YAMAHA WR 250F 2017 Owners Manual

Manufacturer: YAMAHA, Model Year: 2017, Model line: WR 250F, Model: YAMAHA WR 250F 2017Pages: 432, PDF Size: 14.14 MB

Page 261 of 432

CYLINDER AND PISTON

6-32

EAS2GBB256

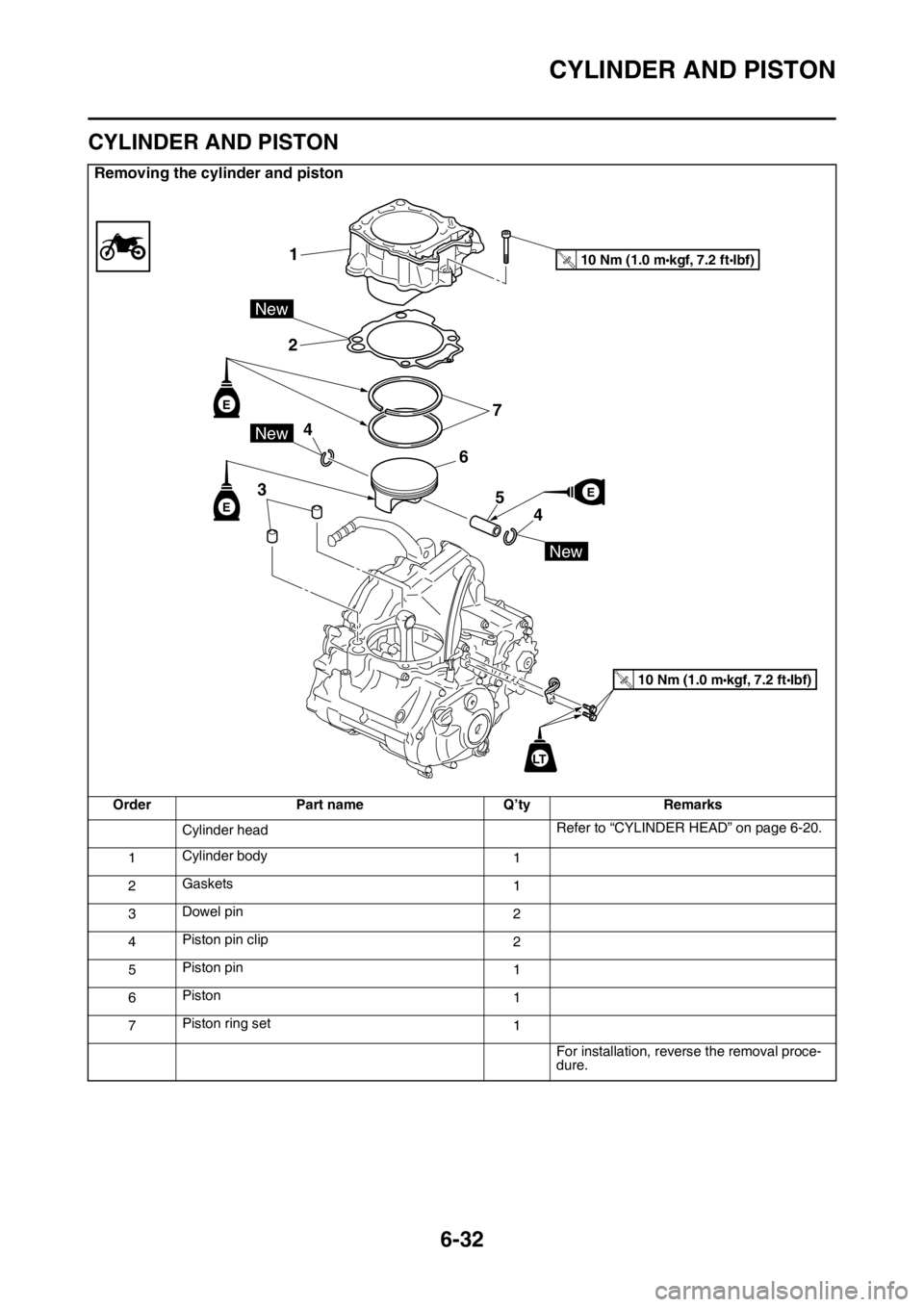

CYLINDER AND PISTON

Removing the cylinder and piston

Order Part name QŌĆÖty Remarks

Cylinder headRefer to ŌĆ£CYLINDER HEADŌĆØ on page 6-20.

1Cylinder body

1

2Gaskets

1

3Dowel pin

2

4Piston pin clip

2

5Piston pin

1

6Piston

1

7Piston ring set

1

For installation, reverse the removal proce-

dure.

1

2

3

4

4

5

6

7

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

E

E

New

New

New

LT

E

Page 262 of 432

CYLINDER AND PISTON

6-33

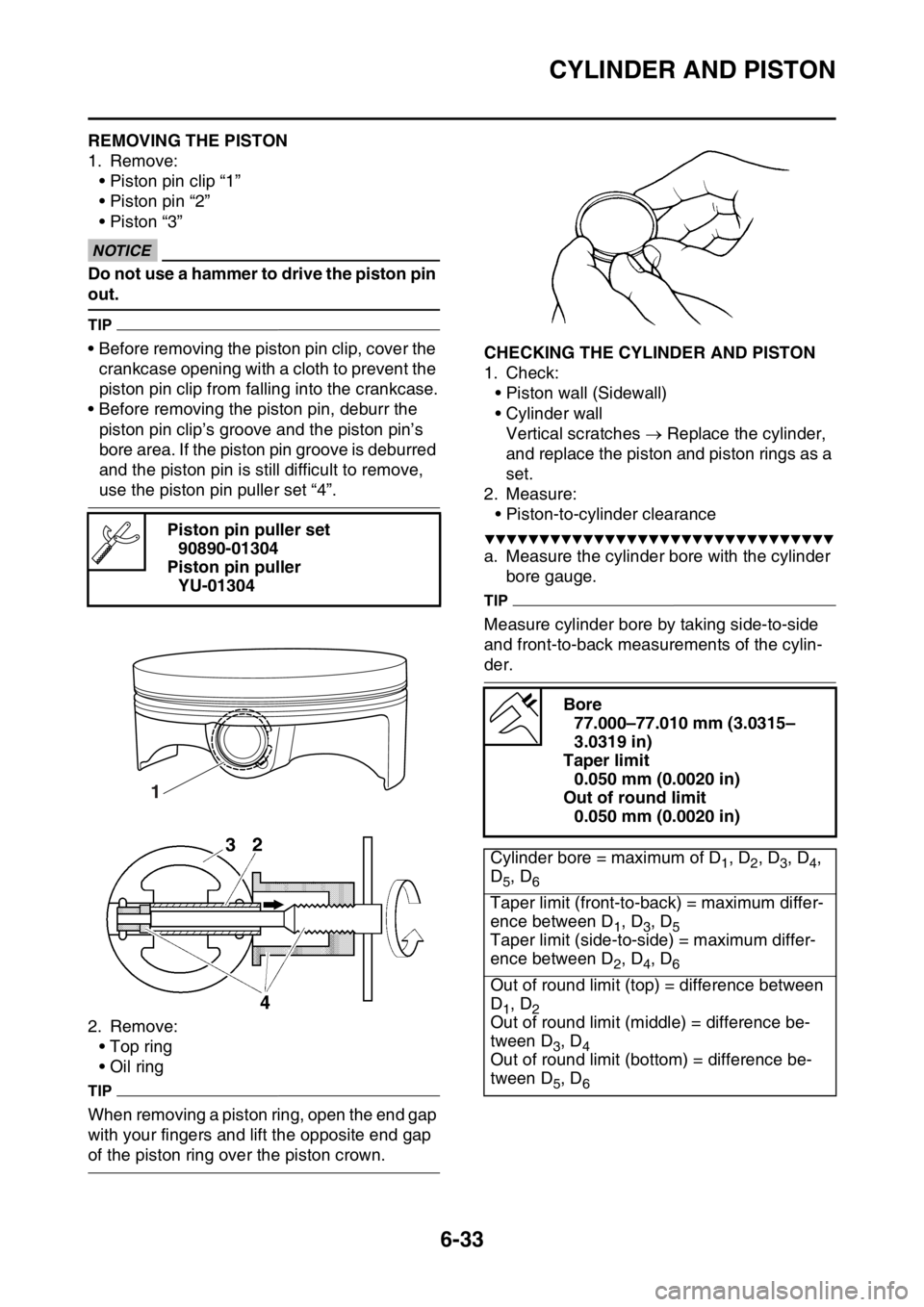

EAS2GBB257REMOVING THE PISTON

1. Remove:

ŌĆó Piston pin clip ŌĆ£1ŌĆØ

ŌĆó Piston pin ŌĆ£2ŌĆØ

ŌĆó Piston ŌĆ£3ŌĆØ

ECA

NOTICE

Do not use a hammer to drive the piston pin

out.

TIP

ŌĆó Before removing the piston pin clip, cover the

crankcase opening with a cloth to prevent the

piston pin clip from falling into the crankcase.

ŌĆó Before removing the piston pin, deburr the

piston pin clipŌĆÖs groove and the piston pinŌĆÖs

bore area. If the piston pin groove is deburred

and the piston pin is still difficult to remove,

use the piston pin puller set ŌĆ£4ŌĆØ.

2. Remove:

ŌĆó Top ring

ŌĆó Oil ring

TIP

When removing a piston ring, open the end gap

with your fingers and lift the opposite end gap

of the piston ring over the piston crown.

EAS2GBB258CHECKING THE CYLINDER AND PISTON

1. Check:

ŌĆó Piston wall (Sidewall)

ŌĆó Cylinder wall

Vertical scratches ’é« Replace the cylinder,

and replace the piston and piston rings as a

set.

2. Measure:

ŌĆó Piston-to-cylinder clearance

Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝

a. Measure the cylinder bore with the cylinder

bore gauge.

TIP

Measure cylinder bore by taking side-to-side

and front-to-back measurements of the cylin-

der. Piston pin puller set

90890-01304

Piston pin puller

YU-01304

1

Bore

77.000ŌĆō77.010 mm (3.0315ŌĆō

3.0319 in)

Taper limit

0.050 mm (0.0020 in)

Out of round limit

0.050 mm (0.0020 in)

Cylinder bore = maximum of D

1, D2, D3, D4,

D

5, D6

Taper limit (front-to-back) = maximum differ-

ence between D

1, D3, D5Taper limit (side-to-side) = maximum differ-

ence between D

2, D4, D6

Out of round limit (top) = difference between

D

1, D2Out of round limit (middle) = difference be-

tween D

3, D4Out of round limit (bottom) = difference be-

tween D

5, D6

Page 263 of 432

CYLINDER AND PISTON

6-34

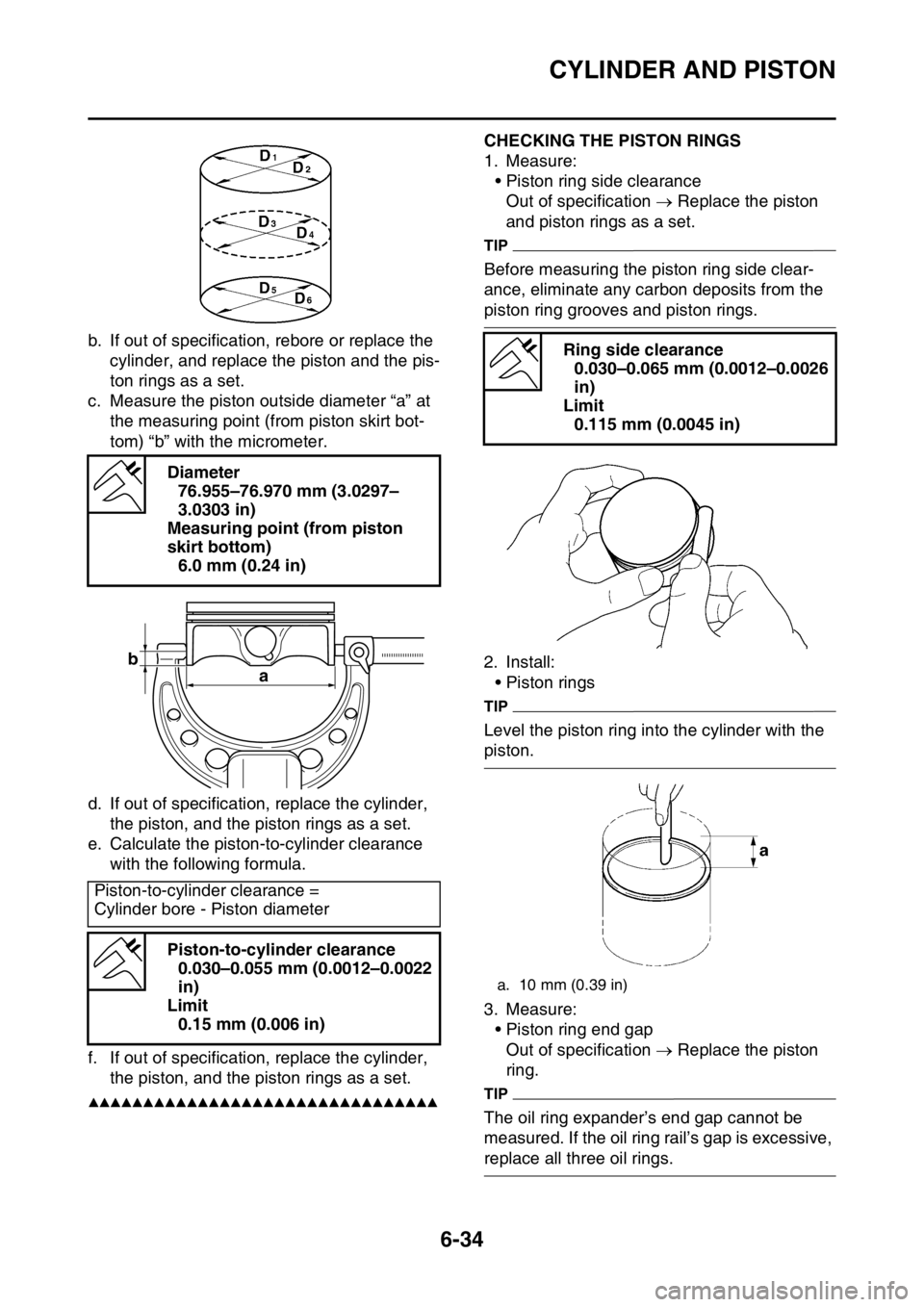

b. If out of specification, rebore or replace the

cylinder, and replace the piston and the pis-

ton rings as a set.

c. Measure the piston outside diameter ŌĆ£aŌĆØ at

the measuring point (from piston skirt bot-

tom) ŌĆ£bŌĆØ with the micrometer.

d. If out of specification, replace the cylinder,

the piston, and the piston rings as a set.

e. Calculate the piston-to-cylinder clearance

with the following formula.

f. If out of specification, replace the cylinder,

the piston, and the piston rings as a set.

Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓

EAS2GBB259CHECKING THE PISTON RINGS

1. Measure:

ŌĆó Piston ring side clearance

Out of specification ’é« Replace the piston

and piston rings as a set.

TIP

Before measuring the piston ring side clear-

ance, eliminate any carbon deposits from the

piston ring grooves and piston rings.

2. Install:

ŌĆó Piston rings

TIP

Level the piston ring into the cylinder with the

piston.

3. Measure:

ŌĆó Piston ring end gap

Out of specification ’é« Replace the piston

ring.

TIP

The oil ring expanderŌĆÖs end gap cannot be

measured. If the oil ring railŌĆÖs gap is excessive,

replace all three oil rings. Diameter

76.955ŌĆō76.970 mm (3.0297ŌĆō

3.0303 in)

Measuring point (from piston

skirt bottom)

6.0 mm (0.24 in)

Piston-to-cylinder clearance =

Cylinder bore - Piston diameter

Piston-to-cylinder clearance

0.030ŌĆō0.055 mm (0.0012ŌĆō0.0022

in)

Limit

0.15 mm (0.006 in)

b

a

Ring side clearance

0.030ŌĆō0.065 mm (0.0012ŌĆō0.0026

in)

Limit

0.115 mm (0.0045 in)

a. 10 mm (0.39 in)

Page 264 of 432

CYLINDER AND PISTON

6-35

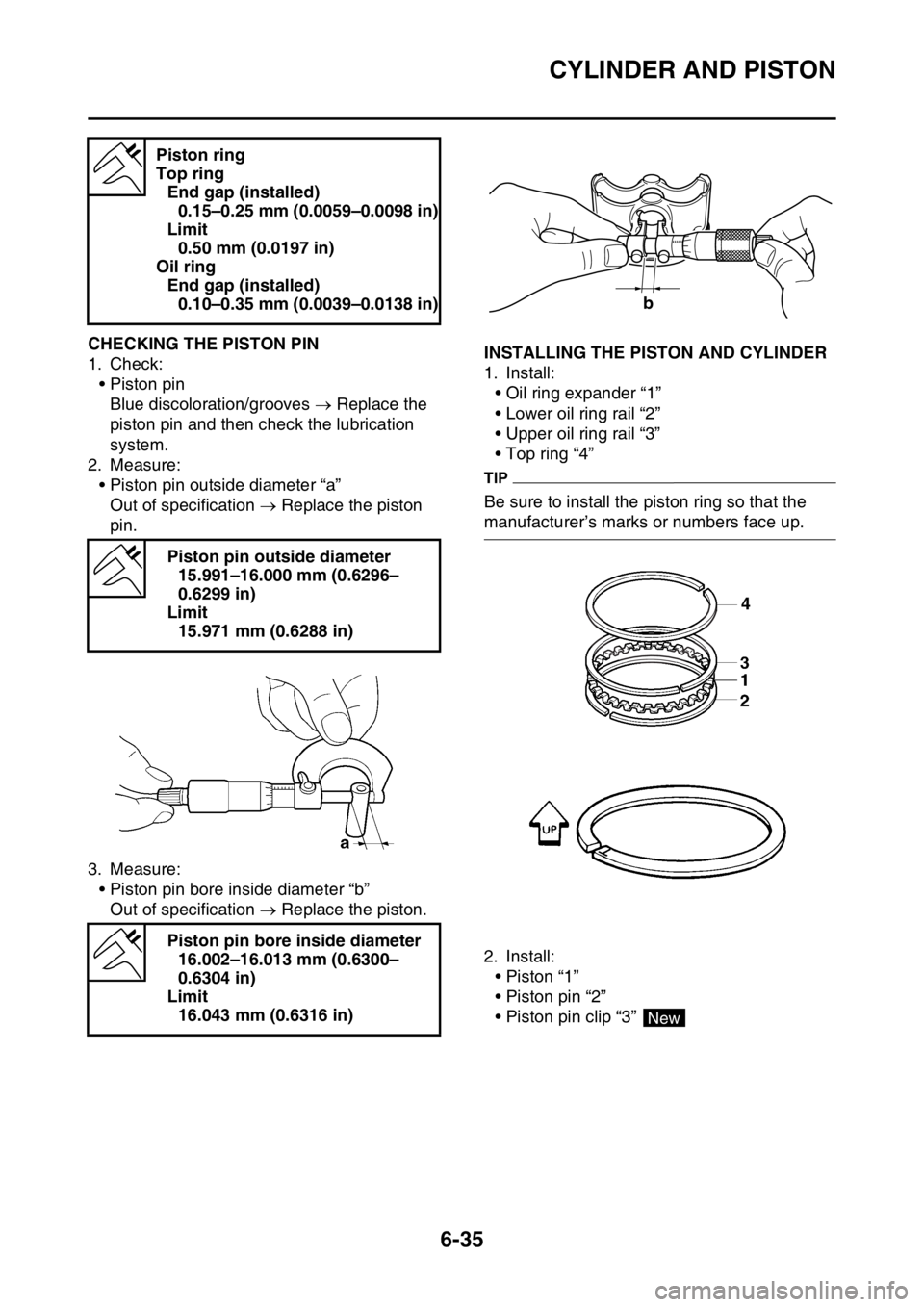

EAS2GBB260CHECKING THE PISTON PIN

1. Check:

ŌĆó Piston pin

Blue discoloration/grooves ’é« Replace the

piston pin and then check the lubrication

system.

2. Measure:

ŌĆó Piston pin outside diameter ŌĆ£aŌĆØ

Out of specification ’é« Replace the piston

pin.

3. Measure:

ŌĆó Piston pin bore inside diameter ŌĆ£bŌĆØ

Out of specification ’é« Replace the piston.EAS2GBB261INSTALLING THE PISTON AND CYLINDER

1. Install:

ŌĆó Oil ring expander ŌĆ£1ŌĆØ

ŌĆó Lower oil ring rail ŌĆ£2ŌĆØ

ŌĆó Upper oil ring rail ŌĆ£3ŌĆØ

ŌĆó Top ring ŌĆ£4ŌĆØ

TIP

Be sure to install the piston ring so that the

manufacturerŌĆÖs marks or numbers face up.

2. Install:

ŌĆó Piston ŌĆ£1ŌĆØ

ŌĆó Piston pin ŌĆ£2ŌĆØ

ŌĆó Piston pin clip ŌĆ£3ŌĆØ Piston ring

Top ring

End gap (installed)

0.15ŌĆō0.25 mm (0.0059ŌĆō0.0098 in)

Limit

0.50 mm (0.0197 in)

Oil ring

End gap (installed)

0.10ŌĆō0.35 mm (0.0039ŌĆō0.0138 in)

Piston pin outside diameter

15.991ŌĆō16.000 mm (0.6296ŌĆō

0.6299 in)

Limit

15.971 mm (0.6288 in)

Piston pin bore inside diameter

16.002ŌĆō16.013 mm (0.6300ŌĆō

0.6304 in)

Limit

16.043 mm (0.6316 in)

b

4

New

Page 265 of 432

CYLINDER AND PISTON

6-36

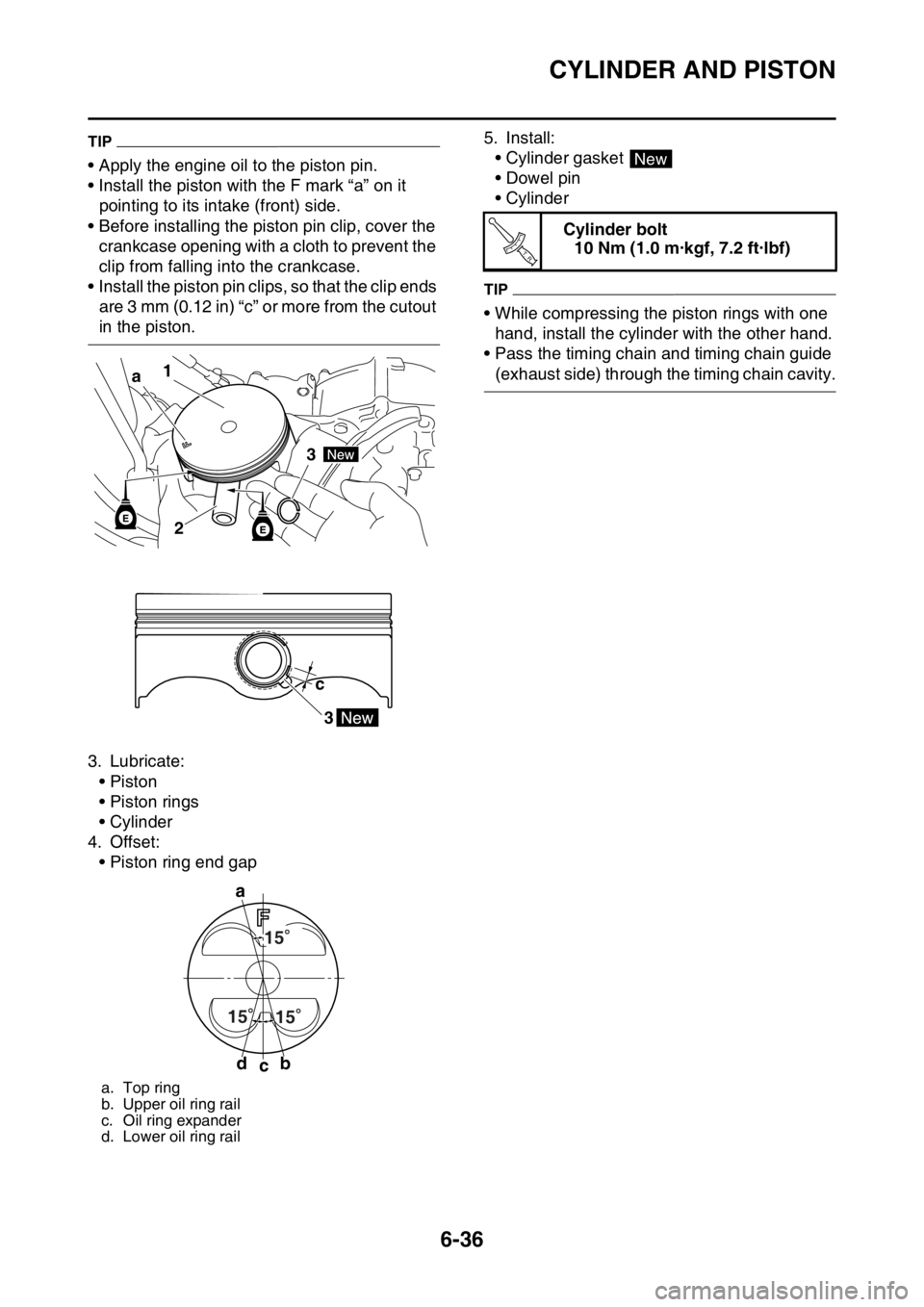

TIP

ŌĆó Apply the engine oil to the piston pin.

ŌĆó Install the piston with the F mark ŌĆ£aŌĆØ on it

pointing to its intake (front) side.

ŌĆó Before installing the piston pin clip, cover the

crankcase opening with a cloth to prevent the

clip from falling into the crankcase.

ŌĆó Install the piston pin clips, so that the clip ends

are 3 mm (0.12 in) ŌĆ£cŌĆØ or more from the cutout

in the piston.

3. Lubricate:

ŌĆóPiston

ŌĆó Piston rings

ŌĆó Cylinder

4. Offset:

ŌĆó Piston ring end gap5. Install:

ŌĆó Cylinder gasket

ŌĆó Dowel pin

ŌĆó Cylinder

TIP

ŌĆó While compressing the piston rings with one

hand, install the cylinder with the other hand.

ŌĆó Pass the timing chain and timing chain guide

(exhaust side) through the timing chain cavity.

a. Top ring

b. Upper oil ring rail

c. Oil ring expander

d. Lower oil ring rail

1

3

2 a

3 c

a

db

c15

15

15

Cylinder bolt

10 Nm (1.0 m┬Ękgf, 7.2 ft┬Ęlbf)

New

T R..

Page 266 of 432

ELECTRIC STARTER

6-37

EAS2GBB262

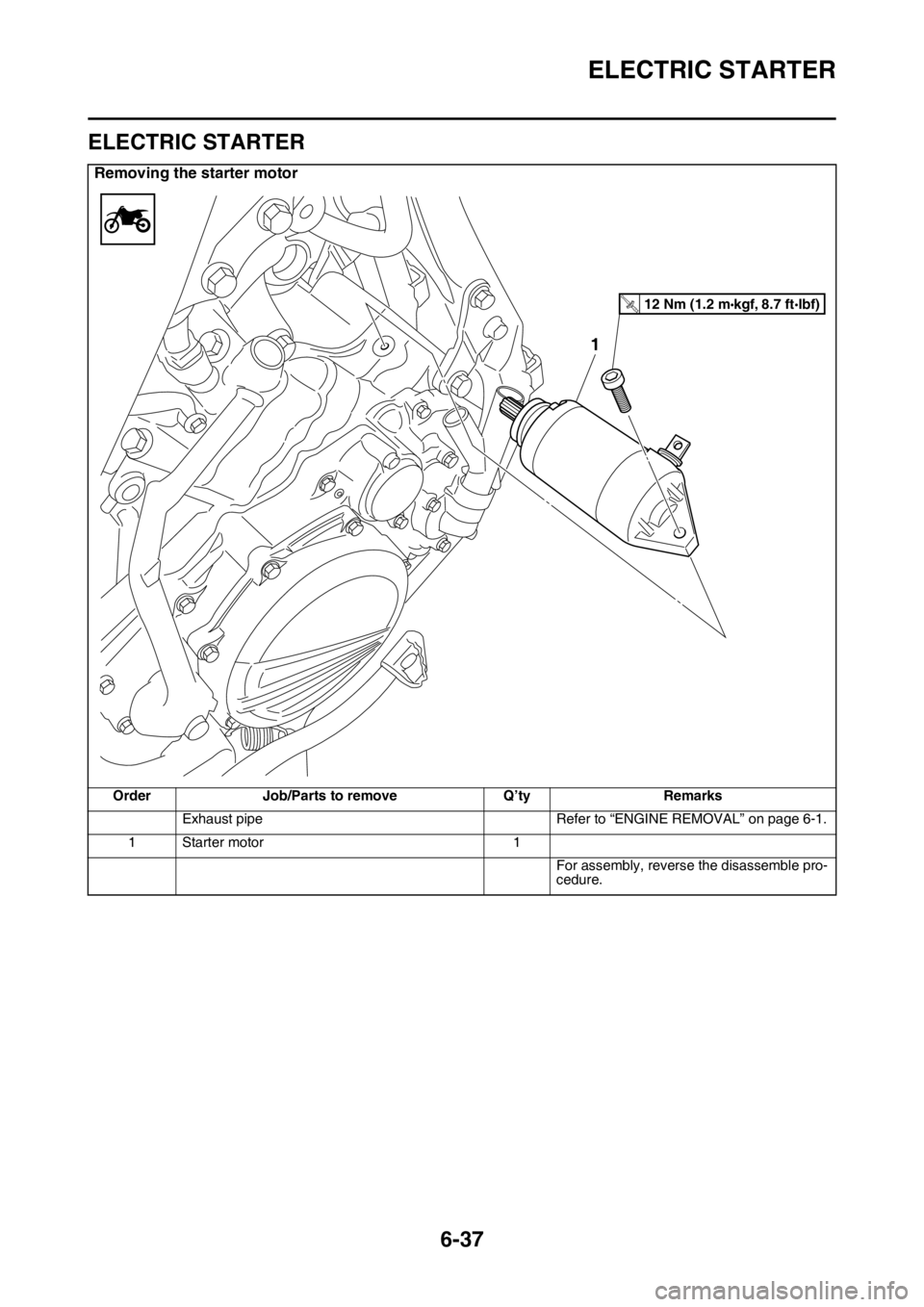

ELECTRIC STARTER

Removing the starter motor

Order Job/Parts to remove QŌĆÖty Remarks

Exhaust pipe Refer to ŌĆ£ENGINE REMOVALŌĆØ on page 6-1.

1 Starter motor 1

For assembly, reverse the disassemble pro-

cedure.

1

12 Nm (1.2 m kgf, 8.7 ft Ibf)T.R.

Page 267 of 432

ELECTRIC STARTER

6-38

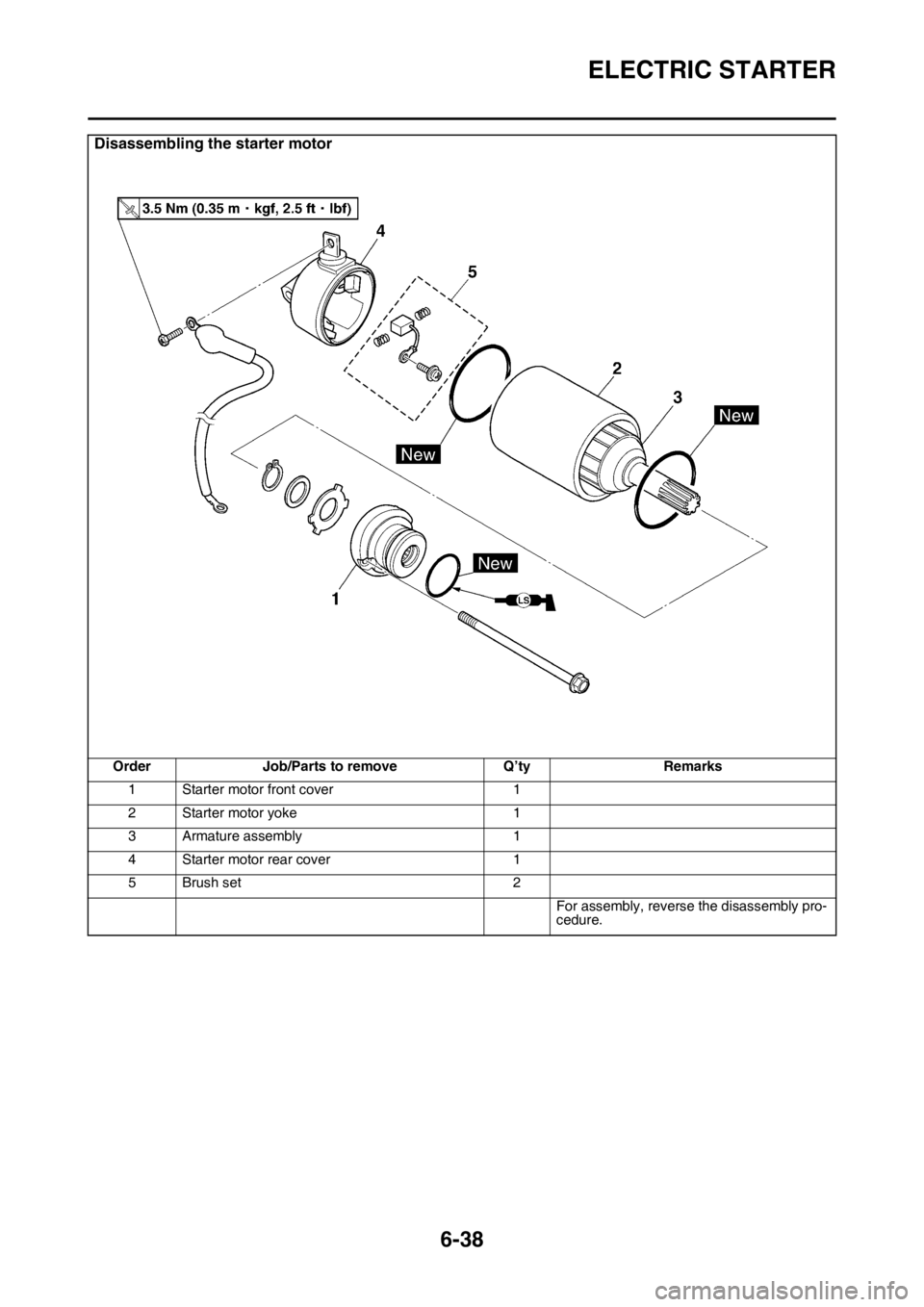

Disassembling the starter motor

Order Job/Parts to remove QŌĆÖty Remarks

1 Starter motor front cover 1

2 Starter motor yoke 1

3 Armature assembly 1

4 Starter motor rear cover 1

5 Brush set 2

For assembly, reverse the disassembly pro-

cedure.

Page 268 of 432

ELECTRIC STARTER

6-39

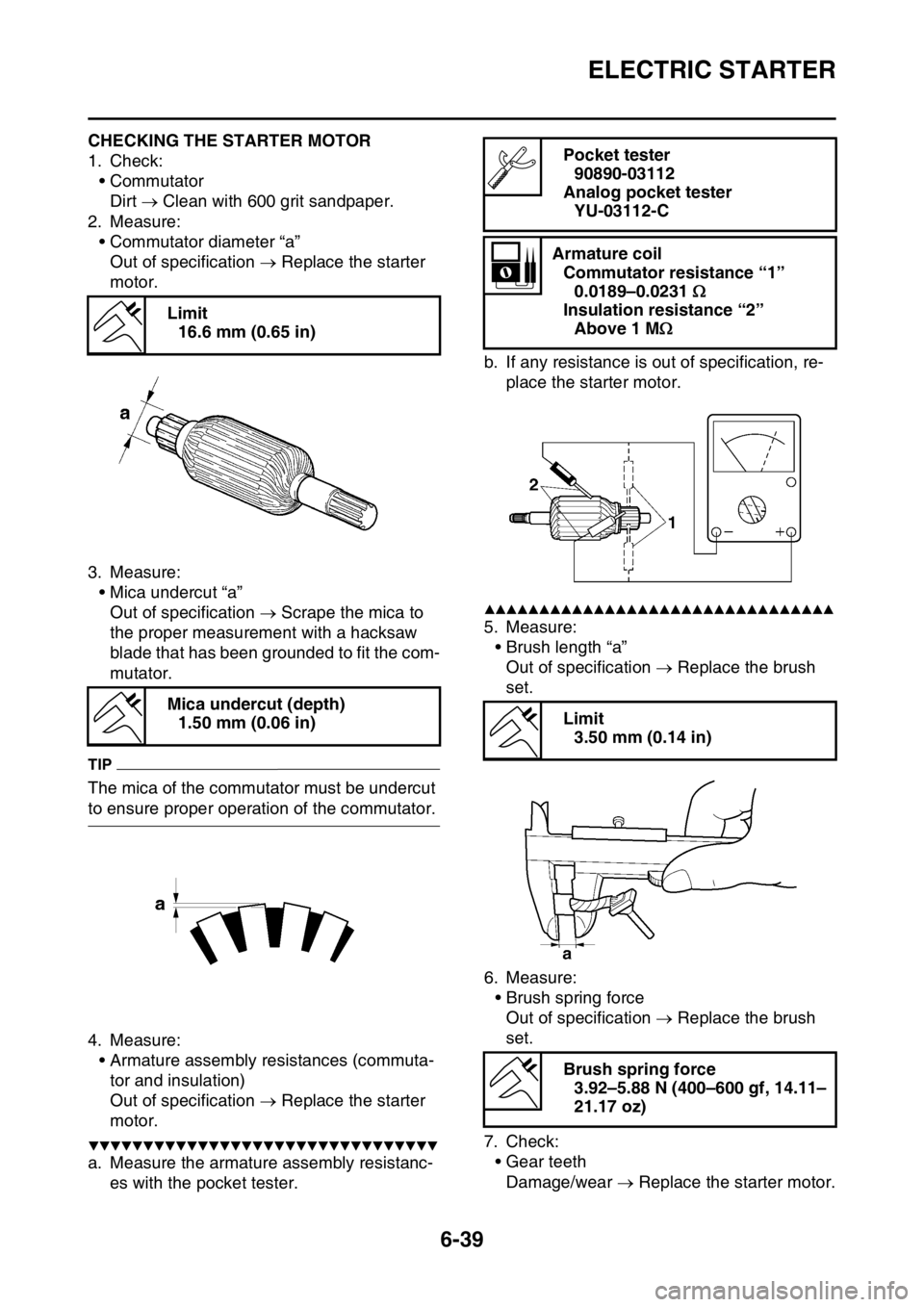

EAS2GBB263CHECKING THE STARTER MOTOR

1. Check:

ŌĆóCommutator

Dirt ’é« Clean with 600 grit sandpaper.

2. Measure:

ŌĆó Commutator diameter ŌĆ£aŌĆØ

Out of specification ’é« Replace the starter

motor.

3. Measure:

ŌĆó Mica undercut ŌĆ£aŌĆØ

Out of specification ’é« Scrape the mica to

the proper measurement with a hacksaw

blade that has been grounded to fit the com-

mutator.

TIP

The mica of the commutator must be undercut

to ensure proper operation of the commutator.

4. Measure:

ŌĆó Armature assembly resistances (commuta-

tor and insulation)

Out of specification ’é« Replace the starter

motor.

Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝Ō¢╝

a. Measure the armature assembly resistanc-

es with the pocket tester.b. If any resistance is out of specification, re-

place the starter motor.

Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓Ō¢▓

5. Measure:

ŌĆó Brush length ŌĆ£aŌĆØ

Out of specification ’é« Replace the brush

set.

6. Measure:

ŌĆó Brush spring force

Out of specification ’é« Replace the brush

set.

7. Check:

ŌĆó Gear teeth

Damage/wear ’é« Replace the starter motor. Limit

16.6 mm (0.65 in)

Mica undercut (depth)

1.50 mm (0.06 in)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Armature coil

Commutator resistance ŌĆ£1ŌĆØ

0.0189ŌĆō0.0231 ’üŚ

Insulation resistance ŌĆ£2ŌĆØ

Above 1 M’üŚ

Limit

3.50 mm (0.14 in)

Brush spring force

3.92ŌĆō5.88 N (400ŌĆō600 gf, 14.11ŌĆō

21.17 oz)

Page 269 of 432

ELECTRIC STARTER

6-40

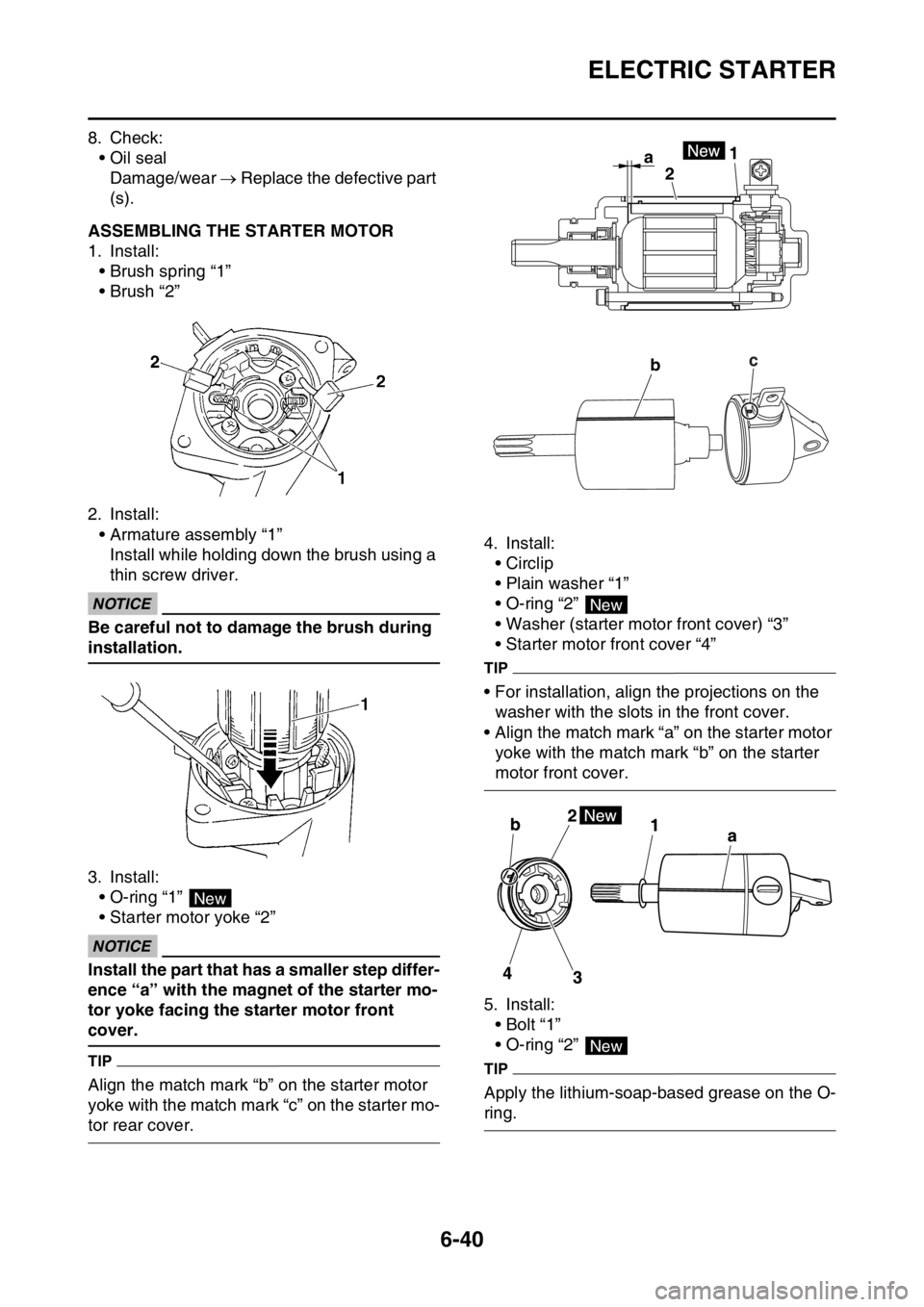

8. Check:

ŌĆó Oil seal

Damage/wear ’é« Replace the defective part

(s).

EAS2GBB264ASSEMBLING THE STARTER MOTOR

1. Install:

ŌĆó Brush spring ŌĆ£1ŌĆØ

ŌĆó Brush ŌĆ£2ŌĆØ

2. Install:

ŌĆó Armature assembly ŌĆ£1ŌĆØ

Install while holding down the brush using a

thin screw driver.

ECA

NOTICE

Be careful not to damage the brush during

installation.

3. Install:

ŌĆó O-ring ŌĆ£1ŌĆØ

ŌĆó Starter motor yoke ŌĆ£2ŌĆØ

ECA

NOTICE

Install the part that has a smaller step differ-

ence ŌĆ£aŌĆØ with the magnet of the starter mo-

tor yoke facing the starter motor front

cover.

TIP

Align the match mark ŌĆ£bŌĆØ on the starter motor

yoke with the match mark ŌĆ£cŌĆØ on the starter mo-

tor rear cover.4. Install:

ŌĆó Circlip

ŌĆóPlain washer ŌĆ£1ŌĆØ

ŌĆó O-ring ŌĆ£2ŌĆØ

ŌĆó Washer (starter motor front cover) ŌĆ£3ŌĆØ

ŌĆó Starter motor front cover ŌĆ£4ŌĆØ

TIP

ŌĆó For installation, align the projections on the

washer with the slots in the front cover.

ŌĆó Align the match mark ŌĆ£aŌĆØ on the starter motor

yoke with the match mark ŌĆ£bŌĆØ on the starter

motor front cover.

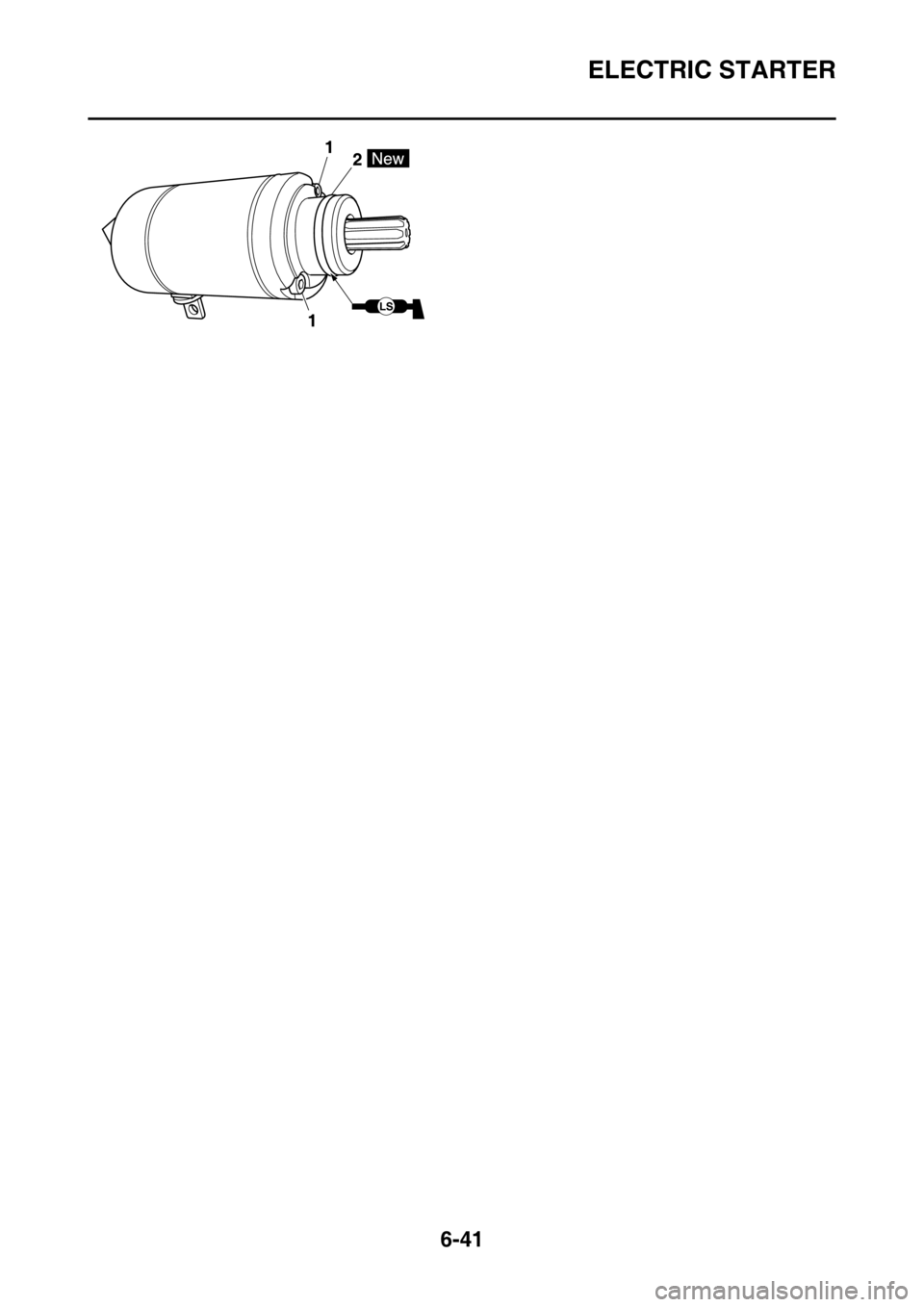

5. Install:

ŌĆóBolt ŌĆ£1ŌĆØ

ŌĆó O-ring ŌĆ£2ŌĆØ

TIP

Apply the lithium-soap-based grease on the O-

ring.

New

a1

2

bc

New

New

Page 270 of 432

ELECTRIC STARTER

6-41