engine ACURA NSX 1991 Service Service Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 150 of 1640

Oil Filte r

Replacemen t

CAUTION: Loose n th e oi l filte r carefull y whil e th e

engin e is hot , th e ho t oi l ma y caus e scalding .

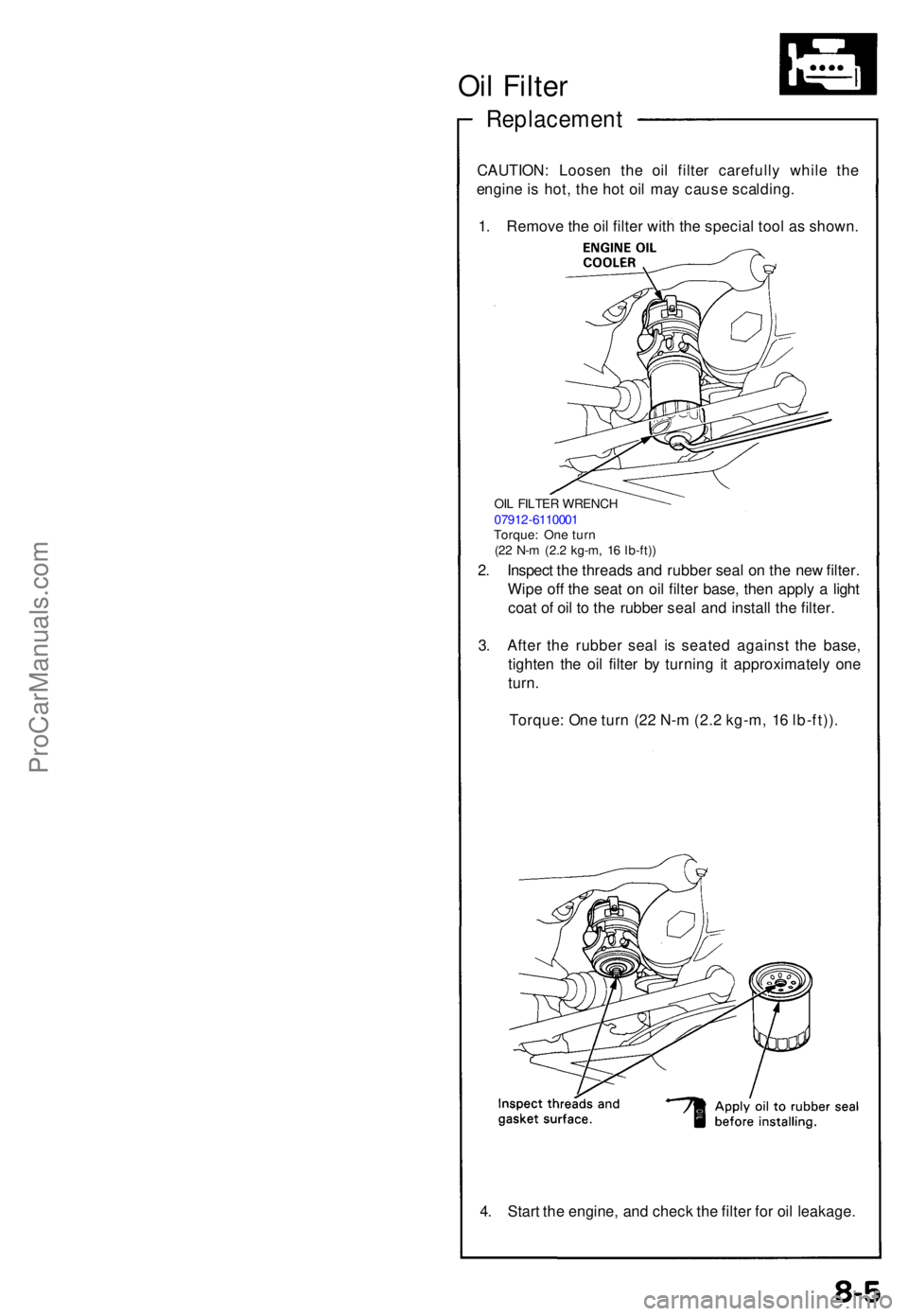

1 . Remov e th e oi l filte r wit h th e specia l too l a s shown .

2 . Inspec t th e thread s an d rubbe r sea l o n th e ne w filter .

Wip e of f th e sea t o n oi l filte r base , the n appl y a ligh t

coa t o f oi l t o th e rubbe r sea l an d instal l th e filter .

3 . Afte r th e rubbe r sea l i s seate d agains t th e base ,

tighte n th e oi l filte r b y turnin g i t approximatel y on e

turn .

Torque : On e tur n (2 2 N- m (2. 2 kg-m , 1 6 lb-ft)) .

OIL FILTE R WRENC H

0791 2-611000 1

Torque : On e tur n

(2 2 N- m (2. 2 kg-m , 1 6 lb-ft) )

4. Star t th e engine , an d chec k th e filte r fo r oi l leakage .

ProCarManuals.com

Page 151 of 1640

Oil Pressur e

Testing

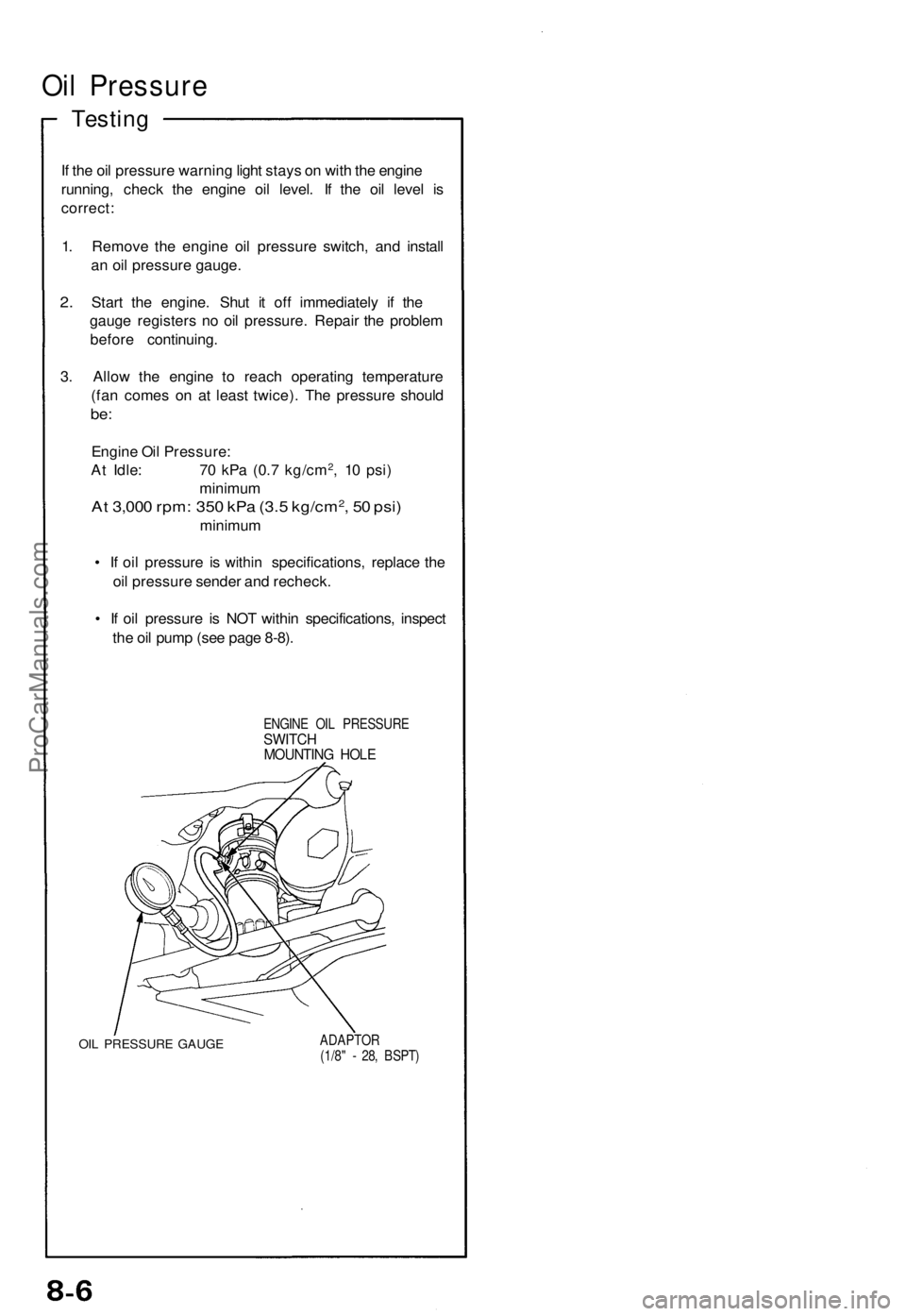

If th e oi l pressur e warnin g ligh t stay s o n wit h th e engin e

running , chec k th e engin e oi l level . I f th e oi l leve l i s

correct :

1 . Remov e th e engin e oi l pressur e switch , an d instal l

a n oi l pressur e gauge .

2. Star t th e engine . Shu t i t of f immediatel y i f th e

gaug e register s n o oi l pressure . Repai r th e proble m

befor e continuing .

3 . Allo w th e engin e t o reac h operatin g temperatur e

(fa n come s o n a t leas t twice) . Th e pressur e shoul d

be:

Engin e Oi l Pressure :

A t Idle : 7 0 kP a (0. 7 kg/cm2, 1 0 psi )

minimu m

At 3,00 0 rpm : 35 0 kP a (3. 5 kg/cm2, 5 0 psi )

minimu m

• I f oi l pressur e i s

within specifications , replac e th e

oi l pressur e sende r an d recheck .

• I f oi l pressur e i s NO T withi n specifications , inspec t

th e oi l pum p (se e pag e 8-8) .

ENGIN E OI L PRESSUR ESWITCHMOUNTIN G HOL E

OIL PRESSUR E GAUG E ADAPTO R

(1/8 " - 28 , BSPT )

ProCarManuals.com

Page 153 of 1640

Oil Pump

Removal/lnspection/lnstallation

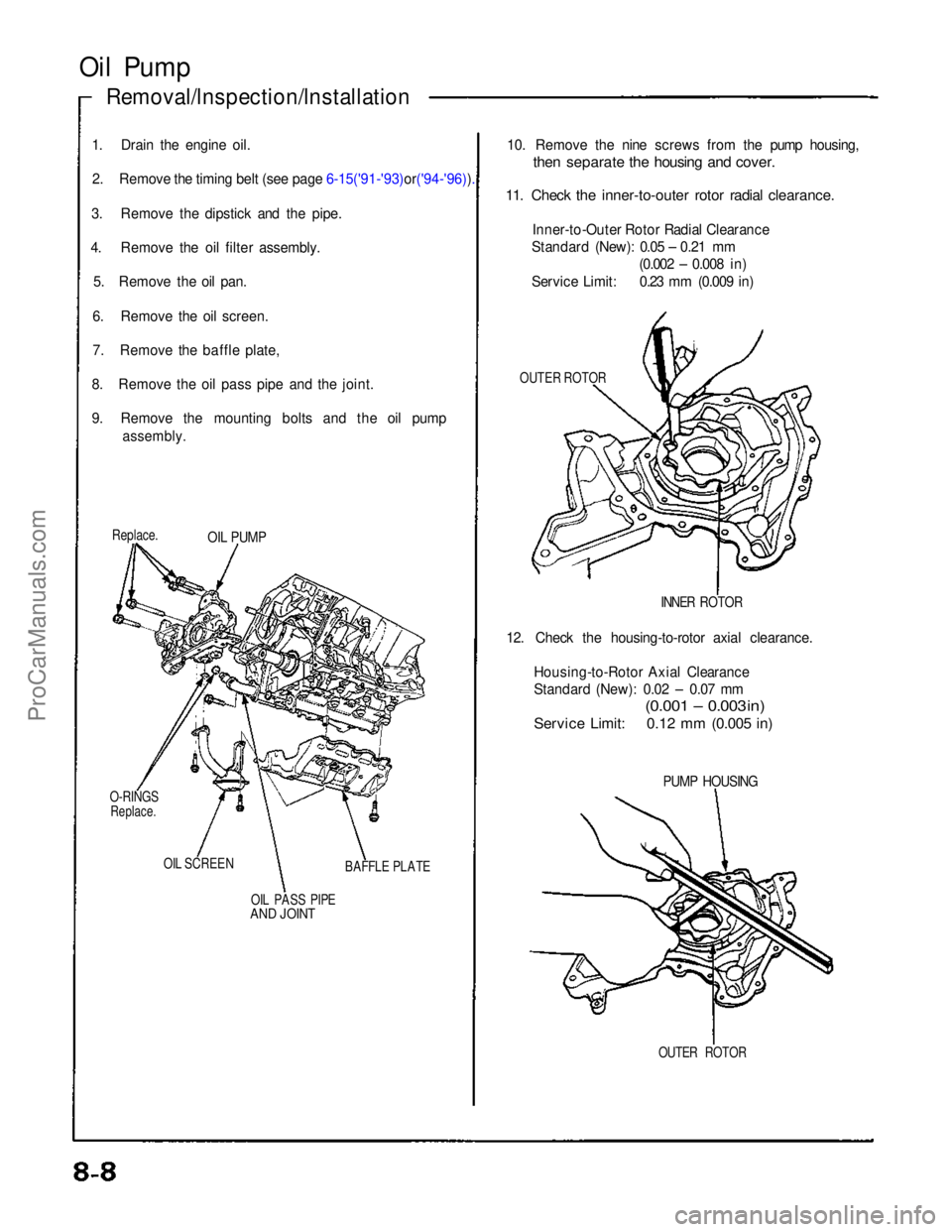

1. Drain the engine oil. 2. Remove the timing belt (see page 6-15('91-'93)or('94-'96)).

3. Remove the dipstick and the pipe.

4. Remove the oil filter assembly.

5. Remove the oil pan.

6. Remove the oil screen.

7. Remove the baffle plate,

8. Remove the oil pass

pipe and the joint.

9. Remove the mounting bolts and the oil pump

assembly.

Replace.

O-RINGS

Replace.

OIL SCREEN OIL PASS PIPE

AND JOINT

BAFFLE PLATE

OIL PUMP

10. Remove the nine screws from the pump housing,

then separate the housing and cover.

11. Check the inner-to-outer rotor radial clearance.

Inner-to-Outer Rotor Radial Clearance

Standard (New): 0.05 – 0.21 mm (0.002 – 0.008 in)

Service Limit: 0.23 mm (0.009 in)

OUTER ROTOR

INNER ROTOR

12. Check the housing-to-rotor axial clearance. Housing-to-Rotor Axial Clearance

Standard (New): 0.02 – 0.07 mm

(0.001 – 0.003 in)

Service Limit: 0.12 mm (0.005 in)

PUMP HOUSING

OUTER ROTORProCarManuals.com

Page 154 of 1640

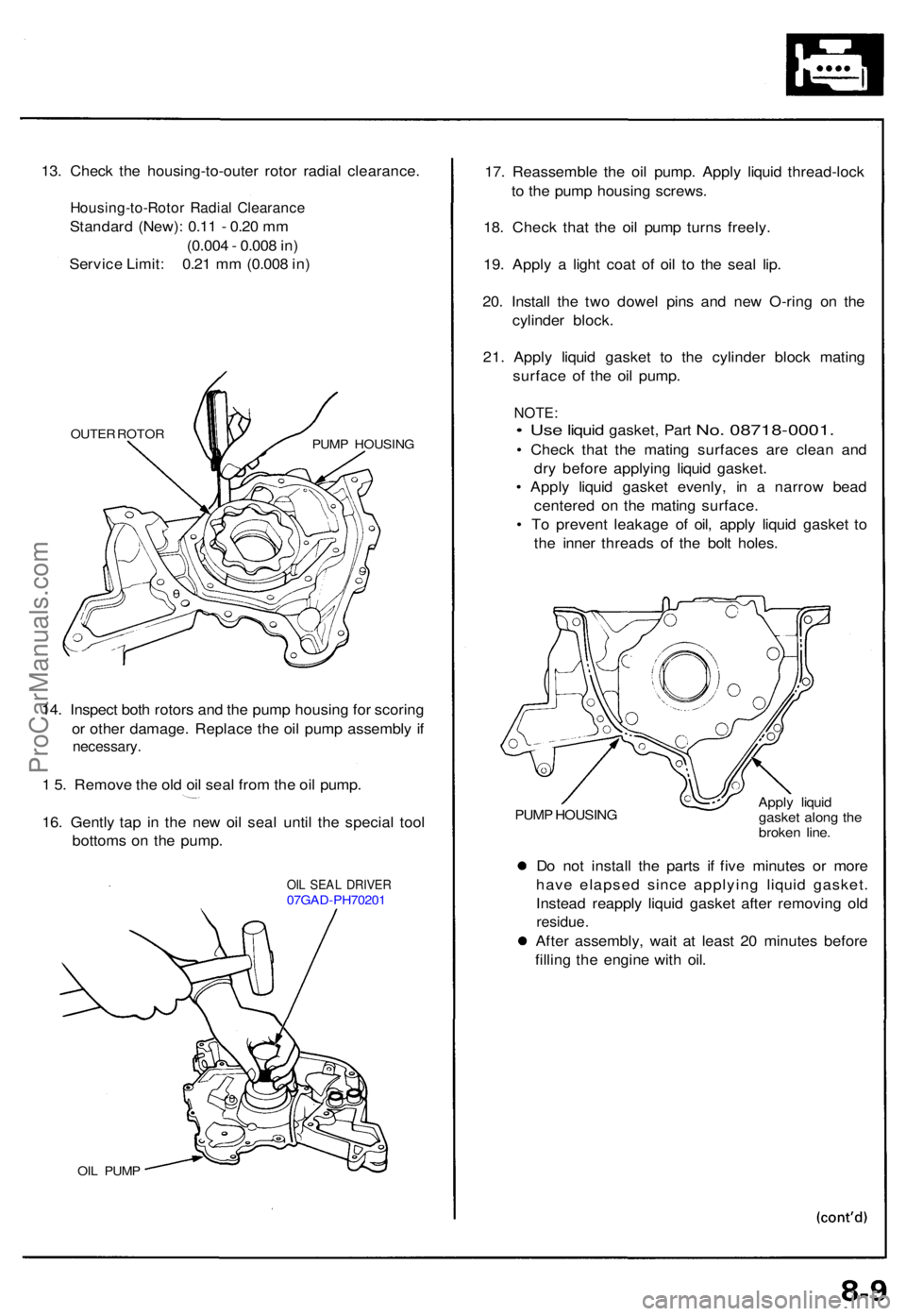

13. Chec k th e housing-to-oute r roto r radia l clearance .

Housing-to-Roto r Radia l Clearanc e

Standard (New) : 0.1 1 - 0.2 0 m m

(0.00 4 - 0.00 8 in )

Servic e Limit : 0.2 1 m m (0.00 8 in )

OUTE R ROTO R

PUMP HOUSIN G

14. Inspec t bot h rotors and th e pum p housin g fo r scorin g

o r othe r damage . Replac e th e oi l pum p assembl y i f

necessary .

1 5 . Remov e th e ol d oi l sea l fro m th e oi l pump .

16 . Gentl y ta p i n th e ne w oi l sea l unti l th e specia l too l

bottom s o n th e pump .

OIL SEA L DRIVE R07GAD-PH7020 1

OIL PUM P

17. Reassembl e th e oi l pump . Appl y liqui d thread-loc k

t o th e pum p housin g screws .

18 . Chec k tha t th e oi l pum p turn s freely .

19 . Appl y a ligh t coa t o f oi l t o th e sea l lip .

20 . Instal l th e tw o dowe l pin s an d ne w O-rin g o n th e

cylinde r block .

21 . Appl y liqui d gaske t t o th e cylinde r bloc k matin g

surfac e o f th e oi l pump .

NOTE:

• Use liqui d gasket , Par t No. 08718-0001 .

• Chec k tha t th e matin g surface s ar e clea n an d

dr y befor e applyin g liqui d gasket .

• Appl y liqui d gaske t evenly , i n a narro w bea d

centere d o n th e matin g surface .

• T o preven t leakag e o f oil , appl y liqui d gaske t t o

th e inne r thread s of the bol t holes .

PUMP HOUSIN G Appl

y liqui d

gaske t alon g th e

broke n line .

Do no t instal l th e part s i f fiv e minute s o r mor e

hav e elapse d sinc e applyin g liqui d gasket .

Instea d reappl y liqui d gaske t afte r removin g ol d

residue .

After assembly , wai t a t leas t 2 0 minute s befor e

fillin g th e engine with oil .

ProCarManuals.com

Page 162 of 1640

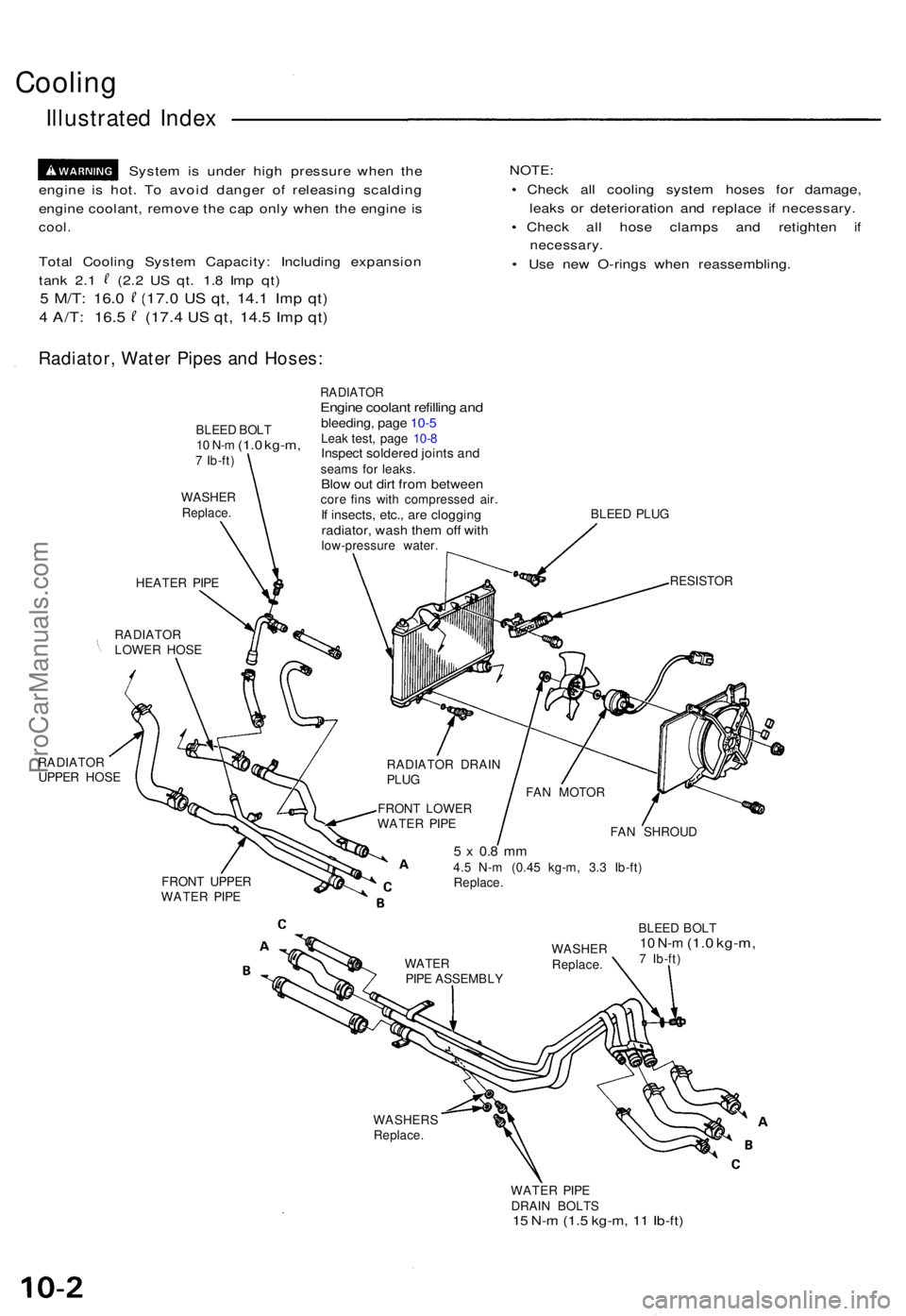

Cooling

Illustrated Index

Syste m is unde r hig h pressur e whe n th e

engin e i s hot . T o avoi d dange r o f releasin g scaldin g

engin e coolant , remov e th e ca p onl y whe n th e engin e i s

cool .

Tota l Coolin g Syste m Capacity : Includin g expansio n

tank 2. 1 (2. 2 U S qt . 1. 8 Im p qt )

5 M/T : 16. 0 (17. 0 US qt , 14. 1 Imp qt )

4 A/T : 16. 5 (17. 4 US qt , 14. 5 Imp qt )

NOTE :

• Chec k al l coolin g syste m hose s fo r damage ,

leak s o r deterioratio n an d replac e i f necessary .

• Chec k al l hos e clamp s an d retighte n i f

necessary .

• Us e ne w O-ring s whe n reassembling .

Radiator, Wate r Pipe s an d Hoses :

BLEED BOL T10 N- m (1. 0 kg-m ,7 Ib-ft )

WASHE RReplace .

HEATER PIP E

RADIATO R

LOWE R HOS E

RADIATO R

UPPE R HOS E

RADIATO REngine coolan t refillin g an dbleeding , pag e 10- 5Leak test , pag e 10- 8Inspec t soldere d joint s an dseam s fo r leaks .Blow ou t dir t fro m betwee ncore fin s wit h compresse d air .If insects , etc. , ar e cloggin gradiator, was h the m of f wit hlow-pressur e water . BLEE

D PLU G

RESISTO R

RADIATO R DRAI N

PLU G

FRON T LOWE R

WATE R PIP E

FRON T UPPE R

WATE R PIP E FA

N SHROU D

5 x 0. 8 m m4.5 N- m (0.4 5 kg-m , 3. 3 Ib-ft )

Replace .

BLEED BOL T

10 N- m (1. 0 kg-m ,7 Ib-ft )

WASHER S

Replace .

WATER PIP E

DRAI N BOLT S

15 N- m (1. 5 kg-m , 1 1 Ib-ft )

WATE RPIPE ASSEMBL YWASHE

RReplace .

FAN MOTO R

ProCarManuals.com

Page 163 of 1640

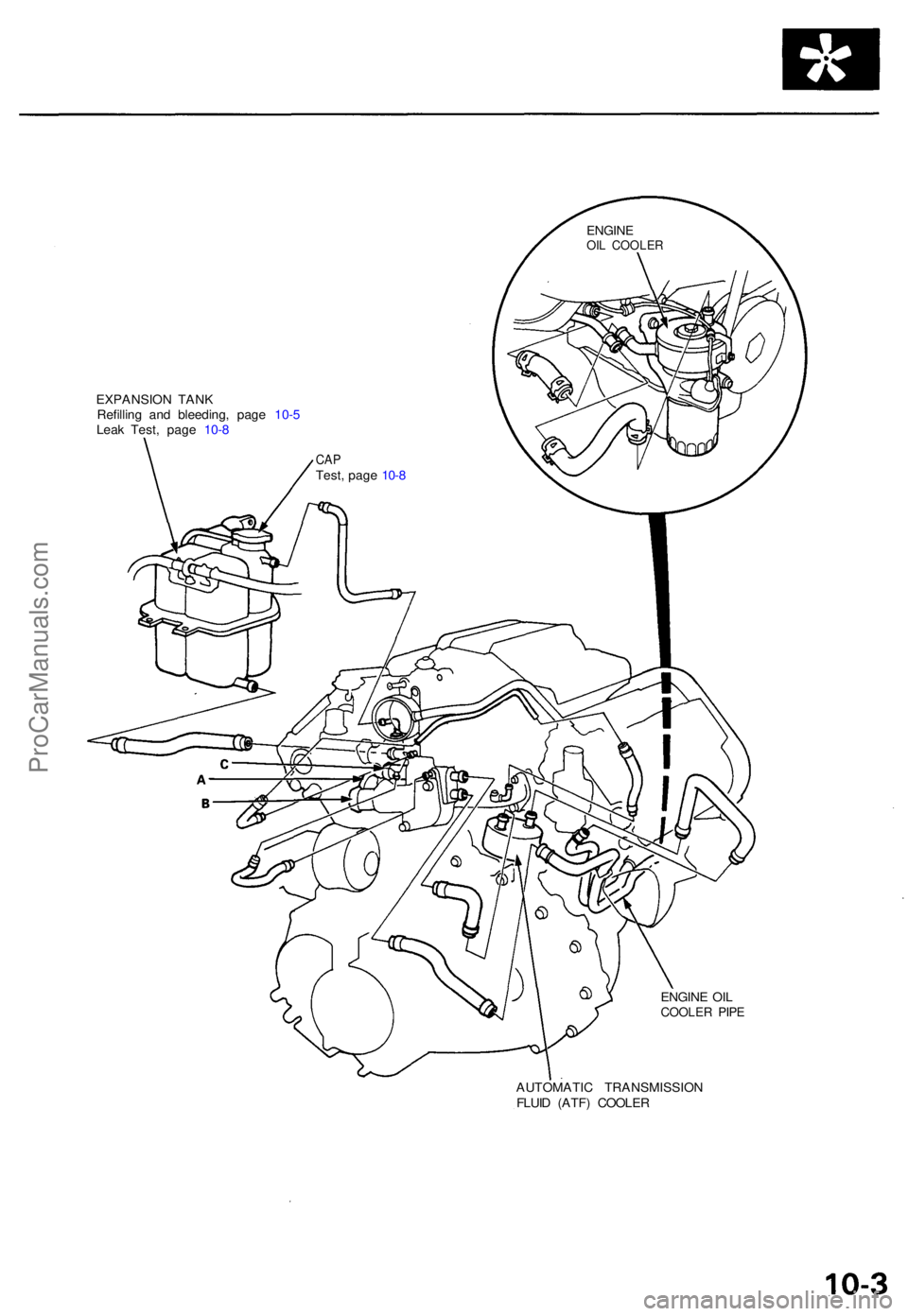

EXPANSION TAN K

Refillin g an d bleeding , pag e 10- 5

Lea k Test , pag e 10- 8

ENGINE OI L

COOLE R PIP E

AUTOMATI C TRANSMISSIO N

FLUI D (ATF ) COOLE R

ENGINEOIL COOLE R

CAPTest , pag e 10- 8

ProCarManuals.com

Page 165 of 1640

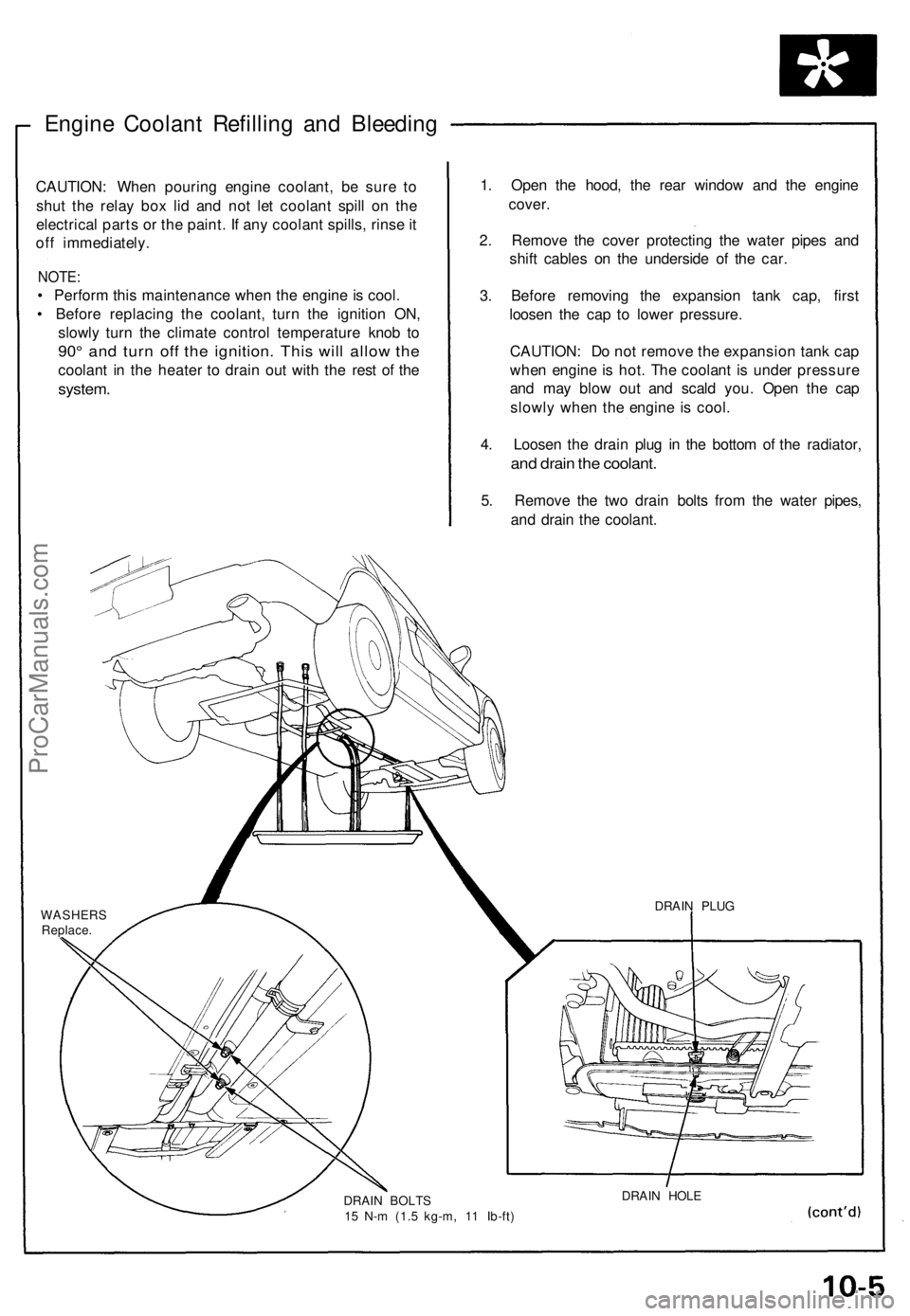

Engine Coolant Refilling and Bleeding

CAUTION: When pouring engine coolant, be sure to

shut the relay box lid and not let coolant spill on the

electrical parts or the paint. If any coolant spills, rinse it

off immediately.

NOTE:

• Perform this maintenance when the engine is cool.

• Before replacing the coolant, turn the ignition ON,

slowly turn the climate control temperature knob to

90° and turn off the ignition. This will allow the

coolant in the heater to drain out with the rest of the

system.

1. Open the hood, the rear window and the engine

cover.

2. Remove the cover protecting the water pipes and

shift cables on the underside of the car.

3. Before removing the expansion tank cap, first

loosen the cap to lower pressure.

CAUTION: Do not remove the expansion tank cap

when engine is hot. The coolant is under pressure

and may blow out and scald you. Open the cap

slowly when the engine is cool.

4. Loosen the drain plug in the bottom of the radiator,

and drain the coolant.

5. Remove the two drain bolts from the water pipes,

and drain the coolant.

WASHERS

Replace.

DRAIN BOLTS

15 N-m (1.5 kg-m, 11 Ib-ft)

DRAIN HOLE

DRAIN PLUGProCarManuals.com

Page 166 of 1640

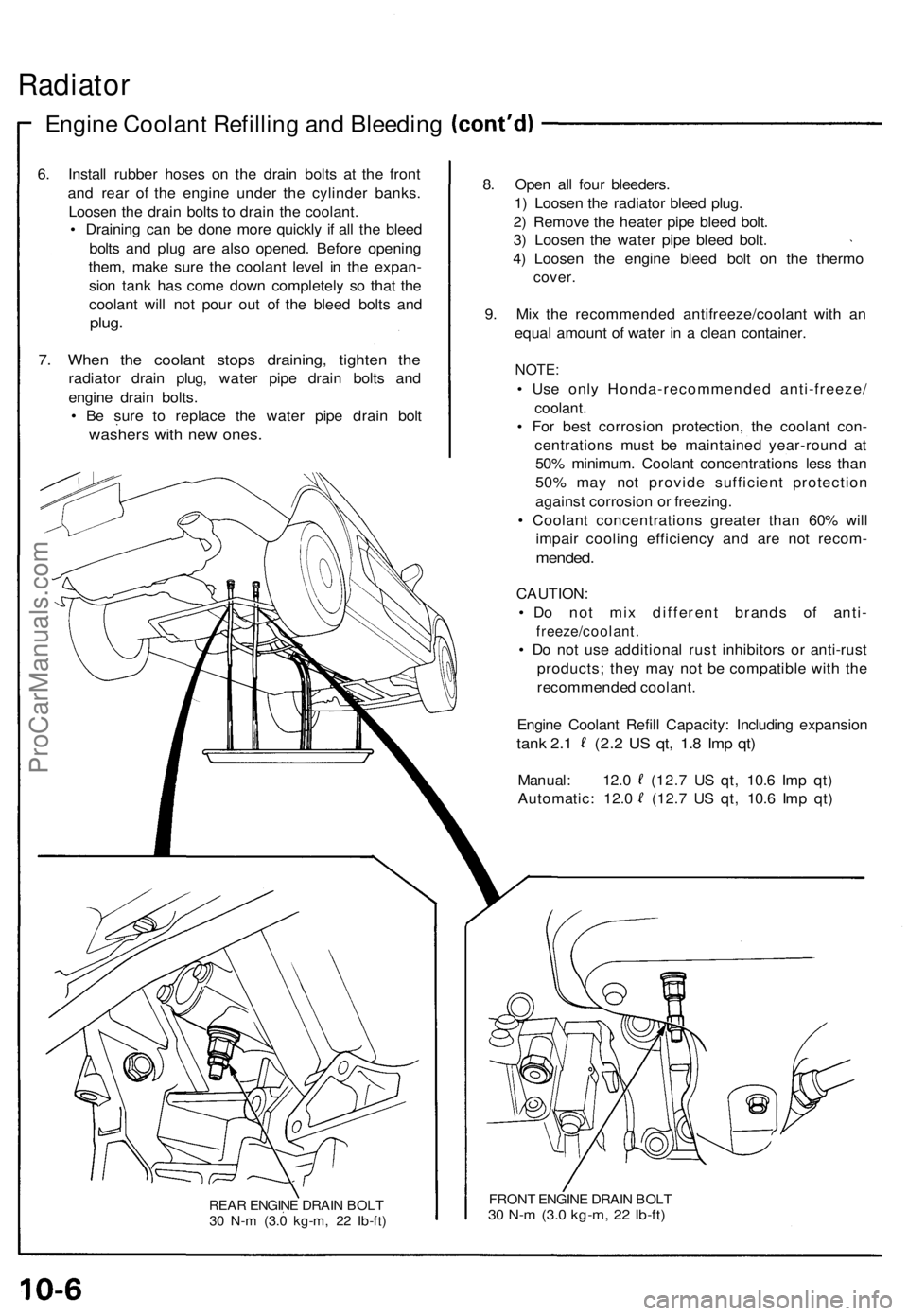

Radiator

Engine Coolan t Refillin g an d Bleedin g

6. Instal l rubbe r hose s o n th e drai n bolt s a t th e fron t

an d rea r of the engin e unde r th e cylinde r banks .

Loose n th e drai n bolt s t o drai n th e coolant .

• Drainin g ca n b e don e mor e quickl y i f al l th e blee d

bolt s an d plu g ar e als o opened . Befor e openin g

them , mak e sur e th e coolan t leve l i n th e expan -

sio n tan k ha s com e dow n completel y s o tha t th e

coolan t wil l no t pou r ou t o f th e blee d bolt s an d

plug .

7. Whe n th e coolan t stop s draining , tighte n th e

radiato r drai n plug , wate r pip e drai n bolt s an d

engin e drai n bolts .

• B e sur e t o replac e th e wate r pip e drai n bol t

washer s wit h ne w ones .

REAR ENGIN E DRAI N BOL T

3 0 N- m (3. 0 kg-m , 2 2 Ib-ft )

8. Ope n al l fou r bleeders .

1 ) Loose n th e radiato r blee d plug .

2 ) Remov e th e heate r pip e blee d bolt .

3 ) Loose n th e wate r pip e blee d bolt .

4 ) Loose n th e engin e blee d bol t o n th e therm o

cover.

9. Mi x th e recommende d antifreeze/coolan t wit h a n

equa l amoun t o f wate r i n a clea n container .

NOTE:

• Us e onl y Honda-recommende d anti-freeze /

coolant.

• Fo r bes t corrosio n protection , th e coolan t con -

centration s mus t b e maintaine d year-roun d a t

50 % minimum . Coolan t concentration s les s tha n

50 % ma y no t provid e sufficien t protectio n

agains t corrosio n o r freezing .

• Coolan t concentration s greate r tha n 60 % wil l

impai r coolin g efficienc y an d ar e no t recom -

mended.

CAUTION :

• D o no t mi x differen t brand s o f anti -

freeze/coolant .

• D o no t us e additiona l rus t inhibitor s o r anti-rus t

products ; the y ma y no t b e compatibl e wit h th e

recommende d coolant .

Engin e Coolan t Refil l Capacity : Includin g expansio n

tank 2. 1 (2. 2 U S qt , 1. 8 Im p qt )

Manual : 12. 0 (12. 7 U S qt , 10. 6 Im p qt )

Automatic : 12. 0 (12. 7 U S qt , 10. 6 Im p qt )

FRON T ENGIN E DRAI N BOL T30 N- m (3. 0 kg-m , 2 2 Ib-ft )

ProCarManuals.com

Page 167 of 1640

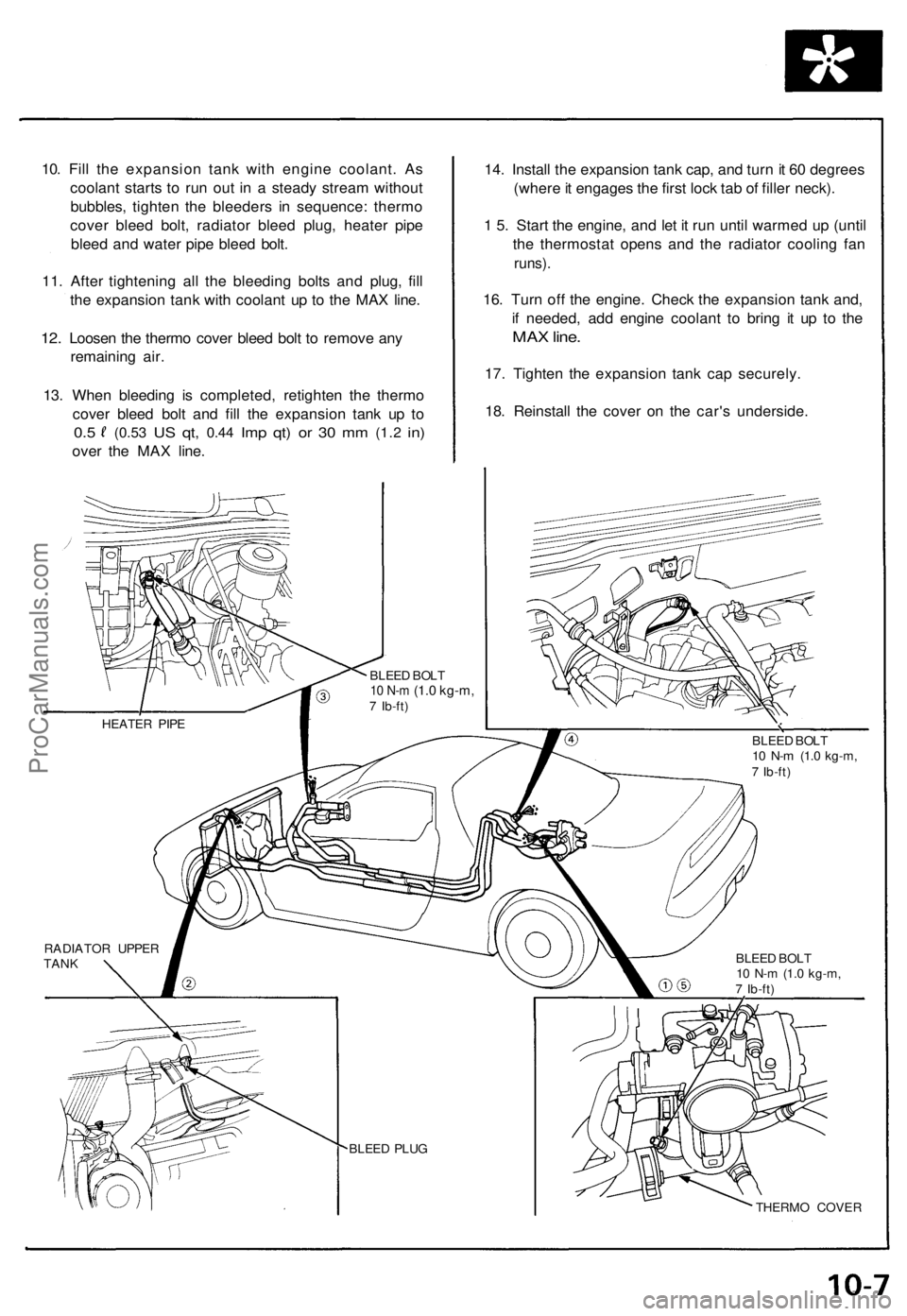

10. Fil l th e expansio n tan k wit h engin e coolant . A s

coolan t start s t o ru n ou t i n a stead y strea m withou t

bubbles , tighte n th e bleeder s i n sequence : therm o

cove r blee d bolt , radiato r blee d plug , heate r pip e

blee d an d wate r pip e blee d bolt .

11 . Afte r tightenin g al l th e bleedin g bolt s an d plug , fil l

th e expansio n tan k wit h coolan t u p t o th e MA X line .

12. Loose n th e therm o cove r blee d bol t t o remov e an y

remainin g air .

13 . Whe n bleedin g i s completed , retighte n th e therm o

cove r blee d bol t an d fill the expansio n tan k u p t o

0. 5 (0.5 3 US qt , 0.4 4 Imp qt ) o r 3 0 m m (1. 2 in)

ove r th e MA X line . 14

. Instal l th e expansio n tan k cap , an d tur n it 6 0 degree s

(wher e it engage s th e firs t loc k ta b o f fille r neck) .

1 5 . Star t th e engine , an d le t i t ru n unti l warme d u p (unti l

th e thermosta t open s an d th e radiato r coolin g fa n

runs) .

16. Tur n of f th e engine . Chec k th e expansio n tan k and ,

i f needed , ad d engin e coolan t t o brin g i t u p t o th e

MA X line .

17. Tighte n th e expansio n tan k ca p securely .

18 . Reinstal l th e cove r o n th e car' s underside .

THERMO COVE R

BLEE

D PLU G

RADIATO

R UPPE R

TAN K HEATE

R PIP E

BLEED BOL T

10 N- m (1. 0 kg-m ,7 Ib-ft )

BLEE

D BOL T

10 N- m (1. 0 kg-m ,7 Ib-ft )

BLEE

D BOL T

10 N- m (1. 0 kg-m ,7 Ib-ft )

ProCarManuals.com

Page 171 of 1640

Inspection

Replacement

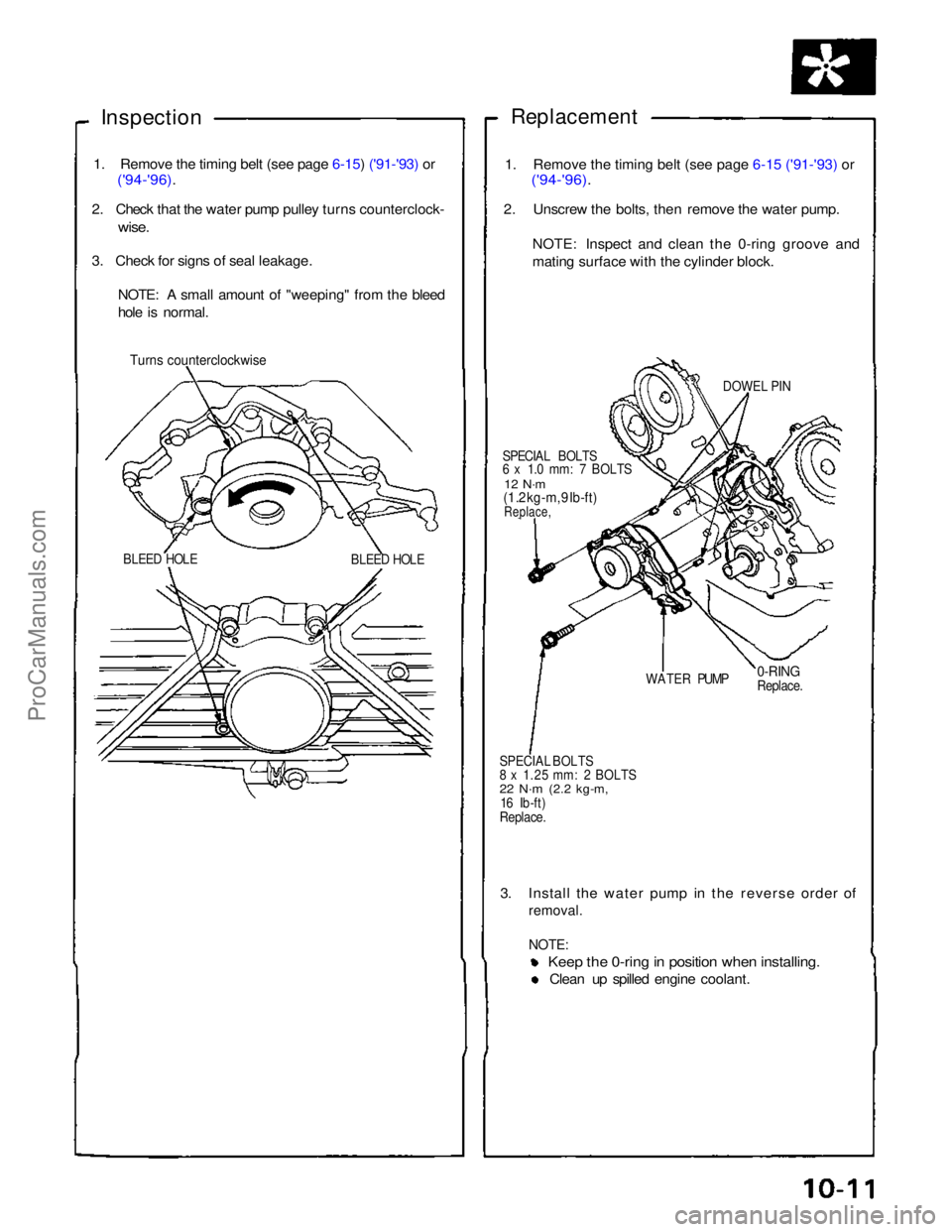

1. Remove the timing belt (see page 6-15) ('91-'93) or

('94-'96).

2. Check that the water pump pulley turns counterclock-

wise.

3. Check for signs of seal leakage.

NOTE: A small amount of "weeping" from the bleed

hole is normal.

Turns

counterclockwise

BLEED HOLE

BLEED HOLE

1. Remove the timing belt (see page 6-15 ('91-'93) or

('94-'96).

2. Unscrew the bolts, then remove the water pump.

NOTE: Inspect and clean the 0-ring groove and

mating surface with the cylinder block.

DOWEL PIN

SPECIAL BOLTS

6 x 1.0 mm: 7 BOLTS

12 N·m

(1 .2 kg-m, 9 Ib-ft)

Replace,

WATER PUMP

0-RING

Replace.

SPECIAL BOLTS

8 x 1.25 mm: 2 BOLTS

22 N·m

(2.2 kg-m,

16 Ib-ft)

Replace.

3. Install the water pump in the reverse order of

removal.

NOTE:

Keep the 0-ring in position when installing.

Clean up spilled engine coolant.ProCarManuals.com