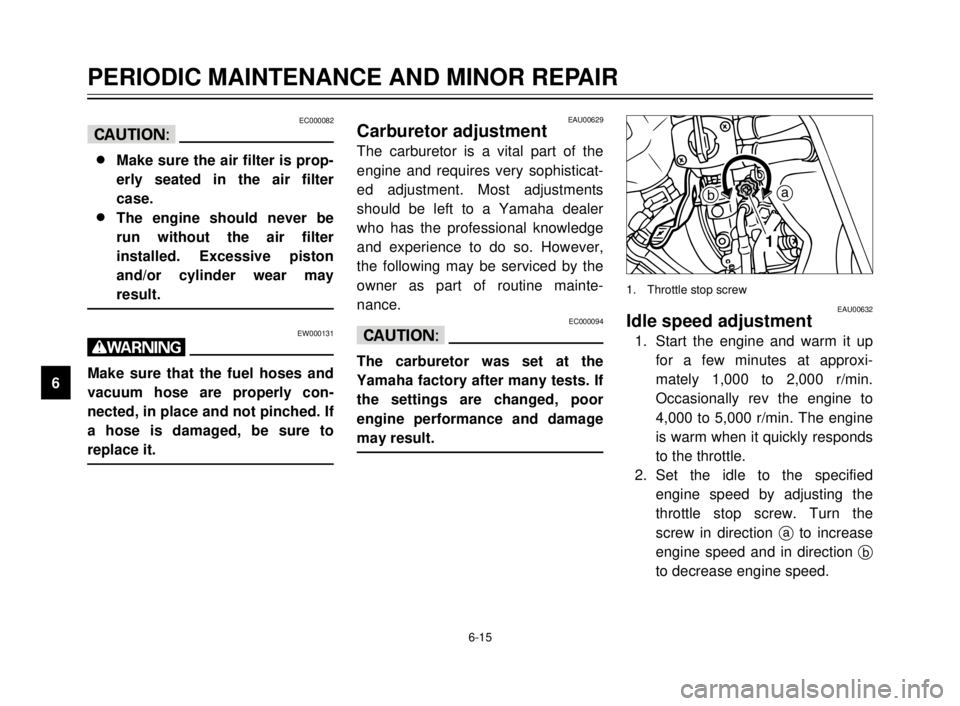

ba

1

EAU00632Idle speed adjustment

1. Start the engine and warm it up

for a few minutes at approxi-

mately 1,000 to 2,000 r/min.

Occasionally rev the engine to

4,000 to 5,000 r/min. The engine

is warm when it quickly responds

to the throttle.

2. Set the idle to the specified

engine speed by adjusting the

throttle stop screw. Turn the

screw in direction ato increase

engine speed and in direction b

to decrease engine speed.

1. Throttle stop screw

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 58