engine ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1020 of 1640

Cylinder Heads

Removal (cont'd)

47. Disconnect the connectors and remove the engine

wire harness.

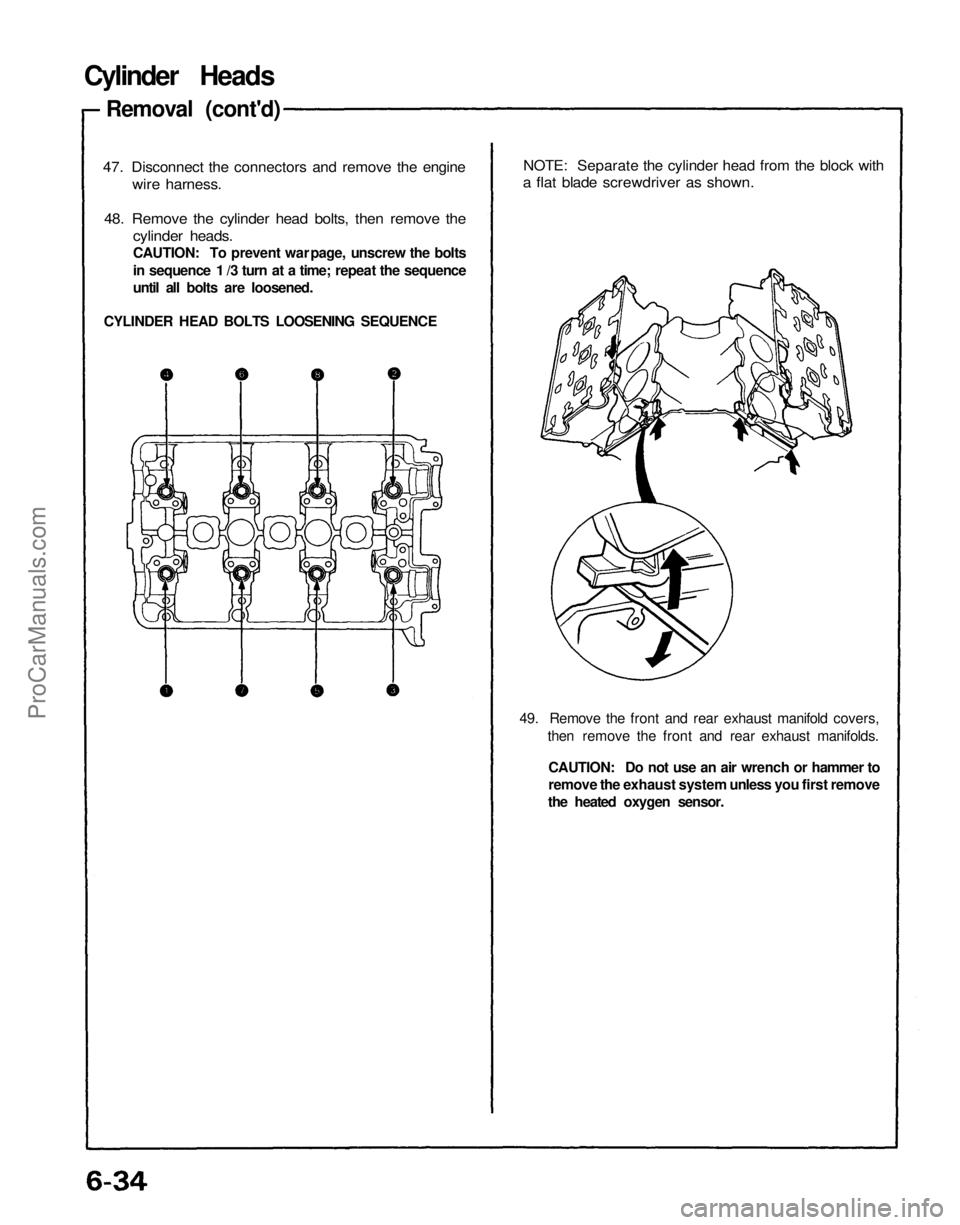

48. Remove the cylinder head bolts, then remove the

cylinder heads.

CAUTION: To prevent war page, unscrew the bolts

in sequence 1 /3 turn at a time; repeat the sequence

until all bolts are loosened.

CYLINDER HEAD BOLTS LOOSENING SEQUENCE

49. Remove the front and rear exhaust manifold covers,

then remove the front and rear exhaust manifolds.

CAUTION: Do not use an air wrench or hammer to

remove the exhaust system unless you first remove

the heated oxygen sensor.

NOTE: Separate the cylinder head from the block with

a flat blade screwdriver as shown.ProCarManuals.com

Page 1024 of 1640

Camshafts

Inspection

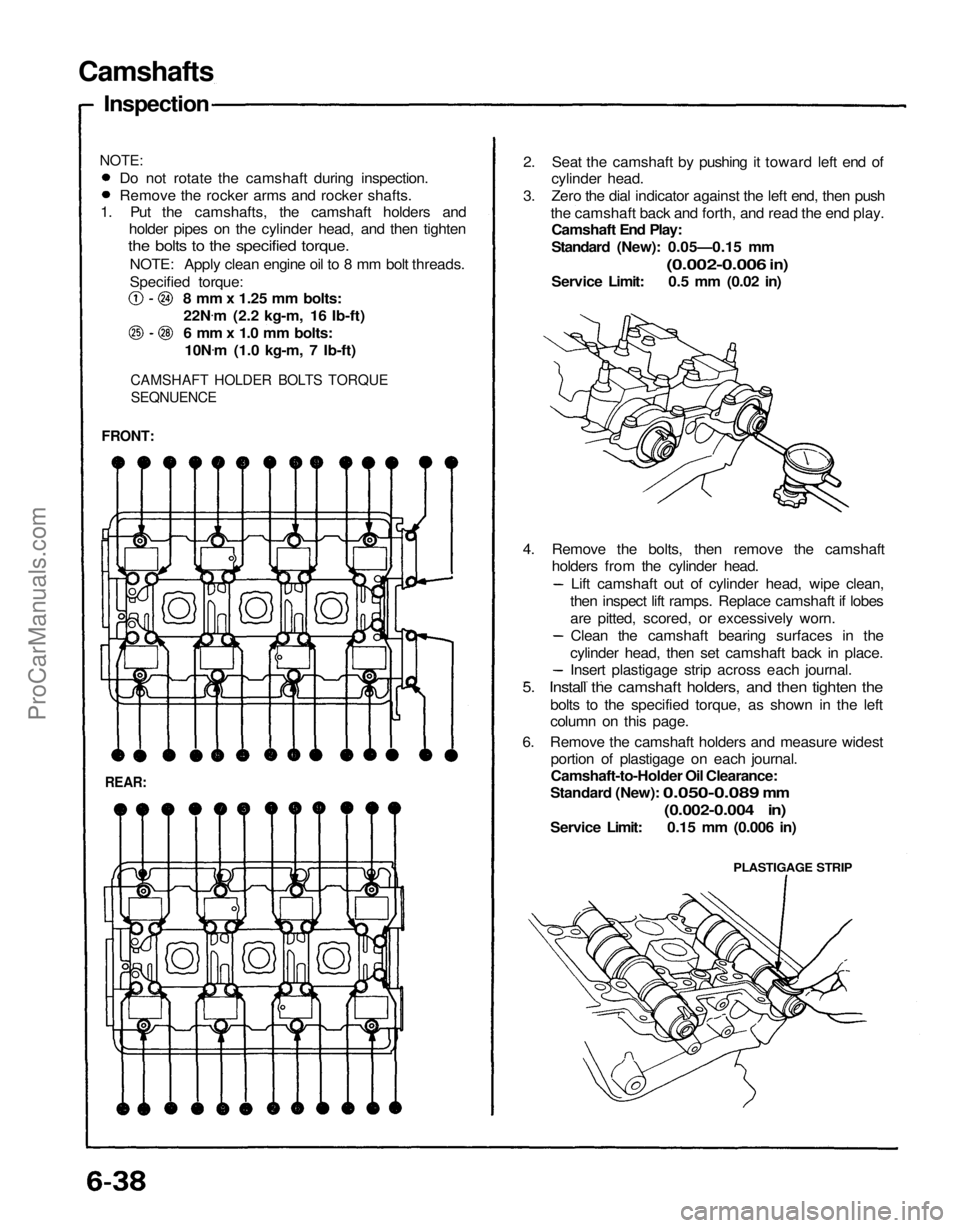

1. Put the camshafts, the camshaft holders and holder pipes on the cylinder head, and then tighten

the bolts to the specified torque.

NOTE: Apply clean engine oil to 8 mm bolt threads.

Specified torque: 8 mm x 1.25 mm bolts:

22N .

m (2.2 kg-m, 16 Ib-ft)

6 mm x 1.0 mm bolts: 10N .

m (1.0 kg-m, 7 Ib-ft)

CAMSHAFT HOLDER BOLTS TORQUE

SEQNUENCE

FRONT:

REAR:

PLASTIGAGE STRIP

2. Seat the camshaft by pushing it toward left end of

cylinder head.

3. Zero the dial indicator against the left end, then push the camshaft back and forth, and read the end play.Camshaft End Play:

Standard (New): 0.05—0.15 mm

(0.002-0.006

in)

Service Limit: 0.5 mm (0.02 in)

4. Remove the bolts, then remove the camshaft holders from the cylinder head.

Do not rotate the camshaft during inspection.

Remove the rocker arms and rocker shafts.

NOTE:

Lift camshaft out of cylinder head, wipe clean,

then inspect lift ramps. Replace camshaft if lobes

are pitted, scored, or excessively worn. Clean the camshaft bearing surfaces in the

cylinder head, then set camshaft back in place.

Insert plastigage strip across each journal.

5. Install the camshaft holders, and then tighten the

bolts to the specified torque, as shown in the left

column on this page.

6. Remove the camshaft holders and measure widest portion of plastigage on each journal.

Camshaft-to-Holder Oil Clearance:

Standard (New):

0.050-0.089

mm

(0.002-0.004 in)

Service Limit: 0.15 mm (0.006 in)ProCarManuals.com

Page 1035 of 1640

Cylinder Heads

Installation

2. Install the exhaust manifold covers.

Front:

HEATED OXYGEN

SENSOR

45 N .

m (4.5 kg-m, 33 Ib-ft)

Be careful not to damage.

6 x 1.0 mm

12 N .

m

(1.2 kg-m.

9 Ib-ft)

GASKET

Replace.

SELF-LOCKING

NUT

8x

1.25

mm

34 N .

m

(3.4 kg-m,

25 Ib-ft)

Replace.

EXHAUST MANIFOLD

COVER

(cont'd)

8x

1.25

mm

22 N

.

m

(2.2 kg-m.

16 Ib-ft) FRONT EXHAUST

MANIFOLD

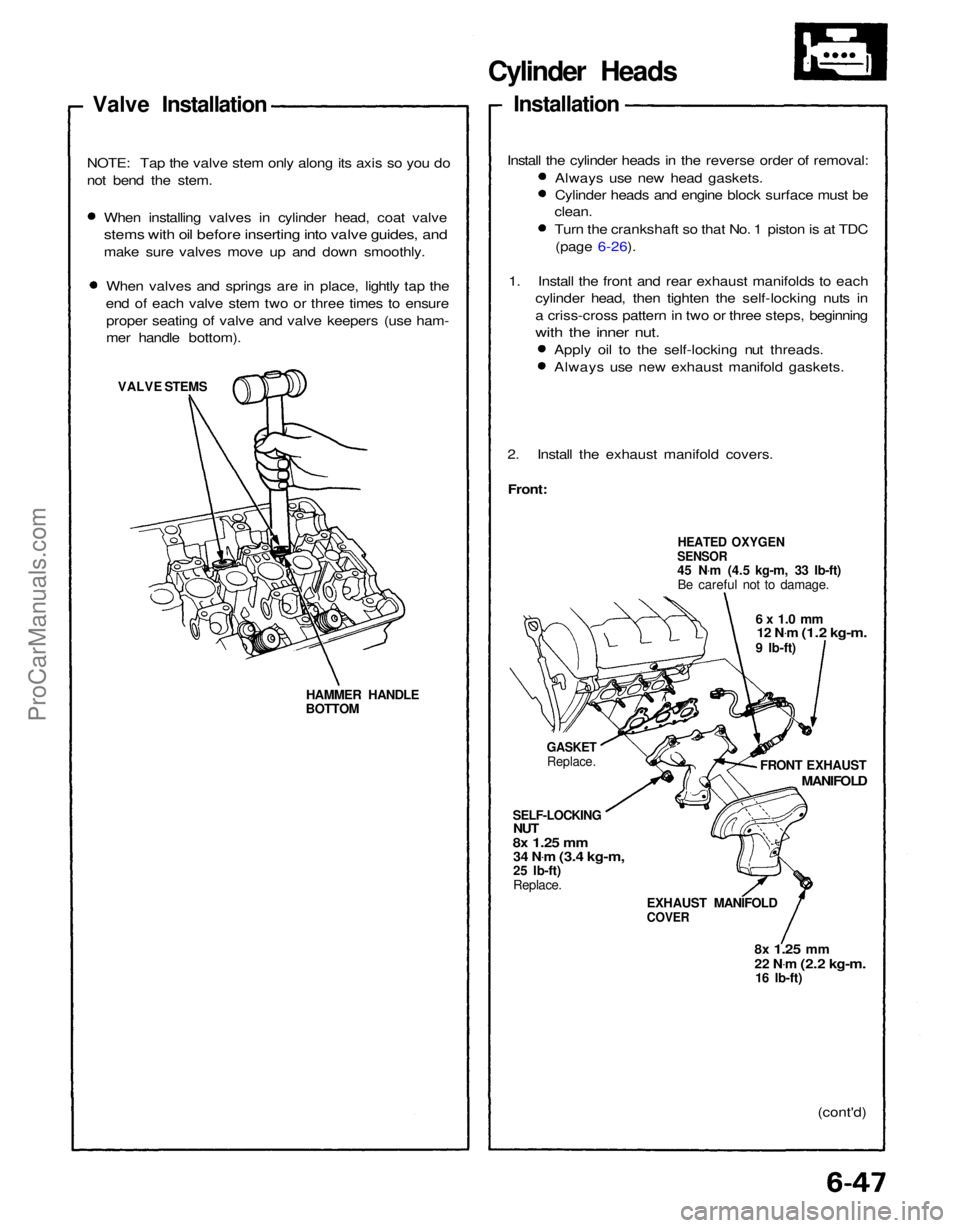

Valve Installation

When installing valves in cylinder head, coat valve

stems with oil before inserting into valve guides, and

make sure valves move up and down smoothly.When valves and springs are in place, lightly tap the

end of each valve stem two or three times to ensure proper seating of valve and valve keepers (use ham-

mer handle bottom).

VALVE STEMS

HAMMER HANDLE

BOTTOM

NOTE: Tap the valve stem only along its axis so you do

not bend the stem.

Apply oil to the self-locking nut threads.

Always use new exhaust manifold gaskets.

1. Install the front and rear exhaust manifolds to each

cylinder head, then tighten the self-locking nuts in

a criss-cross pattern in two or three steps, beginning

with the inner nut.

Always use new head gaskets.

Cylinder heads and engine block surface must be

clean.

Turn the crankshaft so that No. 1 piston is at TDC

(page 6-26).

Install the cylinder heads in the reverse order of removal:ProCarManuals.com

Page 1036 of 1640

Cylinder Heads

Installation (cont'd)

Rear:

8 x

1.25

mm

22 N .

m

(2.2 kg-m,

16 Ib-ft)

HEATED OXYGEN

SENSOR

45 N .

m

(4.5 kg-m,

33 Ib-ft) Be careful not to damage.

GASKET

Replace.

REAR EXHAUST

MANIFOLD

EXHAUST

MANIFOLD

COVER

SELF LOCKING NUTS

8 x

1.25

mm

34 N .

m

(3.4 kg-m,

25 Ib-ft)

Replace.

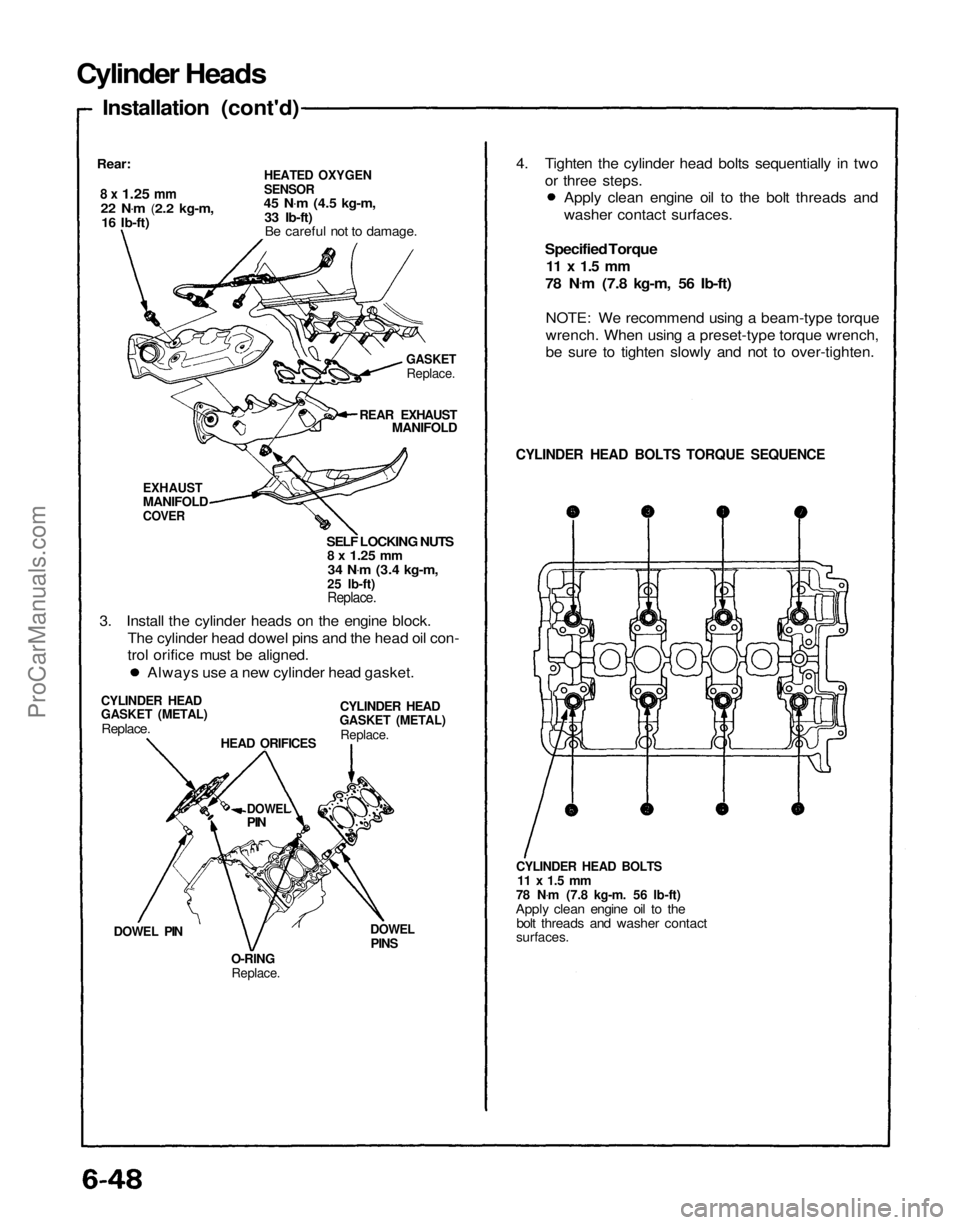

3. Install the cylinder heads on the engine block. The cylinder head dowel pins and the head oil con-

trol orifice must be aligned.

CYLINDER HEAD

GASKET (METAL)

Replace.

CYLINDER HEAD

GASKET (METAL)

Replace.

HEAD ORIFICES

DOWEL

PIN

DOWEL PIN

O-RING

Replace.

DOWEL

PINS

CYLINDER HEAD BOLTS

11 x 1.5 mm

78 N .

m (7.8 kg-m. 56 Ib-ft)

Apply clean engine oil to the bolt threads and washer contact

surfaces.

CYLINDER HEAD BOLTS TORQUE SEQUENCE

Specified Torque

11 x 1.5 mm

78 N .

m (7.8 kg-m, 56 Ib-ft)

NOTE: We recommend using a beam-type torque

wrench. When using a preset-type torque wrench,

be sure to tighten slowly and not to over-tighten.

Always use a new cylinder head gasket. Apply clean engine oil to the bolt threads and

washer contact surfaces.

4. Tighten the cylinder head bolts sequentially in two

or three steps.ProCarManuals.com

Page 1038 of 1640

Camshafts

Installation (cont'd)

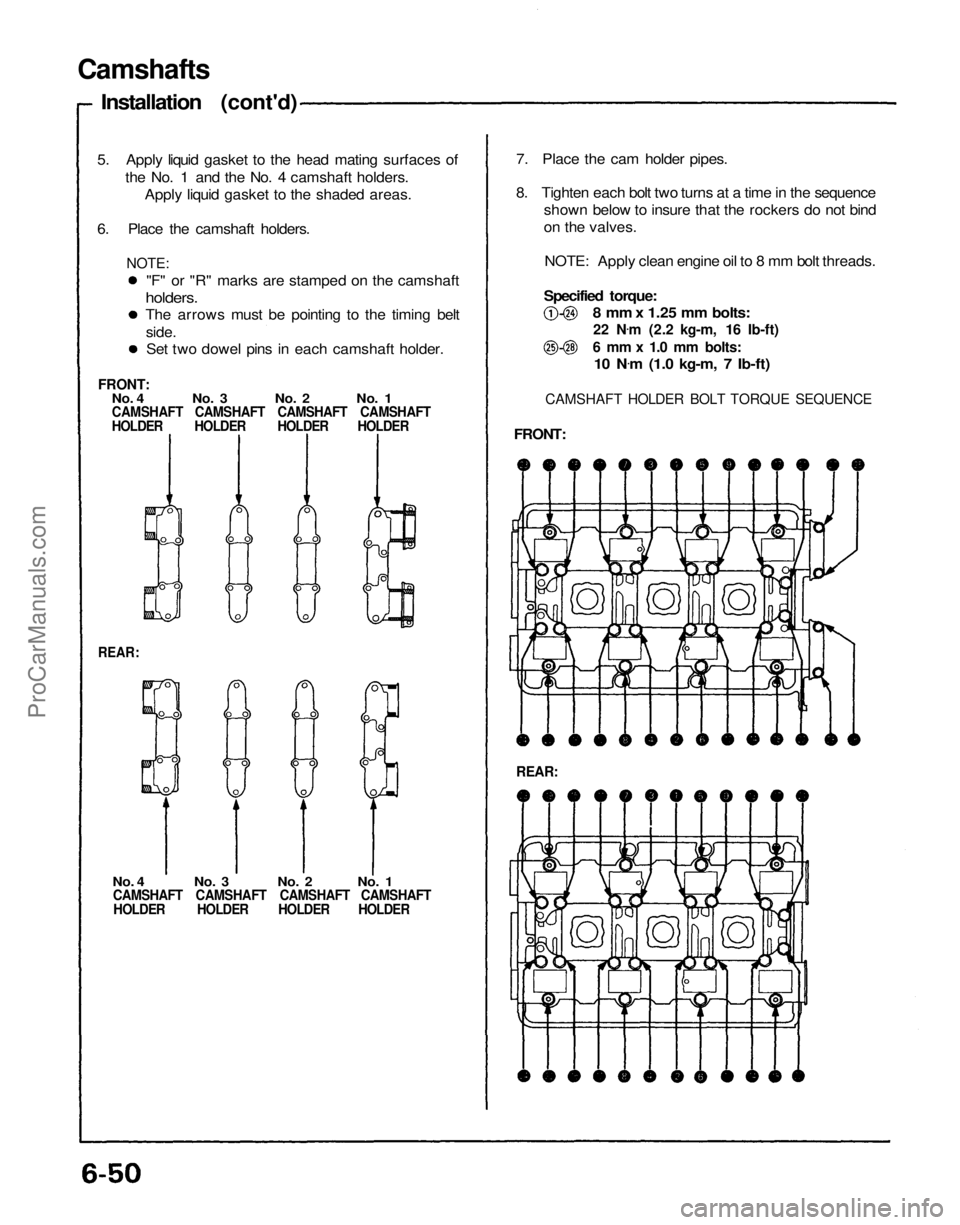

5. Apply liquid gasket to the head mating surfaces of the No. 1 and the No. 4 camshaft holders.Apply liquid gasket to the shaded areas.

6. Place the camshaft holders.

REAR:

No. 4 No. 3 No. 2 No. 1

CAMSHAFT CAMSHAFT CAMSHAFT CAMSHAFT

HOLDER HOLDER HOLDER HOLDER

REAR:

7. Place the cam holder pipes.

8. Tighten each bolt two turns at a time in the sequence

shown below to insure that the rockers do not bind

on the valves.

NOTE: Apply clean engine oil to 8 mm bolt threads.

Specified torque: 8 mm x 1.25 mm bolts:

22 N .

m (2.2 kg-m, 16 Ib-ft)

6 mm x 1.0 mm bolts:

10 N .

m (1.0 kg-m, 7 Ib-ft)

CAMSHAFT HOLDER BOLT TORQUE SEQUENCE

FRONT:

NOTE:

"F" or "R" marks are stamped on the camshaft

holders.

The arrows must be pointing to the timing belt

side.Set two dowel pins in each camshaft holder.

FRONT:

No. 4 No. 3 No. 2 No. 1

CAMSHAFT CAMSHAFT CAMSHAFT CAMSHAFT

HOLDER HOLDER HOLDER HOLDERProCarManuals.com

Page 1039 of 1640

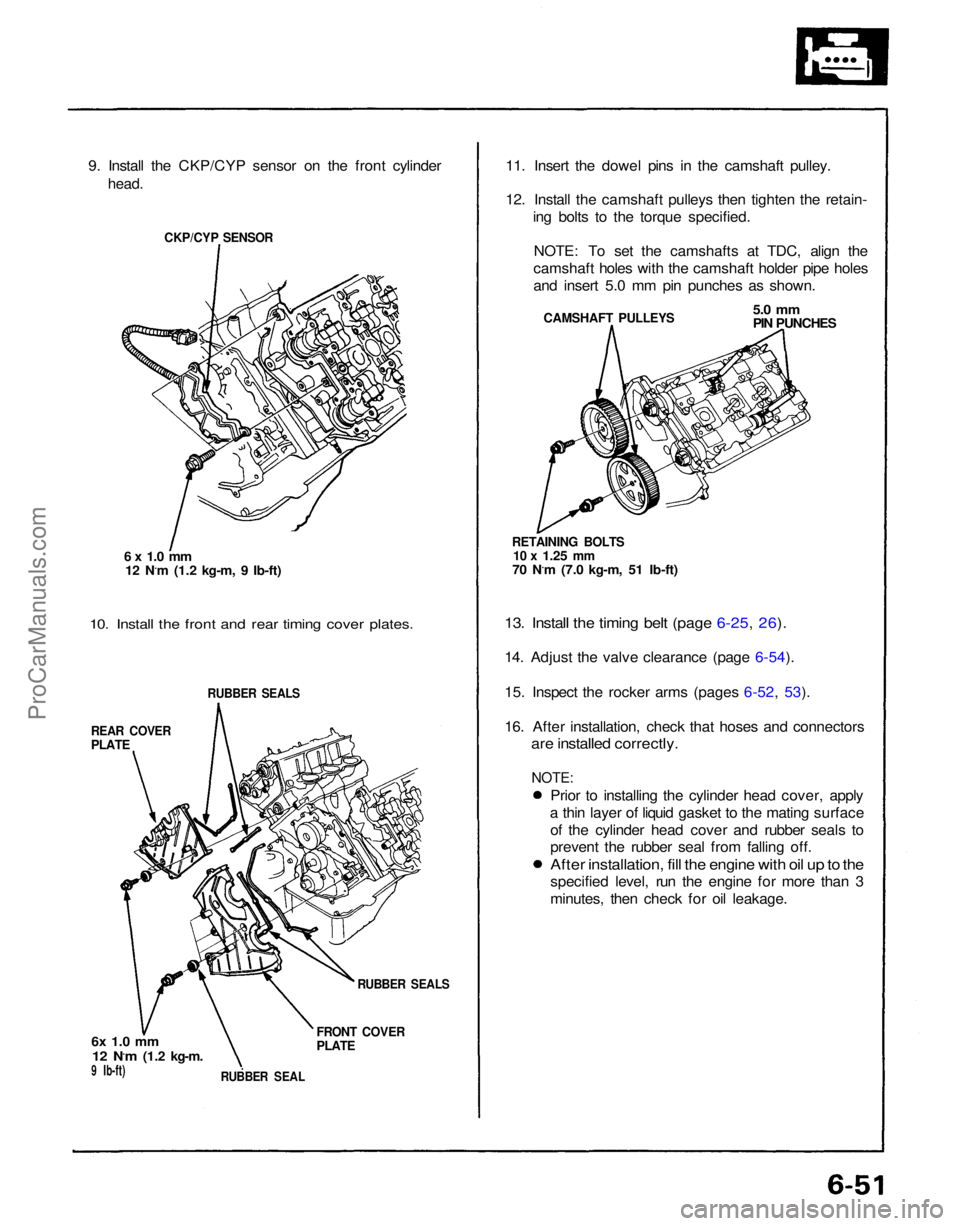

9. Install the CKP/CYP sensor on the front cylinder

head.

CKP/CYP SENSOR

6 x 1.0 mm

12 N.m (1.2 kg-m, 9 Ib-ft)

10. Install the front and rear timing cover plates.

RUBBER SEALS

REAR COVER

PLATE

6x 1.0 mm

12 N.m

(1.2 kg-m.

9 Ib-ft)

RUBBER SEAL

FRONT COVER

PLATE

RUBBER SEALS

11. Insert the dowel pins in the camshaft pulley.

12. Install the camshaft pulleys then tighten the retain-

ing bolts to the torque specified.

NOTE: To set the camshafts at TDC, align the

camshaft holes with the camshaft holder pipe holes

and insert 5.0 mm pin punches as shown.

CAMSHAFT PULLEYS

5.0 mm

PIN PUNCHES

RETAINING BOLTS

10 x

1.25

mm

70 N.m (7.0 kg-m, 51 Ib-ft)

13. Install the timing belt (page 6-25, 26).

14. Adjust the valve clearance (page 6-54).

15. Inspect the rocker arms (pages 6-52, 53).

16. After installation, check that hoses and connectors

are installed correctly.

Prior to installing the cylinder head cover, apply

a thin layer of liquid gasket to the mating surface of the cylinder head cover and rubber seals to

prevent the rubber seal from falling off.

After installation, fill the engine with oil up to the

specified level, run the engine for more than 3

minutes, then check for oil leakage.

NOTE:ProCarManuals.com

Page 1041 of 1640

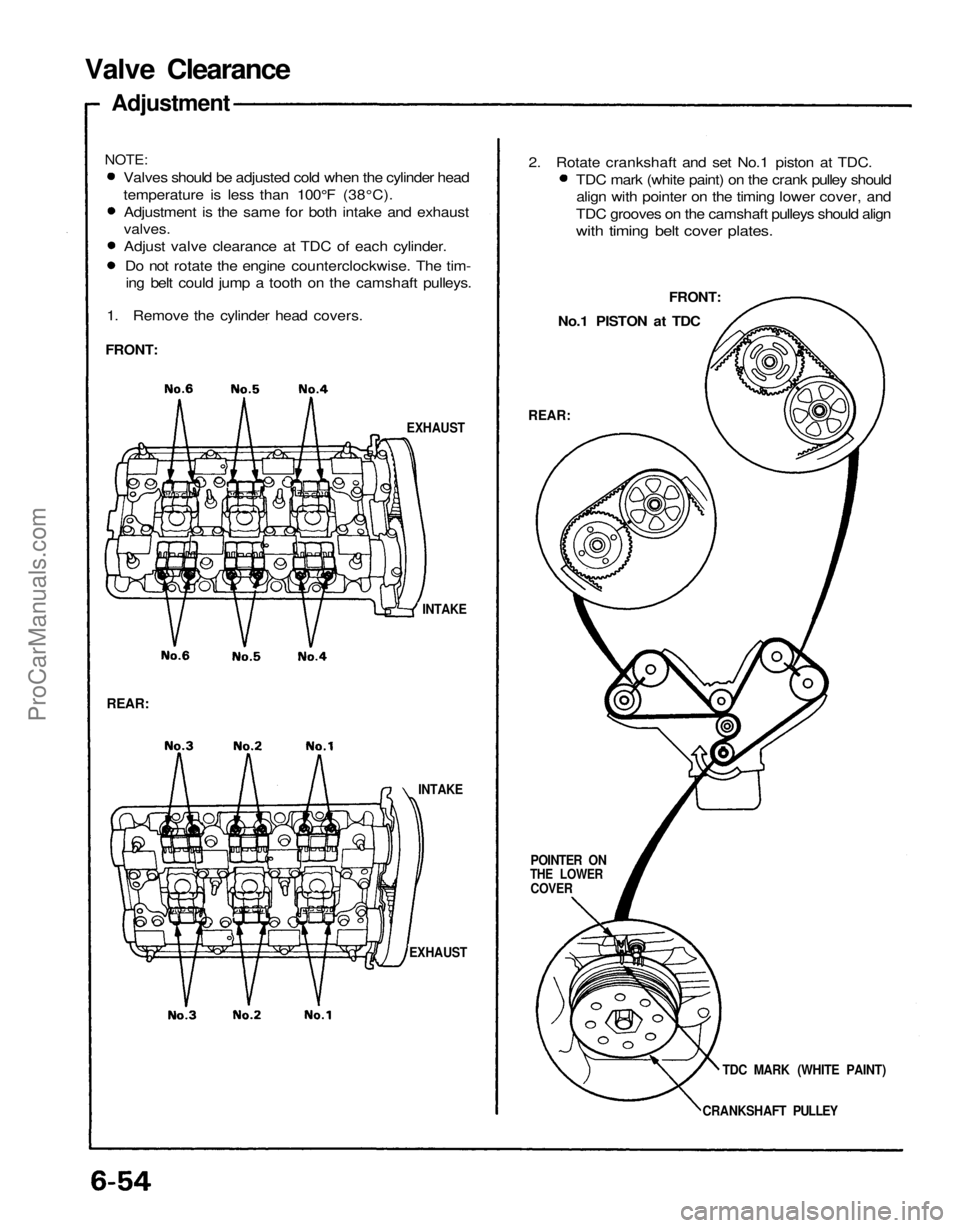

Valve Clearance

Adjustment

Valves should be adjusted cold when the cylinder head

temperature is less than 100°F (38°C).

Adjustment is the same for both intake and exhaust

valves.

Adjust valve clearance at TDC of each cylinder.

Do not rotate the engine counterclockwise. The tim-

ing belt could jump a tooth on the camshaft pulleys.

EXHAUST

INTAKE

INTAKE

EXHAUST

TDC MARK (WHITE PAINT)

CRANKSHAFT PULLEY

POINTER ON

THE LOWER

COVER

TDC mark (white paint) on the crank pulley should

align with pointer on the timing lower cover, and

TDC grooves on the camshaft pulleys should align

with timing belt cover plates.

FRONT:

No.1 PISTON at TDC

REAR:

NOTE:

1. Remove the cylinder head covers.

FRONT:

REAR:

2. Rotate crankshaft and set No.1 piston at TDC.ProCarManuals.com

Page 1044 of 1640

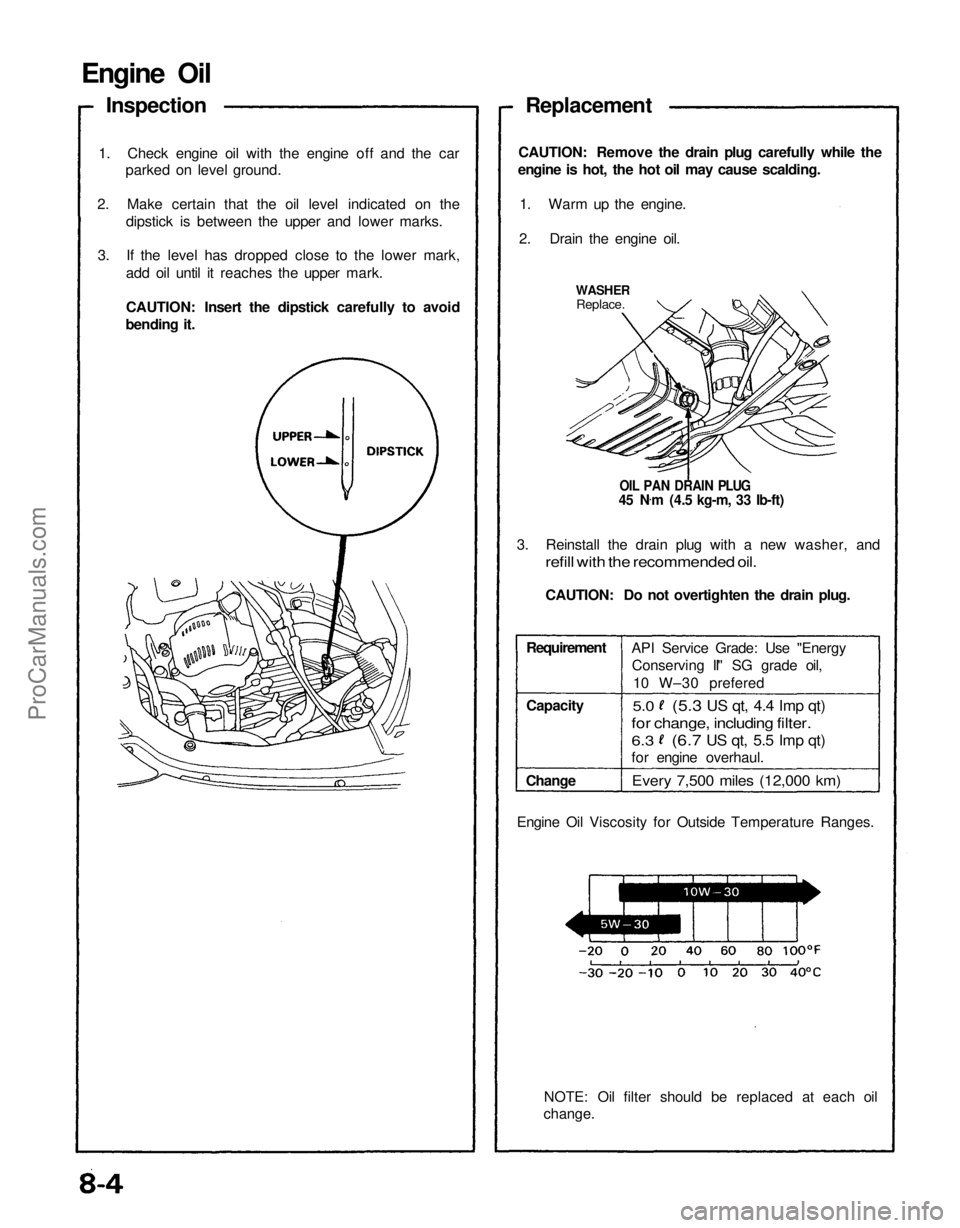

Engine Oil

Inspection

1. Check engine oil with the engine off and the car parked on level ground.

2. Make certain that the oil level indicated on the dipstick is between the upper and lower marks.

3. If the level has dropped close to the lower mark, add oil until it reaches the upper mark.

CAUTION: Insert the dipstick carefully to avoid

bending it. Replacement

CAUTION: Remove the drain plug carefully while the

engine is hot, the hot oil may cause scalding.

1. Warm up the engine.

2. Drain the engine oil.

WASHER

Replace.

OIL PAN DRAIN PLUG

45 N .

m (4.5 kg-m, 33 Ib-ft)

3. Reinstall the drain plug with a new washer, and

refill with the recommended oil.

CAUTION: Do not overtighten the drain plug.

Requirement

Capacity

Change API Service Grade: Use "Energy

Conserving II" SG grade oil,

10 W–30 prefered

5.0

Every 7,500 miles (12,000 km)

NOTE: Oil filter should be replaced at each oil

change.

Engine Oil Viscosity for Outside Temperature Ranges.

(5.3

US qt, 4.4 Imp qt)

for change, including filter.

6.3

(6.7

US qt, 5.5 Imp qt)

for engine overhaul.ProCarManuals.com

Page 1047 of 1640

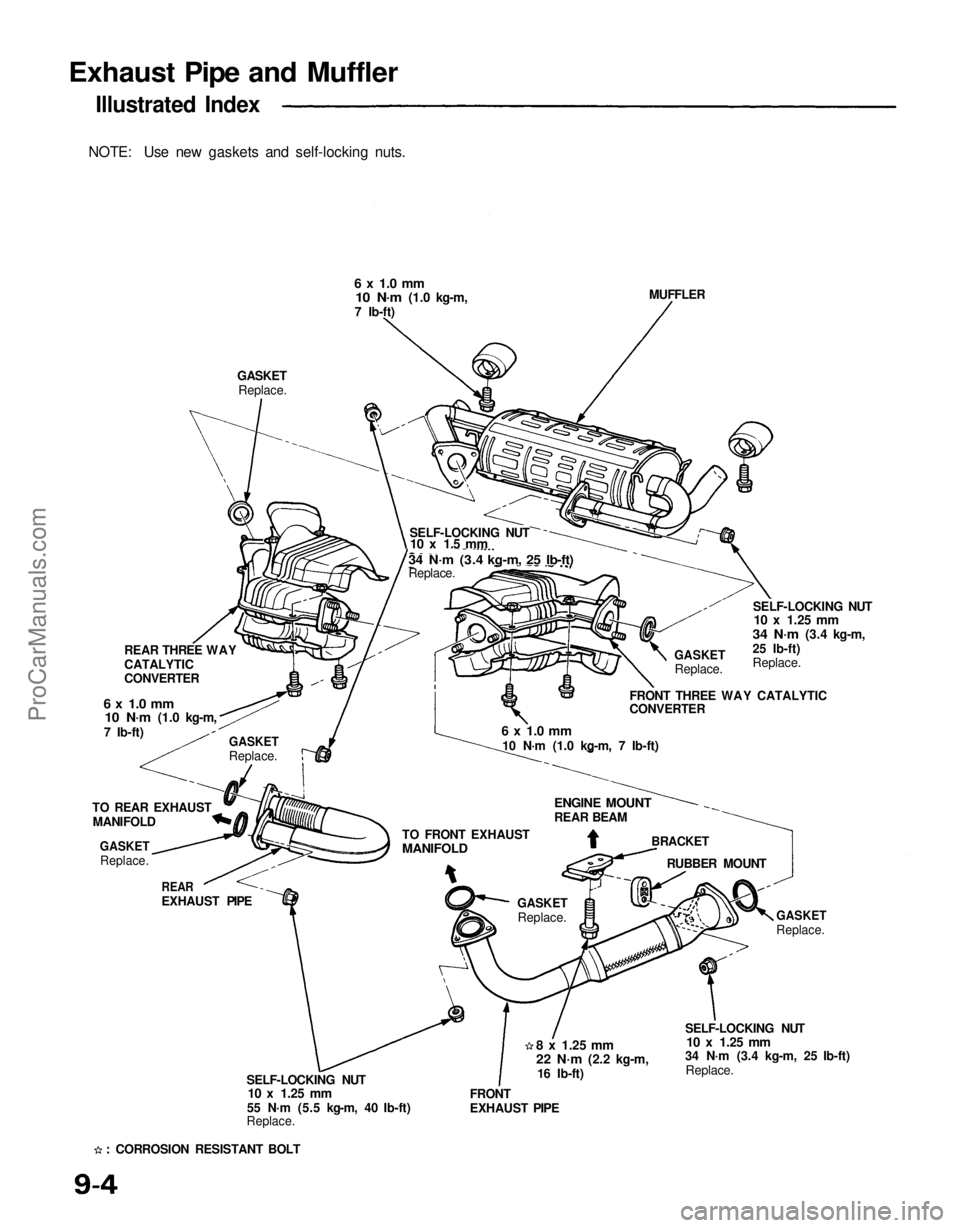

Exhaust Pipe and Muffler

Illustrated Index

NOTE: Use new gaskets and self-locking nuts.

6 x 1.0 mm

10 N·m

(1.0 kg-m,

7 Ib-ft)

GASKET Replace.

REAR THREE WAY

CATALYTIC

CONVERTER

6 x 1.0 mm

10 N·m

(1.0 kg-m,

7 Ib-ft)

GASKET

Replace.

TO REAR EXHAUST MANIFOLD

GASKET

Replace.

EXHAUST PIPE

REAR

TO FRONT EXHAUST

MANIFOLD

GASKET

Replace.

SELF-LOCKING NUT

10 x

1.25

mm

55 N·m (5.5 kg-m, 40 Ib-ft)

Replace.

: CORROSION RESISTANT BOLT FRONT

EXHAUST PIPEMUFFLER

SELF-LOCKING NUT

10 x

1.5

mm

34 N·m (3.4 kg-m, 25 Ib-ft)

Replace.

6 x 1.0 mm

10 N·m (1.0 kg-m, 7 Ib-ft) FRONT THREE WAY CATALYTIC

CONVERTER

GASKET

Replace. SELF-LOCKING NUT

10 x

1.25

mm

34 N·m

(3.4 kg-m,

25 Ib-ft)

Replace.

ENGINE MOUNT

REAR BEAM

BRACKET

RUBBER MOUNT

GASKET

Replace.

SELF-LOCKING NUT

10 x

1.25

mm

34 N·m (3.4 kg-m, 25 Ib-ft)

Replace.

8 x

1.25

mm

22 N·m

(2.2 kg-m,

16 Ib-ft)ProCarManuals.com

Page 1049 of 1640

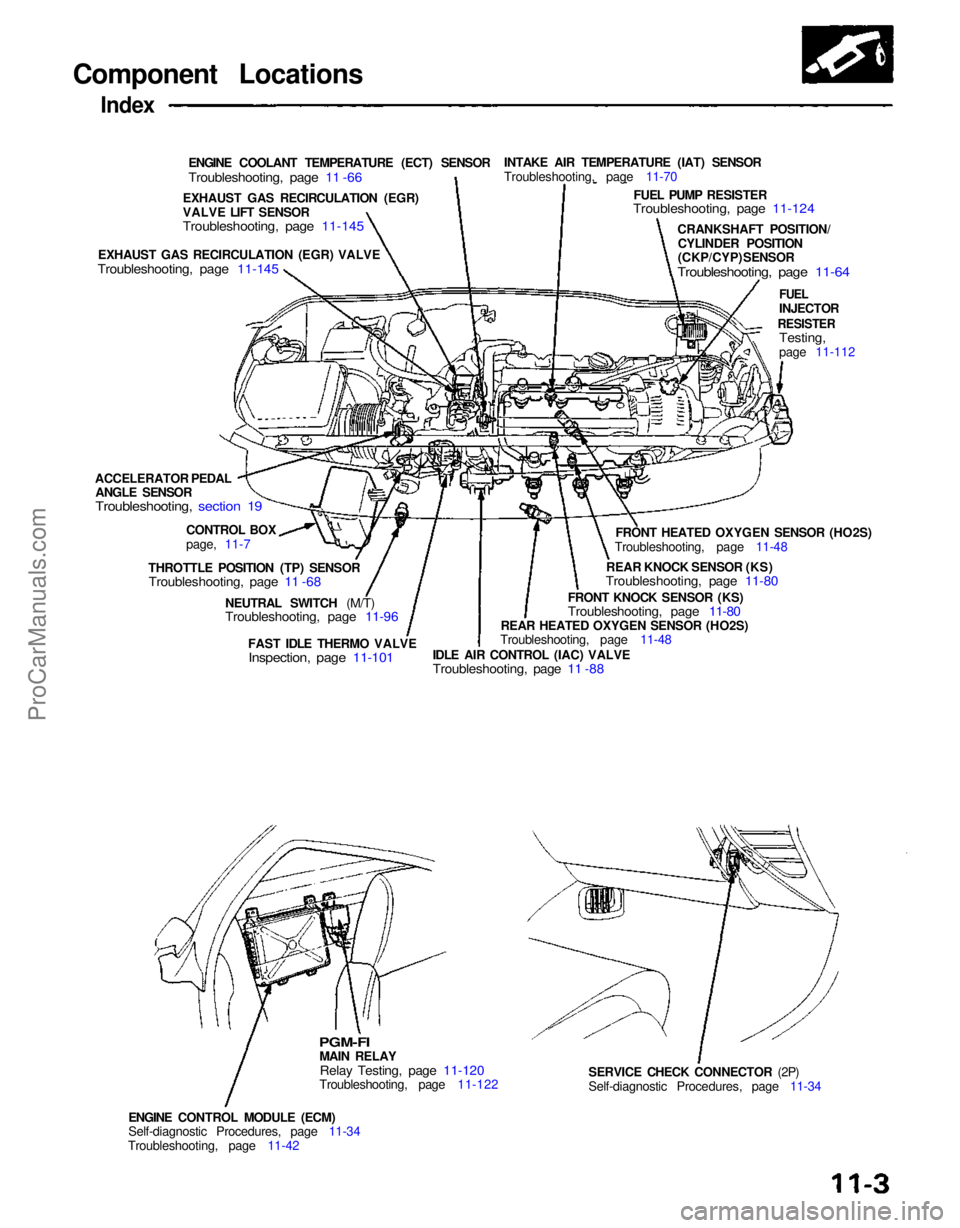

Component Locations

Index

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

Troubleshooting, page 11 -66

INTAKE AIR TEMPERATURE (IAT) SENSOR

Troubleshooting, page 11-70

FUEL PUMP RESISTER

Troubleshooting, page 11-124

CRANKSHAFT POSITION/CYLINDER POSITION

(CKP/CYP) SENSOR

Troubleshooting, page 11-64

FUEL

INJECTOR

RESISTER

Testing,

page 11-112

FRONT HEATED OXYGEN SENSOR (HO2S)

Troubleshooting, page 11-48

REAR KNOCK SENSOR (KS)

Troubleshooting, page 11-80

FRONT KNOCK SENSOR (KS)

Troubleshooting, page 11-80

REAR HEATED OXYGEN SENSOR (HO2S)

Troubleshooting, page 11-48

IDLE AIR CONTROL (IAC) VALVE

Troubleshooting, page 11 -88

FAST IDLE THERMO VALVE

Inspection, page 11-101

NEUTRAL SWITCH (M/T)

Troubleshooting, page 11-96

SERVICE CHECK CONNECTOR (2P)

Self-diagnostic Procedures, page 11-34

ENGINE CONTROL MODULE (ECM)

Self-diagnostic Procedures, page 11-34

Troubleshooting, page 11-42

PGM-FI

MAIN RELAY

Relay Testing, page 11-120

Troubleshooting, page 11-122

THROTTLE POSITION (TP) SENSOR

Troubleshooting, page 11 -68

CONTROL BOX

page, 11-7

ACCELERATOR PEDAL

ANGLE SENSOR

Troubleshooting, section 19

EXHAUST GAS RECIRCULATION (EGR) VALVE

Troubleshooting, page 11-145

EXHAUST GAS RECIRCULATION (EGR)

VALVE LIFT SENSOR

Troubleshooting, page 11-145ProCarManuals.com