ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1491 of 1640

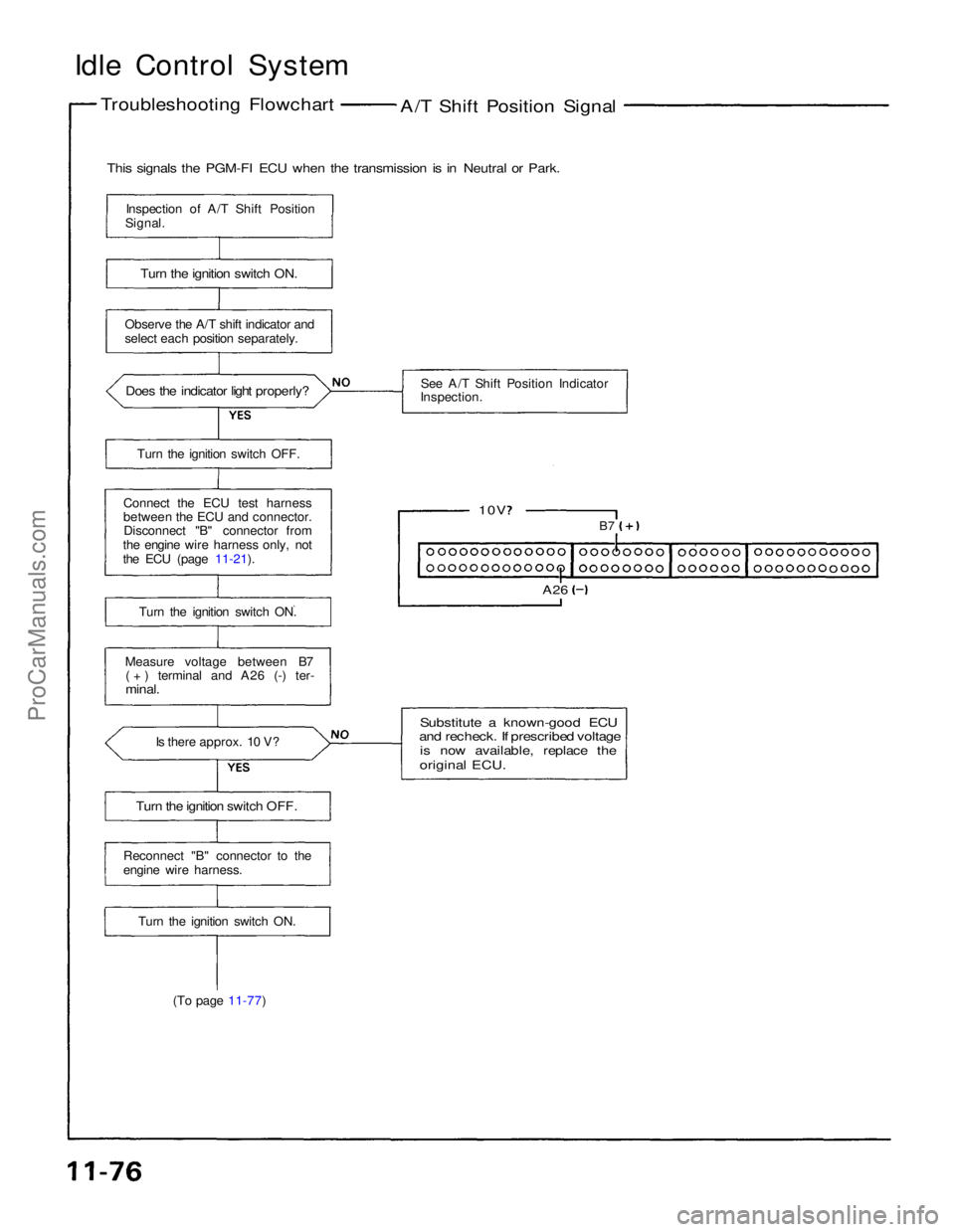

Idle Control System

Troubleshooting Flowchart

A/T Shift Position Signal

This signals the PGM-FI ECU when the transmission is in Neutral or Park.

Inspection of A/T Shift Position

Signal.

Turn the ignition switch ON.

Observe the A/T shift indicator and

select each position separately. See A/T Shift Position Indicator

Inspection.

Does the indicator light properly?

Turn the ignition switch OFF.

Connect the ECU test harness

between the ECU and connector. Disconnect "B" connector from

the engine wire harness only, not

the ECU (page 11-21).

10V

B7

A26

Turn the ignition switch ON.

Measure voltage between B7 ( + ) terminal and A26 (-) ter-

minal.

Is there approx. 10 V?

Substitute a known-good ECU

and recheck. If prescribed voltage

is now available, replace the

original ECU.

Turn the ignition switch OFF.

Reconnect "B" connector to the

engine wire harness.

Turn the ignition switch ON.

(To page 11-77)ProCarManuals.com

Page 1492 of 1640

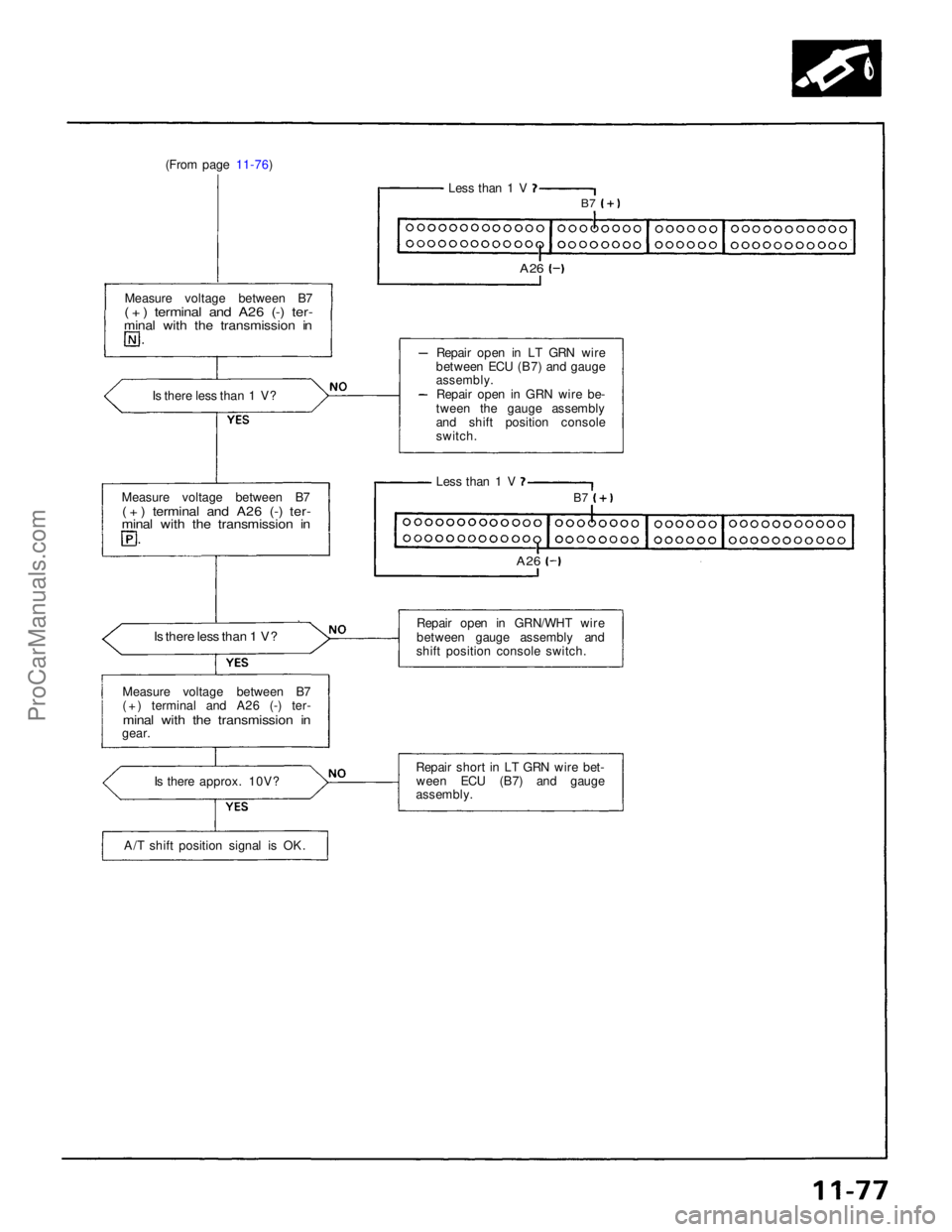

(From page 11-76)

Less than 1 V

B7

A26

Measure voltage between B7

( + ) terminal and A26 (-) ter-

minal with the transmission in

Is there less than 1 V?

Repair open in LT GRN wire

between ECU (B7) and gauge

assembly.

Repair open in GRN wire be-

tween the gauge assembly

and shift position console

switch.

Measure voltage between B7

( + ) terminal and A26 (-) ter-

minal with the transmission in

Less than 1 V

B7

A26

Is there less than 1 V?

Repair open in GRN/WHT wire

between gauge assembly and

shift position console switch.

Measure voltage between B7

(+) terminal and A26 (-) ter-

minal with the transmission in

gear.

Repair short in LT GRN wire bet-ween ECU (B7) and gauge

assembly.

Is there approx. 10V?

A/T shift position signal is OK.ProCarManuals.com

Page 1493 of 1640

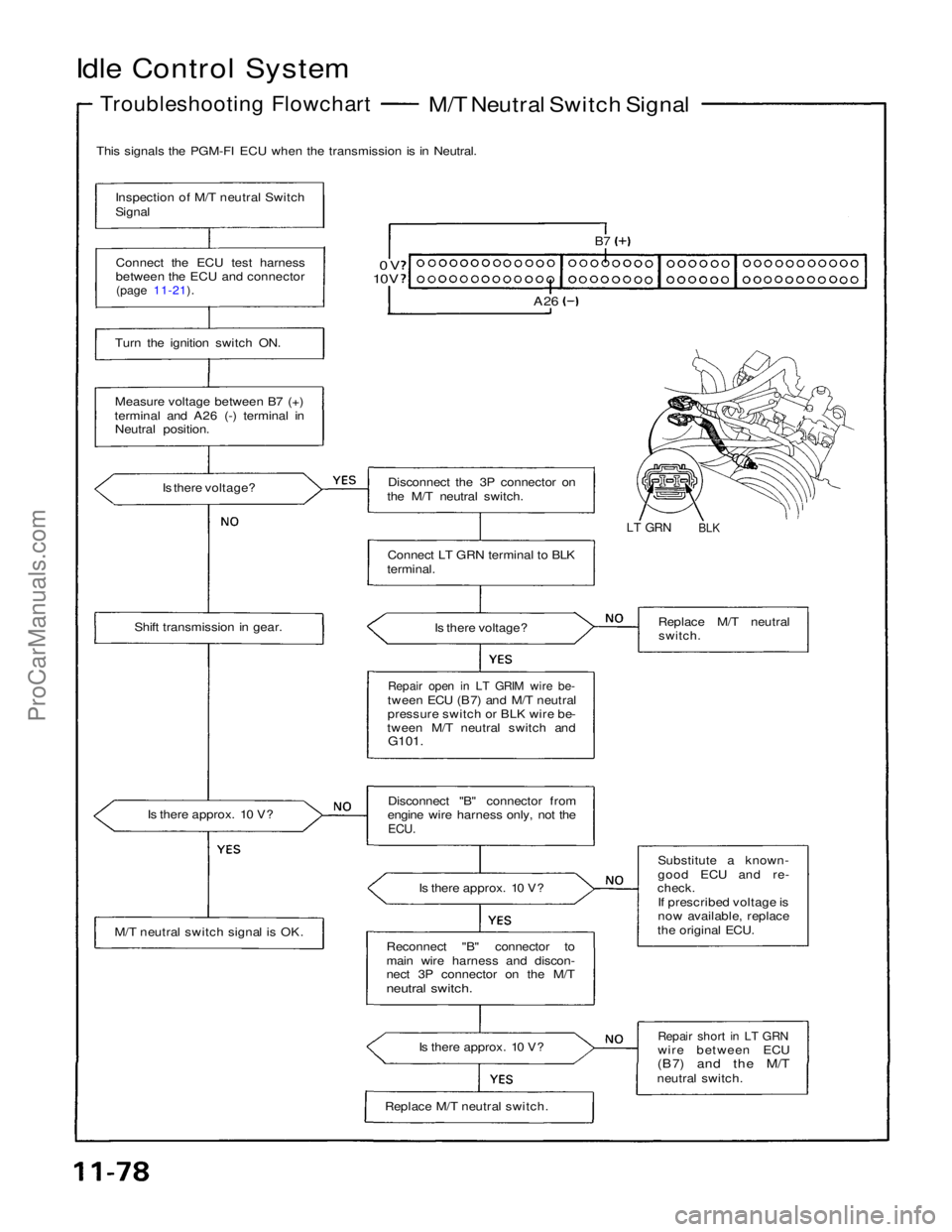

Idle Control System

Troubleshooting Flowchart

M/T Neutral Switch Signal

This signals the PGM-FI ECU when the transmission is in Neutral.

Inspection of M/T neutral Switch

Signal

Connect the ECU test harness

between the ECU and connector

(page 11-21).

0V

10V

B7

A26

Turn the ignition switch ON.

Measure voltage between B7 (+)

terminal and A26 (-) terminal in Neutral position.

Is there voltage? Disconnect the 3P connector on

the M/T neutral switch.

LT GRN

BLK

Connect LT GRN terminal to BLK

terminal.

Is there voltage?

Shift transmission in gear. Replace M/T neutral

switch.

Repair open in LT GRIM wire be-

tween ECU (B7) and M/T neutral

pressure switch or BLK wire be-

tween M/T neutral switch and G101.

Is there approx. 10 V? Disconnect "B" connector from

engine wire harness only, not the

ECU.

Is there approx. 10 V?

M/T neutral switch signal is OK. Substitute a known-

good ECU and re-

check.

If prescribed voltage is

now available, replace

the original ECU.

Reconnect "B" connector to

main wire harness and discon-

nect 3P connector on the M/T

neutral switch.

Is there approx. 10 V?

Repair short in LT GRN

wire between ECU

(B7)

and the M/T

neutral switch.

Replace M/T neutral switch.ProCarManuals.com

Page 1494 of 1640

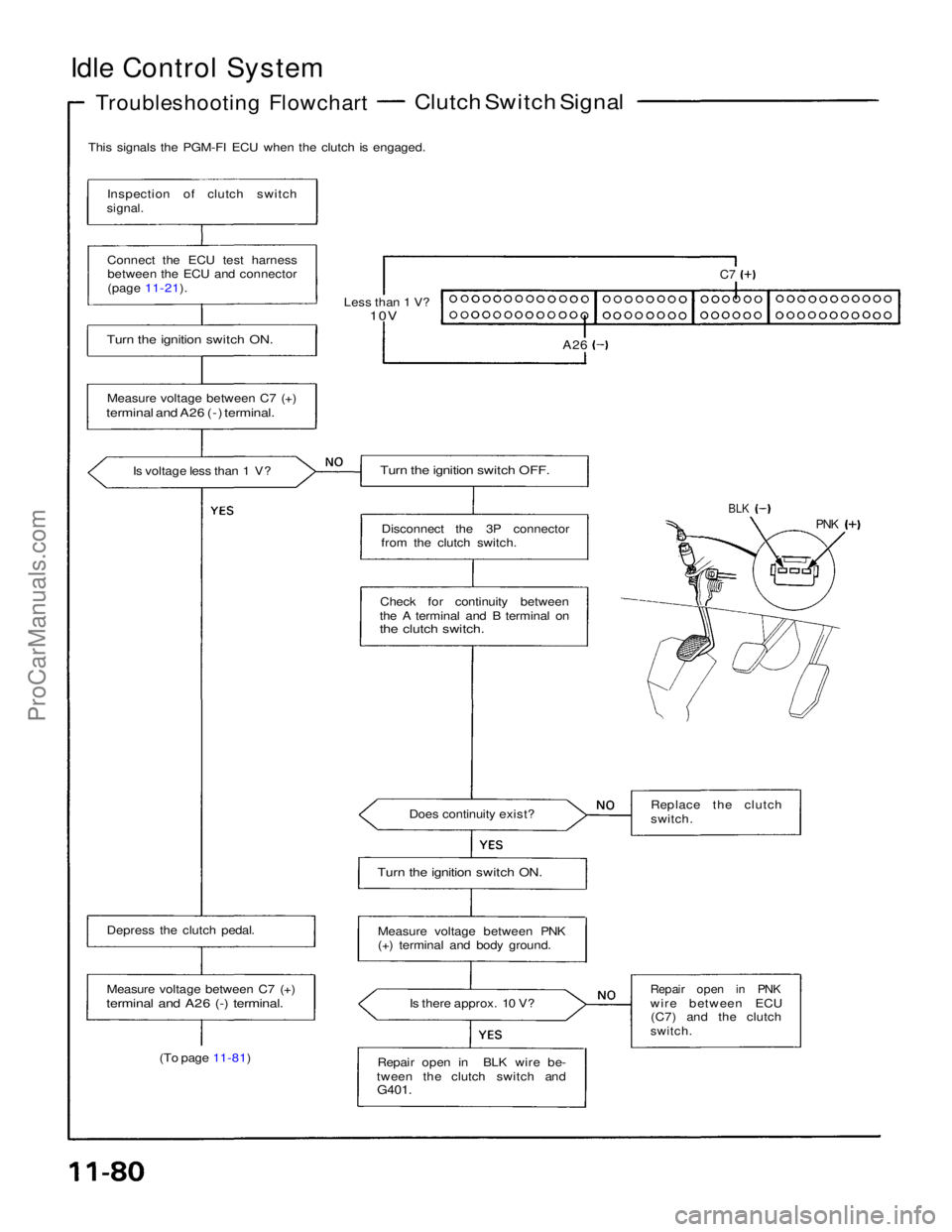

Idle Control System

Troubleshooting Flowchart

Clutch Switch Signal

This signals the PGM-FI ECU when the clutch is engaged.

Inspection of clutch switch

signal.

Connect the ECU test harnessbetween the ECU and connector

(page 11-21).

Less than 1 V?

10V

A26

C7

Turn the ignition switch ON.

Measure voltage between C7 (+)

terminal and A26 (-) terminal.

Is voltage less than 1 V?

Turn the ignition switch OFF.

Disconnect the 3P connector

from the clutch switch.

BLK

PNK

Check for continuity between

the A terminal and B terminal on

the clutch switch.

Does continuity exist? Replace the clutch

switch.

Turn the ignition switch ON.

Depress the clutch pedal.

Measure voltage between C7 (+)

terminal and A26 (-) terminal.

(To page 11-81) Measure voltage between PNK

(+) terminal and body ground.

Is there approx. 10 V?

Repair open in BLK wire be-

tween the clutch switch and G401.

Repair open in PNK

wire between ECU

(C7) and the clutch

switch.ProCarManuals.com

Page 1495 of 1640

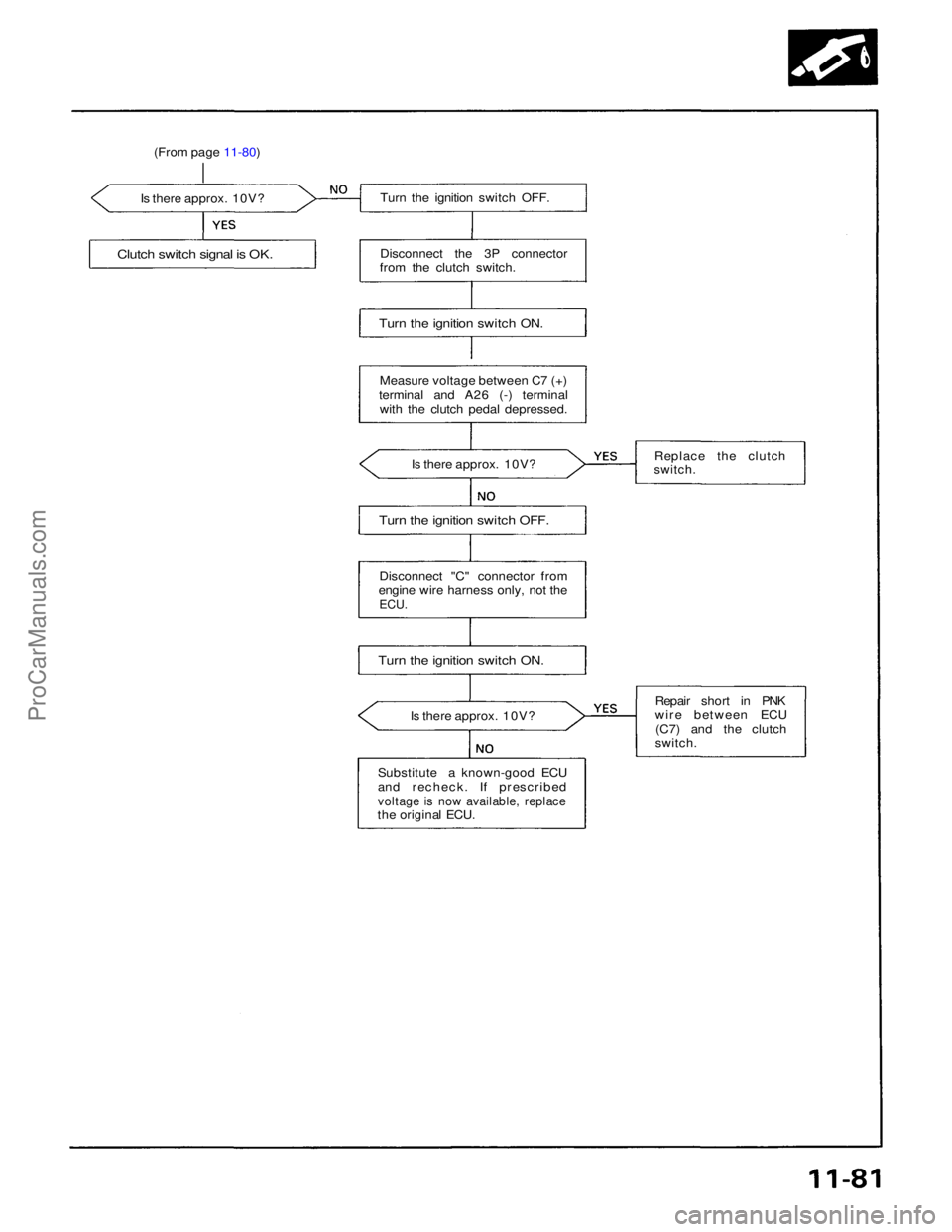

(From page 11-80)

Is there approx. 10V?

Clutch switch signal is OK.

Turn the ignition switch OFF.

Disconnect the 3P connector

from the clutch switch.

Turn the ignition switch ON.

Measure voltage between C7 (+)

terminal and A26 (-) terminal with the clutch pedal depressed.

Is there approx. 10V? Replace the clutch

switch.

Turn the ignition switch OFF.

Disconnect "C" connector from

engine wire harness only, not the

ECU.

Turn the ignition switch ON.

Is there approx. 10V? Repair short in PNK

wire between ECU

(C7) and the clutch

switch.

Substitute a known-good ECU

and recheck. If prescribed

voltage is now available, replace

the original ECU.ProCarManuals.com

Page 1496 of 1640

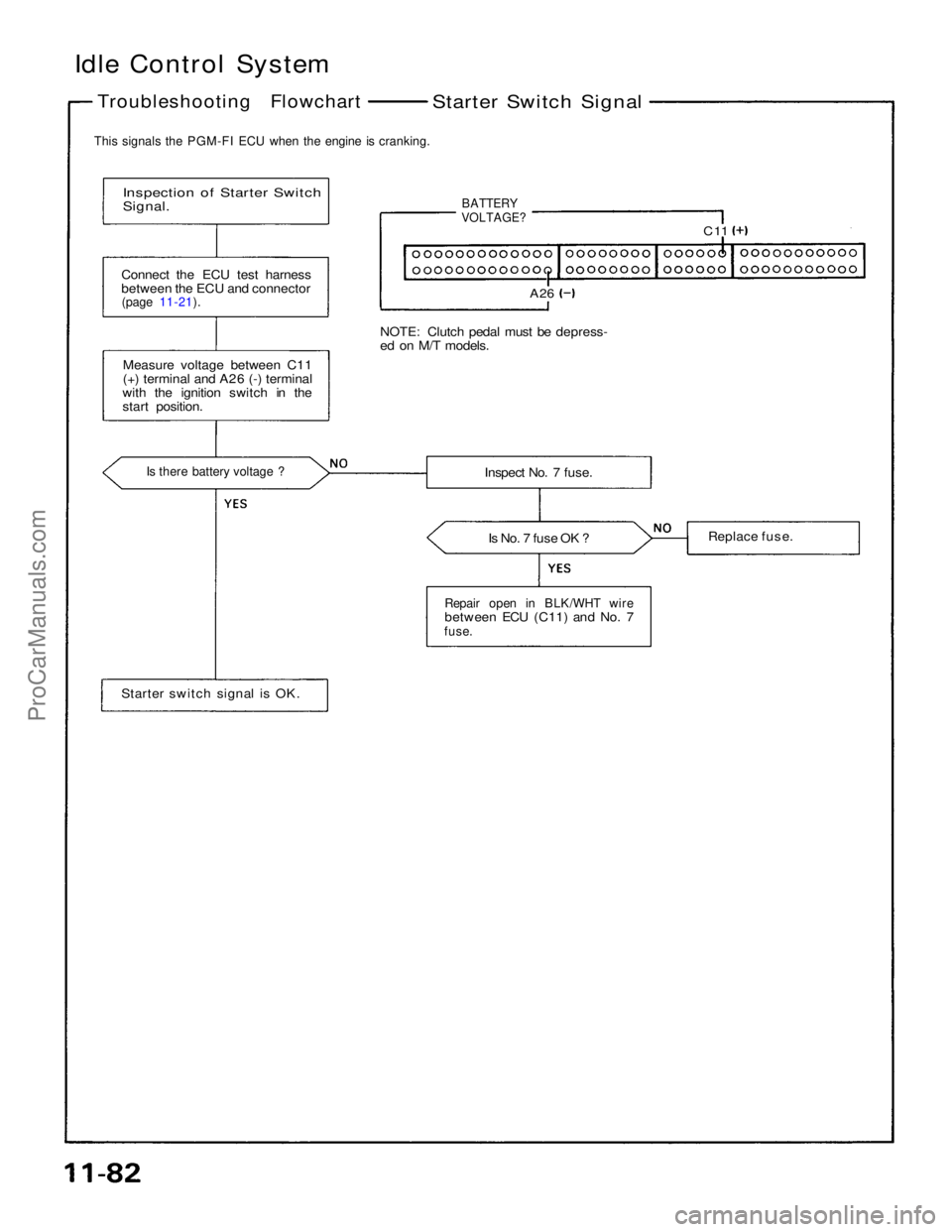

Idle Control System

Troubleshooting Flowchart

Starter Switch Signal

This signals the PGM-FI ECU when the engine is cranking.

Inspection of Starter Switch

Signal.

BATTERY

VOLTAGE?

C 11

A26

NOTE: Clutch pedal must be depress-

ed on M/T models.

Connect the ECU test harness

between the ECU and connector

(page 11-21).

Measure voltage between C11

(+) terminal and A26 (-) terminal

with the ignition switch in the

start position.

Is there battery voltage ?

Inspect No. 7 fuse.

Is No. 7 fuse OK ?

Replace fuse.

Repair open in BLK/WHT wire

between ECU (C11) and No. 7

fuse.

Starter switch signal is OK.ProCarManuals.com

Page 1497 of 1640

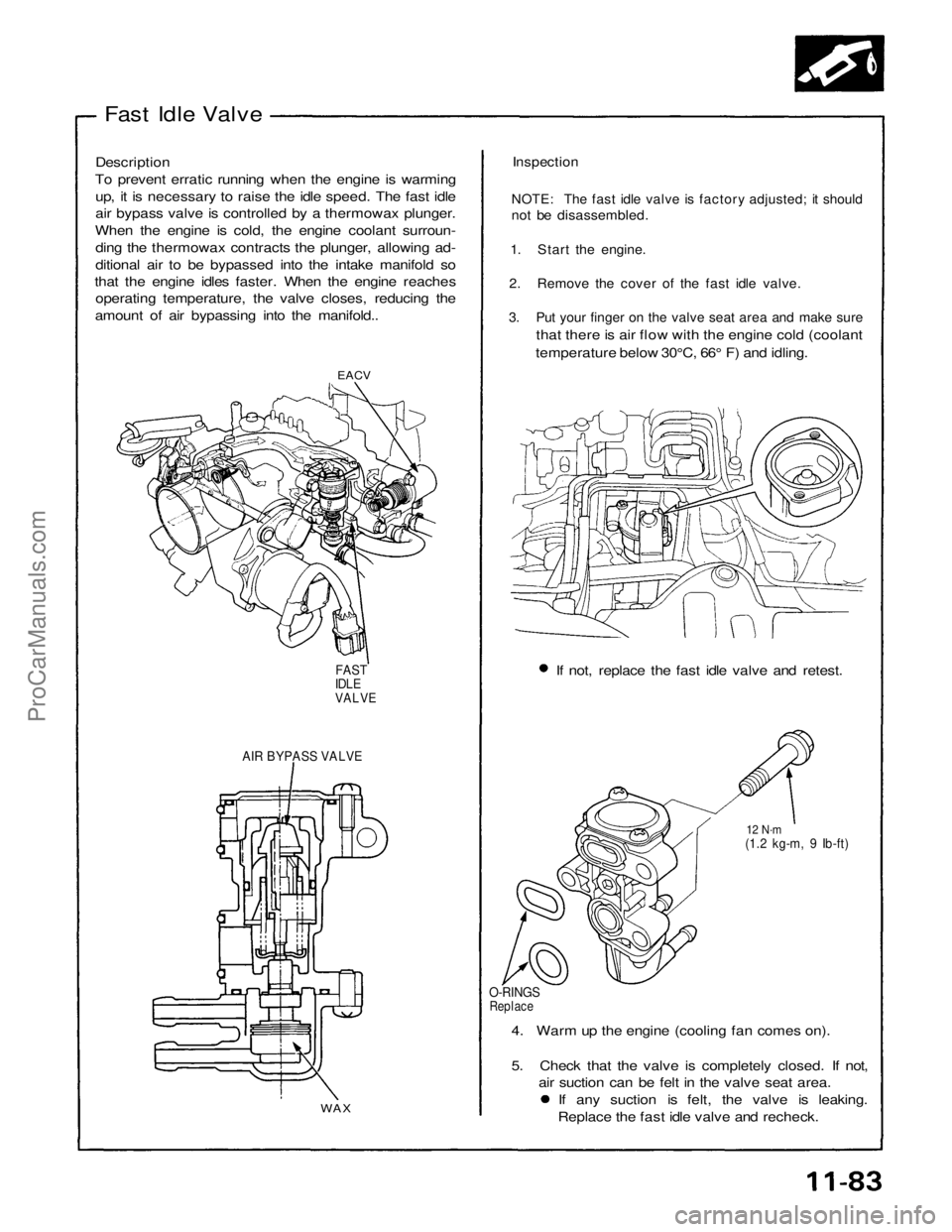

Fast Idle Valve

Description

To prevent erratic running when the engine is warming up, it is necessary to raise the idle speed. The fast idle

air bypass valve is controlled by a thermowax plunger.

When the engine is cold, the engine coolant surroun- ding the thermowax contracts the plunger, allowing ad-

ditional air to be bypassed into the intake manifold so

that the engine idles faster. When the engine reaches operating temperature, the valve closes, reducing the

amount of air bypassing into the manifold..

Inspection

NOTE: The fast idle valve is factory adjusted; it should

not be disassembled.

1. Start the engine.

2. Remove the cover of the fast idle valve.

3. Put your finger on the valve seat area and make sure

that there is air flow with the engine cold (coolant

temperature below 30°C, 66° F) and idling.

EACV

If not, replace the fast idle valve and retest.

FAST

IDLE

VALVE

AIR BYPASS VALVE

12 N·m

(1.2 kg-m, 9 Ib-ft)

O-RINGS

Replace

4. Warm up the engine (cooling fan comes on).

5. Check that the valve is completely closed. If not, air suction can be felt in the valve seat area. If any suction is felt, the valve is leaking.

Replace the fast idle valve and recheck.

WAXProCarManuals.com

Page 1498 of 1640

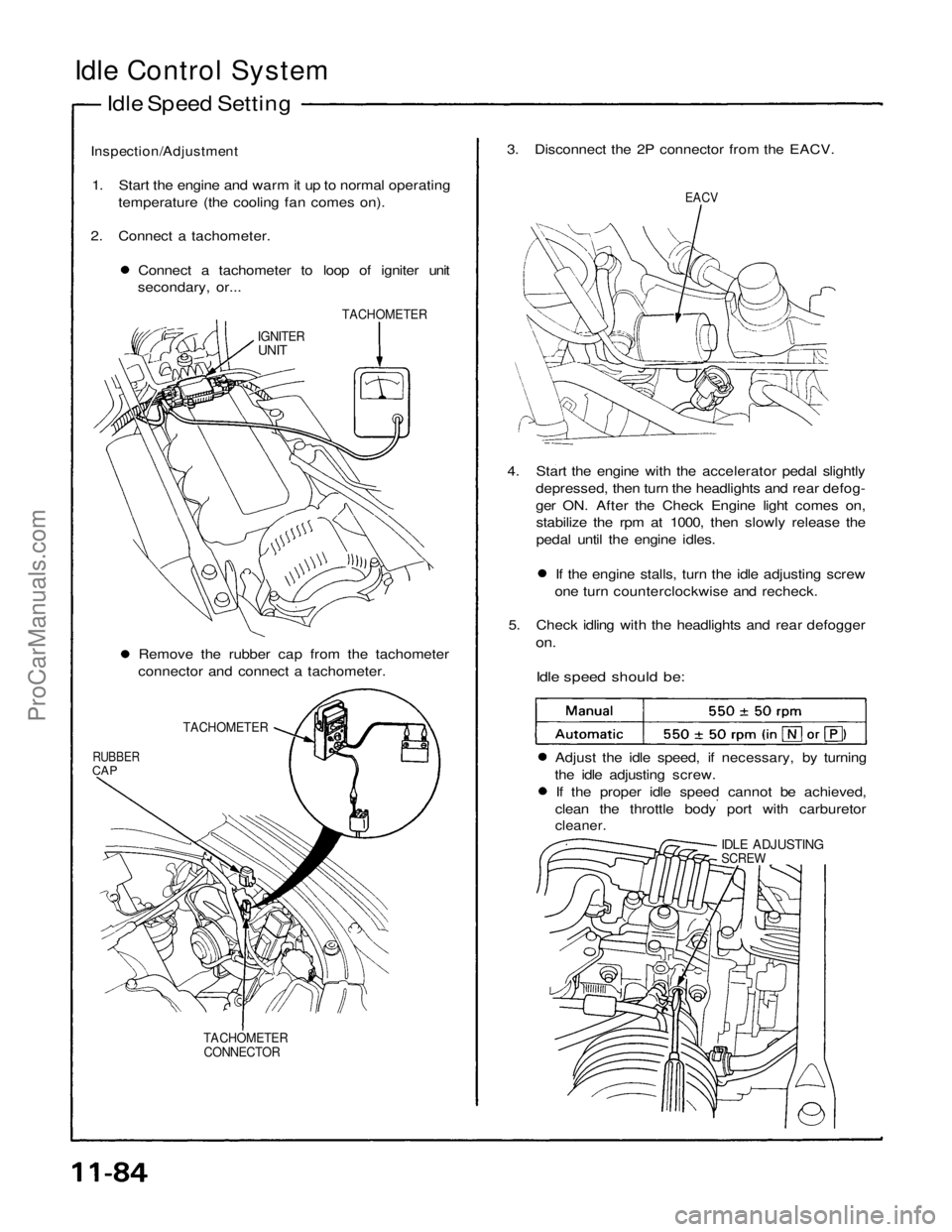

Idle Control System

Idle Speed Setting

Inspection/Adjustment

1. Start the engine and warm it up to normal operating temperature (the cooling fan comes on).

2. Connect a tachometer. Connect a tachometer to loop of igniter unit

secondary, or... 3. Disconnect the 2P connector from the EACV.

EACV

TACHOMETER

IGNITER

UNIT

4. Start the engine with the accelerator pedal slightlydepressed, then turn the headlights and rear defog-

ger ON. After the Check Engine light comes on,stabilize the rpm at 1000, then slowly release the

pedal until the engine idles. If the engine stalls, turn the idle adjusting screw

one turn counterclockwise and recheck.

5. Check idling with the headlights and rear defogger

on.

Idle speed should be:

Remove the rubber cap from the tachometer

connector and connect a tachometer.

TACHOMETER

RUBBER

CAP

Adjust the idle speed, if necessary, by turning

the idle adjusting screw. If the proper idle speed cannot be achieved,

clean the throttle body port with carburetor

cleaner.

IDLE ADJUSTING

SCREW

TACHOMETER CONNECTORProCarManuals.com

Page 1499 of 1640

6. Turn the ignition switch OFF.

7. Reconnect the 2P connector on the EACV, then

remove CLOCK fuse in the under-hood fuse/relay

box for 10 seconds to reset ECU.

8. Restart and idle the engine with no-load conditions

in which the headlights, blower fan, rear defogger,

cooling fan, and air conditioner are not operating

for one minute, then check the idle speed.

Idle speed should be:ProCarManuals.com

Page 1500 of 1640

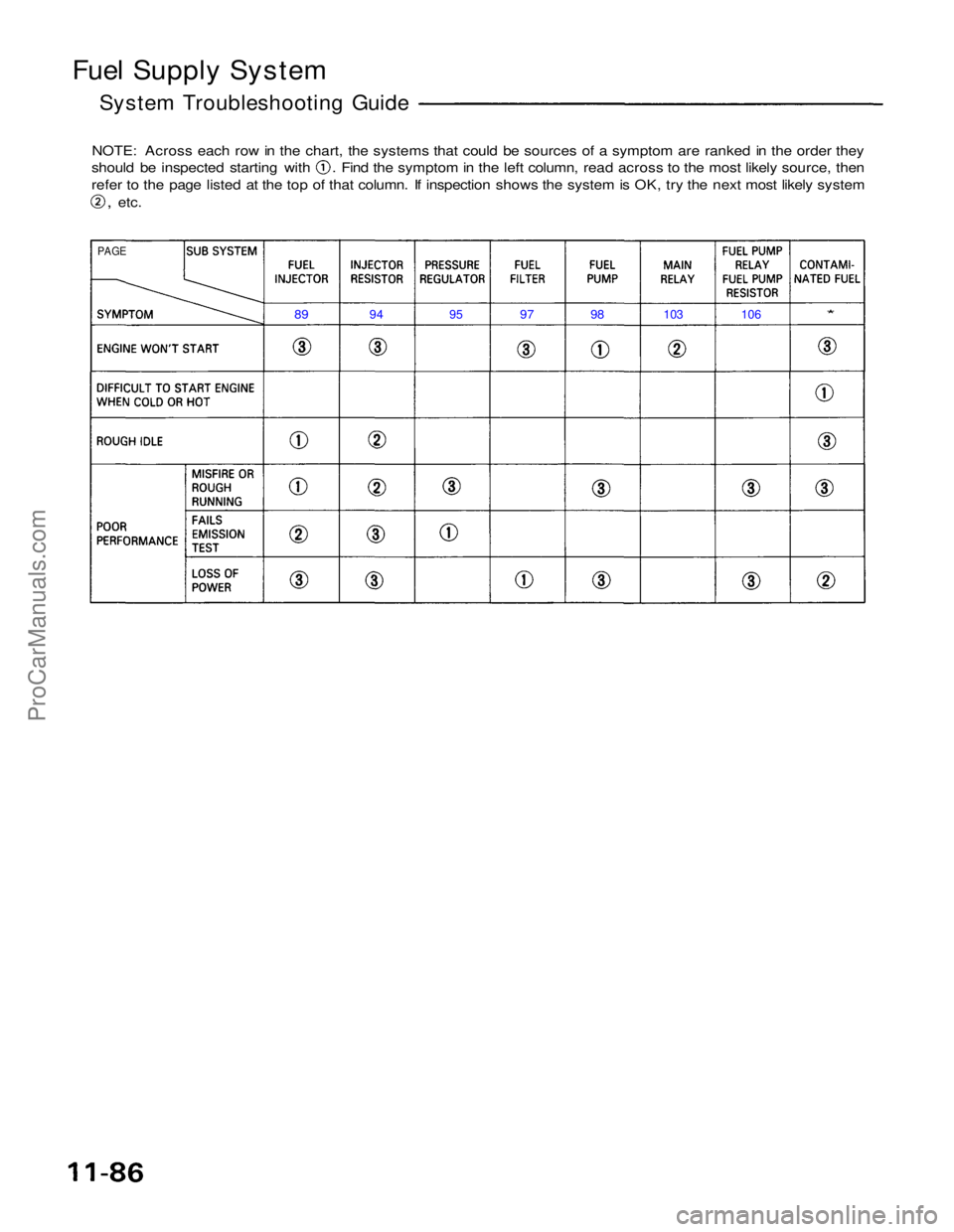

Fuel Supply System

System Troubleshooting Guide

NOTE: Across each row in the chart, the systems that could be sources of a symptom are ranked in the order they should be inspected starting with . Find the symptom in the left column, read across to the most likely source, then

refer to the page listed at the top of that column. If inspection shows the system is OK, try the next most likely system

,

etc.

PAGE

89

94

95

97

98

103 106

*

ProCarManuals.com