engine ACURA NSX 1991 Service Owner's Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 131 of 1640

Main Bearing s

Clearanc e

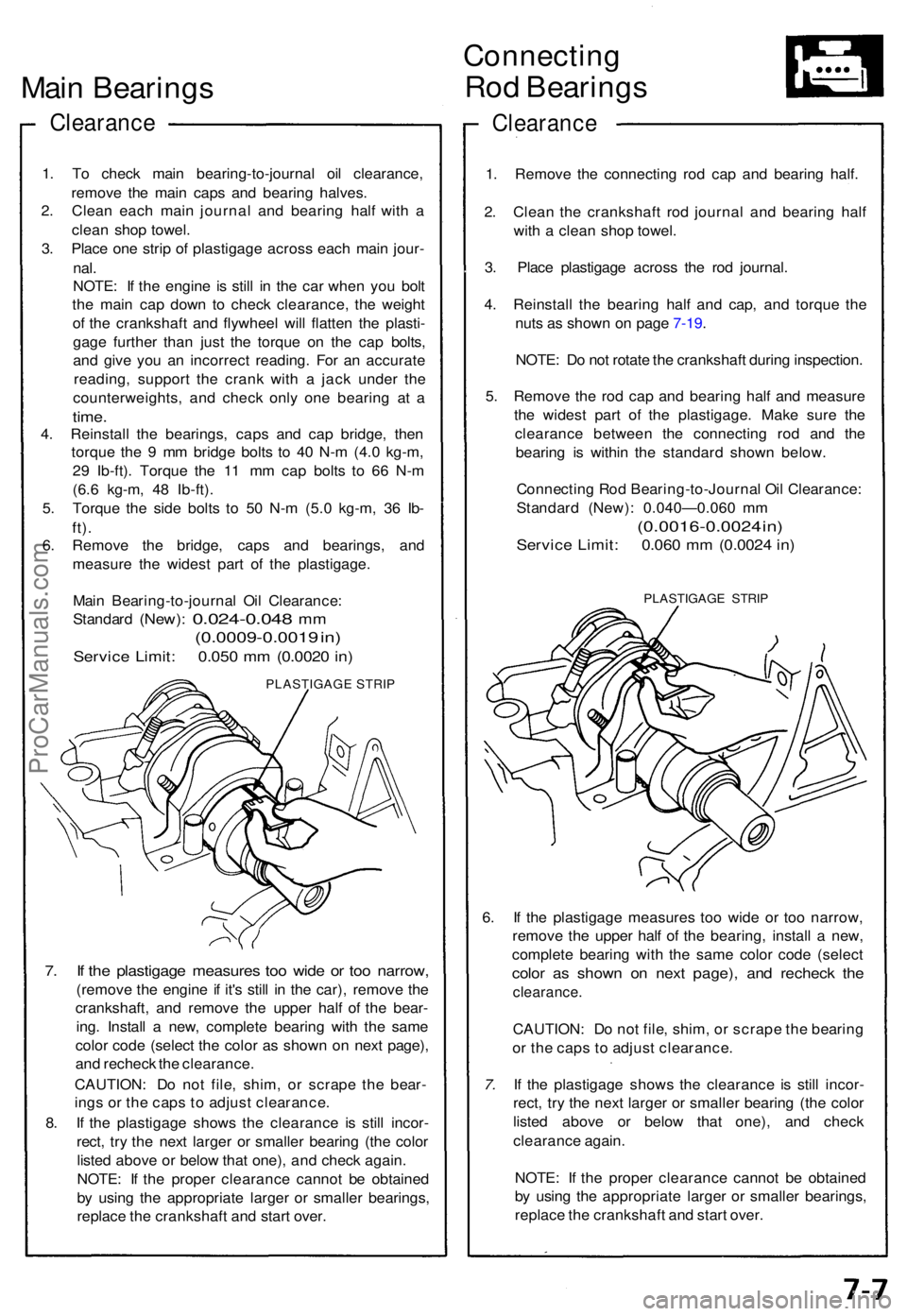

1. T o chec k mai n bearing-to-journa l oi l clearance ,

remov e th e mai n cap s an d bearin g halves .

2 . Clea n eac h mai n journa l an d bearin g hal f wit h a

clea n sho p towel.

3 . Plac e on e stri p o f plastigag e acros s eac h mai n jour -

nal.

NOTE : I f th e engine is stil l i n th e ca r whe n yo u bol t

th e mai n ca p dow n t o chec k clearance , th e weigh t

o f th e crankshaf t an d flywhee l wil l flatte n th e plasti -

gag e furthe r tha n jus t th e torqu e o n th e ca p bolts ,

an d giv e yo u a n incorrec t reading . Fo r a n accurat e

reading , suppor t th e cran k wit h a jac k unde r th e

counterweights , an d chec k onl y on e bearin g a t a

time .

4. Reinstal l th e bearings , cap s an d ca p bridge , the n

torqu e th e 9 m m bridg e bolt s t o 4 0 N- m (4. 0 kg-m ,

2 9 Ib-ft) . Torqu e th e 1 1 m m ca p bolt s t o 6 6 N- m

(6. 6 kg-m , 4 8 Ib-ft) .

5 . Torqu e th e sid e bolt s t o 5 0 N- m (5. 0 kg-m , 3 6 Ib -

ft).

6. Remov e th e bridge , cap s an d bearings , an d

measur e th e wides t par t o f th e plastigage .

Mai n Bearing-to-journa l Oi l Clearance :

Standar d

(New): 0.024-0.04 8 mm

(0.0009-0.001 9 in )

Servic e Limit : 0.05 0 m m (0.002 0 in )

PLASTIGAG E STRI P

7. I f th e plastigag e measure s to o wid e o r to o narrow ,

(remove th e engine if it' s stil l i n th e car) , remov e th e

crankshaft , an d remov e th e uppe r hal f o f th e bear -

ing . Instal l a new , complet e bearin g wit h th e sam e

colo r cod e (selec t th e colo r a s show n o n nex t page) ,

an d rechec k th e clearance .

CAUTION : D o no t file , shim , o r scrap e th e bear -

ing s o r th e cap s t o adjus t clearance .

8 . I f th e plastigag e show s th e clearanc e i s stil l incor -

rect , tr y th e nex t large r o r smalle r bearin g (th e colo r

liste d abov e o r belo w tha t one) , an d chec k again .

NOTE : I f th e prope r clearanc e canno t b e obtaine d

b y usin g th e appropriat e large r o r smalle r bearings ,

replac e th e crankshaf t an d star t over .

Connectin g

Rod Bearing s

Clearanc e

1. Remov e th e connectin g ro d ca p an d bearin g half .

2 . Clea n th e crankshaf t ro d journa l an d bearin g hal f

wit h a clea n sho p towel .

3 . Plac e plastigag e acros s th e ro d journal .

4 . Reinstal l th e bearin g hal f an d cap , an d torqu e th e

nut s a s show n o n pag e 7-19 .

NOTE : D o no t rotat e th e crankshaft during inspection .

5 . Remov e th e ro d ca p an d bearin g hal f an d measur e

th e wides t par t o f th e plastigage . Mak e sur e th e

clearanc e betwee n th e connectin g ro d an d th e

bearin g i s withi n th e standar d show n below .

Connectin g Ro d Bearing-to-Journa l Oi l Clearance :

Standar d (New) : 0.040—0.06 0 m m

(0.0016-0.002 4 in )

Servic e Limit : 0.06 0 m m (0.002 4 in )

PLASTIGAG E STRI P

6. I f th e plastigag e measure s to o wid e o r to o narrow ,

remov e th e uppe r hal f of the bearing , instal l a new ,

complet e bearin g wit h th e sam e colo r cod e (selec t

color a s show n o n nex t page) , an d rechec k th e

clearance .

CAUTION: D o no t file , shim , o r scrap e th e bearin g

o r th e cap s t o adjus t clearance .

7. I f th e plastigag e show s th e clearanc e i s stil l incor -

rect , tr y th e nex t large r o r smalle r bearin g (th e colo r

liste d abov e o r belo w tha t one) , an d chec k

clearanc e again .

NOTE : I f th e prope r clearanc e canno t b e obtaine d

b y usin g th e appropriat e large r o r smalle r bearings ,

replac e th e crankshaf t an d star t over .

ProCarManuals.com

Page 134 of 1640

Piston/Connecting Rod Assemblies and Crankshaft

Removal

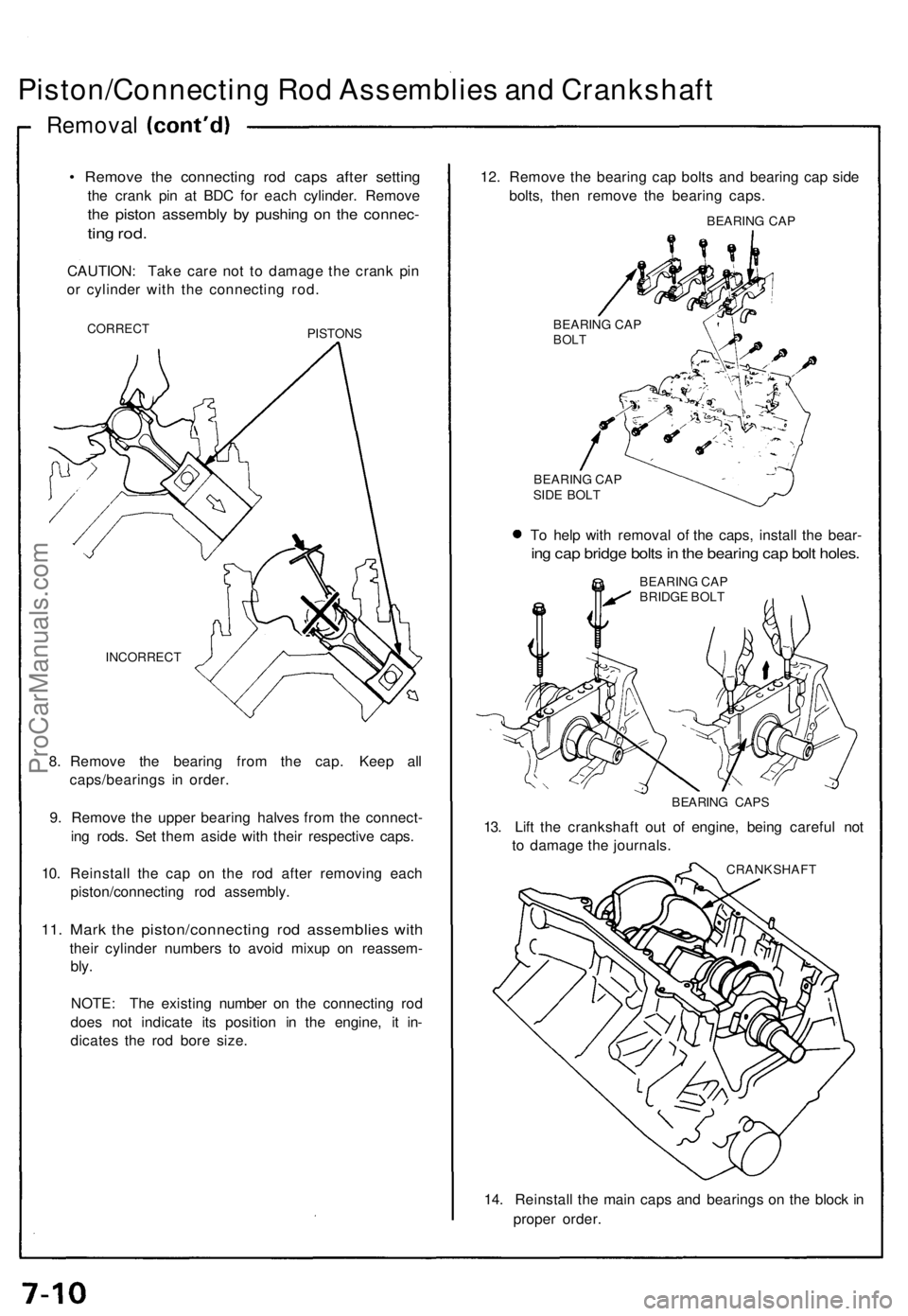

• Remove the connecting rod caps after setting

the crank pin at BDC for each cylinder. Remove

the piston assembly by pushing on the connec-

ting rod.

CAUTION: Take care not to damage the crank pin

or cylinder with the connecting rod.

CORRECT

PISTONS

INCORRECT

8. Remove the bearing from the cap. Keep all

caps/bearings in order.

9. Remove the upper bearing halves from the connect-

ing rods. Set them aside with their respective caps.

10. Reinstall the cap on the rod after removing each

piston/connecting rod assembly.

11. Mark the piston/connecting rod assemblies with

their cylinder numbers to avoid mixup on reassem-

bly.

NOTE: The existing number on the connecting rod

does not indicate its position in the engine, it in-

dicates the rod bore size.

12. Remove the bearing cap bolts and bearing cap side

bolts, then remove the bearing caps.

BEARING CAP

BEARING CAP

BOLT

BEARING CAP

SIDE BOLT

To help with removal of the caps, install the bear-

ing cap bridge bolts in the bearing cap bolt holes.

BEARING CAP

BRIDGE BOLT

BEARING CAPS

13. Lift the crankshaft out of engine, being careful not

to damage the journals.

CRANKSHAFT

14. Reinstall the main caps and bearings on the block in

proper order.ProCarManuals.com

Page 136 of 1640

Cylinder Bloc k

Inspectio n

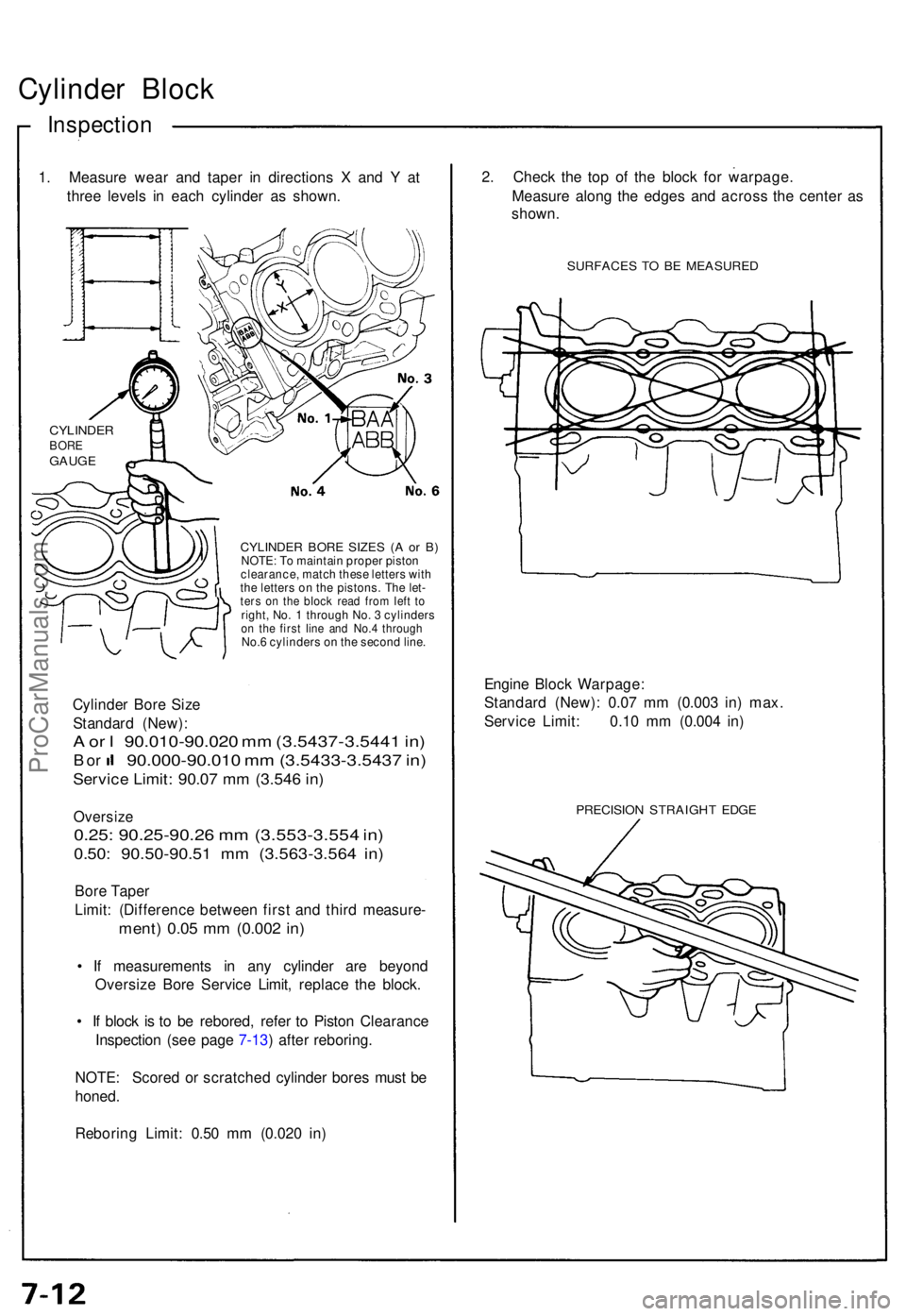

1. Measur e wea r an d tape r i n direction s X an d Y at

thre e level s i n eac h cylinde r a s shown .

CYLINDE R BOR E SIZE S ( A o r B )NOTE : T o maintai n prope r pisto n

clearance , matc h thes e letter s wit h

th e letter s o n th e pistons . Th e let -

ters o n th e bloc k rea d fro m lef t t oright , No . 1 throug h No . 3 cylinder son th e firs t lin e an d No. 4 throug hNo.6 cylinder s o n th e secon d line .

Cylinde r Bor e Siz e

Standar d (New) :

A o r I 90.010-90.02 0 m m (3.5437-3.544 1 in )

B or 90.000-90.01 0 m m (3.5433-3.543 7 in )

Servic e Limit : 90.0 7 m m (3.54 6 in )

Oversiz e

0.25: 90.25-90.2 6 m m (3.553-3.55 4 in )

0.50 : 90.50-90.5 1 m m (3.563-3.56 4 in )

Bor e Tape r

Limit : (Differenc e betwee n firs t an d thir d measure -

ment) 0.0 5 m m (0.00 2 in )

• I f measurement s i n an y cylinde r ar e beyon d

Oversiz e Bor e Servic e Limit , replac e th e block .

• I f bloc k i s t o b e rebored , refe r t o Pisto n Clearanc e

Inspectio n (se e pag e 7-13 ) afte r reboring .

NOTE : Score d o r scratche d cylinde r bore s mus t b e

honed .

Reborin g Limit : 0.5 0 m m (0.02 0 in ) 2

. Chec k th e to p o f th e bloc k fo r warpage .

Measur e alon g th e edge s an d acros s th e cente r a s

shown .

SURFACE S T O B E MEASURE D

Engine Bloc k Warpage :

Standar d (New) : 0.0 7 m m (0.00 3 in ) max .

Servic e Limit : 0.1 0 m m (0.00 4 in )

PRECISIO N STRAIGH T EDG E

CYLINDE RBOREGAUG E

ProCarManuals.com

Page 139 of 1640

Connecting Rod s

Selectio n

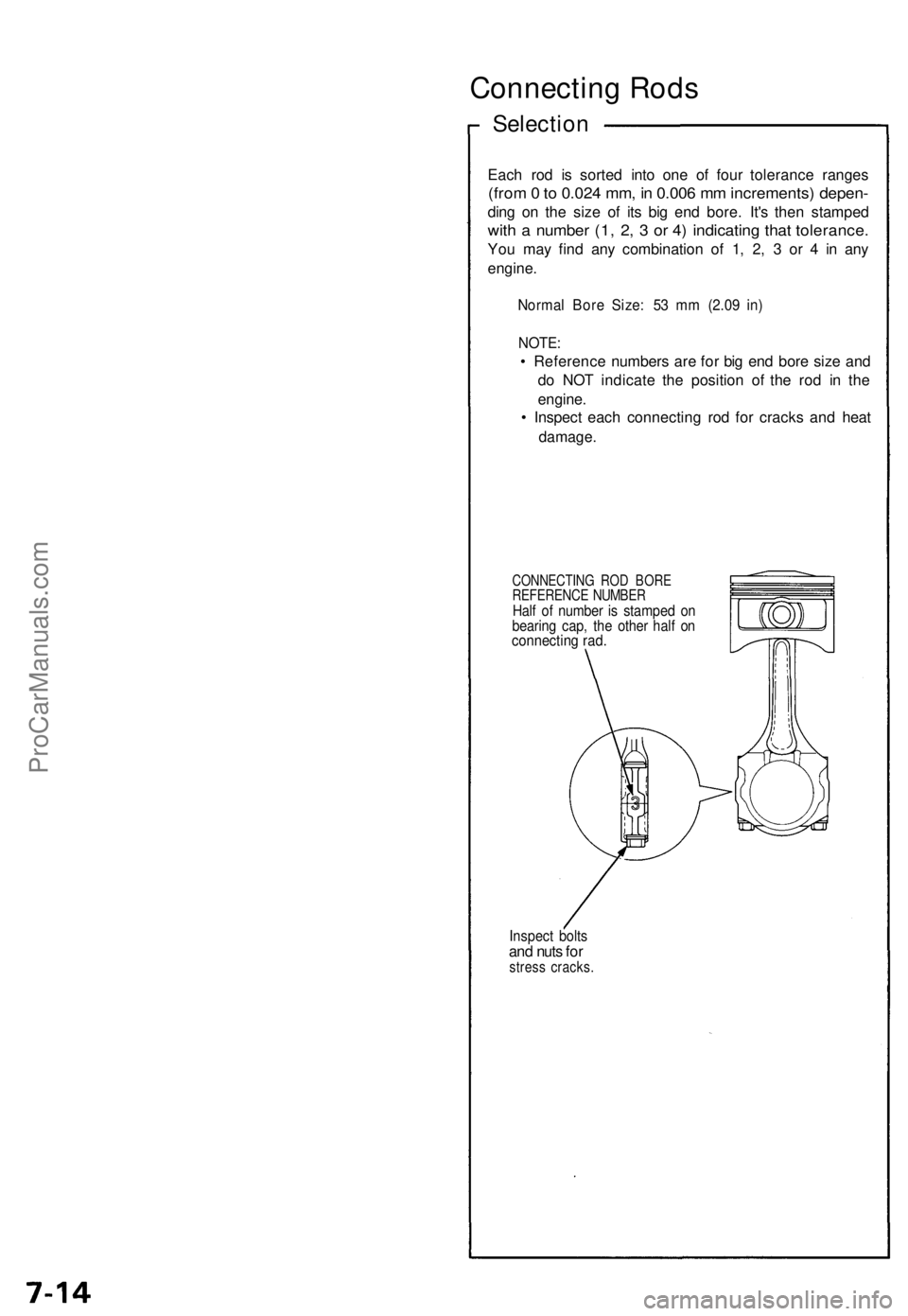

Each ro d i s sorte d int o on e o f fou r toleranc e range s

(from 0 to 0.02 4 mm , i n 0.00 6 m m increments ) depen -

ding o n th e siz e o f it s bi g en d bore . It' s the n stampe d

with a numbe r (1 , 2 , 3 or 4 ) indicatin g tha t tolerance .

You ma y fin d an y combinatio n o f 1 , 2 , 3 or 4 in an y

engine .

Norma l Bor e Size : 5 3 m m (2.0 9 in )

NOTE :

• Referenc e number s ar e fo r bi g en d bor e siz e an d

d o NO T indicat e th e positio n of the ro d i n th e

engine .

• Inspec t eac h connectin g ro d fo r crack s an d hea t

damage .

CONNECTIN G RO D BOR EREFERENC E NUMBE RHalf o f numbe r i s stampe d o nbearin g cap , th e othe r hal f o nconnectin g rad .

Inspec t bolt sand nut s fo rstres s cracks .

ProCarManuals.com

Page 140 of 1640

Piston Ring s

End Ga p

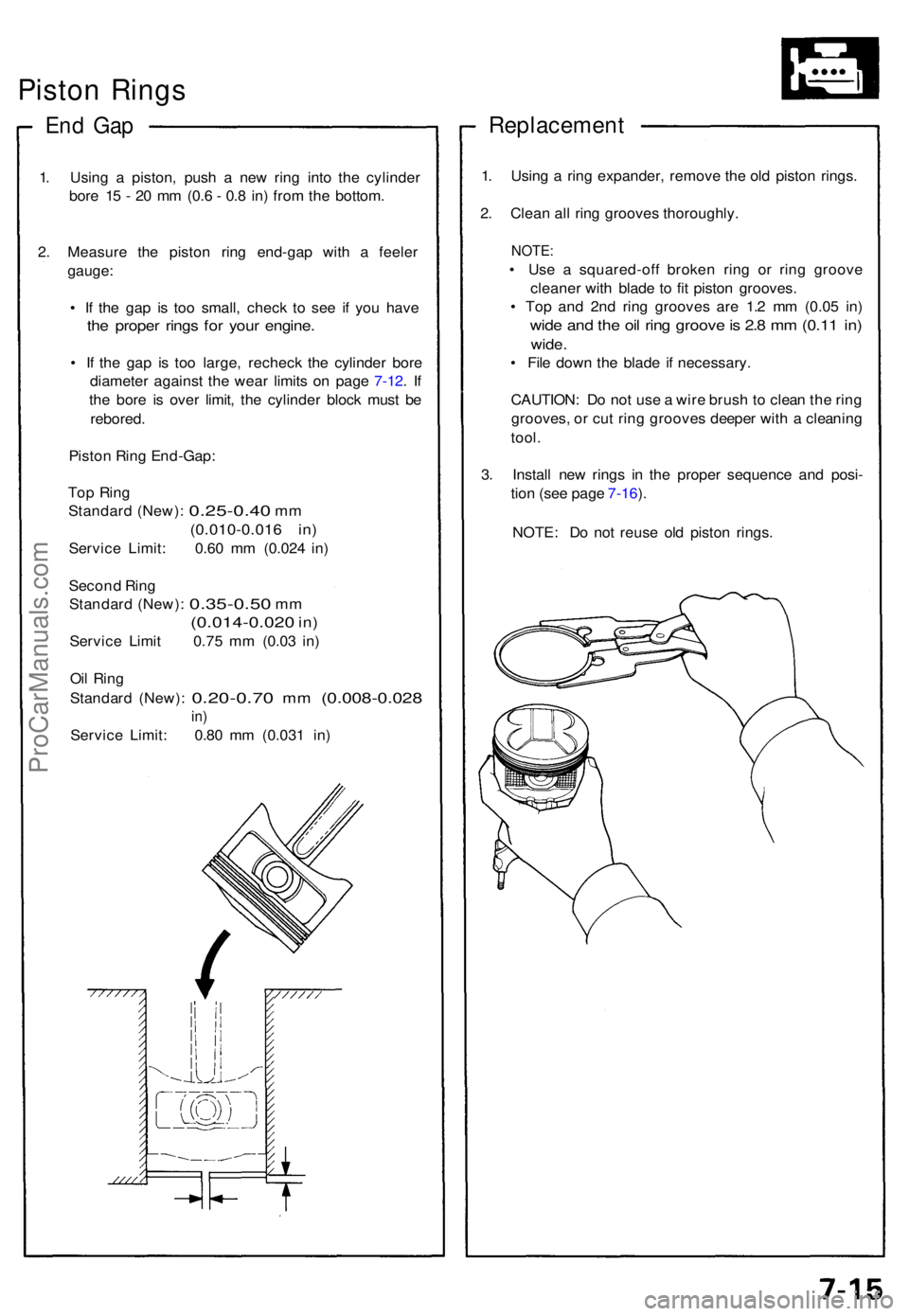

1. Usin g a piston , pus h a ne w rin g int o th e cylinde r

bor e 1 5 - 2 0 m m (0. 6 - 0. 8 in ) fro m th e bottom .

2 . Measur e th e pisto n rin g end-ga p wit h a feele r

gauge :

• I f th e ga p i s to o small , chec k t o se e i f yo u hav e

the prope r ring s fo r you r engine .

• I f th e ga p i s to o large , rechec k th e cylinde r bor e

diameter against th e wea r limit s o n pag e 7-12 . I f

th e bor e i s ove r limit , th e cylinde r bloc k mus t b e

rebored .

Pisto n Rin g End-Gap :

To p Rin g

Standar d (New) :

0.25-0.4 0 mm

(0.010-0.01 6 in )

Servic e Limit : 0.6 0 m m (0.02 4 in )

Secon d Rin g

Standar d (New) :

0.35-0.5 0 mm

(0.014-0.02 0 in)

Servic e Limi t 0.7 5 m m (0.0 3 in )

Oi l Rin g

Standar d (New) :

0.20-0.7 0 mm (0.008-0.02 8

in)

Servic e Limit : 0.8 0 m m (0.03 1 in )

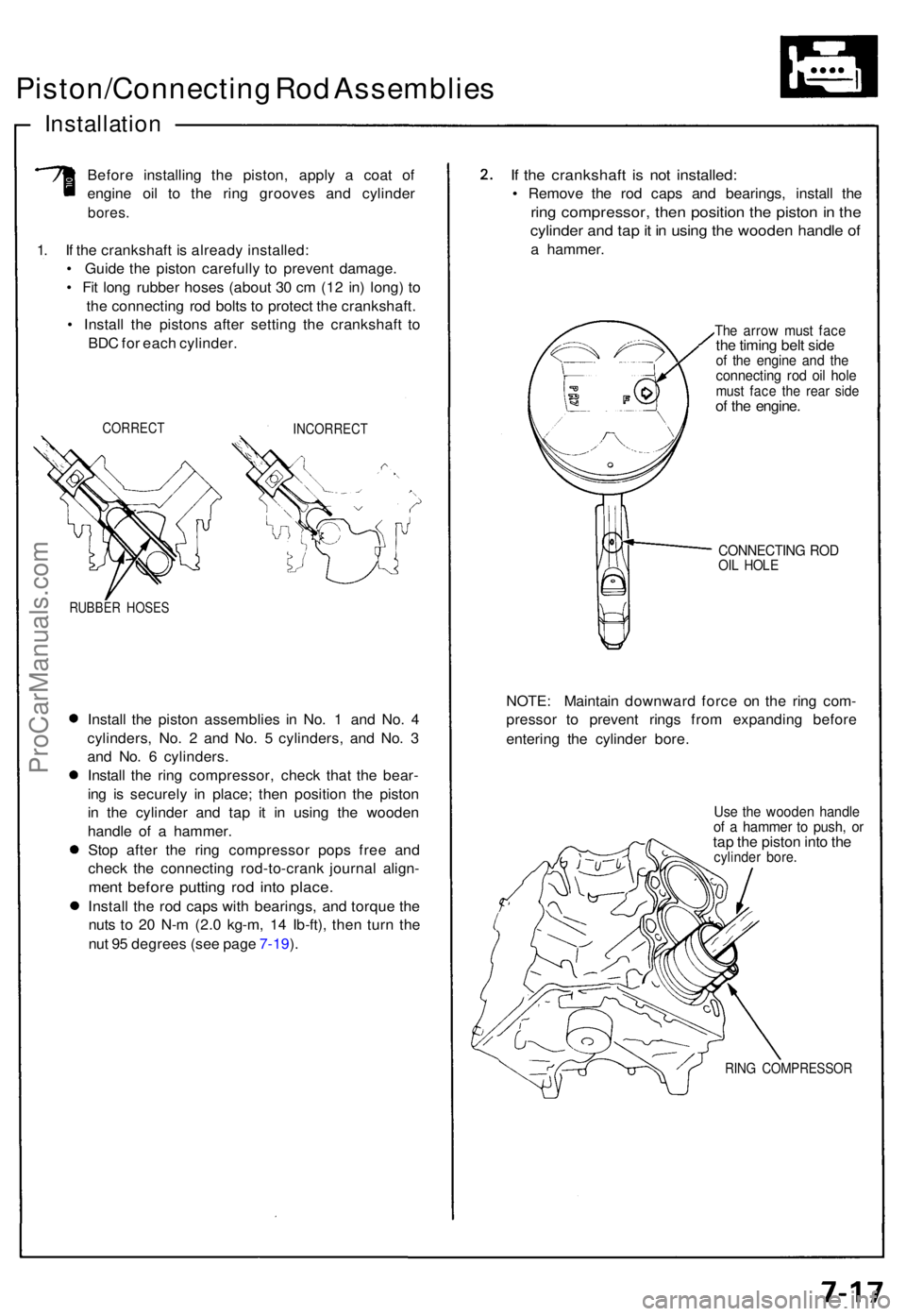

Replacemen t

1. Usin g a rin g expander , remov e th e ol d pisto n rings .

2 . Clea n al l rin g groove s thoroughly .

NOTE:

• Us e a squared-of f broke n rin g o r rin g groov e

cleane r wit h blad e t o fi t pisto n grooves .

• To p an d 2n d rin g groove s ar e 1. 2 m m (0.0 5 in )

wid e an d th e oi l rin g groov e is 2. 8 m m (0.1 1 in )

wide .

• Fil e dow n th e blad e i f necessary .

CAUTION : D o no t us e a wir e brus h to clea n th e rin g

grooves , o r cu t rin g groove s deepe r wit h a cleanin g

tool .

3 . Instal l ne w ring s i n th e prope r sequenc e an d posi -

tio n (se e pag e 7-16 ).

NOTE : D o no t reus e ol d pisto n rings .

ProCarManuals.com

Page 142 of 1640

Piston/Connecting Ro d Assemblie s

Installation

Before installin g th e piston , appl y a coa t o f

engin e oi l t o th e rin g groove s an d cylinde r

bores.

1. I f th e crankshaf t i s alread y installed :

• Guid e th e pisto n carefull y t o preven t damage .

• Fi t lon g rubbe r hose s (abou t 3 0 c m (1 2 in ) long ) t o

th e connectin g ro d bolt s t o protec t th e crankshaft .

• Instal l th e piston s afte r settin g th e crankshaf t t o

BD C fo r eac h cylinder .

CORREC TINCORREC T

RUBBER HOSE S

Install th e pisto n assemblie s i n No . 1 an d No . 4

cylinders , No . 2 an d No . 5 cylinders , an d No . 3

an d No . 6 cylinders .

Instal l th e rin g compressor , chec k tha t th e bear -

in g i s securel y i n place ; the n positio n th e pisto n

i n th e cylinde r an d ta p i t i n usin g th e woode n

handl e of a hammer .

Sto p afte r th e rin g compresso r pop s fre e an d

chec k th e connectin g rod-to-cran k journa l align -

ment befor e puttin g ro d int o place .

Install th e ro d cap s wit h bearings , an d torqu e th e

nut s t o 2 0 N- m (2. 0 kg-m , 1 4 Ib-ft) , the n tur n th e

nu t 9 5 degree s (se e pag e 7-19 ).

If th e crankshaf t i s no t installed :

• Remov e th e ro d cap s an d bearings , instal l th e

ring compressor , the n positio n th e pisto n in th e

cylinde r an d ta p it i n usin g th e woode n handl e of

a hammer .

The arro w mus t fac ethe timin g bel t sid eof th e engin e an d th econnectin g ro d oi l hol emus t fac e th e rea r sid eof th e engine .

CONNECTIN G RO DOIL HOL E

NOTE : Maintai n downwar d forc e o n th e rin g com -

presso r t o preven t ring s fro m expandin g befor e

enterin g th e cylinde r bore .

Use th e woode n handl eof a hamme r t o push , o rtap th e pisto n int o th ecylinde r bore .

RING COMPRESSO R

ProCarManuals.com

Page 143 of 1640

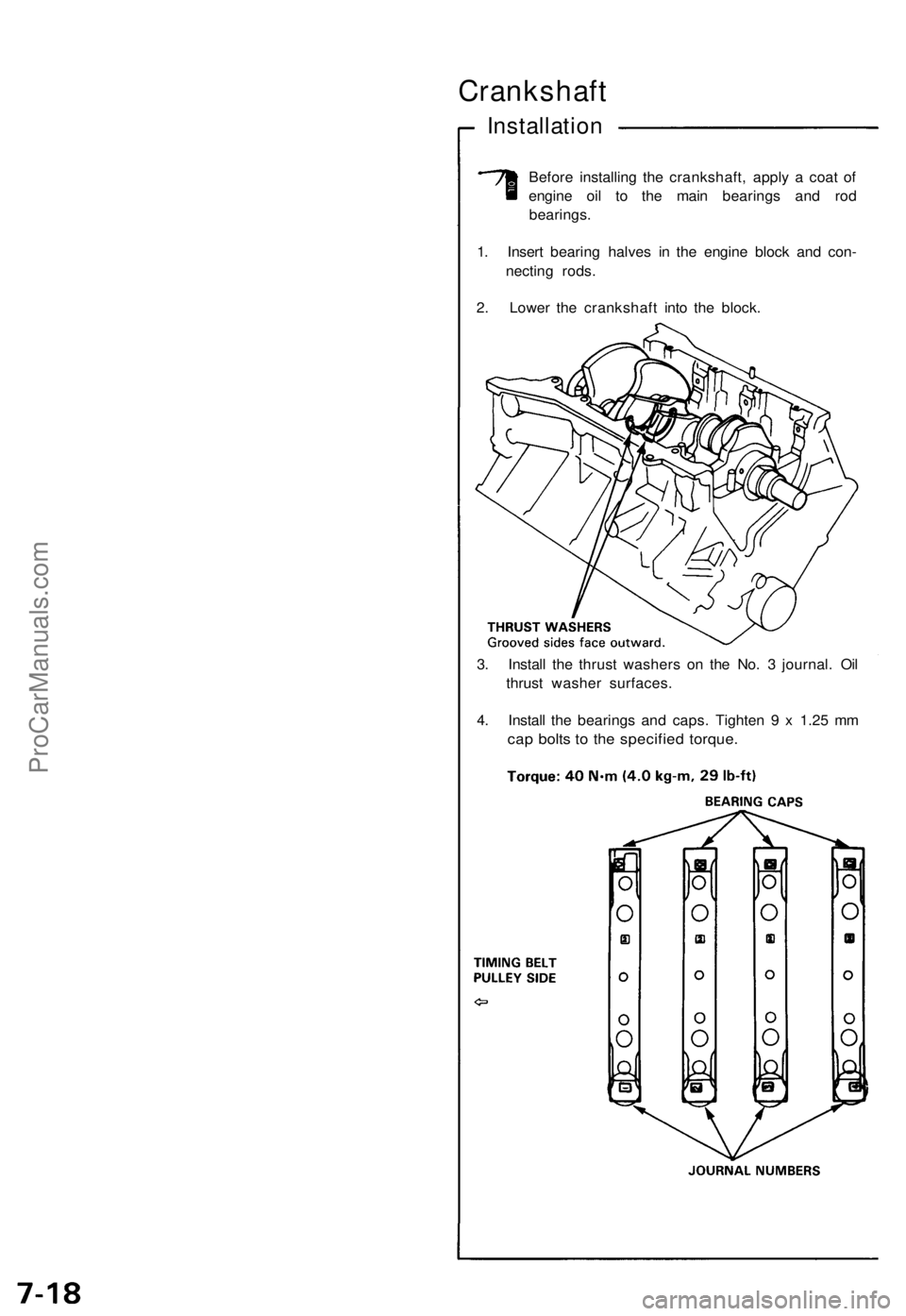

Crankshaft

Installation

Before installing the crankshaft, apply a coat of

engine oil to the main bearings and rod

bearings.

1. Insert bearing halves in the engine block and con-

necting rods.

2. Lower the crankshaft into the block.

3. Install the thrust washers on the No. 3 journal. Oil

thrust washer surfaces.

4. Install the bearings and caps. Tighten 9 x 1.25 mm

cap bolts to the specified torque.ProCarManuals.com

Page 144 of 1640

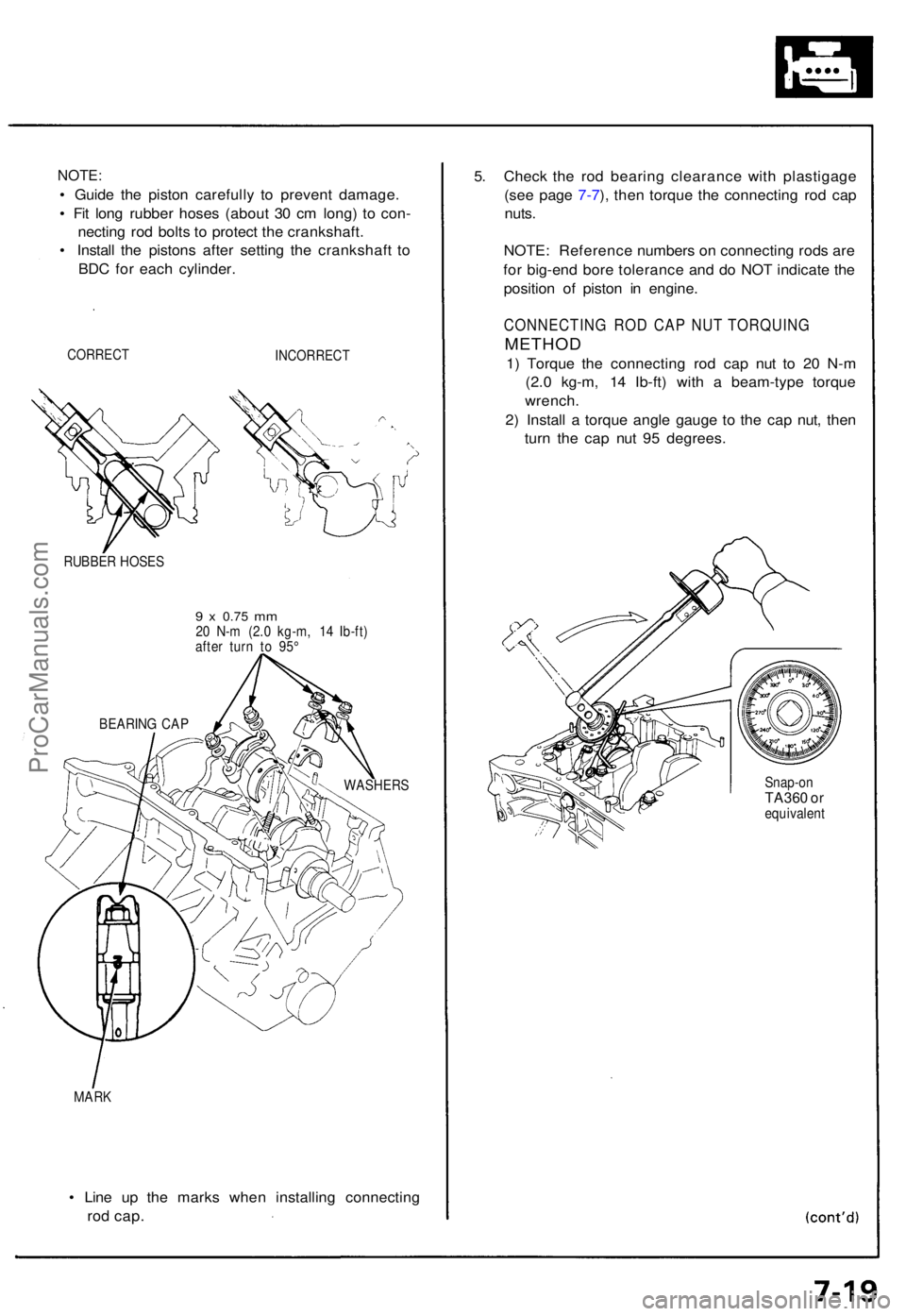

NOTE:

• Guid e th e pisto n carefull y t o preven t damage .

• Fi t lon g rubbe r hose s (abou t 3 0 c m long ) t o con -

nectin g ro d bolt s t o protec t th e crankshaft .

• Instal l th e piston s afte r settin g th e crankshaf t t o

BD C fo r eac h cylinder .

CORREC TINCORREC T

RUBBER HOSE S

9 x 0.7 5 mm20 N- m (2. 0 kg-m , 1 4 Ib-ft )

afte r tur n t o 95 °

MAR K

• Lin e u p th e mark s whe n installin g connectin g

rod cap .

5. Chec k th e ro d bearin g clearanc e wit h plastigag e

(se e pag e 7-7 ), the n torqu e th e connectin g ro d ca p

nuts .

NOTE : Referenc e number s o n connectin g rod s ar e

fo r big-en d bor e toleranc e an d d o NO T indicat e th e

positio n o f pisto n i n engine .

CONNECTIN G RO D CA P NU T TORQUIN G

METHOD

1) Torqu e th e connectin g ro d ca p nu t t o 2 0 N- m

(2. 0 kg-m , 1 4 Ib-ft ) wit h a beam-typ e torqu e

wrench .

2 ) Instal l a torqu e angl e gaug e t o th e ca p nut , the n

tur n th e ca p nu t 9 5 degrees .

Snap-onTA360 o requivalen t

BEARIN

G CA P

WASHERS

ProCarManuals.com

Page 148 of 1640

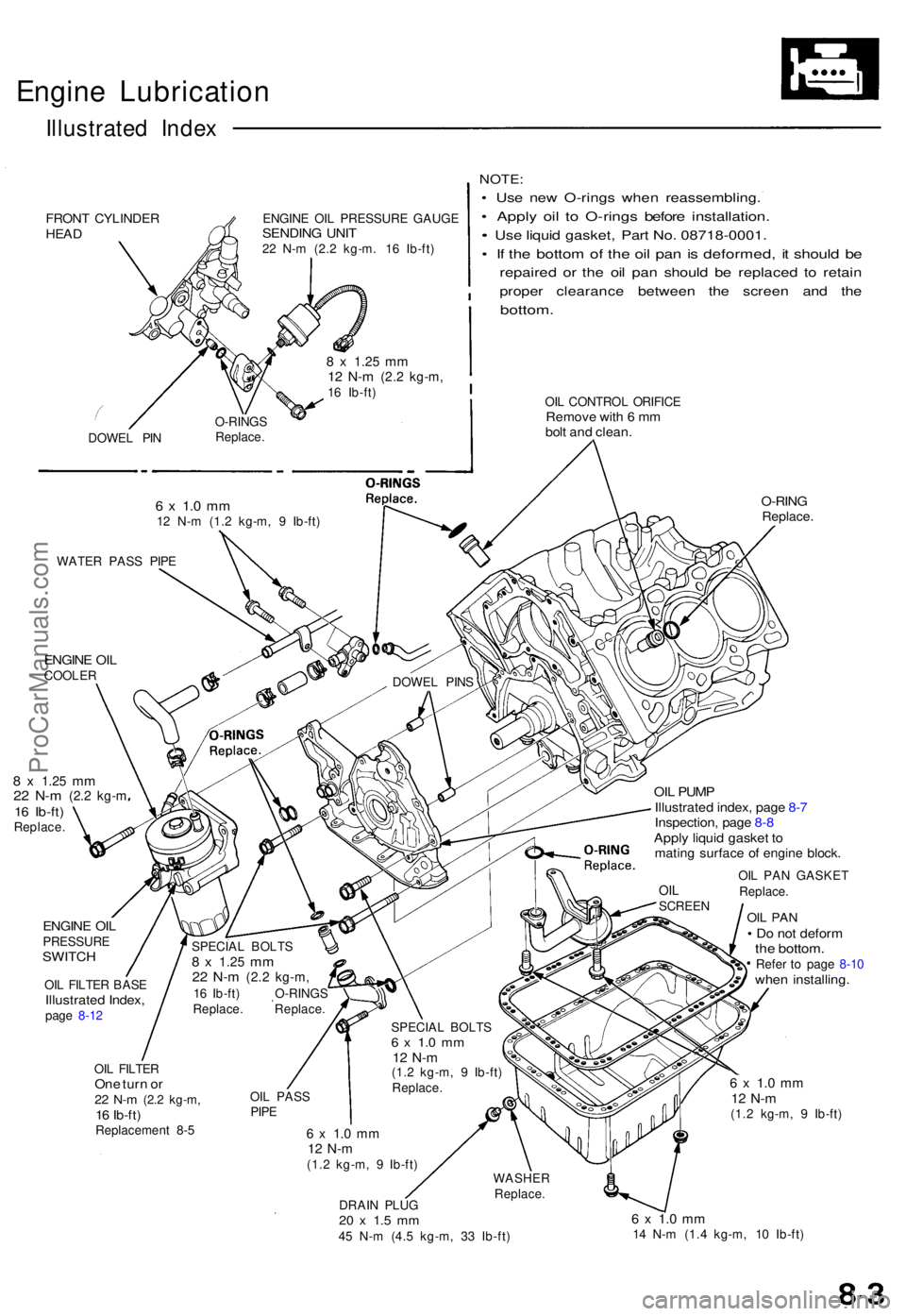

Engine Lubricatio n

Illustrated Inde x

FRON T CYLINDE RHEADENGIN E OI L PRESSUR E GAUG ESENDIN G UNI T22 N- m (2. 2 kg-m . 1 6 Ib-ft )

NOTE :

• Us e ne w O-ring s whe n reassembling .

• Appl y oi l t o O-ring s befor e installation .

• Us e liqui d gasket , Par t No . 08718-0001 .

• I f th e botto m o f th e oi l pa n is deformed , i t shoul d b e

repaire d o r th e oi l pa n shoul d b e replace d t o retai n

prope r clearanc e betwee n th e scree n an d th e

bottom .

OIL CONTRO L ORIFIC ERemove wit h 6 m mbol t an d clean .

O-RIN GReplace .

8 x 1.2 5 mm22 N- m (2. 2 kg- m16 Ib-ft )Replace .

ENGINE OI LPRESSUR ESWITCH

OIL FILTE R BAS EIllustrate d Index ,page 8-1 2

OIL PUM PIllustrate d index , pag e 8- 7Inspection , pag e 8 -8Appl y liqui d gaske t t omatin g surfac e o f engin e block .

OIL PA N GASKE T

Replace .

OIL PA N• D o no t defor mthe bottom .Refer t o pag e 8-1 0whe n installing .

OIL FILTE ROne tur n o r22 N- m (2. 2 kg-m ,16 Ib-ft )Replacemen t 8- 5

6 x 1. 0 m m12 N- m(1.2 kg-m , 9 Ib-ft )

6 x 1. 0 m m12 N- m(1.2 kg-m , 9 Ib-ft )

DRAI N PLU G

20 x 1. 5 m m45 N- m (4. 5 kg-m , 3 3 Ib-ft )

6 x 1. 0 m m14 N- m (1. 4 kg-m , 1 0 Ib-ft )

ENGIN E OI LCOOLE R

WATE

R PAS S PIP E

DOWEL PIN S

SPECIA L BOLT S

8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft ) O-RING S

Replace . Replace .

OI L PAS S

PIPE

SPECIA L BOLT S6 x 1. 0 m m12 N- m(1.2 kg-m , 9 Ib-ft )

Replace .

6 x 1. 0 m m12 N- m (1. 2 kg-m , 9 Ib-ft )

DOWE

L PI N O-RING

S

Replace .

8 x 1.2 5 mm12 N- m (2. 2 kg-m ,16 Ib-ft )

OILSCREE N

WASHE R

Replace .

ProCarManuals.com

Page 149 of 1640

Engine Oil

Inspection

1. Check engine oil with the engine off and the car

parked on level ground.

2. Make certain that the oil level indicated on the

dipstick is between the upper and lower marks.

3. If the level has dropped close to the lower mark,

add oil until it reaches the upper mark.

CAUTION: Insert the dipstick carefully to avoid

bending it.ProCarManuals.com