sensor YAMAHA WR 250F 2015 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: WR 250F, Model: YAMAHA WR 250F 2015Pages: 430, PDF Size: 14.14 MB

Page 234 of 430

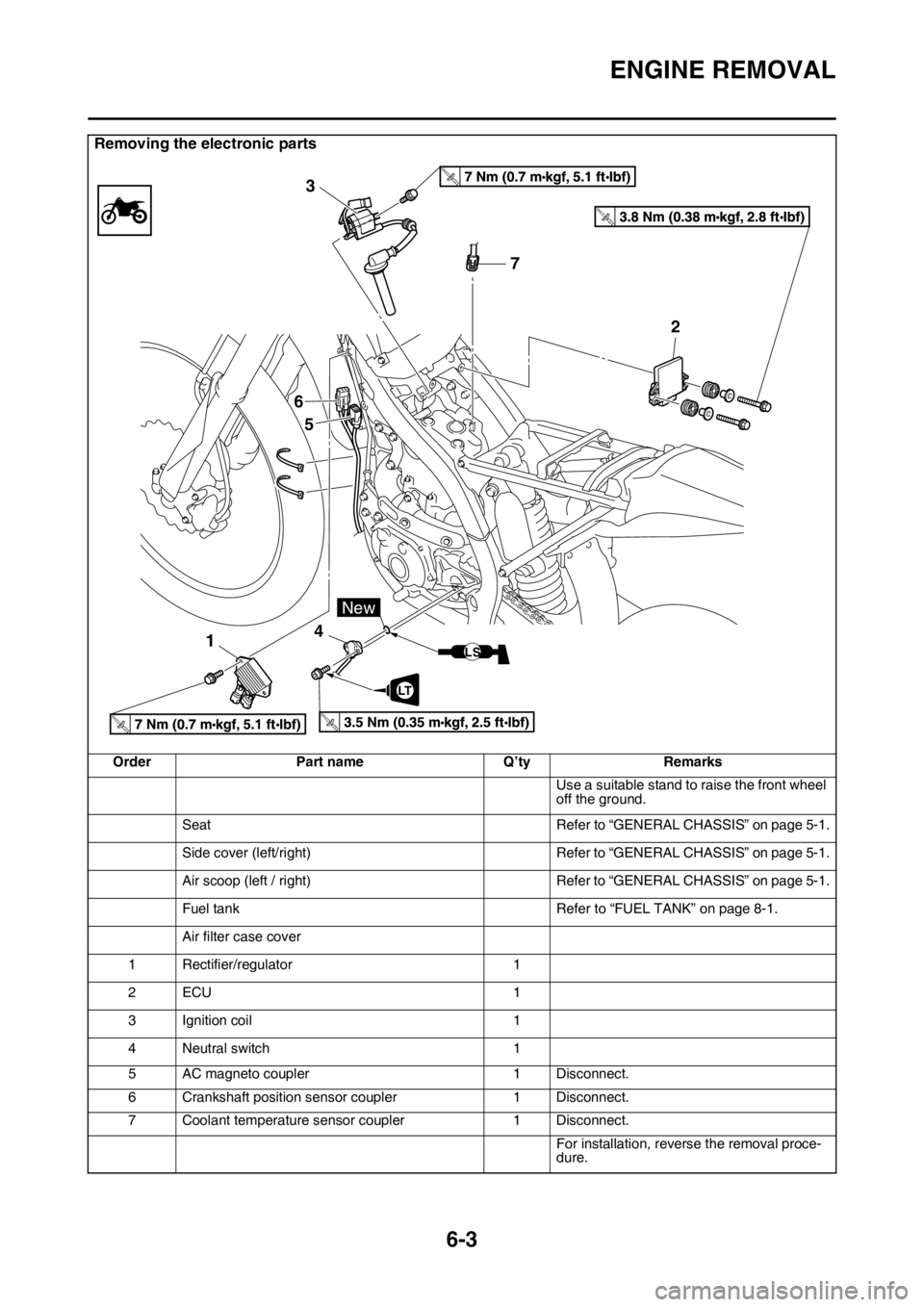

ENGINE REMOVAL

6-3

Removing the electronic parts

Order Part name Q’ty Remarks

Use a suitable stand to raise the front wheel

off the ground.

Seat Refer to “GENERAL CHASSIS” on page 5-1.

Side cover (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Air scoop (left / right) Refer to “GENERAL CHASSIS” on page 5-1.

Fuel tank Refer to “FUEL TANK” on page 8-1.

Air filter case cover

1 Rectifier/regulator 1

2ECU 1

3 Ignition coil 1

4 Neutral switch 1

5 AC magneto coupler 1 Disconnect.

6 Crankshaft position sensor coupler 1 Disconnect.

7 Coolant temperature sensor coupler 1 Disconnect.

For installation, reverse the removal proce-

dure.

T.R.

T.R.

T.R.T.R.

7 3

6

5

142

LT

New

LS

Page 249 of 430

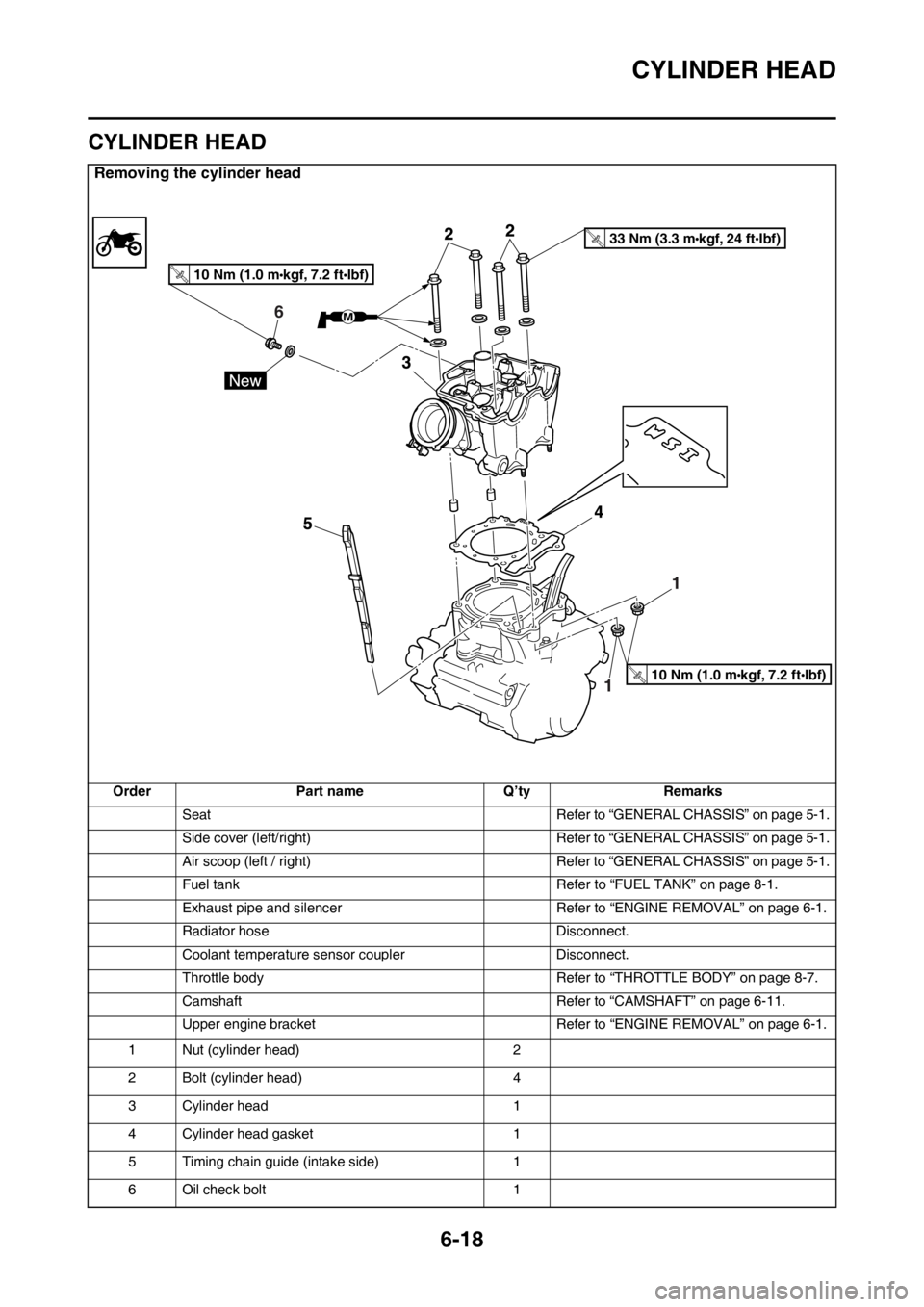

CYLINDER HEAD

6-18

EAS2GB2246

CYLINDER HEAD

Removing the cylinder head

Order Part name Q’ty Remarks

Seat Refer to “GENERAL CHASSIS” on page 5-1.

Side cover (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Air scoop (left / right) Refer to “GENERAL CHASSIS” on page 5-1.

Fuel tank Refer to “FUEL TANK” on page 8-1.

Exhaust pipe and silencer Refer to “ENGINE REMOVAL” on page 6-1.

Radiator hose Disconnect.

Coolant temperature sensor coupler Disconnect.

Throttle body Refer to “THROTTLE BODY” on page 8-7.

Camshaft Refer to “CAMSHAFT” on page 6-11.

Upper engine bracket Refer to “ENGINE REMOVAL” on page 6-1.

1 Nut (cylinder head) 2

2 Bolt (cylinder head) 4

3 Cylinder head 1

4 Cylinder head gasket 1

5 Timing chain guide (intake side) 1

6 Oil check bolt 1

6

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.

33 Nm (3.3 m kgf, 24 ft Ibf)T.R.

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.

Page 294 of 430

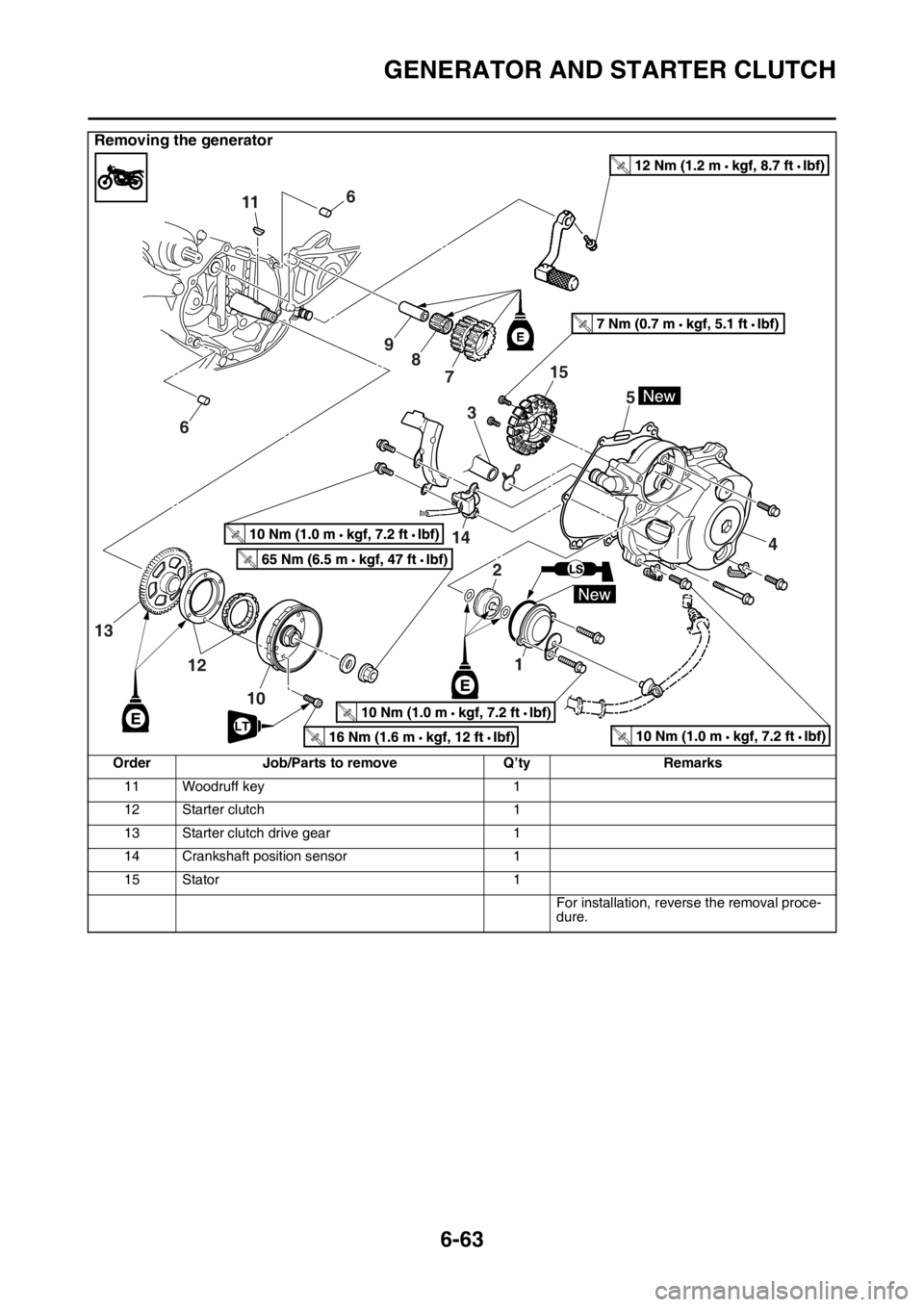

GENERATOR AND STARTER CLUTCH

6-63

11 Woodruff key 1

12 Starter clutch 1

13 Starter clutch drive gear 1

14 Crankshaft position sensor 1

15 Stator 1

For installation, reverse the removal proce-

dure.

Removing the generator

Order Job/Parts to remove Q’ty Remarks

T R..

T R..

6

611

9

8

7

2

3

1

14

4 5

12

10

13

T R..

T R..

T R..LTT R..

T R..

15

Page 296 of 430

GENERATOR AND STARTER CLUTCH

6-65

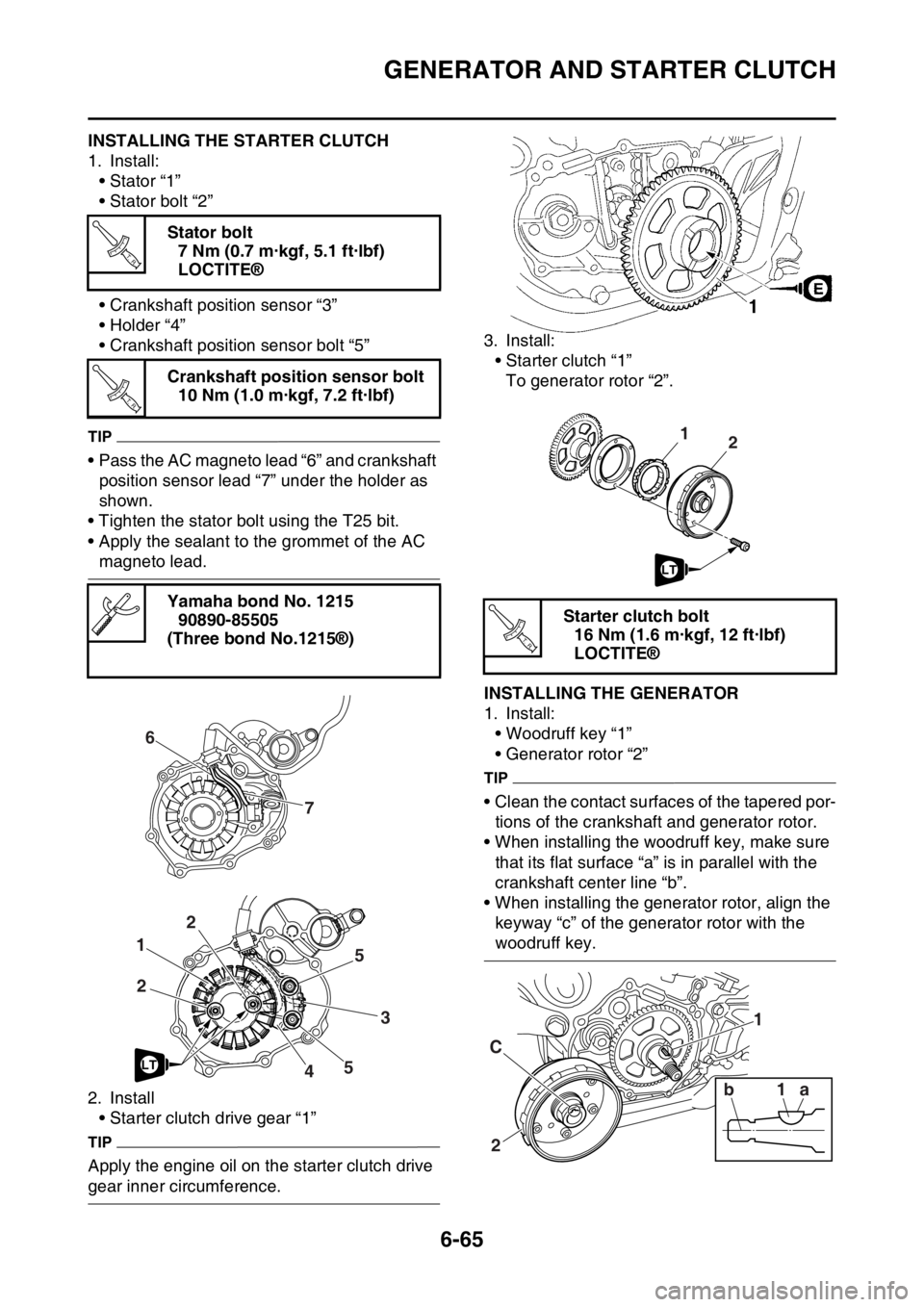

EAS2GB2310INSTALLING THE STARTER CLUTCH

1. Install:

• Stator “1”

• Stator bolt “2”

• Crankshaft position sensor “3”

• Holder “4”

• Crankshaft position sensor bolt “5”

TIP

• Pass the AC magneto lead “6” and crankshaft

position sensor lead “7” under the holder as

shown.

• Tighten the stator bolt using the T25 bit.

• Apply the sealant to the grommet of the AC

magneto lead.

2. Install

• Starter clutch drive gear “1”

TIP

Apply the engine oil on the starter clutch drive

gear inner circumference.3. Install:

• Starter clutch “1”

To generator rotor “2”.

EAS2GB2311INSTALLING THE GENERATOR

1. Install:

• Woodruff key “1”

• Generator rotor “2”

TIP

• Clean the contact surfaces of the tapered por-

tions of the crankshaft and generator rotor.

• When installing the woodruff key, make sure

that its flat surface “a” is in parallel with the

crankshaft center line “b”.

• When installing the generator rotor, align the

keyway “c” of the generator rotor with the

woodruff key. Stator bolt

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

LOCTITE®

Crankshaft position sensor bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Yamaha bond No. 1215

90890-85505

(Three bond No.1215®)

T R..

T R..

6

7

1

3

22

5

5

4LT

Starter clutch bolt

16 Nm (1.6 m·kgf, 12 ft·lbf)

LOCTITE®

21

LT

T R..

2 C1 1

1a b

Page 315 of 430

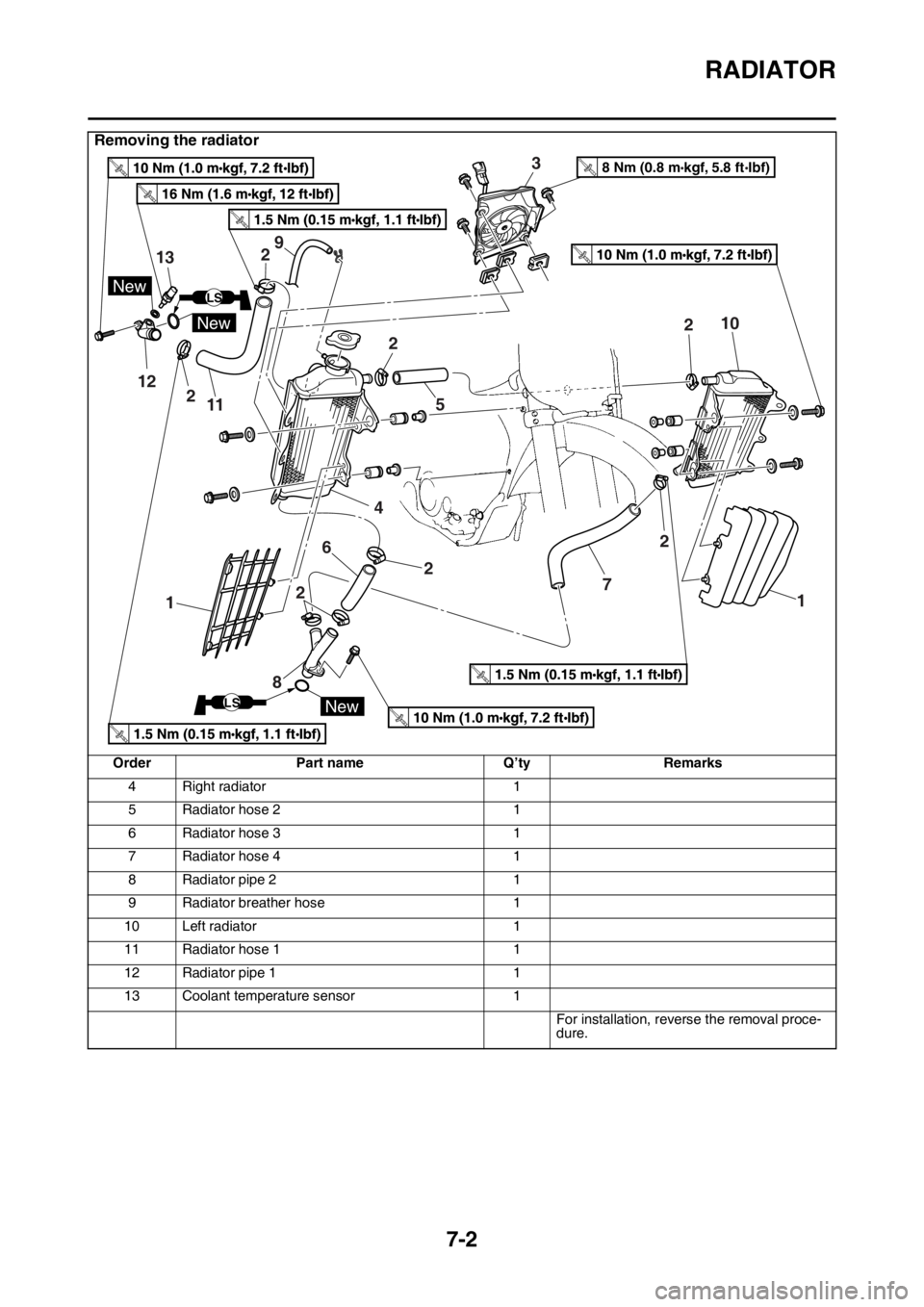

RADIATOR

7-2

4 Right radiator 1

5 Radiator hose 2 1

6 Radiator hose 3 1

7 Radiator hose 4 1

8 Radiator pipe 2 1

9 Radiator breather hose 1

10 Left radiator 1

11 Radiator hose 1 1

12 Radiator pipe 1 1

13 Coolant temperature sensor 1

For installation, reverse the removal proce-

dure.

Removing the radiator

Order Part name Q’ty Remarks

12

13

New

New

New

LS

LS

3

458 Nm (0.8 m kgf, 5.8 ft Ibf)T.R.

6

7

89

10

112

2

2

2 22 2

1

1

Page 321 of 430

8

FUEL SYSTEM

FUEL TANK...................................................................................................... 8-1

REMOVING THE FUEL TANK ................................................................... 8-3

REMOVING THE FUEL PUMP .................................................................. 8-3

CHECKING THE FUEL PUMP BODY........................................................ 8-3

INSTALLING THE FUEL PUMP ................................................................. 8-3

REMOVING THE FUEL SENDER.............................................................. 8-4

CHECKING THE FUEL SENDER .............................................................. 8-4

INSTALLING THE FUEL SENDER ............................................................ 8-4

INSTALLING THE FUEL TANK.................................................................. 8-4

CHECKING THE FUEL PRESSURE ......................................................... 8-5

CHECKING THE DAMPER ........................................................................ 8-5

CHECKING AND REPLACING THE PROTECTOR .................................. 8-6

THROTTLE BODY............................................................................................ 8-7

CHECKING THE INJECTOR ................................................................... 8-10

CHECKING THE THROTTLE BODY ....................................................... 8-10

CHECKING THE THROTTLE BODY JOINT ............................................ 8-10

ADJUSTING THE THROTTLE POSITION SENSOR............................... 8-11

Page 328 of 430

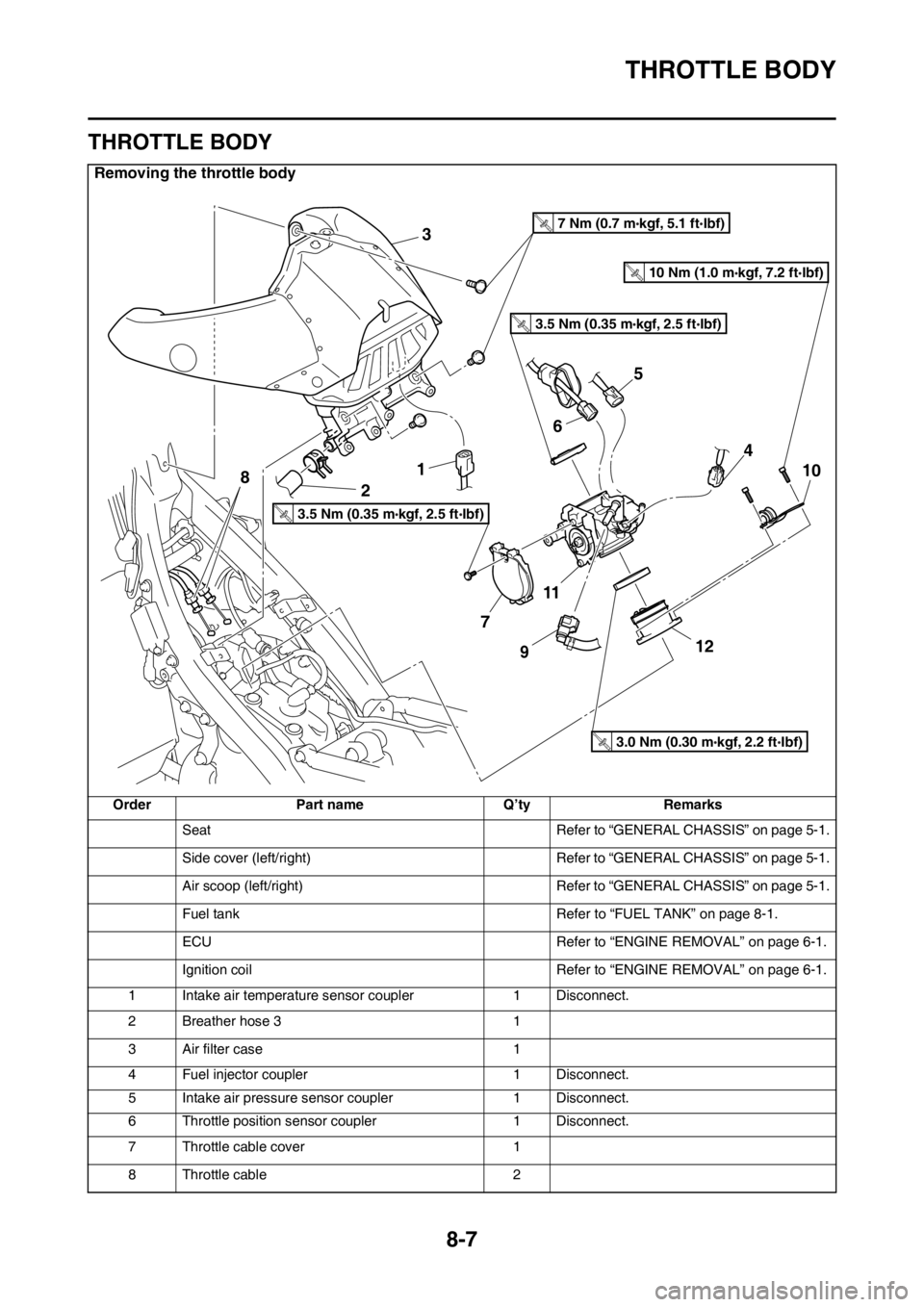

THROTTLE BODY

8-7

EAS2GB2353

THROTTLE BODY

Removing the throttle body

Order Part name Q’ty Remarks

Seat Refer to “GENERAL CHASSIS” on page 5-1.

Side cover (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Air scoop (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Fuel tank Refer to “FUEL TANK” on page 8-1.

ECU Refer to “ENGINE REMOVAL” on page 6-1.

Ignition coil Refer to “ENGINE REMOVAL” on page 6-1.

1 Intake air temperature sensor coupler 1 Disconnect.

2 Breather hose 3 1

3 Air filter case 1

4 Fuel injector coupler 1 Disconnect.

5 Intake air pressure sensor coupler 1 Disconnect.

6 Throttle position sensor coupler 1 Disconnect.

7 Throttle cable cover 1

8 Throttle cable 2

3

1

2

7

11

12

10

9

4

8

6

5

3.5 Nm (0.35 m kgf, 2.5 ft Ibf)T.R.

3.5 Nm (0.35 m kgf, 2.5 ft Ibf)T.R.

7 Nm (0.7 m kgf, 5.1 ft Ibf)T.R.

3.0 Nm (0.30 m kgf, 2.2 ft Ibf)T.R.

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.

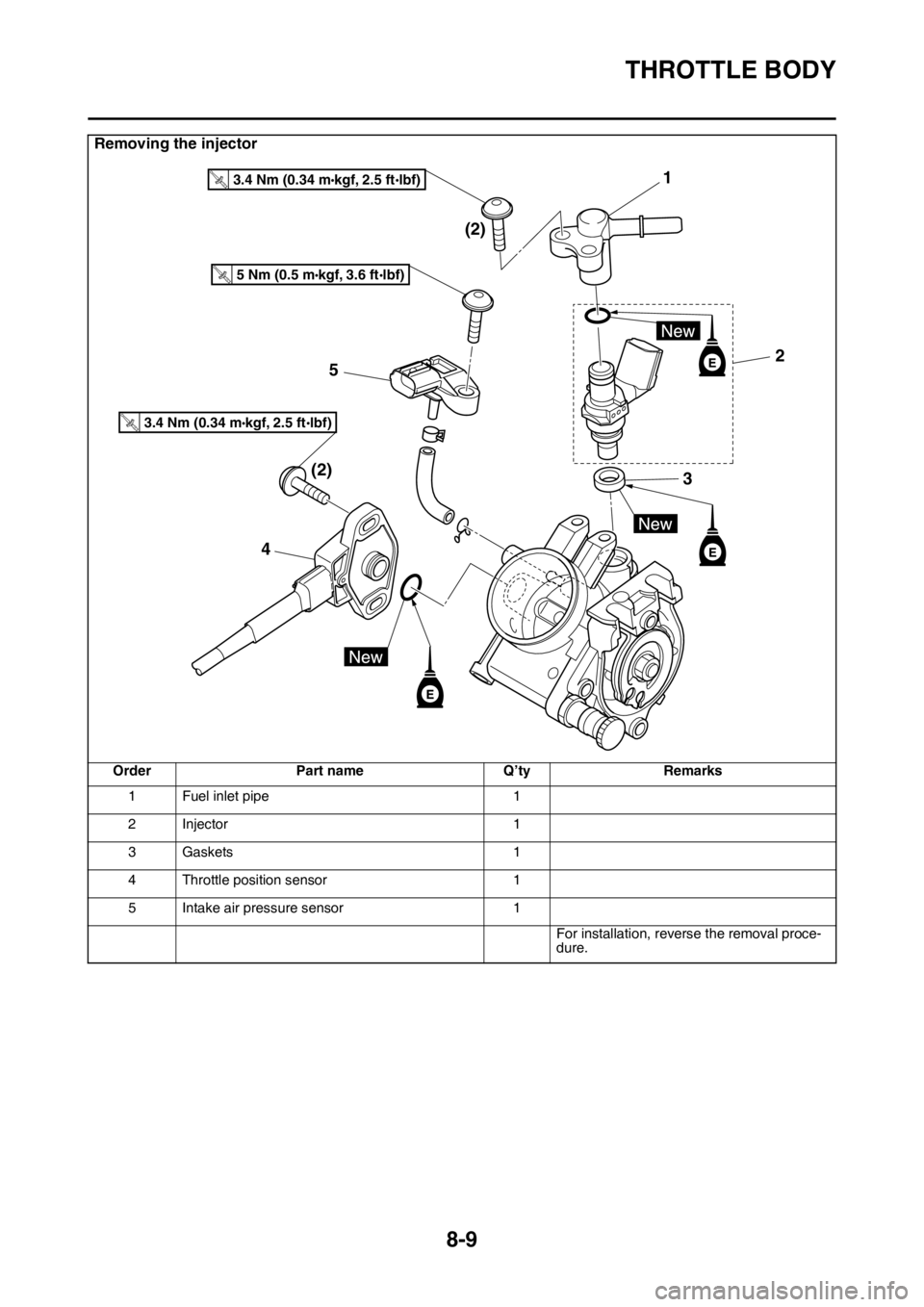

Page 330 of 430

THROTTLE BODY

8-9

Removing the injector

Order Part name Q’ty Remarks

1 Fuel inlet pipe 1

2Injector 1

3 Gaskets 1

4 Throttle position sensor 1

5 Intake air pressure sensor 1

For installation, reverse the removal proce-

dure.

1

2 (2)

(2)5

43

T.R.3.4 Nm (0.34 mlbf) kgf, 2.5 ft

T.R.5 Nm (0.5 mlbf) kgf, 3.6 ft

T.R.3.4 Nm (0.34 mlbf) kgf, 2.5 ft

Page 331 of 430

THROTTLE BODY

8-10

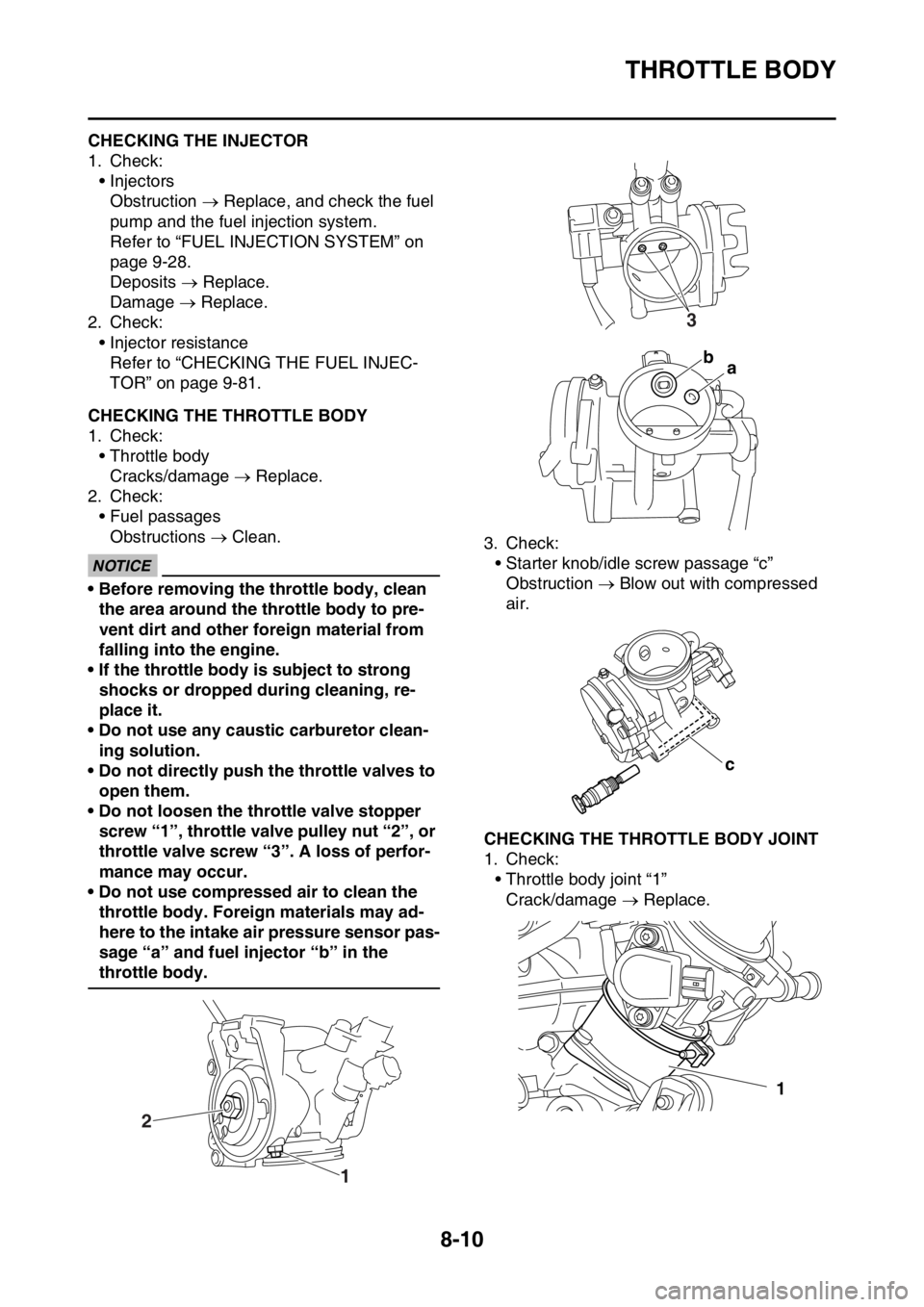

EAS2GB2354CHECKING THE INJECTOR

1. Check:

• Injectors

Obstruction Replace, and check the fuel

pump and the fuel injection system.

Refer to “FUEL INJECTION SYSTEM” on

page 9-28.

Deposits Replace.

Damage Replace.

2. Check:

• Injector resistance

Refer to “CHECKING THE FUEL INJEC-

TOR” on page 9-81.

EAS2GB2355CHECKING THE THROTTLE BODY

1. Check:

• Throttle body

Cracks/damage Replace.

2. Check:

• Fuel passages

Obstructions Clean.

ECA

NOTICE

• Before removing the throttle body, clean

the area around the throttle body to pre-

vent dirt and other foreign material from

falling into the engine.

• If the throttle body is subject to strong

shocks or dropped during cleaning, re-

place it.

• Do not use any caustic carburetor clean-

ing solution.

• Do not directly push the throttle valves to

open them.

• Do not loosen the throttle valve stopper

screw “1”, throttle valve pulley nut “2”, or

throttle valve screw “3”. A loss of perfor-

mance may occur.

• Do not use compressed air to clean the

throttle body. Foreign materials may ad-

here to the intake air pressure sensor pas-

sage “a” and fuel injector “b” in the

throttle body.3. Check:

• Starter knob/idle screw passage “c”

Obstruction Blow out with compressed

air.

EAS2GB2356CHECKING THE THROTTLE BODY JOINT

1. Check:

• Throttle body joint “1”

Crack/damage Replace.

1 2

3

ba

c

1

Page 332 of 430

THROTTLE BODY

8-11

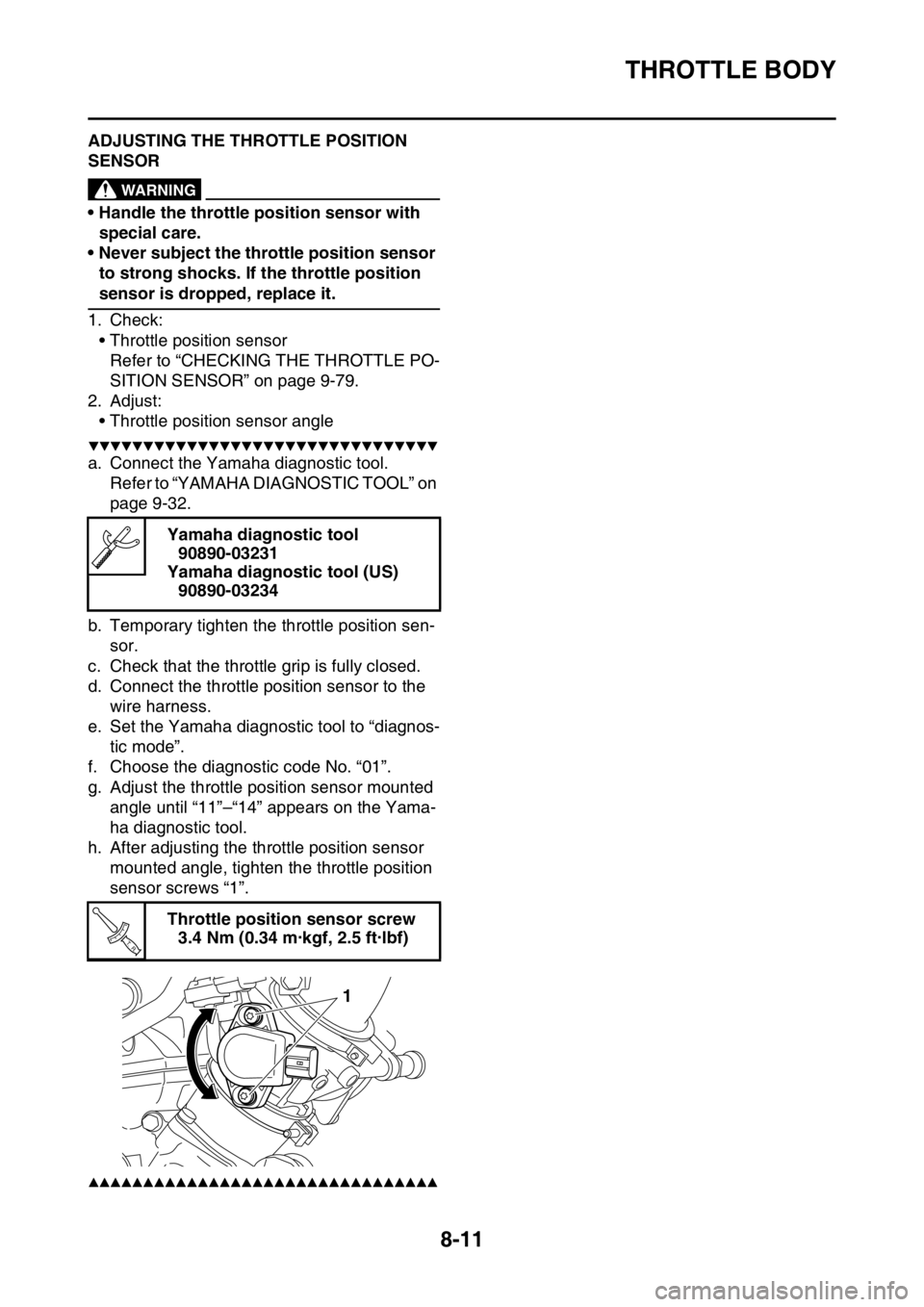

EAS2GB2357ADJUSTING THE THROTTLE POSITION

SENSOR

EWA

WARNING

• Handle the throttle position sensor with

special care.

• Never subject the throttle position sensor

to strong shocks. If the throttle position

sensor is dropped, replace it.

1. Check:

• Throttle position sensor

Refer to “CHECKING THE THROTTLE PO-

SITION SENSOR” on page 9-79.

2. Adjust:

• Throttle position sensor angle

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the Yamaha diagnostic tool.

Refer to “YAMAHA DIAGNOSTIC TOOL” on

page 9-32.

b. Temporary tighten the throttle position sen-

sor.

c. Check that the throttle grip is fully closed.

d. Connect the throttle position sensor to the

wire harness.

e. Set the Yamaha diagnostic tool to “diagnos-

tic mode”.

f. Choose the diagnostic code No. “01”.

g. Adjust the throttle position sensor mounted

angle until “11”–“14” appears on the Yama-

ha diagnostic tool.

h. After adjusting the throttle position sensor

mounted angle, tighten the throttle position

sensor screws “1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Yamaha diagnostic tool

90890-03231

Yamaha diagnostic tool (US)

90890-03234

Throttle position sensor screw

3.4 Nm (0.34 m·kgf, 2.5 ft·lbf)

T R..

1