YAMAHA TDR 125 2000 Repair Manual

Manufacturer: YAMAHA, Model Year: 2000, Model line: TDR 125, Model: YAMAHA TDR 125 2000Pages: 104, PDF Size: 4.88 MB

Page 61 of 104

6-16

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

NOTE:

If the specified idle speed cannot be

obtained by performing the above

adjustment, consult a Yamaha deal-

er.

Standard idle speed:

1,300 ~ 1,500 r/min

1,400 ~ 1,500 r/min

(A, CH only)

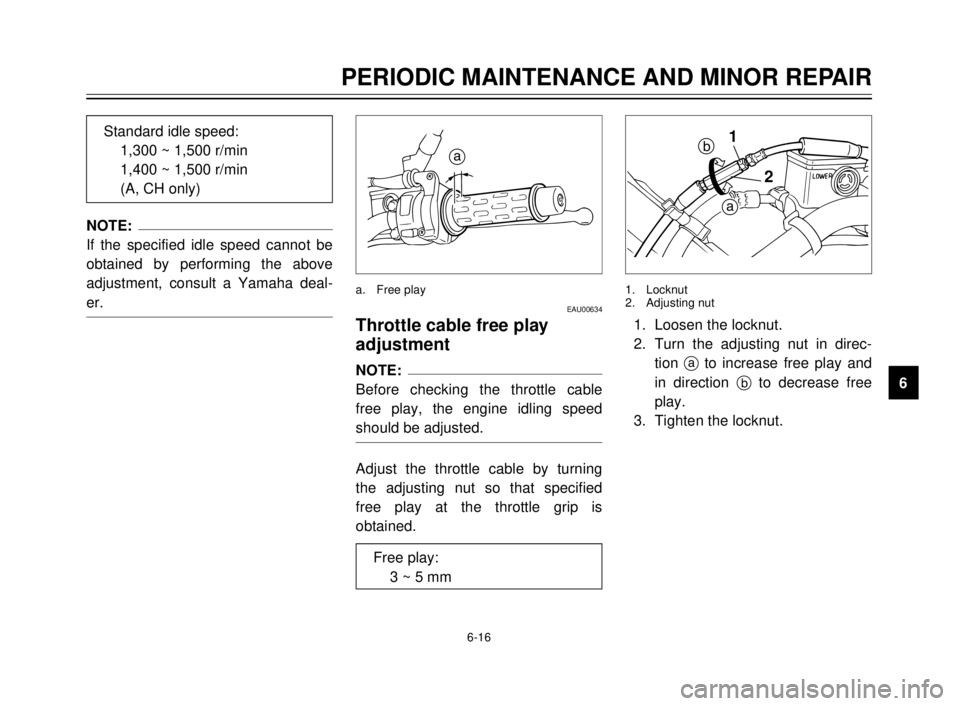

EAU00634

Throttle cable free play

adjustment

NOTE:

Before checking the throttle cable

free play, the engine idling speed

should be adjusted.

Adjust the throttle cable by turning

the adjusting nut so that specified

free play at the throttle grip is

obtained.

a. Free play

a

Free play:

3 ~ 5 mm

2 1

b

a

1. Loosen the locknut.

2. Turn the adjusting nut in direc-

tion ato increase free play and

in direction bto decrease free

play.

3. Tighten the locknut.

1. Locknut

2. Adjusting nut

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 59

Page 62 of 104

6-17

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

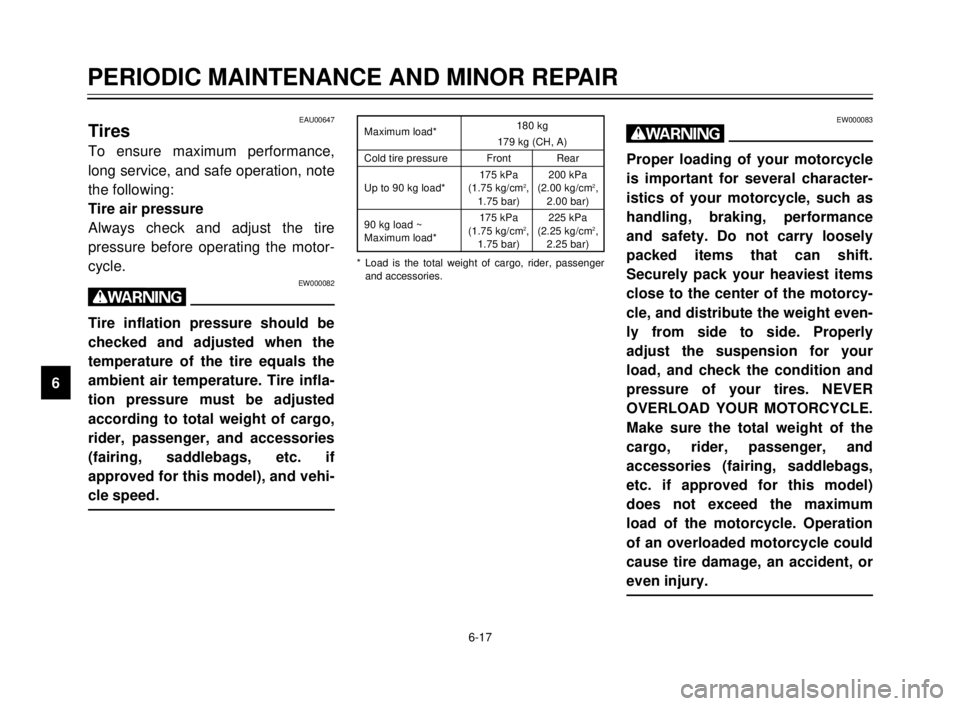

EAU00647Tires

To ensure maximum performance,

long service, and safe operation, note

the following:

Tire air pressure

Always check and adjust the tire

pressure before operating the motor-

cycle.

EW000082

w

Tire inflation pressure should be

checked and adjusted when the

temperature of the tire equals the

ambient air temperature. Tire infla-

tion pressure must be adjusted

according to total weight of cargo,

rider, passenger, and accessories

(fairing, saddlebags, etc. if

approved for this model), and vehi-

cle speed.

* Load is the total weight of cargo, rider, passenger

and accessories. Maximum load*180 kg

179 kg (CH, A)

Cold tire pressure Front Rear

175 kPa 200 kPa

Up to 90 kg load* (1.75 kg/cm

2, (2.00 kg/cm2,1.75 bar) 2.00 bar)

90 kg load ~175 kPa 225 kPa

Maximum load*(1.75 kg/cm

2, (2.25 kg/cm2,

1.75 bar) 2.25 bar)

EW000083

w

Proper loading of your motorcycle

is important for several character-

istics of your motorcycle, such as

handling, braking, performance

and safety. Do not carry loosely

packed items that can shift.

Securely pack your heaviest items

close to the center of the motorcy-

cle, and distribute the weight even-

ly from side to side. Properly

adjust the suspension for your

load, and check the condition and

pressure of your tires. NEVER

OVERLOAD YOUR MOTORCYCLE.

Make sure the total weight of the

cargo, rider, passenger, and

accessories (fairing, saddlebags,

etc. if approved for this model)

does not exceed the maximum

load of the motorcycle. Operation

of an overloaded motorcycle could

cause tire damage, an accident, or

even injury.

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 60

Page 63 of 104

6-18

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

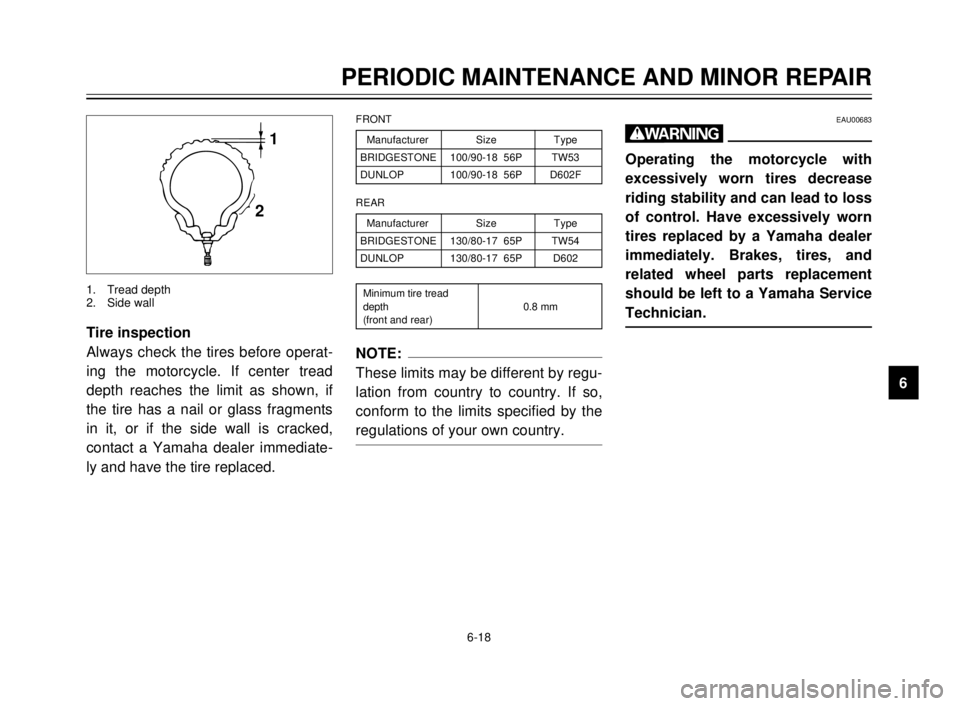

9 Tire inspection

Always check the tires before operat-

ing the motorcycle. If center tread

depth reaches the limit as shown, if

the tire has a nail or glass fragments

in it, or if the side wall is cracked,

contact a Yamaha dealer immediate-

ly and have the tire replaced.

1

2

1. Tread depth

2. Side wall

NOTE:

These limits may be different by regu-

lation from country to country. If so,

conform to the limits specified by the

regulations of your own country.

Manufacturer Size Type

BRIDGESTONE 100/90-18 56P TW53

DUNLOP 100/90-18 56P D602F

FRONT

Manufacturer Size Type

BRIDGESTONE 130/80-17 65P TW54

DUNLOP 130/80-17 65P D602

REAR

Minimum tire tread

depth 0.8 mm

(front and rear)

EAU00683

w

Operating the motorcycle with

excessively worn tires decrease

riding stability and can lead to loss

of control. Have excessively worn

tires replaced by a Yamaha dealer

immediately. Brakes, tires, and

related wheel parts replacement

should be left to a Yamaha Service

Technician.

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 61

Page 64 of 104

6-19

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

EAU00687Wheels

To ensure maximum performance,

long service, and safe operation, note

the following:

8Always inspect the wheels

before a ride. Check for cracks,

bends, or warpage of the wheels.

If any abnormal condition exists

in a wheel, consult a Yamaha

dealer. Do not attempt even

small repairs to the wheel. If a

wheel is deformed or cracked, it

must be replaced.

8Tires and wheels should be bal-

anced whenever either one is

changed or replaced. Failure to

have a wheel balanced can

result in poor performance,

adverse handling characteristics,

and shortened tire life.

8Ride at moderate speeds after

changing a tire since the tire sur-

face must first be broken in for it

to develop its optimal character-

istics.

a

b12 3

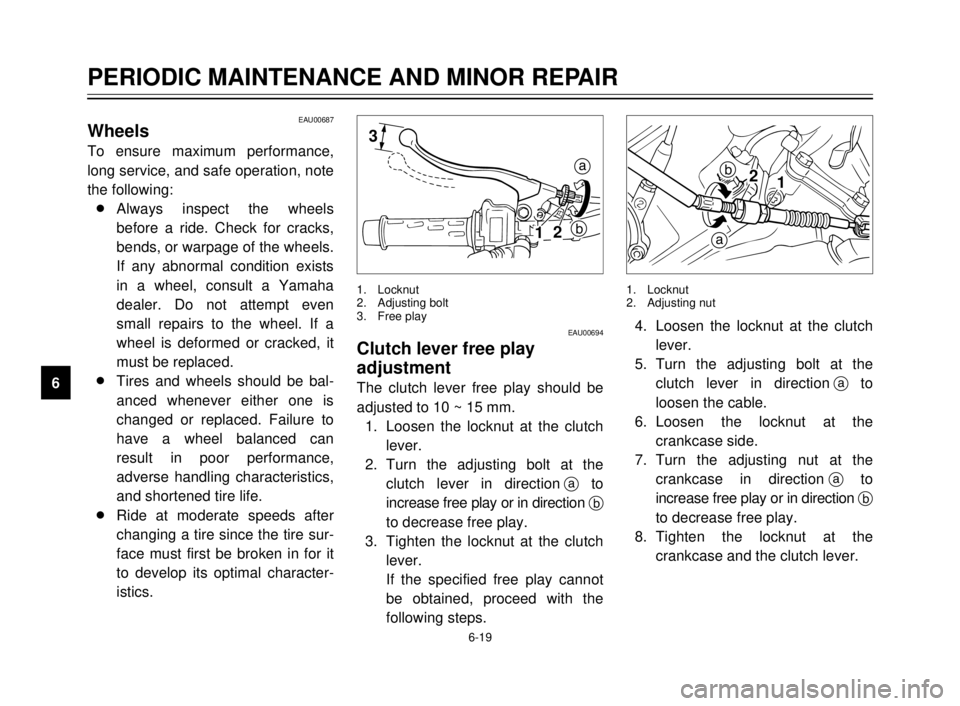

EAU00694

Clutch lever free play

adjustment

The clutch lever free play should be

adjusted to 10 ~ 15 mm.

1. Loosen the locknut at the clutch

lever.

2. Turn the adjusting bolt at the

clutch lever in directionato

increase free play or in direction b

to decrease free play.

3. Tighten the locknut at the clutch

lever.

If the specified free play cannot

be obtained, proceed with the

following steps.

1. Locknut

2. Adjusting bolt

3. Free play

b

a

12

4. Loosen the locknut at the clutch

lever.

5. Turn the adjusting bolt at the

clutch lever in directionato

loosen the cable.

6. Loosen the locknut at the

crankcase side.

7. Turn the adjusting nut at the

crankcase in directionato

increase free play or in direction b

to decrease free play.

8. Tighten the locknut at the

crankcase and the clutch lever.

1. Locknut

2. Adjusting nut

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 62

Page 65 of 104

6-20

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

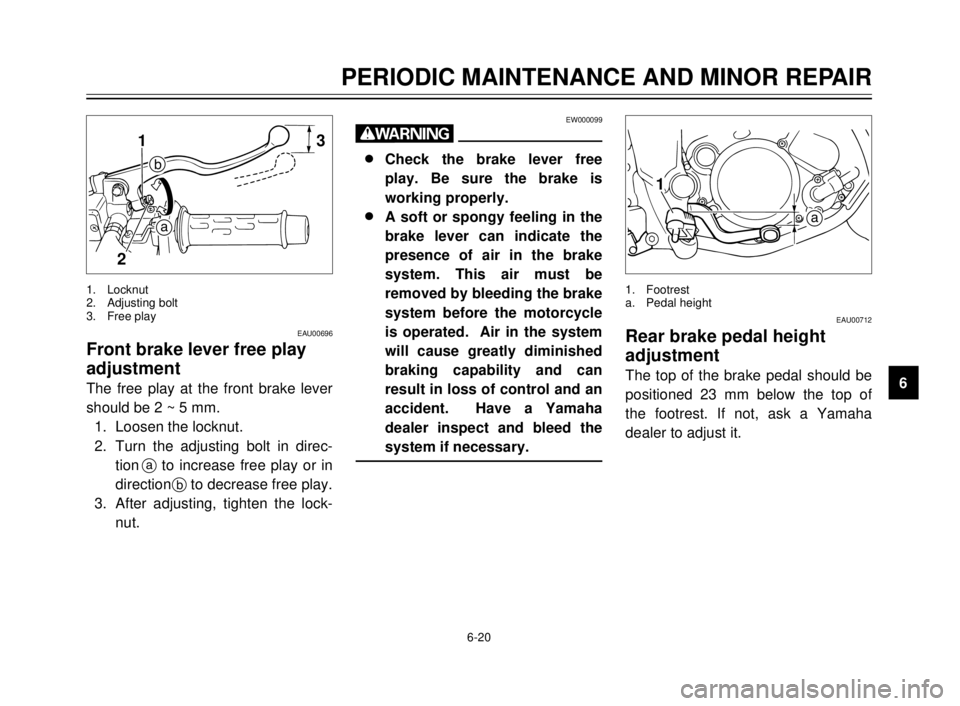

1

2

b

a3

EAU00696

Front brake lever free play

adjustment

The free play at the front brake lever

should be 2 ~ 5 mm.

1. Loosen the locknut.

2. Turn the adjusting bolt in direc-

tionato increase free play or in

directionbto decrease free play.

3. After adjusting, tighten the lock-

nut.

1. Locknut

2. Adjusting bolt

3. Free play

EW000099

w

8 8

Check the brake lever free

play. Be sure the brake is

working properly.

8 8

A soft or spongy feeling in the

brake lever can indicate the

presence of air in the brake

system. This air must be

removed by bleeding the brake

system before the motorcycle

is operated. Air in the system

will cause greatly diminished

braking capability and can

result in loss of control and an

accident. Have a Yamaha

dealer inspect and bleed the

system if necessary.

a

1

EAU00712

Rear brake pedal height

adjustment

The top of the brake pedal should be

positioned 23 mm below the top of

the footrest. If not, ask a Yamaha

dealer to adjust it.

1. Footrest

a. Pedal height

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 63

Page 66 of 104

6-21

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

EW000109

w

A soft or spongy feeling in the

brake pedal can indicate the pres-

ence of air in the brake system.

This air must be removed by

bleeding the brake system before

the motorcycle is operated. Air in

the system will cause greatly

diminished braking capability and

can result in loss of control and an

accident. Have a Yamaha dealer

inspect and bleed the system if

necessary.

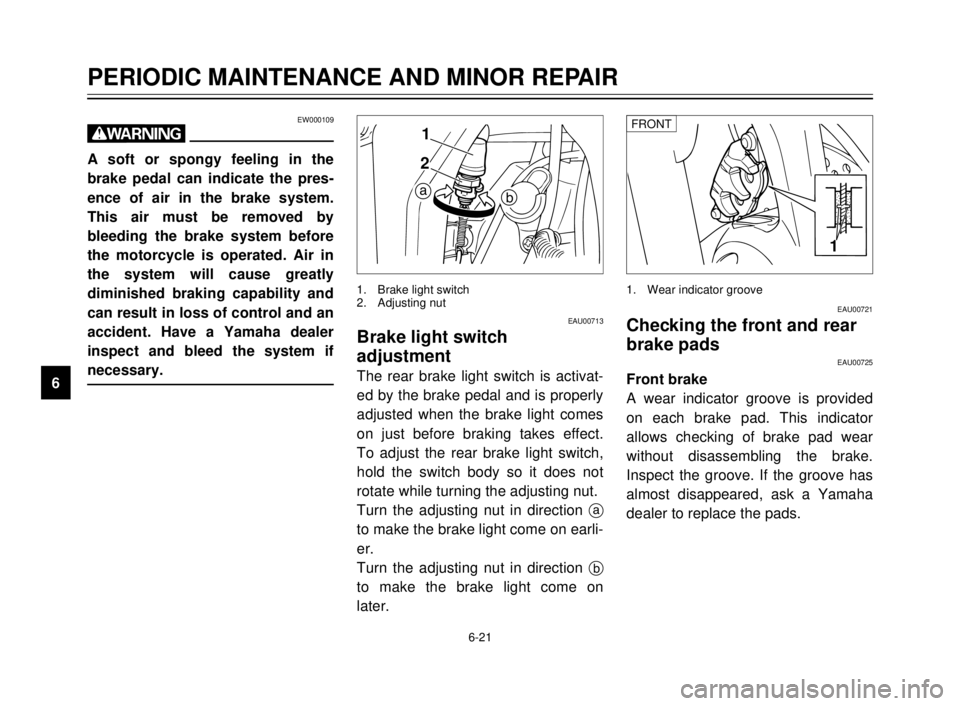

EAU00713

Brake light switch

adjustment

The rear brake light switch is activat-

ed by the brake pedal and is properly

adjusted when the brake light comes

on just before braking takes effect.

To adjust the rear brake light switch,

hold the switch body so it does not

rotate while turning the adjusting nut.

Turn the adjusting nut in direction a

to make the brake light come on earli-

er.

Turn the adjusting nut in direction b

to make the brake light come on

later.

ba

1

2

1. Brake light switch

2. Adjusting nut

EAU00721

Checking the front and rear

brake pads

EAU00725

Front brake

A wear indicator groove is provided

on each brake pad. This indicator

allows checking of brake pad wear

without disassembling the brake.

Inspect the groove. If the groove has

almost disappeared, ask a Yamaha

dealer to replace the pads.

1

1. Wear indicator grooveFRONT

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 64

Page 67 of 104

6-22

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

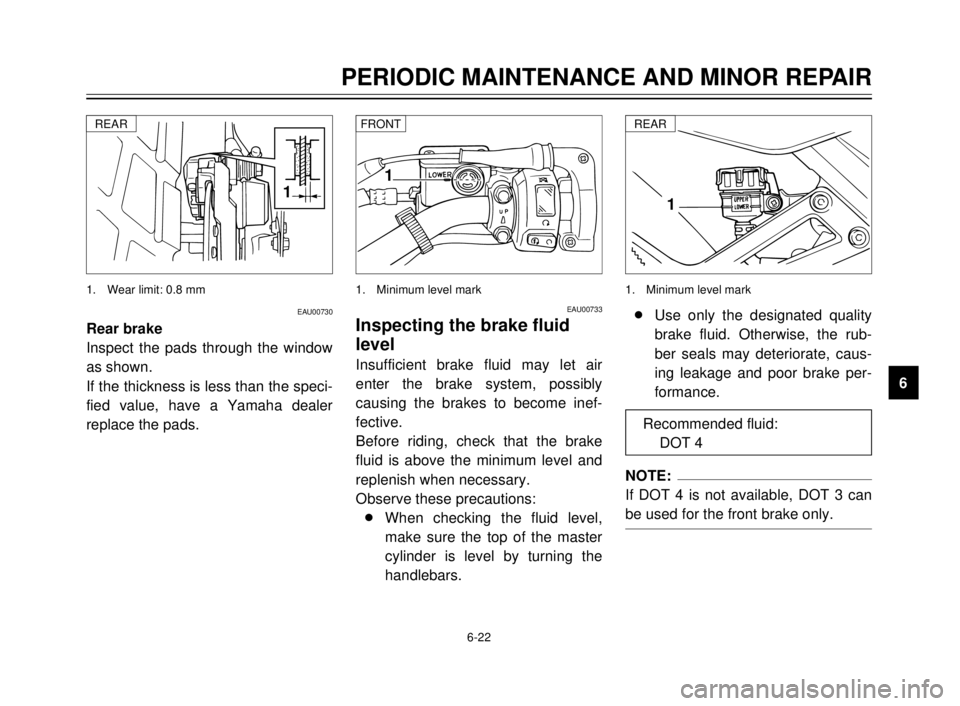

1

1. Wear limit: 0.8 mmREAR

EAU00733

Inspecting the brake fluid

level

Insufficient brake fluid may let air

enter the brake system, possibly

causing the brakes to become inef-

fective.

Before riding, check that the brake

fluid is above the minimum level and

replenish when necessary.

Observe these precautions:

8When checking the fluid level,

make sure the top of the master

cylinder is level by turning the

handlebars.

1

1. Minimum level markFRONT

1

1. Minimum level mark

8Use only the designated quality

brake fluid. Otherwise, the rub-

ber seals may deteriorate, caus-

ing leakage and poor brake per-

formance.

NOTE:

If DOT 4 is not available, DOT 3 can

be used for the front brake only.

REAR

Recommended fluid:

DOT 4

EAU00730

Rear brake

Inspect the pads through the window

as shown.

If the thickness is less than the speci-

fied value, have a Yamaha dealer

replace the pads.

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 65

Page 68 of 104

6-23

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

98Refill with the same type of brake

fluid. Mixing fluids may result in a

harmful chemical reaction and

lead to poor brake performance.

8Be careful that water does not

enter the master cylinder when

refilling. Water will significantly

lower the boiling point of the fluid

and may result in vapor lock.

8Brake fluid may deteriorate paint-

ed surfaces or plastic parts.

Always clean up spilled fluid

immediately.

8Have a Yamaha dealer check

the cause if the brake fluid level

goes down.

EAU00742Brake fluid replacement

The brake fluid should be replaced

only by trained Yamaha service per-

sonnel. Have the Yamaha dealer

replace the following components

during periodic maintenance or when

they are damaged or leaking:

8oil seals (every two years)

8brake hoses (every four years)

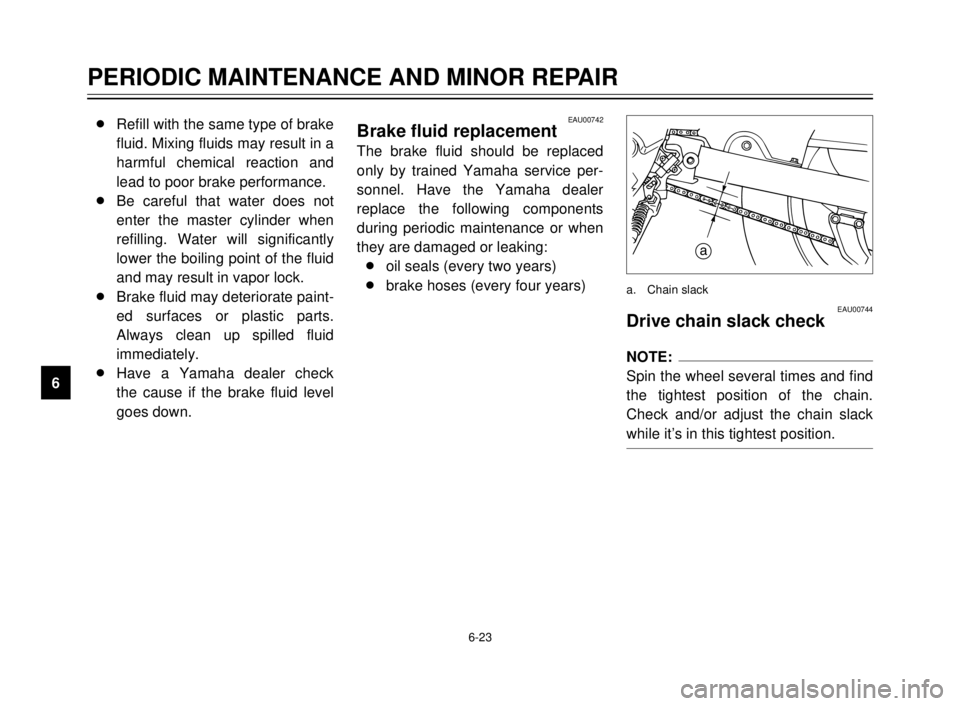

EAU00744Drive chain slack check

NOTE:

Spin the wheel several times and find

the tightest position of the chain.

Check and/or adjust the chain slack

while it’s in this tightest position.

a

a. Chain slack

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 66

Page 69 of 104

6-24

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

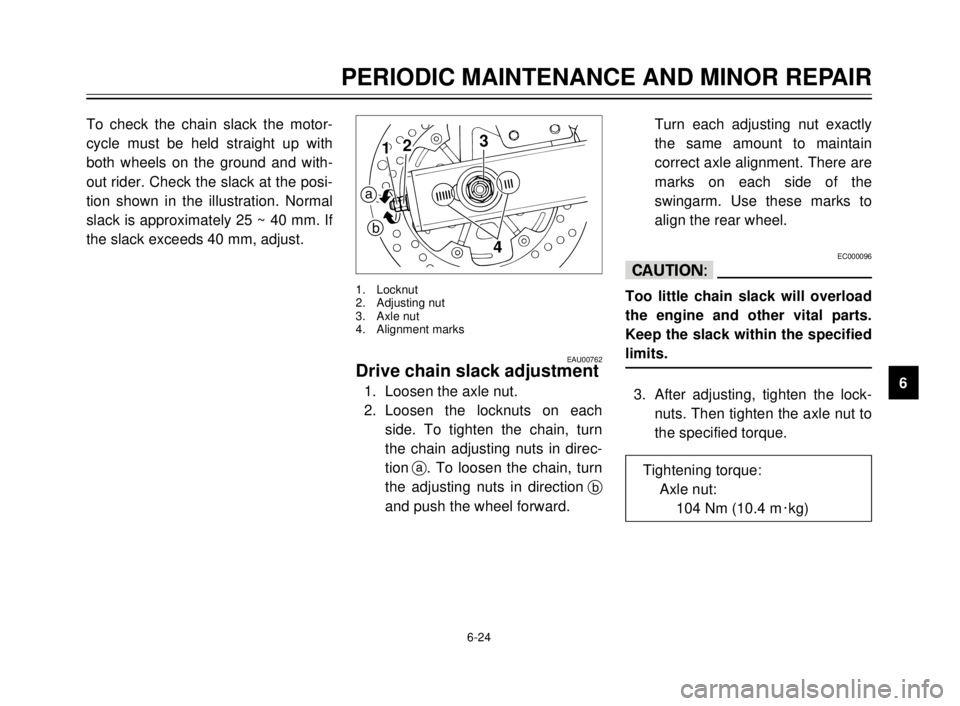

9 To check the chain slack the motor-

cycle must be held straight up with

both wheels on the ground and with-

out rider. Check the slack at the posi-

tion shown in the illustration. Normal

slack is approximately 25 ~ 40 mm. If

the slack exceeds 40 mm, adjust.

EAU00762Drive chain slack adjustment

1. Loosen the axle nut.

2. Loosen the locknuts on each

side. To tighten the chain, turn

the chain adjusting nuts in direc-

tiona. To loosen the chain, turn

the adjusting nuts in directionb

and push the wheel forward.

3

412

a

b

1. Locknut

2. Adjusting nut

3. Axle nut

4. Alignment marks

Turn each adjusting nut exactly

the same amount to maintain

correct axle alignment. There are

marks on each side of the

swingarm. Use these marks to

align the rear wheel.

EC000096

cC

Too little chain slack will overload

the engine and other vital parts.

Keep the slack within the specified

limits.

3. After adjusting, tighten the lock-

nuts. Then tighten the axle nut to

the specified torque.

Tightening torque:

Axle nut:

104 Nm (10.4 m0kg)

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 67

Page 70 of 104

6-25

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

EAU03006

Drive chain lubrication

The chain consists of many parts

which work with each other. If the

chain is not maintained properly, it

will wear out quickly. Therefore, the

chain must be serviced regularly.

This service is especially necessary

when riding in dusty areas. This

motorcycle is equipped with a sealed

type chain. Steam cleaning, high-

pressure washers, and solvents can

damage the drive chain, so do not

use these for cleaning it. Use only

kerosene to clean the drive chain.

Wipe it dry, and thoroughly lubricate it

with SAE 30 ~ 50W motor oil. Do not

use any other lubricants on the drive

chain. They may contain solvents

that could damage the sealed chain.

EC000097

cC

Be sure to oil the chain after wash-

ing the motorcycle or riding in the

rain.

EAU02962

Cable inspection and

lubrication

EW000112

w

Damage to the outer housing of

cables may lead to internal rusting

and interfere with the cable move-

ment. Replace damaged cables as

soon as possible to prevent unsafe

conditions.

Lubricate the cables and cable ends.

If a cable does not operate smoothly,

ask a Yamaha dealer to replace it.

Recommended lubricant:

Engine oil

EAU00773

Throttle cable and grip

lubrication

The throttle twist grip assembly

should be greased at the time that

the cable is lubricated, since the grip

must be removed to get at the end of

the throttle cable. After removing the

screws, hold the end of the cable up

in the air and put in several drops of

lubricant. With the throttle grip disas-

sembled, coat the metal surface of

the grip assembly with a suitable all-

purpose grease.

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 68