YAMAHA WR 450F 2016 Owners Manual

Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 321 of 426

FUEL TANK

8-4

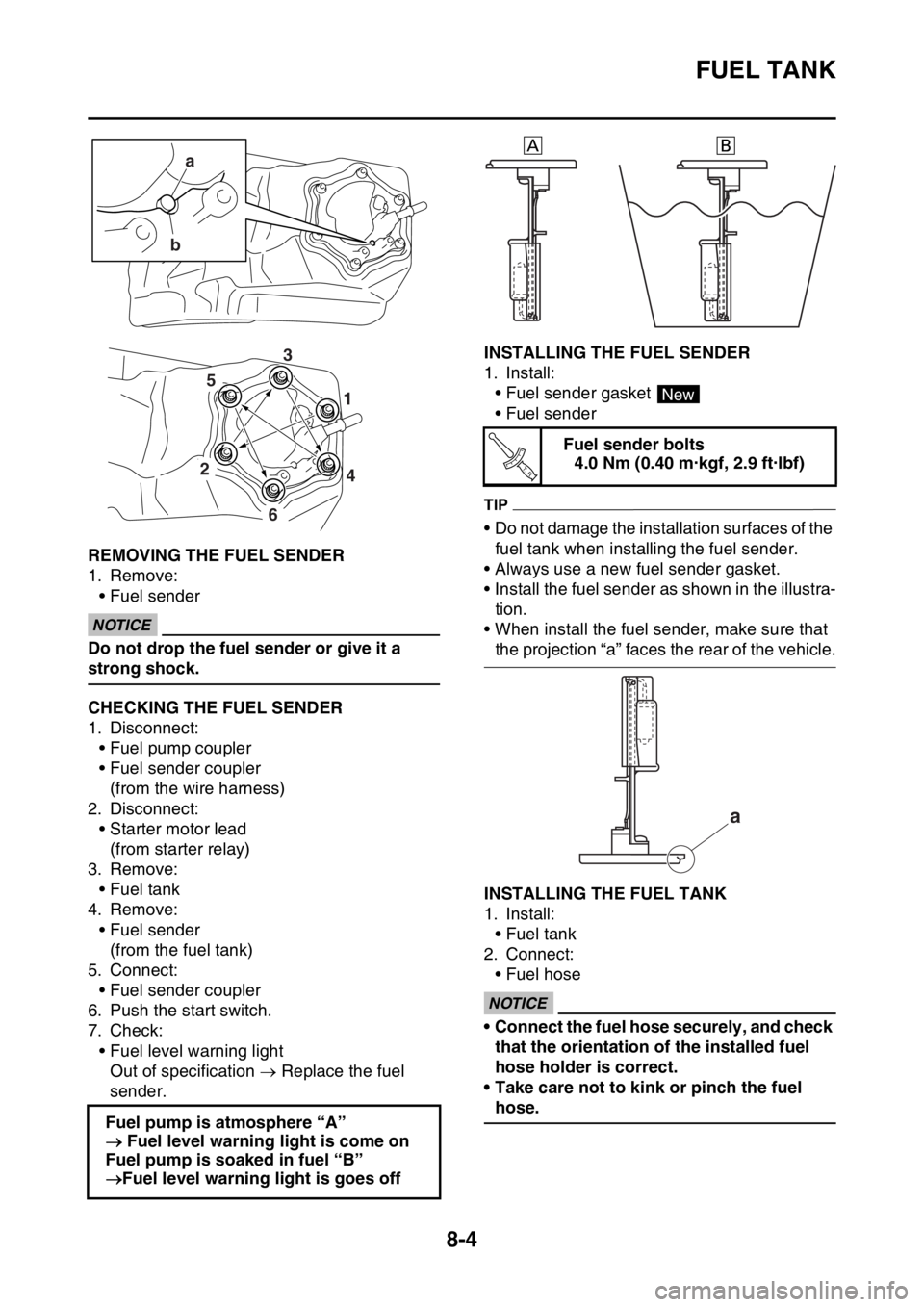

EAS2GC1344REMOVING THE FUEL SENDER

1. Remove:• Fuel sender

ECA

NOTICE

Do not drop the fuel sender or give it a

strong shock.

EAS2GC1345CHECKING THE FUEL SENDER

1. Disconnect:• Fuel pump coupler

• Fuel sender coupler

(from the wire harness)

2. Disconnect: • Starter motor lead

(from starter relay)

3. Remove: • Fuel tank

4. Remove: • Fuel sender(from the fuel tank)

5. Connect: • Fuel sender coupler

6. Push the start switch.

7. Check:

• Fuel level warning lightOut of specification Replace the fuel

sender.

EAS2GC1346INSTALLING THE FUEL SENDER

1. Install: • Fuel sender gasket

• Fuel sender

TIP

• Do not damage the installation surfaces of the

fuel tank when installing the fuel sender.

• Always use a new fuel sender gasket.

• Install the fuel sender as shown in the illustra-

tion.

• When install the fuel sender, make sure that

the projection “a” faces the rear of the vehicle.

EAS2GC1347INSTALLING THE FUEL TANK

1. Install: • Fuel tank

2. Connect:

• Fuel hose

ECA

NOTICE

• Connect the fuel hose securely, and check that the orientation of the installed fuel

hose holder is correct.

• Take care not to kink or pinch the fuel

hose.

Fuel pump is atmosphere “A”

Fuel level warning light is come on

Fuel pump is soaked in fuel “B”

Fuel level warning light is goes off

a

b

4

1

2

6

5 3

Fuel sender bolts

4.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

New

T R..

a

Page 322 of 426

FUEL TANK

8-5

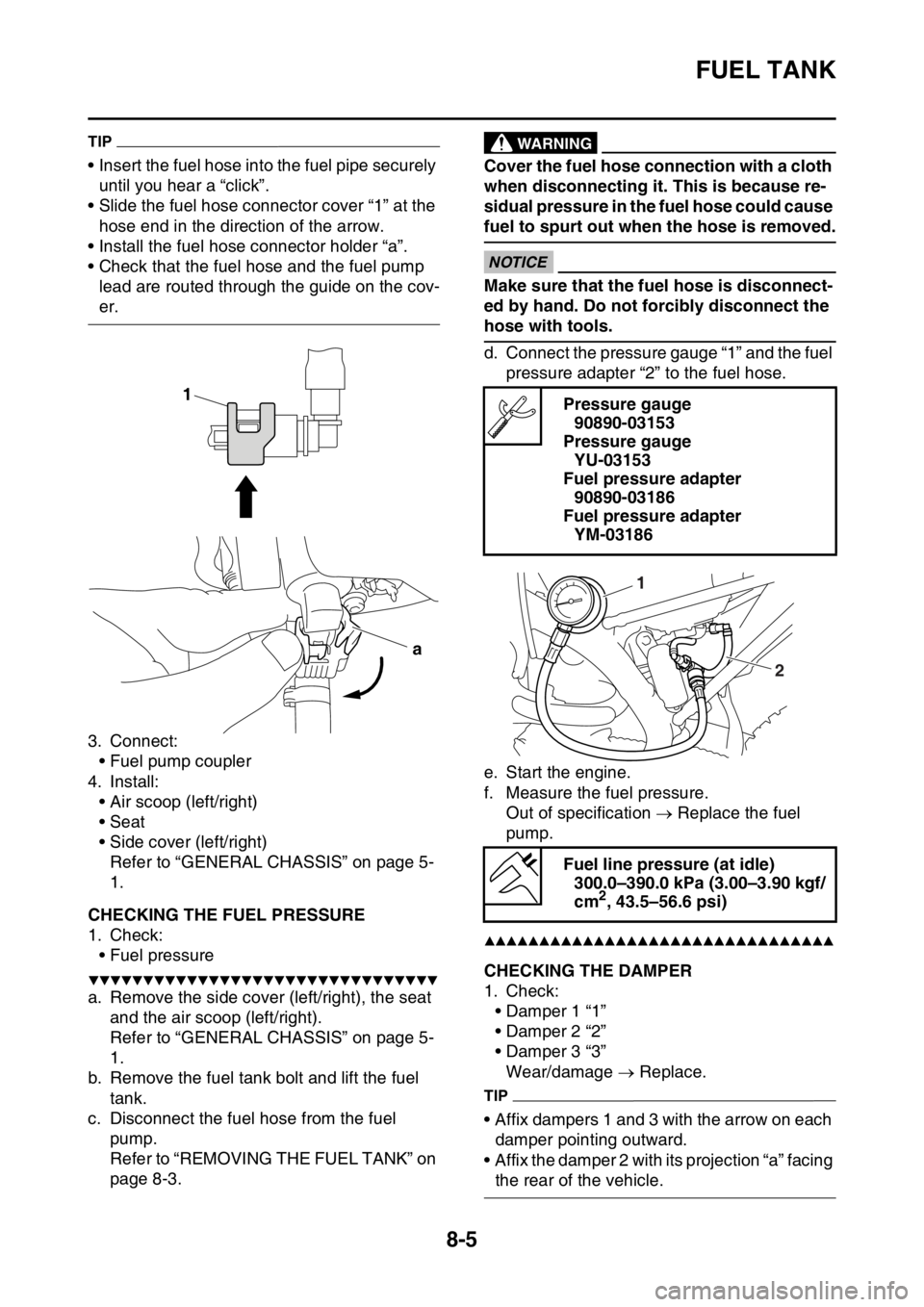

TIP

• Insert the fuel hose into the fuel pipe securely until you hear a “click”.

• Slide the fuel hose connector cover “1” at the hose end in the direction of the arrow.

• Install the fuel hose connector holder “a”.

• Check that the fuel hose and the fuel pump

lead are routed through the guide on the cov-

er.

3. Connect: • Fuel pump coupler

4. Install: • Air scoop (left/right)

• Seat

• Side cover (left/right)Refer to “GENERAL CHASSIS” on page 5-

1.

EAS2GC1348CHECKING THE FUEL PRESSURE

1. Check:• Fuel pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the side cover (left/right), the seat and the air scoop (left/right).

Refer to “GENERAL CHASSIS” on page 5-

1.

b. Remove the fuel tank bolt and lift the fuel

tank.

c. Disconnect the fuel hose from the fuel pump.

Refer to “REMOVING THE FUEL TANK” on

page 8-3.

EWA

WARNING

Cover the fuel hose connection with a cloth

when disconnecting it. This is because re-

sidual pressure in the fuel hose could cause

fuel to spurt out when the hose is removed.

ECA

NOTICE

Make sure that the fuel hose is disconnect-

ed by hand. Do not forcibly disconnect the

hose with tools.

d. Connect the pressure gauge “1” and the fuel pressure adapter “2” to the fuel hose.

e. Start the engine.

f. Measure the fuel pressure. Out of specification Replace the fuel

pump.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GC1349CHECKING THE DAMPER

1. Check:

• Damper 1 “1”

• Damper 2 “2”

• Damper 3 “3”Wear/damage Replace.

TIP

• Affix dampers 1 and 3 with the arrow on each

damper pointing outward.

• Affix the damper 2 with its projection “a” facing

the rear of the vehicle.

1

a

Pressure gauge 90890-03153

Pressure gauge YU-03153

Fuel pressure adapter 90890-03186

Fuel pressure adapter YM-03186

Fuel line pressure (at idle) 300.0–390.0 kPa (3.00–3.90 kgf/

cm

2, 43.5–56.6 psi)

1

2

Page 323 of 426

FUEL TANK

8-6

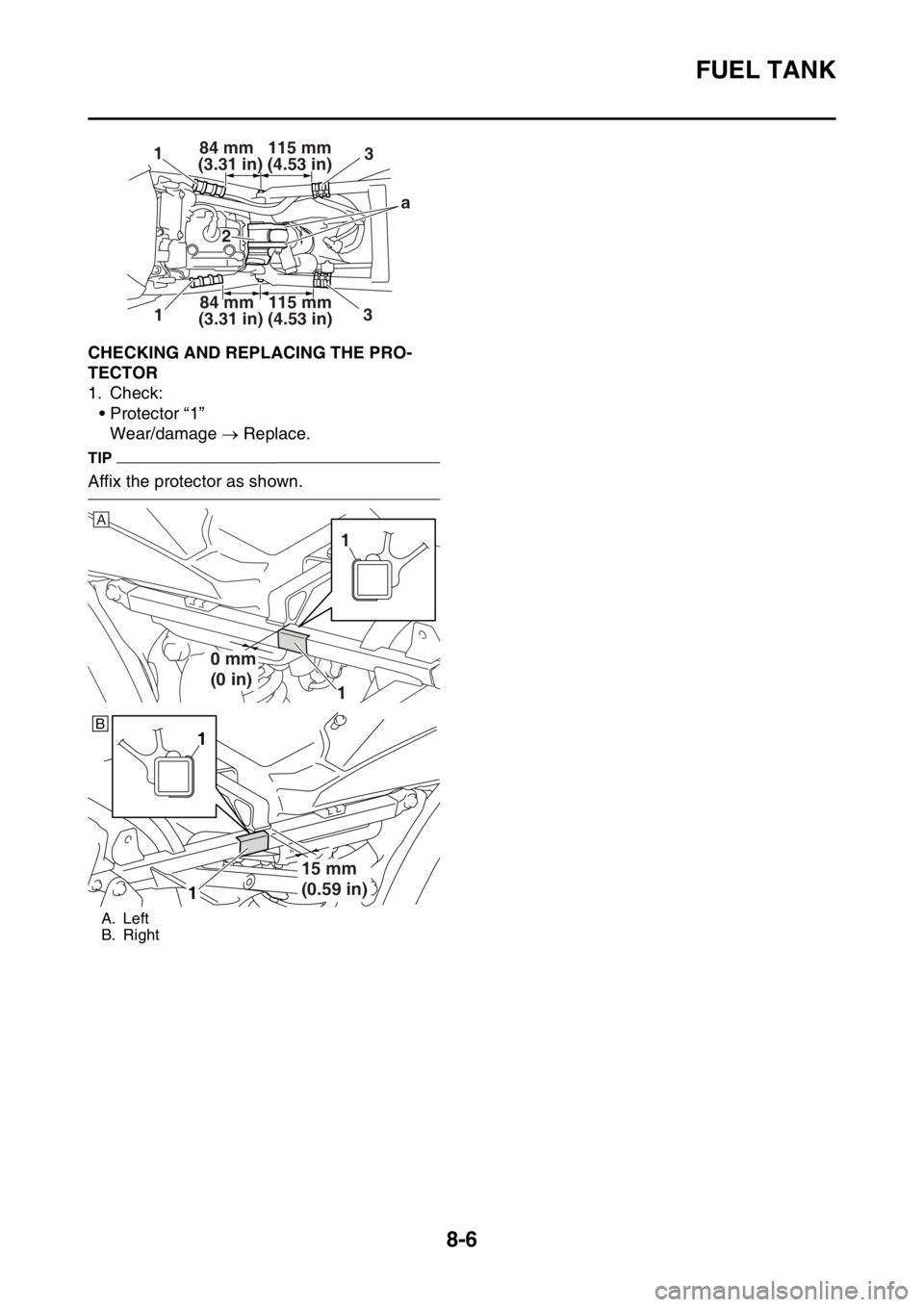

EAS2GC1350CHECKING AND REPLACING THE PRO-

TECTOR

1. Check:• Protector “1”Wear/damage Replace.

TIP

Affix the protector as shown.

A. Left

B. Right

(3.31 in) (4.53 in)

84 mm 115 mm3

1

1 3a

2

(3.31 in) (4.53 in) 84 mm 115 mm

1

1

A

0 mm

(0 in)

B

1

1

15 mm

(0.59 in)

Page 324 of 426

THROTTLE BODY

8-7

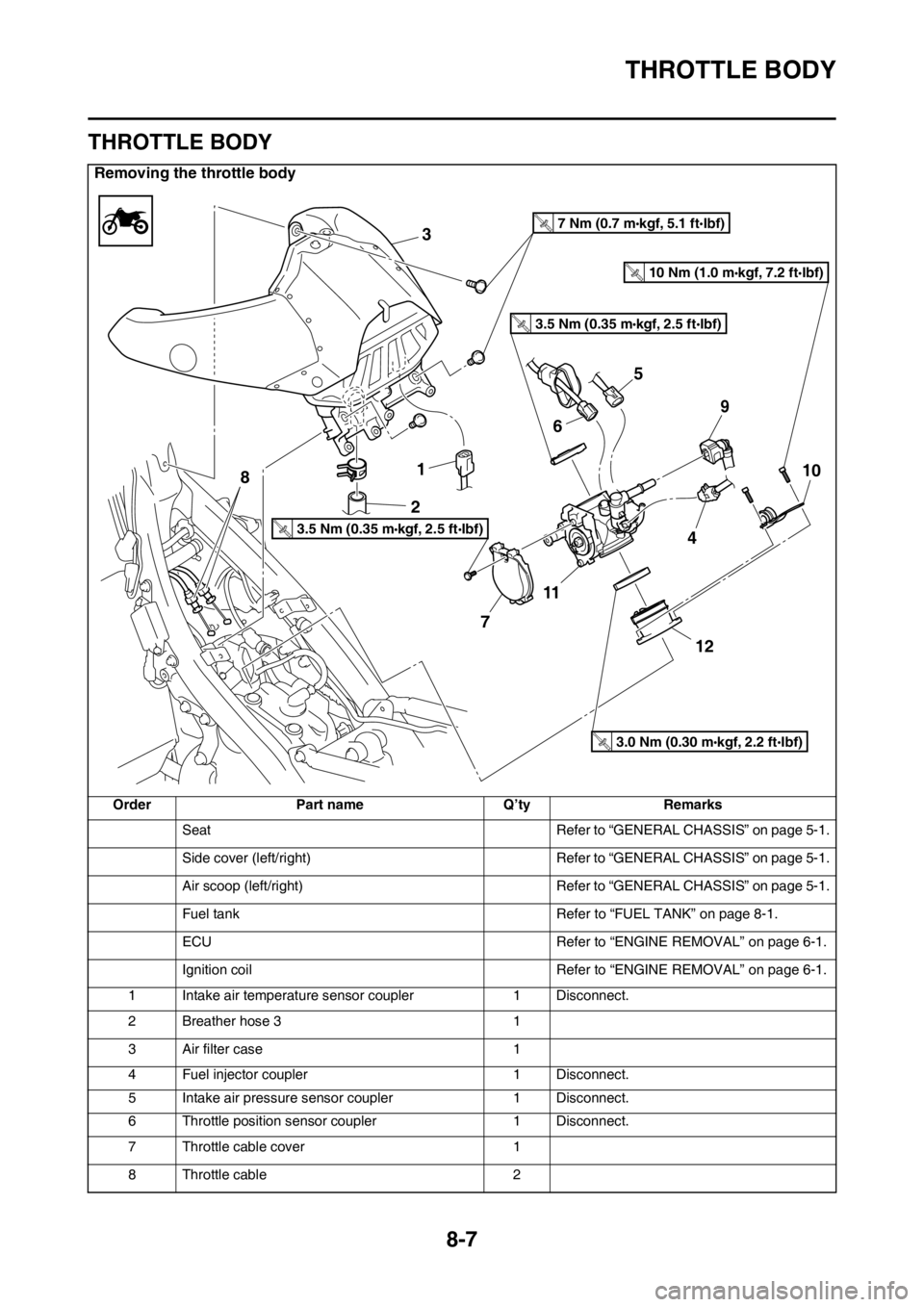

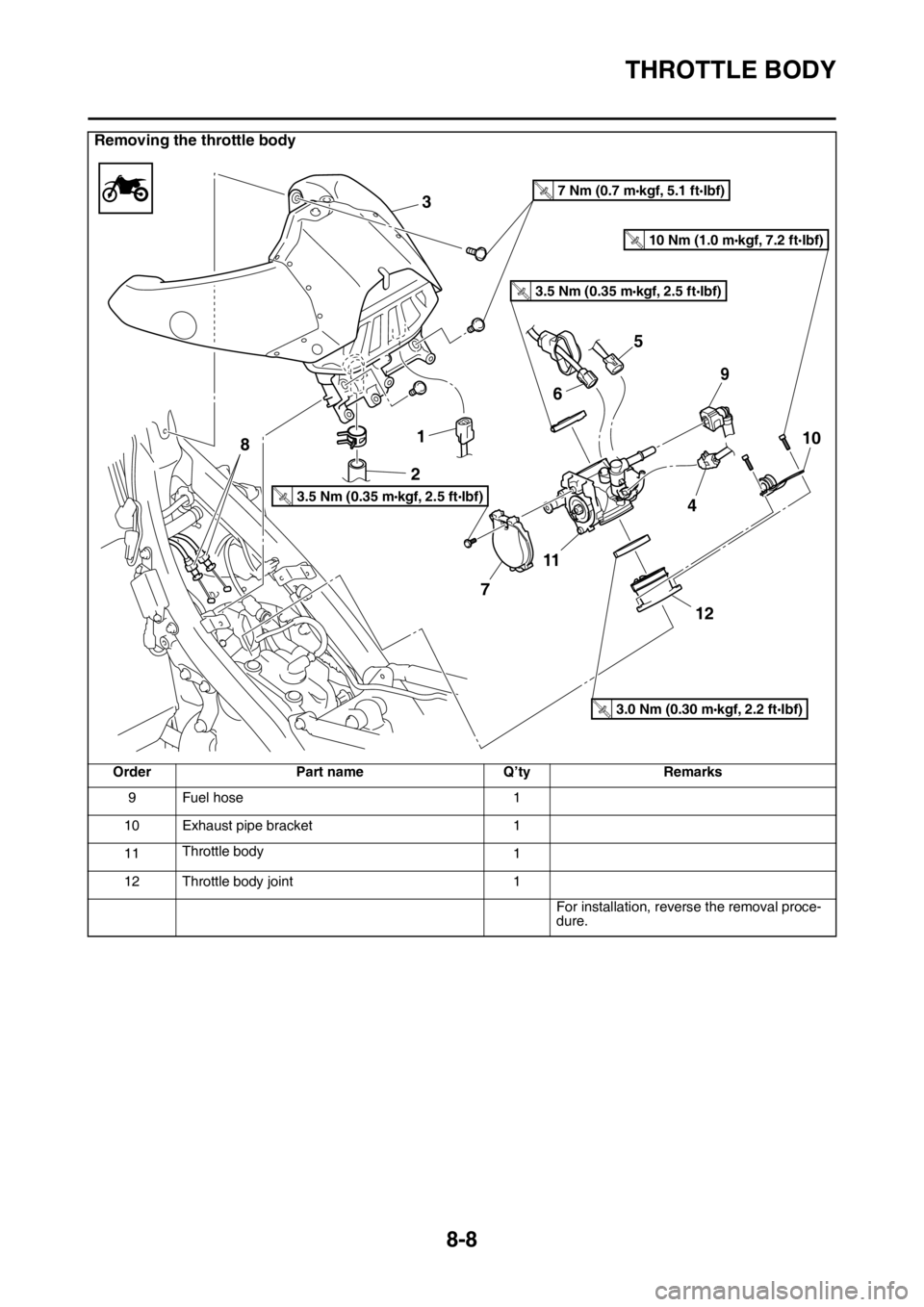

EAS2GC1351

THROTTLE BODY

Removing the throttle body

OrderPart name Q’tyRemarks

Seat Refer to “GENERAL CHASSIS” on page 5-1.

Side cover (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Air scoop (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Fuel tank Refer to “FUEL TANK” on page 8-1.

ECU Refer to “ENGINE REMOVAL” on page 6-1.

Ignition coil Refer to “ENGINE REMOVAL” on page 6-1.

1 Intake air temperature sensor coupler 1 Disconnect.

2 Breather hose 3 1

3 Air filter case 1

4 Fuel injector coupler 1 Disconnect.

5 Intake air pressure sensor coupler 1 Disconnect.

6 Throttle position sensor coupler 1 Disconnect.

7 Throttle cable cover 1

8 Throttle cable 2

3

1

2

7

11

12

10

9

4

8

6

5

3.5 Nm (0.35 m kgf, 2.5 ft Ibf)T.R.

3.5 Nm (0.35 m kgf, 2.5 ft Ibf)T.R.

7 Nm (0.7 m kgf, 5.1 ft Ibf)T.R.

3.0 Nm (0.30 m kgf, 2.2 ft Ibf)T.R.

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.

Page 325 of 426

THROTTLE BODY

8-8

9 Fuel hose1

10 Exhaust pipe bracket 1

11 Throttle body

1

12 Throttle body joint 1

For installation, reverse the removal proce-

dure.

Removing the throttle body

Order Part name Q’tyRemarks

3

1

2

7

11

12

10

9

4

8

6

5

3.5 Nm (0.35 m kgf, 2.5 ft Ibf)T.R.

3.5 Nm (0.35 m kgf, 2.5 ft Ibf)T.R.

7 Nm (0.7 m kgf, 5.1 ft Ibf)T.R.

3.0 Nm (0.30 m kgf, 2.2 ft Ibf)T.R.

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.

Page 326 of 426

THROTTLE BODY

8-9

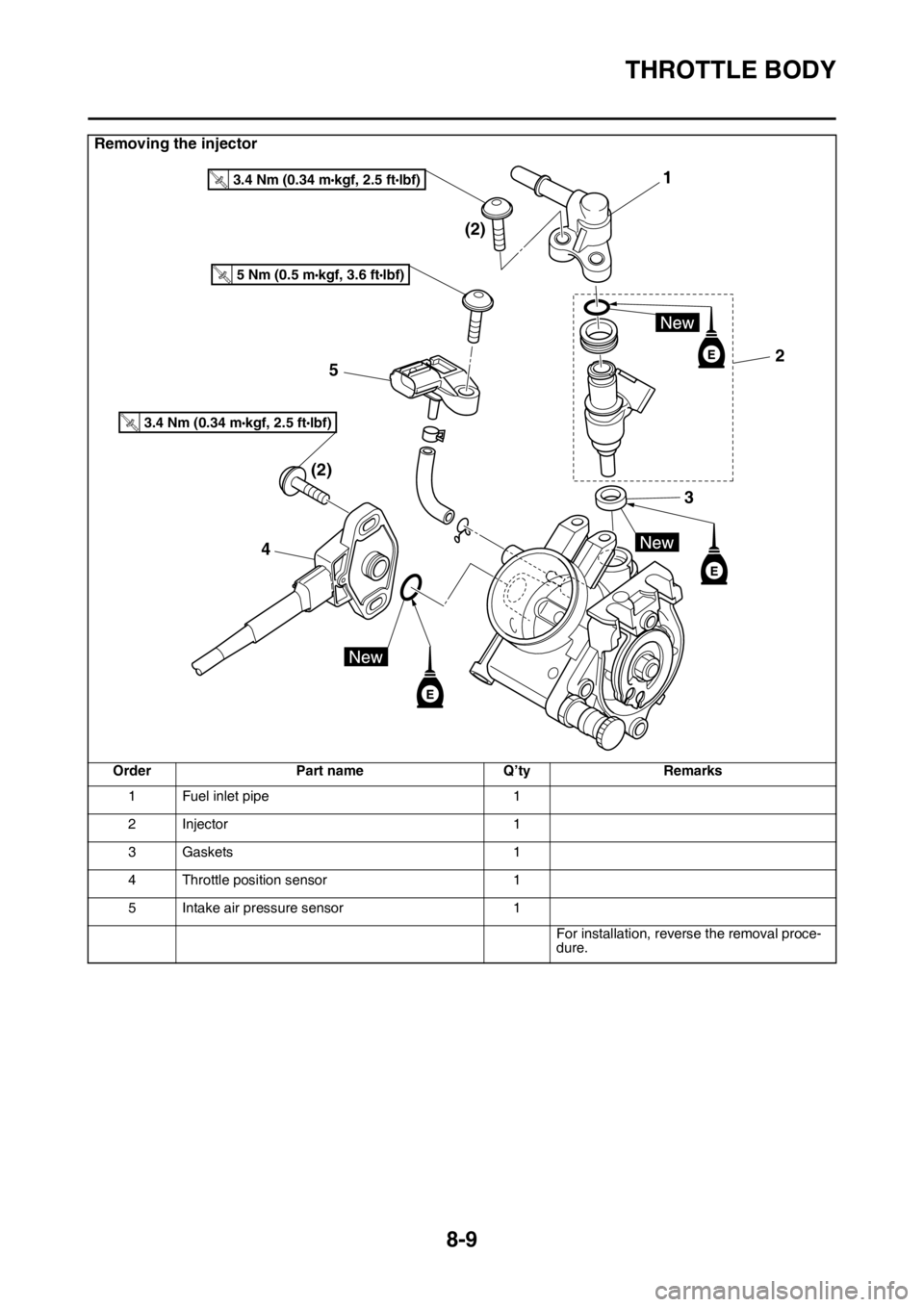

Removing the injector

OrderPart name Q’tyRemarks

1 Fuel inlet pipe 1

2Injector 1

3 Gaskets 1

4 Throttle position sensor 1

5 Intake air pressure sensor 1

For installation, reverse the removal proce-

dure.

1

2

(2)

(2) 5

4 3

T.R.3.4 Nm (0.34 mlbf)

kgf, 2.5 ft

T.R.5 Nm (0.5 mlbf)

kgf, 3.6 ft

T.R.3.4 Nm (0.34 mlbf)

kgf, 2.5 ft

Page 327 of 426

THROTTLE BODY

8-10

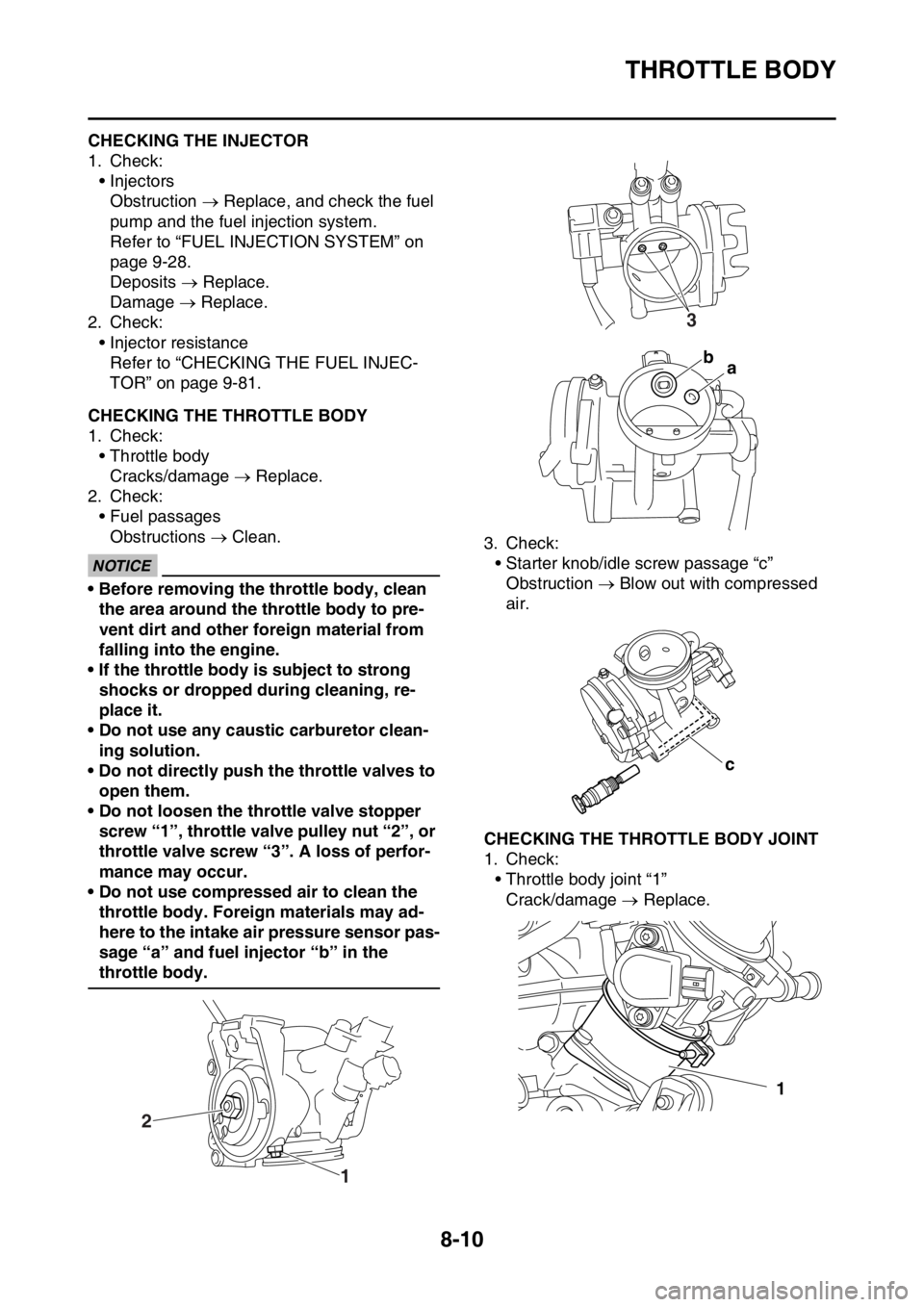

EAS2GC1352CHECKING THE INJECTOR

1. Check:• InjectorsObstruction Replace, and check the fuel

pump and the fuel injection system.

Refer to “FUEL INJECTION SYSTEM” on

page 9-28.

Deposits Replace.

Damage Replace.

2. Check:

• Injector resistanceRefer to “CHECKING THE FUEL INJEC-

TOR” on page 9-81.

EAS2GC1353CHECKING THE THROTTLE BODY

1. Check:• Throttle bodyCracks/damage Replace.

2. Check:

• Fuel passagesObstructions Clean.

ECA

NOTICE

• Before removing the throttle body, clean

the area around the throttle body to pre-

vent dirt and other foreign material from

falling into the engine.

• If the throttle body is subject to strong shocks or dropped during cleaning, re-

place it.

• Do not use any caustic carburetor clean- ing solution.

• Do not directly push the throttle valves to open them.

• Do not loosen the throttle valve stopper screw “1”, throttle valve pulley nut “2”, or

throttle valve screw “3”. A loss of perfor-

mance may occur.

• Do not use compressed air to clean the throttle body. Foreign materials may ad-

here to the intake air pressure sensor pas-

sage “a” and fuel injector “b” in the

throttle body. 3. Check:

• Starter knob/idle screw passage “c”Obstruction Blow out with compressed

air.

EAS2GC1354CHECKING THE THROTTLE BODY JOINT

1. Check: • Throttle body joint “1”Crack/damage Replace.

1

2

3

ba

c

1

Page 328 of 426

THROTTLE BODY

8-11

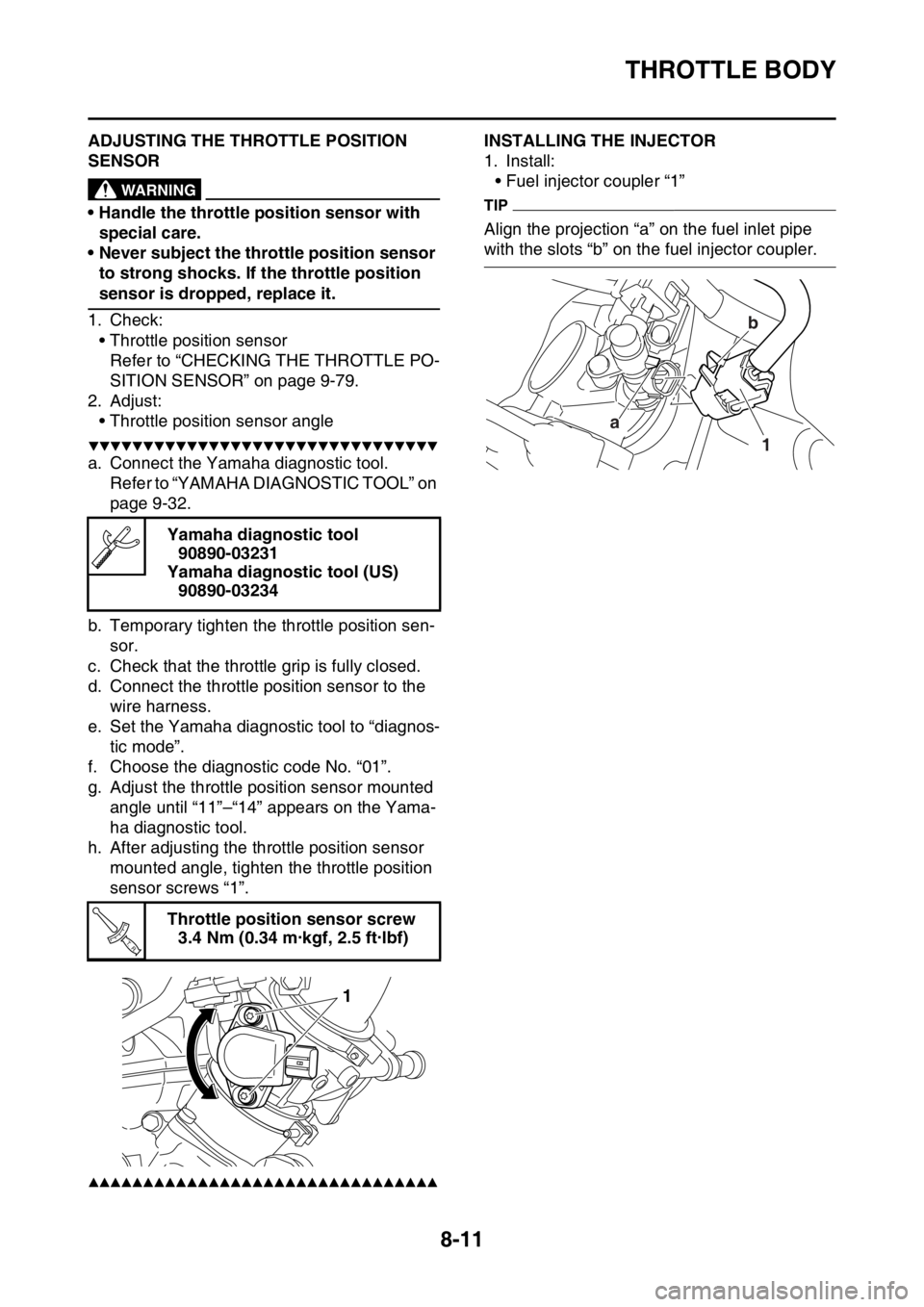

EAS2GC1355ADJUSTING THE THROTTLE POSITION

SENSOR

EWA

WARNING

• Handle the throttle position sensor with special care.

• Never subject the throttle position sensor

to strong shocks. If the throttle position

sensor is dropped, replace it.

1. Check: • Throttle position sensorRefer to “CHECKING THE THROTTLE PO-

SITION SENSOR” on page 9-79.

2. Adjust: • Throttle position sensor angle

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the Yamaha diagnostic tool. Refer to “YAMAHA DIAGNOSTIC TOOL” on

page 9-32.

b. Temporary tighten the throttle position sen- sor.

c. Check that the throttle grip is fully closed.

d. Connect the throttle position sensor to the wire harness.

e. Set the Yamaha diagnostic tool to “diagnos- tic mode”.

f. Choose the diagnostic code No. “01”.

g. Adjust the throttle position sensor mounted

angle until “11”–“14” appears on the Yama-

ha diagnostic tool.

h. After adjusting the throttle position sensor mounted angle, tighten the throttle position

sensor screws “1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GC1356INSTALLING THE INJECTOR

1. Install:• Fuel injector coupler “1”

TIP

Align the projection “a” on the fuel inlet pipe

with the slots “b” on the fuel injector coupler.

Yamaha diagnostic tool 90890-03231

Yamaha diagnostic tool (US) 90890-03234

Throttle position sensor screw 3.4 Nm (0.34 m·kgf, 2.5 ft·lbf)

T R..

1

1

a

b

Page 329 of 426

9

ELECTRICAL SYSTEM

IGNITION SYSTEM.......................................................................................... 9-2

CIRCUIT DIAGRAM ................................................................................... 9-2

TROUBLESHOOTING ............................................................................... 9-4

ELECTRIC STARTING SYSTEM ..................................................................... 9-6

CIRCUIT DIAGRAM ................................................................................... 9-6

STARTING CIRCUIT CUT-OFF SYSTEM OPERATION ........................... 9-8

TROUBLESHOOTING ............................................................................. 9-10

CHARGING SYSTEM ..................................................................................... 9-12

CIRCUIT DIAGRAM ................................................................................. 9-12

TROUBLESHOOTING ............................................................................. 9-14

LIGHTING SYSTEM ....................................................................................... 9-16

CIRCUIT DIAGRAM ................................................................................. 9-16

TROUBLESHOOTING ............................................................................. 9-18

SIGNALING SYSTEM .................................................................................... 9-20

CIRCUIT DIAGRAM ................................................................................. 9-20

TROUBLESHOOTING ............................................................................. 9-22

COOLING SYSTEM ........................................................................................ 9-24

CIRCUIT DIAGRAM ................................................................................. 9-24

TROUBLESHOOTING ............................................................................. 9-26

FUEL INJECTION SYSTEM ........................................................................... 9-28

CIRCUIT DIAGRAM ................................................................................. 9-28

ECU SELF-DIAGNOSTIC FUNCTION ..................................................... 9-30

TROUBLESHOOTING METHOD ............................................................. 9-31

YAMAHA DIAGNOSTIC TOOL ................................................................ 9-32

TROUBLESHOOTING DETAILS ............................................................. 9-35

FUEL PUMP SYSTEM .................................................................................... 9-56

CIRCUIT DIAGRAM ................................................................................. 9-56

TROUBLESHOOTING ............................................................................. 9-58

Page 330 of 426

ELECTRICAL COMPONENTS....................................................................... 9-60

CHECKING THE SWITCHES .................................................................. 9-64

CHECKING THE BULBS AND BULB SOCKETS .................................... 9-67

CHECKING THE FUSES ......................................................................... 9-68

CHECKING AND CHARGING THE BATTERY ........................................ 9-69

CHECKING THE RELAYS ....................................................................... 9-72

CHECKING THE DIODE .......................................................................... 9-73

CHECKING THE IGNITION SPARK GAP................................................ 9-73

CHECKING THE SPARK PLUG CAP ...................................................... 9-73

CHECKING THE IGNITION COIL ............................................................ 9-74

CHECKING THE CRANKSHAFT POSITION SENSOR........................... 9-74

CHECKING THE LEAN ANGLE SENSOR............................................... 9-75

CHECKING THE STARTER MOTOR OPERATION ................................ 9-75

CHECKING THE STATOR COIL ............................................................. 9-76

CHECKING THE RECTIFIER/REGULATOR ........................................... 9-76

CHECKING THE SPEED SENS OR ......................................................... 9-77

CHECKING THE FUEL SENDER ............................................................ 9-77

CHECKING THE RESISTER ................................................................... 9-77

CHECKING THE RADIATOR FAN MOTOR ............................................ 9-78

CHECKING THE COOLANT TEMPERATURE SENSOR........................ 9-78

CHECKING THE THROTTLE POSITION SENSOR ................................ 9-79

CHECKING THE THROTTLE POSITION SENSOR INPUT VOLTAGE .. 9-79

CHECKING THE INTAKE AIR PR ESSURE SENSOR ............................ 9-80

CHECKING THE INTAKE AIR TEMPERATURE SENSOR ..................... 9-80

CHECKING THE FUEL INJECTOR ......................................................... 9-81