ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991,

Model line: NSX,

Model: ACURA NSX 1991

Pages: 1640, PDF Size: 60.48 MB

ACURA NSX 1991 Service Repair Manual

NSX 1991

ACURA

ACURA

https://www.carmanualsonline.info/img/32/56988/w960_56988-0.png

ACURA NSX 1991 Service Repair Manual

Trending: width, radio antenna, turn signal, open hood, oil reset, oil, AUX

Page 1471 of 1640

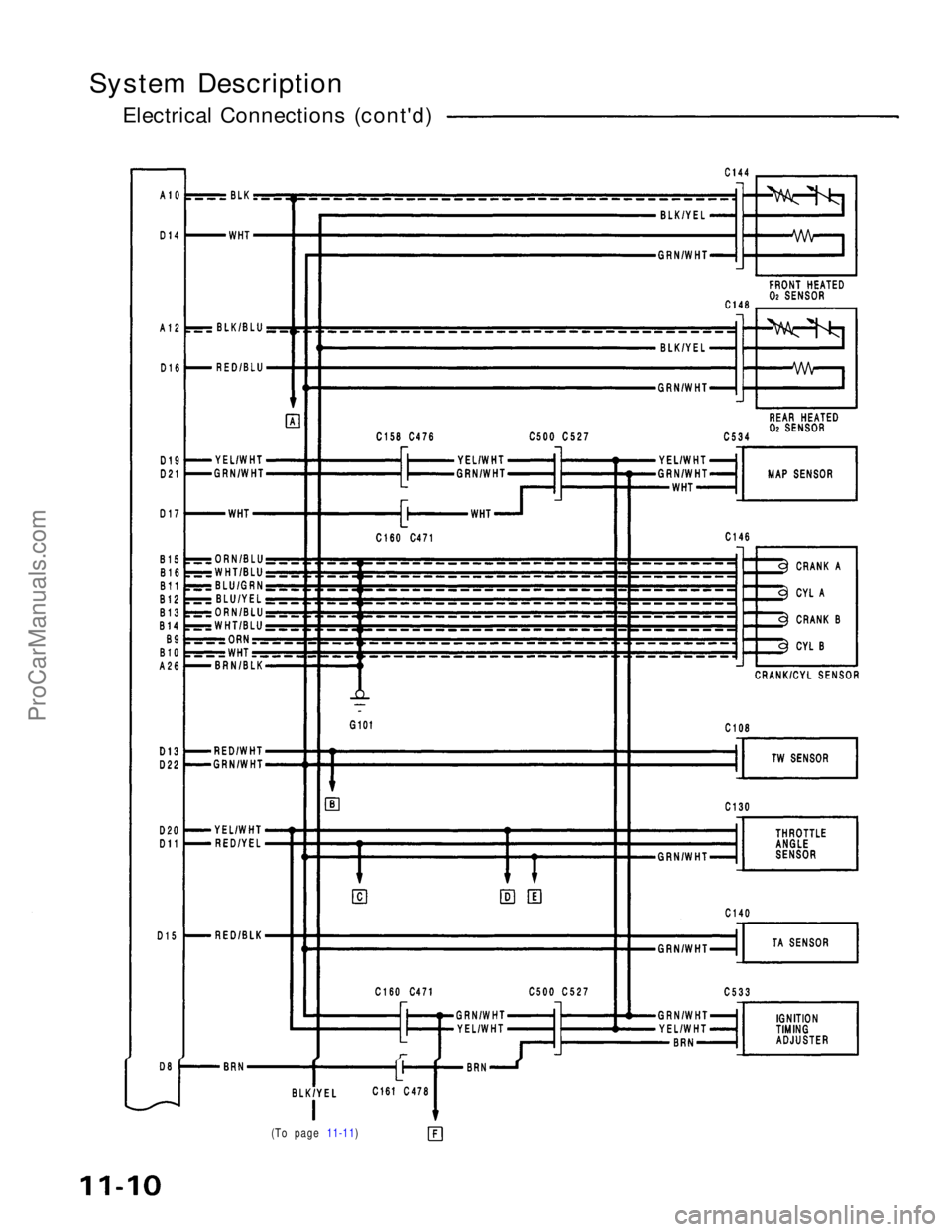

System Description

Electrical Connections (cont'd)

(To page 11-11)ProCarManuals.com

Page 1472 of 1640

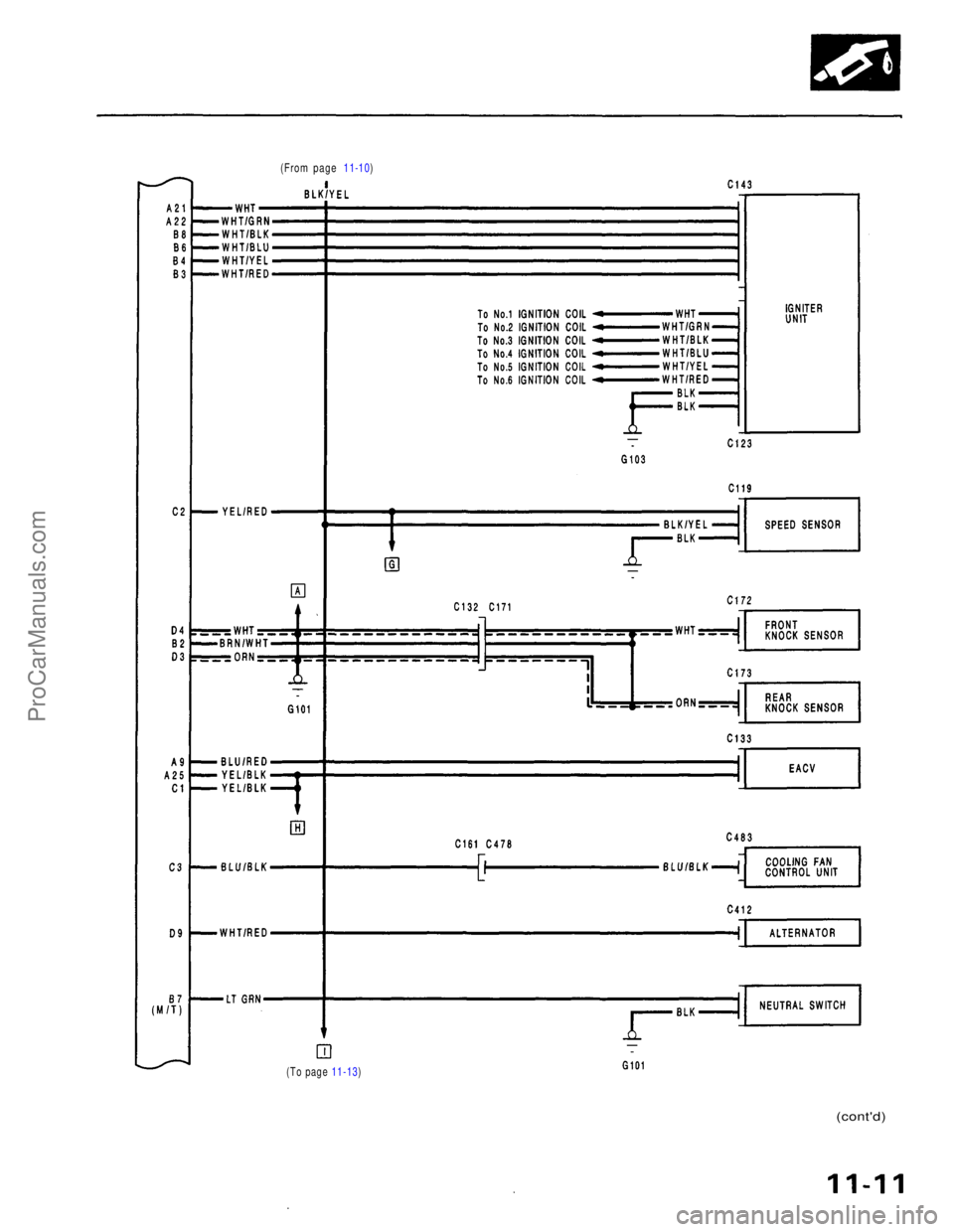

(From page 11-10)

(cont'd)

(To page 11-13)ProCarManuals.com

Page 1473 of 1640

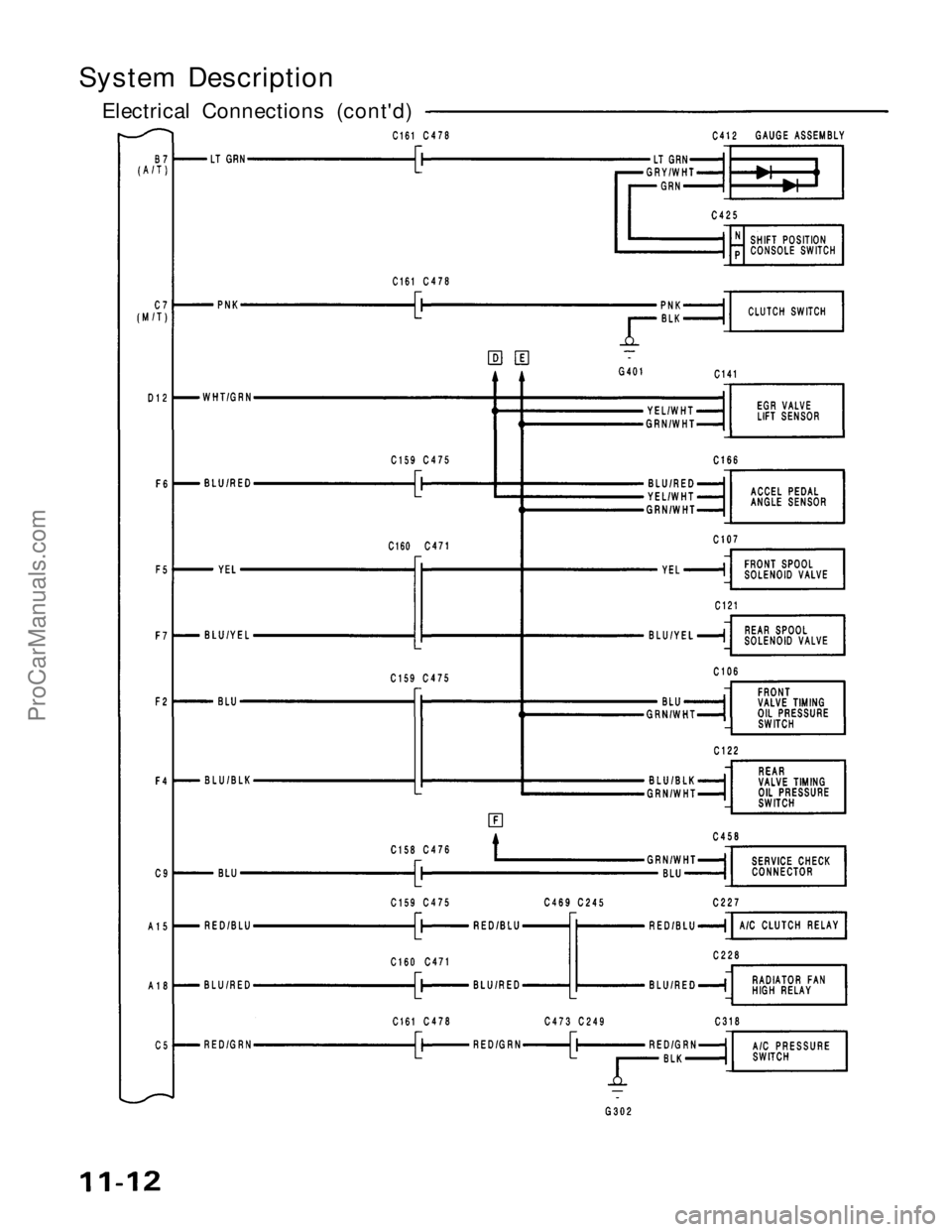

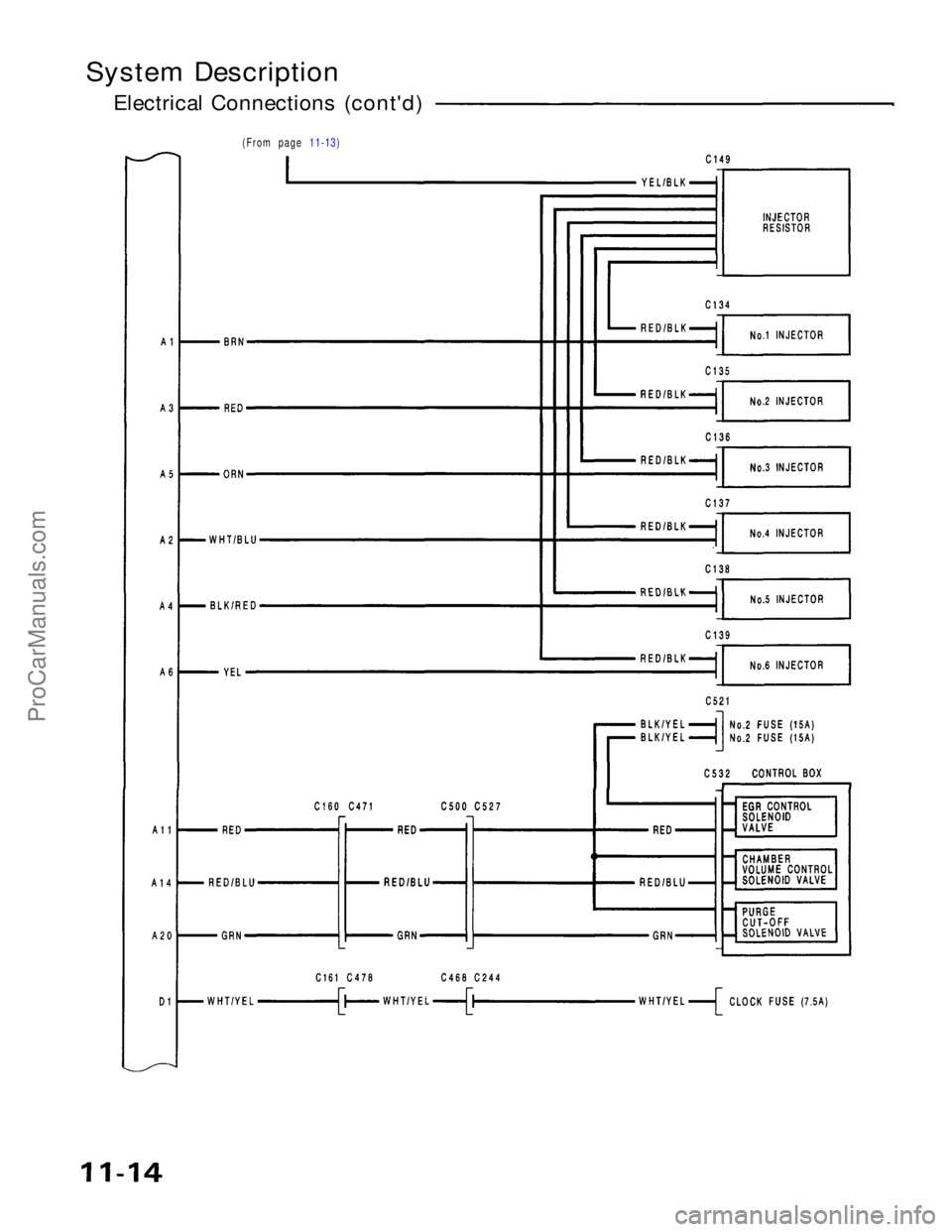

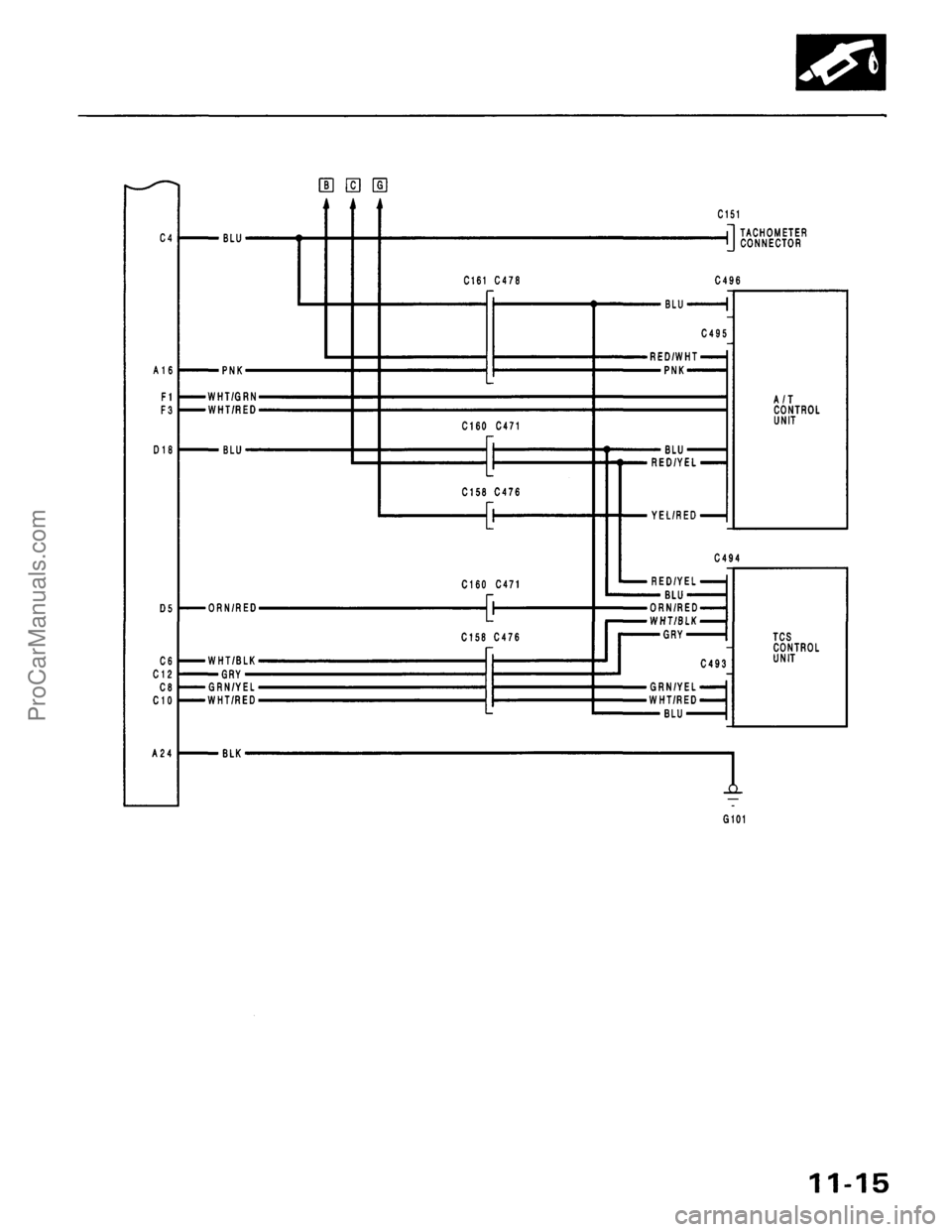

System Description

Electrical Connections (cont'd)ProCarManuals.com

Page 1474 of 1640

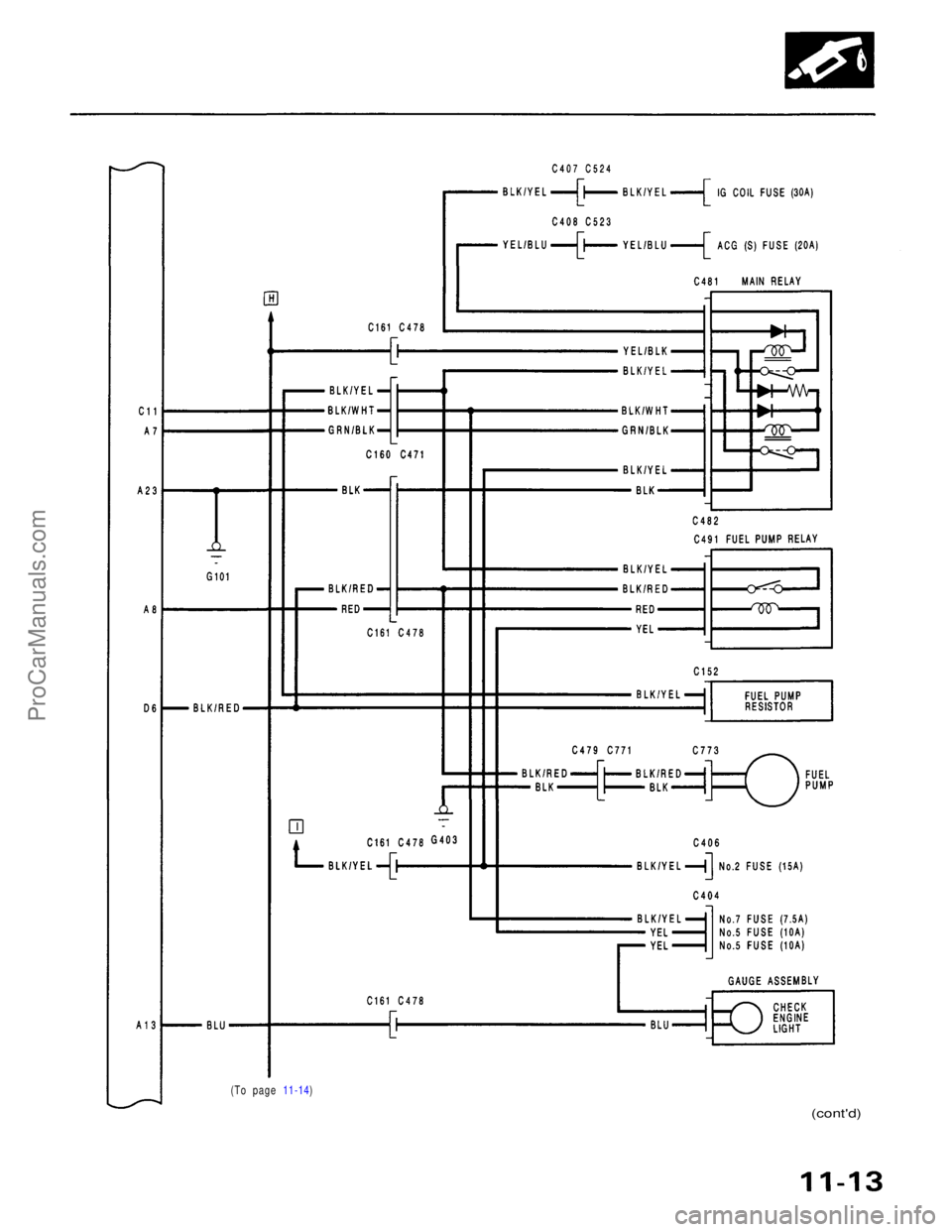

(To page 11-14)

(cont'd)ProCarManuals.com

Page 1475 of 1640

System Description

Electrical Connections (cont'd)

(From page 11-13)ProCarManuals.com

Page 1476 of 1640

Page 1477 of 1640

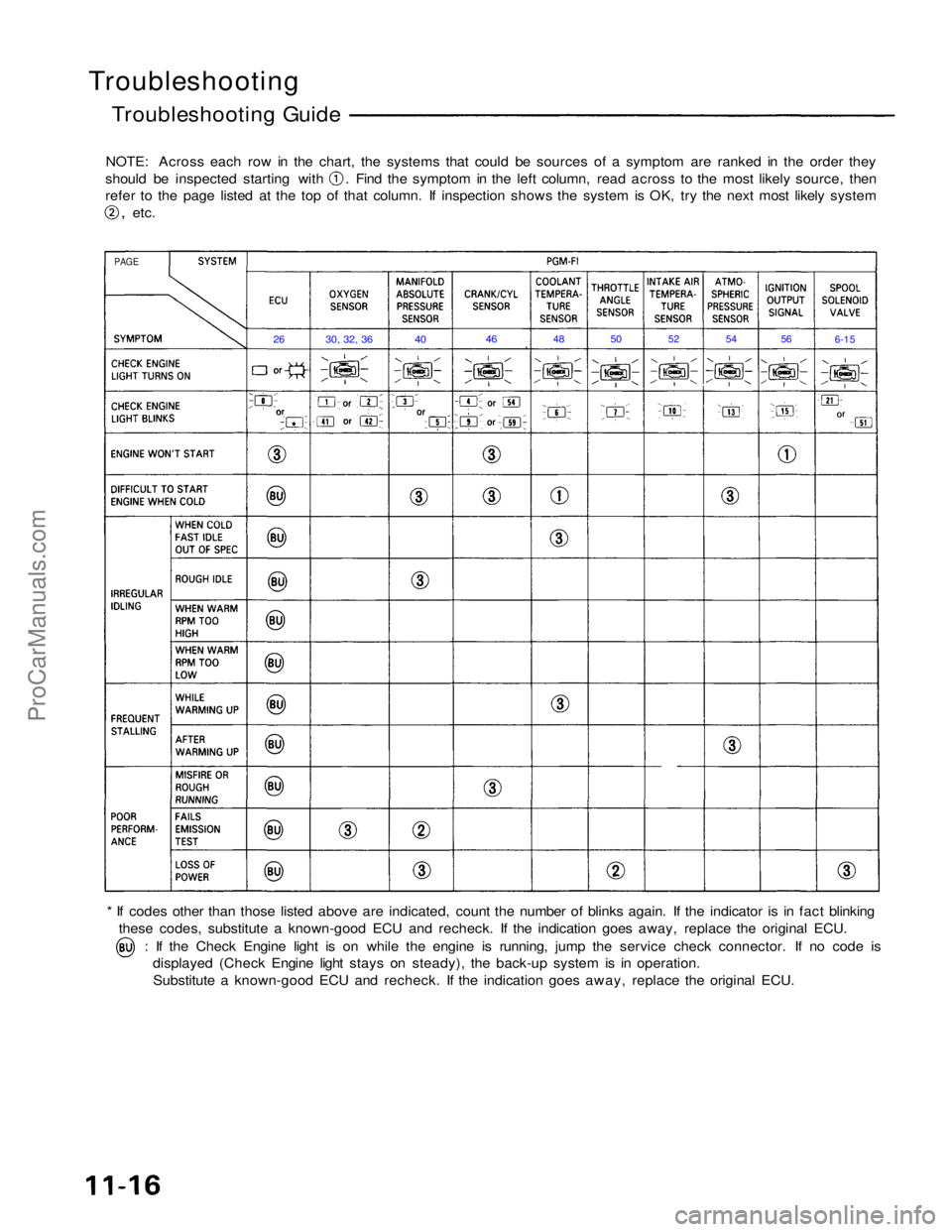

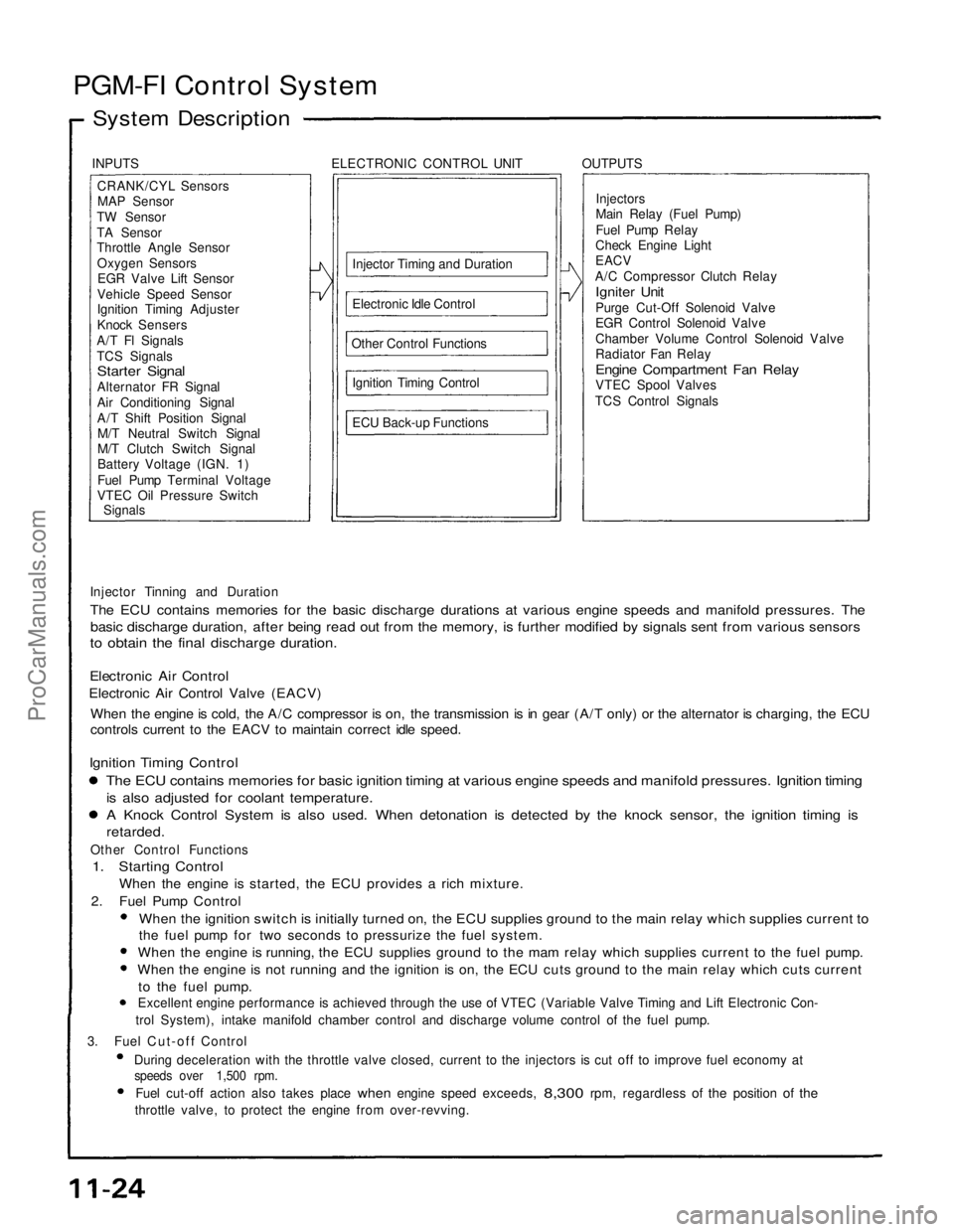

Troubleshooting

Troubleshooting Guide

NOTE: Across each row in the chart, the systems that could be sources of a symptom are ranked in the order they should be inspected starting with . Find the symptom in the left column, read across to the most likely source, then

refer to the page listed at the top of that column. If inspection shows the system is OK, try the next most likely system

,

etc.

* If codes other than those listed above are indicated, count the number of blinks again. If the indicator is in fact blinking these codes, substitute a known-good ECU and recheck. If the indication goes away, replace the original ECU. : If the Check Engine light is on while the engine is running, jump the service check connector. If no code is

displayed (Check Engine light stays on steady), the back-up system is in operation.

Substitute a known-good ECU and recheck. If the indication goes away, replace the original ECU.

PAGE

26

30, 32, 36

40

46

48

50

52

54

56

6-15ProCarManuals.com

Page 1478 of 1640

Page 1479 of 1640

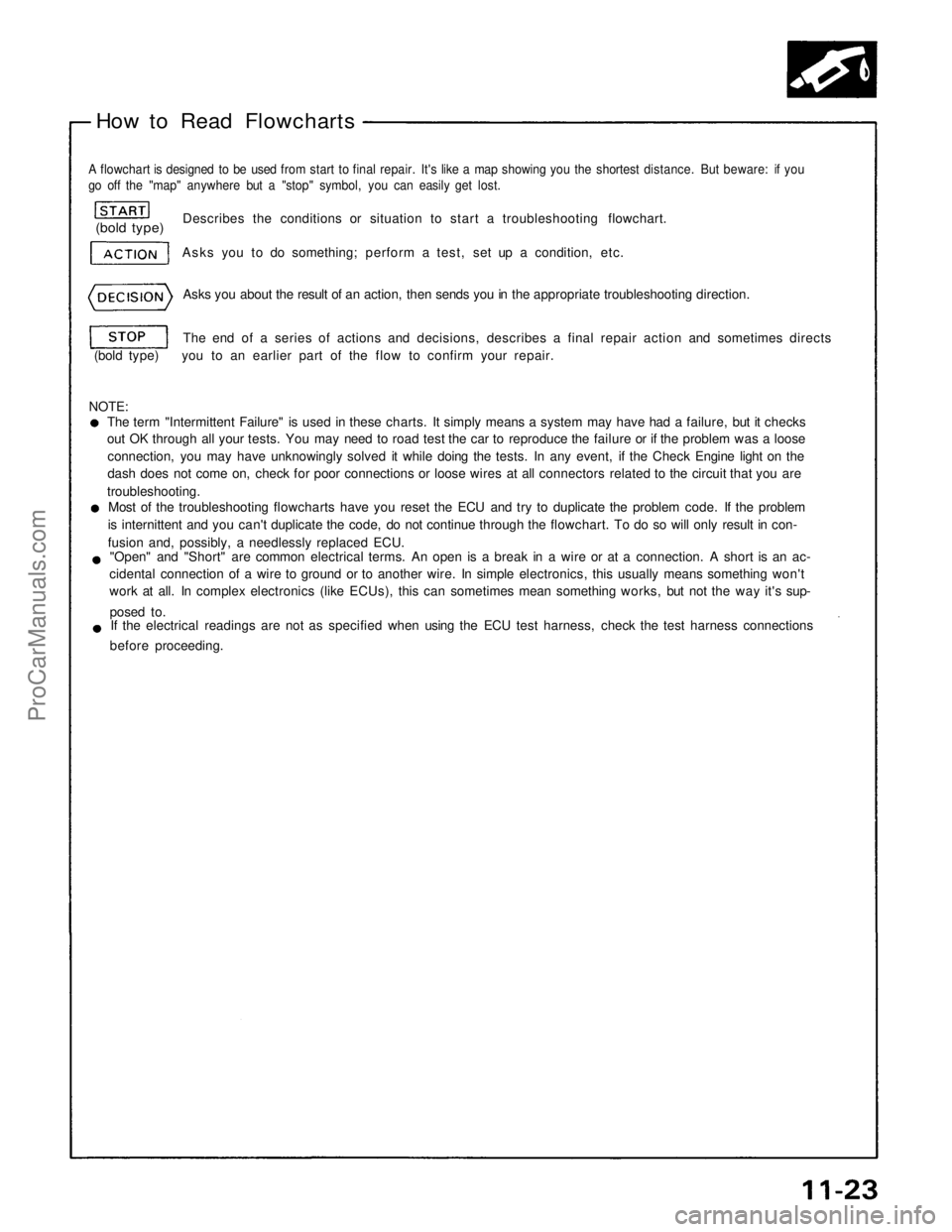

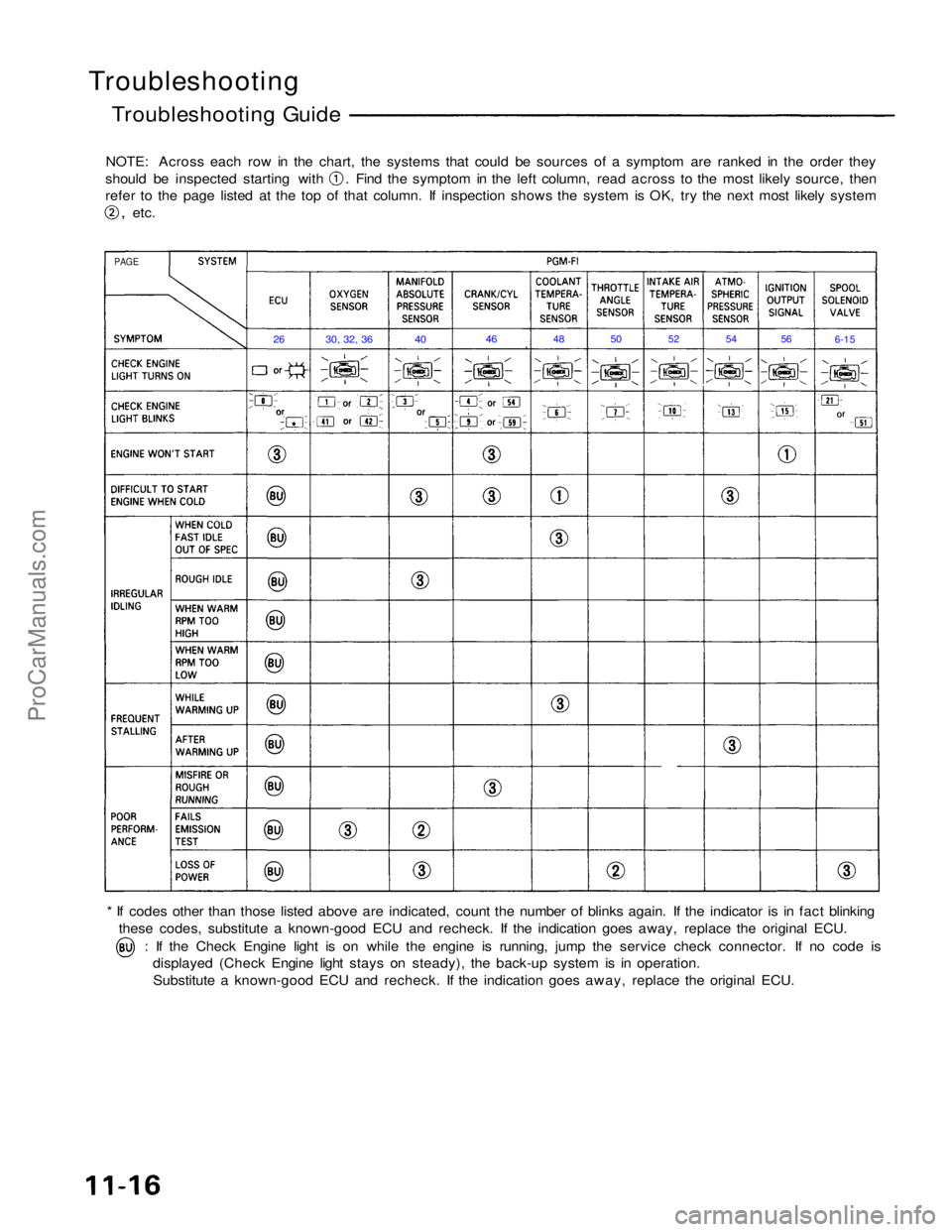

How to Read Flowcharts

A flowchart is designed to be used from start to final repair. It's like a map showing you the shortest distance. But beware: if you

go off the "map" anywhere but a "stop" symbol, you can easily get lost.

Describes the conditions or situation to start a troubleshooting flowchart.

(bold type)

Asks you to do something; perform a test, set up a condition, etc.

Asks you about the result of an action, then sends you in the appropriate troubleshooting direction.

The end of a series of actions and decisions, describes a final repair action and sometimes directs

(bold type) you to an earlier part of the flow to confirm your repair.

NOTE: The term "Intermittent Failure" is used in these charts. It simply means a system may have had a failure, but it checks

out OK through all your tests. You may need to road test the car to reproduce the failure or if the problem was a loose

connection, you may have unknowingly solved it while doing the tests. In any event, if the Check Engine light on the

dash does not come on, check for poor connections or loose wires at all connectors related to the circuit that you are

troubleshooting. Most of the troubleshooting flowcharts have you reset the ECU and try to duplicate the problem code. If the problem

is internittent and you can't duplicate the code, do not continue through the flowchart. To do so will only result in con-

fusion and, possibly, a needlessly replaced ECU. "Open" and "Short" are common electrical terms. An open is a break in a wire or at a connection. A short is an ac-

cidental connection of a wire to ground or to another wire. In simple electronics, this usually means something won't

work at all. In complex electronics (like ECUs), this can sometimes mean something works, but not the way it's sup-

posed to. If the electrical readings are not as specified when using the ECU test harness, check the test harness connections

before proceeding.ProCarManuals.com

Page 1480 of 1640

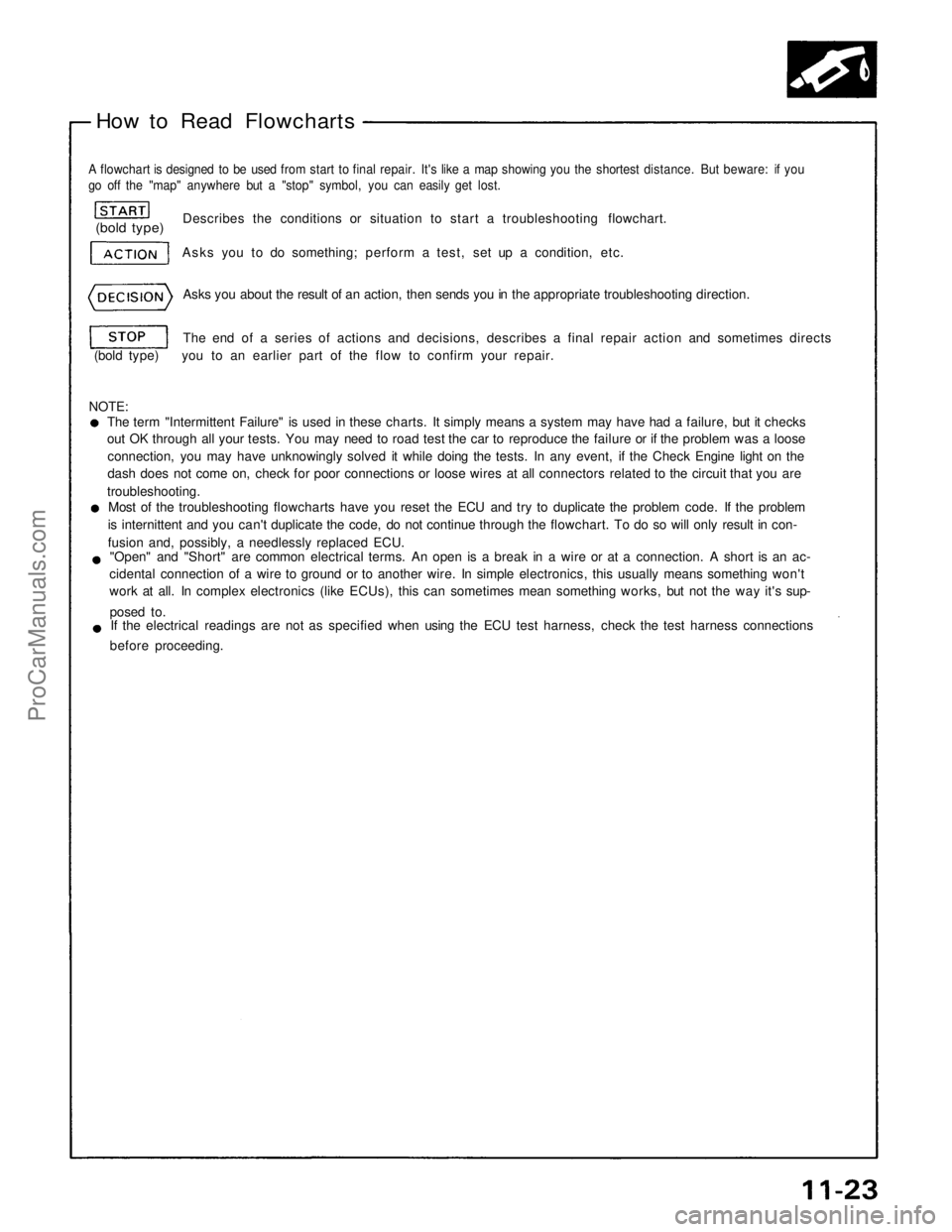

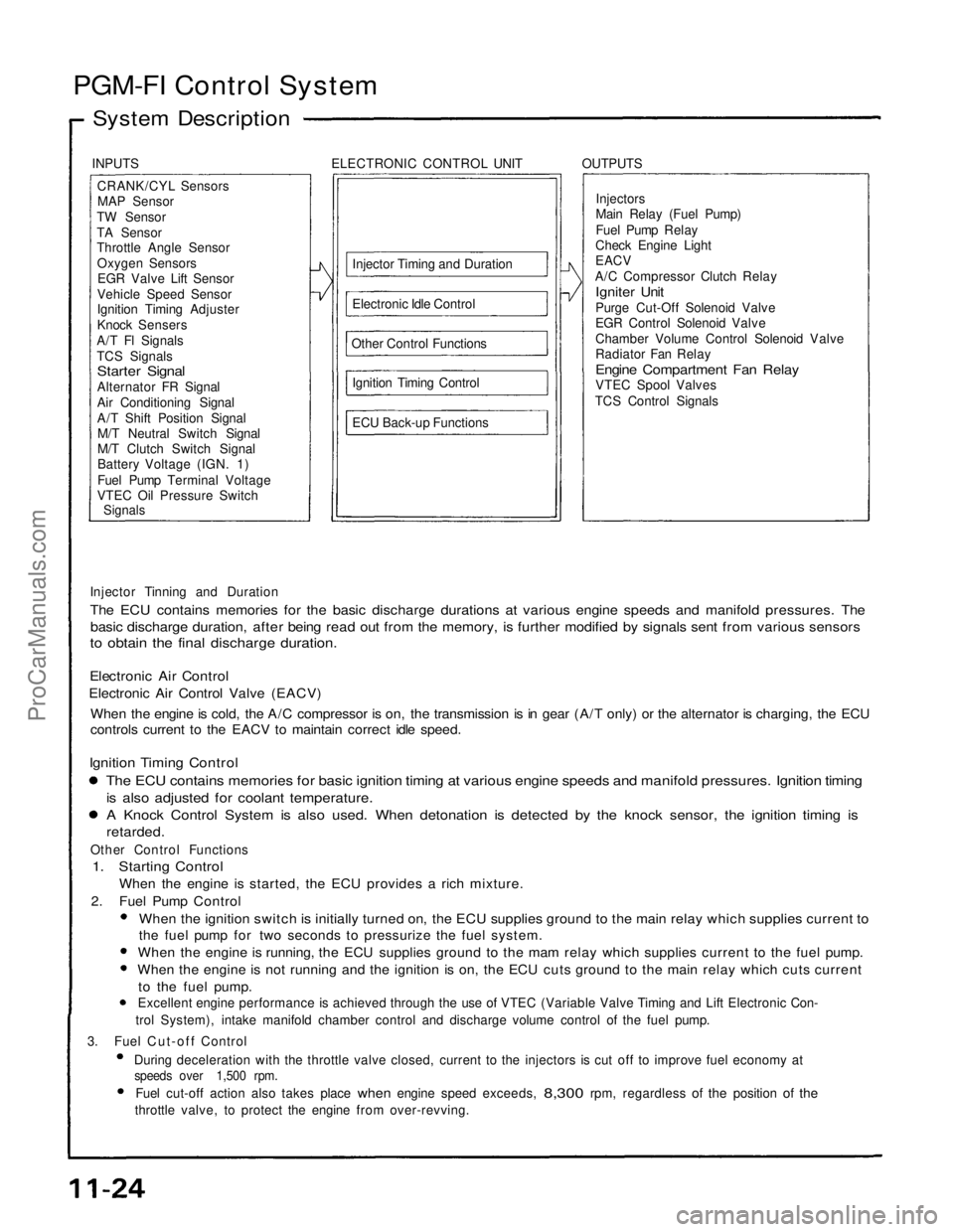

PGM-FI Control System

System Description

INPUTS ELECTRONIC CONTROL UNIT OUTPUTSCRANK/CYL SensorsMAP Sensor

TW Sensor

TA Sensor

Throttle Angle Sensor Oxygen SensorsEGR Valve Lift Sensor

Vehicle Speed Sensor

Ignition Timing Adjuster

Knock Sensers

A/T Fl Signals

TCS Signals

Starter Signal

Alternator FR Signal

Air Conditioning Signal

A/T Shift Position Signal M/T Neutral Switch Signal

M/T Clutch Switch Signal

Battery Voltage (IGN. 1)

Fuel Pump Terminal Voltage

VTEC Oil Pressure Switch

Signals

Injector Timing and Duration

Electronic Idle Control

Other Control Functions Ignition Timing Control

ECU Back-up Functions Injectors

Main Relay (Fuel Pump)

Fuel Pump Relay

Check Engine Light

EACV

A/C Compressor Clutch Relay

Igniter Unit

Purge Cut-Off Solenoid Valve

EGR Control Solenoid Valve

Chamber Volume Control Solenoid Valve

Radiator Fan Relay

Engine Compartment Fan Relay

VTEC Spool Valves

TCS Control Signals

Injector Tinning and Duration

The ECU contains memories for the basic discharge durations at various engine speeds and manifold pressures. The

basic discharge duration, after being read out from the memory, is further modified by signals sent from various sensors

to obtain the final discharge duration.

Electronic Air Control

Electronic Air Control Valve (EACV)

When the engine is cold, the A/C compressor is on, the transmission is in gear (A/T only) or the alternator is charging, the ECU

controls current to the EACV to maintain correct idle speed.

Ignition Timing Control

The ECU contains memories for basic ignition timing at various engine speeds and manifold pressures. Ignition timing

is also adjusted for coolant temperature.

A Knock Control System is also used. When detonation is detected by the knock sensor, the ignition timing is

retarded.

Other Control Functions

1. Starting Control

When the engine is started, the ECU provides a rich mixture.

2. Fuel Pump Control

When the ignition switch is initially turned on, the ECU supplies ground to the main relay which supplies current to

the fuel pump for two seconds to pressurize the fuel system.

When the engine is running, the ECU supplies ground to the mam relay which supplies current to the fuel pump.

When the engine is not running and the ignition is on, the ECU cuts ground to the main relay which cuts current

to the fuel pump.

Excellent engine performance is achieved through the use of VTEC (Variable Valve Timing and Lift Electronic Con-

trol System), intake manifold chamber control and discharge volume control of the fuel pump.

3. Fuel Cut-off Control During deceleration with the throttle valve closed, current to the injectors is cut off to improve fuel economy at

speeds over 1,500 rpm.

Fuel cut-off action also takes place

when

engine speed exceeds,

8,300

rpm, regardless

of the

position

of the

throttle valve, to protect the engine from over-revving.ProCarManuals.com

Trending: charging, low oil pressure, trunk release, light, radio, hood open, engine