engine ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1005 of 1640

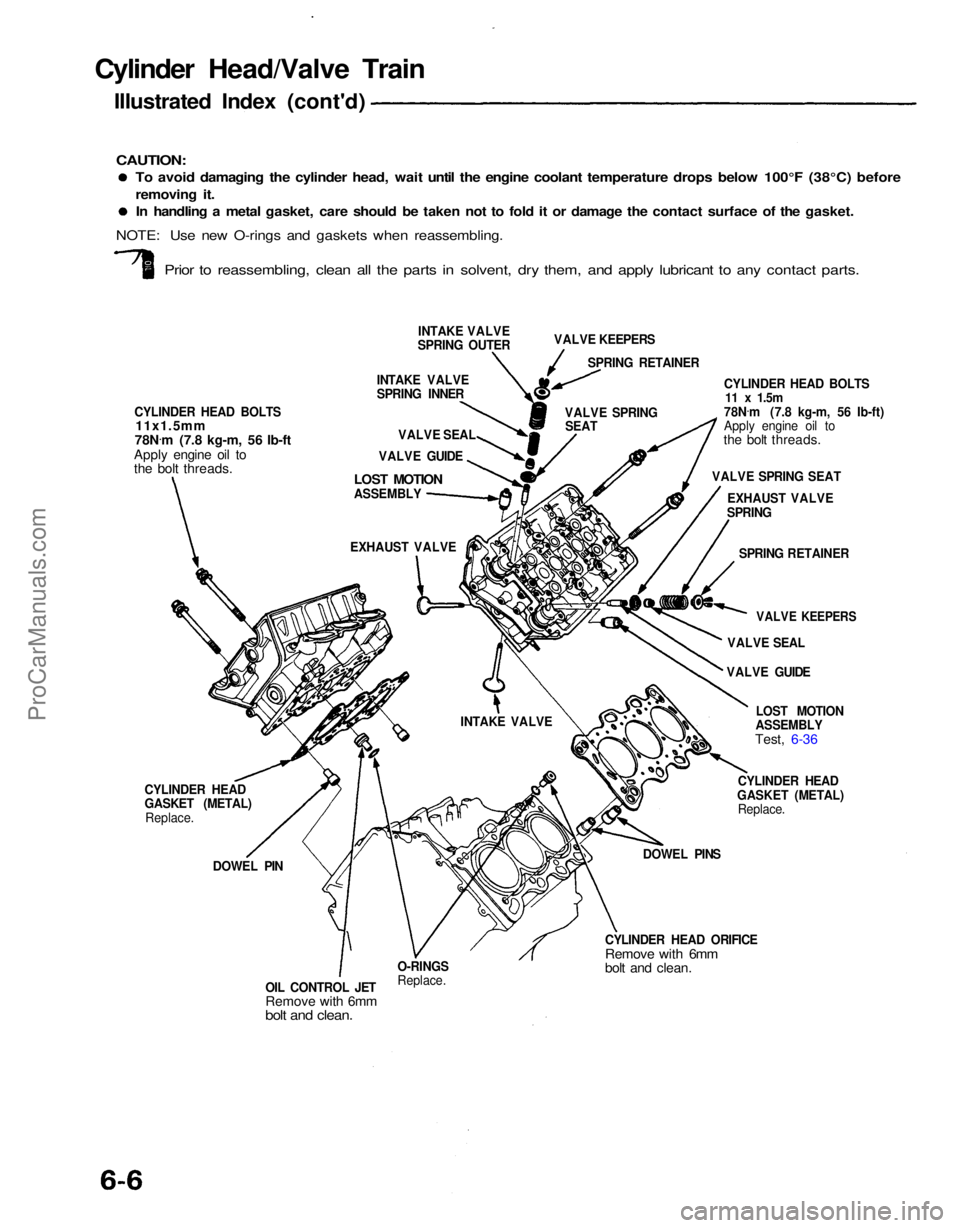

Cylinder Head/Valve Train

Illustrated Index (cont'd)

To avoid damaging the cylinder head, wait until the engine coolant temperature drops below 100°F (38°C) before

removing it.

In handling a metal gasket, care should be taken not to fold it or damage the contact surface of the gasket.

Prior to reassembling, clean all the parts in solvent, dry them, and apply lubricant to any contact parts.

INTAKE VALVE

SPRING OUTER

CYLINDER HEAD BOLTS

11x1.5mm

78N .

m (7.8 kg-m, 56 Ib-ft

Apply engine oil to

the bolt threads.

INTAKE VALVE

SPRING INNER

VALVE SEAL

VALVE GUIDE

LOST MOTION

ASSEMBLY

VALVE KEEPERS

SPRING RETAINER

VALVE SPRING SEAT CYLINDER HEAD BOLTS

11 x

1.5m

78N .

m (7.8 kg-m, 56 Ib-ft)

Apply engine oil to

the bolt threads.

VALVE SPRING SEAT EXHAUST VALVE

SPRING

SPRING RETAINER

VALVE KEEPERS

VALVE SEAL

VALVE GUIDE

LOST MOTION

ASSEMBLY

Test, 6-36

CYLINDER HEAD

GASKET (METAL) Replace.

DOWEL PINS

CYLINDER HEAD ORIFICE

Remove with 6mm

bolt and clean.

O-RINGS

Replace.

OIL CONTROL JET

Remove with 6mm

bolt and clean.

DOWEL PIN

CYLINDER HEAD

GASKET (METAL)

Replace. EXHAUST VALVE

INTAKE VALVE

CAUTION:

NOTE: Use new O-rings and gaskets when reassembling.ProCarManuals.com

Page 1006 of 1640

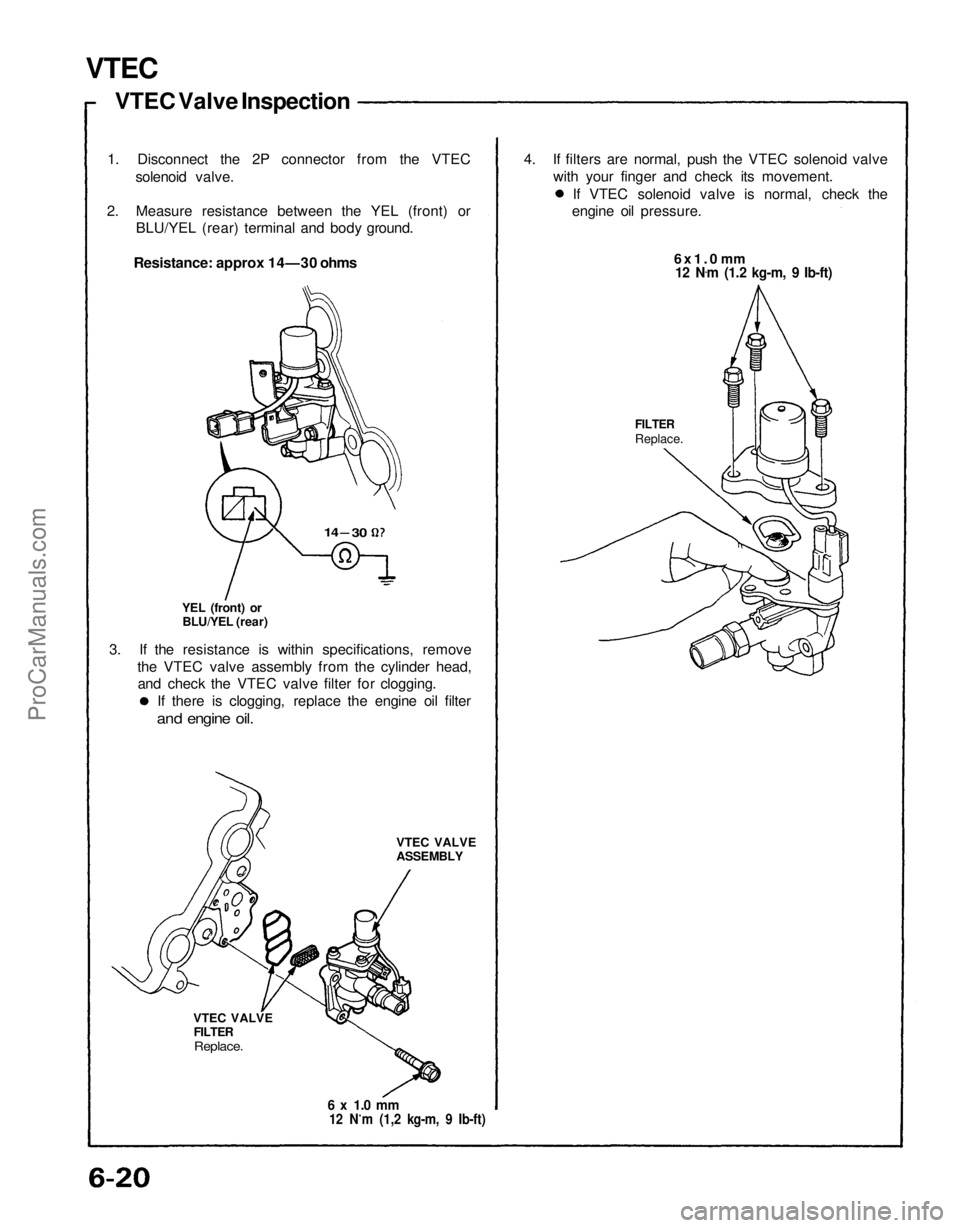

1. Disconnect the 2P connector from the VTEC

solenoid valve.

2. Measure resistance between the YEL (front) or BLU/YEL (rear) terminal and body ground.

Resistance: approx 14—30 ohms 4. If filters are normal, push the VTEC solenoid valve

with your finger and check its movement.

FILTER

Replace.

YEL (front) or BLU/YEL (rear)

3. If the resistance is within specifications, remove the VTEC valve assembly from the cylinder head,and check the VTEC valve filter for clogging.

VTEC VALVE

ASSEMBLY

VTEC VALVE

FILTER

Replace.

6 x 1.0 mm

12 N ·

m (1,2 kg-m, 9 Ib-ft)

If there is clogging, replace the engine oil filter

and engine oil.

6x1.0

mm

12 N .

m (1.2 kg-m, 9 Ib-ft)

If VTEC solenoid valve is normal, check the

engine oil pressure.

VTEC Valve Inspection

VTEC

14

30ProCarManuals.com

Page 1007 of 1640

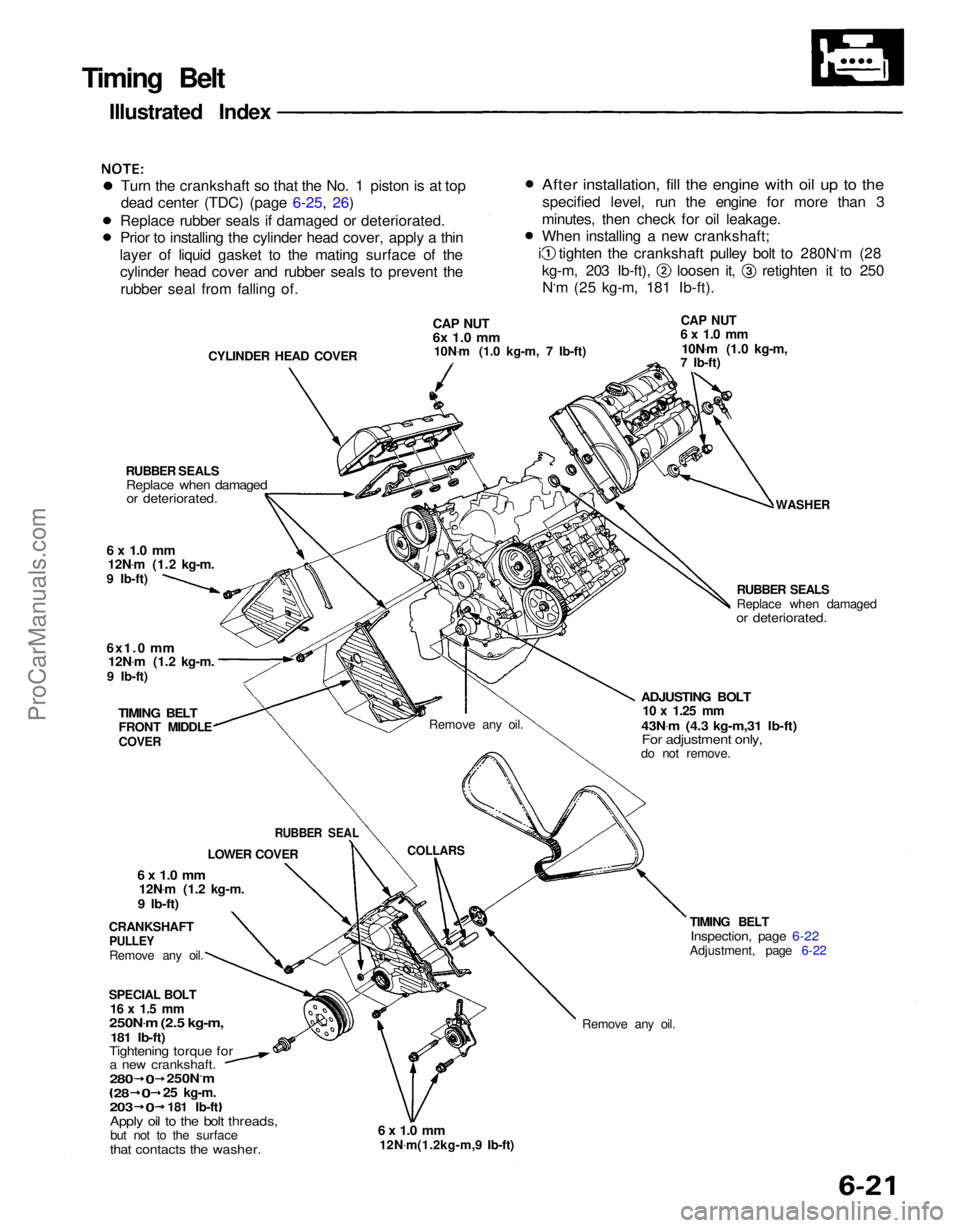

Remove any oil.

TIMING BELT

Inspection, page 6-22

Adjustment, page 6-22

6 x 1.0 mm

12N .

m(1.2kg-m,9 Ib-ft)

Timing Belt

Illustrated Index

Turn the crankshaft so that the No. 1 piston is at top

dead center (TDC) (page 6-25, 26)

Replace rubber seals if damaged or deteriorated.

Prior to installing the cylinder head cover, apply a thin

layer of liquid gasket to the mating surface of the cylinder head cover and rubber seals to prevent the

rubber seal from falling of.

CYLINDER HEAD COVER

CAP NUT

6x 1.0 mm

10N .

m (1.0 kg-m, 7 Ib-ft)

CAP NUT

6 x 1.0 mm

10N .

m (1.0 kg-m,

7 Ib-ft)

WASHER

RUBBER SEALS

Replace when damaged

or deteriorated.

ADJUSTING BOLT

10 x

1.25

mm

43N .

m (4.3 kg-m,31 Ib-ft)

For adjustment only,

do not remove.

Remove any oil.

COLLARS

RUBBER SEALS

Replace when damaged

or deteriorated.

6 x 1.0 mm

12N .

m (1.2 kg-m.

9 Ib-ft)

6x1.0

mm

12N .

m (1.2 kg-m.

9 Ib-ft)

TIMING BELT

FRONT MIDDLE

COVER

CRANKSHAFT

PULLEY

Remove any oil.

6 x 1.0 mm

12N .

m (1.2 kg-m.

9 Ib-ft)

SPECIAL BOLT

16 x 1.5 mm

250N .

m (2.5 kg-m,

181 Ib-ft)

Tightening torque for

a new crankshaft.

Apply oil to the bolt threads,

but not to the surface

that contacts the washer.

280

0

250N.m

28

0

25

kg-m.

203

0

181 Ib-ft LOWER COVER

RUBBER SEAL

After installation, fill the engine with oil up to the

specified level, run the engine for more than 3

minutes, then check for oil leakage.

When installing a new crankshaft; i tighten the crankshaft pulley bolt to 280N.m (28

kg-m, 203 Ib-ft), loosen it, retighten it to 250

N.m (25 kg-m, 181 Ib-ft).ProCarManuals.com

Page 1008 of 1640

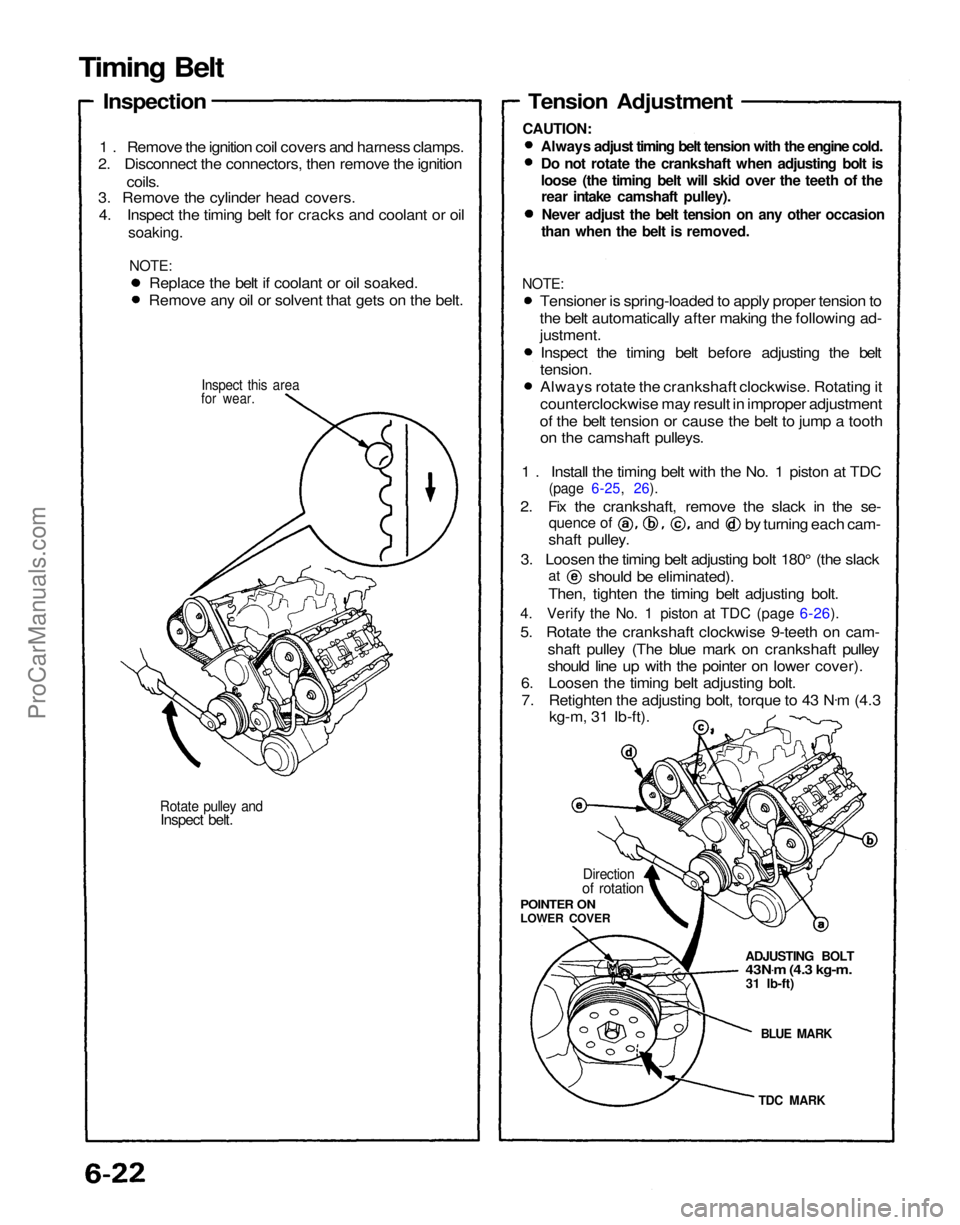

Rotate pulley and

Inspect belt.

for wear.

1 . Remove the ignition coil covers and harness clamps.

2. Disconnect the connectors, then remove the ignition

coils.

3. Remove the cylinder head covers.

4. Inspect the timing belt for cracks and coolant or oil

soaking.

NOTE:

TDC MARK

BLUE MARK

ADJUSTING BOLT

43N

.

m (4.3 kg-m.

31 Ib-ft)

Direction

of rotation

POINTER ON

LOWER COVER

Tension Adjustment

Always adjust timing belt tension with the engine cold.

Do not rotate the crankshaft when adjusting bolt is

loose (the timing belt will skid over the teeth of the

rear intake camshaft pulley).

Never adjust the belt tension on any other occasion

than when the belt is removed.

shaft pulley.

3. Loosen the timing belt adjusting bolt 180° (the slack

Then, tighten the timing belt adjusting bolt.

4. Verify the No. 1 piston at TDC (page 6-26).

5. Rotate the crankshaft clockwise 9-teeth on cam- shaft pulley (The blue mark on crankshaft pulley

should line up with the pointer on lower cover).

6. Loosen the timing belt adjusting bolt.

7. Retighten the adjusting bolt, torque to 43 N .

m (4.3

kg-m, 31 Ib-ft).

at

should be eliminated).

quence of

and

by turning each cam-

Replace the belt if coolant or oil soaked.

Remove any oil or solvent that gets on the belt.

Inspect this area

Timing Belt

Inspection

CAUTION:

NOTE:

Tensioner is spring-loaded to apply proper tension to

the belt automatically after making the following ad-

justment.

Inspect the timing belt before adjusting the belt

tension.

Always rotate the crankshaft clockwise. Rotating it

counterclockwise may result in improper adjustment

of the belt tension or cause the belt to jump a tooth on the camshaft pulleys.

1 . Install the timing belt with the No. 1 piston at TDC

(page 6-25, 26).

2. Fix the crankshaft, remove the slack in the se-ProCarManuals.com

Page 1009 of 1640

13. Remove the breather hose, and the air cleaner case

(page 5-22).

(cont'd)

WATER HOSES

Do not disconnect.

EXPANSION TANK

12. Remove the expansion tank.

NOTE: Do not disconnect water hoses.

6x 1.0 mm

10N .

m (1.0kg-m, 7 Ib-ft)

IGNITION COIL

CONNECTOR

6 x 1.0 mm

12N .

m (1.2kg-m,

9 Ib-ft)

6x1.0

mm

12 N .

m

(1.2 kg-m.

IGNITION COIL

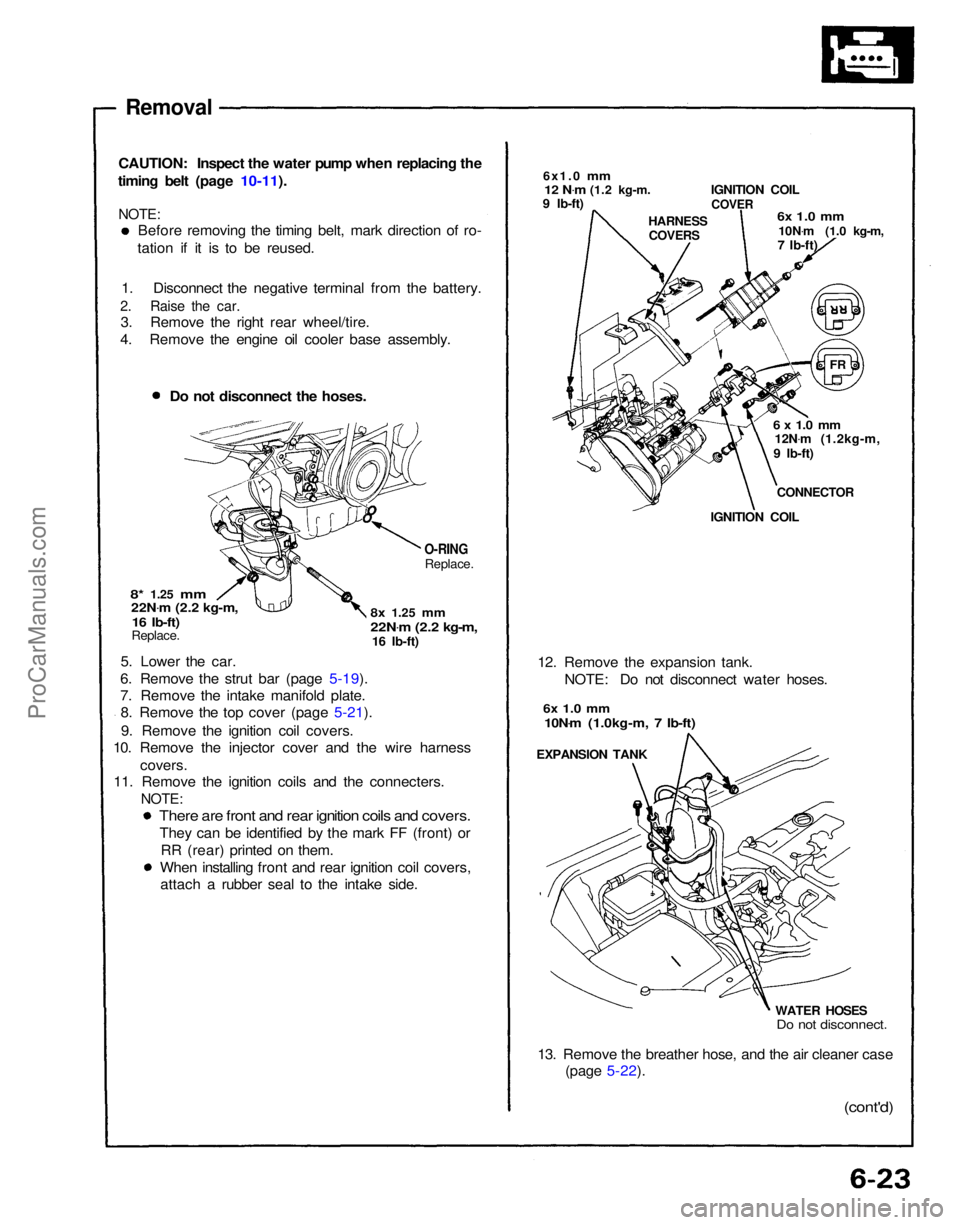

CAUTION: Inspect the water pump when replacing the

timing belt (page 10-11).

O-RING

Replace.

8*

1.25

mm

8x

1.25

mm

22N.

m (2.2 kg-m,

16 Ib-ft)

5. Lower the car.

6. Remove the strut bar (page 5-19).

7. Remove the intake manifold plate. 8. Remove the top cover (page 5-21).

9. Remove the ignition coil covers.

10. Remove the injector cover and the wire harness

covers.

11. Remove the ignition coils and the connecters.

22N

.

m (2.2 kg-m,

16 Ib-ft)

Replace.

Removal

9 Ib-ft)

HARNESS

COVERS

COVER

6x 1.0 mm

10N .

m (1.0 kg-m,

7 Ib-ft)

FR

There are front and rear ignition coils and covers.

They can be identified by the mark FF (front) or RR (rear) printed on them.

When installing front and rear ignition coil covers, attach a rubber seal to the intake side.

NOTE:

Before removing the timing belt, mark direction of ro-

tation if it is to be reused.

NOTE:

1. Disconnect the negative terminal from the battery.

2. Raise the car.

3. Remove the right rear wheel/tire.

4. Remove the engine oil cooler base assembly.

Do not disconnect the hoses.ProCarManuals.com

Page 1010 of 1640

45N

.

m (4.5 kg-m. 33 Ib-ft)

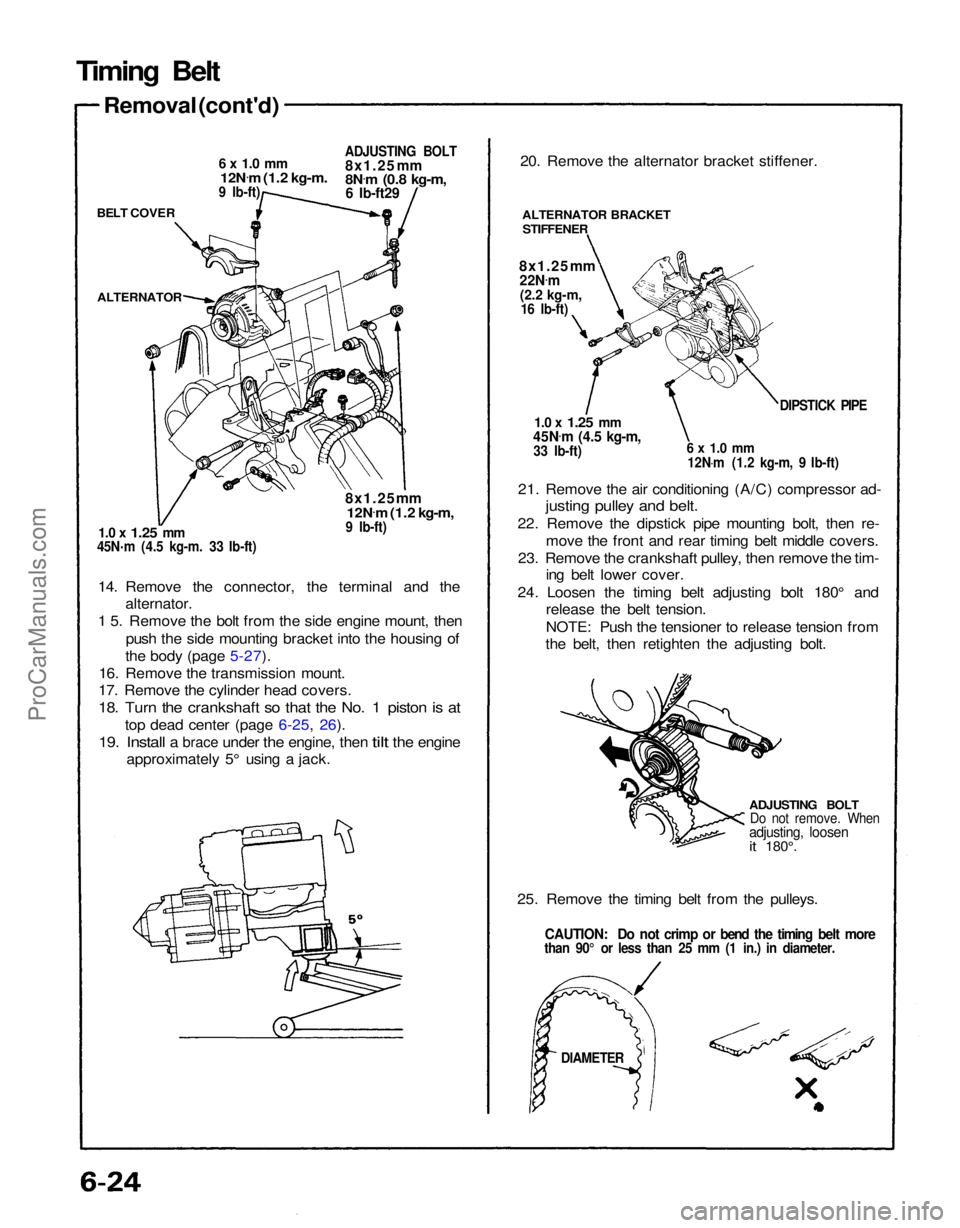

14. Remove the connector, the terminal and the alternator.

1 5. Remove the bolt from the side engine mount, then

push the side mounting bracket into the housing of

the body (page 5-27).

16. Remove the transmission mount.

17. Remove the cylinder head covers.

18. Turn the crankshaft so that the No. 1 piston is at

top dead center (page 6-25, 26).

19.

Install

a

brace

under

the

engine, then

tilt

the

engine approximately 5° using a jack.

Timing Belt

Removal (cont'd)

BELT COVER

ALTERNATOR

20. Remove the alternator bracket stiffener.

ALTERNATOR BRACKET

STIFFENER

21. Remove the air conditioning (A/C) compressor ad-

justing pulley and belt.

22. Remove the dipstick pipe mounting bolt, then re- move the front and rear timing belt middle covers.

23. Remove the crankshaft pulley, then remove the tim- ing belt lower cover.

24. Loosen the timing belt adjusting bolt 180° and release the belt tension.

NOTE: Push the tensioner to release tension from

the belt, then retighten the adjusting bolt.

ADJUSTING BOLT

Do not remove. When

adjusting, loosen

it

180°.

25. Remove the timing belt from the pulleys.

CAUTION: Do not crimp or bend the timing belt more

than 90° or less than 25 mm (1 in.) in diameter.

DIAMETER

1.0 x

1.25

mm

45N .

m (4.5 kg-m,

33 Ib-ft)

6 x 1.0 mm

12N .

m (1.2 kg-m, 9 Ib-ft) DIPSTICK PIPE

8x1.25 mm

22N .

m

(2.2 kg-m,

16 Ib-ft)

9 Ib-ft)

6 x 1.0 mm

12N .

m (1.2 kg-m.

6 Ib-ft29

ADJUSTING BOLT

8x1.25 mm

8N .

m (0.8 kg-m,

1.0 x

1.25

mm

8x1.25 mm

12N .

m (1.2 kg-m,

9 Ib-ft)ProCarManuals.com

Page 1012 of 1640

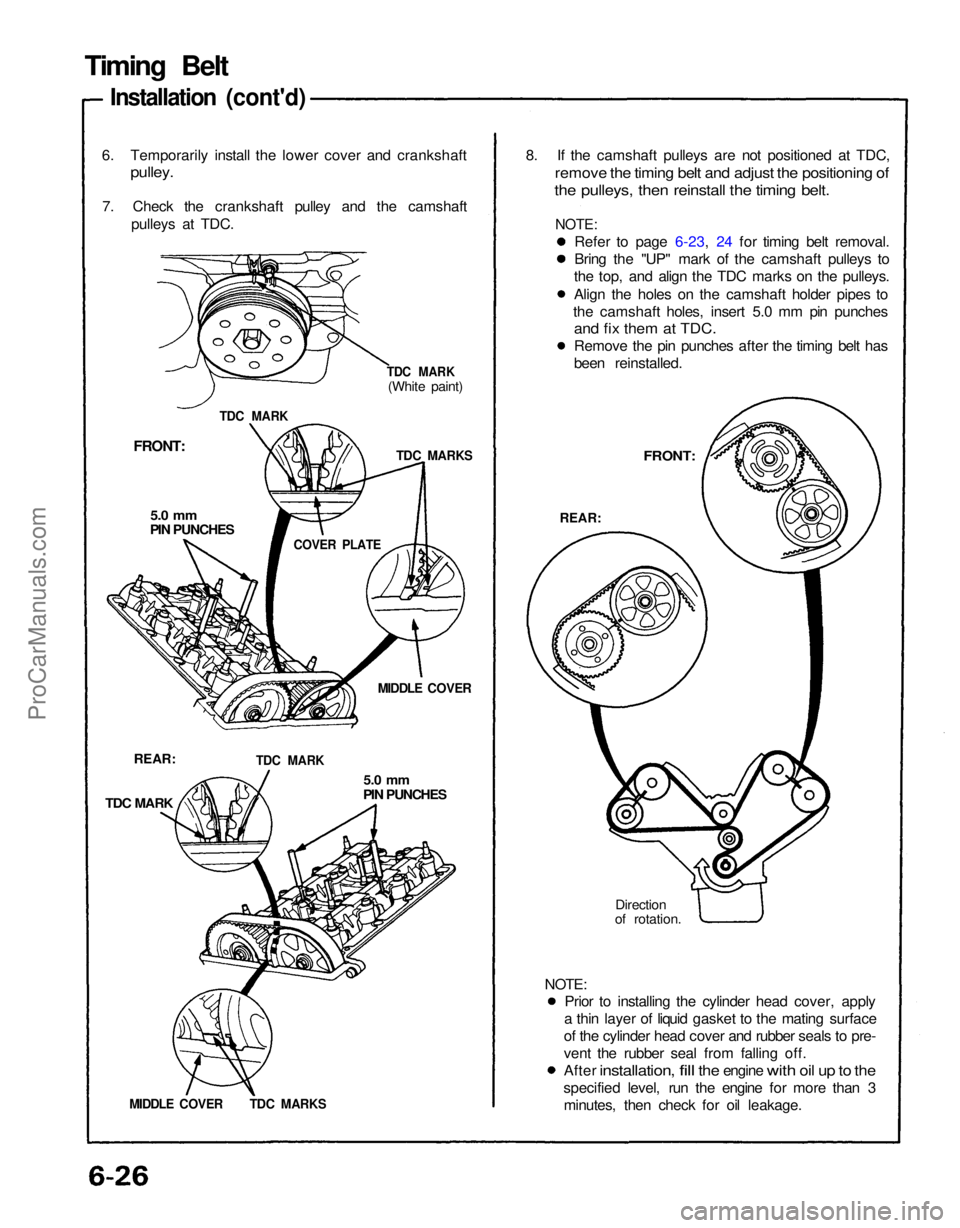

Prior to installing the cylinder head cover, apply

a thin layer of liquid gasket to the mating surface

of the cylinder head cover and rubber seals to pre-

vent the rubber seal from falling off.

After

installation,

fill

the

engine

with

oil up to the

specified level, run the engine for more than 3 minutes, then check for oil leakage.

8. If the camshaft pulleys are not positioned at TDC,

remove the timing belt and adjust the positioning of

the pulleys, then reinstall the timing belt.

6. Temporarily install the lower cover and crankshaft

pulley.

7. Check the crankshaft pulley and the camshaft pulleys at TDC.

FRONT:

5.0 mm

PIN PUNCHES

MIDDLE COVER

REAR:

TDC MARK

5.0 mm

PIN PUNCHES

Direction

of rotation.

FRONT:

REAR:

TDC MARK

TDC MARK

(White paint)

TDC MARKS

COVER PLATE

TDC MARK

MIDDLE COVER TDC MARKS

Timing Belt

Installation (cont'd)

Refer to page 6-23, 24 for timing belt removal.

Bring the "UP" mark of the camshaft pulleys to

the top, and align the TDC marks on the pulleys.

Align the holes on the camshaft holder pipes to

the camshaft holes, insert 5.0 mm pin punches

and fix them at TDC.

Remove the pin punches after the timing belt has

been reinstalled.

NOTE:

NOTE:ProCarManuals.com

Page 1014 of 1640

Cylinder Heads

Removal

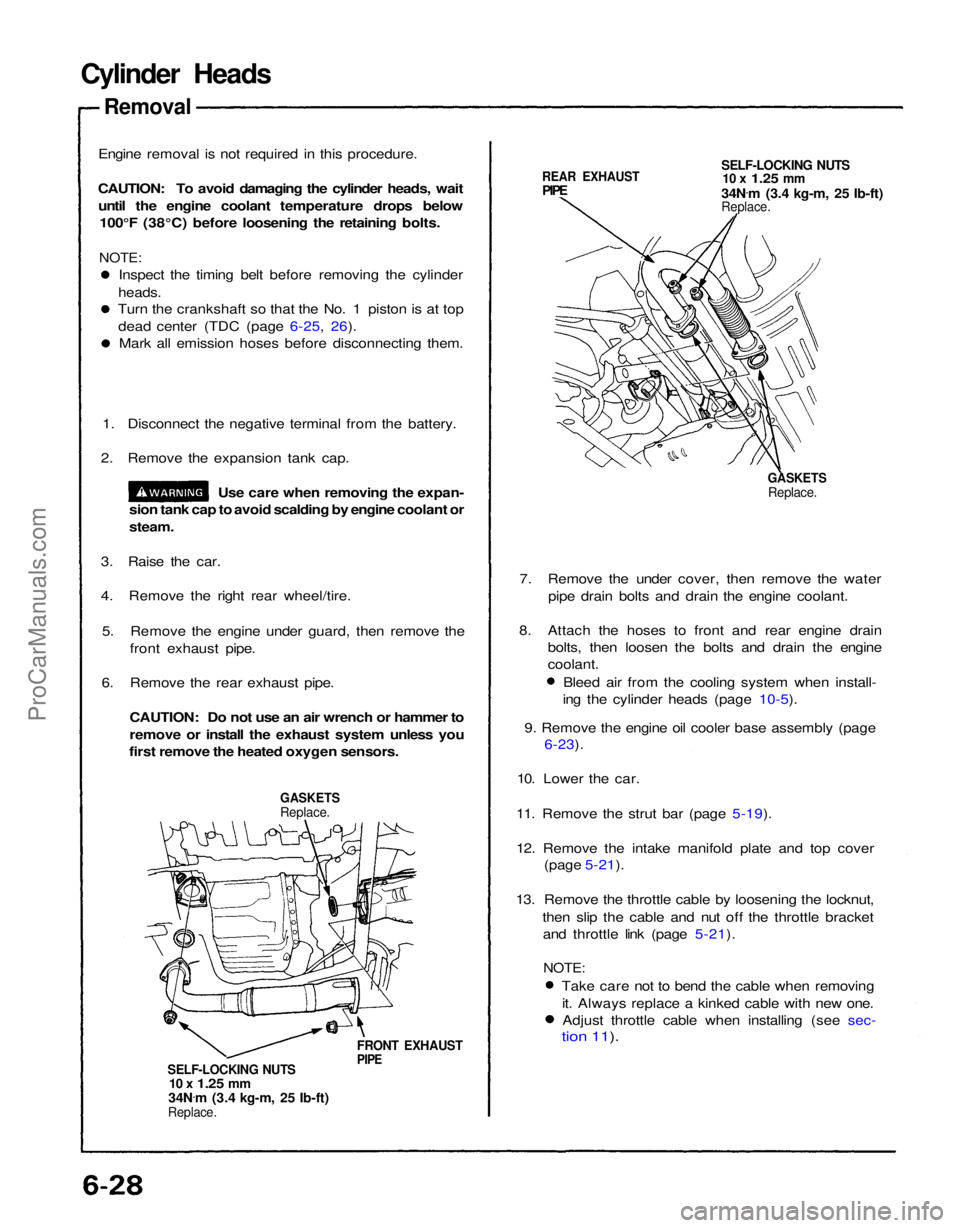

Engine removal is not required in this procedure.

CAUTION: To avoid damaging the cylinder heads, wait until the engine coolant temperature drops below 100°F (38°C) before loosening the retaining bolts.

NOTE:

Inspect the timing belt before removing the cylinder

heads.

Turn the crankshaft so that the No. 1 piston is at top

dead center (TDC (page 6-25, 26). Mark all emission hoses before disconnecting them.

1. Disconnect the negative terminal from the battery.

2. Remove the expansion tank cap.

Use care when removing the expan-

sion tank cap to avoid scalding by engine coolant or

steam.

3. Raise the car.

4. Remove the right rear wheel/tire.

5. Remove the engine under guard, then remove the front exhaust pipe.

6. Remove the rear exhaust pipe.

CAUTION: Do not use an air wrench or hammer to

remove or install the exhaust system unless you

first remove the heated oxygen sensors.

GASKETS

Replace.

FRONT EXHAUST

PIPE

SELF-LOCKING NUTS

10 x

1.25

mm

34N .

m (3.4 kg-m, 25 Ib-ft)

Replace.

REAR EXHAUST

PIPE

SELF-LOCKING NUTS

10 x

1.25

mm

34N .

m (3.4 kg-m, 25 Ib-ft)

Replace.

GASKETS

Replace.

7. Remove the under cover, then remove the water pipe drain bolts and drain the engine coolant.

8. Attach the hoses to front and rear engine drain bolts, then loosen the bolts and drain the engine

coolant.

Bleed air from the cooling system when install-

ing the cylinder heads (page 10-5).

9. Remove the engine oil cooler base assembly (page

6-23).

10. Lower the car.

11. Remove the strut bar (page 5-19).

12. Remove the intake manifold plate and top cover (page 5-21).

13. Remove the throttle cable by loosening the locknut, then slip the cable and nut off the throttle bracketand throttle link (page 5-21).

NOTE:

Take care not to bend the cable when removingit. Always replace a kinked cable with new one.Adjust throttle cable when installing (see sec-

tion 11).ProCarManuals.com

Page 1015 of 1640

14. Relieve fuel pressure (see section 11).

Do not smoke while working on fuel

system; keep open flame or spark away from work

area. Drain fuel only into an approved container.

1 5. Disconnect the fuel feed pipe and the return hose

(page 5-21).

16. Remove the ignition coil covers, the wire harness covers, the ignition coils and the connectors (page

6-23).

17. Remove the water hoses, then remove the expan- sion tank (page 5-21).

18. Remove the breather hose, and the air cleaner housing (page 5-22).

19. Remove the brake booster hose, the evaporative emission (EVAP) control canister hose and other

hoses from the intake manifold and throttle body

(page 5-22).

20. Remove the emission control box (page 5-23). Do not disconnect emission hose.Disconnect the three connectors before

removing.

21. Remove the connector, the terminal and the alternator.

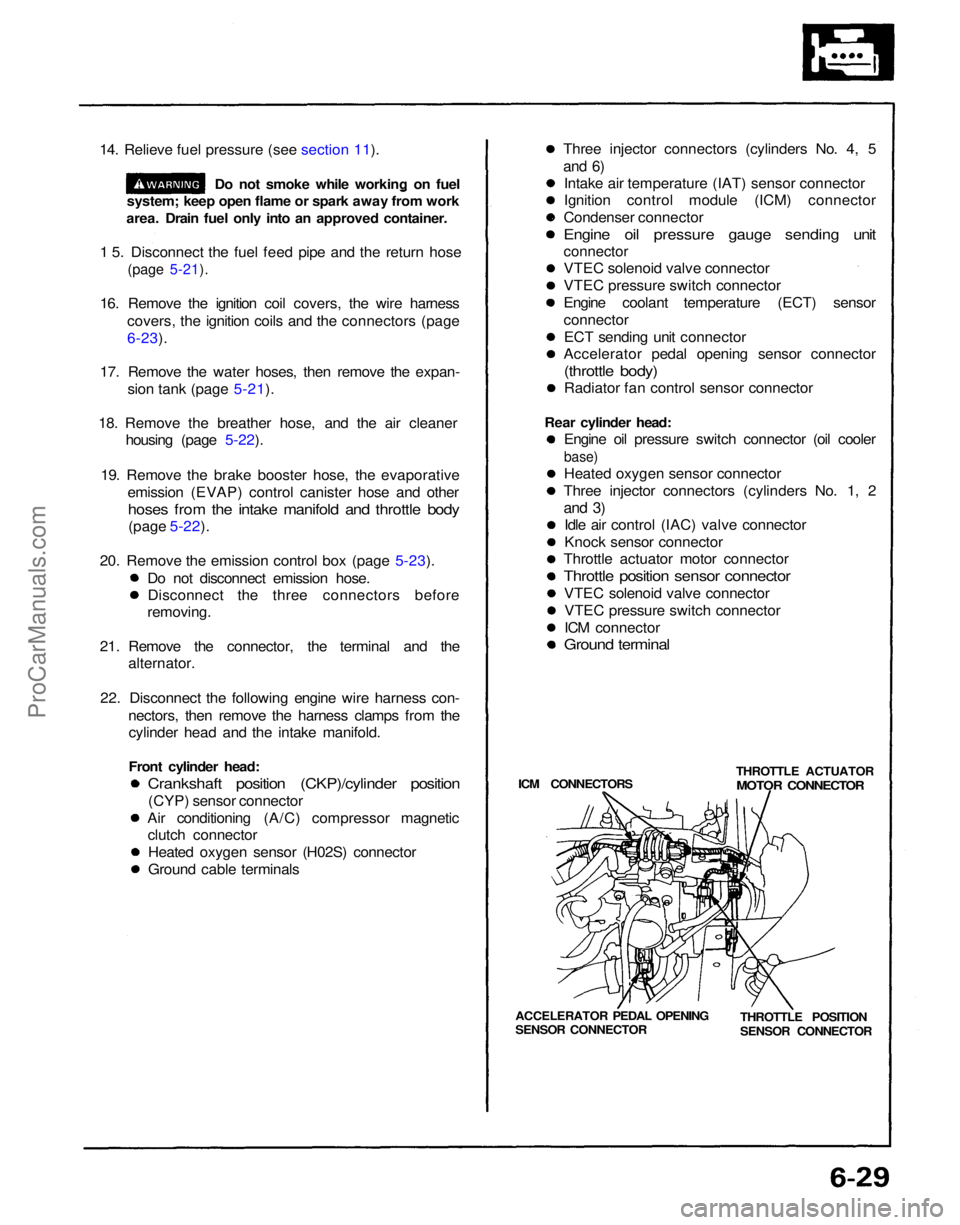

22. Disconnect the following engine wire harness con- nectors, then remove the harness clamps from thecylinder head and the intake manifold.

Front cylinder head:

Crankshaft position (CKP)/cylinder position

(CYP) sensor connector

Air conditioning (A/C) compressor magnetic clutch connector

Heated oxygen sensor (H02S) connector

Ground cable terminals Three injector connectors (cylinders No. 4, 5

and 6)

Intake air temperature (IAT) sensor connector

Ignition control module (ICM) connector

Condenser connector

Engine oil pressure gauge sending unit

connector

VTEC solenoid valve connector

VTEC pressure switch connector

Engine coolant temperature (ECT) sensor

connector

ECT sending unit connector

Accelerator pedal opening sensor connector

(throttle body)

Radiator fan control sensor connector

Rear cylinder head: Engine oil pressure switch connector (oil cooler

base)

Heated oxygen sensor connector

Three injector connectors (cylinders No. 1, 2

and 3)

Idle air control (IAC) valve connector

Knock sensor connector

Throttle actuator motor connector

Throttle position sensor connector

VTEC solenoid valve connectorVTEC pressure switch connector

ICM connector

Ground terminal

ICM CONNECTORS THROTTLE ACTUATOR

MOTOR CONNECTOR

THROTTLE POSITION

SENSOR CONNECTOR

ACCELERATOR PEDAL OPENING

SENSOR CONNECTORProCarManuals.com

Page 1017 of 1640

(cont'd)

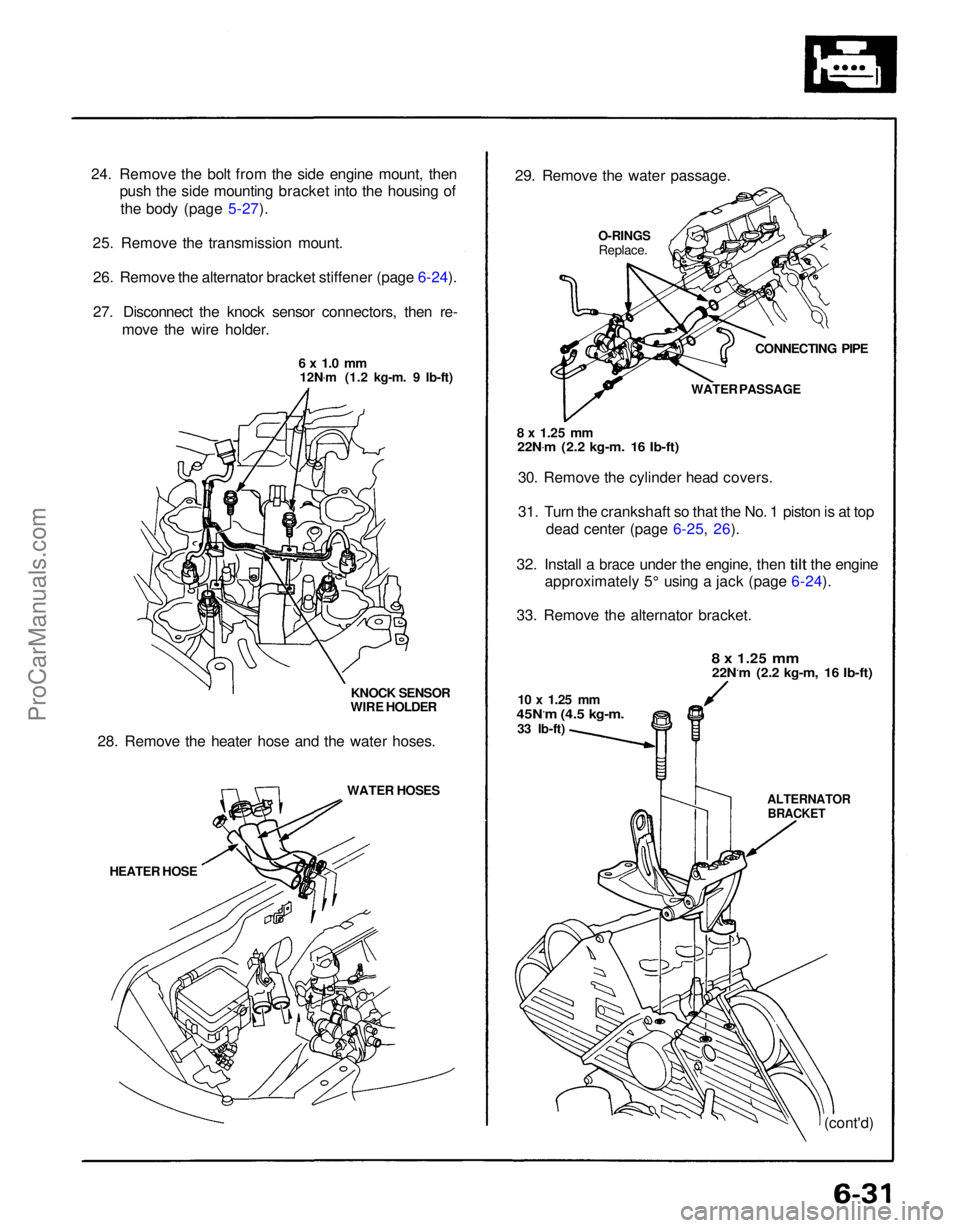

29. Remove the water passage.

O-RINGS

Replace.

CONNECTING PIPE

WATER PASSAGE

8 x

1.25

mm

22N .

m (2.2 kg-m. 16 Ib-ft)

30. Remove the cylinder head covers.

31. Turn the crankshaft so that the No. 1 piston is at top dead center (page 6-25, 26).

32.

Install

a

brace

under

the

engine, then

tilt

the

engine approximately 5° using a jack (page 6-24).

33. Remove the alternator bracket.

8 x

1.25

mm

22N.m (2.2 kg-m, 16 Ib-ft)

10 x

1.25

mm

45N.m (4.5 kg-m.

33 Ib-ft)

ALTERNATOR

BRACKET

24. Remove the bolt from the side engine mount, then

push the side mounting bracket into the housing of

the body (page 5-27).

25. Remove the transmission mount. 26. Remove the alternator bracket stiffener (page 6-24).

27. Disconnect the knock sensor connectors, then re- move the wire holder.

6 x 1.0 mm

12N .

m (1.2 kg-m. 9 Ib-ft)

KNOCK SENSOR

WIRE HOLDER

28. Remove the heater hose and the water hoses.

WATER HOSES

HEATER HOSEProCarManuals.com