engine ACURA NSX 1991 Service User Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 72 of 1640

9. Relieve fuel pressure by loosening the service bolt

on the fuel filter about one turn (see section 11).

Do not smoke while working on the

fuel

system.

Keep open flame away from work

area. Drain fuel only into an approved container.

10. Remove the fuel feed pipe and fuel return hose.

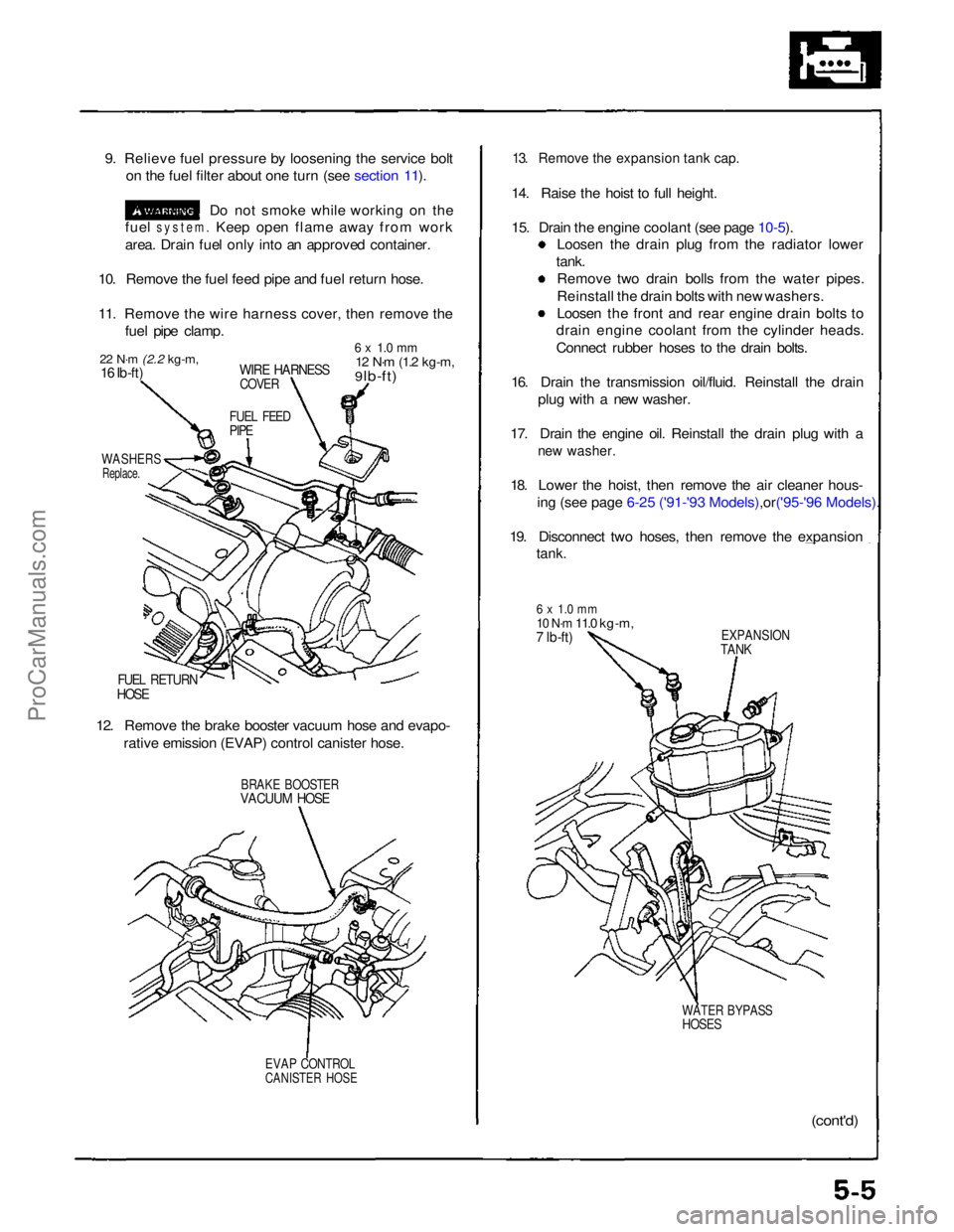

11. Remove the wire harness cover, then remove the fuel pipe clamp.

22 N·m

(2.2 kg-m,

16 Ib-ft)

WIRE HARNESS

COVER

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 lb-ft)

FUEL FEED

PIPE

WASHERS

Replace.

FUEL RETURN

HOSE

12. Remove the brake booster vacuum hose and evapo- rative emission (EVAP) control canister hose.

BRAKE BOOSTER

VACUUM HOSE

EVAP CONTROL

CANISTER HOSE

13. Remove the expansion tank cap.

14. Raise the hoist to full height.

15. Drain the engine coolant (see page

10-5).

Loosen the drain plug from the radiator lower

tank. Remove two drain bolls from the water pipes.

Reinstall the drain bolts with new washers.

Loosen the front and rear engine drain bolts to

drain engine coolant from the cylinder heads.

Connect rubber hoses to the drain bolts.

16. Drain the transmission oil/fluid. Reinstall the drain plug with a new washer.

17. Drain the engine oil. Reinstall the drain plug with a

new washer.

18. Lower the hoist, then remove the air cleaner hous-

ing (see page 6-25 ('91-'93 Mode ls),or('95-'96 Models).

19. Disconnect two hoses, then remove the expansion

tank.

6 x 1.0 mm

10 N·m

11.0 kg-m,

7 lb-ft)

EXPANSION

TANK

WATER BYPASS

HOSES

(cont'd)ProCarManuals.com

Page 73 of 1640

Engine Removal/Installation

Removal

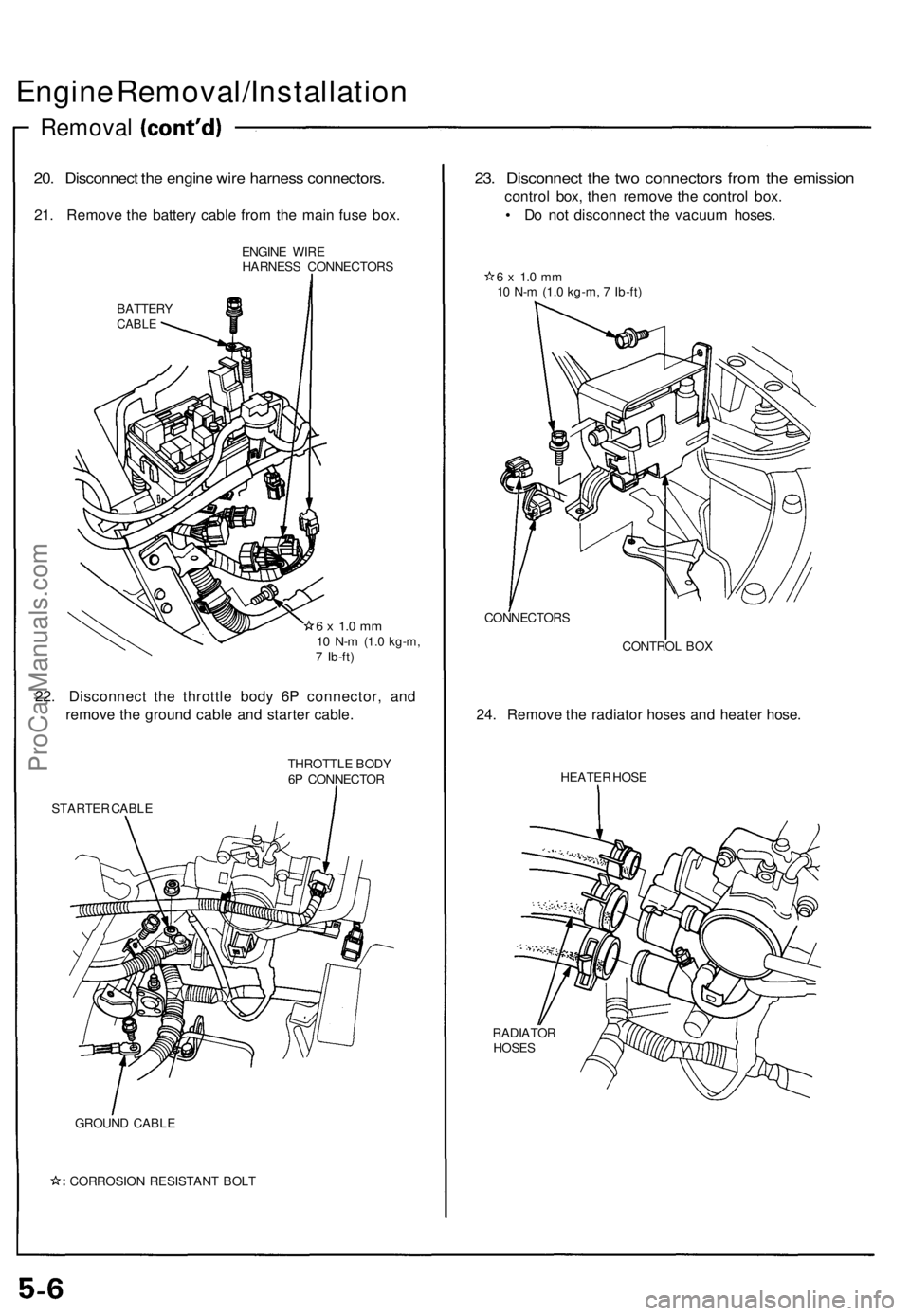

20. Disconnect the engine wire harness connectors.

21. Remove the battery cable from the main fuse box.

ENGINE WIRE

HARNESS CONNECTORS

BATTERY

CABLE

6 x 1.0 mm

10 N-m

(1.0 kg-m,

7 Ib-ft)

22. Disconnect the throttle body 6P connector, and

remove the ground cable and starter cable.

STARTER CABLE

THROTTLE BODY

6P CONNECTOR

GROUND CABLE

CORROSION RESISTANT BOLT

23. Disconnect the two connectors from the emission

control box, then remove the control box.

• Do not disconnect the vacuum hoses.

6 x 1.0 mm

10 N-m (1.0 kg-m, 7 Ib-ft)

CONNECTORS

CONTROL BOX

24. Remove the radiator hoses and heater hose.

HEATER HOSE

RADIATOR

HOSESProCarManuals.com

Page 75 of 1640

Engine Removal/Installatio n

Removal

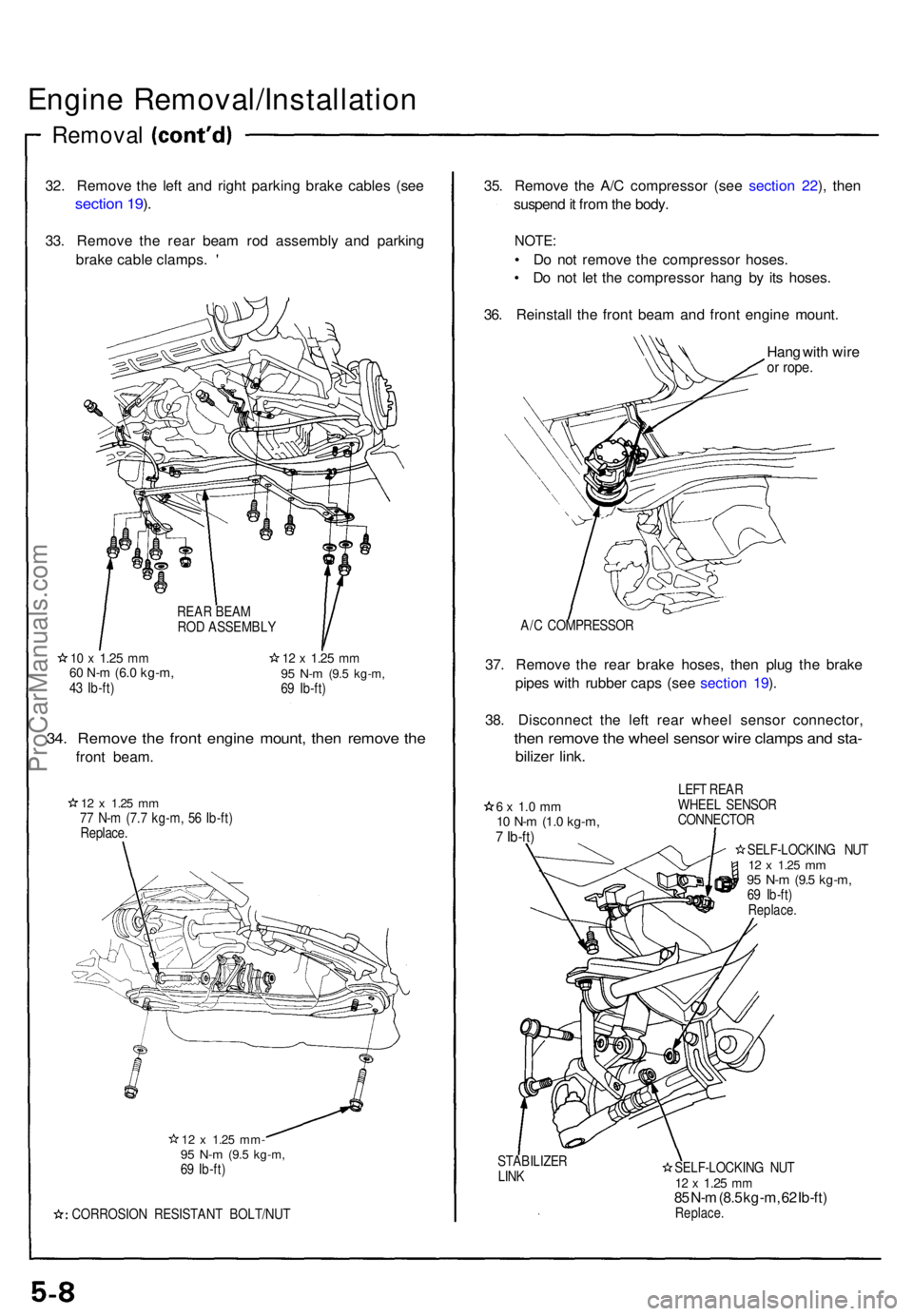

32. Remov e th e lef t an d righ t parkin g brak e cable s (se e

sectio n 19 ).

33 . Remov e th e rea r bea m ro d assembl y an d parkin g

brak e cabl e clamps . '

1 0 x 1.2 5 mm60 N- m (6. 0 kg-m ,43 Ib-ft )

12 x 1.2 5 mm95 N- m (9. 5 kg-m ,69 Ib-ft )

34. Remov e th e fron t engin e mount , the n remov e th e

fron t beam .

12 x 1.2 5 mm77 N- m (7. 7 kg-m , 5 6 Ib-ft )

Replace .

12 x 1.2 5 mm -95 N- m (9. 5 kg-m ,69 Ib-ft )

CORROSIO N RESISTAN T BOLT/NU T

35. Remov e th e A/ C compresso r (se e sectio n 22 ), the n

suspen d it fro m th e body .

NOTE :

• D o no t remov e th e compresso r hoses .

• D o no t le t th e compresso r han g b y it s hoses .

36 . Reinstal l th e fron t bea m an d fron t engin e mount .

Han g wit h wir e

or rope .

A/C COMPRESSO R

37. Remov e th e rea r brak e hoses , the n plu g th e brak e

pipe s wit h rubbe r cap s (se e sectio n 19 ).

38 . Disconnec t th e lef t rea r whee l senso r connector ,

then remov e th e whee l senso r wir e clamp s an d sta -

bilize r link .

6 x 1. 0 m m10 N- m (1. 0 kg-m ,7 Ib-ft )

LEFT REA R

WHEE L SENSO R

CONNECTO R

SELF-LOCKIN G NU T

12 x 1.2 5 mm95 N- m (9. 5 kg-m ,69 Ib-ft )Replace .

STABILIZE R

LIN K SELF-LOCKIN

G NU T

12 x 1.2 5 mm85 N- m (8. 5 kg-m , 6 2 Ib-ft )Replace .

REAR BEA M

RO D ASSEMBL Y

ProCarManuals.com

Page 76 of 1640

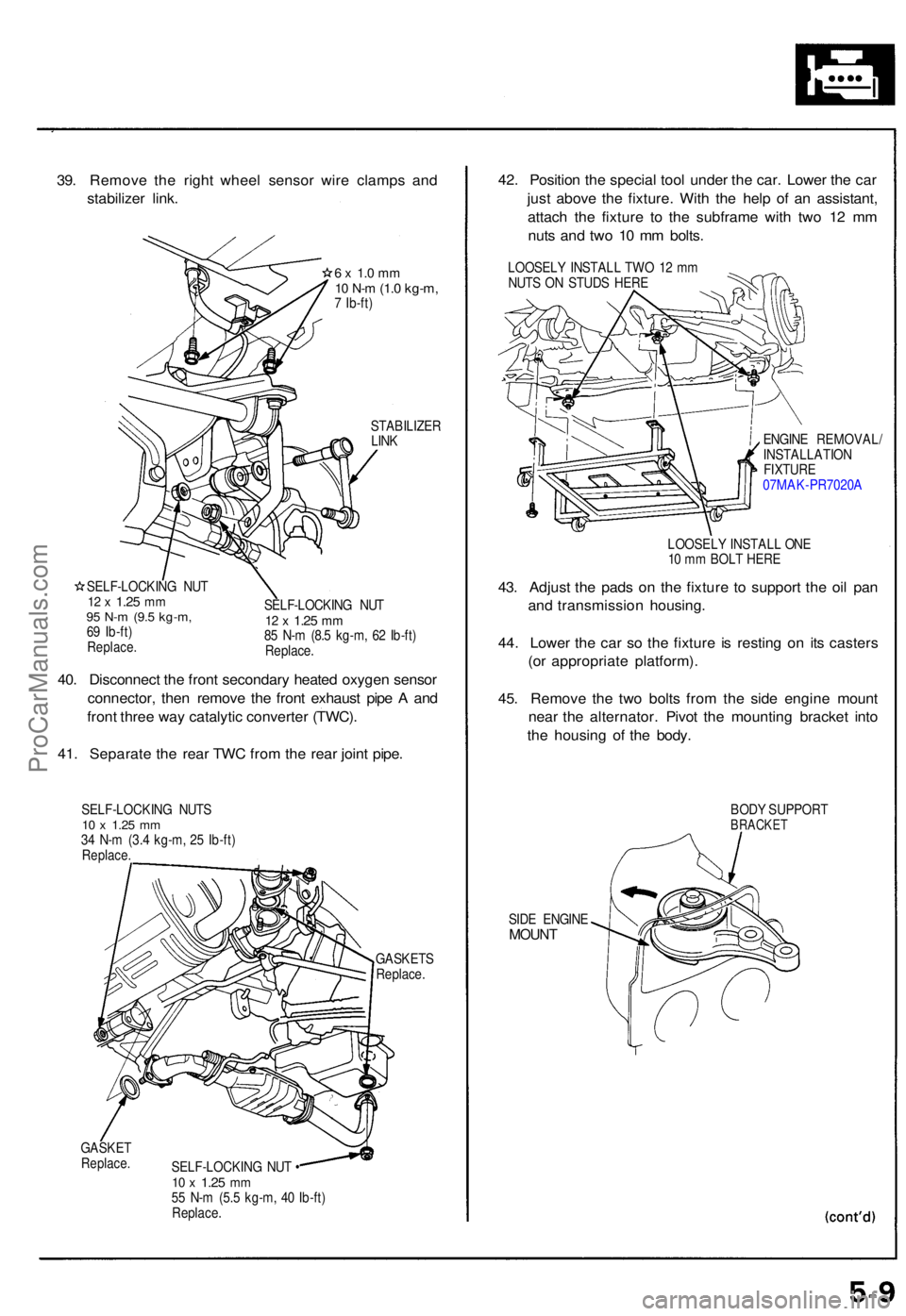

39. Remov e th e righ t whee l senso r wir e clamp s an d

stabilize r link .

6 x 1. 0 m m10 N- m (1. 0 kg-m ,7 Ib-ft )

STABILIZE RLINK

SELF-LOCKIN G NU T

12 x 1.2 5 mm95 N- m (9. 5 kg-m ,69 Ib-ft )Replace .

SELF-LOCKIN G NU T12 x 1.2 5 mm85 N- m (8. 5 kg-m , 6 2 Ib-ft )

Replace .

40. Disconnec t th e fron t secondar y heate d oxyge n senso r

connector , the n remov e th e fron t exhaus t pip e A an d

fron t thre e wa y catalyti c converte r (TWC) .

41 . Separat e th e rea r TW C fro m th e rea r join t pipe .

SELF-LOCKIN G NUT S10 x 1.2 5 mm34 N- m (3. 4 kg-m , 2 5 Ib-ft )Replace .

GASKET SReplace.

GASKETReplace .SELF-LOCKIN G NU T •10 x 1.2 5 mm55 N- m (5. 5 kg-m , 4 0 Ib-ft )Replace .

42. Positio n th e specia l too l unde r th e car . Lowe r th e ca r

jus t abov e th e fixture . Wit h th e hel p o f a n assistant ,

attac h th e fixtur e t o th e subfram e wit h tw o 1 2 m m

nut s an d tw o 1 0 m m bolts .

LOOSEL Y INSTAL L TW O 1 2 m m

NUT S O N STUD S HER E

ENGINE REMOVAL /

INSTALLATIO N

FIXTURE07MAK-PR7020 A

LOOSEL Y INSTAL L ON E

1 0 m m BOL T HER E

43. Adjus t th e pad s o n th e fixtur e t o suppor t th e oi l pa n

an d transmissio n housing .

44 . Lowe r th e ca r s o th e fixtur e i s restin g o n it s caster s

(o r appropriat e platform) .

45 . Remov e th e tw o bolt s fro m th e sid e engin e moun t

nea r th e alternator . Pivo t th e mountin g bracke t int o

th e housin g o f th e body .

BODY SUPPOR TBRACKET

SIDE ENGIN EMOUNT

ProCarManuals.com

Page 77 of 1640

Engine Removal/Installatio n

Removal

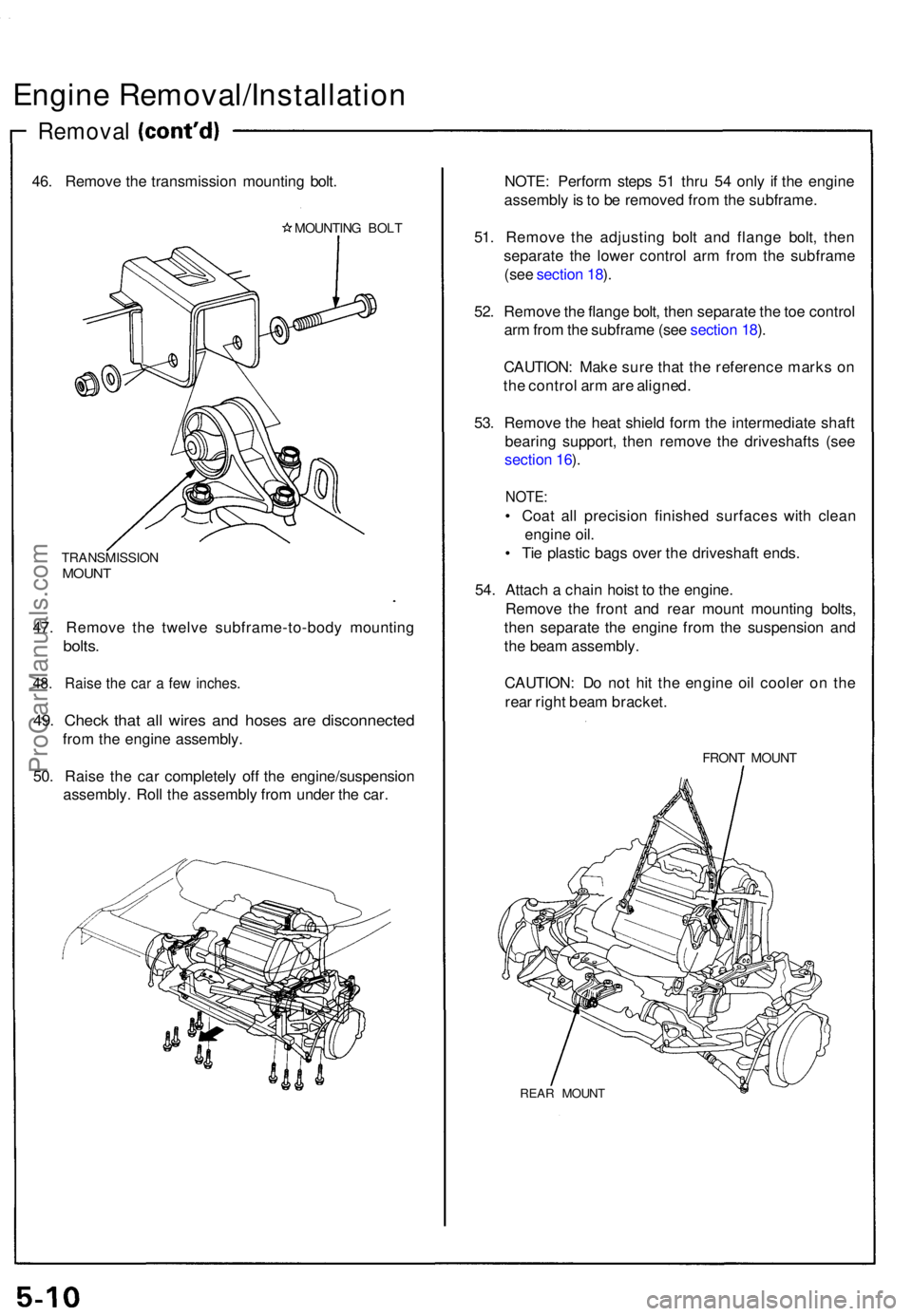

46. Remov e th e transmissio n mountin g bolt .

MOUNTIN G BOL T

TRANSMISSIO NMOUNT

47. Remov e th e twelv e subframe-to-bod y mountin g

bolts.

48. Rais e th e ca r a fe w inches .

49. Chec k tha t al l wire s an d hose s ar e disconnecte d

from th e engin e assembly .

50 . Rais e th e ca r completel y of f th e engine/suspensio n

assembly . Rol l th e assembl y fro m unde r th e car . NOTE

: Perfor m step s 5 1 thr u 5 4 onl y i f th e engin e

assembl y is t o b e remove d fro m th e subframe .

51 . Remov e th e adjustin g bol t an d flang e bolt , the n

separat e th e lowe r contro l ar m fro m th e subfram e

(se e sectio n 18 ).

52 . Remov e th e flang e bolt , the n separat e th e to e contro l

ar m fro m th e subfram e (se e sectio n 18 ).

CAUTION : Mak e sur e tha t th e referenc e mark s o n

th e contro l ar m ar e aligned .

53 . Remov e th e hea t shiel d for m th e intermediat e shaf t

bearin g support , the n remov e th e driveshaft s (se e

sectio n 16 ).

NOTE :

• Coa t al l precisio n finishe d surface s wit h clea n

engin e oil .

• Ti e plasti c bag s ove r th e driveshaf t ends .

54 . Attac h a chai n hois t t o th e engine .

Remov e th e fron t an d rea r moun t mountin g bolts ,

the n separat e th e engine from th e suspensio n an d

th e bea m assembly .

CAUTION : D o no t hi t th e engin e oi l coole r o n th e

rea r righ t bea m bracket .

FRONT MOUN T

REAR MOUN T

ProCarManuals.com

Page 78 of 1640

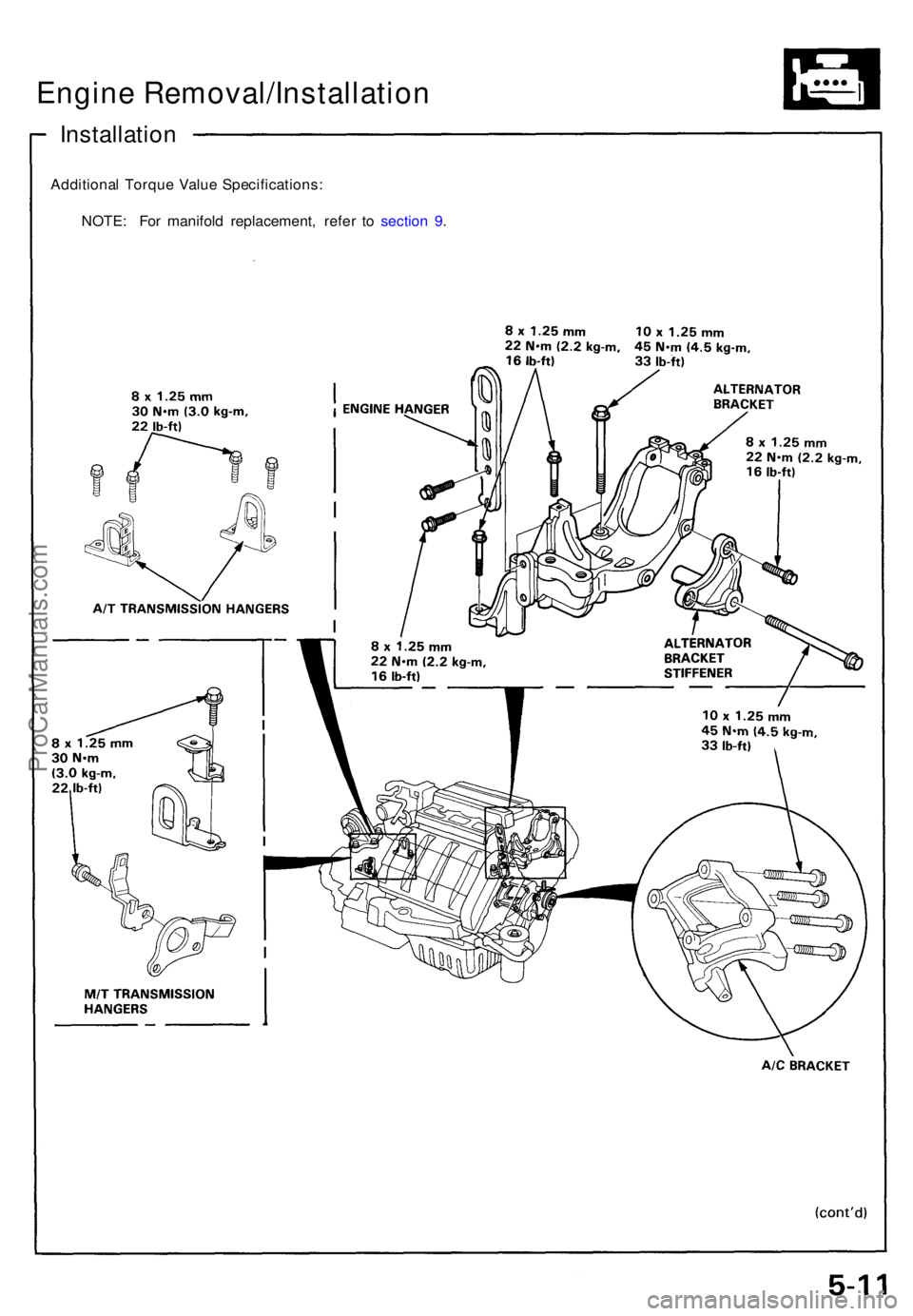

Installation

Additional Torqu e Valu e Specifications :

NOTE : Fo r manifol d replacement , refe r t o sectio n 9 .

Engine Removal/Installation

ProCarManuals.com

Page 79 of 1640

Engine Removal/Installatio n

Installation

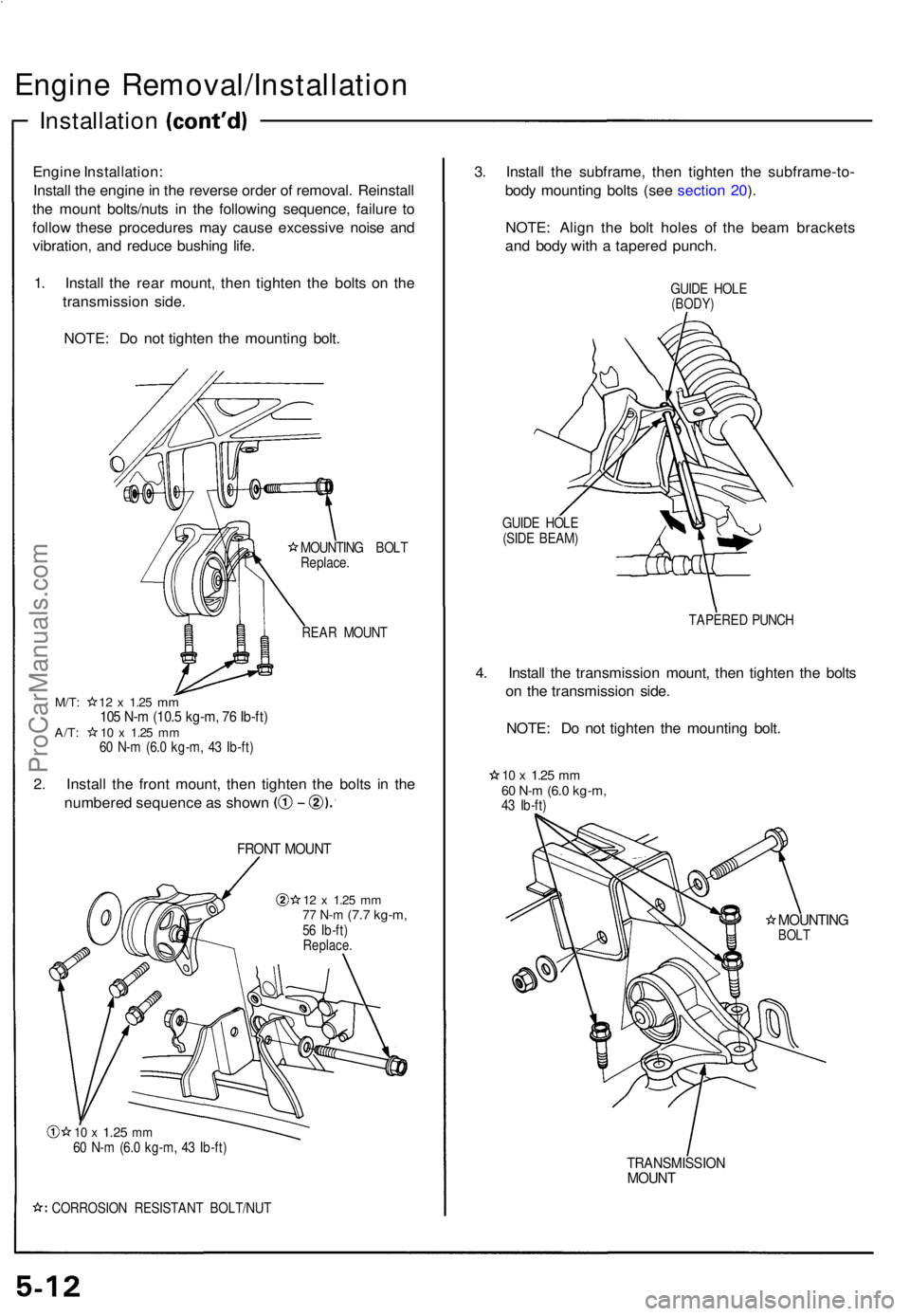

Engine Installation :

Instal l th e engin e in th e revers e orde r o f removal . Reinstal l

th e moun t bolts/nut s i n th e followin g sequence , failur e t o

follo w thes e procedure s ma y caus e excessiv e nois e an d

vibration , an d reduc e bushin g life .

1 . Instal l th e rea r mount , the n tighte n th e bolt s o n th e

transmissio n side .

NOTE : D o no t tighte n th e mountin g bolt .

MOUNTIN G BOL T

Replace .

REA R MOUN T

M/T: 1 2 x 1.2 5 mm105 N- m (10. 5 kg-m , 7 6 Ib-ft )A/T: 1 0 x 1.2 5 mm60 N- m (6. 0 kg-m , 4 3 Ib-ft )

2. Instal l th e fron t mount , the n tighte n th e bolt s i n th e

numbere d sequenc e a s show n

FRONT MOUN T

12 x 1.2 5 mm77 N- m (7. 7 kg-m ,56 Ib-ft )Replace .

10 x 1.2 5 mm60 N- m (6. 0 kg-m , 4 3 Ib-ft )

CORROSIO N RESISTAN T BOLT/NU T

3. Instal l th e subframe , the n tighte n th e subframe-to -

bod y mountin g bolt s (se e sectio n 20 ).

NOTE : Alig n th e bol t hole s o f th e bea m bracket s

an d bod y wit h a tapere d punch .

GUIDE HOL E(BODY )

GUIDE HOL E

(SID E BEAM )

TAPERED PUNC H

4. Instal l th e transmissio n mount , the n tighte n th e bolt s

o n th e transmissio n side .

NOTE : D o no t tighte n th e mountin g bolt .

10 x 1.2 5 mm60 N- m (6. 0 kg-m ,43 Ib-ft )

MOUNTIN GBOLT

TRANSMISSIO NMOUNT

ProCarManuals.com

Page 80 of 1640

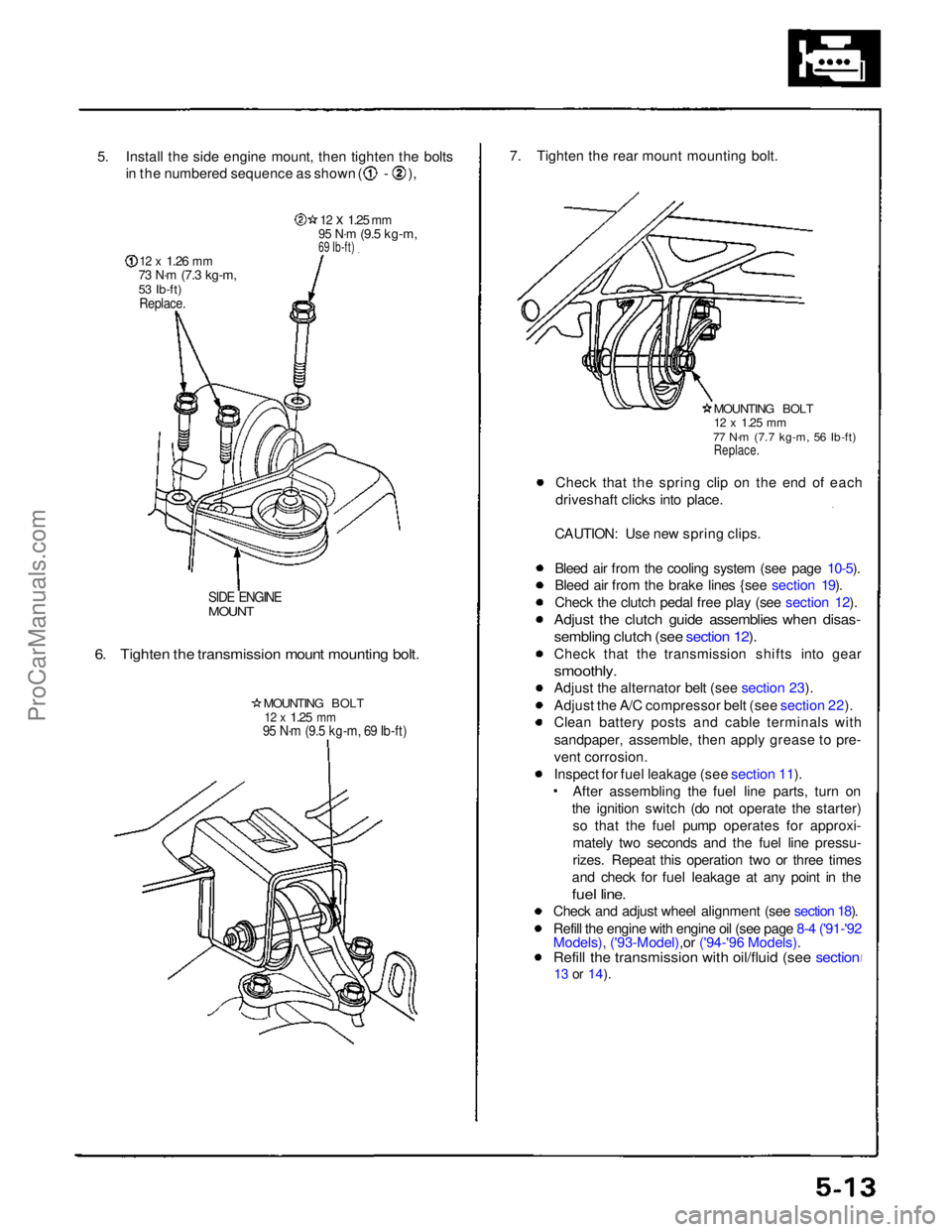

5. Install the side engine mount, then tighten the bolts

in the numbered sequence as shown ( - ),

12 x

1.26

mm

73 N·m

(7.3 kg-m,

53 Ib-ft)

Replace.

12 x

1.25

mm

95 N·m

(9.5 kg-m,

69 Ib-ft)

SIDE ENGINE

MOUNT

6. Tighten the transmission mount mounting bolt.

MOUNTING BOLT

12 x

1.25

mm

95 N·m (9.5 kg-m, 69 Ib-ft)

7. Tighten the rear mount mounting bolt.

MOUNTING BOLT

12 x

1.25

mm

77 N·m (7.7 kg-m, 56 Ib-ft)

Replace.

Check that the spring clip on the end of each

driveshaft clicks into place.

CAUTION: Use new spring clips.

Bleed air from the cooling system (see page 10-5).

Bleed air from the brake lines {see section 19).

Check the clutch pedal free play (see section 12).

Adjust the clutch guide assemblies when disas-

sembling clutch (see section 12).

Check that the transmission shifts into gear

smoothly.

Adjust the alternator belt (see section 23).

Adjust the A/C compressor belt (see section 22).

Clean battery posts and cable terminals with

sandpaper, assemble, then apply grease to pre-

vent corrosion.

Inspect for fuel leakage (see section 11). After assembling the fuel line parts, turn on

the ignition switch (do not operate the starter) so that the fuel pump operates for approxi-

mately two seconds and the fuel line pressu-

rizes. Repeat this operation two or three times

and check for fuel leakage at any point in the

fuel line.

Check and adjust wheel alignment (see section 18).

Refill the engine with engine oil (see page 8-4 ('91-'92

Models), ('93-Model),or ('94-'96 Models).

Refill the transmission with oil/fluid (see section

13 or

14).ProCarManuals.com

Page 84 of 1640

Valve Clearance

Adjustment

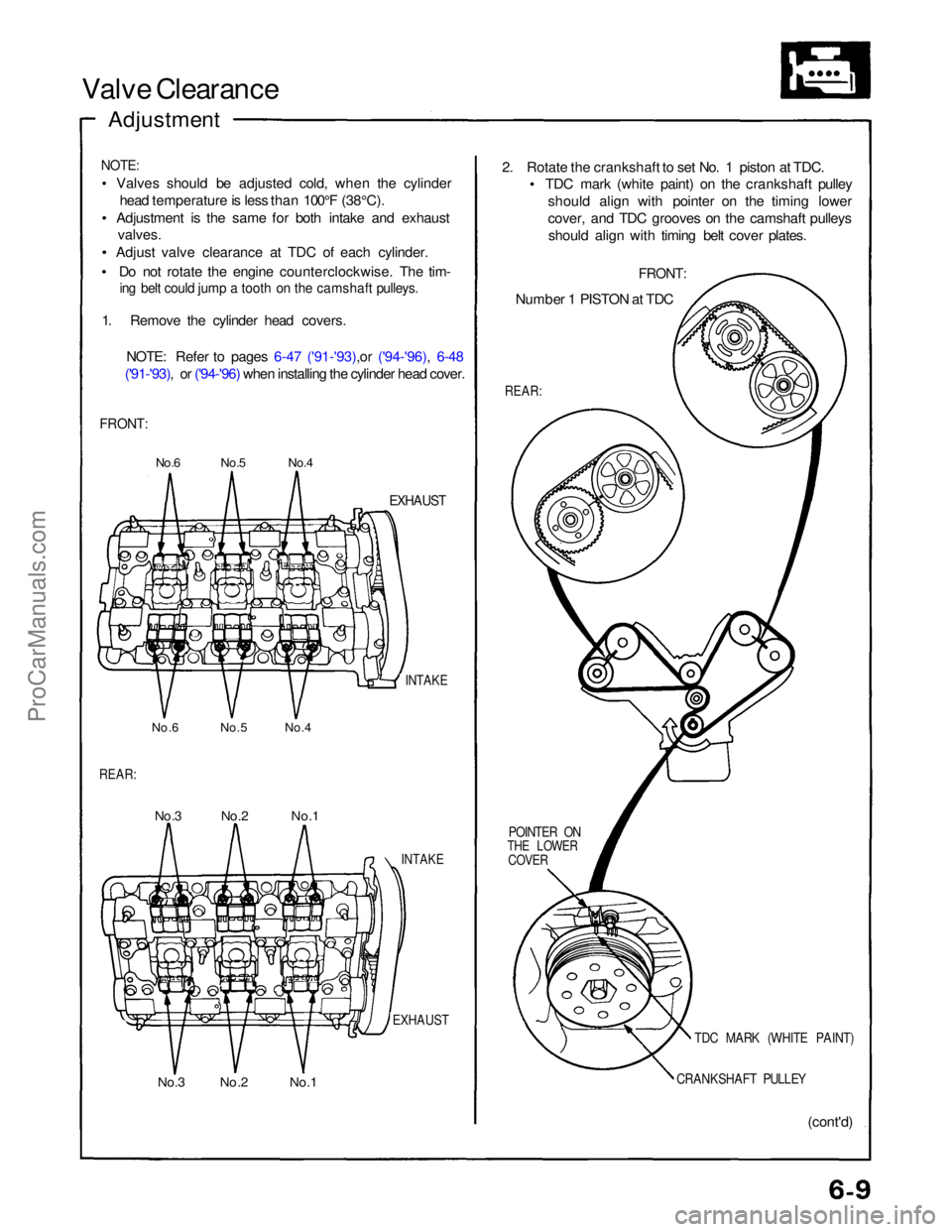

NOTE:

Valves should be adjusted cold, when the cylinderhead temperature is less than 100°F (38°C).

Adjustment is the same for both intake and exhaust valves.

Adjust valve clearance at TDC of each cylinder.

Do not rotate the engine counterclockwise. The tim-

ing belt could jump a tooth on the camshaft pulleys.

1. Remove the cylinder head covers.

NOTE: Refer to pages 6-47 ('91-'93),or ('94-'96), 6-48

('91-'93), or ('94-'96) when installing the cylinder head cover.

FRONT:

No.6 No.5 No.4

EXHAUST

INTAKE

No.6 No.5 No.4

REAR:

No.3 No.2 No.1

INTAKE

EXHAUST

No.3 No.2 No.1 (cont'd)

CRANKSHAFT PULLEY

TDC MARK (WHITE PAINT)

POINTER ON

THE LOWER

COVER

REAR:

Number 1 PISTON at TDC

FRONT:

2. Rotate the crankshaft to set No. 1 piston at TDC.

TDC mark (white paint) on the crankshaft pulley

should align with pointer on the timing lower

cover, and TDC grooves on the camshaft pulleysshould align with timing belt cover plates.ProCarManuals.com

Page 89 of 1640

Timing Belt

Inspection

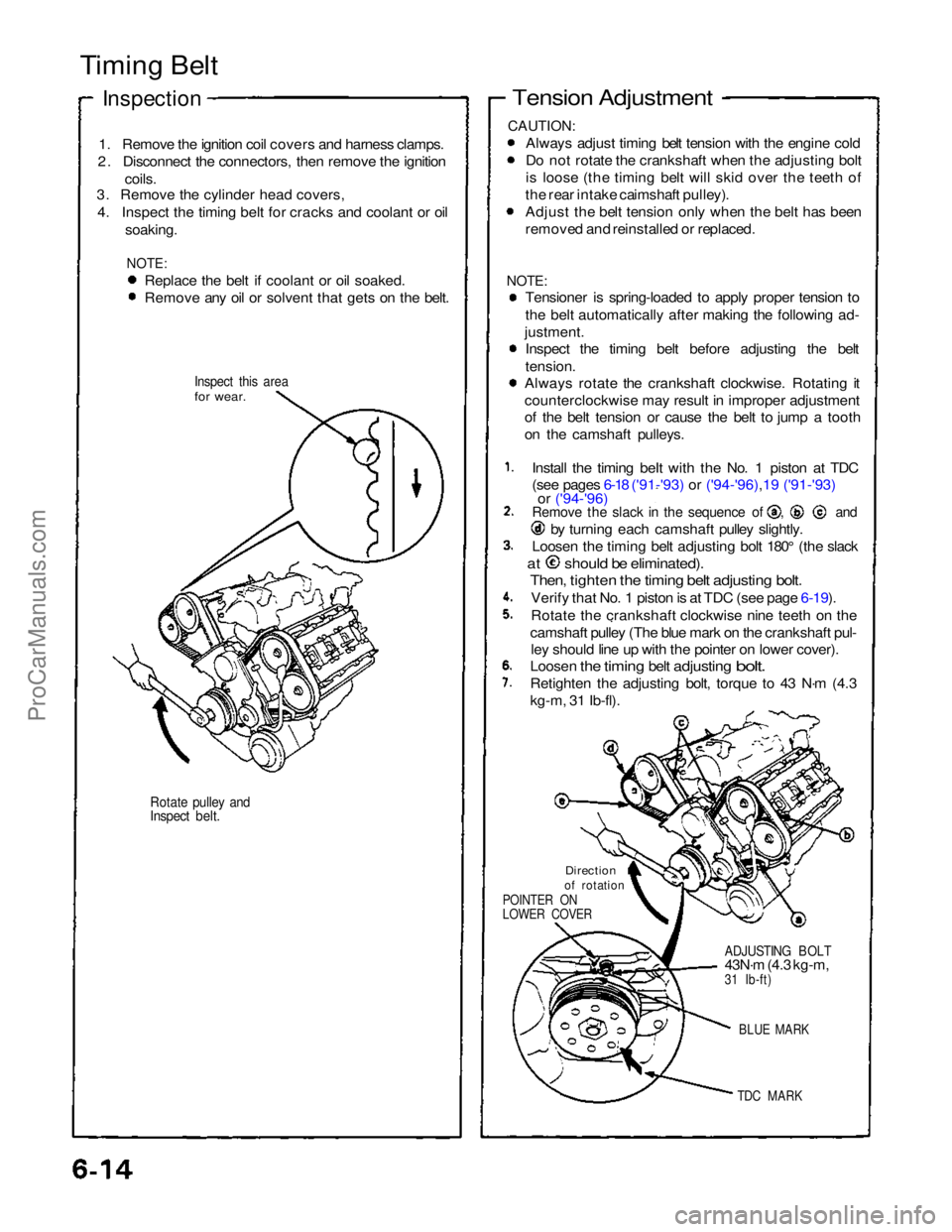

1. Remove the ignition coil covers and harness clamps.

2. Disconnect the connectors, then remove the ignition

coils.

3. Remove the cylinder head covers,

4. Inspect the timing belt for cracks and coolant or oil soaking.

NOTE:

Replace the belt if coolant or oil soaked.

Remove any oil or solvent that gets on the belt.

Inspect this area

for wear.

Rotate pulley and

Inspect belt.

Tension Adjustment

CAUTION:

Always adjust timing belt tension with the engine cold

Do not rotate the crankshaft when the adjusting bolt

is loose (the timing belt will skid over the teeth of

the rear intake caimshaft pulley).

Adjust the belt tension only when the belt has been

removed and reinstalled or replaced.

NOTE:

Tensioner is spring-loaded to apply proper tension to

the belt automatically after making the following ad-

justment. Inspect the timing belt before adjusting the belt

tension.

Always rotate the crankshaft clockwise. Rotating it

counterclockwise may result in improper adjustment

of the belt tension or cause the belt to jump a tooth

on the camshaft pulleys.

Install the timing beIt with the No. 1 piston at TDC

(see pages 6-18 ('91-'93) or ('94-'96),19 ('91-'93)

or ('94-'96) Remove the slack in the sequence of , and

by turning each camshaft pulley slightly.

Loosen the timing belt adjusting bolt 180° (the slack

at should be eliminated).

Then, tighten the timing belt adjusting bolt.

Verify that No. 1 piston is at TDC (see page 6-19).

Rotate the crankshaft clockwise nine teeth on the

camshaft pulley (The blue mark on the crankshaft pul- ley should line up with the pointer on lower cover).

Loosen

the

timing

belt

adjusting

bolt.

Retighten the adjusting bolt, torque to 43 N·m (4.3

kg-m, 31 Ib-fl).

Direction

of rotation

POINTER ON

LOWER COVER

ADJUSTING BOLT

43N·m (4.3 kg-m,

31 Ib-ft)

BLUE MARK

TDC MARK

ProCarManuals.com