ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991,

Model line: NSX,

Model: ACURA NSX 1991

Pages: 1640, PDF Size: 60.48 MB

ACURA NSX 1991 Service Repair Manual

NSX 1991

ACURA

ACURA

https://www.carmanualsonline.info/img/32/56988/w960_56988-0.png

ACURA NSX 1991 Service Repair Manual

Trending: octane, headlights, child lock, oil dipstick, tire size, jack points, low beam

Page 1521 of 1640

Page 1522 of 1640

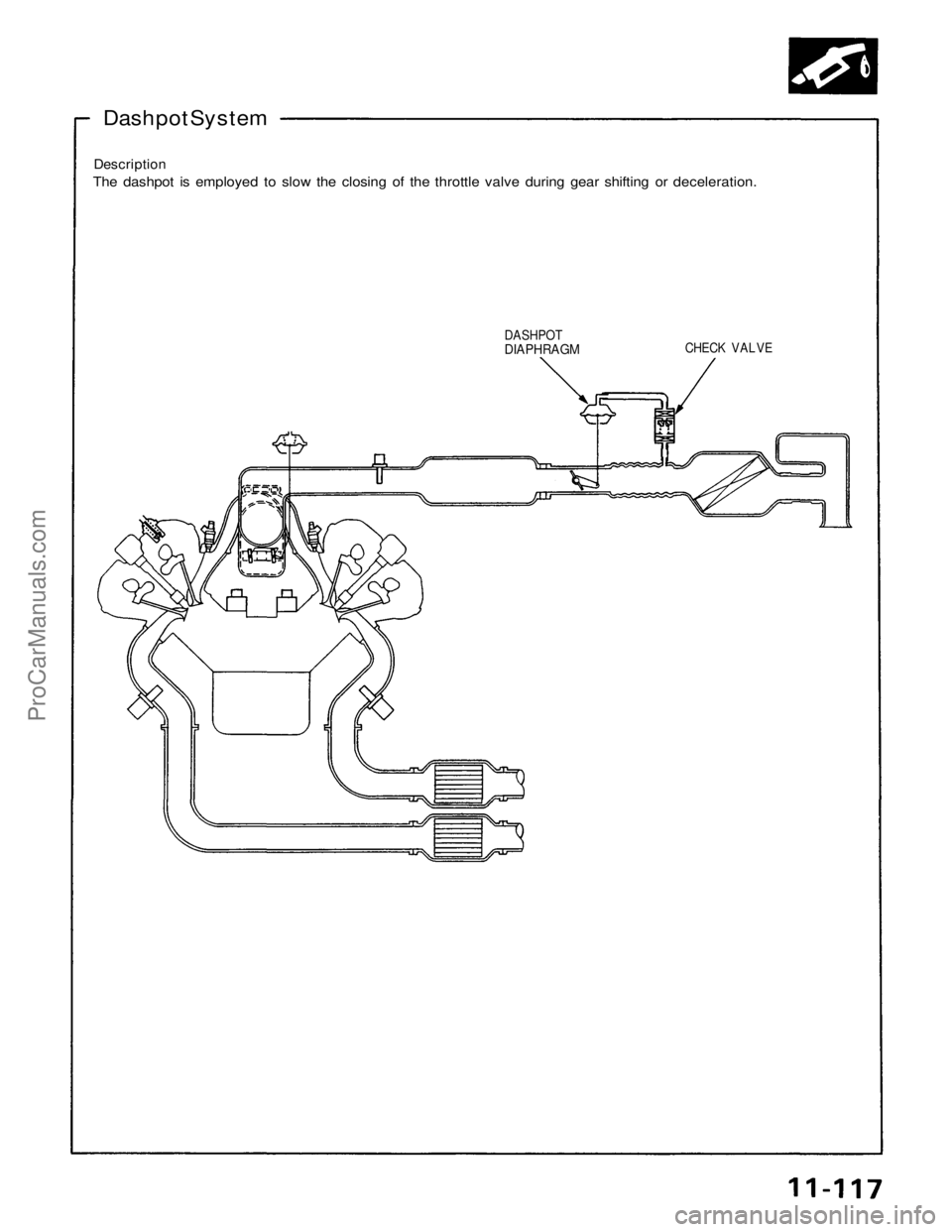

Dashpot System

Description

The dashpot is employed to slow the closing of the throttle valve during gear shifting or deceleration.

DASHPOT

DIAPHRAGM

CHECK VALVEProCarManuals.com

Page 1523 of 1640

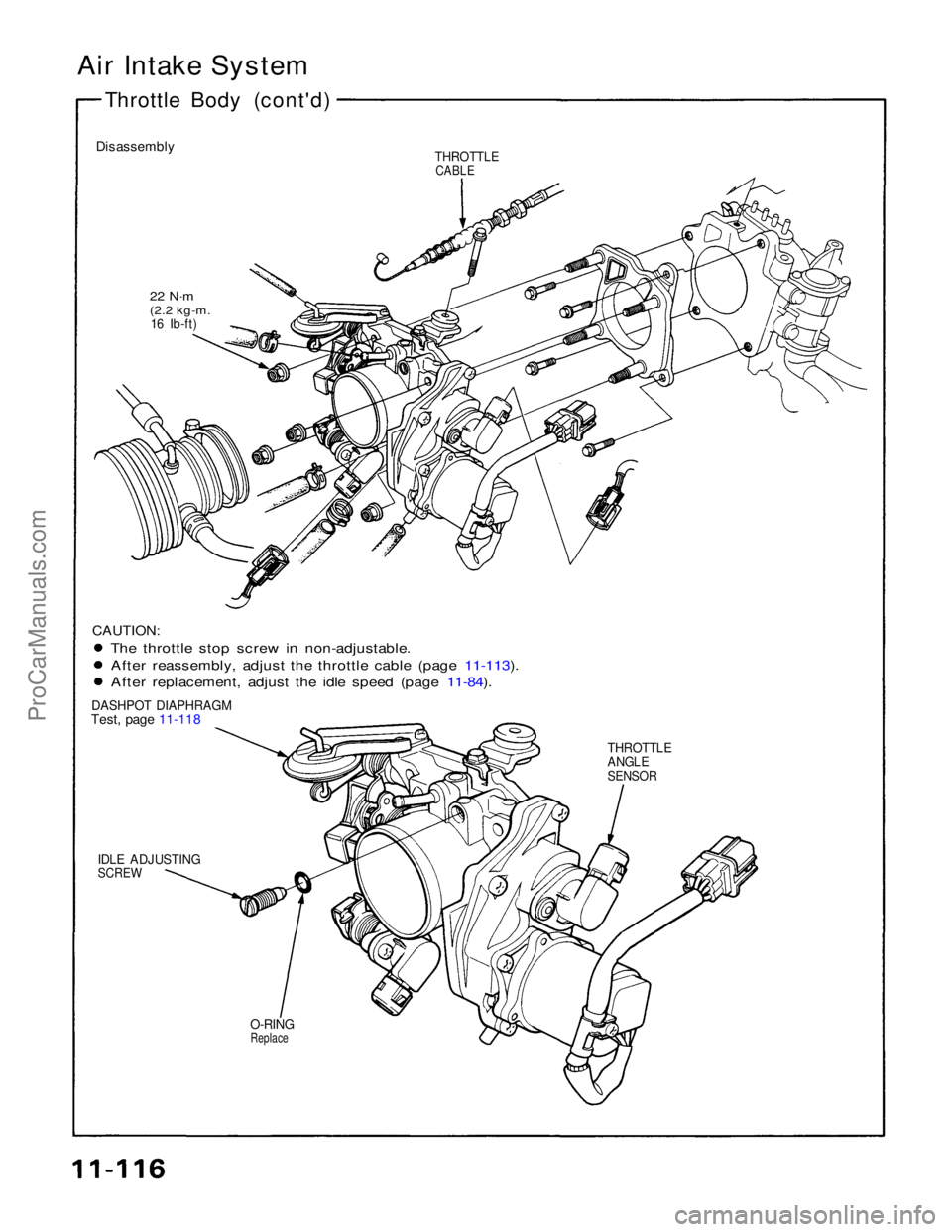

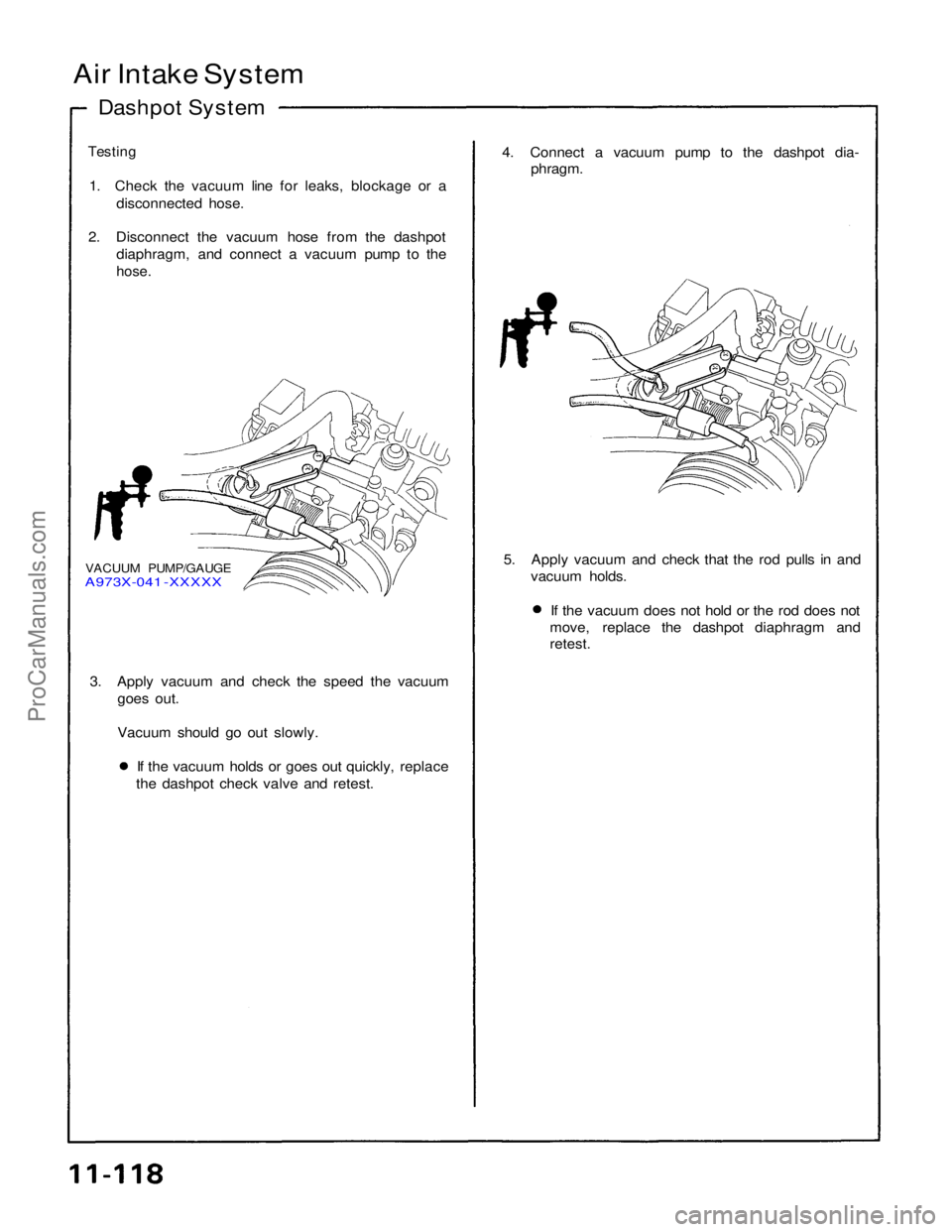

Air Intake System

Dashpot System

Testing

1. Check the vacuum line for leaks, blockage or a disconnected hose.

2. Disconnect the vacuum hose from the dashpot diaphragm, and connect a vacuum pump to the

hose.

4. Connect a vacuum pump to the dashpot dia-

phragm.

VACUUM PUMP/GAUGE

A973X-041 -XXXXX

5. Apply vacuum and check that the rod pulls in and

vacuum holds. If the vacuum does not hold or the rod does not

move, replace the dashpot diaphragm and

retest.

3. Apply vacuum and check the speed the vacuum goes out.

Vacuum should go out slowly. If the vacuum holds or goes out quickly, replace

the dashpot check valve and retest.ProCarManuals.com

Page 1524 of 1640

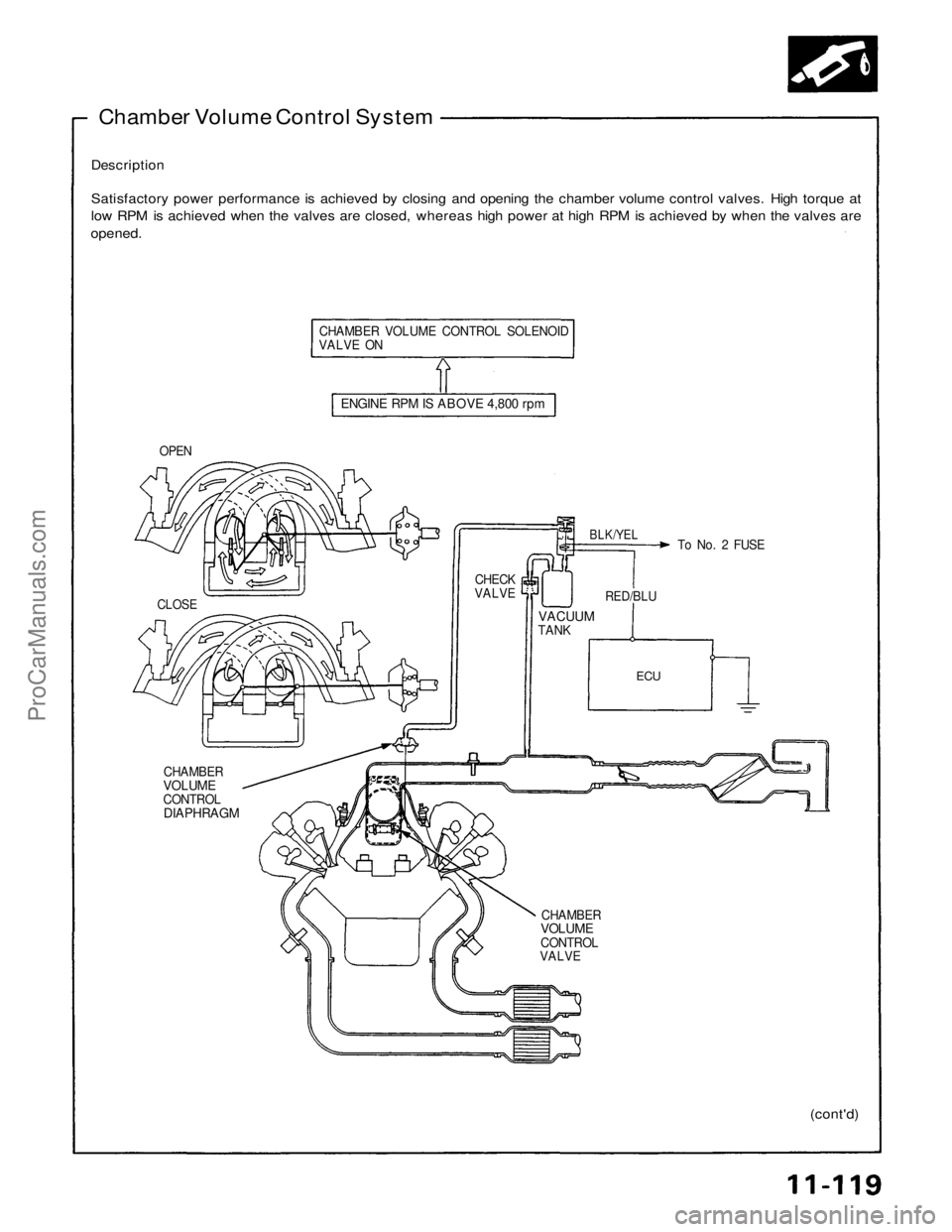

Chamber Volume Control System

Description

Satisfactory power performance is achieved by closing and opening the chamber volume control valves. High torque at

low RPM is achieved when the valves are closed, whereas high power at high RPM is achieved by when the valves are

opened.

CHAMBER VOLUME CONTROL SOLENOID

VALVE ON

ENGINE RPM IS ABOVE 4,800 rpm

OPEN

BLK/YEL

To No. 2 FUSE

CLOSE

CHECK

VALVE

VACUUM

TANK

RED/BLU

ECU

CHAMBER

VOLUME

CONTROL

DIAPHRAGM

CHAMBER

VOLUME

CONTROL

VALVE

(cont'd)ProCarManuals.com

Page 1525 of 1640

Air Intake System

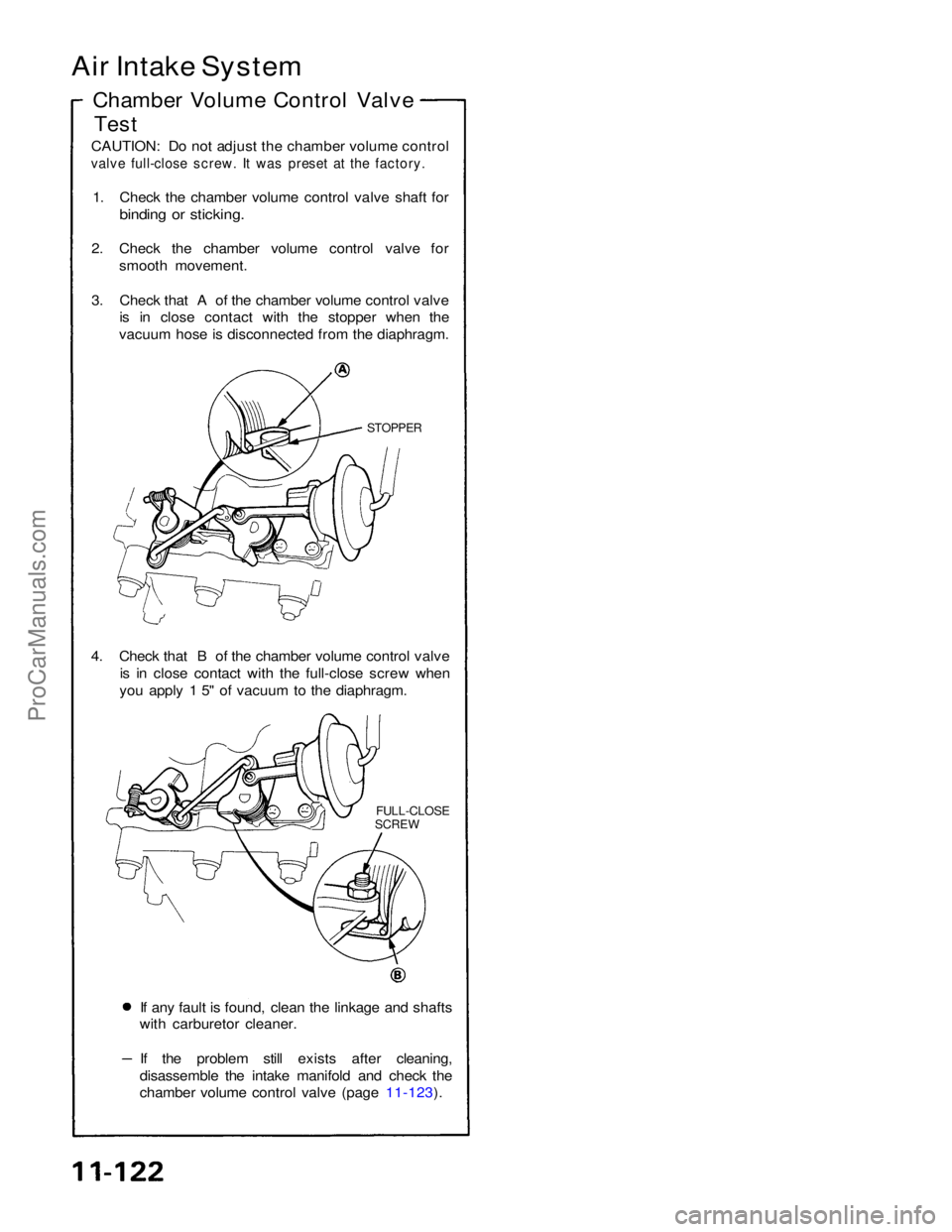

Chamber Volume Control Valve

Test

CAUTION: Do not adjust the chamber volume control

valve full-close screw. It was preset at the factory.

1. Check the chamber volume control valve shaft for

binding or sticking.

2. Check the chamber volume control valve for smooth movement.

3. Check that A of the chamber volume control valve is in close contact with the stopper when the

vacuum hose is disconnected from the diaphragm.

STOPPER

4. Check that B of the chamber volume control valve is in close contact with the full-close screw when

you apply 1 5" of vacuum to the diaphragm.

FULL-CLOSE

SCREW

If any fault is found, clean the linkage and shafts

with carburetor cleaner. If the problem still exists after cleaning,

disassemble the intake manifold and check the

chamber volume control valve (page 11-123).ProCarManuals.com

Page 1526 of 1640

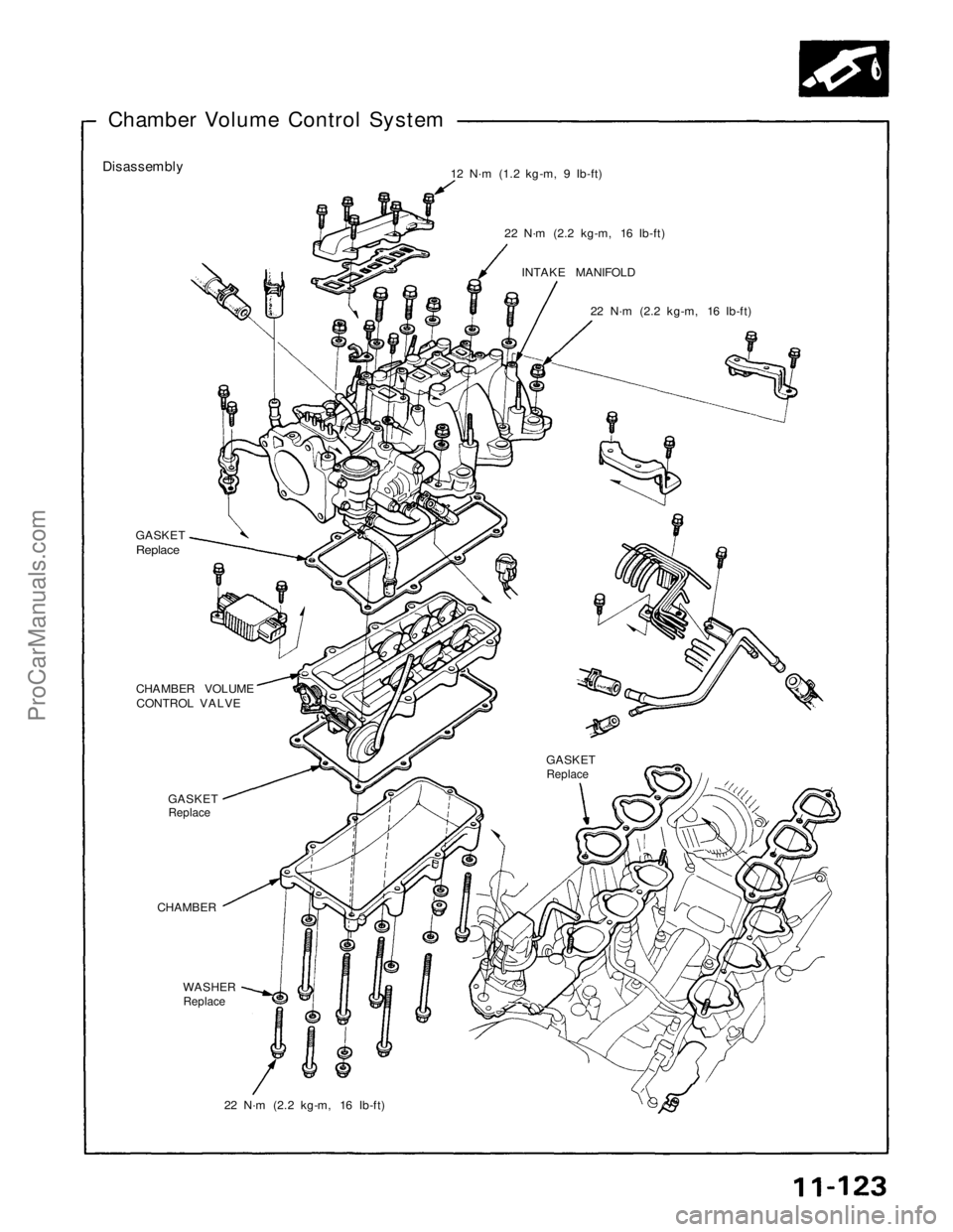

Chamber Volume Control System

Disassembly

12 N·m (1.2 kg-m, 9 Ib-ft)

22 N·m (2.2 kg-m, 16 Ib-ft)INTAKE MANIFOLD 22 N·m (2.2 kg-m, 16 Ib-ft)

GASKETReplace

CHAMBER VOLUME

CONTROL VALVE

GASKET

Replace

GASKET

Replace

CHAMBER

WASHER

Replace

22 N·m (2.2 kg-m, 16 Ib-ft)ProCarManuals.com

Page 1527 of 1640

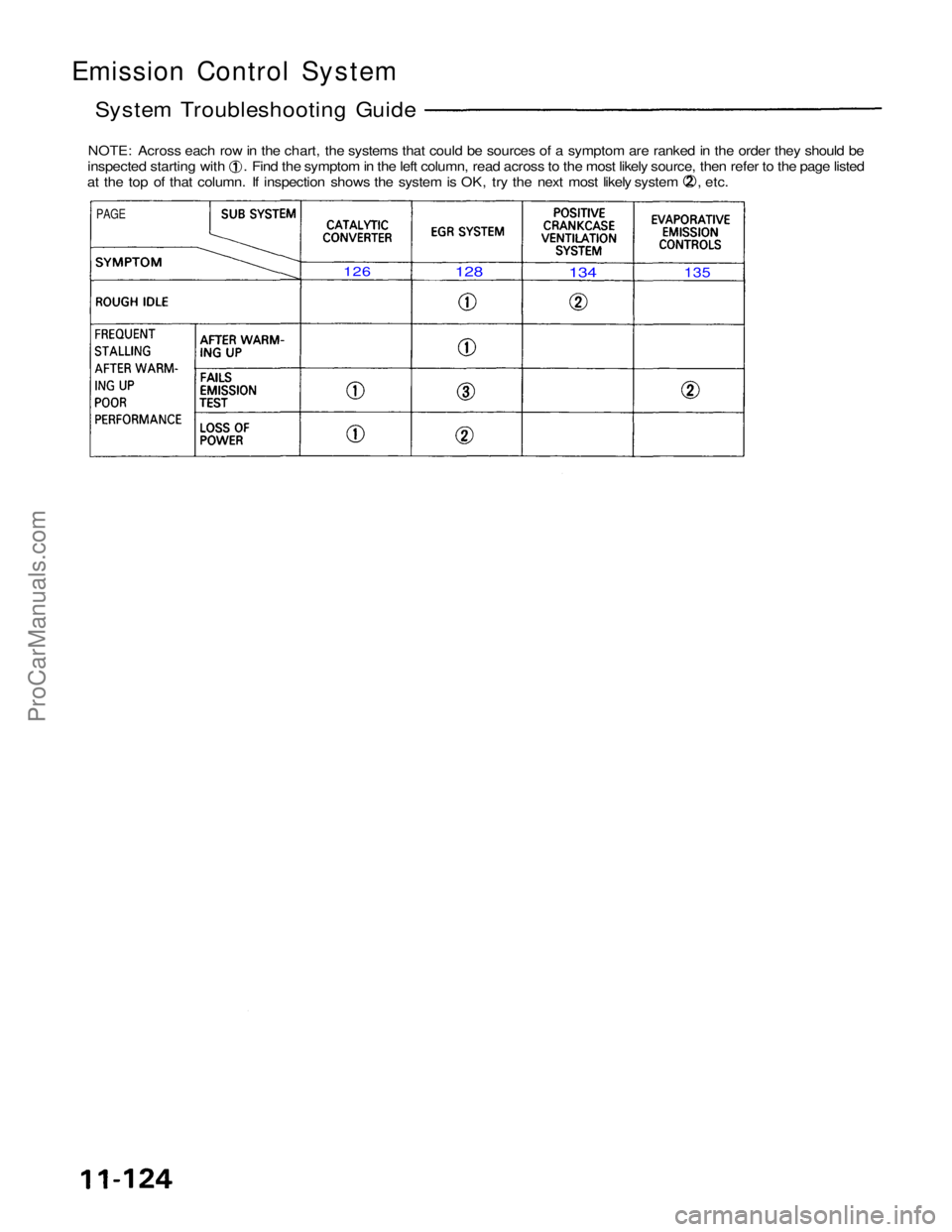

Emission Control System

System Troubleshooting Guide

NOTE: Across each row in the chart, the systems that could be sources of a symptom are ranked in the order they should be inspected starting with . Find the symptom in the left column, read across to the most likely source, then refer to the page listed

at the top of that column. If inspection shows the system is OK, try the next most likely system , etc.

PAGE

126

128

134

135

ProCarManuals.com

Page 1528 of 1640

System Description

Tailpipe Emission

The emission control system includes a three-way catalytic converter, exhaust gas recirculation (EGR) system,

crankcase ventilation system and evaporative control

system.

The emission control system is designed to meet federal and

state emission standards.

Inspection

Do not smoke during this procedure. Keep

any open flame away from your work area.

1. Starting the engine and warm it up to normal operating temperature by driving the car on theroad.

2. Connect a tachometer.

3. Check idle speed and adjust the idle speed, if necessary (page 11-84).

4. Warm up and calibrate the CO meter according to the meter manufacturer's instructions.

5. Check idle CO with the headlights, heater blower, rear window defogger, cooling fan, and air conditioner off.

CO meter should indicate 0.1 % maximum.ProCarManuals.com

Page 1529 of 1640

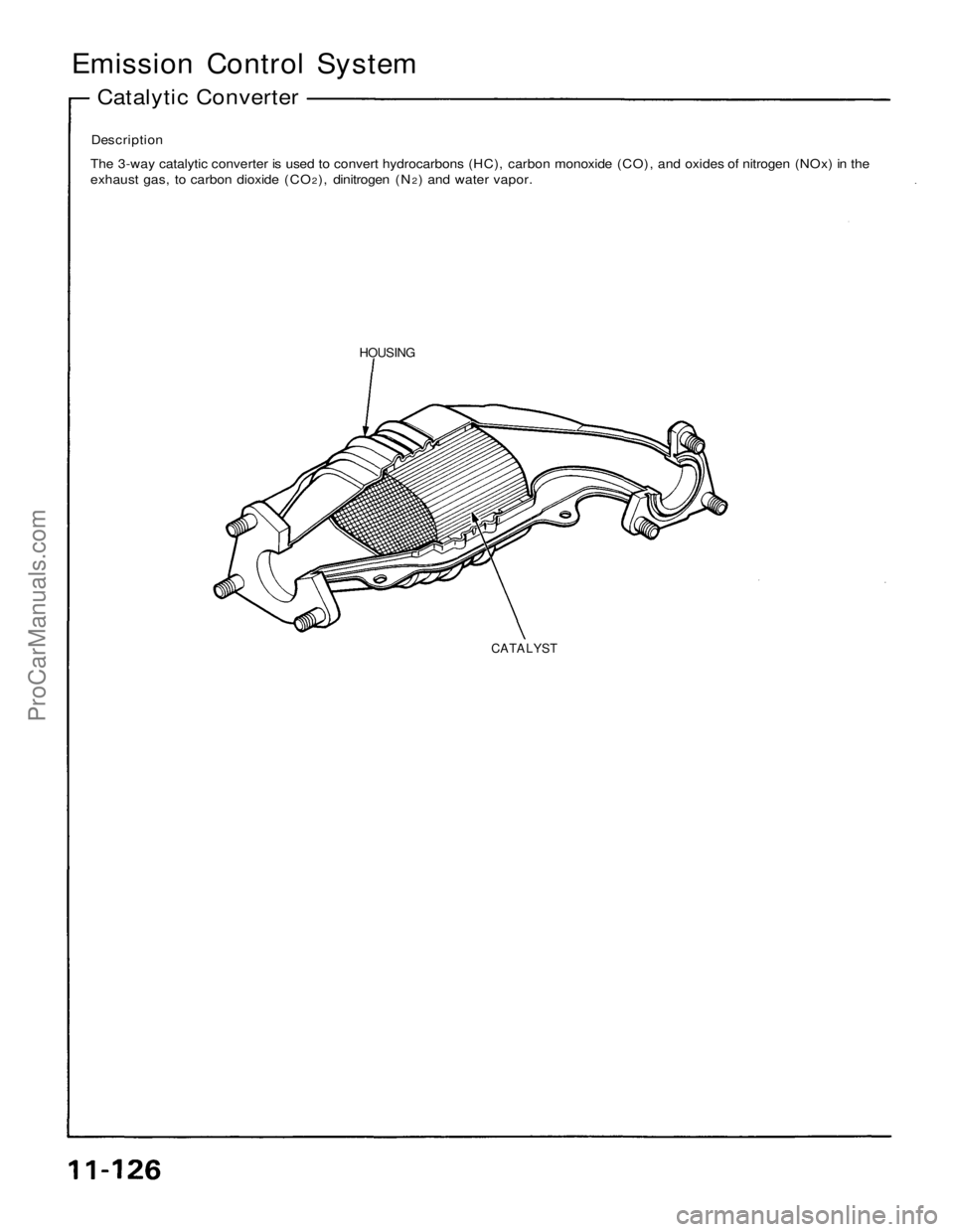

Emission Control System

Catalytic Converter

Description

The 3-way catalytic converter is used to convert hydrocarbons (HC), carbon monoxide (CO), and oxides of nitrogen (NOx) in the

exhaust gas, to carbon dioxide (CO2), dinitrogen (N2) and water vapor.

HOUSING

CATALYSTProCarManuals.com

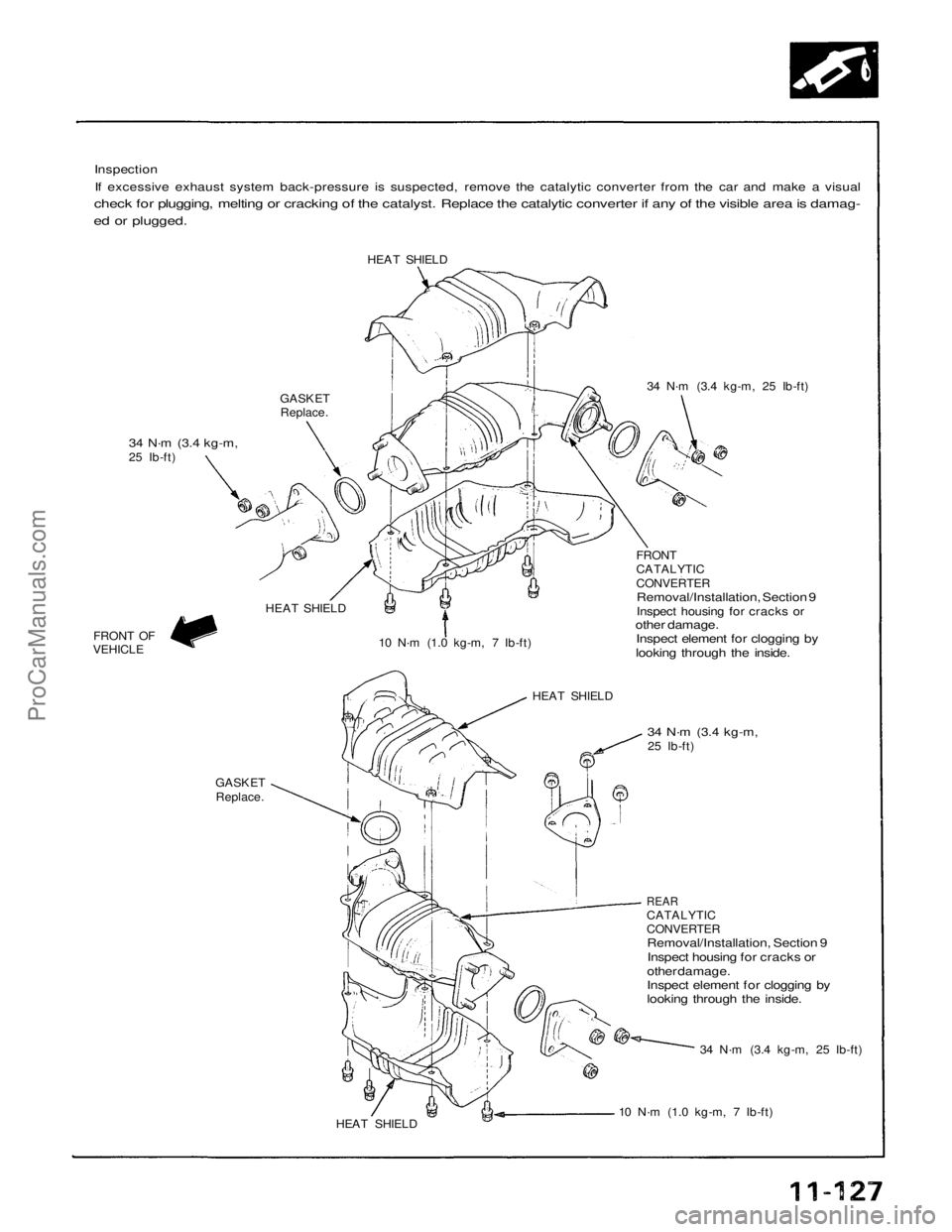

Page 1530 of 1640

Inspection

If excessive exhaust system back-pressure is suspected, remove the catalytic converter from the car and make a visual

check for plugging, melting or cracking of the catalyst. Replace the catalytic converter if any of the visible area is damag-

ed or plugged.

HEAT SHIELD

GASKET

Replace.

34 N·m

(3.4 kg-m,

25 Ib-ft) 34 N·m (3.4 kg-m, 25 Ib-ft)

HEAT SHIELD 10 N·m (1.0 kg-m, 7 Ib-ft)

HEAT SHIELDFRONT

CATALYTIC

CONVERTER

Removal/Installation, Section 9

Inspect housing for cracks or

other damage.

Inspect element for clogging by

looking through the inside.

FRONT OF

VEHICLE

GASKET

Replace.

34 N·m

(3.4 kg-m,

25 Ib-ft)

REAR

CATALYTIC

CONVERTER

Removal/Installation, Section 9

Inspect housing for cracks or

other damage.

Inspect element for clogging by

looking through the inside.

34 N·m (3.4 kg-m, 25 Ib-ft)

10 N·m (1.0 kg-m, 7 Ib-ft)

HEAT SHIELDProCarManuals.com

Trending: battery replacement, buttons, fog light bulb, mirror, turn signal, horn, wiring