sensor YAMAHA WR 250F 2015 Workshop Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: WR 250F, Model: YAMAHA WR 250F 2015Pages: 430, PDF Size: 14.14 MB

Page 377 of 430

FUEL INJECTION SYSTEM

9-43

TIP

• Make sure that the engine is completely cool before checking the intake air temperature sensor.

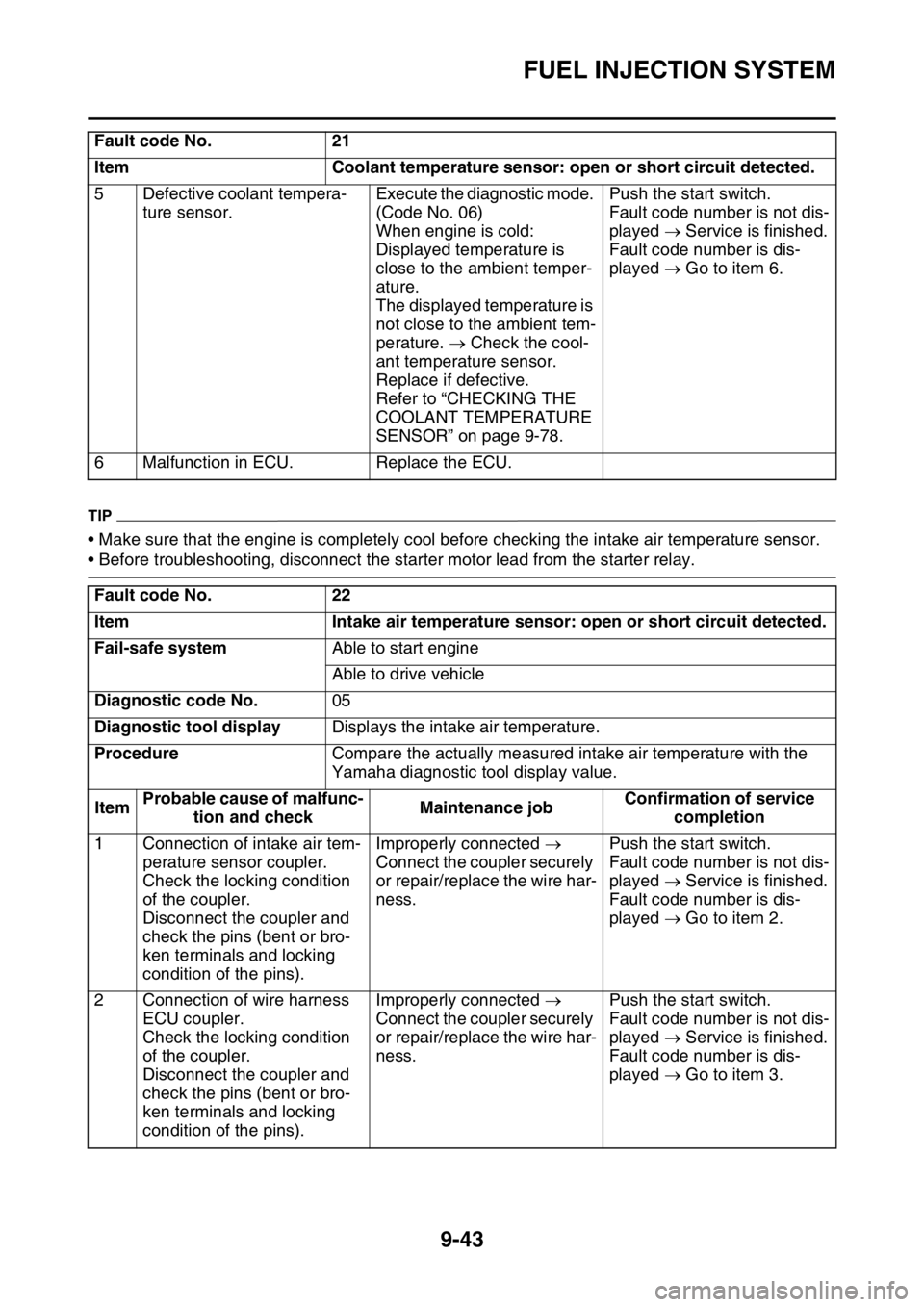

• Before troubleshooting, disconnect the starter motor lead from the starter relay. 5 Defective coolant tempera-

ture sensor.Execute the diagnostic mode.

(Code No. 06)

When engine is cold:

Displayed temperature is

close to the ambient temper-

ature.

The displayed temperature is

not close to the ambient tem-

perature. Check the cool-

ant temperature sensor.

Replace if defective.

Refer to “CHECKING THE

COOLANT TEMPERATURE

SENSOR” on page 9-78.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 6.

6 Malfunction in ECU. Replace the ECU.

Fault code No. 22

Item Intake air temperature sensor: open or short circuit detected.

Fail-safe systemAble to start engine

Able to drive vehicle

Diagnostic code No.05

Diagnostic tool displayDisplays the intake air temperature.

ProcedureCompare the actually measured intake air temperature with the

Yamaha diagnostic tool display value.

ItemProbable cause of malfunc-

tion and checkMaintenance jobConfirmation of service

completion

1 Connection of intake air tem-

perature sensor coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins).Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 2.

2 Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins).Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 3. Fault code No. 21

Item Coolant temperature sensor: open or short circuit detected.

Page 378 of 430

FUEL INJECTION SYSTEM

9-44

TIP

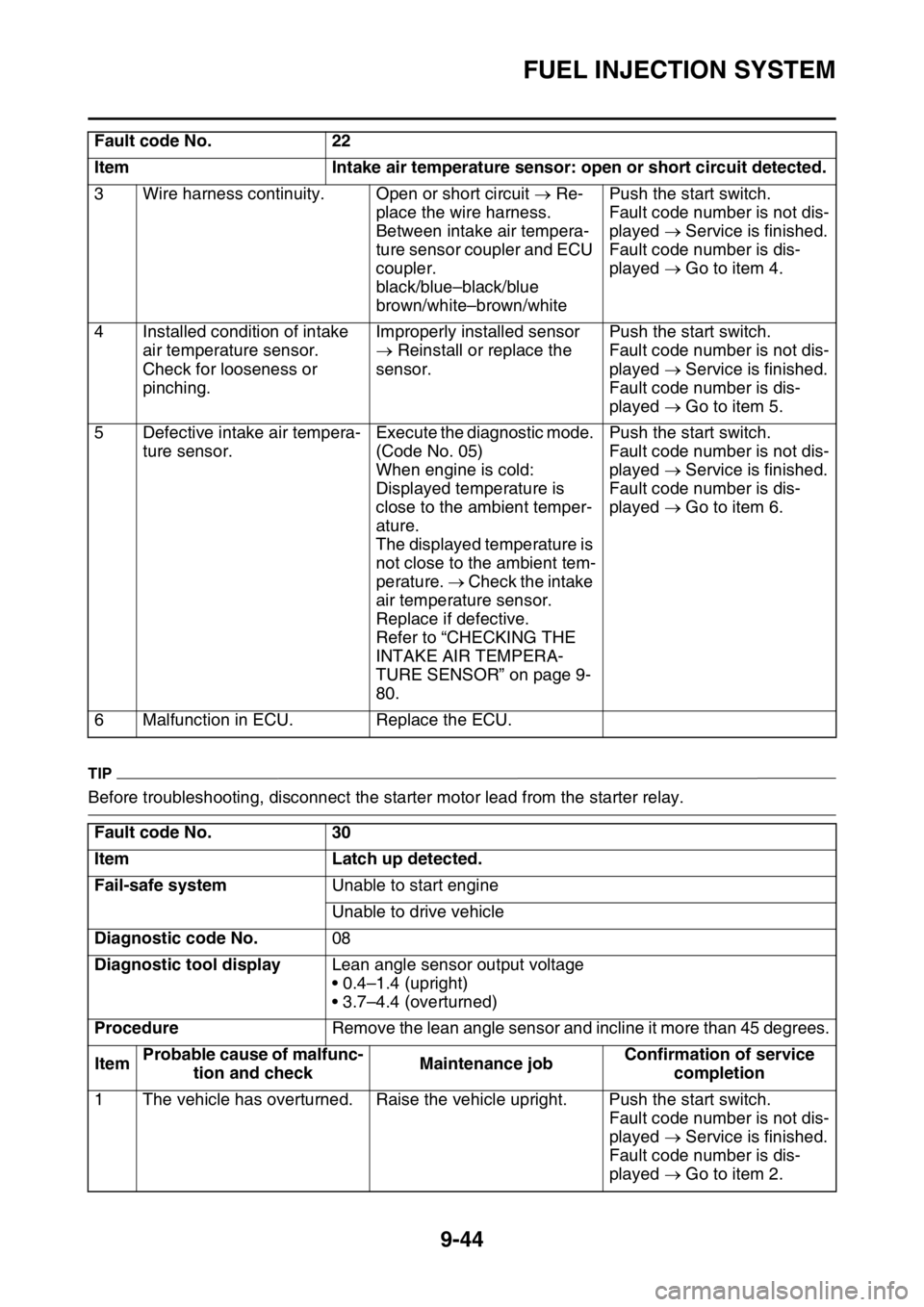

Before troubleshooting, disconnect the starter motor lead from the starter relay. 3 Wire harness continuity. Open or short circuit Re-

place the wire harness.

Between intake air tempera-

ture sensor coupler and ECU

coupler.

black/blue–black/blue

brown/white–brown/whitePush the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 4.

4 Installed condition of intake

air temperature sensor.

Check for looseness or

pinching.Improperly installed sensor

Reinstall or replace the

sensor.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 5.

5 Defective intake air tempera-

ture sensor.Execute the diagnostic mode.

(Code No. 05)

When engine is cold:

Displayed temperature is

close to the ambient temper-

ature.

The displayed temperature is

not close to the ambient tem-

perature. Check the intake

air temperature sensor.

Replace if defective.

Refer to “CHECKING THE

INTAKE AIR TEMPERA-

TURE SENSOR” on page 9-

80.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 6.

6 Malfunction in ECU. Replace the ECU.

Fault code No. 30

Item Latch up detected.

Fail-safe systemUnable to start engine

Unable to drive vehicle

Diagnostic code No.08

Diagnostic tool displayLean angle sensor output voltage

• 0.4–1.4 (upright)

• 3.7–4.4 (overturned)

ProcedureRemove the lean angle sensor and incline it more than 45 degrees.

ItemProbable cause of malfunc-

tion and checkMaintenance jobConfirmation of service

completion

1 The vehicle has overturned. Raise the vehicle upright. Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 2. Fault code No. 22

Item Intake air temperature sensor: open or short circuit detected.

Page 379 of 430

FUEL INJECTION SYSTEM

9-45

2 Installed condition of lean an-

gle sensor.Check the installed direction

and condition of the sensor.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 3.

3 Defective lean angle sensor. Execute the diagnostic mode.

(Code No. 08)

Replace if defective.

Refer to “CHECKING THE

LEAN ANGLE SENSOR” on

page 9-75.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 4.

4 Malfunction in ECU. Replace the ECU.

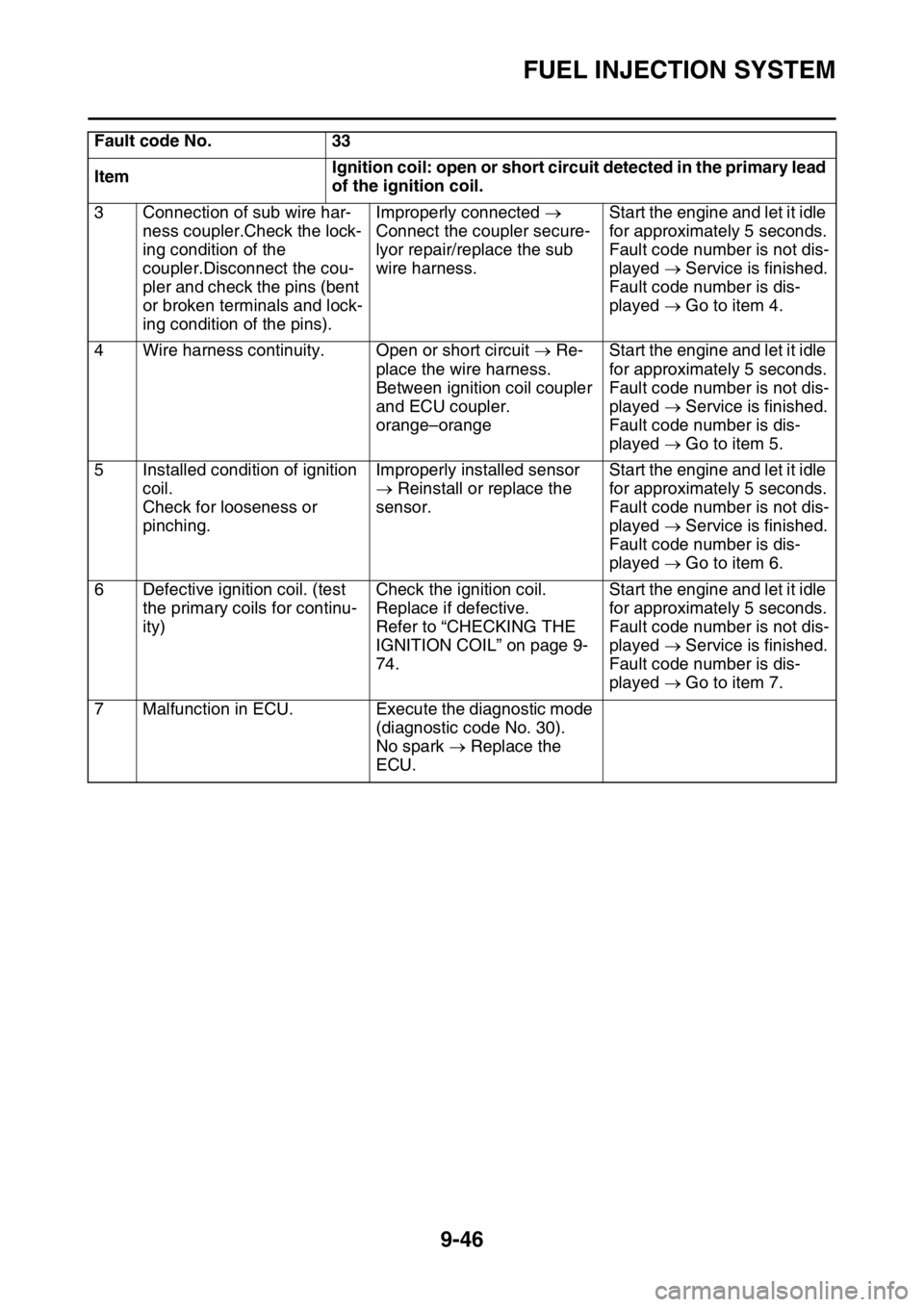

Fault code No. 33

ItemIgnition coil: open or short circuit detected in the primary lead

of the ignition coil.

Fail-safe systemUnable to start engine

Unable to drive vehicle

Diagnostic code No.30

ActuationActuates the ignition coil five times at one-second intervals.

The engine trouble warning light and the “WARNING” on the

Yamaha diagnostic tool screen come on each time the ignition coil

is actuated.

ProcedureCheck that a spark is generated five times.

• Connect an ignition checker.

ItemProbable cause of malfunc-

tion and checkMaintenance jobConfirmation of service

completion

1 Connection of ignition coil

coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins).Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness.Start the engine and let it idle

for approximately 5 seconds.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 2.

2 Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins).Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness.Start the engine and let it idle

for approximately 5 seconds.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 3. Fault code No. 30

Item Latch up detected.

Page 380 of 430

FUEL INJECTION SYSTEM

9-46

3 Connection of sub wire har-

ness coupler.Check the lock-

ing condition of the

coupler.Disconnect the cou-

pler and check the pins (bent

or broken terminals and lock-

ing condition of the pins).Improperly connected

Connect the coupler secure-

lyor repair/replace the sub

wire harness.Start the engine and let it idle

for approximately 5 seconds.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 4.

4 Wire harness continuity. Open or short circuit Re-

place the wire harness.

Between ignition coil coupler

and ECU coupler.

orange–orangeStart the engine and let it idle

for approximately 5 seconds.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 5.

5 Installed condition of ignition

coil.

Check for looseness or

pinching.Improperly installed sensor

Reinstall or replace the

sensor.Start the engine and let it idle

for approximately 5 seconds.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 6.

6 Defective ignition coil. (test

the primary coils for continu-

ity)Check the ignition coil.

Replace if defective.

Refer to “CHECKING THE

IGNITION COIL” on page 9-

74.Start the engine and let it idle

for approximately 5 seconds.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 7.

7 Malfunction in ECU. Execute the diagnostic mode

(diagnostic code No. 30).

No spark Replace the

ECU. Fault code No. 33

ItemIgnition coil: open or short circuit detected in the primary lead

of the ignition coil.

Page 382 of 430

FUEL INJECTION SYSTEM

9-48

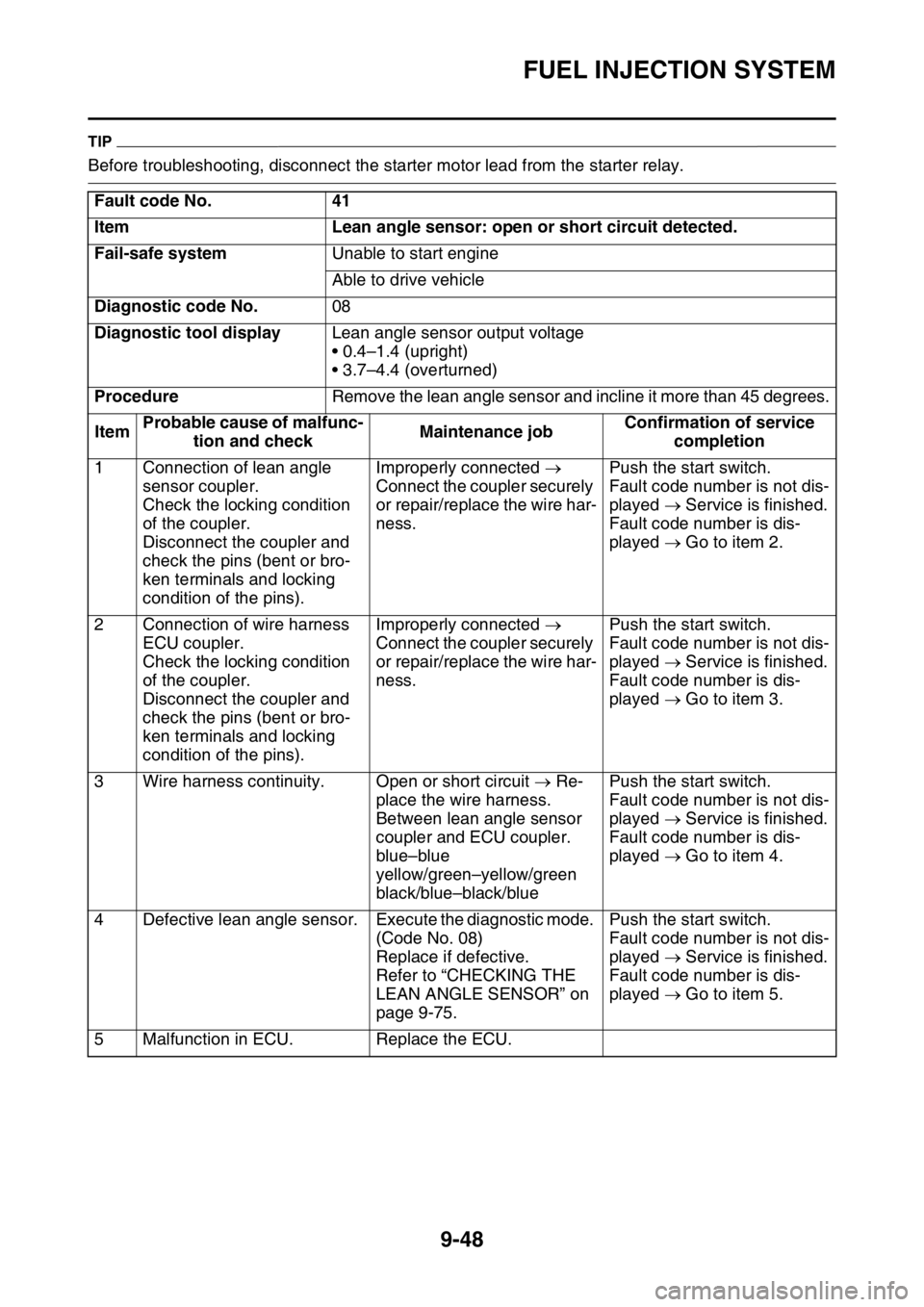

TIP

Before troubleshooting, disconnect the starter motor lead from the starter relay.

Fault code No. 41

Item Lean angle sensor: open or short circuit detected.

Fail-safe systemUnable to start engine

Able to drive vehicle

Diagnostic code No.08

Diagnostic tool displayLean angle sensor output voltage

• 0.4–1.4 (upright)

• 3.7–4.4 (overturned)

ProcedureRemove the lean angle sensor and incline it more than 45 degrees.

ItemProbable cause of malfunc-

tion and checkMaintenance jobConfirmation of service

completion

1 Connection of lean angle

sensor coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins).Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 2.

2 Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins).Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 3.

3 Wire harness continuity. Open or short circuit Re-

place the wire harness.

Between lean angle sensor

coupler and ECU coupler.

blue–blue

yellow/green–yellow/green

black/blue–black/bluePush the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 4.

4 Defective lean angle sensor. Execute the diagnostic mode.

(Code No. 08)

Replace if defective.

Refer to “CHECKING THE

LEAN ANGLE SENSOR” on

page 9-75.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 5.

5 Malfunction in ECU. Replace the ECU.

Page 397 of 430

ELECTRICAL COMPONENTS

9-63

1. Intake air temperature sensor

2. Intake air pressure sensor

3. Throttle position sensor

4. Starter relay

5. Main fuse

6. Headlight relay

7. Starting circuit cut-off relay

8. Lean angle sensor

9. Radiator fan motor fuse

10.Radiator fan motor relay

11.Main relay

12.Coolant temperature sensor

Page 408 of 430

ELECTRICAL COMPONENTS

9-74

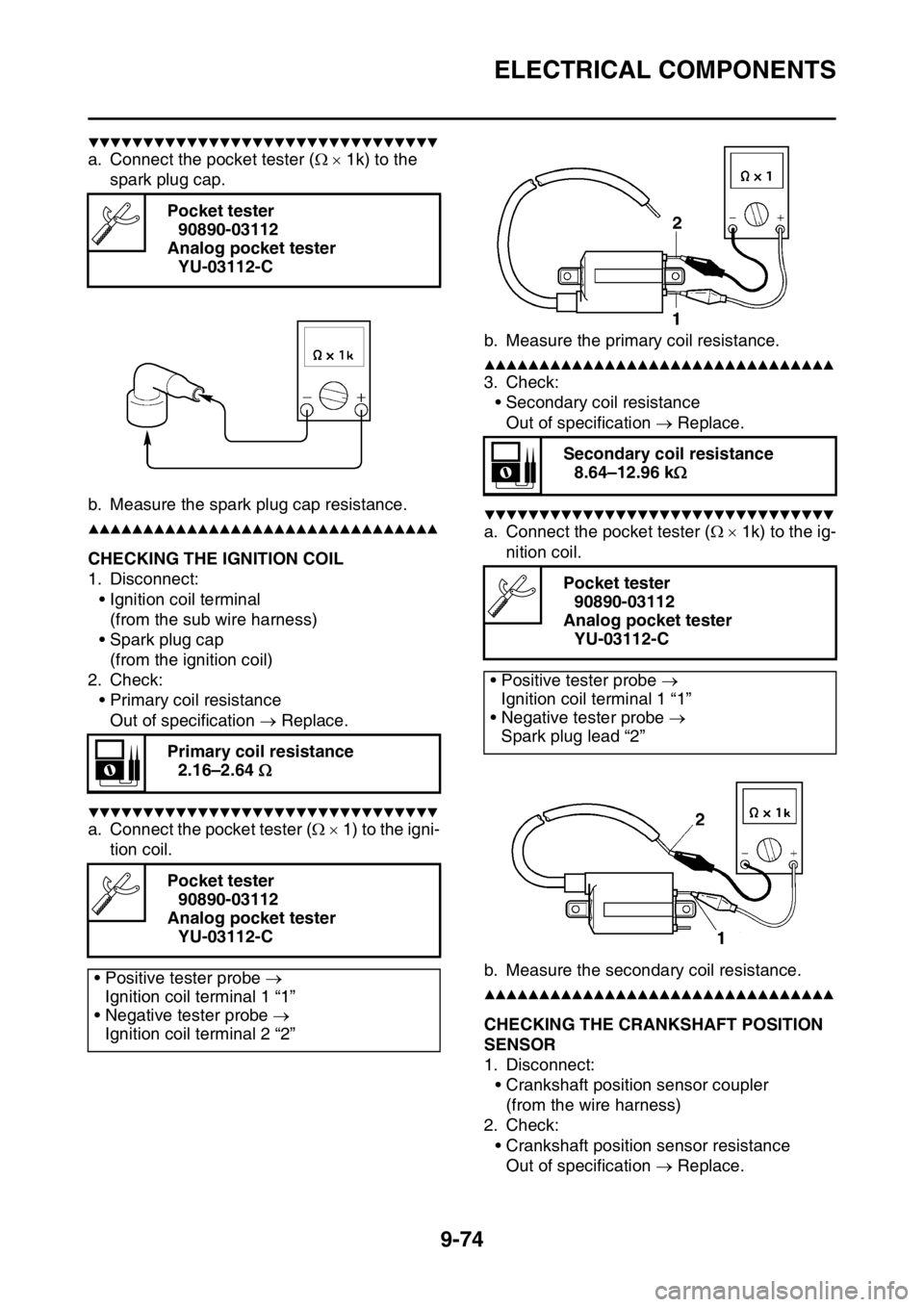

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k) to the

spark plug cap.

b. Measure the spark plug cap resistance.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2392CHECKING THE IGNITION COIL

1. Disconnect:

• Ignition coil terminal

(from the sub wire harness)

• Spark plug cap

(from the ignition coil)

2. Check:

• Primary coil resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1) to the igni-

tion coil.b. Measure the primary coil resistance.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Check:

• Secondary coil resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k) to the ig-

nition coil.

b. Measure the secondary coil resistance.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2393CHECKING THE CRANKSHAFT POSITION

SENSOR

1. Disconnect:

• Crankshaft position sensor coupler

(from the wire harness)

2. Check:

• Crankshaft position sensor resistance

Out of specification Replace. Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Primary coil resistance

2.16–2.64

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Ignition coil terminal 1 “1”

• Negative tester probe

Ignition coil terminal 2 “2”

Secondary coil resistance

8.64–12.96 k

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Ignition coil terminal 1 “1”

• Negative tester probe

Spark plug lead “2”

Page 409 of 430

ELECTRICAL COMPONENTS

9-75

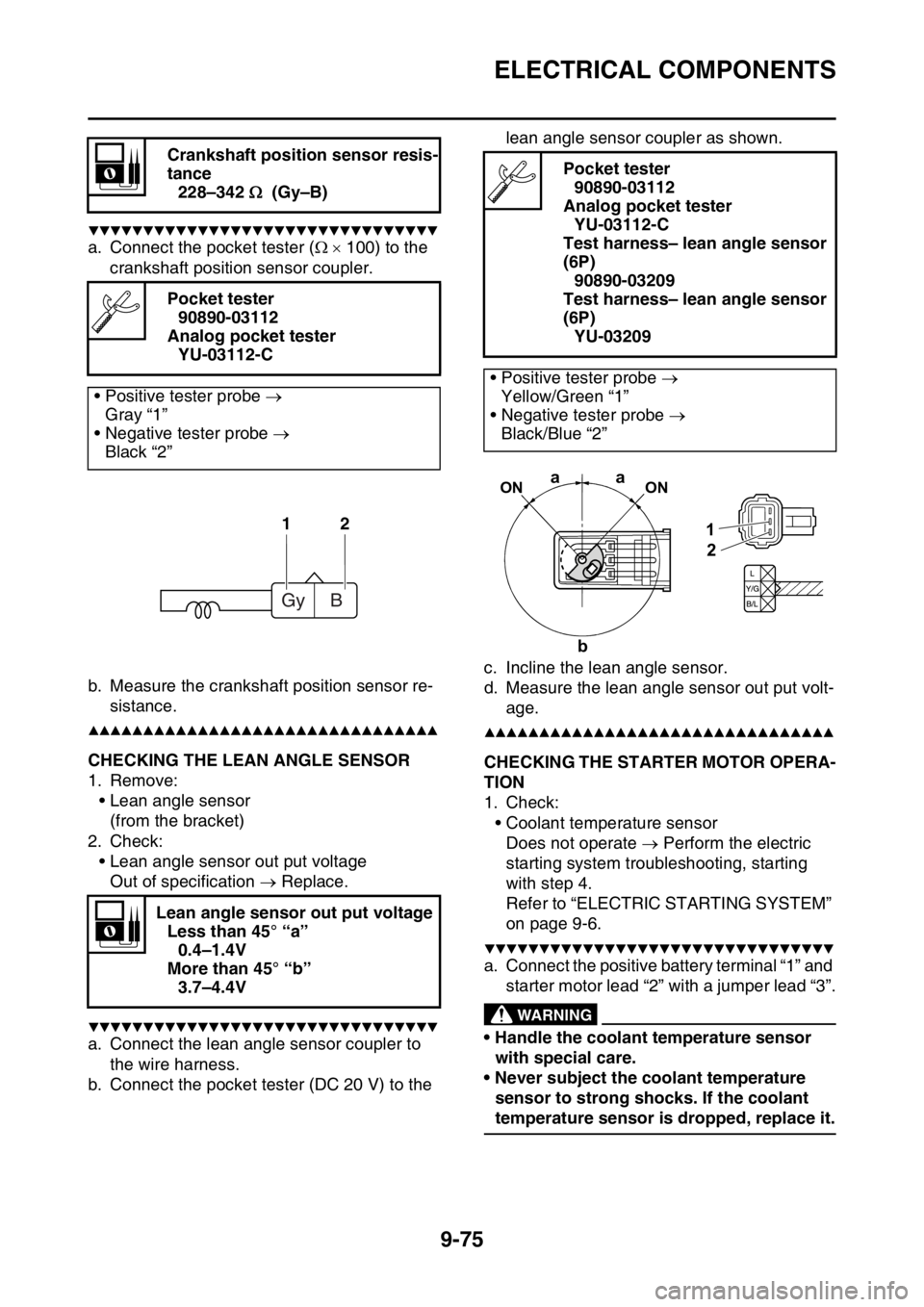

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 100) to the

crankshaft position sensor coupler.

b. Measure the crankshaft position sensor re-

sistance.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2394CHECKING THE LEAN ANGLE SENSOR

1. Remove:

• Lean angle sensor

(from the bracket)

2. Check:

• Lean angle sensor out put voltage

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the lean angle sensor coupler to

the wire harness.

b. Connect the pocket tester (DC 20 V) to the lean angle sensor coupler as shown.

c. Incline the lean angle sensor.

d. Measure the lean angle sensor out put volt-

age.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2395CHECKING THE STARTER MOTOR OPERA-

TION

1. Check:

• Coolant temperature sensor

Does not operate Perform the electric

starting system troubleshooting, starting

with step 4.

Refer to “ELECTRIC STARTING SYSTEM”

on page 9-6.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the positive battery terminal “1” and

starter motor lead “2” with a jumper lead “3”.

EWA

WARNING

• Handle the coolant temperature sensor

with special care.

• Never subject the coolant temperature

sensor to strong shocks. If the coolant

temperature sensor is dropped, replace it. Crankshaft position sensor resis-

tance

228–342 (Gy–B)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Gray “1”

• Negative tester probe

Black “2”

Lean angle sensor out put voltage

Less than 45° “a”

0.4–1.4V

More than 45° “b”

3.7–4.4V

12

Gy B

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Test harness– lean angle sensor

(6P)

90890-03209

Test harness– lean angle sensor

(6P)

YU-03209

• Positive tester probe

Yellow/Green “1”

• Negative tester probe

Black/Blue “2”

2 1

aa

bON ON

Page 411 of 430

ELECTRICAL COMPONENTS

9-77

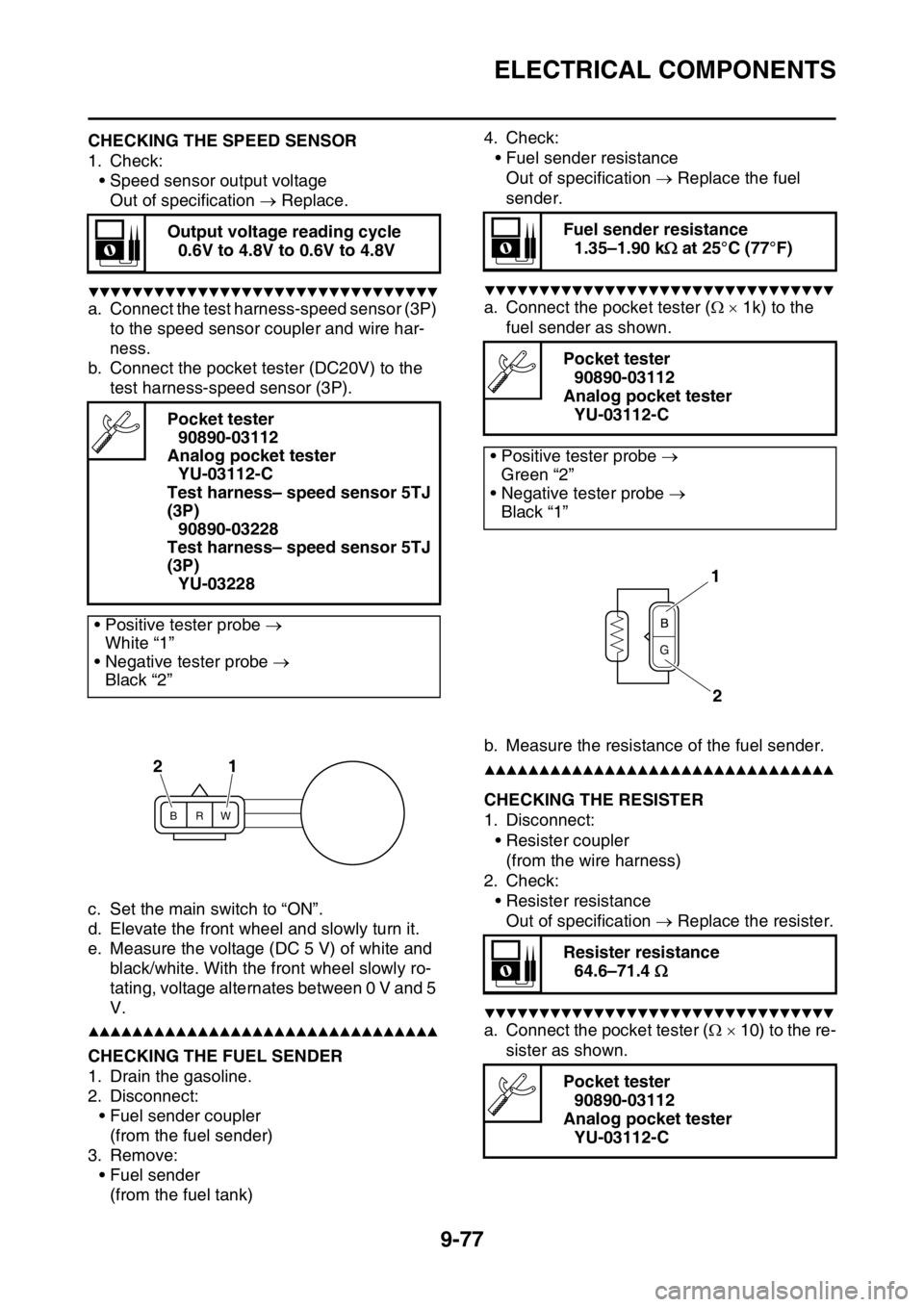

EAS2GB2397CHECKING THE SPEED SENSOR

1. Check:

• Speed sensor output voltage

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the test harness-speed sensor (3P)

to the speed sensor coupler and wire har-

ness.

b. Connect the pocket tester (DC20V) to the

test harness-speed sensor (3P).

c. Set the main switch to “ON”.

d. Elevate the front wheel and slowly turn it.

e. Measure the voltage (DC 5 V) of white and

black/white. With the front wheel slowly ro-

tating, voltage alternates between 0 V and 5

V.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲EAS2GB2398CHECKING THE FUEL SENDER

1. Drain the gasoline.

2. Disconnect:

• Fuel sender coupler

(from the fuel sender)

3. Remove:

• Fuel sender

(from the fuel tank)4. Check:

• Fuel sender resistance

Out of specification Replace the fuel

sender.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k) to the

fuel sender as shown.

b. Measure the resistance of the fuel sender.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2399CHECKING THE RESISTER

1. Disconnect:

• Resister coupler

(from the wire harness)

2. Check:

• Resister resistance

Out of specification Replace the resister.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 10) to the re-

sister as shown. Output voltage reading cycle

0.6V to 4.8V to 0.6V to 4.8V

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Test harness– speed sensor 5TJ

(3P)

90890-03228

Test harness– speed sensor 5TJ

(3P)

YU-03228

• Positive tester probe

White “1”

• Negative tester probe

Black “2”

BRW

21

Fuel sender resistance

1.35–1.90 k at 25°C (77°F)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Green “2”

• Negative tester probe

Black “1”

Resister resistance

64.6–71.4

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

1

2

Page 412 of 430

ELECTRICAL COMPONENTS

9-78

b. Measure the resistance of the resister.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

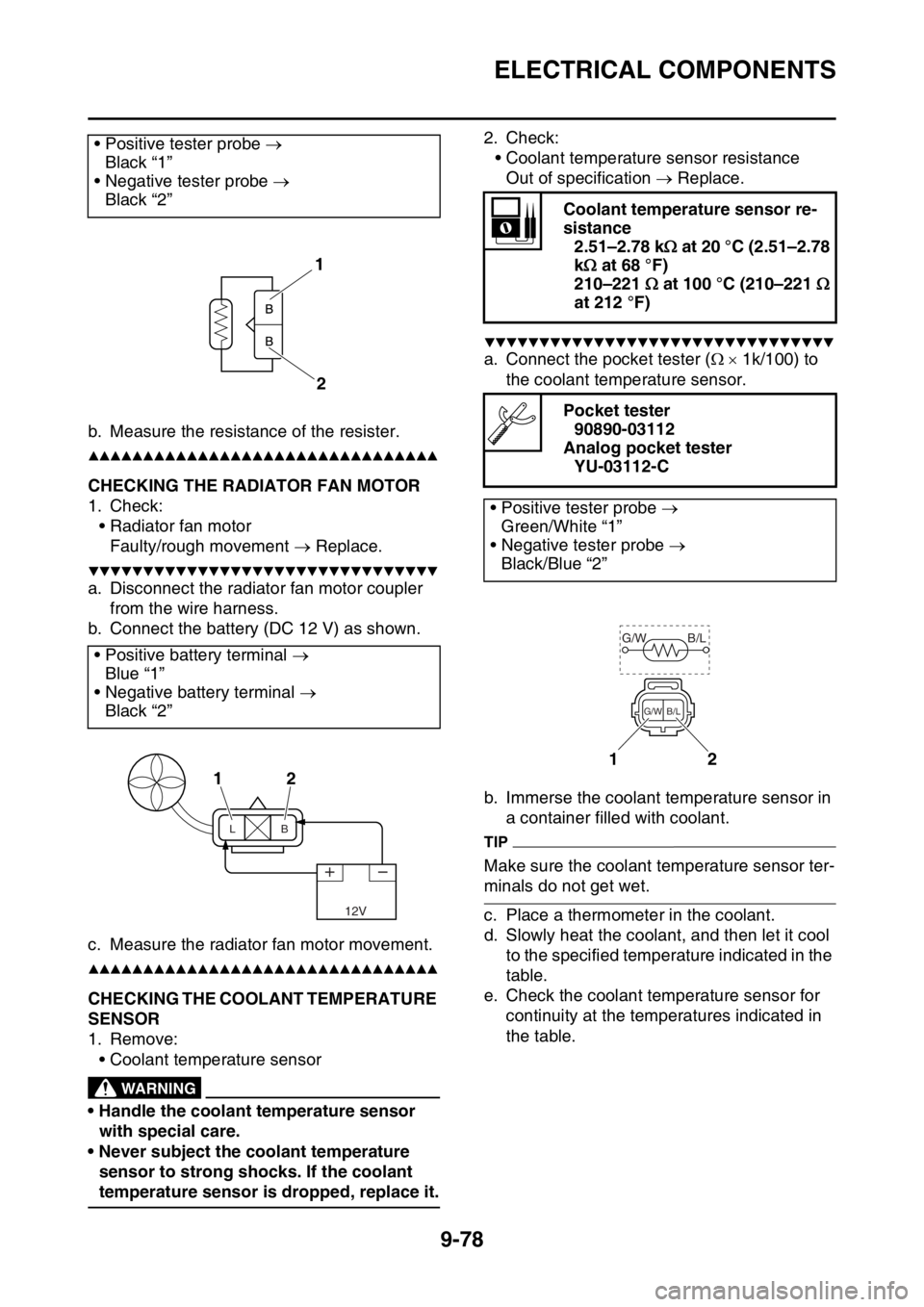

EAS2GB2400CHECKING THE RADIATOR FAN MOTOR

1. Check:

• Radiator fan motor

Faulty/rough movement Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Disconnect the radiator fan motor coupler

from the wire harness.

b. Connect the battery (DC 12 V) as shown.

c. Measure the radiator fan motor movement.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2401CHECKING THE COOLANT TEMPERATURE

SENSOR

1. Remove:

• Coolant temperature sensor

EWA

WARNING

• Handle the coolant temperature sensor

with special care.

• Never subject the coolant temperature

sensor to strong shocks. If the coolant

temperature sensor is dropped, replace it.2. Check:

• Coolant temperature sensor resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k/100) to

the coolant temperature sensor.

b. Immerse the coolant temperature sensor in

a container filled with coolant.

TIP

Make sure the coolant temperature sensor ter-

minals do not get wet.

c. Place a thermometer in the coolant.

d. Slowly heat the coolant, and then let it cool

to the specified temperature indicated in the

table.

e. Check the coolant temperature sensor for

continuity at the temperatures indicated in

the table. • Positive tester probe

Black “1”

• Negative tester probe

Black “2”

• Positive battery terminal

Blue “1”

• Negative battery terminal

Black “2”

1

2

12

12V

LB

Coolant temperature sensor re-

sistance

2.51–2.78 k at 20 °C (2.51–2.78

k at 68 °F)

210–221 at 100 °C (210–221

at 212 °F)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Green/White “1”

• Negative tester probe

Black/Blue “2”

12

G/W B/L

B/L G/W