sensor YAMAHA WR 250F 2015 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: WR 250F, Model: YAMAHA WR 250F 2015Pages: 430, PDF Size: 14.14 MB

Page 334 of 430

ELECTRICAL COMPONENTS....................................................................... 9-60

CHECKING THE SWITCHES .................................................................. 9-64

CHECKING THE BULBS AND BULB SOCKETS .................................... 9-67

CHECKING THE FUSES ......................................................................... 9-68

CHECKING AND CHARGING THE BATTERY ........................................ 9-69

CHECKING THE RELAYS ....................................................................... 9-72

CHECKING THE DIODE .......................................................................... 9-73

CHECKING THE IGNITION SPARK GAP................................................ 9-73

CHECKING THE SPARK PLUG CAP ...................................................... 9-73

CHECKING THE IGNITION COIL ............................................................ 9-74

CHECKING THE CRANKSHAFT POSITION SENSOR........................... 9-74

CHECKING THE LEAN ANGLE SENSOR............................................... 9-75

CHECKING THE STARTER MOTOR OPERATION ................................ 9-75

CHECKING THE STATOR COIL ............................................................. 9-76

CHECKING THE RECTIFIER/REGULATOR ........................................... 9-76

CHECKING THE SPEED SENSOR ......................................................... 9-77

CHECKING THE FUEL SENDER ............................................................ 9-77

CHECKING THE RESISTER ................................................................... 9-77

CHECKING THE RADIATOR FAN MOTOR ............................................ 9-78

CHECKING THE COOLANT TEMPERATURE SENSOR........................ 9-78

CHECKING THE THROTTLE POSITION SENSOR ................................ 9-79

CHECKING THE THROTTLE POSITION SENSOR INPUT VOLTAGE .. 9-79

CHECKING THE INTAKE AIR PRESSURE SENSOR ............................ 9-80

CHECKING THE INTAKE AIR TEMPERATURE SENSOR ..................... 9-80

CHECKING THE FUEL INJECTOR ......................................................... 9-81

Page 337 of 430

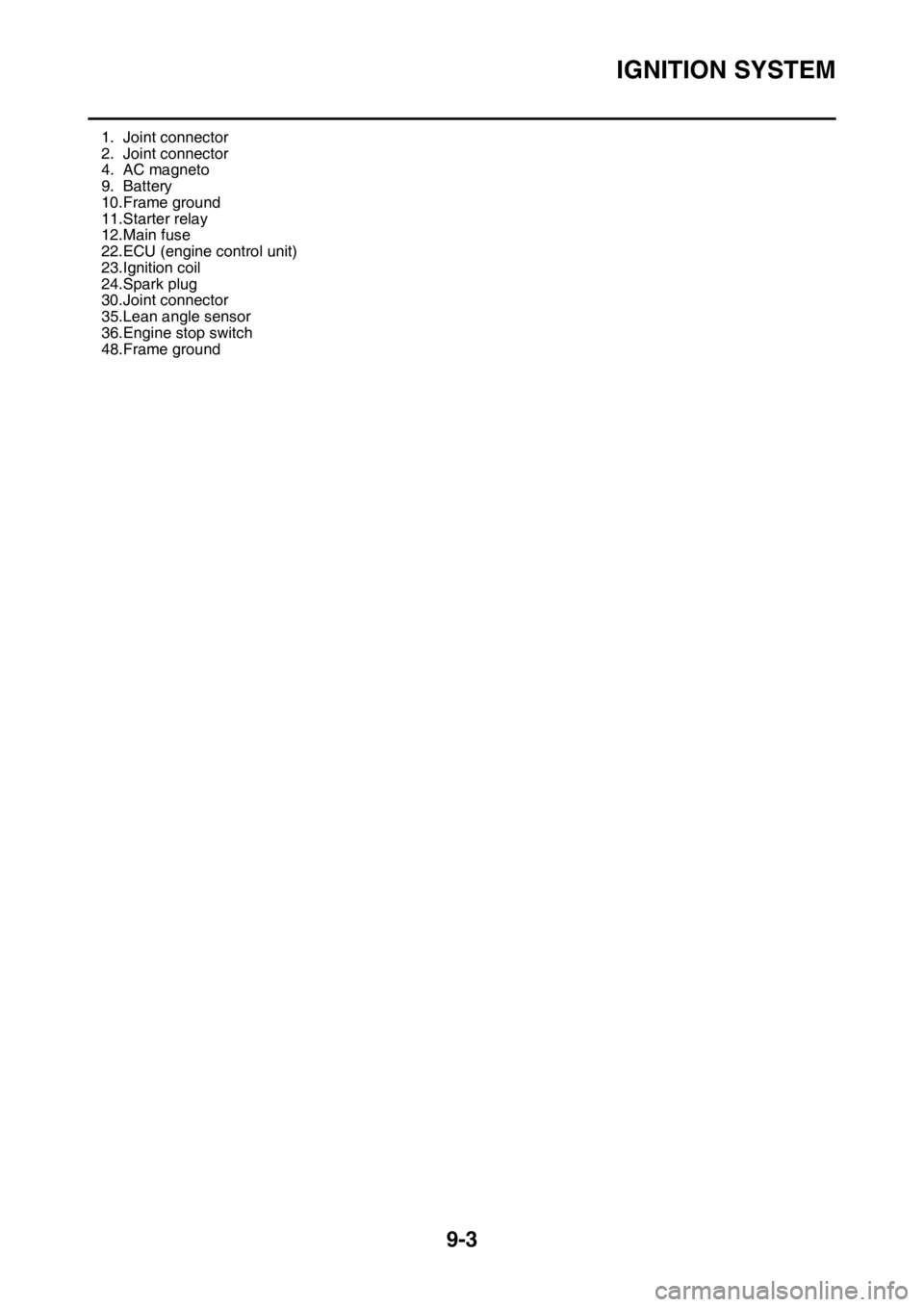

IGNITION SYSTEM

9-3

1. Joint connector

2. Joint connector

4. AC magneto

9. Battery

10.Frame ground

11.Starter relay

12.Main fuse

22.ECU (engine control unit)

23.Ignition coil

24.Spark plug

30.Joint connector

35.Lean angle sensor

36.Engine stop switch

48.Frame ground

Page 338 of 430

IGNITION SYSTEM

9-4

EAS2GB2361TROUBLESHOOTING

The ignition system fails to operate (no spark or intermittent spark).

TIP

Before troubleshooting, remove the following part (s):

1. Seat

2. Side cover (left/right)

3. Air scoop (left/right)

4. Fuel tank

5. Fuel tank

1. Check the fuse.

Refer to “CHECKING THE FUSES”

on page 9-68.NG

Replace the fuse(s).

OK

2. Check the battery.

Refer to “CHECKING AND

CHARGING THE BATTERY” on

page 9-69.NG

• Clean the battery terminals.

• Recharge or replace the battery.

OK

3. Check the spark plug.

Refer to “CHECKING THE FUSES”

on page 9-68.NG

Re-gap or replace the spark plug.

OK

4. Check the ignition spark gap.

Refer to “CHECKING THE IGNI-

TION SPARK GAP” on page 9-73.OK

The ignition system is normal.

NG

5. Check the ignition coil.

Refer to “CHECKING THE IGNI-

TION COIL” on page 9-74.NG

Replace the ignition coil.

OK

6. Check the crankshaft position sen-

sor.

Refer to “CHECKING THE CRANK-

SHAFT POSITION SENSOR” on

page 9-74.NG

Replace the stator assembly.

OK

7. Check the engine stop switch.

Refer to “CHECKING THE

SWITCHES” on page 9-64.NG

Replace the engine stop switch.

OK

Page 339 of 430

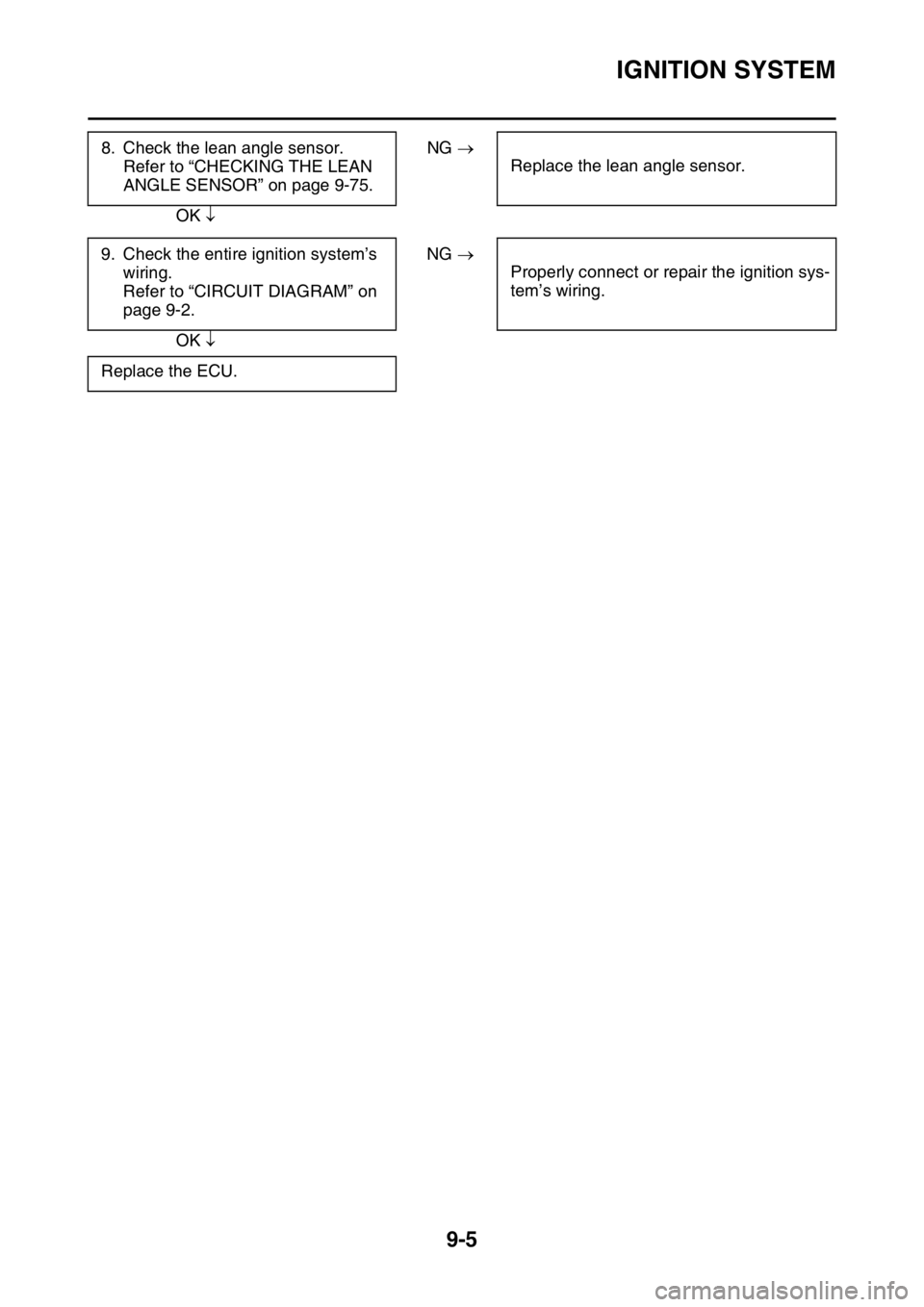

IGNITION SYSTEM

9-5

8. Check the lean angle sensor.

Refer to “CHECKING THE LEAN

ANGLE SENSOR” on page 9-75.NG

Replace the lean angle sensor.

OK

9. Check the entire ignition system’s

wiring.

Refer to “CIRCUIT DIAGRAM” on

page 9-2.NG

Properly connect or repair the ignition sys-

tem’s wiring.

OK

Replace the ECU.

Page 355 of 430

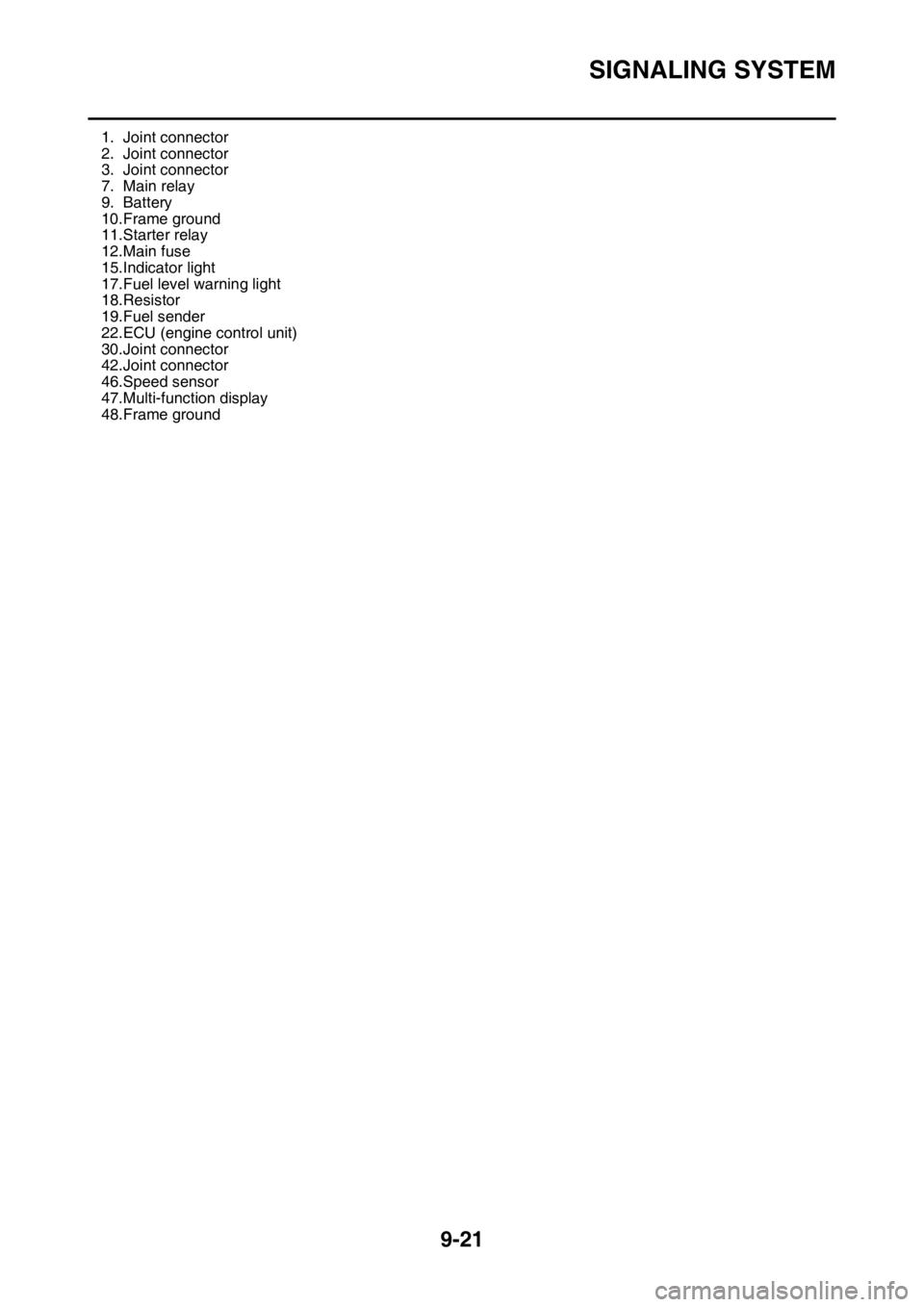

SIGNALING SYSTEM

9-21

1. Joint connector

2. Joint connector

3. Joint connector

7. Main relay

9. Battery

10.Frame ground

11.Starter relay

12.Main fuse

15.Indicator light

17.Fuel level warning light

18.Resistor

19.Fuel sender

22.ECU (engine control unit)

30.Joint connector

42.Joint connector

46.Speed sensor

47.Multi-function display

48.Frame ground

Page 356 of 430

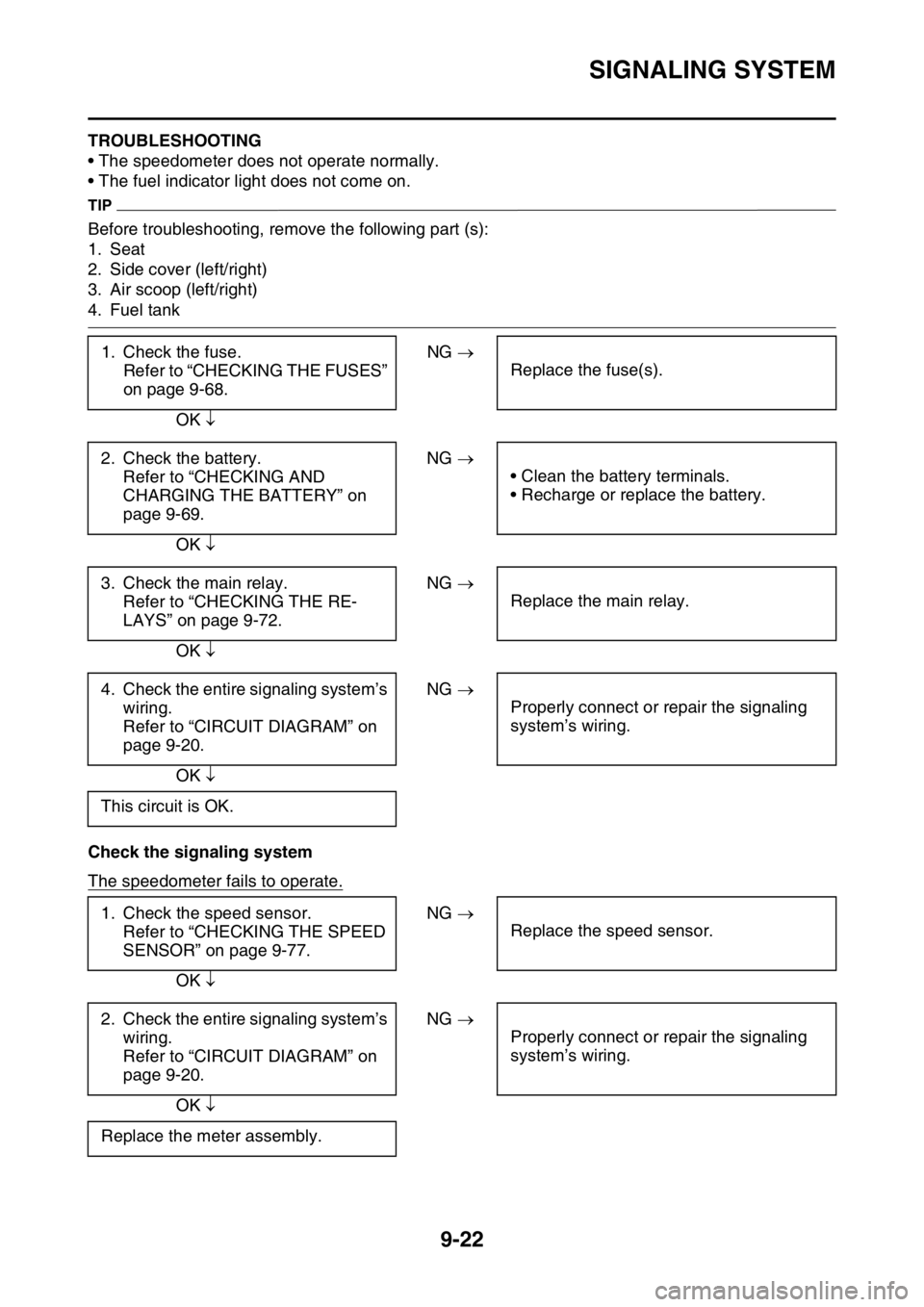

SIGNALING SYSTEM

9-22

EAS2GB2370TROUBLESHOOTING

• The speedometer does not operate normally.

• The fuel indicator light does not come on.

TIP

Before troubleshooting, remove the following part (s):

1. Seat

2. Side cover (left/right)

3. Air scoop (left/right)

4. Fuel tank

Check the signaling system

The speedometer fails to operate.

1. Check the fuse.

Refer to “CHECKING THE FUSES”

on page 9-68.NG

Replace the fuse(s).

OK

2. Check the battery.

Refer to “CHECKING AND

CHARGING THE BATTERY” on

page 9-69.NG

• Clean the battery terminals.

• Recharge or replace the battery.

OK

3. Check the main relay.

Refer to “CHECKING THE RE-

LAYS” on page 9-72.NG

Replace the main relay.

OK

4. Check the entire signaling system’s

wiring.

Refer to “CIRCUIT DIAGRAM” on

page 9-20.NG

Properly connect or repair the signaling

system’s wiring.

OK

This circuit is OK.

1. Check the speed sensor.

Refer to “CHECKING THE SPEED

SENSOR” on page 9-77.NG

Replace the speed sensor.

OK

2. Check the entire signaling system’s

wiring.

Refer to “CIRCUIT DIAGRAM” on

page 9-20.NG

Properly connect or repair the signaling

system’s wiring.

OK

Replace the meter assembly.

Page 359 of 430

COOLING SYSTEM

9-25

1. Joint connector

2. Joint connector

3. Joint connector

7. Main relay

9. Battery

10.Frame ground

11.Starter relay

12.Main fuse

22.ECU (engine control unit)

27.Radiator fan motor relay

28.Radiator fan motor fuse

29.Radiator fan motor

30.Joint connector

32.Coolant temperature sensor

48.Frame ground

Page 360 of 430

COOLING SYSTEM

9-26

EAS2GB2373TROUBLESHOOTING

The radiator fan motor fails to turn.

TIP

Before troubleshooting, remove the following part(s):

1. Seat

2. Side cover (left)

3. Air scoop (left/right)

4. Fuel tank

1. Check the fuse.

Refer to “CHECKING THE FUSES”

on page 9-68.NG

Replace the fuse(s).

OK

2. Check the battery.

Refer to “CHECKING AND

CHARGING THE BATTERY” on

page 9-69.NG

• Clean the battery terminals.

• Recharge or replace the battery.

OK

3. Check the main relay.

Refer to “CHECKING THE RE-

LAYS” on page 9-72.NG

Replace the main relay.

OK

4. Check the radiator fan motor.

Refer to “CHECKING THE RADIA-

TOR FAN MOTOR” on page 9-78.NG

Replace the radiator fan motor.

OK

5. Check the radiator fan motor relay.

Refer to “CHECKING THE RE-

LAYS” on page 9-72.NG

Replace the radiator fan motor relay.

OK

6. Check the coolant temperature sen-

sor.

Refer to “CHECKING THE COOL-

ANT TEMPERATURE SENSOR”

on page 9-78.NG

Replace the coolant temperature sensor.

OK

7. Check the entire cooling system’s

wiring.

Refer to “CIRCUIT DIAGRAM” on

page 9-16.NG

Properly connect or repair the cooling sys-

tem’s wiring.

OK

Replace the ECU.

Page 363 of 430

FUEL INJECTION SYSTEM

9-29

1. Joint connector

2. Joint connector

3. Joint connector

4. AC magneto

7. Main relay

9. Battery

10.Frame ground

11.Starter relay

12.Main fuse

15.Indicator light

16.Engine trouble warning light

22.ECU (engine control unit)

25.Injector

30.Joint connector

31.Intake air temperature sensor

32.Coolant temperature sensor

33.Throttle position sensor

34.Intake air pressure sensor

35.Lean angle sensor

36.Engine stop switch

37.Neutral switch

38.Diode

39.Starting circuit cut-off relay

40.Clutch switch

42.Joint connector

48.Frame ground

Page 364 of 430

FUEL INJECTION SYSTEM

9-30

EAS2GB2376ECU SELF-DIAGNOSTIC FUNCTION

The ECU is equipped with a self-diagnostic function in order to ensure that the fuel injection system

is operating normally. If this function detects a malfunction in the system, it immediately operates the

engine under substitute characteristics and illuminates the engine trouble warning light to alert the

rider that a malfunction has occurred in the system. Once a malfunction has been detected, a fault

code number is stored in the memory of the ECU.

• To inform the rider that the fuel injection system is not functioning, the engine trouble warning light

flashes while the start switch is being pushed to start the engine.

• If a malfunction is detected in the system by the self-diagnostic function, the ECU provides an ap-

propriate substitute characteristic operation, and alerts the rider of the detected malfunction by illu-

minating the engine trouble warning light.

Engine trouble warning light indication and fuel injection system operation

* The warning light flashes when any one of the following conditions is present and the start switch

is pushed:

Checking the engine trouble warning light

The engine trouble warning light comes on for around 2 seconds when pushing the start switch to

turn on the meter light and the engine trouble warning light comes on while the start switch is being

pushed.Warning light indica-

tionECU operationFuel injection opera-

tionVehicle operation

Flashing* Warning provided

when unable to start

engineOperation stopped Cannot be operated

Remains on Malfunction detected Operated with substi-

tute characteristics in

accordance with the

description of the mal-

functionCan or cannot be oper-

ated depending on the

fault code

12: Crankshaft position sensor 41: Lean angle sensor

(open or short circuit)

30: Lean angle sensor

(latch up detected)50: ECU internal malfunction

(faulty ECU memory)

33: Ignition coil

(Malfunction detected in the primary wire

of the ignition coil)

a. The meter light does not come on.

b. The meter light comes on.

c. Light OFF

d. Light ON for 2 seconds

ab

c cd