check engine ACURA NSX 1991 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 729 of 1640

Troubleshooting

Tips and Precautions

Before Troubleshooting

• Check applicable fuses in the appropriate fuse box.

• Check the battery for damage, state of charge, and

clean and tight connections.

• Check the alternator belt tension.

CAUTION:

• Do not quick-charge a battery unless the battery

ground cable has been disconnected.

Otherwise you will damage the alternator

diodes.

• Do not attempt to crank the engine with the bat-

tery ground cable loosely connected or you will

severely damage the wiring.

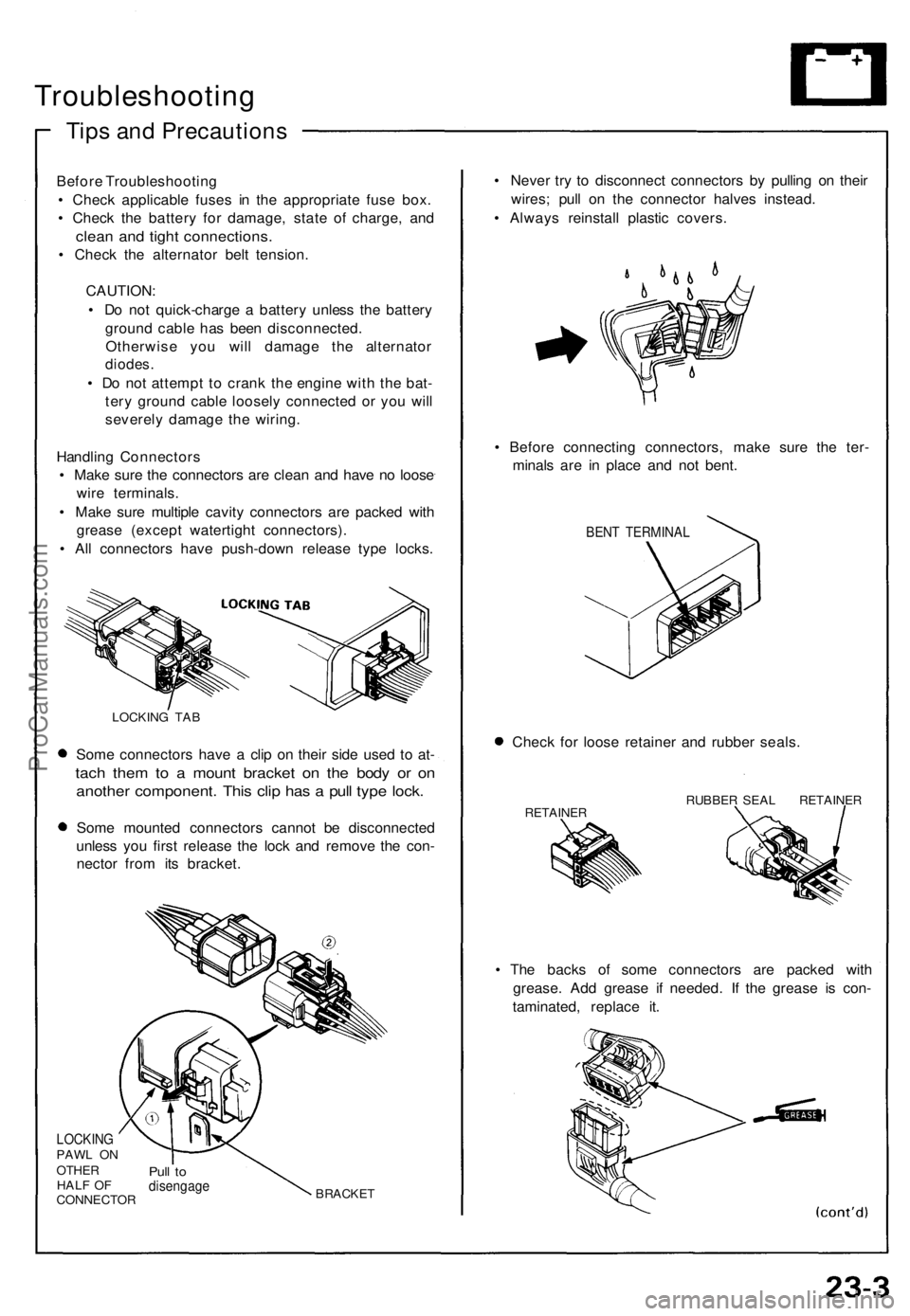

Handling Connectors

• Make sure the connectors are clean and have no loose

wire terminals.

• Make sure multiple cavity connectors are packed with

grease (except watertight connectors).

• All connectors have push-down release type locks.

LOCKING TAB

Some connectors have a clip on their side used to at-

tach them to a mount bracket on the body or on

another component. This clip has a pull type lock.

Some mounted connectors cannot be disconnected

unless you first release the lock and remove the con-

nector from its bracket.

LOCKING

PAWL ON

OTHER

HALF OF

CONNECTOR

Pull to

disengage

BRACKET

• Never try to disconnect connectors by pulling on their

wires; pull on the connector halves instead.

• Always reinstall plastic covers.

• Before connecting connectors, make sure the ter-

minals are in place and not bent.

BENT TERMINAL

Check for loose retainer and rubber seals.

RETAINER

RUBBER SEAL RETAINER

• The backs of some connectors are packed with

grease. Add grease if needed. If the grease is con-

taminated, replace it.ProCarManuals.com

Page 749 of 1640

- I f th e starte r stil l doe s no t cran k th e engine ,

remov e th e starte r an d diagnos e it s interna l

problems .

- I f th e starte r crank s th e engine , chec k fo r a n

ope n i n th e BLK/WH T wir e an d connector s be -

twee n th e starte r an d ignitio n switch . Chec k th e

ignitio n switch .

On car s wit h automati c transmission , chec k th e

A/ T gea r positio n switc h (neutra l positio n

switch ) an d connector .

O n car s with manua l transmission , chec k th e

starte r cu t relay , clutc h interloc k switc h an d

connectors .

NOTE : Chec k th e No . 2 9 (5 0 A ) fus e an d th e

starte r cu t relay , an d inspec t th e securit y alar m

system .

3 . Chec k fo r wea r o r damage :

Th e starte r shoul d cran k th e engin e smoothl y an d

steadily .

If th e starte r engages , bu t crank s th e engin e er -

ratically , remov e th e starte r motor . Inspec t th e

starter , driv e gea r an d flywhee l rin g gea r fo r

damage .

Check th e driv e gea r overrunnin g clutc h fo r bindin g

or slippin g whe n th e armatur e i s rotated with th e

driv e gea r held . Replac e th e gear s i f damaged .

4 . Chec k crankin g voltag e an d curren t draw :

Voltag e shoul d b e n o les s tha n 8. 5 volts .

Curren t shoul d b e n o mor e tha n 35 0 amperes .

I f voltag e i s to o low , o r curren t dra w to o high ,

chec k for :

• Lo w battery .

• Ope n circui t i n starte r armatur e commutato r

segments .

• Starte r armatur e dragging .

• Shorte d armatur e winding .

• Excessiv e dra g i n engine . 5

. Chec k crankin g rpm :

Engin e spee d durin g crankin g shoul d b e abov e 10 0

rpm .

If spee d i s to o low , chec k for :

Loos e batter y o r starte r terminals .

Excessivel y wor n starte r brushes .

Ope n circui t i n commutato r segments .

Dirt y o r damage d helica l splin e o r driv e gear .

Defectiv e driv e gea r overrunnin g clutch .

6 . Chec k th e starte r disengagement :

Depres s th e clutc h peda l al l th e wa y (M/T ) o r shif t

to positio n (A/T) , tur n th e ignitio n switc h

to "Star t (III) " an d releas e to O N (II) .

The starter drive gea r shoul d disengag e fro m th e

flywhee l rin g gear .

I f th e driv e gea r hang s u p o n th e flywhee l rin g gear ,

check :

• Solenoi d plunge r an d switc h fo r malfunction .

• Driv e gea r assembl y fo r dir t o r damage d over -

runnin g clutch .

ProCarManuals.com

Page 751 of 1640

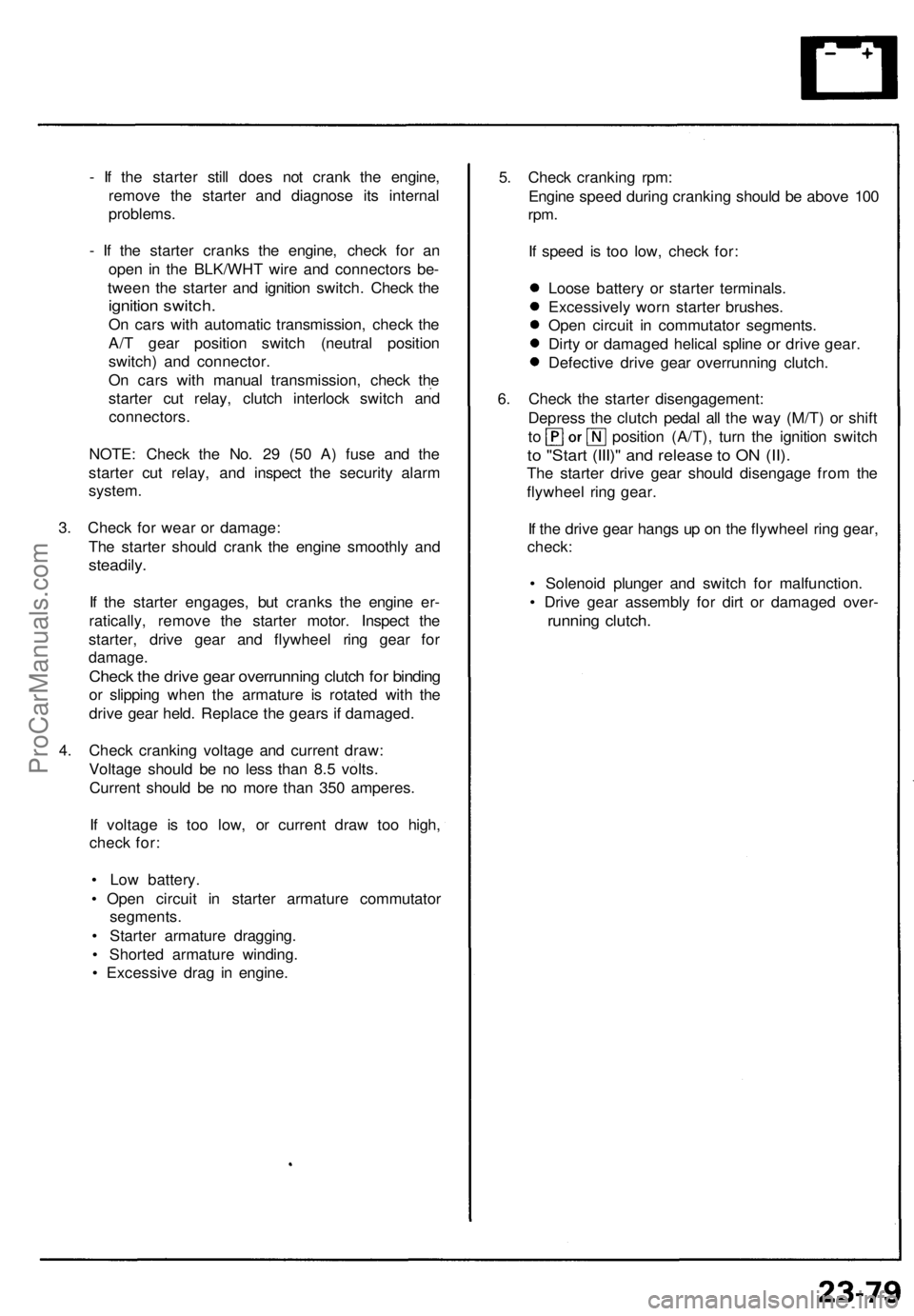

Starter Solenoid Test

1. Check the hold-in coil for continuity between the S

terminal and the armature housing (ground).

The coil is OK if there is continuity.

ARMATURE HOUSING

(GROUND)

PULL - IN COIL HOLD - IN COIL

2. Check the pull-in coil for continuity between the S

and M terminals.

The coil is OK if there is continuity.

Starter Replacement

1. Disconnect the battery negative cable.

2. Remove the engine wire harness from the harness

clip on the starter motor.

3. Disconnect the starter cable and the BLK/WHT

wire.

4. Remove the two bolts holding the starter, and

remove the starter.

UPPER MOUNTING BOLT

75 N-m (7.5 kg-m, 54 Ib-ft)

B-TERMINAL MOUNTING NUT

9 N-m (0.9 kg-m. 6.5 Ib-ft)

STARTER CABLE

LOWER MOUNTING BOLT

75 N-m (7.5 kg-m, 54 Ib-ft)

BLK/WHT WIREProCarManuals.com

Page 760 of 1640

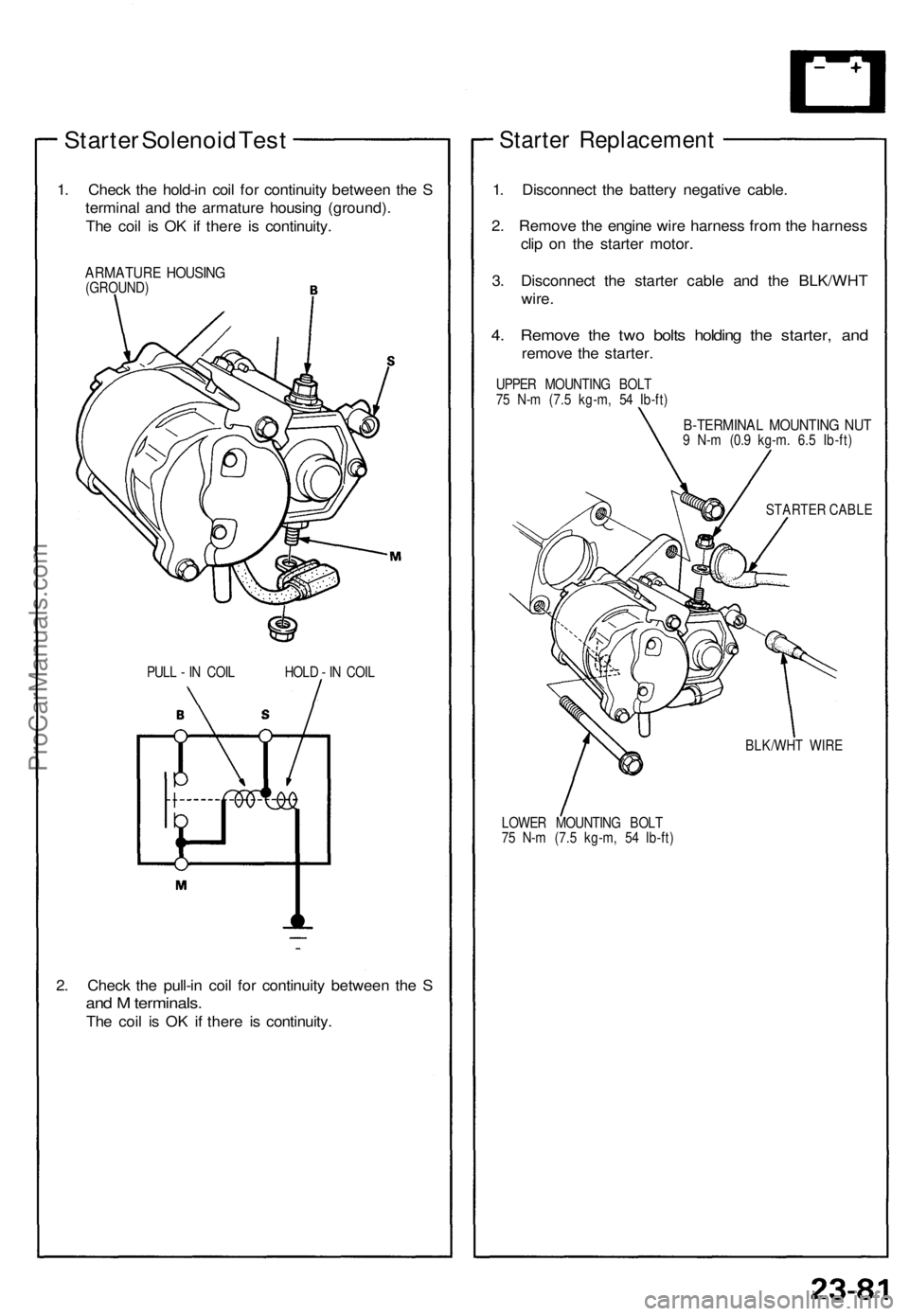

Ignition Timin g Inspectio n

SRS component s ar e locate d in thi s area . Revie w th e SR S

componen t locations , precautions , an d procedure s in th e

SR S sectio n 24 befor e performin g repair s o r service .

1 . Pul l ou t th e servic e chec k connecto r locate d unde r

th e middl e o f th e dash . Connec t th e BL U an d BRN /

BL K terminal s wit h th e SC S servic e connector .

2 . Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

n o loa d (A/ T i n [N ] o r 0 position , M/ T i n neutral )

unti l th e radiato r fa n come s on , the n le t i t idle .

NOTE : I f yo u sto p th e engin e o r tur n th e ignitio n

switc h OF F afte r warm-u p wit h th e SC S servic e con -

necto r connected , th e engin e wil l idl e a t th e bas e

idl e speed . Tha t is , i t wil l no t b e controlle d b y th e

ECM . T o retur n t o th e norma l idl e speed , pres s th e

accelerato r peda l on e time .

SERVIC E CHEC K CONNECTO R (2-P )

SCS SERVIC E CONNECTO R07PAZ - 001010 0

3. Chec k th e idl e spee d (se e pag e 23-92 ).

4 . Connec t a timin g ligh t t o th e servic e loop ; whil e th e

engin e idles , poin t th e ligh t towar d th e pointe r o n

the timin g bel t cover .

SERVIC E LOO P

TIMIN G LIGH T

5. Chec k th e ignitio n timing .

Ignitio n Timing : 15 ° + 2° BTD C (RE D mark )

Idl e Spee d (rpm) :

NOTE : Al l electrica l system s ar e turne d OFF .

POINTE R

WHITE MAR K

RED MAR K

CRANKSHAF T PULLE Y

6. I f i t i s necessar y to adjus t th e ignitio n timing , replac e

the ECM .

7. Remov e th e SC S servic e connecto r fro m th e servic e

check connector .

ProCarManuals.com

Page 784 of 1640

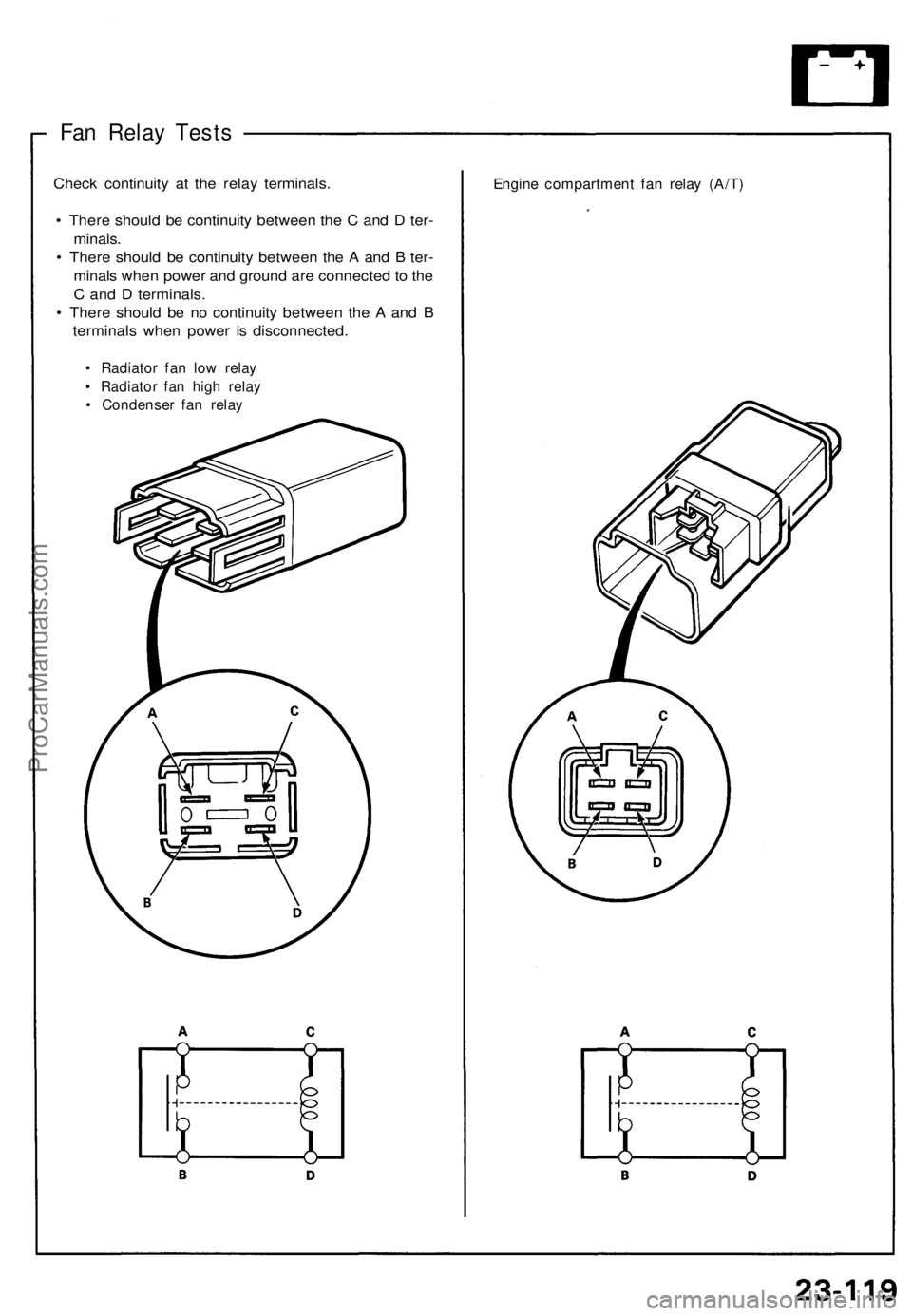

Fan Relay Tests

Check continuity at the relay terminals.

• There should be continuity between the C and D ter-

minals.

• There should be continuity between the A and B ter-

minals when power and ground are connected to the

C and D terminals.

• There should be no continuity between the A and B

terminals when power is disconnected.

• Radiator fan low relay

• Radiator fan high relay

• Condenser fan relay

Engine compartment fan relay (A/T)ProCarManuals.com

Page 860 of 1640

(G551) '95-'96 Models.

(G401,G402,G551) '93-94 Models or

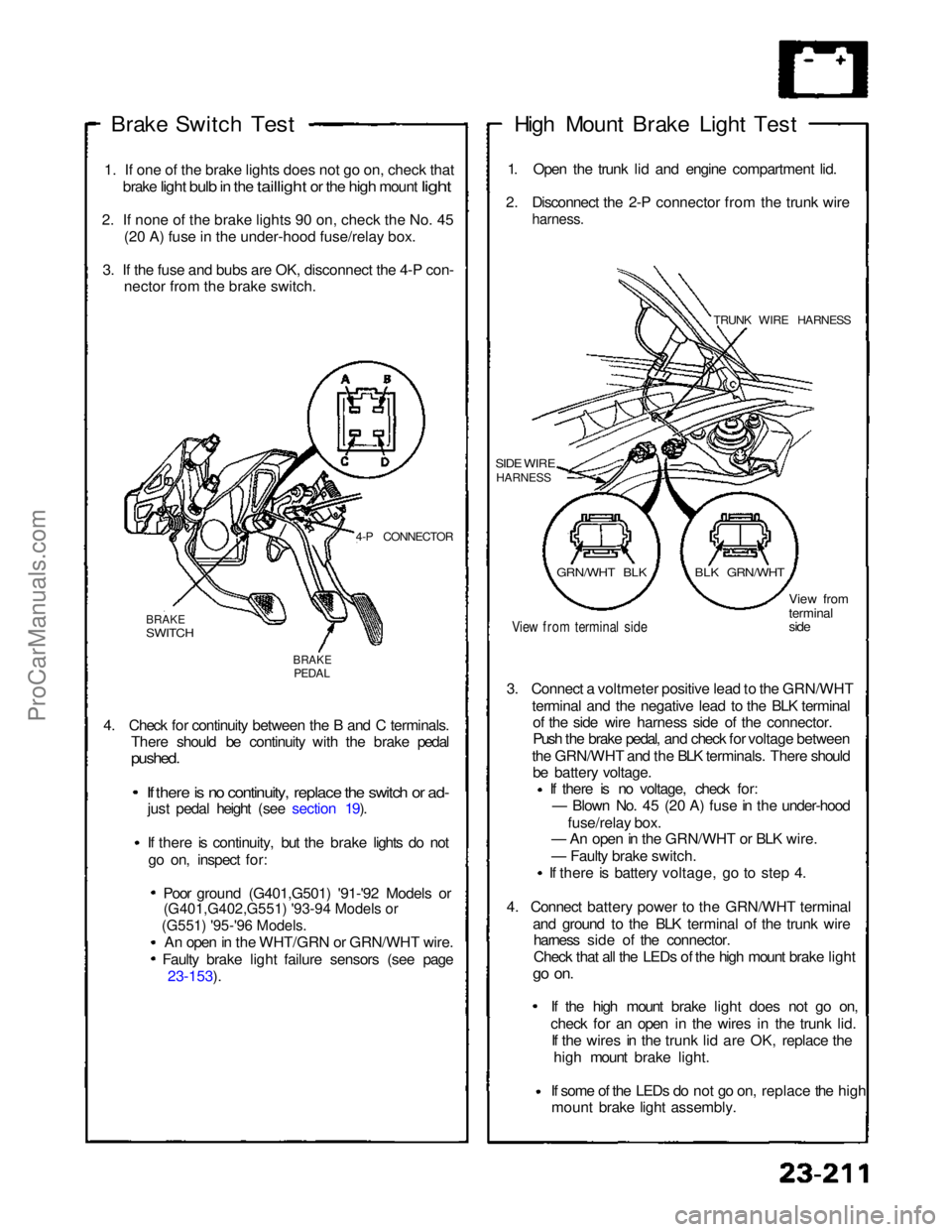

Brake Switch

Test

1

.

If one of the brake lights does not go on, check that

brake

light bulb in the taillight or the high mount light

2

.

If none of the brake lights 90 on, check the No. 45 (2

0

A) fuse in the under-hood fuse/relay box.

3

.

If the fuse and bubs are OK, disconnect the 4-P con- necto

r

from the brake switch.

4-P CONNECTOR

BRAKE

SWITCH

BRAKE

PEDAL

4. Check for continuity between the B and C terminals. There should be continuity with the brake pedal

pushed.

If there is no continuity, replace the switch or ad-

just pedal height (see section 19).

If there is continuity, but the brake lights do not

go on, inspect for:

Poor ground (G401,G501) '91-'92 Models or

An open in the WHT/GRN or GRN/WHT wire. Faulty brake light failure sensors (see page 23-153). High Mount Brake Light Test

1. Open the trunk lid and engine compartment lid.

2. Disconnect the 2-P connector from the trunk wire

harness.

TRUNK WIRE HARNESS

SIDE WIRE

HARNESS

View from terminal side

View from

terminal

side

3. Connect a voltmeter positive lead to the GRN/WHT terminal and the negative lead to the BLK terminalof the side wire harness side of the connector.

Push the brake pedal, and check for voltage between

the GRN/WHT and the BLK terminals. There should be battery voltage. If there is no voltage, check for:

— Blown No. 45 (20 A) fuse in the under-hood

fuse/relay box.

— An open in the GRN/WHT or BLK wire.

— Faulty brake switch.

If there is battery voltage, go to step 4.

4. Connect battery power to the GRN/WHT terminal and ground to the BLK terminal of the trunk wireharness side of the connector.

Check that all the LEDs of the high mount brake light

go on.

If the high mount brake light does not go on,check for an open in the wires

in the trunk lid.

If the wires in the trunk lid are OK, replace the

high mount brake light.

If some of the LEDs do not go on,

replace the high

mount brake light assembly.

GRN/WHT BLK

BLK GRN/WHTProCarManuals.com

Page 956 of 1640

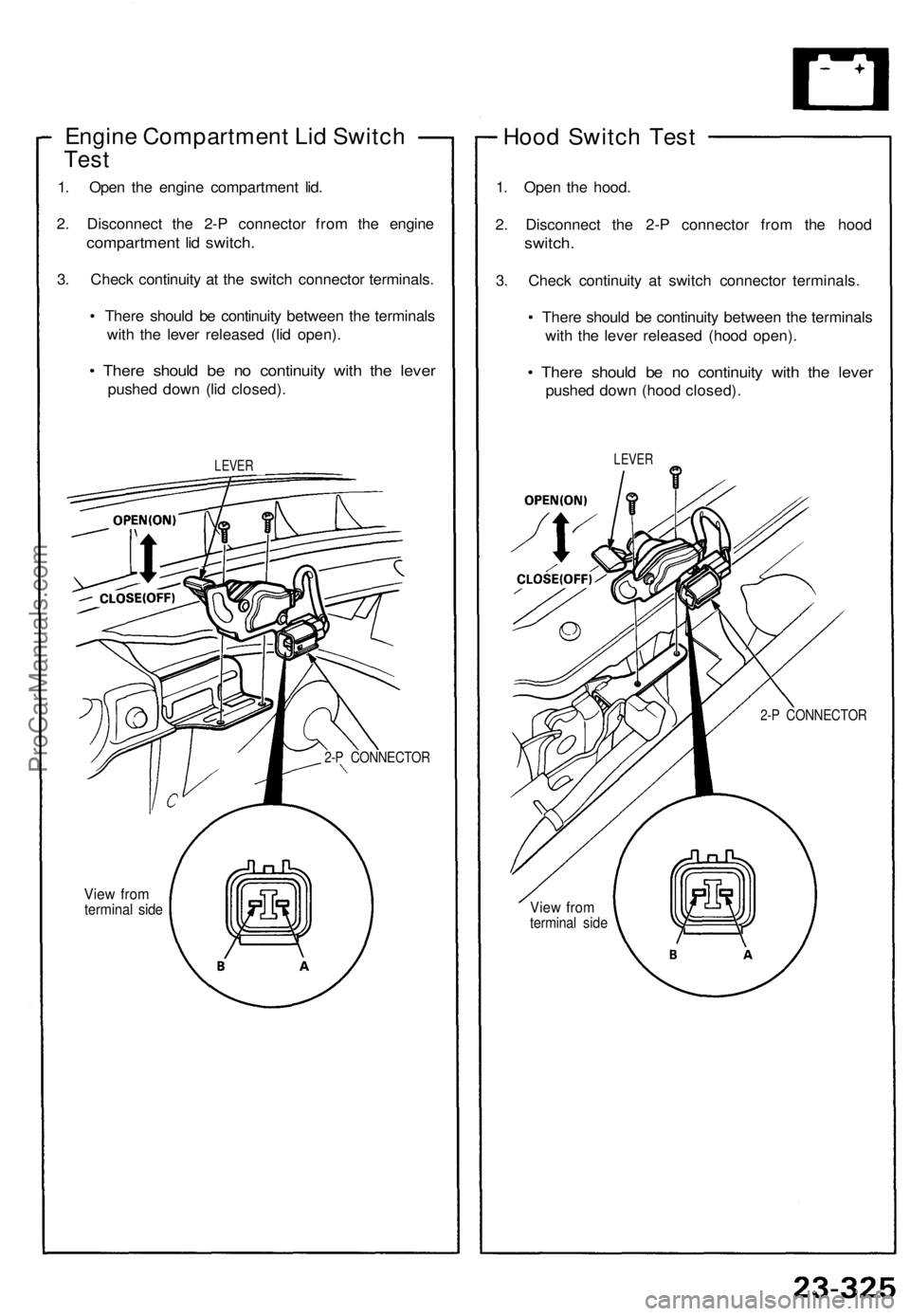

Engine Compartment Lid Switch

Test

1. Open the engine compartment lid.

2. Disconnect the 2-P connector from the engine

compartment lid switch.

3. Check continuity at the switch connector terminals.

• There should be continuity between the terminals

with the lever released (lid open).

• There should be no continuity with the lever

pushed down (lid closed).

LEVER

View from

terminal side

2-P CONNECTOR

Hood Switch Test

1. Open the hood.

2. Disconnect the 2-P connector from the hood

switch.

3. Check continuity at switch connector terminals.

• There should be continuity between the terminals

with the lever released (hood open).

• There should be no continuity with the lever

pushed down (hood closed).

LEVER

2-P CONNECTOR

View from

terminal sideProCarManuals.com

Page 966 of 1640

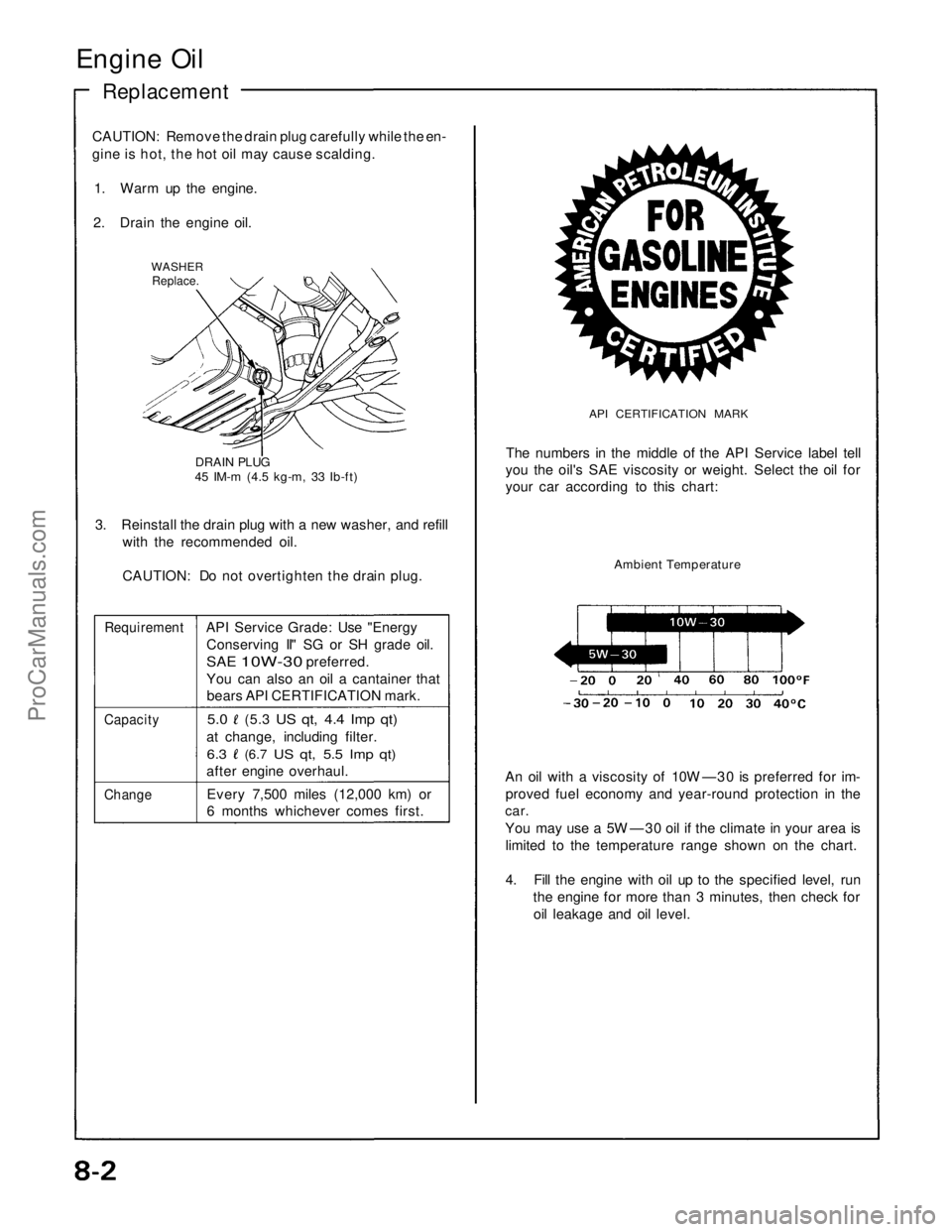

Engine Oil

Replacement

CAUTION: Remove the drain plug carefully while the en-

gine is hot, the hot oil may cause scalding.

1. Warm up the engine.

2. Drain the engine oil.

WASHER

Replace.

DRAIN PLUG

45 IM-m (4.5 kg-m, 33 Ib-ft)

3. Reinstall the drain plug with a new washer, and refill

with the recommended oil.

CAUTION: Do not overtighten the drain plug.

Requirement

API Service Grade: Use "Energy

Conserving II" SG or SH grade oil.

SAE

10W-30

preferred.

You can also an oil a cantainer that

bears API CERTIFICATION mark.

Capacity

5.0

(5.3

US qt, 4.4 Imp qt)

at change, including filter.

6.3

(6.7

US qt, 5.5 Imp qt)

after engine overhaul.

Change

Every 7,500 miles (12,000 km) or

6 months whichever comes first.

API CERTIFICATION MARK

The numbers in the middle of the API Service label tell

you the oil's SAE viscosity or weight. Select the oil for

your car according to this chart:

Ambient Temperature

An oil with a viscosity of 10W —30 is preferred for im-

proved fuel economy and year-round protection in the

car.

You may use a 5W —30 oil if the climate in your area is

limited to the temperature range shown on the chart.

4. Fill the engine with oil up to the specified level, run

the engine for more than 3 minutes, then check for

oil leakage and oil level.ProCarManuals.com

Page 995 of 1640

Engine Removal/Installation

(cont'd)

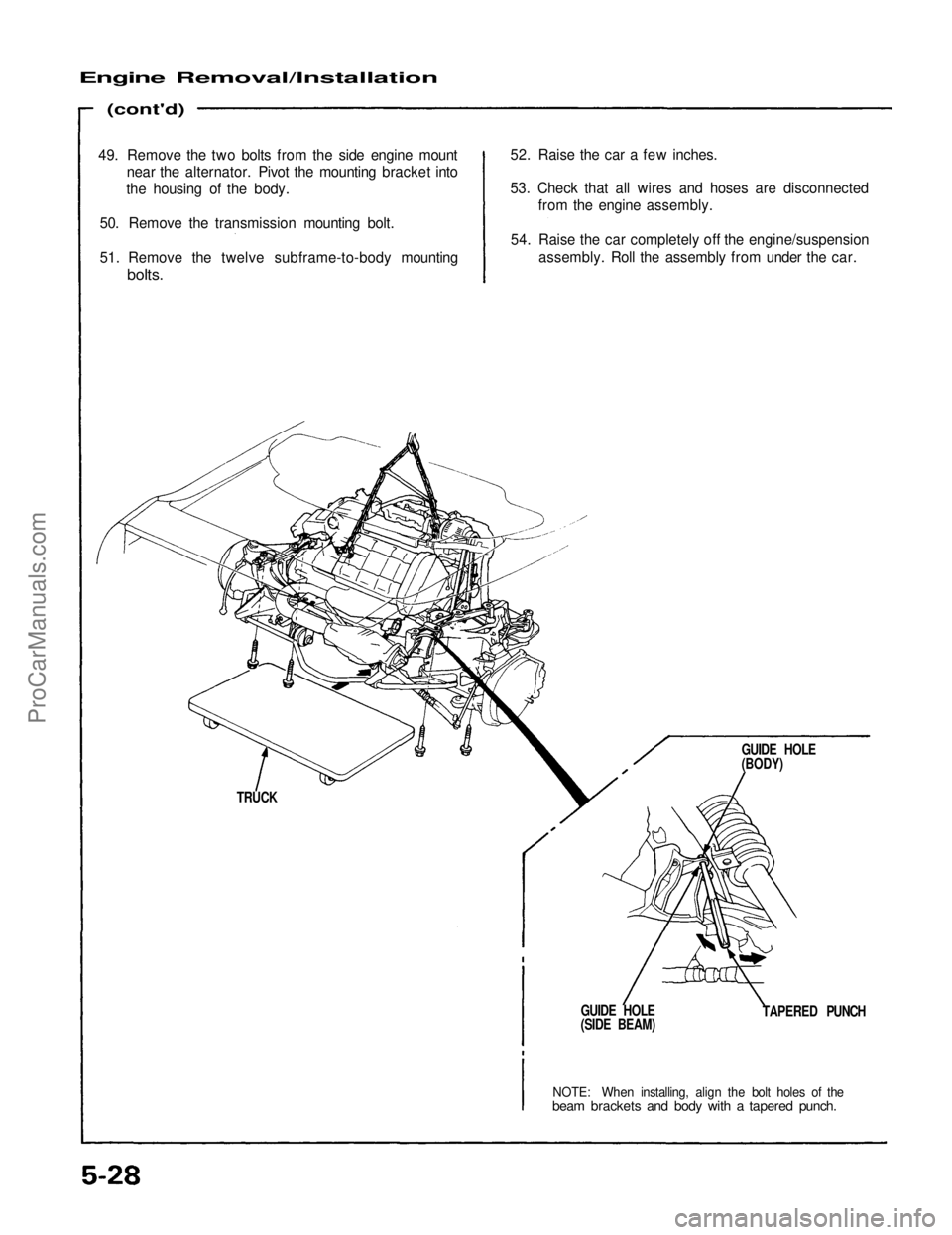

49. Remove the two bolts from the side engine mount near the alternator. Pivot the mounting bracket into

the housing of the body.

50. Remove the transmission mounting bolt.

51. Remove the twelve subframe-to-body mounting

bolts.

52. Raise the car a few inches.

53. Check that all wires and hoses are disconnected

from the engine assembly.

54. Raise the car completely off the engine/suspension assembly. Roll the assembly from under the car.

TRUCK GUIDE HOLE

(BODY)

TAPERED PUNCH

GUIDE HOLE

(SIDE BEAM)

NOTE: When installing, align the bolt holes of the

beam brackets and body with a tapered punch.ProCarManuals.com

Page 996 of 1640

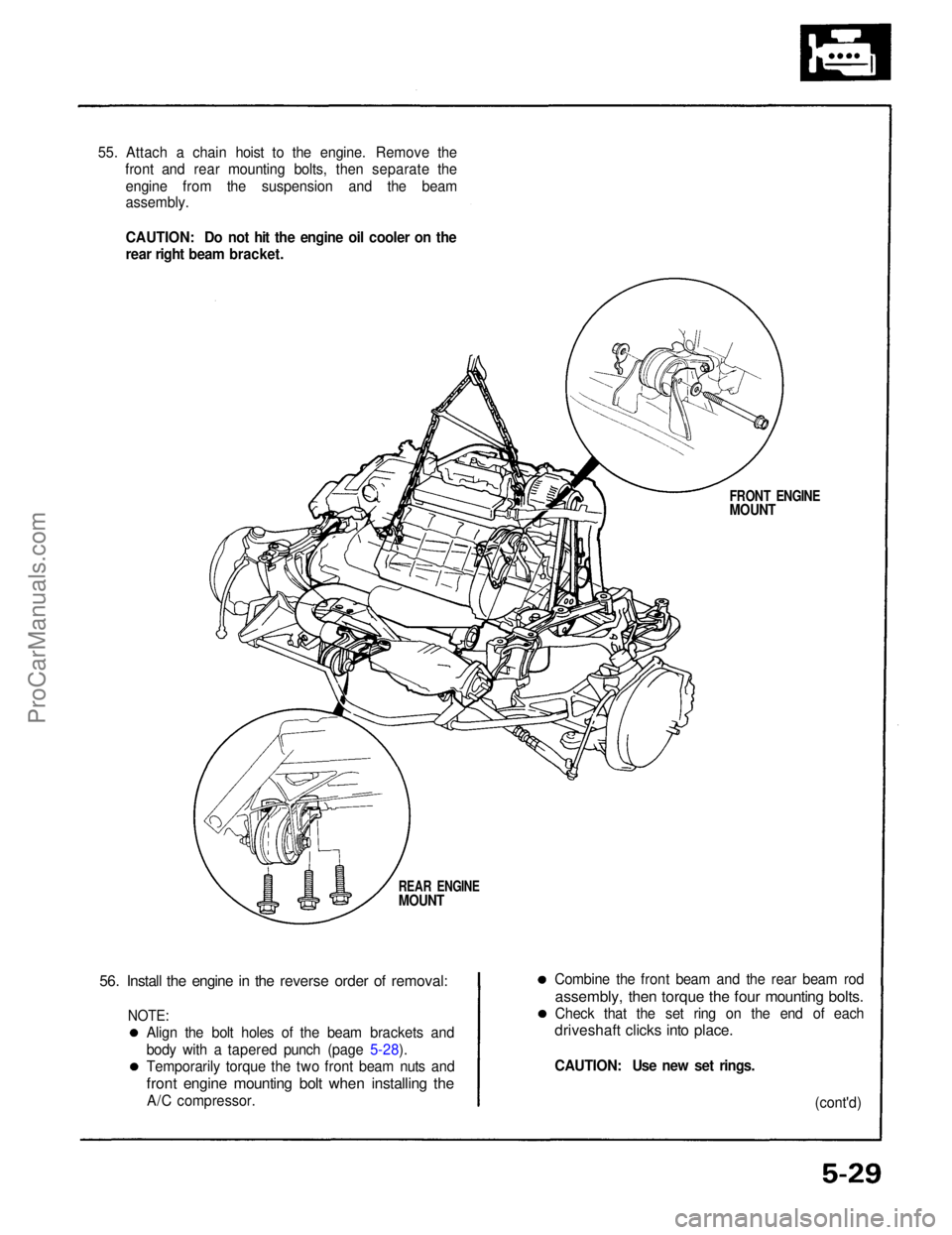

55. Attach a chain hoist to the engine. Remove the

front and rear mounting bolts, then separate the

engine from the suspension and the beam

assembly.

CAUTION: Do not hit the engine oil cooler on the

rear right beam bracket.

FRONT ENGINE

MOUNT

REAR ENGINE

MOUNT

56. Install the engine in the reverse order of removal:

NOTE:

Combine the front beam and the rear beam rod

assembly, then torque the four mounting bolts.

Check that the set ring on the end of each

driveshaft clicks into place.

CAUTION: Use new set rings.

(cont'd)

Align the bolt holes of the beam brackets and

body with a tapered punch (page 5-28).

Temporarily torque the two front beam nuts and

front engine mounting bolt when installing the

A/C compressor.ProCarManuals.com