check engine ACURA NSX 1991 Service User Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 242 of 1640

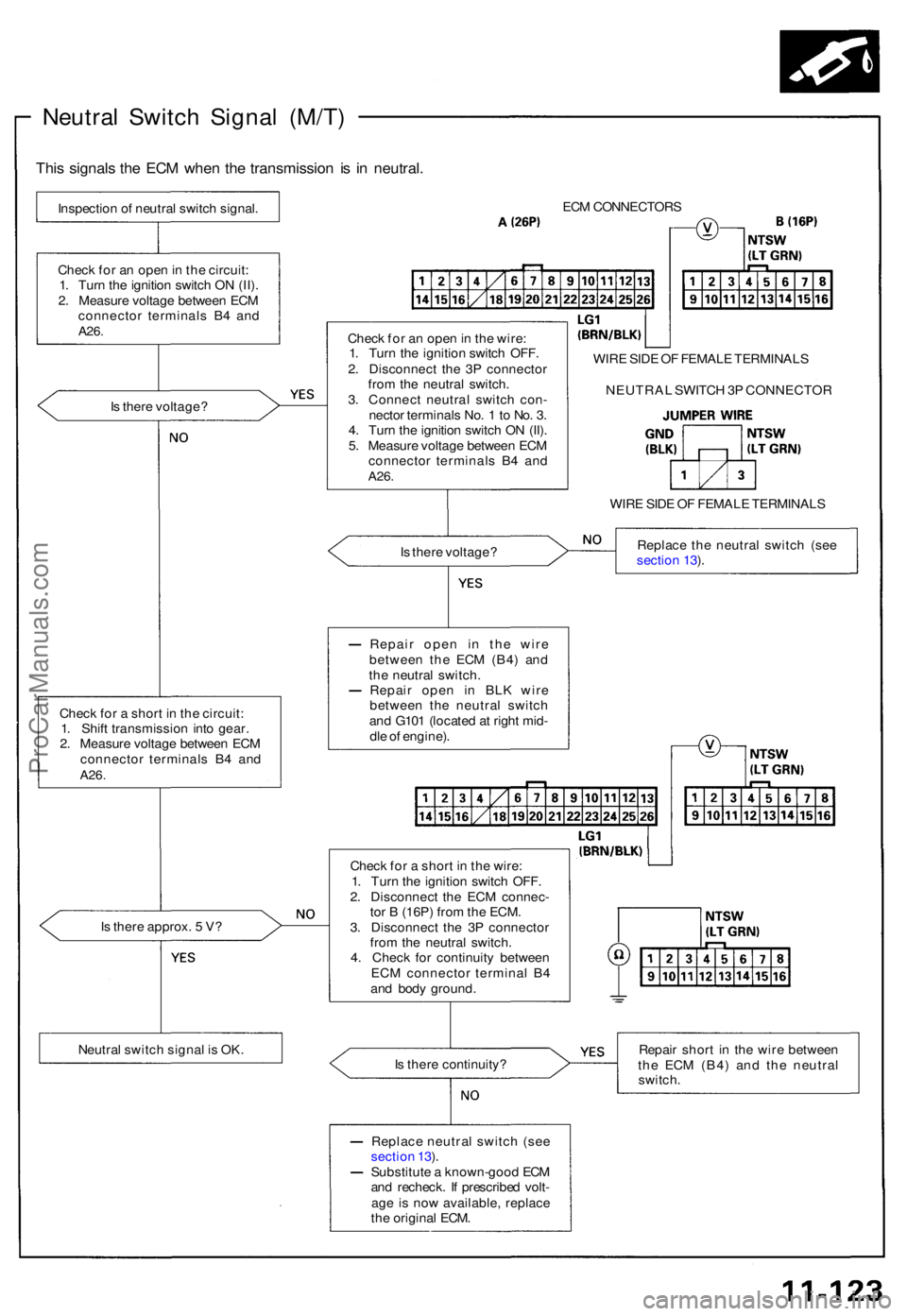

Neutral Switc h Signa l (M/T )

This signal s th e EC M whe n th e transmissio n i s i n neutral .

Inspectio n o f neutra l switc h signal .

Chec k fo r a n ope n in th e circuit :

1 . Tur n th e ignitio n switc h O N (II) .

2 . Measur e voltag e betwee n EC M

connecto r terminal s B 4 an d

A26 .

Is ther e voltage ?

Chec k fo r a shor t i n th e circuit :

1 . Shif t transmissio n int o gear .

2 . Measur e voltag e betwee n EC M

connecto r terminal s B 4 an d

A26 .

Is ther e approx . 5 V ?

Neutra l switc h signa l i s OK . EC

M CONNECTOR S

Chec k fo r a n ope n in th e wire :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e 3 P connecto r

fro m th e neutra l switch .

3 . Connec t neutra l switc h con -

necto r terminal s No . 1 to No . 3 .

4 . Tur n th e ignitio n switc h O N (II) .

5 . Measur e voltag e betwee n EC M

connecto r terminal s B 4 an d

A26 .

WIR E SID E O F FEMAL E TERMINAL S

WIR E SID E O F FEMAL E TERMINAL S

I s ther e voltage ? Replac

e th e neutra l switc h (se e

sectio n 13 ).

Repai r ope n i n th e wir e

betwee n th e EC M (B4 ) an d

th e neutra l switch .

Repai r ope n i n BL K wir e

betwee n th e neutra l switc h

an d G10 1 (locate d a t righ t mid -

dl e o f engine) .

Chec k fo r a shor t i n th e wire :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e EC M connec -

to r B (16P ) fro m th e ECM .

3 . Disconnec t th e 3 P connecto r

fro m th e neutra l switch .

4 . Chec k fo r continuit y betwee n

EC M connecto r termina l B 4

an d bod y ground .

I s ther e continuity ? Repai

r shor t i n th e wir e betwee n

th e EC M (B4 ) an d th e neutra l

switch .

Replac e neutra l switc h (se e

sectio n 13 ).

Substitut e a known-goo d EC M

an d recheck . I f prescribe d volt -

ag e i s no w available , replac e

th e origina l ECM . NEUTRA

L SWITC H 3 P CONNECTO R

ProCarManuals.com

Page 248 of 1640

6. Disconnect the SCS service connector.

7. Depress the accelerator pedal and stabilize the

engine speed at 1,000 rpm, then slowly release the

pedal until the engine idles, then check the idle

speed.

Idle speed should be:ProCarManuals.com

Page 259 of 1640

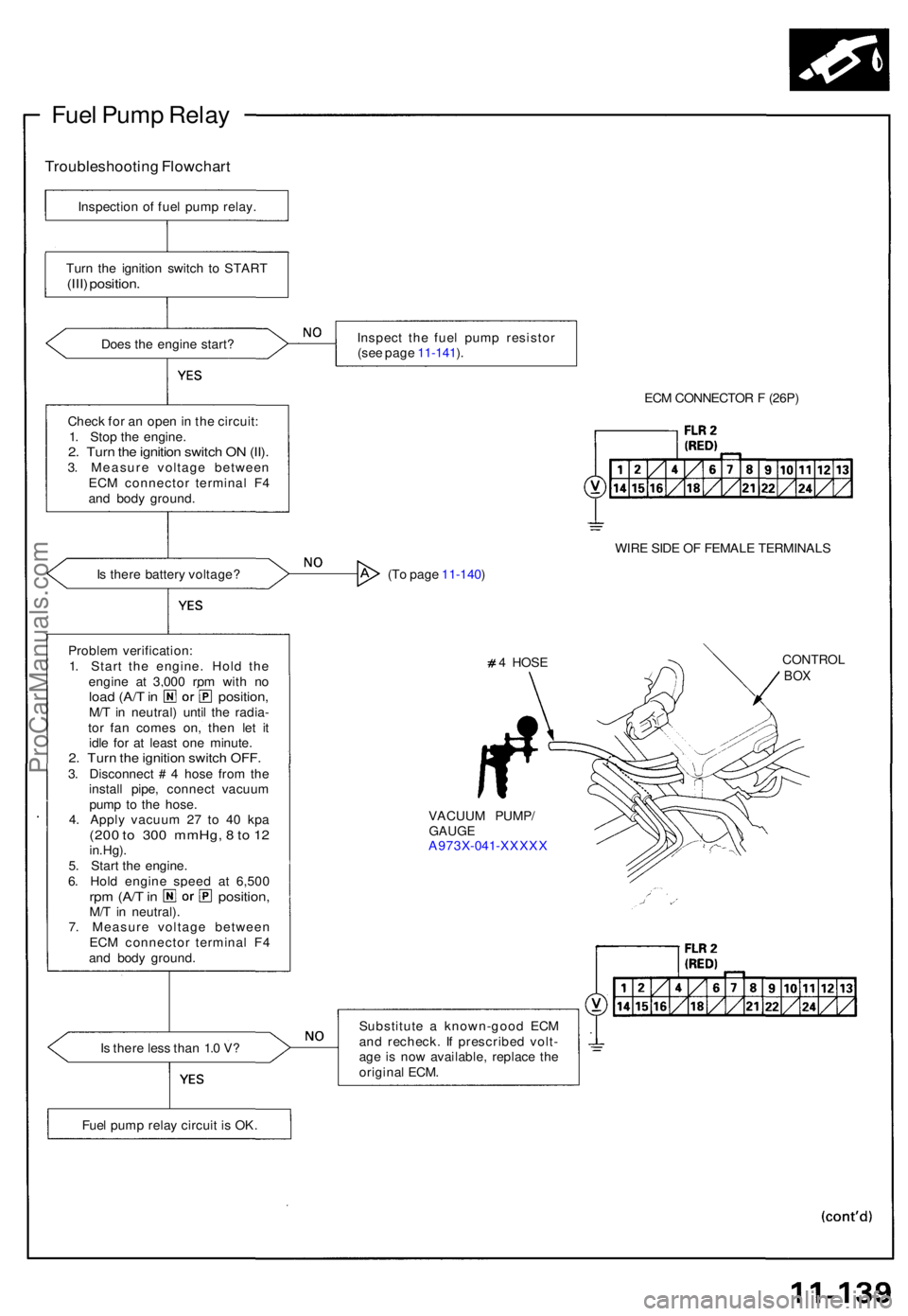

Fuel Pum p Rela y

Troubleshootin g Flowchar t

Inspection o f fue l pum p relay .

Tur n th e ignitio n switc h t o STAR T

(III) position .

Does th e engin e start ?

Chec k fo r a n ope n in th e circuit :

1 . Sto p th e engine .

2. Tur n th e ignitio n switc h O N (II) .3. Measur e voltag e betwee n

EC M connecto r termina l F 4

an d bod y ground .

I s ther e batter y voltage ?

Proble m verification :

1 . Star t th e engine . Hol d th e

engin e a t 3,00 0 rp m wit h n o

loa d (A/ T in position ,M/T in neutral ) unti l th e radia -

to r fa n come s on , the n le t i t

idl e fo r a t leas t on e minute .

2. Tur n th e ignitio n switc h OFF .3. Disconnec t # 4 hos e fro m th e

instal l pipe , connec t vacuu m

pum p t o th e hose .

4 . Appl y vacuu m 2 7 t o 4 0 kp a

(200 t o 300 mmHg , 8 to 1 2in.Hg) .

5 . Star t th e engine .

6 . Hol d engin e spee d a t 6,50 0

rpm (A/ T in position ,M/T in neutral) .

7 . Measur e voltag e betwee n

EC M connecto r termina l F 4

an d bod y ground .

I s ther e les s tha n 1. 0 V ? Inspec

t th e fue l pum p resisto r

(se e pag e 11-141 ).

ECM CONNECTO R F (26P )

WIR E SID E O F FEMAL E TERMINAL S

(T o pag e 11-140 )

4 HOS E

CONTRO LBOX

VACUU M PUMP /GAUGEA973X-04 1-XXXX X

Substitut e a known-goo d EC M

an d recheck . I f prescribe d volt -

ag e i s no w available , replac e th e

origina l ECM .

Fue l pum p rela y circui t i s OK .

ProCarManuals.com

Page 296 of 1640

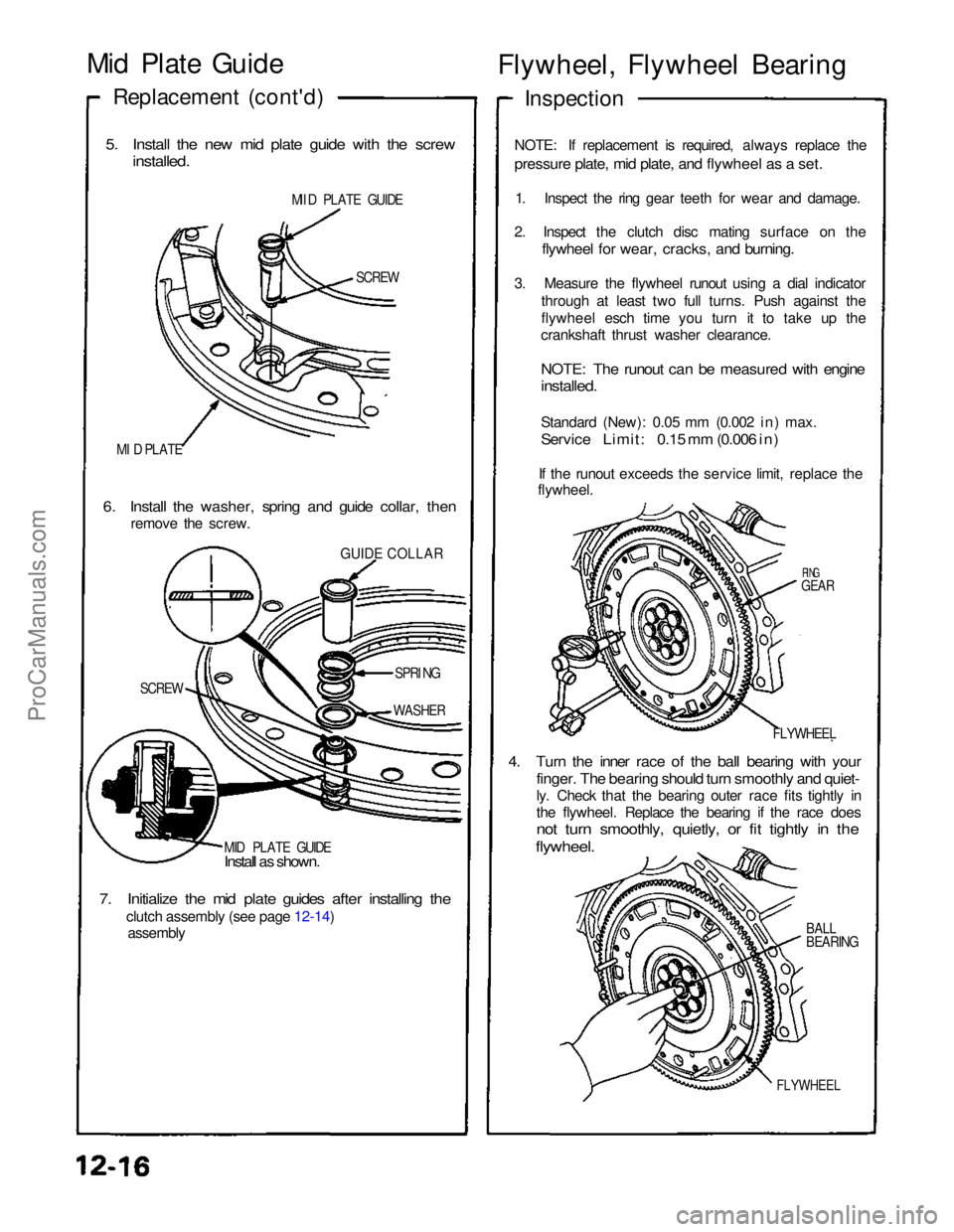

Mid Plate Guide

Replacement (cont'd)

5. Install the new mid plate guide with the screw

installed.

MII D PLATE GUIDE

SCREW

MI D PLATE

6. Install the washer, spring and guide collar, then

remove the screw.

GUIDE COLLAR

SCREW SPRI

NG

WASHER

MID PLATE GUIDE

Install as shown.

7. Initialize the mid plate guides after installing the

clutch assembly (see page 12-14)

assembly Flywheel, Flywheel Bearing

Inspection

NOTE: If replacement is required, always replace the

pressure plate, mid plate, and flywheel as a set.

1. Inspect the ring gear teeth for wear and damage.

2. Inspect the clutch disc mating surface on the

flywheel for wear, cracks, and burning.

3. Measure the flywheel runout using a dial indicator through at least two full turns. Push against the

flywheel esch time you turn it to take up the

crankshaft thrust washer clearance.

NOTE: The runout can be measured with engine

installed.

Standard (New): 0.05 mm (0.002 in) max.

Service Limit: 0.15 mm (0.006 in)

If the runout exceeds the service limit, replace the

flywheel.

RING

GEAR

FLYWHEEL

4. Turn the inner race of the ball bearing with your

finger. The bearing should turn smoothly and quiet-

ly. Check that the bearing outer race fits tightly in

the flywheel. Replace the bearing if the race does

not turn smoothly, quietly, or fit tightly in the

flywheel.

BALL

BEARING

FLYWHEELProCarManuals.com

Page 420 of 1640

Troubleshooting Precautions

EPS Indicator Light

Under normal conditions, the EPS indicator light in the gauge assembly comes on when the ignition switch is turned to

the ON (II) position, then goes off after the engine is started. This indicates that the bulb and its circuits are operating cor-

rectly. If there is any trouble in the system, the EPS indicator light turns on during driving, and the power steering assist is

turned off. When the EPS indicator light comes on, the control unit memorizes the DTC. In this case, the control unit does

not activate the EPS system after the engine starts again but it keeps the EPS indicator light on.

Diagnostic Trouble Code (DTC)

• The lowest DTC is indicated first.

• The DTCs continue blinking until the ignition switch is turned off.

• The DTCs are erased from the control unit when the EPS control unit VBU power supply or connector is disconnected.

• The EPS system can be reset and the control unit's memory can be erased by disconnecting the CLOCK (7.5 A) fuse for

more than ten seconds.

Self-diagnosis:

The CPU (central processing unit) controls the following when it detects a problem during self-diagnosis:

1. Turns the EPS indicator light ON to alert the driver.

2. Power assist stops, and normal manual steering operation resumes (except DTC 21 and DTC 33).

3. The EPS control unit memorizes the diagnostic trouble code (DTC).

4. After the DTC is stored in the control unit, the CPU stops self-diagnosis.

Troubleshooting:

• Before starting the troubleshooting, clear the DTC by disconnecting the CLOCK (7.5 A) fuse for ten seconds or more,

and test-drive the car. Check that the symptom of the trouble appears again, and then troubleshoot. If the problem is an

intermittent problem, the system does not become active after the engine starts even though the problem is solved.

• When both EPS indicator light and A/T "D" indicator light come on, perform the A/T troubleshooting first.

• When the customer's reported problem cannot be verified in the car, ask the customer about the conditions when the

EPS indicator light came ON, then test-drive the car under those conditions, if possible. If the EPS indicator light does

not come ON during the test, check for loose connections or poor contacts at the connectors by wiggling the harness,

etc.

• The connector terminal numbers are viewed from the wire side for the female terminals and from the terminal side for

the male terminals.

• After the repair, test-drive the car and check that the EPS indicator light does not come ON again during the test. (Refer

to the Symptom-to-System Chart for diagnostic period.)ProCarManuals.com

Page 521 of 1640

Anti-lock Brake System (ABS) Description

Features/Construction/Operation (cont'd)

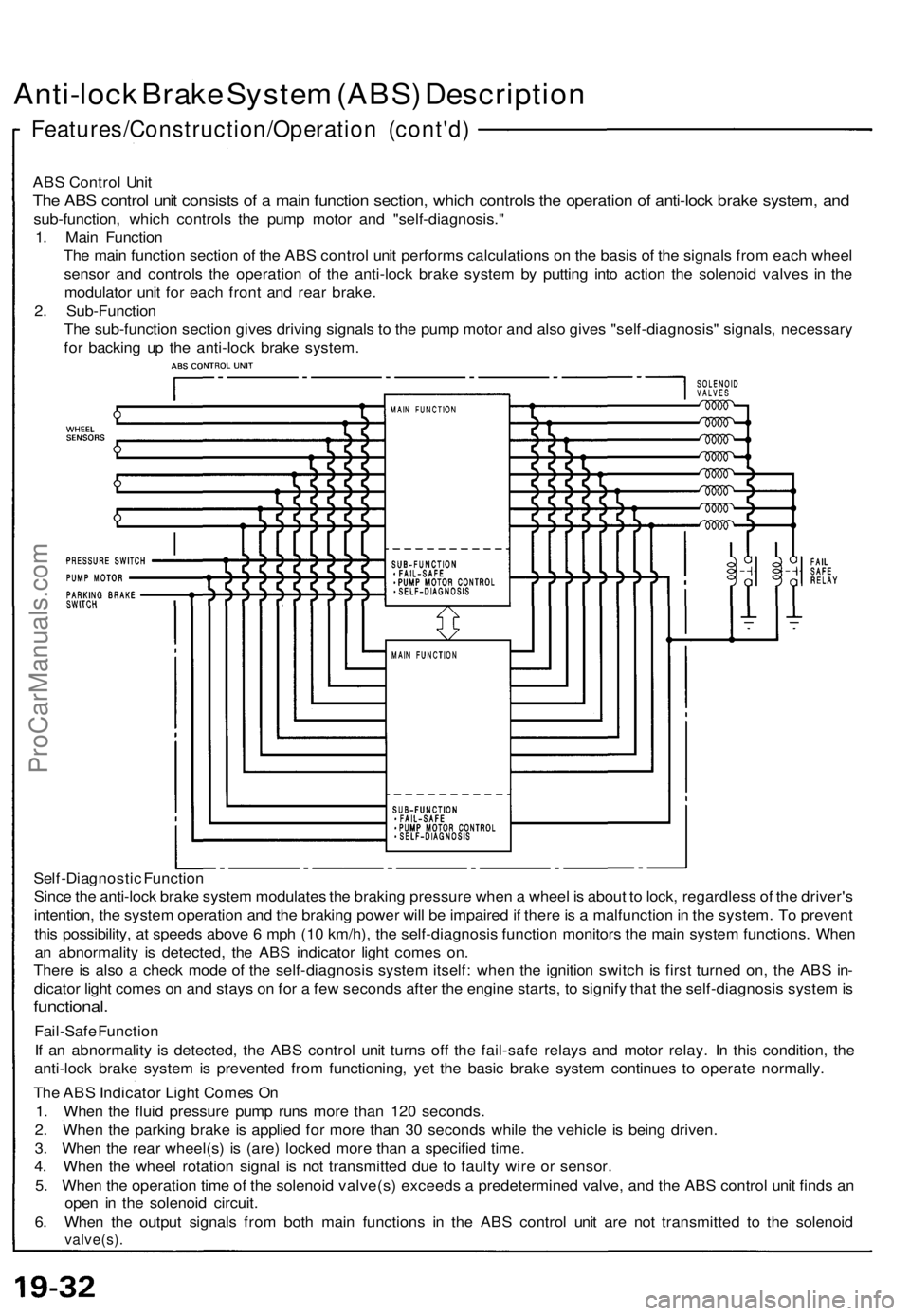

ABS Control Unit

The ABS control unit consists of a main function section, which controls the operation of anti-lock brake system, and

sub-function, which controls the pump motor and "self-diagnosis."

1. Main Function

The main function section of the ABS control unit performs calculations on the basis of the signals from each wheel

sensor and controls the operation of the anti-lock brake system by putting into action the solenoid valves in the

modulator unit for each front and rear brake.

2. Sub-Function

The sub-function section gives driving signals to the pump motor and also gives "self-diagnosis" signals, necessary

for backing up the anti-lock brake system.

Self-Diagnostic Function

Since the anti-lock brake system modulates the braking pressure when a wheel is about to lock, regardless of the driver's

intention, the system operation and the braking power will be impaired if there is a malfunction in the system. To prevent

this possibility, at speeds above 6 mph (10 km/h), the self-diagnosis function monitors the main system functions. When

an abnormality is detected, the ABS indicator light comes on.

There is also a check mode of the self-diagnosis system itself: when the ignition switch is first turned on, the ABS in-

dicator light comes on and stays on for a few seconds after the engine starts, to signify that the self-diagnosis system is

functional.

Fail-Safe Function

If an abnormality is detected, the ABS control unit turns off the fail-safe relays and motor relay. In this condition, the

anti-lock brake system is prevented from functioning, yet the basic brake system continues to operate normally.

The ABS Indicator Light Comes On

1. When the fluid pressure pump runs more than 120 seconds.

2. When the parking brake is applied for more than 30 seconds while the vehicle is being driven.

3. When the rear wheel(s) is (are) locked more than a specified time.

4. When the wheel rotation signal is not transmitted due to faulty wire or sensor.

5. When the operation time of the solenoid valve(s) exceeds a predetermined valve, and the ABS control unit finds an

open in the solenoid circuit.

6. When the output signals from both main functions in the ABS control unit are not transmitted to the solenoid

valve(s).ProCarManuals.com

Page 531 of 1640

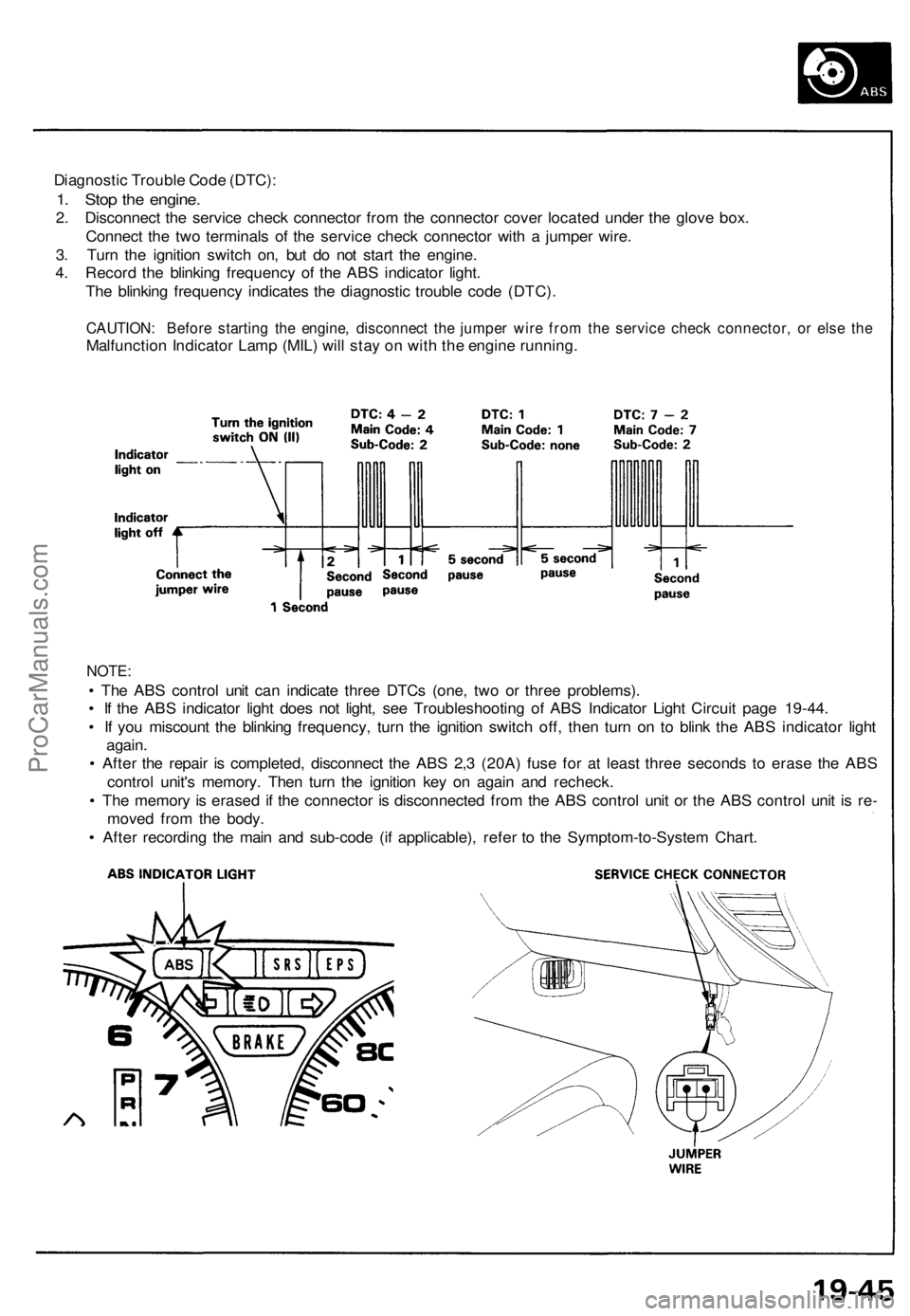

Diagnostic Trouble Code (DTC):

1. Stop the engine.

2. Disconnect the service check connector from the connector cover located under the glove box.

Connect the two terminals of the service check connector with a jumper wire.

3. Turn the ignition switch on, but do not start the engine.

4. Record the blinking frequency of the ABS indicator light.

The blinking frequency indicates the diagnostic trouble code (DTC).

CAUTION: Before starting the engine, disconnect the jumper wire from the service check connector, or else the

Malfunction Indicator Lamp (MIL) will stay on with the engine running.

NOTE:

• The ABS control unit can indicate three DTCs (one, two or three problems).

• If the ABS indicator light does not light, see Troubleshooting of ABS Indicator Light Circuit page 19-44.

• If you miscount the blinking frequency, turn the ignition switch off, then turn on to blink the ABS indicator light

again.

• After the repair is completed, disconnect the ABS 2,3 (20A) fuse for at least three seconds to erase the ABS

control unit's memory. Then turn the ignition key on again and recheck.

• The memory is erased if the connector is disconnected from the ABS control unit or the ABS control unit is re-

moved from the body.

• After recording the main and sub-code (if applicable), refer to the Symptom-to-System Chart.ProCarManuals.com

Page 558 of 1640

Steering angle sensor system check

1. Start the engine,

2. Push the TCS switch three times within three seconds.

NOTE: Always maintain the same number of rota-

tions.

3. Turn the steering wheel slowly from left to right more than 1.5 turns.

NOTE:

Start checking after the steering wheel moves at

least 1.5 turns from right to left.

Turn the steering wheel slowly, no faster than

one turn in four seconds.

4. Push the TCS switch twice within three seconds. NOTE: Always maintain the same number of rota-

tions.

5. Return the steering wheel to the left side slowly, and check the number of times the TCS indicator light

flashes after the wheel has moved approximately

one turn.

NOTE:

Start the check from the beginning when the steer-ing wheel moves at least one turn from left to

right, Turn the steering wheel slowly, no faster than one

turn in four seconds.

Standard number of times the TCS indicator light

flashes:

Manual Transmission: 5 times

Automatic Transmission: 2 times

6. If there is an abnormality, check the troubleshooting flowchart (see page 19-98('91-'93)('94-'96)

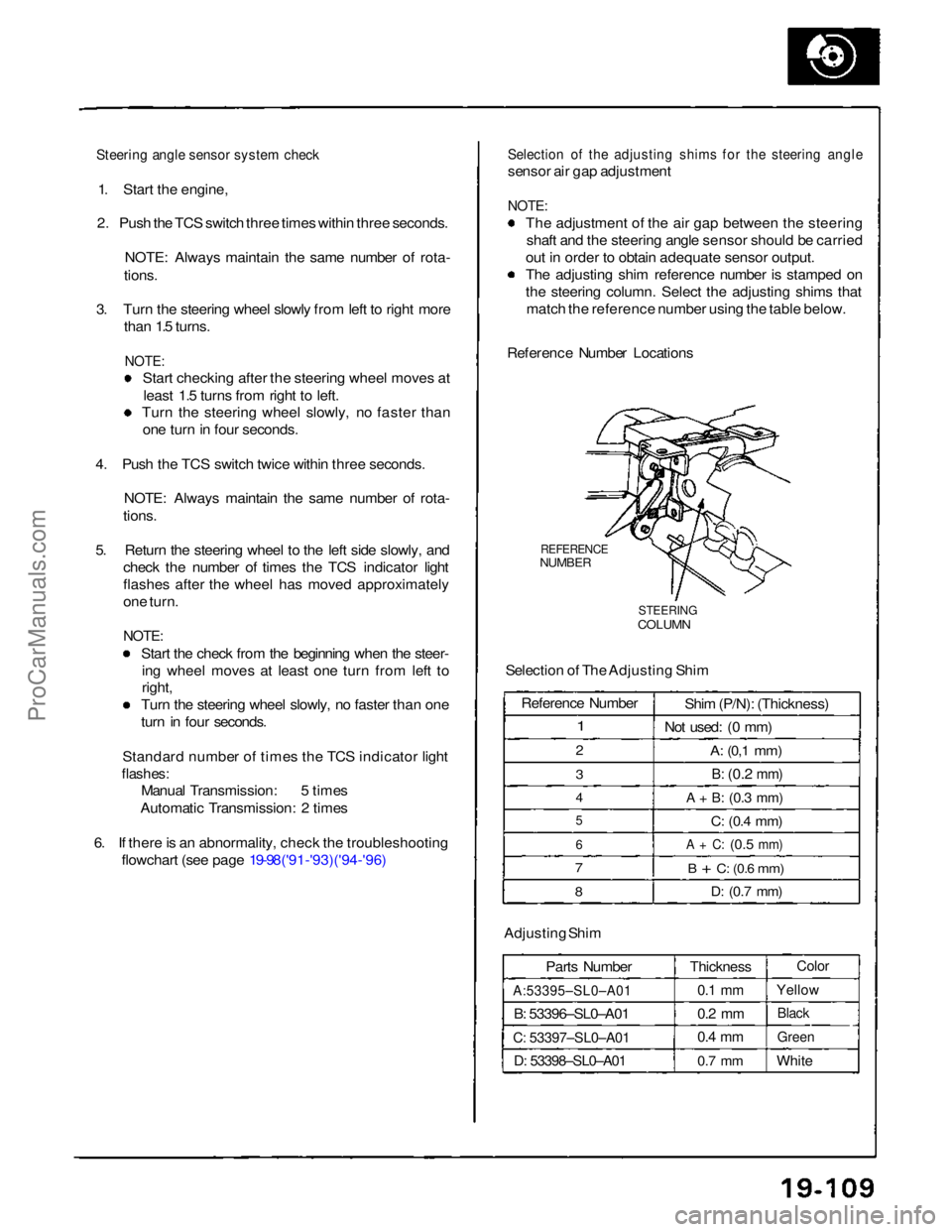

Selection of the adjusting shims for the steering angle

sensor air gap adjustment

NOTE:

The adjustment of the air gap between the steeringshaft and the steering angle sensor should be carried

out in order to obtain adequate sensor output.

The adjusting shim reference number is stamped on

the steering column. Select the adjusting shims that match the reference number using the table below.

Reference Number Locations

REFERENCE

NUMBER

STEERING

COLUMN

Selection of The Adjusting Shim

Adjusting Shim Parts Number

A:53395–SL0–A01

B: 53396–SL0–A01

C: 53397–SL0–A01

D: 53398–SL0–A01

Thickness

0.1 mm

0.2 mm

0.4 mm

0.7 mm

Color

Yellow

Black

Green

White

Reference Number

1

2

3

4

5

6

7

8

Shim (P/N): (Thickness)

Not used: (0 mm)

A:

(0,1

mm)

B:

(0.2

mm)

A + B:

(0.3

mm)

C:

(0.4

mm)

A + C:

(0.5

mm)

B + C:

(0.6

mm)

D:

(0.7

mm)ProCarManuals.com

Page 686 of 1640

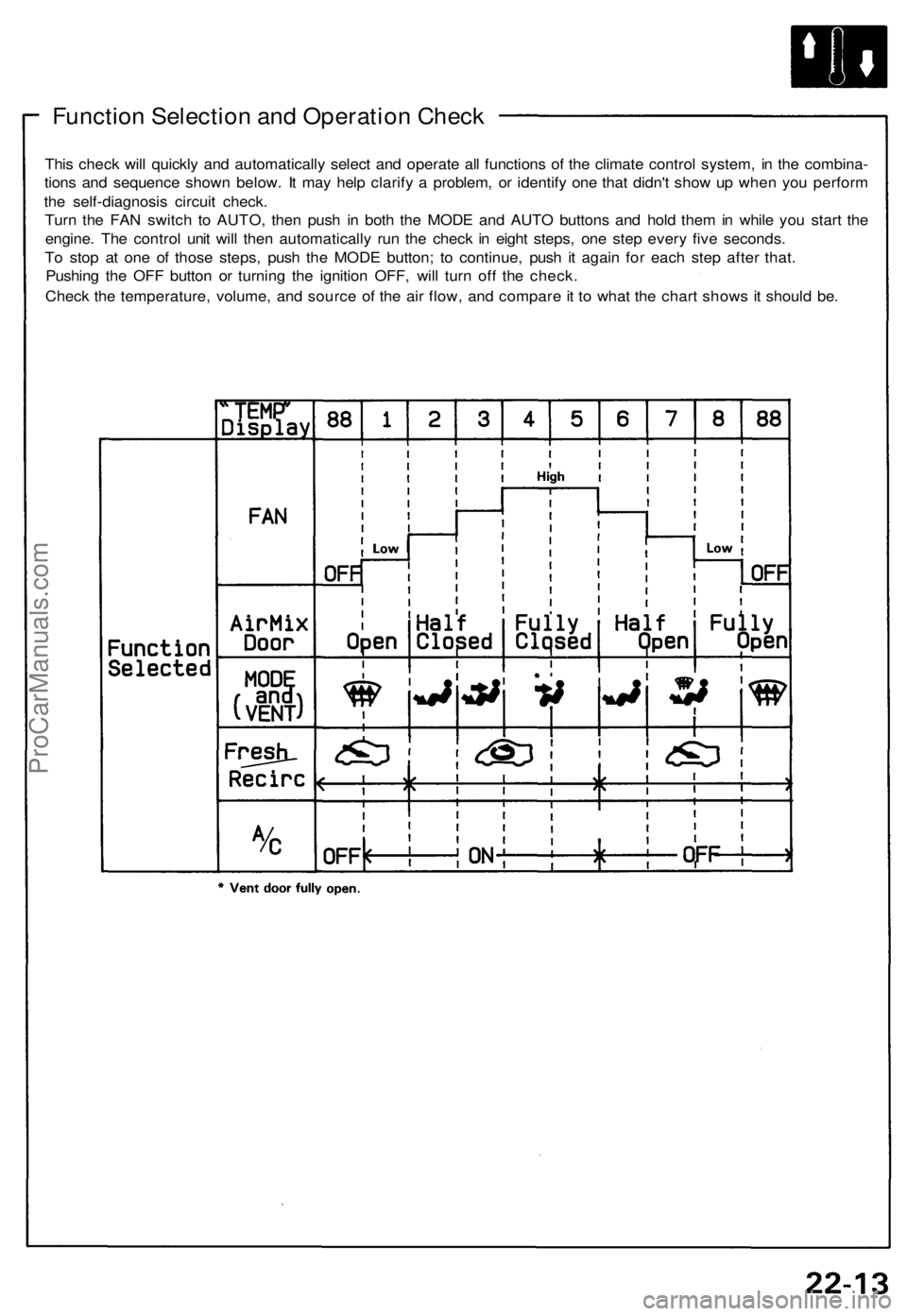

Function Selection and Operation Check

This check will quickly and automatically select and operate all functions of the climate control system, in the combina-

tions and sequence shown below. It may help clarify a problem, or identify one that didn't show up when you perform

the self-diagnosis circuit check.

Turn the FAN switch to AUTO, then push in both the MODE and AUTO buttons and hold them in while you start the

engine. The control unit will then automatically run the check in eight steps, one step every five seconds.

To stop at one of those steps, push the MODE button; to continue, push it again for each step after that.

Pushing the OFF button or turning the ignition OFF, will turn off the check.

Check the temperature, volume, and source of the air flow, and compare it to what the chart shows it should be.ProCarManuals.com

Page 687 of 1640

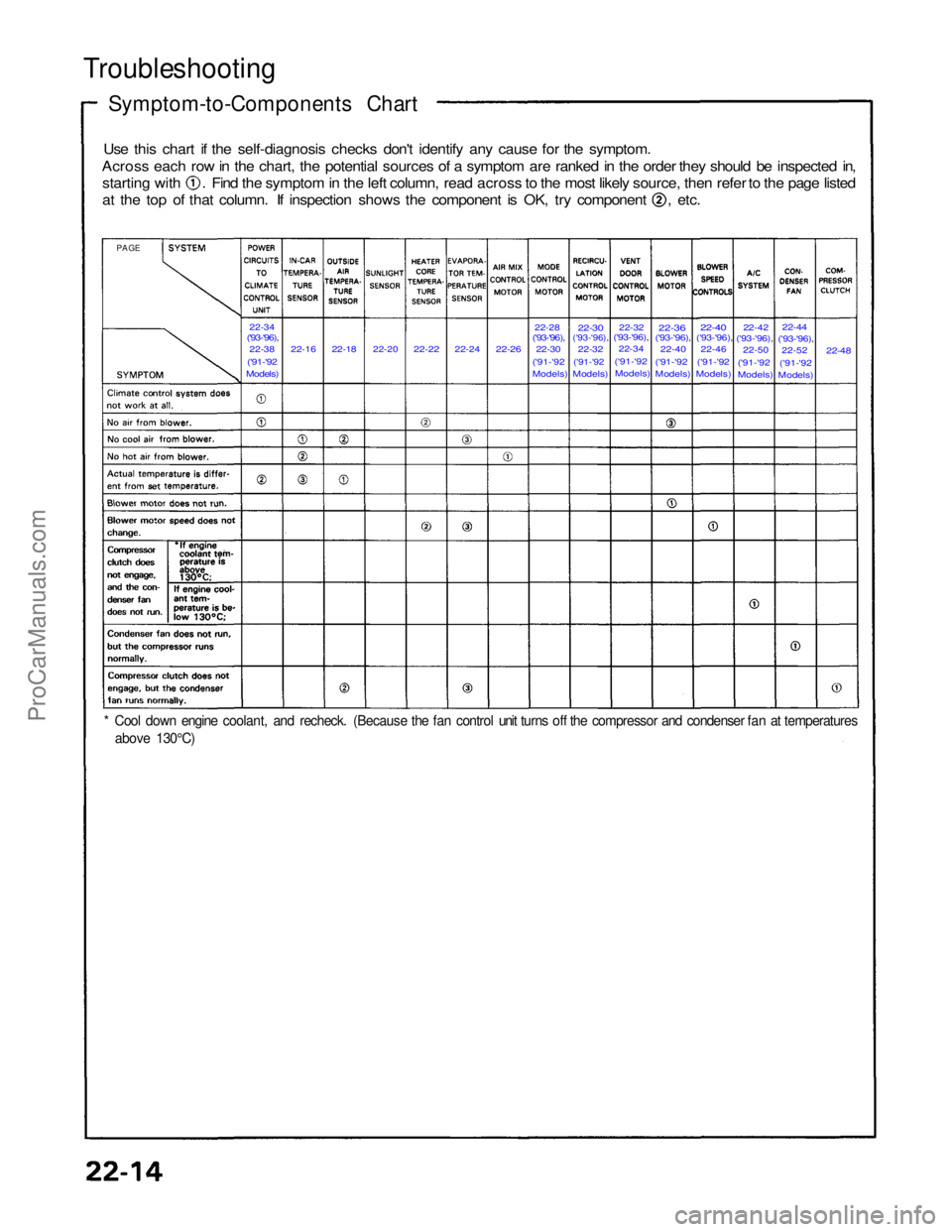

Troubleshooting

Symptom-to-Components Chart

Use this chart if the self-diagnosis checks don't identify any cause for the symptom.

Across each row in the chart, the potential sources of a symptom are ranked in the order they should be inspected in, starting with . Find the symptom in the left column, read across to the most likely source, then refer to the page listed

at the top of that column. If inspection shows the component is OK, try component , etc.

22-34

('93-'96),

22-38

('91-'92

Models)

22-16

22-18

22-20

22-22

22-24

22-26

22-30

('93-'96),22-28

('91-'92

Models)

22-30

('93-'96),

22-32

('91-'92

Models)

22-32

('93-'96),

22-34

('91-'92 Models)

22-36

('93-'96),

22-40

('91-'92 Models)

22-40

('93-'96),

22-46

('91-'92

Models)

22-42

('93-'96),

22-50

('91-'92 Models)

22-44

('93-'96),

22-52

('91-'92

Models)

22-48

PAGE

* Cool down engine coolant, and recheck. (Because the fan control unit turns off the compressor and condenser fan at temperatures above 130°C)ProCarManuals.com