engine ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 966 of 1640

Engine Oil

Replacement

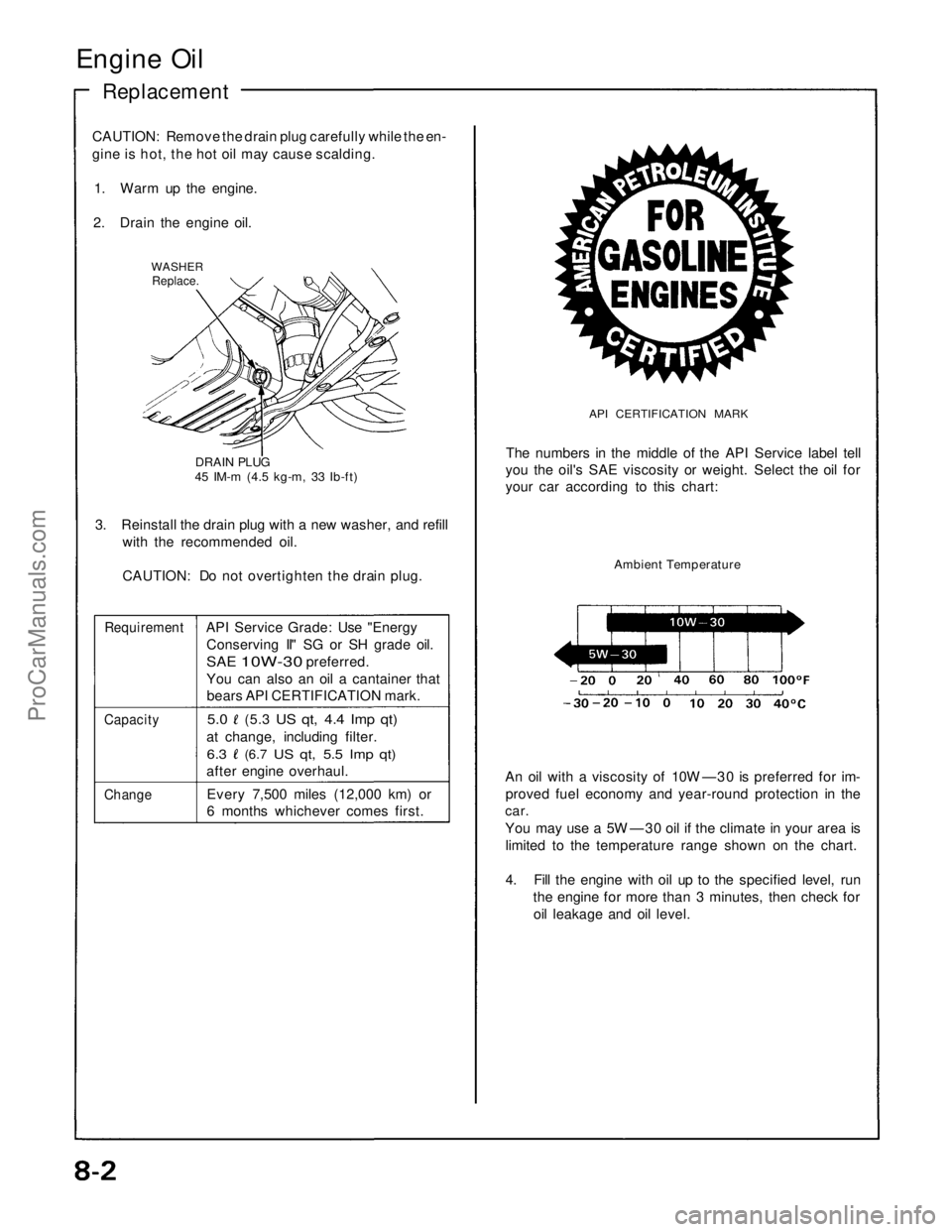

CAUTION: Remove the drain plug carefully while the en-

gine is hot, the hot oil may cause scalding.

1. Warm up the engine.

2. Drain the engine oil.

WASHER

Replace.

DRAIN PLUG

45 IM-m (4.5 kg-m, 33 Ib-ft)

3. Reinstall the drain plug with a new washer, and refill

with the recommended oil.

CAUTION: Do not overtighten the drain plug.

Requirement

API Service Grade: Use "Energy

Conserving II" SG or SH grade oil.

SAE

10W-30

preferred.

You can also an oil a cantainer that

bears API CERTIFICATION mark.

Capacity

5.0

(5.3

US qt, 4.4 Imp qt)

at change, including filter.

6.3

(6.7

US qt, 5.5 Imp qt)

after engine overhaul.

Change

Every 7,500 miles (12,000 km) or

6 months whichever comes first.

API CERTIFICATION MARK

The numbers in the middle of the API Service label tell

you the oil's SAE viscosity or weight. Select the oil for

your car according to this chart:

Ambient Temperature

An oil with a viscosity of 10W —30 is preferred for im-

proved fuel economy and year-round protection in the

car.

You may use a 5W —30 oil if the climate in your area is

limited to the temperature range shown on the chart.

4. Fill the engine with oil up to the specified level, run

the engine for more than 3 minutes, then check for

oil leakage and oil level.ProCarManuals.com

Page 968 of 1640

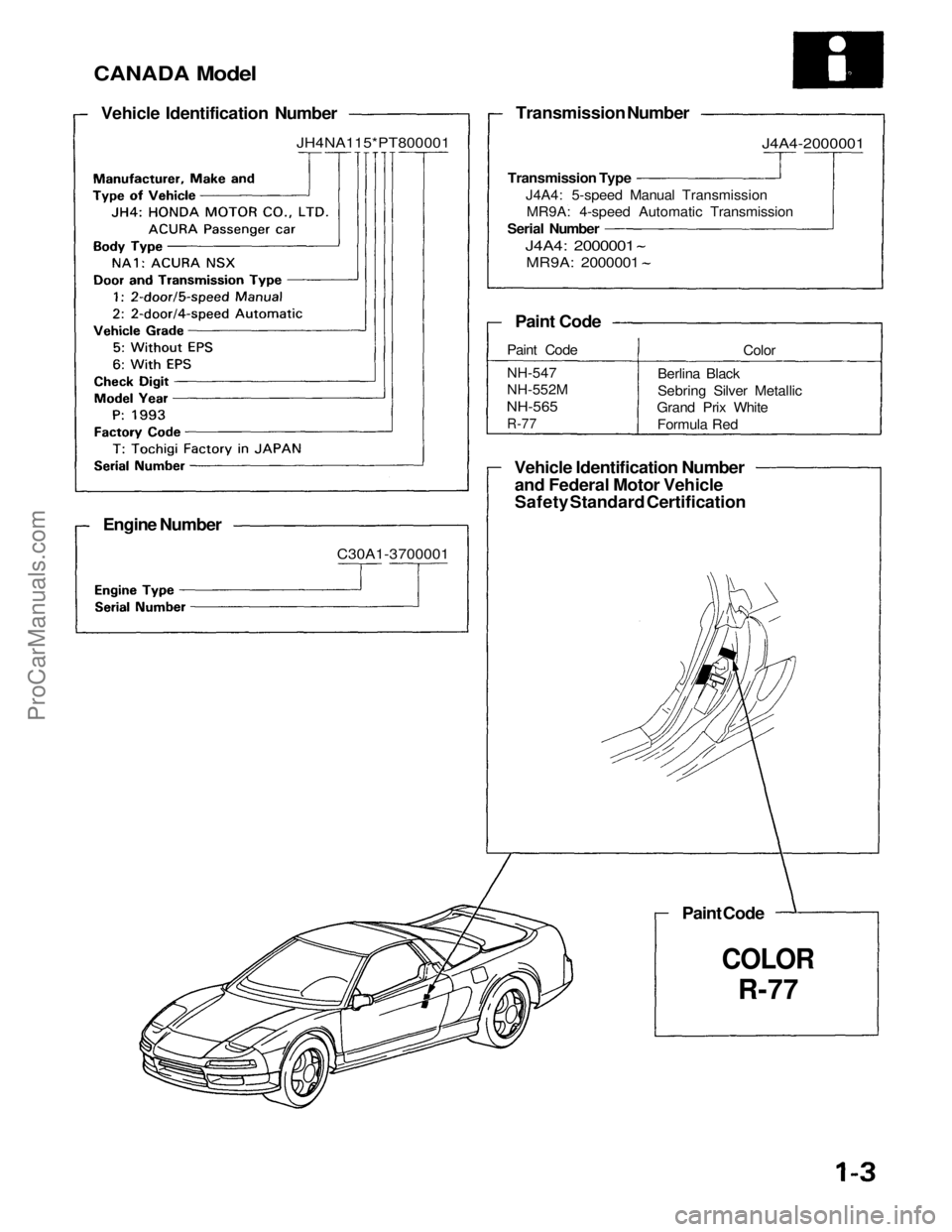

CANADA Model

Vehicle Identification Number

JH4NA115*PT800001

Engine Number

C30A1-3700001

Transmission Number

Transmission Type J4A4: 5-speed Manual TransmissionMR9A: 4-speed Automatic Transmission

Serial Number

J4A4: 2000001

MR9A: 2000001

Paint Code

Paint Code

NH-547

NH-552M

NH-565

R-77

Color

Berlina Black

Sebring Silver Metallic

Grand Prix White

Formula Red

Vehicle Identification Number and Federal Motor Vehicle

Safety Standard Certification

Paint Code

COLOR

R-77

J4A4-2000001ProCarManuals.com

Page 969 of 1640

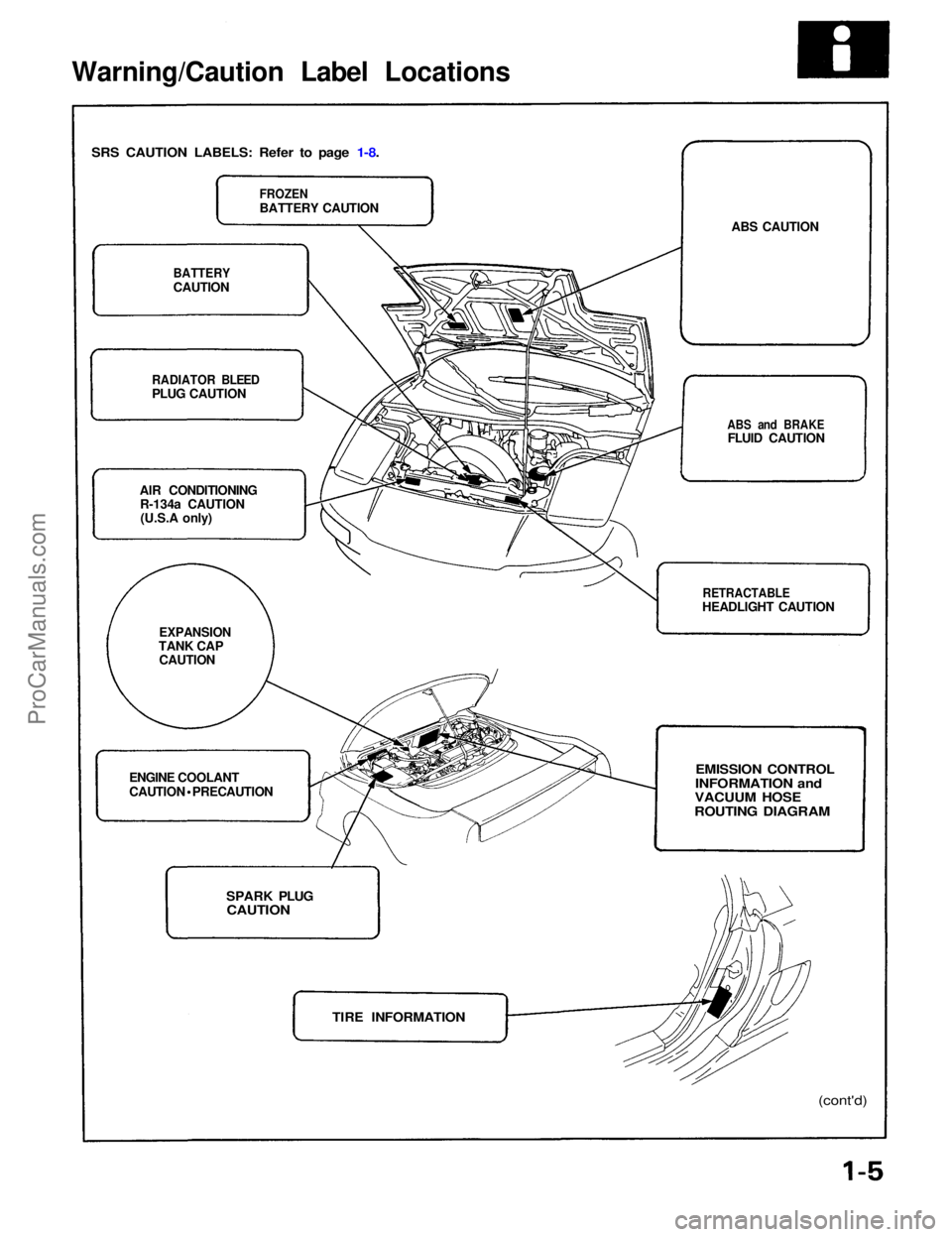

Warning/Caution Label Locations

SRS CAUTION LABELS: Refer to page 1-8.

FROZEN

BATTERY CAUTION

BATTERY

CAUTION

RADIATOR BLEED

PLUG CAUTION

AIR CONDITIONING R-134a CAUTION(U.S.A only)

EXPANSION

TANK CAP CAUTION

ENGINE COOLANT

CAUTION • PRECAUTION

SPARK PLUG

CAUTION

TIRE INFORMATION

EMISSION CONTROL

INFORMATION and

VACUUM HOSE

ROUTING DIAGRAM

RETRACTABLE

HEADLIGHT CAUTION

ABS and BRAKE

FLUID CAUTION ABS CAUTION

(cont'd)ProCarManuals.com

Page 972 of 1640

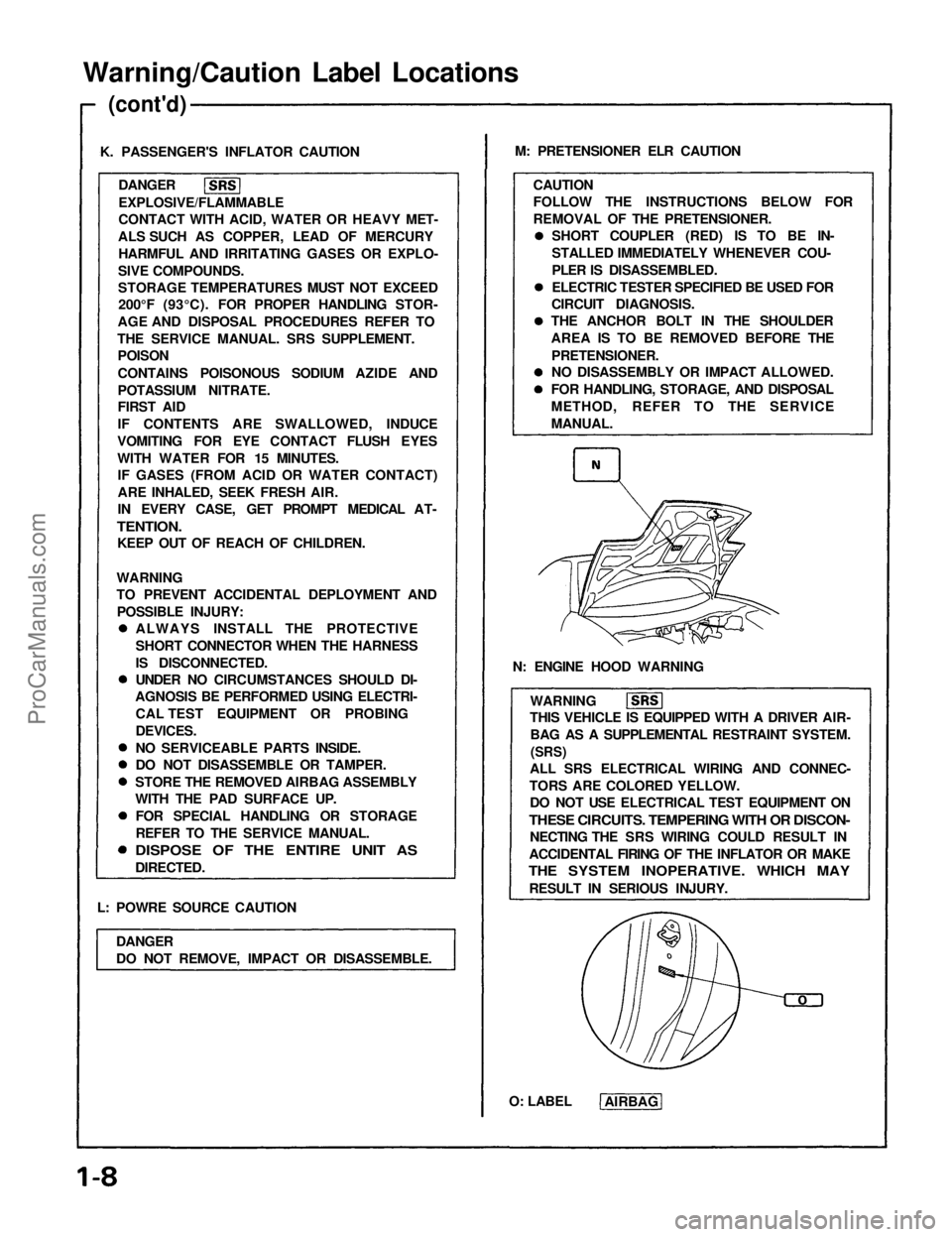

Warning/Caution Label Locations

(cont'd)

K. PASSENGER'S INFLATOR CAUTION DANGER

EXPLOSIVE/FLAMMABLE

CONTACT WITH ACID, WATER OR HEAVY MET-

ALS SUCH AS COPPER, LEAD OF MERCURY HARMFUL AND IRRITATING GASES OR EXPLO-

SIVE COMPOUNDS.

STORAGE TEMPERATURES MUST NOT EXCEED 200°F (93°C). FOR PROPER HANDLING STOR-

AGE AND DISPOSAL PROCEDURES REFER TO

THE SERVICE MANUAL. SRS SUPPLEMENT. POISON

CONTAINS POISONOUS SODIUM AZIDE AND

POTASSIUM NITRATE.

FIRST AID

IF CONTENTS ARE SWALLOWED, INDUCE

VOMITING FOR EYE CONTACT FLUSH EYES

WITH WATER FOR 15 MINUTES. IF GASES (FROM ACID OR WATER CONTACT)

ARE INHALED, SEEK FRESH AIR.

IN EVERY CASE, GET PROMPT MEDICAL AT-

TENTION.

KEEP OUT OF REACH OF CHILDREN.

L: POWRE SOURCE CAUTION DANGER

DO NOT REMOVE, IMPACT OR DISASSEMBLE. M: PRETENSIONER ELR CAUTION

CAUTION

FOLLOW THE INSTRUCTIONS BELOW FOR

REMOVAL OF THE PRETENSIONER.

N: ENGINE HOOD WARNING WARNING

THIS VEHICLE IS EQUIPPED WITH A DRIVER AIR-

BAG AS A SUPPLEMENTAL RESTRAINT SYSTEM.

(SRS)

ALL SRS ELECTRICAL WIRING AND CONNEC-

TORS ARE COLORED YELLOW. DO NOT USE ELECTRICAL TEST EQUIPMENT ON

THESE CIRCUITS. TEMPERING WITH OR DISCON-

NECTING THE SRS WIRING COULD RESULT IN

ACCIDENTAL FIRING OF THE INFLATOR OR MAKE

THE SYSTEM INOPERATIVE. WHICH MAY

RESULT IN SERIOUS INJURY.

O: LABEL AIRBAG

WARNING

TO PREVENT ACCIDENTAL DEPLOYMENT AND

POSSIBLE INJURY: ALWAYS INSTALL THE PROTECTIVE

SHORT CONNECTOR WHEN THE HARNESS

IS DISCONNECTED.

UNDER NO CIRCUMSTANCES SHOULD DI-

AGNOSIS BE PERFORMED USING ELECTRI-

CAL TEST EQUIPMENT OR PROBING

DEVICES.

NO SERVICEABLE PARTS INSIDE.

DO NOT DISASSEMBLE OR TAMPER.

STORE THE REMOVED AIRBAG ASSEMBLY

WITH THE PAD SURFACE UP. FOR SPECIAL HANDLING OR STORAGE

REFER TO THE SERVICE MANUAL.

DISPOSE OF THE ENTIRE UNIT AS

DIRECTED. SHORT COUPLER (RED) IS TO BE IN-

STALLED IMMEDIATELY WHENEVER COU-

PLER IS DISASSEMBLED.

ELECTRIC TESTER SPECIFIED BE USED FOR

CIRCUIT DIAGNOSIS.

THE ANCHOR BOLT IN THE SHOULDER

AREA IS TO BE REMOVED BEFORE THE

PRETENSIONER.

NO DISASSEMBLY OR IMPACT ALLOWED.

FOR HANDLING, STORAGE, AND DISPOSAL

METHOD, REFER TO THE SERVICE

MANUAL.ProCarManuals.com

Page 973 of 1640

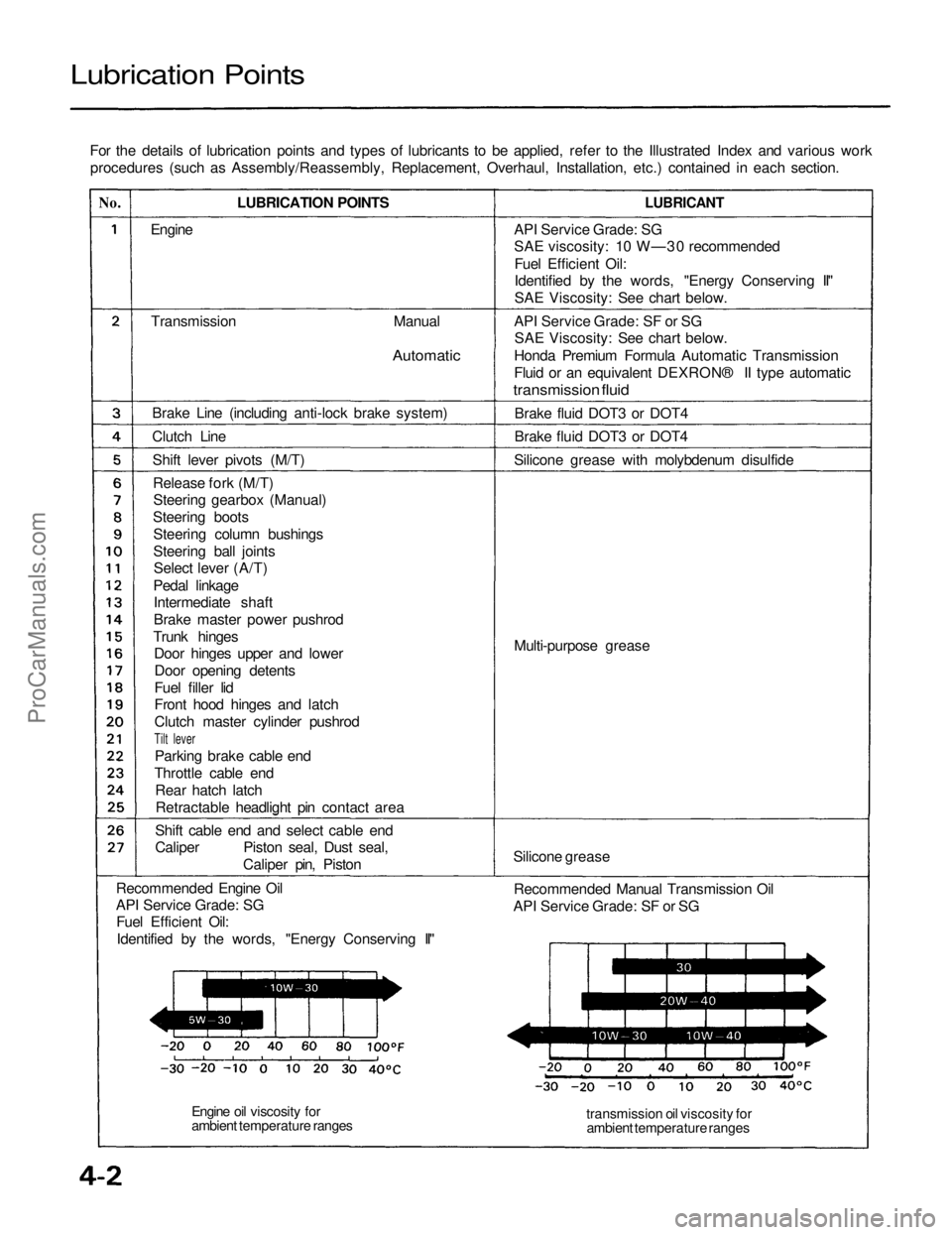

Lubrication Points

For the details of lubrication points and types of lubricants to be applied, refer to the Illustrated Index and various workprocedures (such as Assembly/Reassembly, Replacement, Overhaul, Installation, etc.) contained in each section.

No.

LUBRICATION POINTS

LUBRICANT

Engine

Transmission

Manual

Automatic

Brake Line (including anti-lock brake system)

Clutch Line Shift lever pivots (M/T)Release fork (M/T)Steering gearbox (Manual)

Steering boots Steering column bushings

Steering ball jointsSelect lever (A/T)

Pedal linkage Intermediate shaft

Brake master power pushrod

Trunk hinges Door hinges upper and lower

Door opening detents

Fuel filler lid

Front hood hinges and latch

Clutch master cylinder pushrod

Tilt lever

Parking brake cable end

Throttle cable end Rear hatch latchRetractable headlight pin contact area

Shift cable end and select cable end

Caliper Piston seal, Dust seal, Caliper pin, Piston

Recommended Engine Oil

API Service Grade: SG Fuel Efficient Oil:

Identified by the words, "Energy Conserving II" API Service Grade: SG

SAE viscosity: 10 W—30 recommended

Fuel Efficient Oil:

Identified by the words, "Energy Conserving II"

SAE Viscosity: See chart below.

API Service Grade: SF or SG SAE Viscosity: See chart below.

Honda Premium Formula Automatic Transmission

Fluid or an equivalent DEXRON® II type automatic

transmission fluid

Brake fluid DOT3 or DOT4

Brake fluid DOT3 or DOT4

Silicone grease with molybdenum disulfide

Multi-purpose grease

Silicone grease Recommended Manual Transmission Oil

API Service Grade: SF or SG

transmission oil viscosity forambient temperature ranges

Engine oil viscosity for

ambient temperature rangesProCarManuals.com

Page 976 of 1640

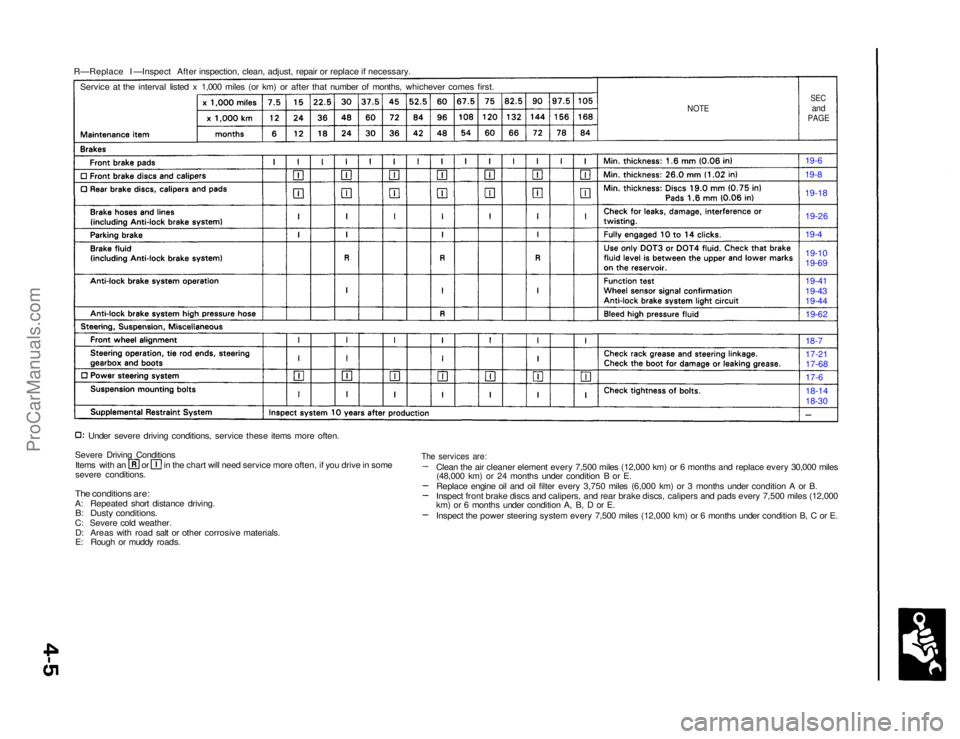

R—Replace I —Inspect After inspection, clean, adjust, repair or replace if necessary.

NOTE

SEC

and

PAGE

Service at the interval listed x 1,000 miles (or km) or after that number of months, whichever comes first.

19-6

19-8

19-18

Under severe driving conditions, service these items more often.

Severe Driving Conditions Items with an or in the chart will need service more often, if you drive in some

severe conditions.

The conditions are:

A: Repeated short distance driving.

B: Dusty conditions.

C: Severe cold weather. D: Areas with road salt or other corrosive materials.

E: Rough or muddy roads. 18-14

18-30

17-6

17-21

17-68

18-7

19-62

19-41

19-43

19-44 19-10

19-69 19-4

19-26

The services are:

Clean the air cleaner element every 7,500 miles (12,000 km) or 6 months and replace every 30,000 miles(48,000 km) or 24 months under condition B or E.

Replace engine oil and oil filter every 3,750 miles (6,000 km) or 3 months under condition A or B.

Inspect front brake discs and calipers, and rear brake discs, calipers and pads every 7,500 miles (12,000

km) or 6 months under condition A, B, D or E.

Inspect the power steering system every 7,500 miles (12,000 km) or 6 months under condition B, C or E.ProCarManuals.com

Page 977 of 1640

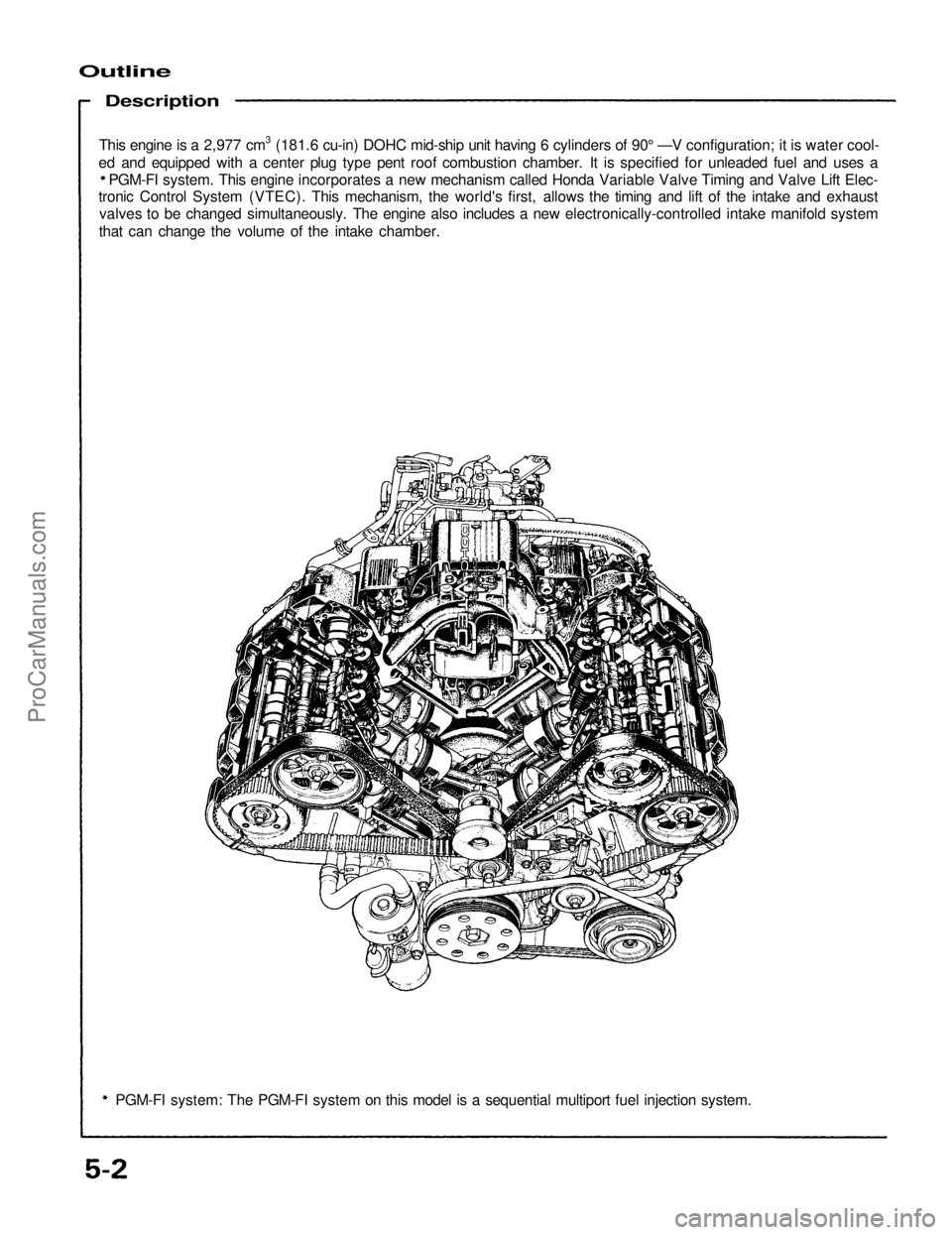

Outline

Description

This engine is a 2,977 cm3 (181.6 cu-in) DOHC mid-ship unit having 6 cylinders of 90° —V configuration; it is water cool-

ed and equipped with a center plug type pent roof combustion chamber. It is specified for unleaded fuel and uses a

PGM-FI system: The PGM-FI system on this model is a sequential multiport fuel injection system.

PGM-FI system. This engine incorporates a new mechanism called Honda Variable Valve Timing and Valve Lift Elec-

tronic Control System (VTEC). This mechanism, the world's first, allows the timing and lift of the intake and exhaust

valves to be changed simultaneously. The engine also includes a new electronically-controlled intake manifold system

that can change the volume of the intake chamber.ProCarManuals.com

Page 978 of 1640

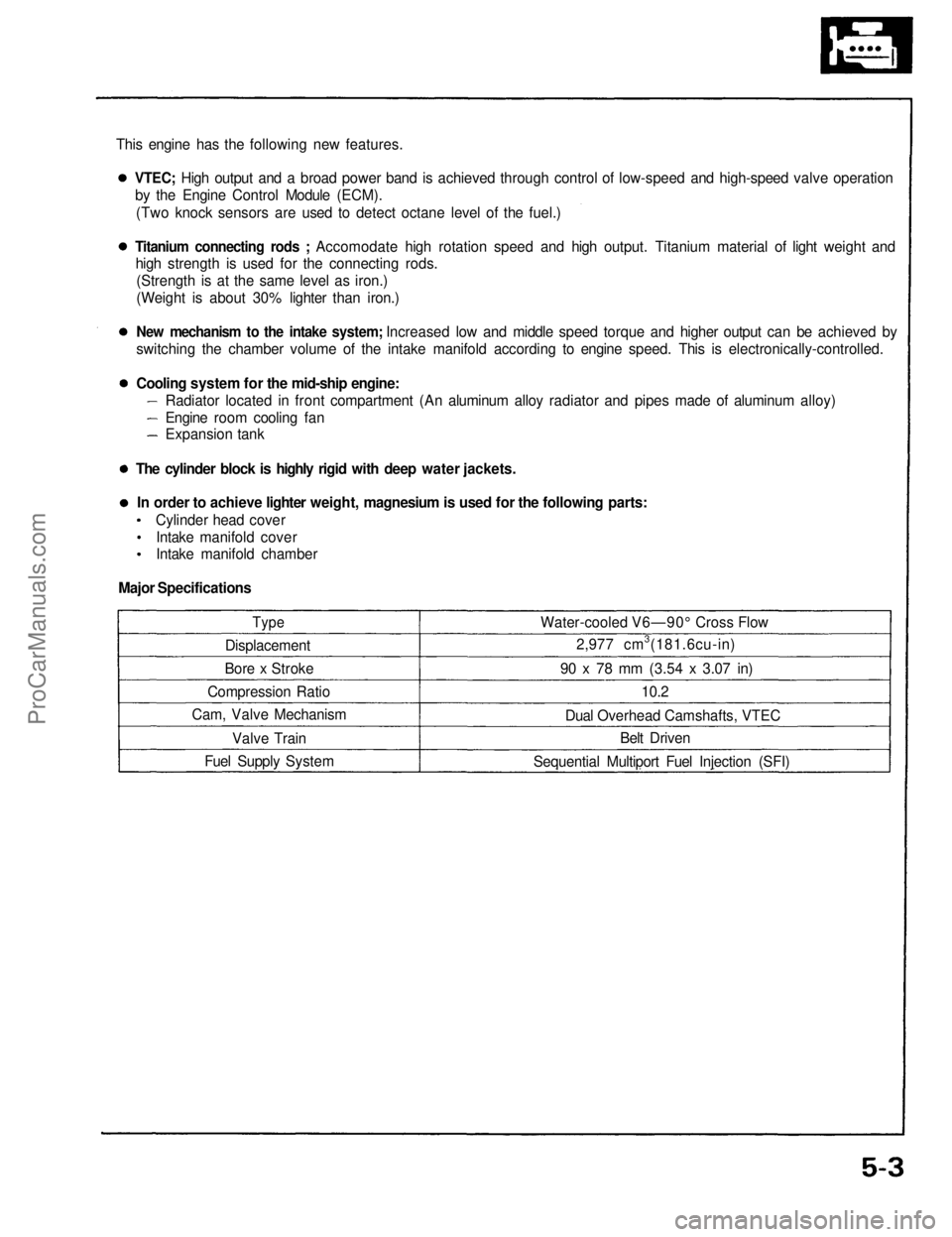

This engine has the following new features.

Type

Displacement

Bore x Stroke

Compression Ratio

Cam, Valve Mechanism

Valve Train

Fuel Supply System Water-cooled V6—90° Cross Flow

2,977 cm3(181.6cu-in)

90 x 78 mm

(3.54

x

3.07

in)

10.2

Dual Overhead Camshafts, VTEC Belt Driven

Sequential Multiport Fuel Injection (SFI)VTEC; High output and a broad power band is achieved through control of low-speed and high-speed valve operation

by the Engine Control Module (ECM).

(Two knock sensors are used to detect octane level of the fuel.)

Titanium connecting rods ; Accomodate high rotation speed and high output. Titanium material of light weight and

high strength is used for the connecting rods.

(Strength is at the same level as iron.)

(Weight is about 30% lighter than iron.)

New mechanism to the intake system; Increased low and middle speed torque and higher output can be achieved by

switching the chamber volume of the intake manifold according to engine speed. This is electronically-controlled.

Cooling system for the mid-ship engine:

Radiator located in front compartment (An aluminum alloy radiator and pipes made of aluminum alloy)

Engine room cooling fan

Expansion tank

The cylinder block is highly rigid with deep water jackets. In order to achieve lighter weight, magnesium is used for the following parts: Cylinder head coverIntake manifold cover

Intake manifold chamber

Major SpecificationsProCarManuals.com

Page 979 of 1640

Variable Valve Timing and Valve Lift Electronic

Control System (VTEC)

Outline

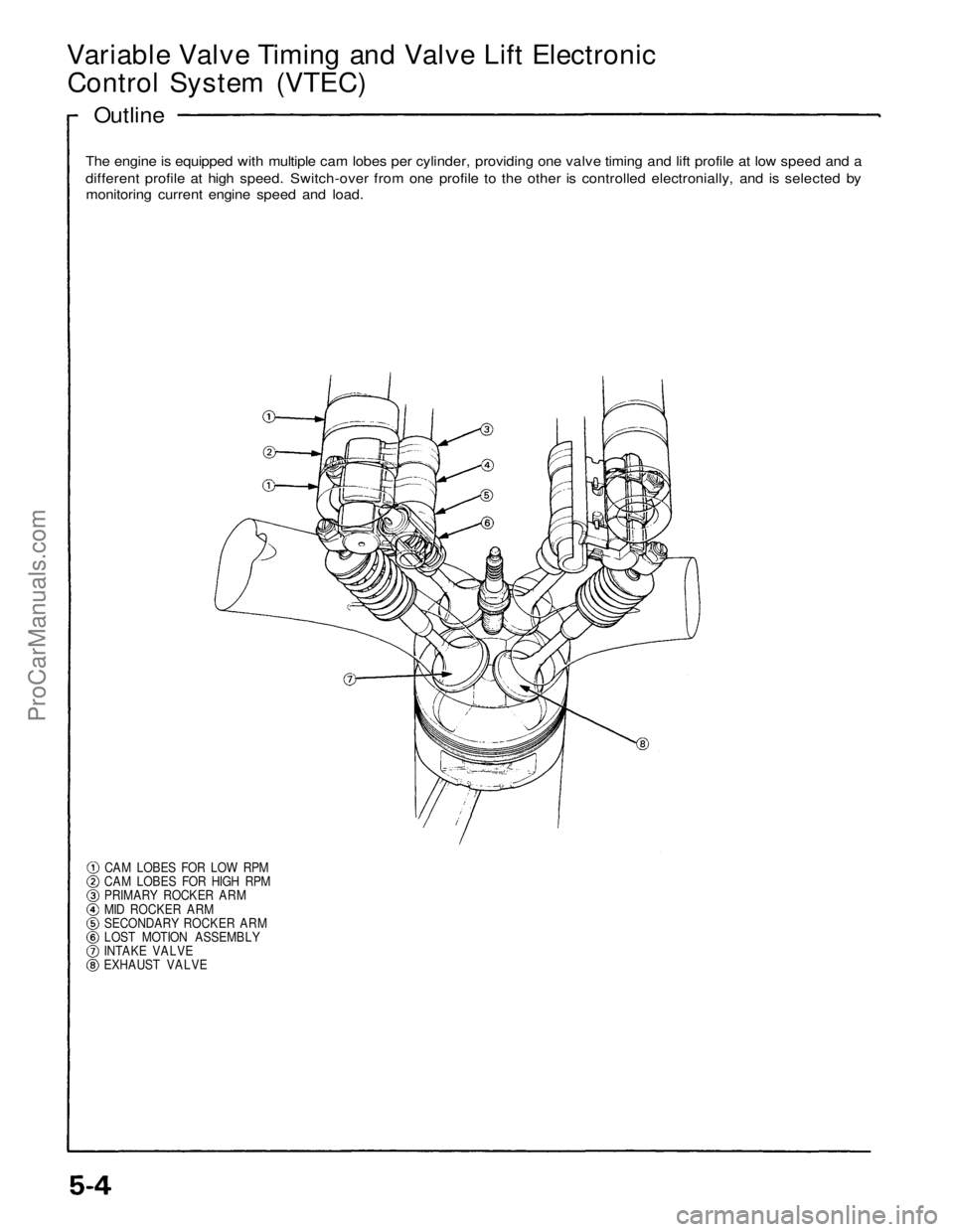

The engine is equipped with multiple cam lobes per cylinder, providing one valve timing and lift profile at low speed and a

different profile at high speed. Switch-over from one profile to the other is controlled electronially, and is selected by monitoring current engine speed and load.

CAM LOBES FOR LOW RPM

CAM LOBES FOR HIGH RPM

PRIMARY ROCKER ARM

MID ROCKER ARM

SECONDARY ROCKER ARM

LOST MOTION ASSEMBLY

INTAKE VALVE

EXHAUST VALVEProCarManuals.com

Page 980 of 1640

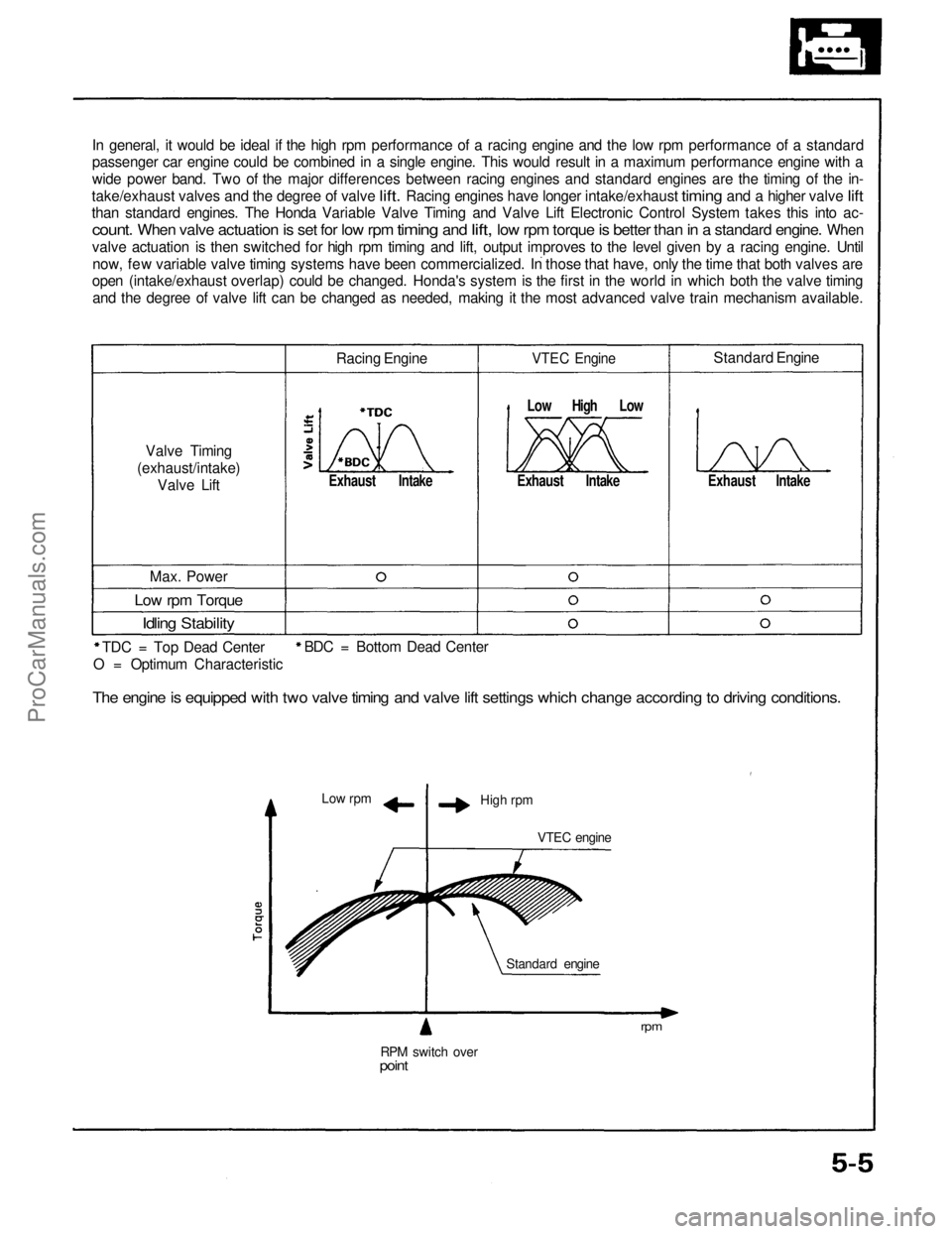

In general, it would be ideal if the high rpm performance of a racing engine and the low rpm performance of a standard

passenger car engine could be combined in a single engine. This would result in a maximum performance engine with a

wide power band. Two of the major differences between racing engines and standard engines are the timing of the in-

take/exhaust valves

and the

degree

of

valve

lift.

Racing engines have longer intake/exhaust

timing

and a

higher valve

lift

than standard engines. The Honda Variable Valve Timing and Valve Lift Electronic Control System takes this into ac-

count.

When

valve

actuation

is set for low rpm

timing

and

lift,

low rpm

torque

is

better

than

in a

standard

engine.

When

valve actuation is then switched for high rpm timing and lift, output improves to the level given by a racing engine. Untilnow, few variable valve timing systems have been commercialized. In those that have, only the time that both valves are

open (intake/exhaust overlap) could be changed. Honda's system is the first in the world in which both the valve timing

and the degree of valve lift can be changed as needed, making it the most advanced valve train mechanism available.

Valve Timing

(exhaust/intake) Valve Lift Racing Engine

Exhaust Intake

VTEC Engine

Low High Low

Exhaust Intake

Standard Engine

Exhaust Intake

Max. Power

Low rpm Torque

Idling Stability

TDC = Top Dead Center

Low rpm

High rpm

VTEC engine

RPM switch over

point

Standard engine

rpm

BDC = Bottom Dead Center

O = Optimum Characteristic

The engine is equipped with two valve timing and valve lift settings which change according to driving conditions.ProCarManuals.com