engine ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1109 of 1640

System Description

The fuel supply system consists of a fuel tank, in-tank high pressure fuel pump, fuel pump relay, fuel pump

resistor, PGM-FI main relay, fuel filter, fuel pressureregulator, fuel injectors and fuel injector resistor.

This system delivers pressure-regulated fuel to the fuel injectors and cuts the fuel delivery when the engine is

not running. Fuel Pressure

Relieving

Do not smoke while working on the fuel system.

Keep open flames or sparks away from your work

area.

Be sure to relieve fuel pressure while the engine is

off.

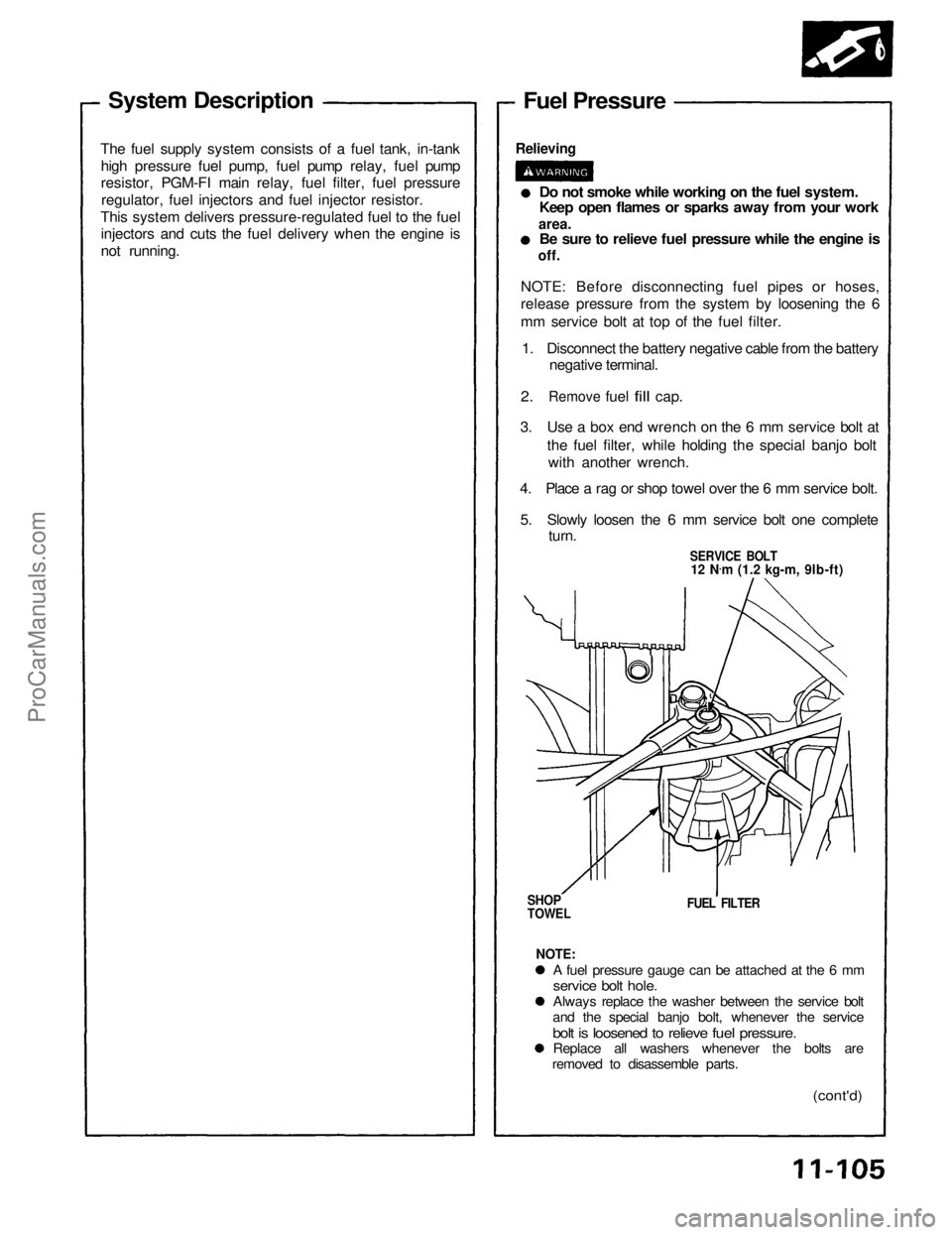

NOTE: Before disconnecting fuel pipes or hoses,

release pressure from the system by loosening the 6

mm service bolt at top of the fuel filter. 1. Disconnect the battery negative cable from the battery negative terminal.

2.

Remove

fuel

fill

cap.

3. Use a box end wrench on the 6 mm service bolt at the fuel filter, while holding the special banjo boltwith another wrench.

4. Place a rag or shop towel over the 6 mm service bolt.

5. Slowly loosen the 6 mm service bolt one complete turn.

SERVICE BOLT

12 N .

m (1.2 kg-m, 9lb-ft)

SHOP

TOWEL

FUEL FILTER

NOTE:

A fuel pressure gauge can be attached at the 6 mm

service bolt hole.

Always replace the washer between the service bolt

and the special banjo bolt, whenever the service

bolt is loosened to relieve fuel pressure.

Replace all washers whenever the bolts are

removed to disassemble parts.

(cont'd)ProCarManuals.com

Page 1110 of 1640

Fuel Supply System

Fuel Pressure (cont'd)

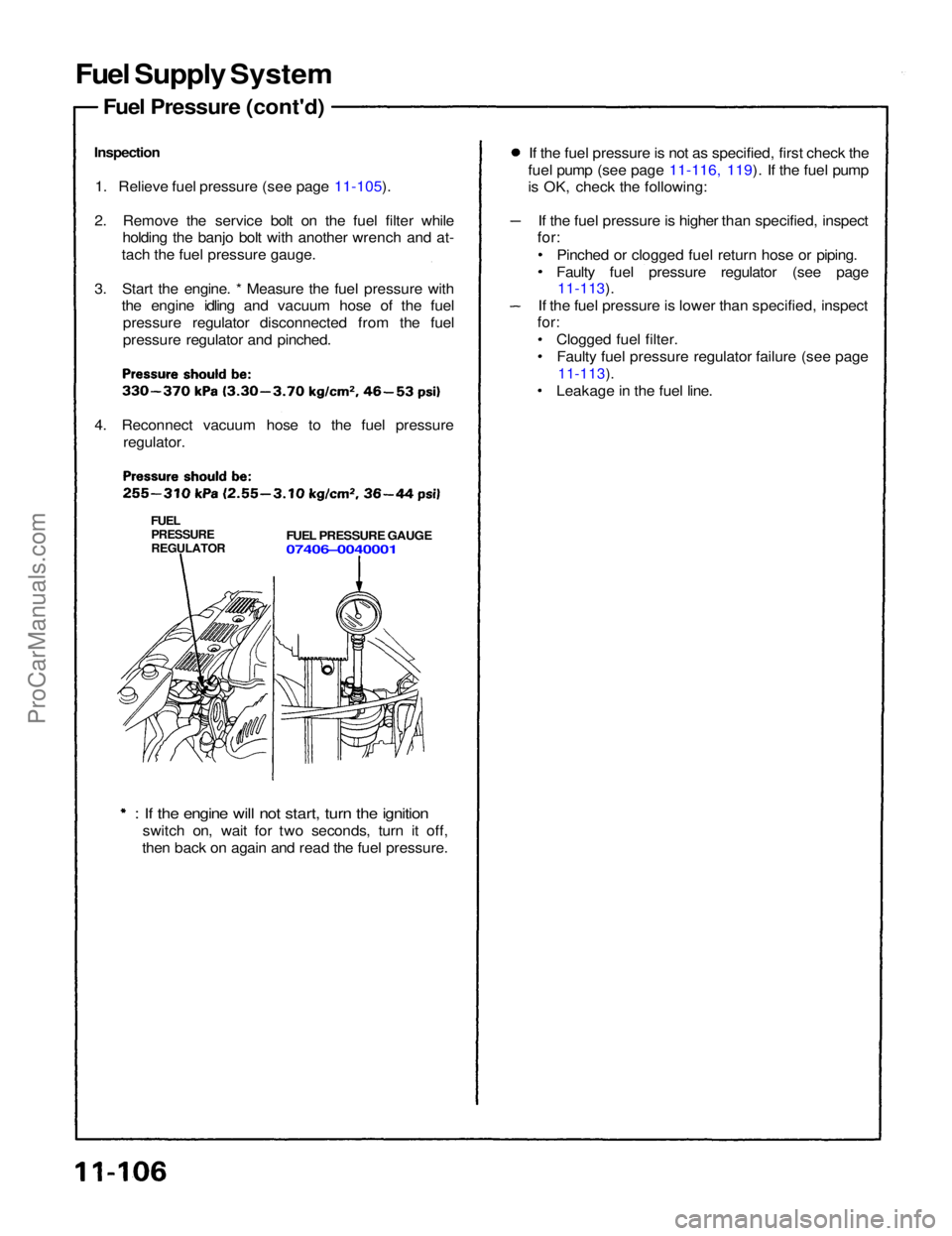

Inspection 1. Relieve fuel pressure (see page 11-105).

2. Remove the service bolt on the fuel filter while holding the banjo bolt with another wrench and at-

tach the fuel pressure gauge.

3. Start the engine. * Measure the fuel pressure with the engine idling and vacuum hose of the fuel

pressure regulator disconnected from the fuel

pressure regulator and pinched.

4. Reconnect vacuum hose to the fuel pressure regulator.

FUEL

PRESSURE

REGULATOR

FUEL PRESSURE GAUGE

07406–0040001

: If the engine will not start, turn the ignition

switch on, wait for two seconds, turn it off,

then back on again and read the fuel pressure. If the fuel pressure is not as specified, first check the

fuel pump (see page 11-116, 119). If the fuel pump

is OK, check the following:

If the fuel pressure is higher than specified, inspect

for:

Pinched or clogged fuel return hose or piping.

Faulty fuel pressure regulator (see page

11-113).

If the fuel pressure is lower than specified, inspect

for:

Clogged fuel filter.Faulty fuel pressure regulator failure (see page

11-113).

Leakage in the fuel line.ProCarManuals.com

Page 1111 of 1640

Fuel Supply System

Fuel Injectors (cont'd)

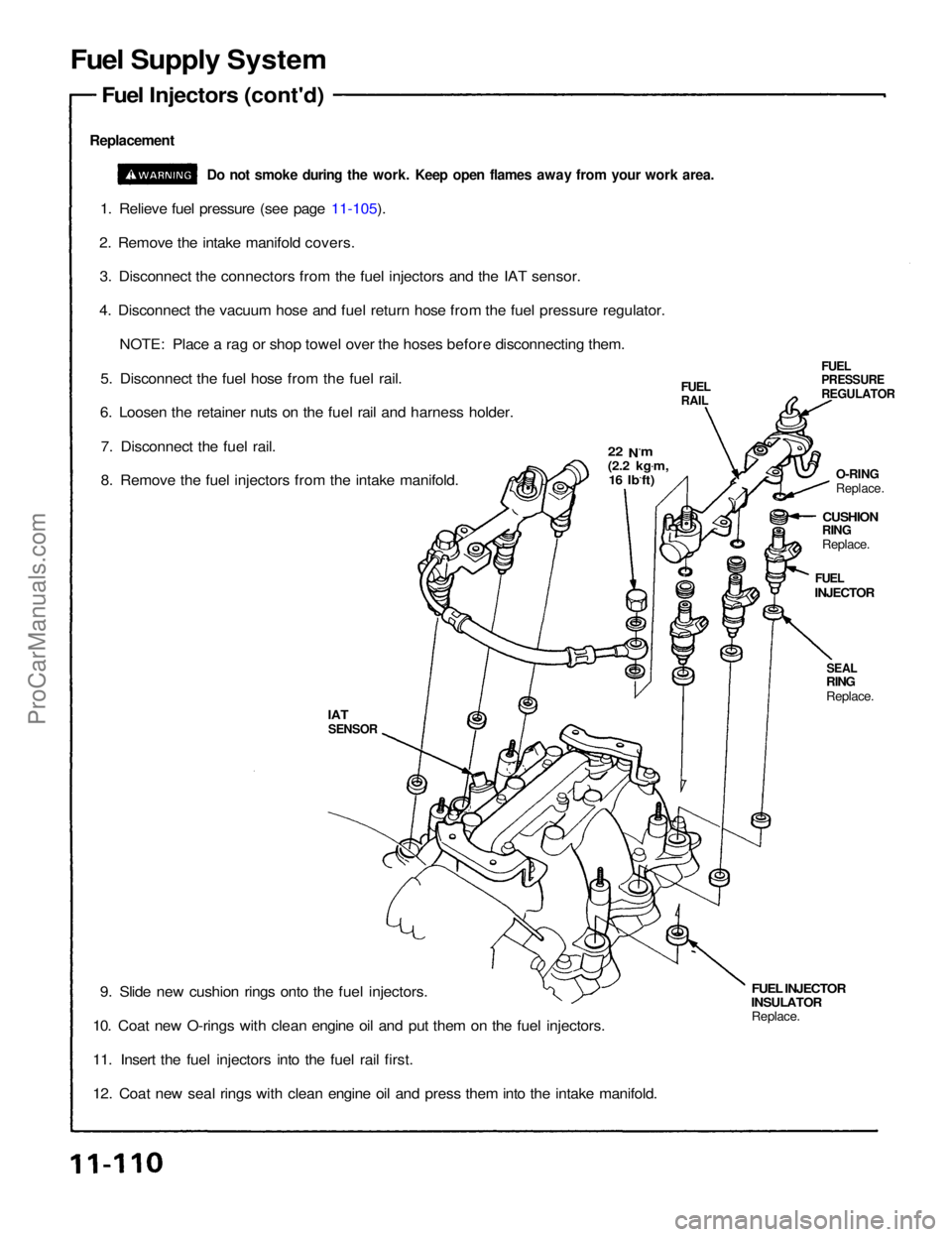

Replacement

Do not smoke during the work. Keep open flames away from your work area.

1. Relieve fuel pressure (see page 11-105).

2. Remove the intake manifold covers. 3. Disconnect the connectors from the fuel injectors and the IAT sensor.

4. Disconnect the vacuum hose and fuel return hose from the fuel pressure regulator. NOTE: Place a rag or shop towel over the hoses before disconnecting them.

5. Disconnect the fuel hose from the fuel rail.

6. Loosen the retainer nuts on the fuel rail and harness holder.

7. Disconnect the fuel rail.

8. Remove the fuel injectors from the intake manifold.

FUEL

PRESSURE

REGULATOR

22 N.m

(2.2 kg .

m,

16 Ib.ft)

FUEL

RAIL

O-RING

Replace.

CUSHION

RING

Replace.

FUEL

INJECTOR

SEAL

RING

Replace.

FUEL INJECTOR

INSULATOR

Replace.

IAT

SENSOR

9. Slide new cushion rings onto the fuel injectors.

10. Coat new O-rings with clean engine oil and put them on the fuel injectors.

11. Insert the fuel injectors into the fuel rail first.

12. Coat new seal rings with clean engine oil and press them into the intake manifold.ProCarManuals.com

Page 1115 of 1640

Fuel Supply System

Fuel Pressure Regulator (cont'd)

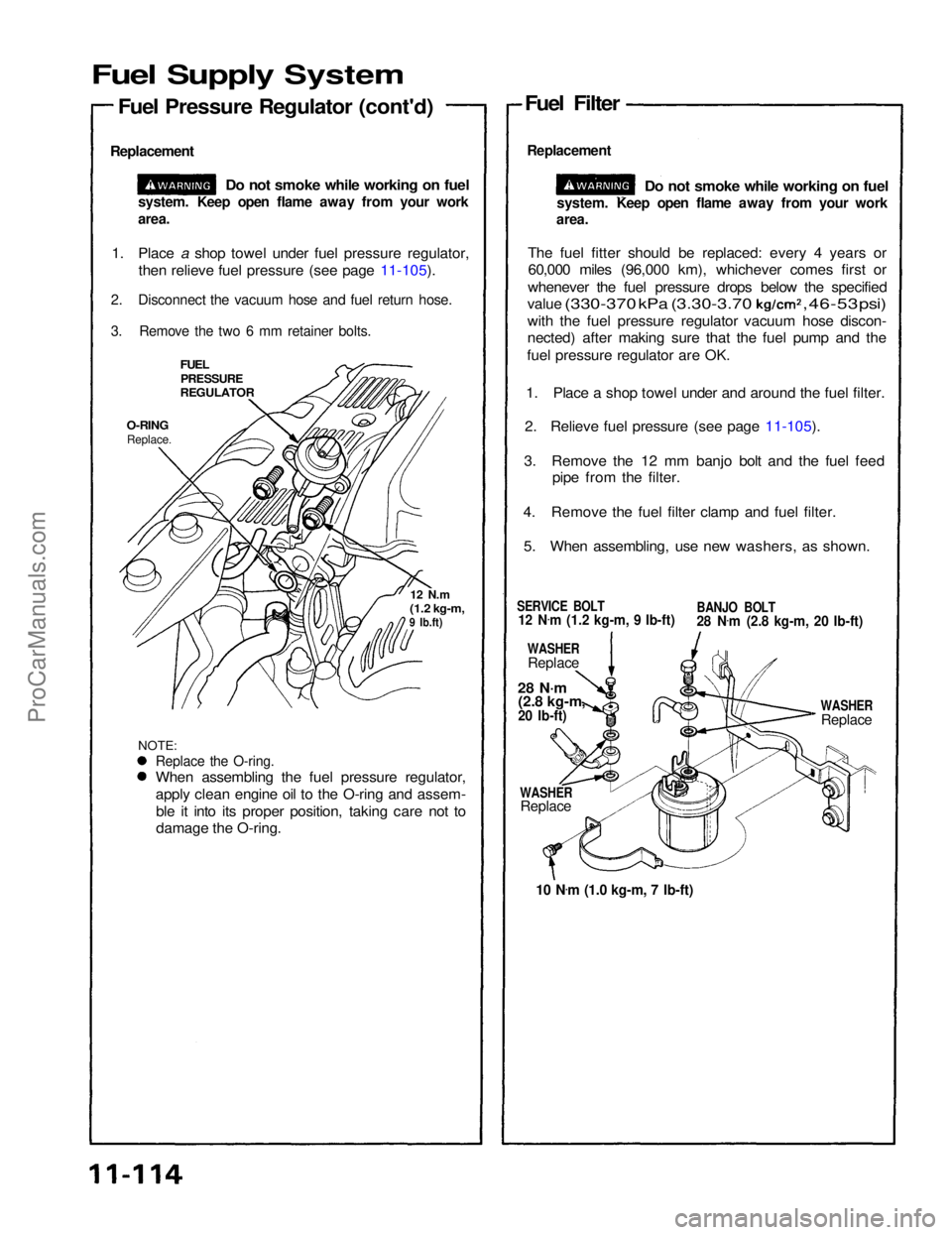

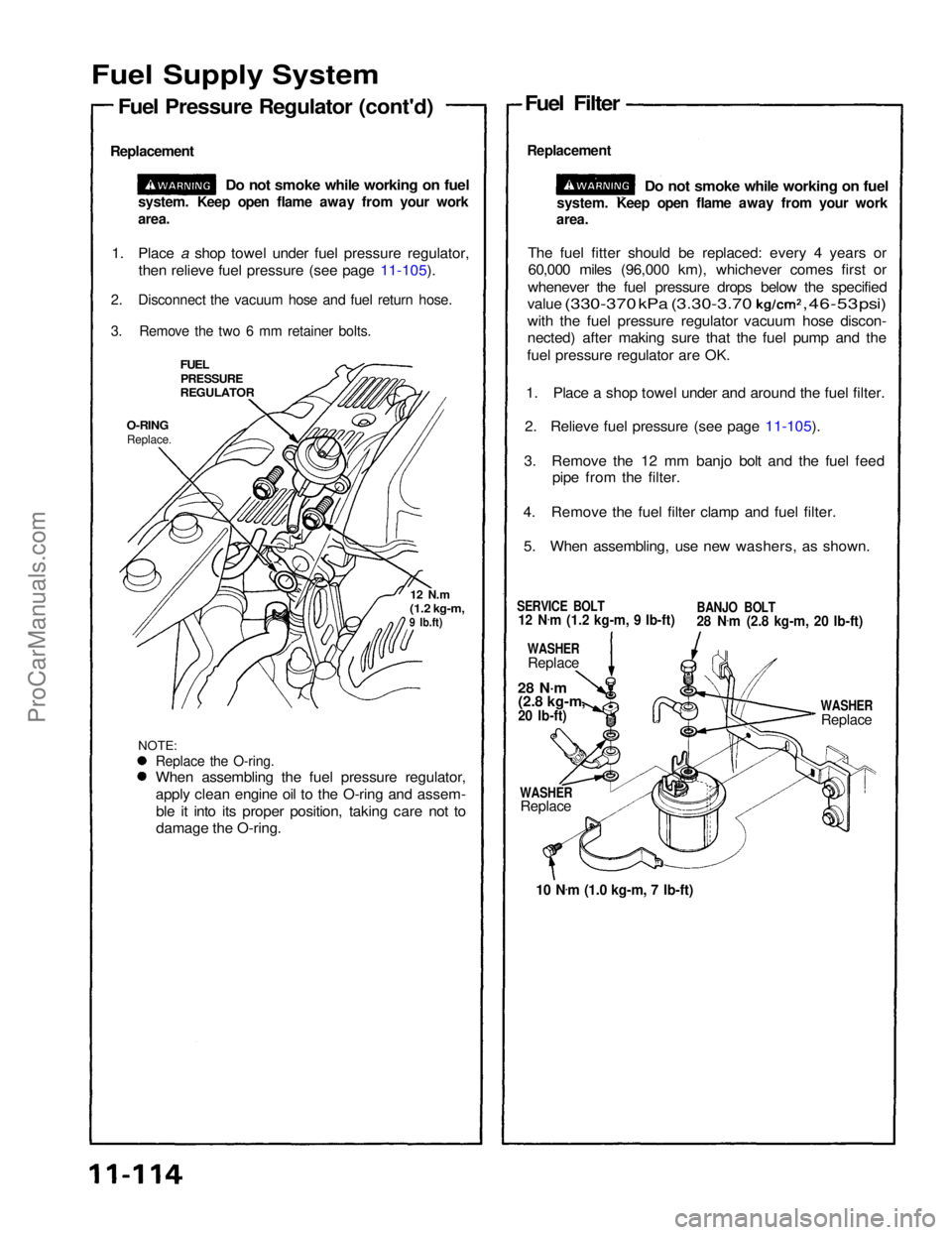

Replacement

Do not smoke while working on fuel Fuel Filter

Replacement

Do not smoke while working on fuel

The fuel fitter should be replaced: every 4 years or 60,000 miles (96,000 km), whichever comes first or

whenever the fuel pressure drops below the specified value

(330-370

kPa

(3.30-3.70

,

46-53

psi)

with the fuel pressure regulator vacuum hose discon-

nected) after making sure that the fuel pump and the

fuel pressure regulator are OK.

1. Place a shop towel under and around the fuel filter.

2. Relieve fuel pressure (see page 11-105).

3. Remove the 12 mm banjo bolt and the fuel feed pipe from the filter.

4. Remove the fuel filter clamp and fuel filter. 5. When assembling, use new washers, as shown.

1. Place a shop towel under fuel pressure regulator,

then relieve fuel pressure (see page 11-105).

2. Disconnect the vacuum hose and fuel return hose.

3. Remove the two 6 mm retainer bolts.

FUEL

PRESSURE

REGULATOR

O-RING

Replace.

NOTE:

12 N.m

(1.2 kg-m,

9 Ib.ft)

SERVICE BOLT

12 N .

m (1.2 kg-m, 9 Ib-ft)

BANJO BOLT

28 N

.

m (2.8 kg-m, 20 Ib-ft)

WASHER

Replace

28 N·m

(2.8 kg-m,

20 Ib-ft)

WASHER

Replace

10 N .

m (1.0 kg-m, 7 Ib-ft)

WASHER

Replace

system. Keep open flame away from your work

area.

system. Keep open flame away from your work

area.

Replace the O-ring.

When assembling the fuel pressure regulator,

apply clean engine oil to the O-ring and assem-ble it into its proper position, taking care not to

damage the O-ring.ProCarManuals.com

Page 1116 of 1640

Fuel Supply System

Fuel Pressure Regulator (cont'd)

Replacement

Do not smoke while working on fuel Fuel Filter

Replacement

Do not smoke while working on fuel

The fuel fitter should be replaced: every 4 years or 60,000 miles (96,000 km), whichever comes first or

whenever the fuel pressure drops below the specified value

(330-370

kPa

(3.30-3.70

,

46-53

psi)

with the fuel pressure regulator vacuum hose discon-

nected) after making sure that the fuel pump and the

fuel pressure regulator are OK.

1. Place a shop towel under and around the fuel filter.

2. Relieve fuel pressure (see page 11-105).

3. Remove the 12 mm banjo bolt and the fuel feed pipe from the filter.

4. Remove the fuel filter clamp and fuel filter. 5. When assembling, use new washers, as shown.

1. Place a shop towel under fuel pressure regulator,

then relieve fuel pressure (see page 11-105).

2. Disconnect the vacuum hose and fuel return hose.

3. Remove the two 6 mm retainer bolts.

FUEL

PRESSURE

REGULATOR

O-RING

Replace.

NOTE:

12 N.m

(1.2 kg-m,

9 Ib.ft)

SERVICE BOLT

12 N .

m (1.2 kg-m, 9 Ib-ft)

BANJO BOLT

28 N

.

m (2.8 kg-m, 20 Ib-ft)

WASHER

Replace

28 N·m

(2.8 kg-m,

20 Ib-ft)

WASHER

Replace

10 N .

m (1.0 kg-m, 7 Ib-ft)

WASHER

Replace

system. Keep open flame away from your work

area.

system. Keep open flame away from your work

area.

Replace the O-ring.

When assembling the fuel pressure regulator,

apply clean engine oil to the O-ring and assem-ble it into its proper position, taking care not to

damage the O-ring.ProCarManuals.com

Page 1117 of 1640

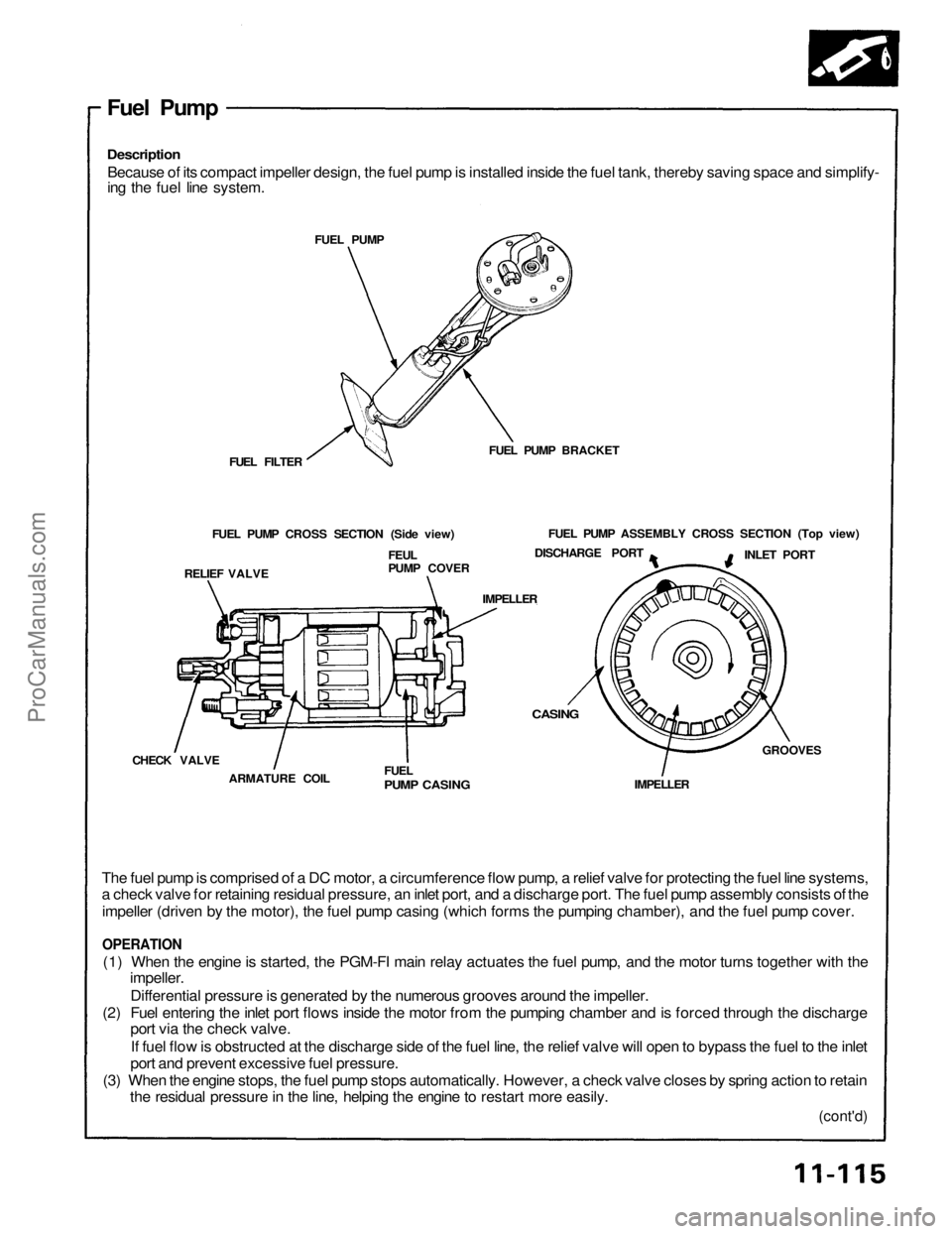

Fuel Pump

Description

Because of its compact impeller design, the fuel pump is installed inside the fuel tank, thereby saving space and simplify-

ing the fuel line system.

FUEL PUMP

FUEL PUMP BRACKET

FUEL FILTER

FUEL PUMP CROSS SECTION (Side view)

RELIEF VALVE

FEUL

PUMP COVER

FUEL PUMP ASSEMBLY CROSS SECTION (Top view)

DISCHARGE PORT

INLET PORT

IMPELLER

CHECK VALVE

ARMATURE COIL

FUEL

PUMP CASING

IMPELLER

GROOVES

CASING

The fuel pump is comprised of a DC motor, a circumference flow pump, a relief valve for protecting the fuel line systems,

a check valve for retaining residual pressure, an inlet port, and a discharge port. The fuel pump assembly consists of the

impeller (driven by the motor), the fuel pump casing (which forms the pumping chamber), and the fuel pump cover.

OPERATION

(1) When the engine is started, the PGM-FI main relay actuates the fuel pump, and the motor turns together with the

impeller.

Differential pressure is generated by the numerous grooves around the impeller.

(2) Fuel entering the inlet port flows inside the motor from the pumping chamber and is forced through the discharge

port via the check valve.

If fuel flow is obstructed at the discharge side of the fuel line, the relief valve will open to bypass the fuel to the inlet

port and prevent excessive fuel pressure.

(3) When the engine stops, the fuel pump stops automatically. However, a check valve closes by spring action to retain

the residual pressure in the line, helping the engine to restart more easily.

(cont'd)ProCarManuals.com

Page 1119 of 1640

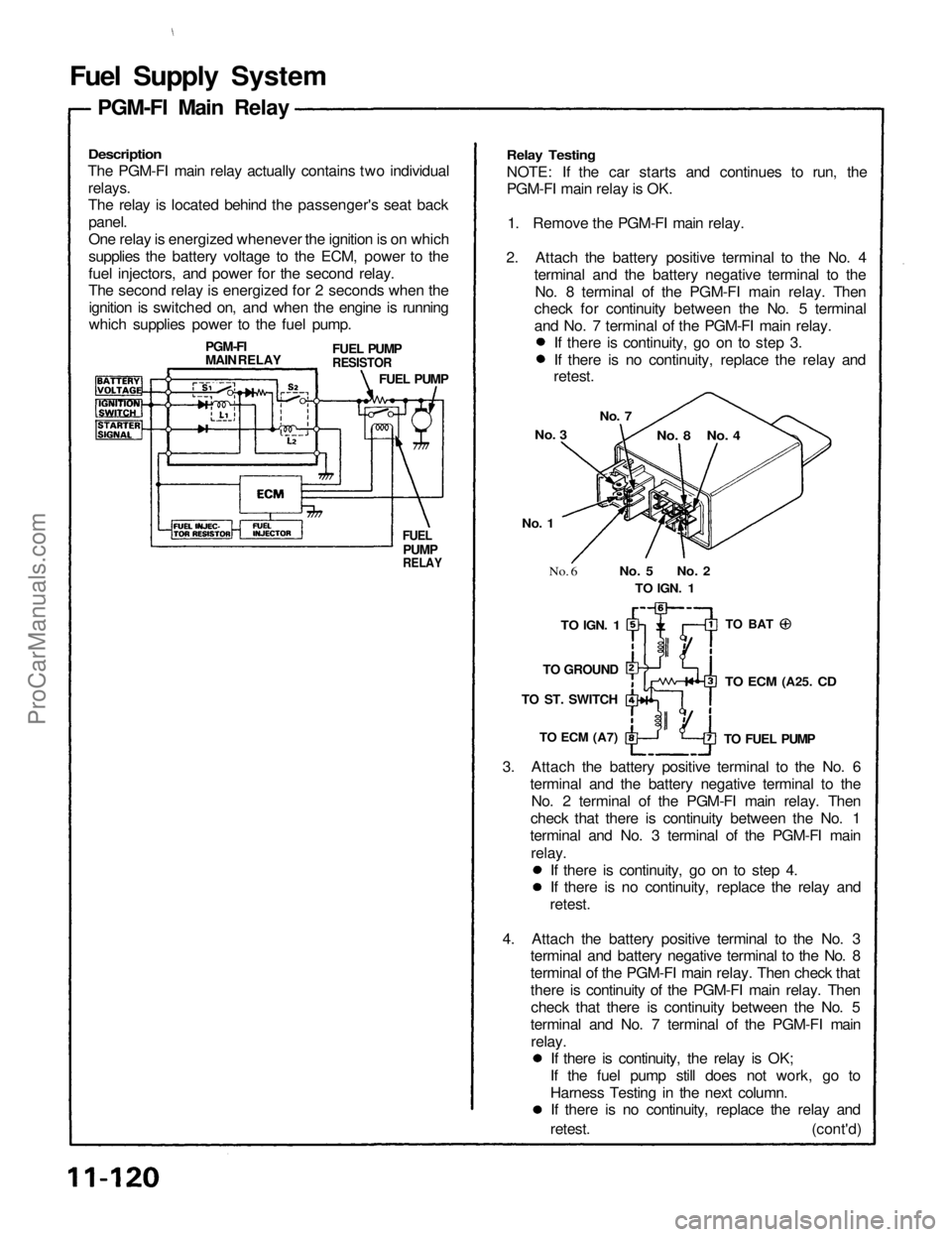

Fuel Supply System

Description

The PGM-FI main relay actually contains two individual

relays.

The relay is located behind the passenger's seat backpanel.

One relay is energized whenever the ignition is on which

supplies the battery voltage to the ECM, power to the

fuel injectors, and power for the second relay.

The second relay is energized for 2 seconds when theignition is switched on, and when the engine is running

which supplies power to the fuel pump.

Relay Testing

NOTE: If the car starts and continues to run, the

PGM-FI main relay is OK.

1. Remove the PGM-FI main relay.

2. Attach the battery positive terminal to the No. 4 terminal and the battery negative terminal to theNo. 8 terminal of the PGM-FI main relay. Then

check for continuity between the No. 5 terminal

and No. 7 terminal of the PGM-FI main relay.

3. Attach the battery positive terminal to the No. 6 terminal and the battery negative terminal to theNo. 2 terminal of the PGM-FI main relay. Then

check that there is continuity between the No. 1

terminal and No. 3 terminal of the PGM-FI main

relay.

FUEL

PUMP

RELAY

FUEL PUMP

RESISTOR

FUEL PUMP

PGM-FI

MAIN RELAY

No. 3

No. 7

No. 8 No. 4

No. 1

No. 6

No. 5 No. 2

TO

IGN.

1

TO BAT

TO

IGN.

1

TO GROUND

TO ST. SWITCH

TO ECM

(A7)

TO ECM

(A25.

CD

TO FUEL PUMP

PGM-FI Main Relay

If there is continuity, go on to step 4.

If there is no continuity, replace the relay and

retest.

4. Attach the battery positive terminal to the No. 3 terminal and battery negative terminal to the No. 8

terminal of the PGM-FI main relay. Then check that

there is continuity of the PGM-FI main relay. Then

check that there is continuity between the No. 5

terminal and No. 7 terminal of the PGM-FI main relay. If there is continuity, the relay is OK;

If the fuel pump still does not work, go to

Harness Testing in the next column. If there is no continuity, replace the relay and

retest. (cont'd) If there is continuity, go on to step 3.

If there is no continuity, replace the relay and

retest.ProCarManuals.com

Page 1120 of 1640

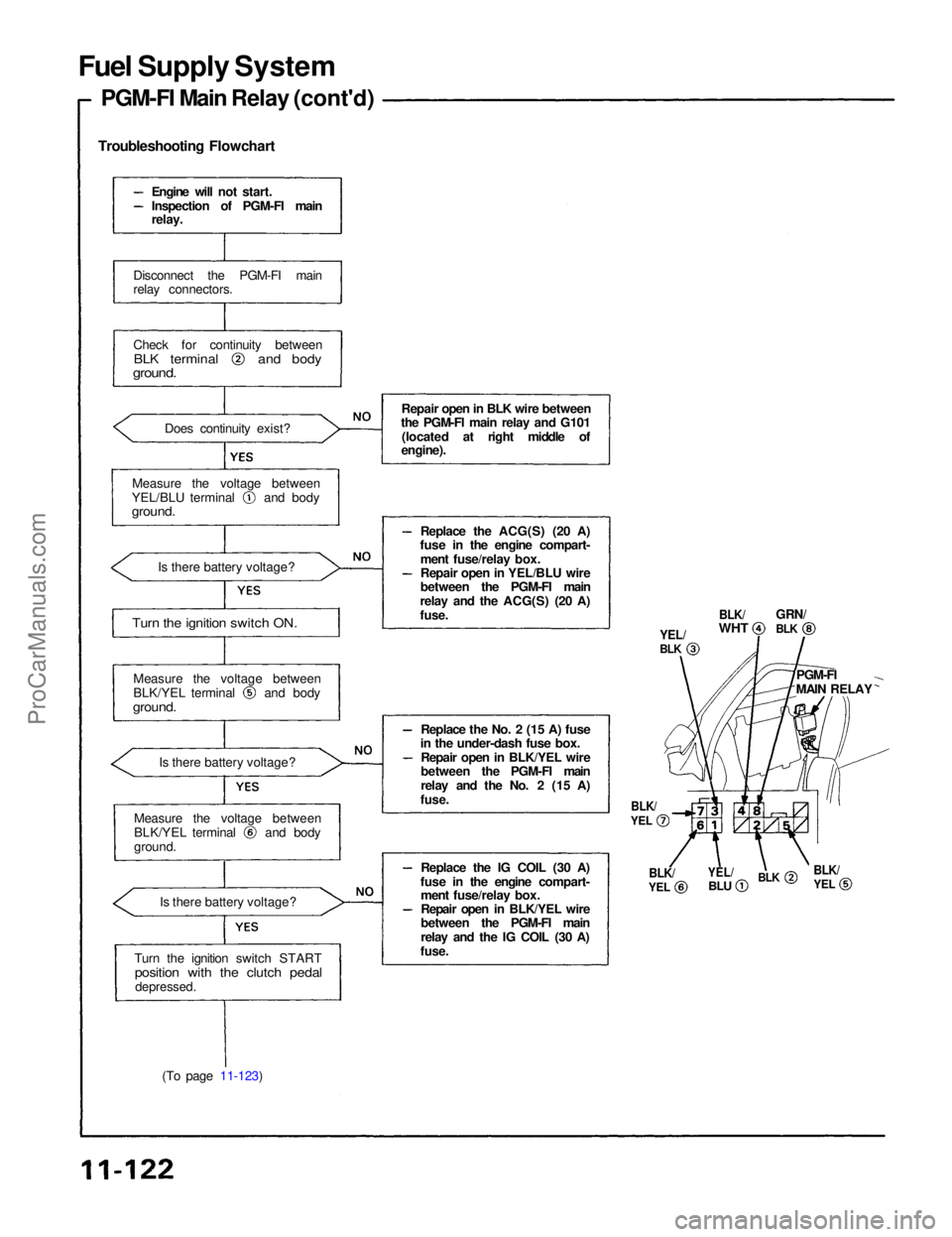

Fuel Supply System

PGM-FI Main Relay (cont'd)

Troubleshooting Flowchart

(To page 11-123)

BLK/

WHT

GRN/

YEL/

BLK

PGM-FI

MAIN RELAY

BLK/

YEL

BLK

YEL/

BLU

BLK/

YEL

BLK/

YEL

BLK

Engine will not start.

Inspection of PGM-FI main

relay.

Disconnect the PGM-FI main

relay connectors.

Check for continuity between

BLK terminal and body

ground.

Does continuity exist?

Measure the voltage between YEL/BLU terminal and body

ground.

Is there battery voltage?

Turn the ignition switch ON.

Measure the voltage between BLK/YEL terminal and body

ground.

Is there battery voltage?

Measure the voltage between BLK/YEL terminal and body

ground.

Is there battery voltage?

Turn the ignition switch START

position with the clutch pedal

depressed.

Repair open in BLK wire between

the PGM-FI main relay and G101

(located at right middle of

engine).

Replace the ACG(S) (20 A)

fuse in the engine compart-

ment fuse/relay box.

Repair open in YEL/BLU wire

between the PGM-FI main

relay and the ACG(S) (20 A)

fuse.

Replace the No. 2 (15 A) fuse

in the under-dash fuse box.

Repair open in BLK/YEL wire

between the PGM-FI main

relay and the No. 2 (15 A)

fuse.

Replace the IG COIL (30 A)

fuse in the engine compart- ment fuse/relay box.

Repair open in BLK/YEL wire

between the PGM-FI main

relay and the IG COIL (30 A)

fuse.ProCarManuals.com

Page 1121 of 1640

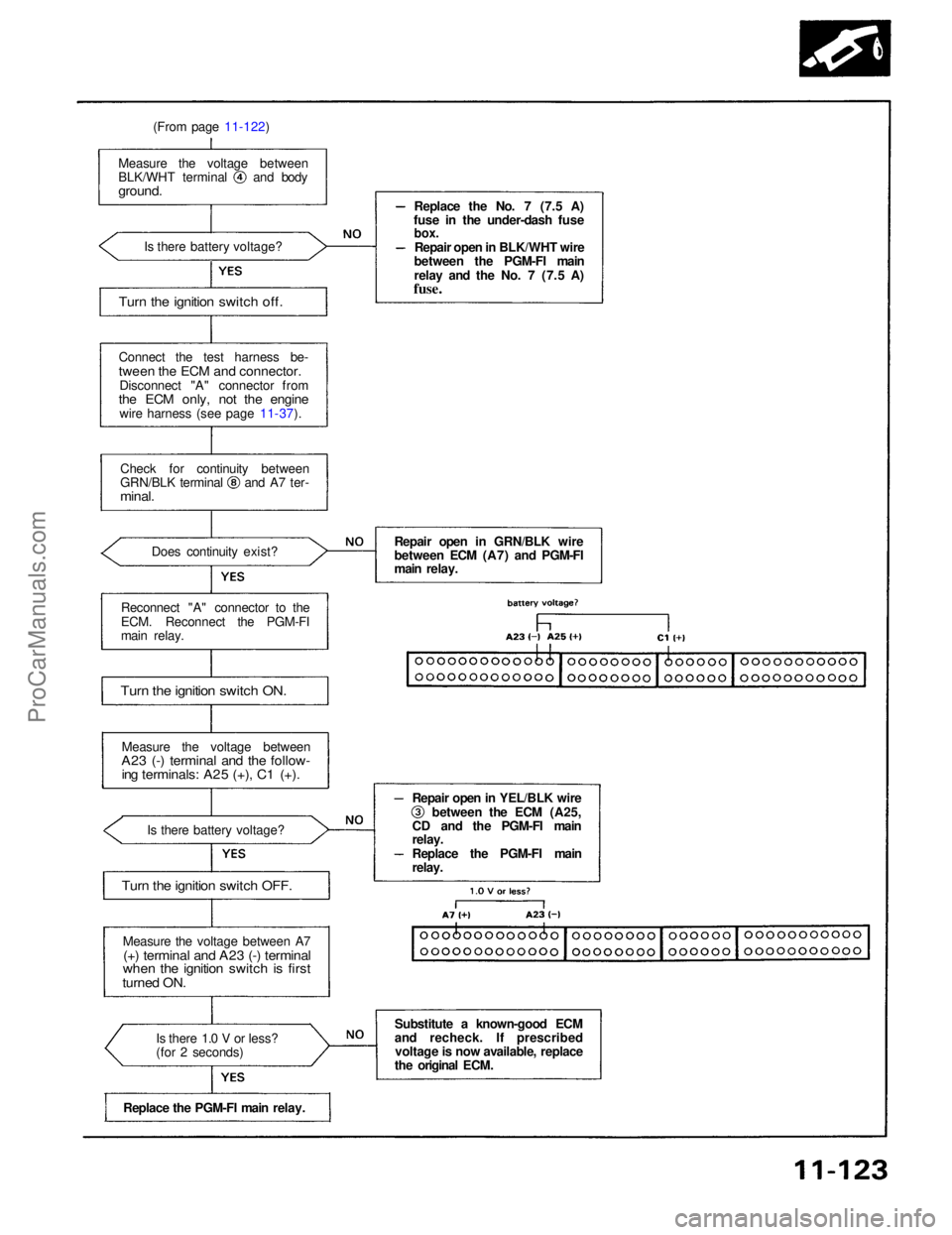

(From page 11-122)

Connect the test harness be-

tween the ECM and connector.

Disconnect "A" connector from

the ECM only, not the engine

wire harness (see page 11-37).

Measure the voltage between BLK/WHT terminal and body

ground.

Is there battery voltage?

Check for continuity between GRN/BLK terminal and A7 ter-

minal.

Does continuity exist?

Reconnect "A" connector to the

ECM. Reconnect the PGM-FI

main relay.

Turn the ignition switch ON.

Measure the voltage between

A23 (-) terminal and the follow-

ing terminals: A25 (+), C1 (+).

Is there battery voltage?

Turn the ignition switch OFF.

Measure the voltage between A7

(+) terminal and A23 (-) terminal

when the ignition switch is first

turned ON.

Is there 1.0 V or less?

(for 2 seconds)

Replace the PGM-FI main relay. Replace the No. 7 (7.5 A)

fuse in the under-dash fuse

box.

Repair open in BLK/WHT wire

between the PGM-FI main

relay and the No. 7 (7.5 A)

fuse.

Repair open in GRN/BLK wire

between ECM (A7) and PGM-FI

main relay. Repair open in YEL/BLK wire between the ECM (A25,

CD and the PGM-FI main

relay.

Replace the PGM-FI main

relay.

Substitute a known-good ECM

and recheck. If prescribed voltage is now available, replace

the original ECM.

Turn the ignition switch off.ProCarManuals.com

Page 1122 of 1640

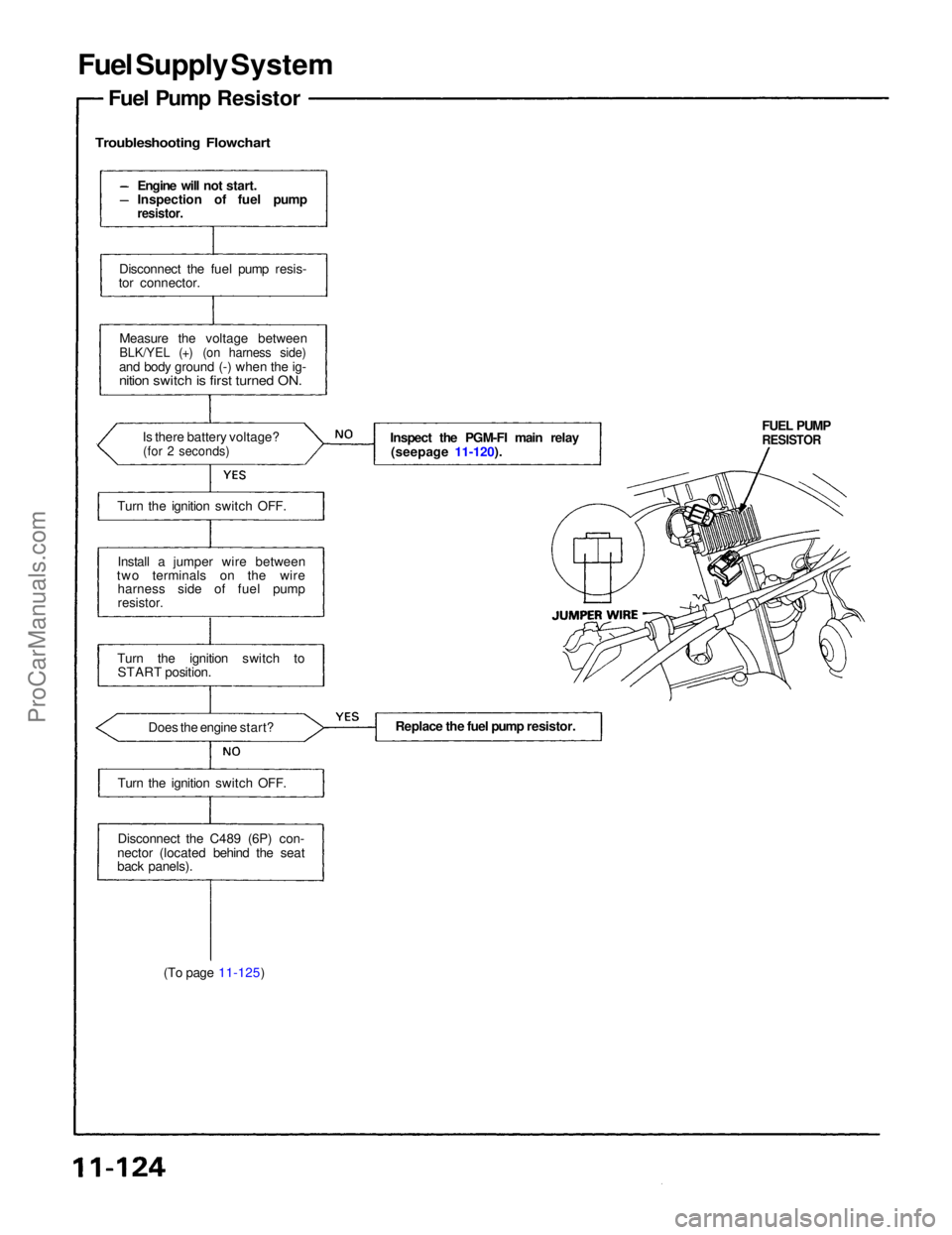

Fuel Supply System

Fuel Pump Resistor

Troubleshooting Flowchart

(To page 11-125) FUEL PUMP

RESISTOR

Inspect the PGM-FI main relay

(seepage 11-120).

Engine will not start.

Inspection of fuel pump

resistor.

Disconnect the fuel pump resis-

tor connector.

Measure the voltage between

BLK/YEL (+) (on harness side)

and body ground (-) when the ig-

nition switch is first turned ON.

Is there battery voltage?

(for 2 seconds)

Turn the ignition switch OFF.

Install a jumper wire between

two terminals on the wire harness side of fuel pump

resistor.

Turn the ignition switch to START position.

Does the engine start?

Turn the ignition switch OFF.

Disconnect the C489 (6P) con-

nector (located behind the seat

back panels). Replace the fuel pump resistor.ProCarManuals.com