engine ACURA NSX 1991 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 90 of 1640

Removal

NOTE:

Before removing the belt, turn the crankshaft pulley

so the No. 8 piston is at top dead center (TDC) (see

page 6-19 ('91-'93) or ('94-'96)

Inspect the water pump after removing the timing

belt (see page 10-11).

If it is to be reused, mark the direction of rotation on

the belt.

1. Disconnect the battery negative terminal first, then the positive terminal,

2. Remove the right rear wheel/tire.

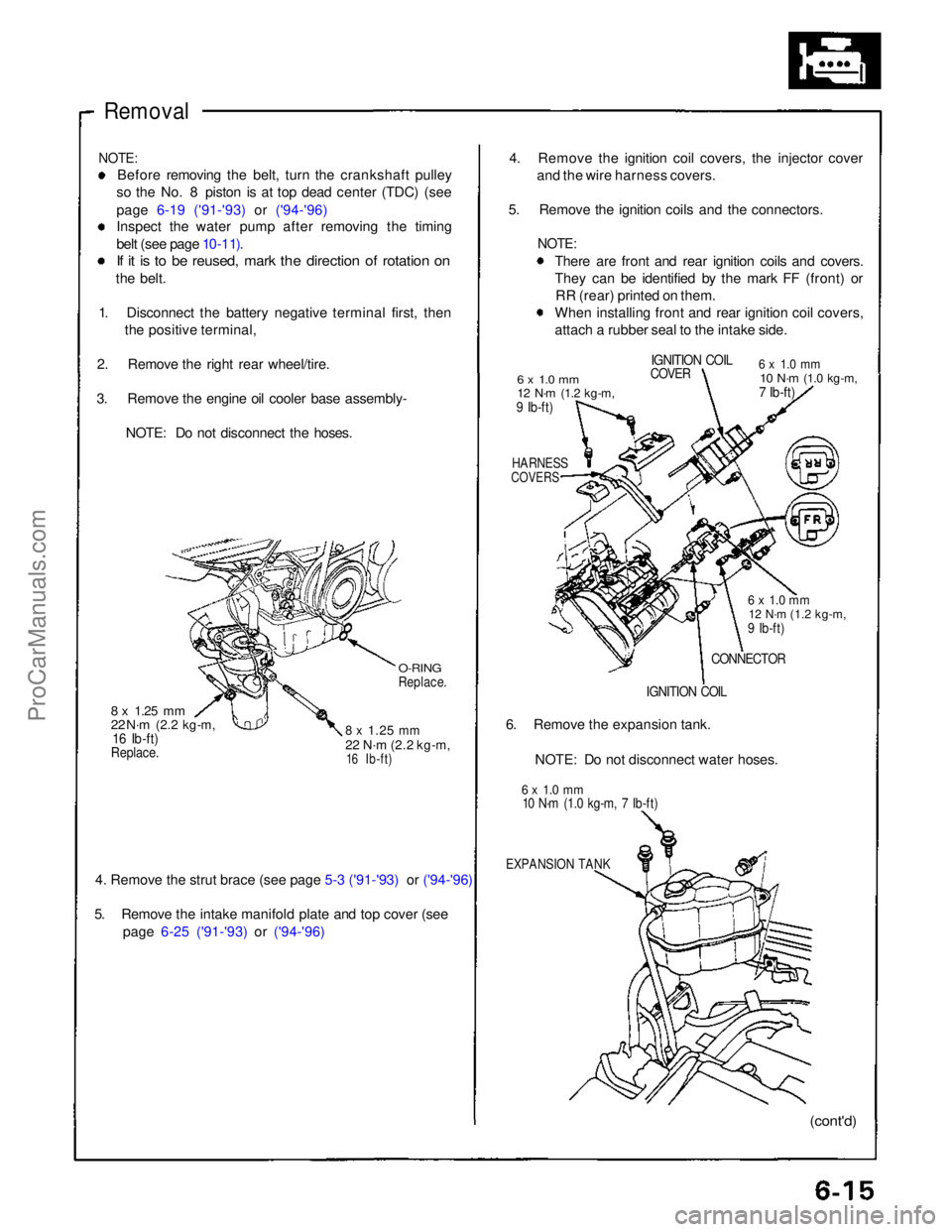

3. Remove the engine oil cooler base assembly- NOTE: Do not disconnect the hoses.

O-RING

Replace.

8 x

1.25

mm

22 N·m

(2.2 kg-m,

16 Ib-ft)

8 x

1.25

mm

22 N·m

(2.2 kg-m,

16 Ib-ft)

Replace.

4. Remove the strut brace (see page 5-3 ('91-'93) or ('94-'96)

5. Remove the intake manifold plate and top cover (see

page 6-25 ('91-'93) or ('94-'96)

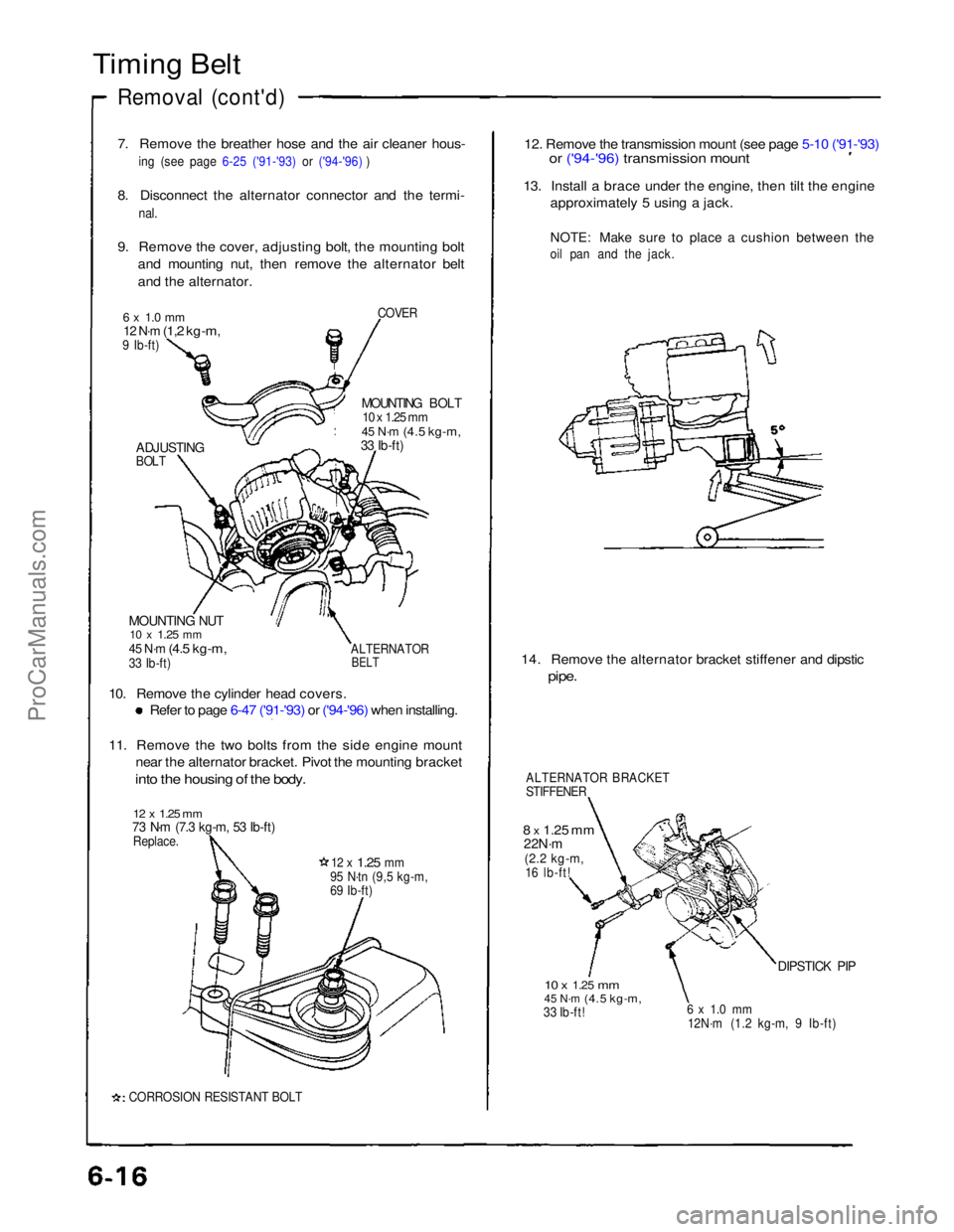

4. Remove the ignition coil covers, the injector cover

and the wire harness covers.

5. Remove the ignition coils and the connectors.

NOTE:

There are front and rear ignition coils and covers.

They can be identified by the mark FF (front) orRR (rear) printed on them.

When installing front and rear ignition coil covers,

attach a rubber seal to the intake side.

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 Ib-ft)

IGNITION COIL

COVER

6 x 1.0 mm

10 N·m

(1.0 kg-m,

7 Ib-ft)

HARNESS

COVERS

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 Ib-ft)

CONNECTOR

IGNITION COIL

6. Remove the expansion tank.

NOTE: Do not disconnect water hoses.

6 x 1.0 mm

10 N·m (1.0 kg-m, 7 Ib-ft)

EXPANSION TANK

(cont'd)ProCarManuals.com

Page 91 of 1640

Timing Belt

Removal (cont'd)

7. Remove the breather hose and the air cleaner hous-

in

g

(see page 6-25 ('91-'93) or ('94-'96) )

8. Disconnect the alternator connector and the termi-

nal.

9. Remove the cover, adjusting bolt, the mounting bolt and mounting nut, then remove the alternator belt

and the alternator.

COVER

6 x 1.0 mm

12 N·m

(1,2 kg-m,

9 Ib-ft)

MOUNTING BOLT

10 x 1.25 mm

45 N·m

(4.5 kg-m,

33 Ib-ft)

ADJUSTING

BOLT

MOUNTING NUT

10 x

1.25

mm

45 N·m

(4.5 kg-m,

33 Ib-ft)

ALTERNATOR

BELT

10. Remove the cylinder head covers.

Refer to page 6-47 ('91-'93) or ('94-'96) when installing.

11. Remove the two bolts from the side engine mount

near the alternator bracket. Pivot the mounting bracket

into the housing of the body.

12 x 1.25 mm

73 N·m (7.3 kg-m, 53 Ib-ft)

Replace.

12 x

1.25

mm

95 N·tn (9,5 kg-m,

69 Ib-ft)

CORROSION RESISTANT BOLT

12. Remove the transmission mount (see page 5-10 ('91-'93)

or ('94-'96) transmission mount

13. Install a brace under the engine, then tilt the engine

approximately 5 using a jack.

NOTE: Make sure to place a cushion between the

oil pan and the jack.

14. Remove the alternator bracket stiffener and dipstic

pipe.

ALTERNATOR BRACKET

STIFFENER

8 x

1.25

mm

22N·m

(2.2 kg-m,

16 lb-ft!

10 x

1.25

mm

45 N·m

(4.5 kg-m,

33 Ib-ft!

6 x 1.0 mm

12N·m (1.2 kg-m, 9 Ib-ft)

DIPSTICK PIPProCarManuals.com

Page 97 of 1640

![ACURA NSX 1991 Service Owners Manual

Cylinder Heads

Illustrated Index (cont'd)

CAUTION:

To

avoid

damage,

wait

until

the

engine

coolant

temperature

drops

below

100°F

(39-C]

before

removing

the

cylin-

der head.

N ACURA NSX 1991 Service Owners Manual

Cylinder Heads

Illustrated Index (cont'd)

CAUTION:

To

avoid

damage,

wait

until

the

engine

coolant

temperature

drops

below

100°F

(39-C]

before

removing

the

cylin-

der head.

N](/img/32/56988/w960_56988-96.png)

Cylinder Heads

Illustrated Index (cont'd)

CAUTION:

To

avoid

damage,

wait

until

the

engine

coolant

temperature

drops

below

100°F

(39-C]

before

removing

the

cylin-

der head.

NOTE: Use new O-rings and gaskets when reassembling.

Prior to reassembling, clean all the parts in solvent, dry them, and apply lubricant to any contact parts.

REAR VARIABLE VALVE TIMING

AND VALVE LIFT ELECTRONIC CONTROL

SYSTEM (VTEC) SOLENOID VALVE

Troubleshooting, page 6-3 ('91-'93) or ('94-'96)

EXHAUST GAS

RECIRCULATI0N (EGR) VALVE

6 x 1 .0 mm

12 N·m

(1.2 kg-m.

9 Ib-ft)

8 x

1.25

mm

22 N·m

(2.2 kg-m,

16 Ib-ft)

ENGINE COOLANT

TEMPERATURE (ECT) SENSOR

18 N·m (1.8 kg-m, 13 Ib-ft)

8 x

1.25

mm

22 N·m (2.2 kg-m. 16 lb-ft)

FRONT VTEC SOLENOID VALVE

Troubleshooting. page 6-3

SEALING BOLTS

60 N·m

(6.0 kg-m,

43 lb-ft)

OIL PRESSURE

GAUSE SENDING

UNIT (section 23)

ROCKER

SHAFTS

WASHERS

Replace.

8 x

1.25

mm

22 N·m

(2.2 kg-m,16 Ib-ft)

DOWEL PIN

0-RING

Replace.

ECT SWITCH

28 N·m

12.8 kg-m.

20 lb-ft

O-RING

Replace.

O-RING

Replace.

ROCKER ARM ASSEMBLY[PRIMARY. MID, SECONDARY]

Inspection, page 6-32 ('91-'93) or ('94-'96)

ROCKER SHAFT

OIL CONTROL

ORIFICE

Remove with 5 mm

boit and clean.

FILTER

Replace.

GASKET

Replace.

O-RING

Replace.ProCarManuals.com

Page 99 of 1640

Cylinder Heads

Removal

Engine removal is not required for this procedure. Make sure jacks and safety stands are

placed properly and hoist brackets ere attached to cor- rect positions on the engine.

CAUTION: Use a fender cover (special tool) to avoid damaging

painted surfaces. Unplug the wiring connectors carefully while holding

the connector portion to avoid damage.

To avoid damaging the cylinder heads, wait until the

engine coolant temperature drops below 100°F

(38°C) before loosening the retaining bolts. Do not open the engine cover when the roof panel is

stored (NSX-T open top).

NOTE:

Unspecified items are common.

Mark all wiring and hoses to avoid misconnection.

Also, be sure that they do not contact other wiring or

hoses or interfere with other parts.

Inspect the timing belt before removing the cylinder

head.

Turn the crankshaft pulley SO that the No. 1 piston is at top dead center (see page 6-19 ('91-'93) or ('94-'96)).

1. Disconnect the negative terminal from the battery.

2. Remove the expansion tank cap. Use care when removing the expan-

sion tank cap to avoid scalding by engine coolant

or steam.

3. Raise the car, then remove the right rear wheel/tire.

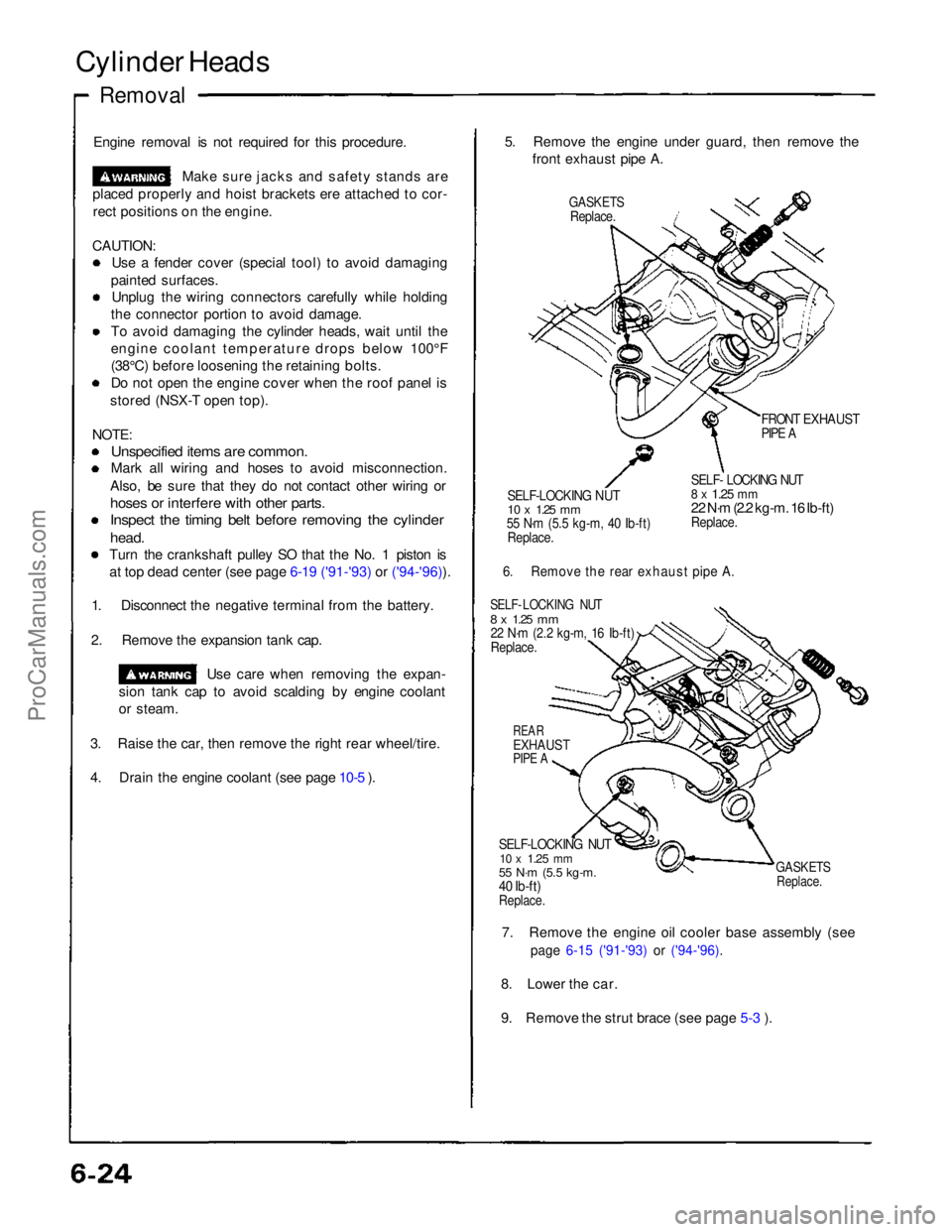

4. Drain the engine coolant (see page 10-5 ). 5. Remove the engine under guard, then remove the

front exhaust pipe A.

GASKETS

Replace.

FRONT EXHAUST

PIPE A

SELF-LOCKING NUT

10 x

1.25

mm

55 N·m (5.5 kg-m, 40 Ib-ft)

Replace.

SELF- LOCKING NUT

8 x

1.25

mm

22 N·m (2.2 kg-m. 16 Ib-ft)

Replace.

6. Remove the rear exhaust pipe A.

SELF- LOCKING NUT

8 x

1.25

mm

22 N·m (2.2 kg-m, 16 Ib-ft)

Replace.

REAR

EXHAUST

PIPE A

SELF-LOCKING NUT

10 x

1.25

mm

55 N·m (5.5 kg-m.

40 Ib-ft)

Replace.

GASKETS

Replace.

7. Remove the engine oil cooler base assembly (see

page 6-15 ('91-'93) or ('94-'96).

8. Lower the car.

9. Remove the strut brace (see page 5-3 ).ProCarManuals.com

Page 100 of 1640

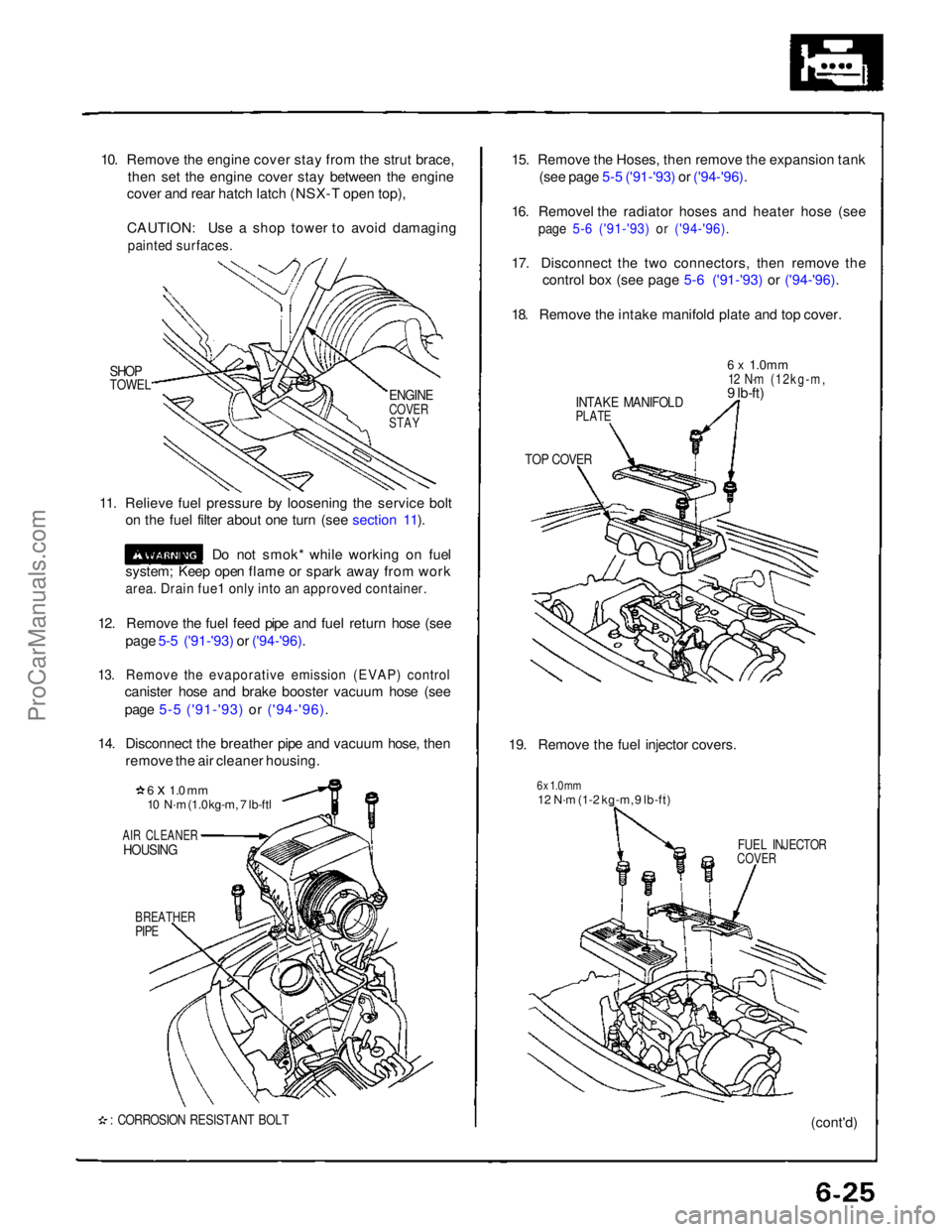

10. Remove the engine cover stay from the strut brace,

then set the engine cover stay between the engine

cover and rear hatch latch (NSX-T open top),

CAUTION: Use a shop tower to avoid damaging

painted surfaces.

SHOP

TOWEL

11. Relieve fuel pressure by loosening the service bolt on the fuel filter about one turn (see section 11).

Do not smok* while working on fuel

system; Keep open flame or spark away from work

area. Drain fue1 only into an approved container.

12. Remove the fuel feed pipe and fuel return hose (see page 5-5 ('91-'93) or ('94-'96).

13. Remove the evaporative emission (EVAP) control

canister hose and brake booster vacuum hose (see

page 5-5 ('91-'93) or ('94-'96).

14. Disconnect the breather pipe and vacuum hose, then remove the air cleaner housing.

6 x 1.0 mm

10 N·m (1.0 kg-m, 7 lb-ftl

AIR CLEANER

HOUSING

BREATHER

PIPE

: CORROSION RESISTANT BOLT

15. Remove the Hoses, then remove the expansion tank

(see page 5-5 ('91-'93) or ('94-'96).

16. Removel the radiator hoses and heater hose (see

page 5-6 ('91-'93) or ('94-'96).

17. Disconnect the two connectors, then remove the

control box (see page 5-6 ('91-'93) or ('94-'96).

18. Remove the intake manifold plate and top cover.

INTAKE MANIFOLD

PLATE

6 x

1.0mm

12 N·m (12kg-m,

9 lb-ft)

TOP COVER

19. Remove the fuel injector covers.

6 x 1.0 mm

12 N·m (1-2 kg-m, 9 lb-ft)

FUEL INJECTOR

COVER

(cont'd)

ENGINE

COVER

STAYProCarManuals.com

Page 102 of 1640

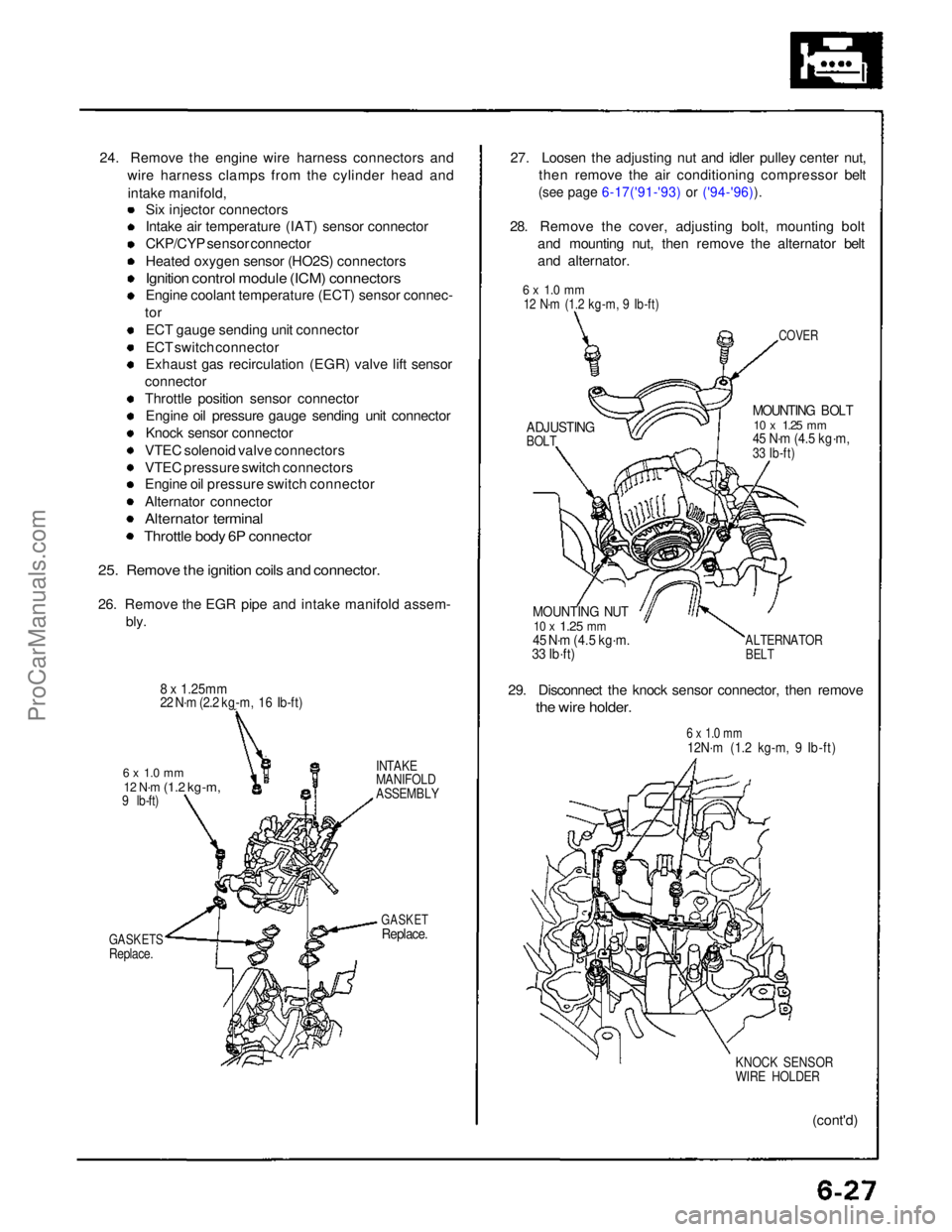

24. Remove the engine wire harness connectors and

wire harness clamps from the cylinder head and

intake manifold, Six injector connectors

Intake air temperature (IAT) sensor connector

CKP/CYP sensor connector

Heated oxygen sensor (HO2S) connectors

Ignition control module (ICM) connectors

Engine coolant temperature (ECT) sensor connec-

tor

ECT gauge sending unit connector

ECT switch connector

Exhaust gas recirculation (EGR) valve lift sensor

connector

Throttle position sensor connector Engine oil pressure gauge sending unit connector

Knock sensor connector

VTEC solenoid valve connectors

VTEC pressure switch connectors

Engine oil pressure switch connector

Alternator connector

Alternator terminal

Throttle body 6P connector

25. Remove the ignition coils and connector.

26. Remove the EGR pipe and intake manifold assem- bly.

8 x 1.25mm

22 N·m (2.2 kg-m, 16 Ib-ft)

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 lb-ft)

GASKETS

Replace. INTAKE

MANIFOLD

ASSEMBLY

GASKET

Replace.

27. Loosen the adjusting nut and idler pulley center nut,

then remove the air conditioning compressor belt

(see page 6-17('91-'93) or ('94-'96)).

28. Remove the cover, adjusting bolt, mounting bolt and mounting nut, then remove the alternator belt

and alternator.

COVER

MOUNTING BOLT

10 x

1.25

mm

45 N·m (4.5 kg·m,

33 Ib-ft)

MOUNTING NUT

10 x

1.25

mm

45 N·m (4.5 kg·m.

33 Ib·ft)

ALTERNATOR

BELT

29. Disconnect the knock sensor connector, then remove

the wire holder.

6 x 1.0 mm

12N·m (1.2 kg-m, 9 Ib-ft)

KNOCK SENSOR

WIRE HOLDER

(cont'd)

6 x 1.0 mm

12 N·m (1.2 kg-m, 9 Ib-ft)

ADJUSTING

BOLTProCarManuals.com

Page 123 of 1640

Camshafts

Installation

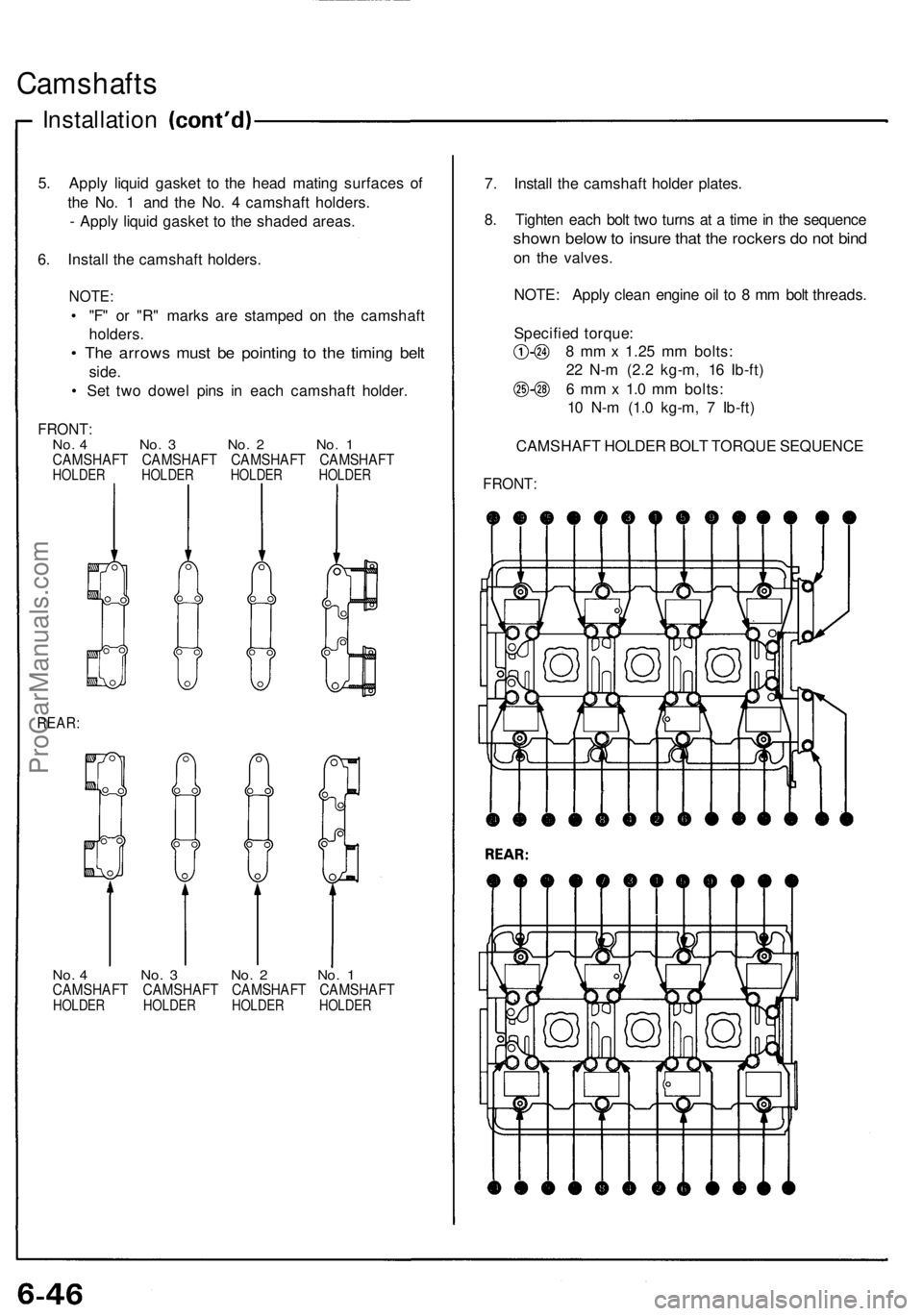

5. Apply liquid gasket to the head mating surfaces of

the No. 1 and the No. 4 camshaft holders.

- Apply liquid gasket to the shaded areas.

6. Install the camshaft holders.

NOTE:

• "F" or "R" marks are stamped on the camshaft

holders.

• The arrows must be pointing to the timing belt

side.

• Set two dowel pins in each camshaft holder.

FRONT:

No. 4 No. 3 No. 2 No. 1

CAMSHAFT CAMSHAFT CAMSHAFT CAMSHAFT

HOLDER HOLDER HOLDER HOLDER

REAR:

No. 4 No. 3 No. 2 No. 1

CAMSHAFT CAMSHAFT CAMSHAFT CAMSHAFT

HOLDER HOLDER HOLDER HOLDER

7. Install the camshaft holder plates.

8. Tighten each bolt two turns at a time in the sequence

shown below to insure that the rockers do not bind

on the valves.

NOTE: Apply clean engine oil to 8 mm bolt threads.

Specified torque:

8 mm x 1.25 mm bolts:

22 N-m (2.2 kg-m, 16 Ib-ft)

6 mm x 1.0 mm bolts:

10 N-m (1.0 kg-m, 7 Ib-ft)

CAMSHAFT HOLDER BOLT TORQUE SEQUENCE

FRONT:ProCarManuals.com

Page 127 of 1640

Engine Bloc k

Illustrate d Inde x

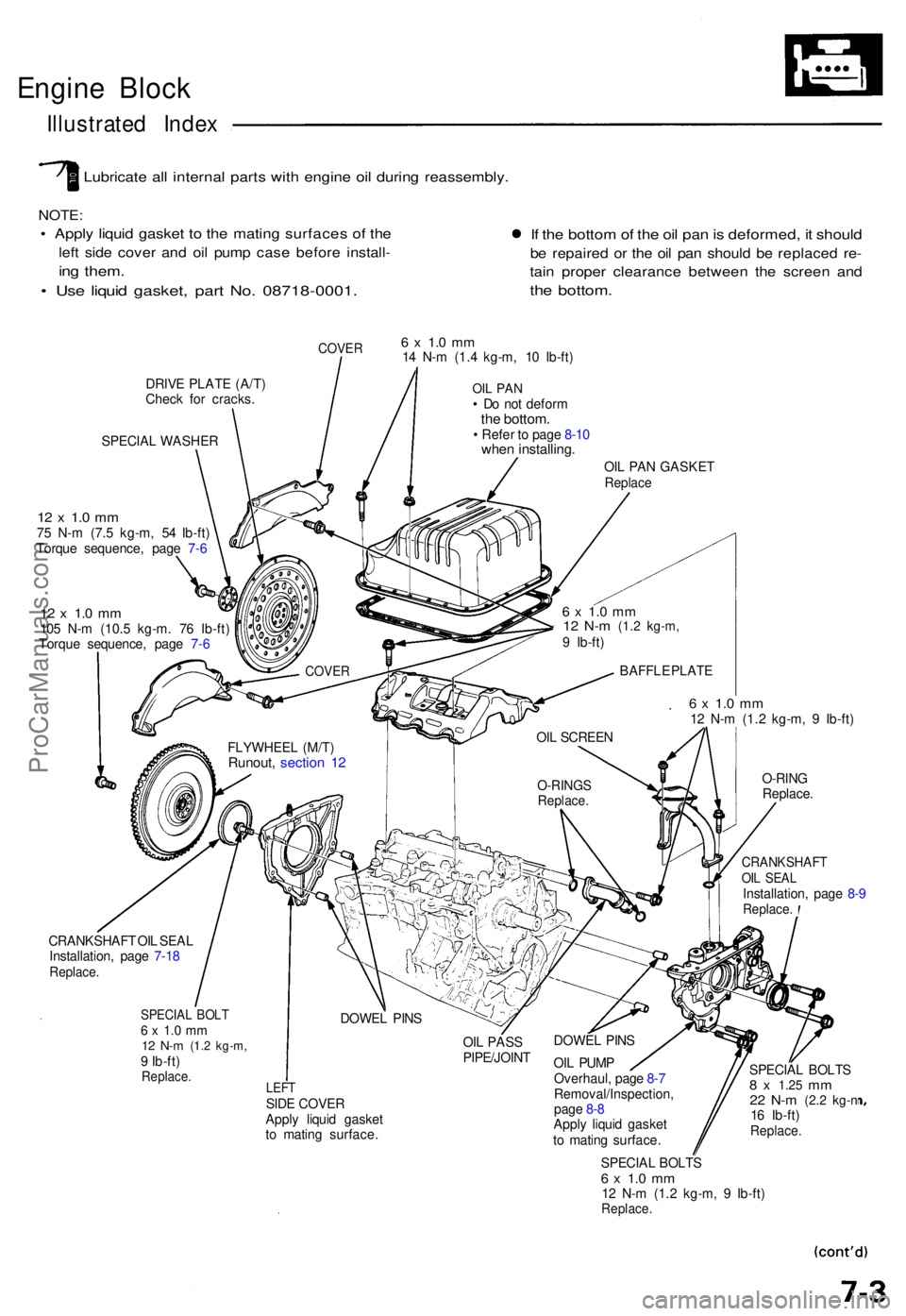

Lubricat e al l interna l part s wit h engin e oi l durin g reassembly .

NOTE:

• Appl y liqui d gaske t t o th e matin g surface s o f th e

left sid e cove r an d oi l pum p cas e befor e install -

ing them .

• Us e liqui d gasket , par t No . 08718-0001 .

If th e botto m of th e oi l pa n is deformed , i t shoul d

be repaire d o r th e oi l pa n shoul d b e replace d re -

tain prope r clearanc e betwee n th e scree n an d

the bottom .

COVER

DRIVE PLAT E (A/T )

Chec k fo r cracks .

SPECIA L WASHE R

12 x 1. 0 m m75 N- m (7. 5 kg-m , 5 4 Ib-ft )

Torqu e sequence , pag e 7- 6

12 x 1. 0 m m105 N- m (10. 5 kg-m . 7 6 Ib-ft )

Torqu e sequence , pag e 7- 6

6 x 1. 0 m m14 N- m (1. 4 kg-m , 1 0 Ib-ft )

OIL PA N• D o no t defor mthe bottom .• Refe r t o pag e 8-1 0whe n installing .

OIL PA N GASKE TReplace

6 x 1. 0 m m12 N- m (1. 2 kg-m , 9 Ib-ft )

O-RIN G

Replace .

CRANKSHAF TOIL SEA LInstallation , pag e 8- 9Replace .

CRANKSHAF T OI L SEA L

Installation , pag e 7-1 8

Replace .

SPECIAL BOL T6 x 1. 0 m m12 N- m (1. 2 kg-m ,9 Ib-ft )Replace .

OIL PAS S

PIPE/JOIN T

LEFTSIDE COVE R

Appl y liqui d gaske t

t o matin g surface . DOWE

L PIN S

OI L PUM P

Overhaul , pag e 8- 7

Removal/Inspection ,

pag e 8- 8

Appl y liqui d gaske t

t o matin g surface . SPECIA

L BOLT S

8 x 1.2 5 mm22 N- m (2. 2 kg- n16 Ib-ft )Replace .

SPECIAL BOLT S6 x 1. 0 m m12 N- m (1. 2 kg-m , 9 Ib-ft )Replace .

DOWEL PIN S

O-RING SReplace .

OIL SCREE N

FLYWHEE L (M/T )

Runout , sectio n 1 2

BAFFL E PLAT E

6 x 1. 0 m m12 N- m (1. 2 kg-m ,9 Ib-ft )

COVE R

ProCarManuals.com

Page 128 of 1640

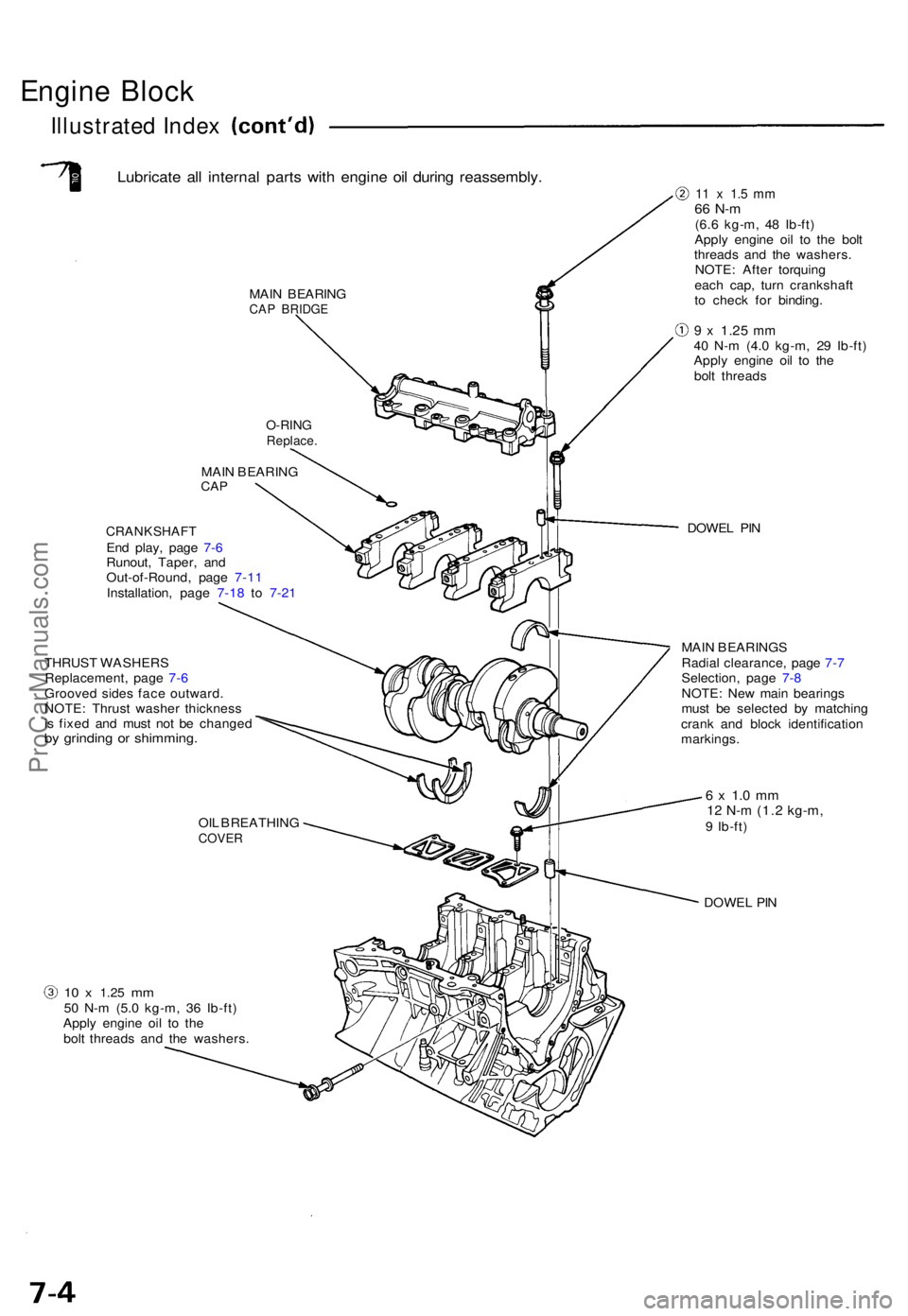

Engine Bloc k

Illustrated Index

Lubricat e al l interna l part s wit h engin e oi l durin g reassembly .

MAIN BEARIN GCAP BRIDG E

10 x 1.2 5 mm50 N- m (5. 0 kg-m , 3 6 Ib-ft )

Appl y engin e oi l t o th e

bol t thread s an d th e washers .

MAI

N BEARIN G

CAP

CRANKSHAF TEnd play , pag e 7- 6

Runout , Taper , an d

Out-of-Round , pag e 7-1 1

Installation , pag e 7-1 8 to 7-2 1

THRUS T WASHER S

Replacement , pag e 7- 6

Groove d side s fac e outward .

NOTE : Thrus t washe r thicknes s

i s fixe d an d mus t no t b e change d

by grindin g o r shimming .

11 x 1. 5 m m66 N- m(6.6 kg-m , 4 8 Ib-ft )

Appl y engin e oi l t o th e bol t

threads and th e washers .

NOTE : Afte r torquin g

eac h cap , tur n crankshaf t

t o chec k fo r binding .

9 x 1.2 5 mm40 N- m (4. 0 kg-m , 2 9 Ib-ft )

Appl y engin e oi l t o th e

bol t thread s

DOWE L PI N

MAI N BEARING S

Radia l clearance , pag e 7- 7

Selection , pag e 7- 8

NOTE : Ne w mai n bearing s

mus t b e selecte d b y matchin g

cran k an d bloc k identificatio n

markings .

6 x 1. 0 m m12 N- m (1. 2 kg-m ,9 Ib-ft )

DOWE L PI N

OI

L BREATHIN GCOVER

O-RINGReplace .

ProCarManuals.com

Page 130 of 1640

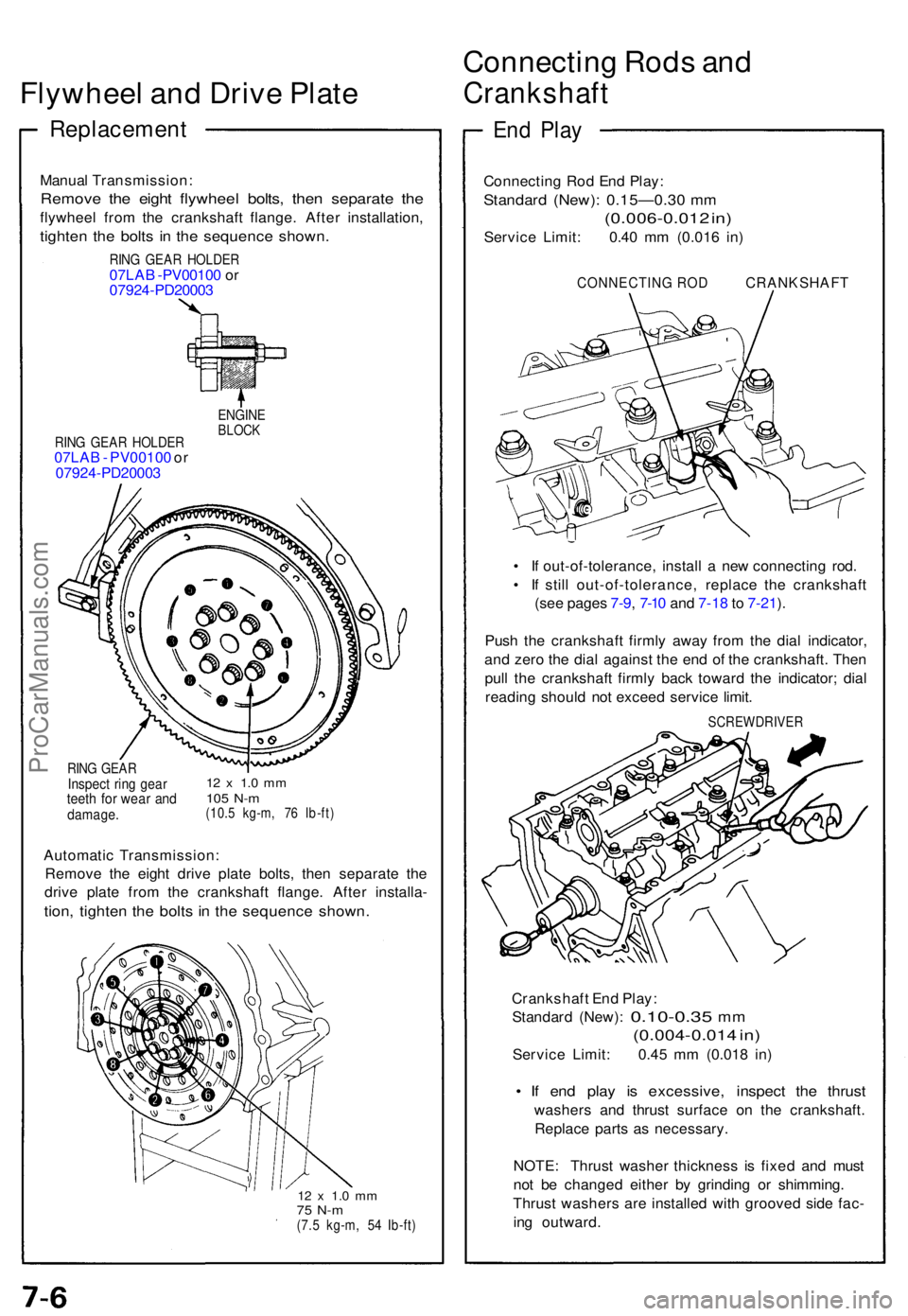

Flywheel an d Driv e Plat e

Replacemen t

Manual Transmission :

Remove th e eigh t flywhee l bolts , the n separat e th e

flywhee l fro m th e crankshaf t flange . Afte r installation ,

tighten th e bolt s i n th e sequenc e shown .

RING GEA R HOLDE R07LAB -PV0010 0 o r

0792 4-PD2000 3

RING GEA R HOLDE R07LAB - PV00100 or

0792 4-PD2000 3

ENGINEBLOCK

RING GEA RInspec t rin g gea rteeth fo r wea r an ddamage .

12 x 1. 0 m m105 N- m(10. 5 kg-m , 7 6 Ib-ft )

Automati c Transmission :

Remov e th e eigh t driv e plat e bolts , the n separat e th e

driv e plat e fro m th e crankshaf t flange . Afte r installa -

tion, tighte n th e bolt s i n th e sequenc e shown .

12 x 1. 0 m m75 N- m(7.5 kg-m , 5 4 Ib-ft )

Connectin g Rod s an d

Crankshaf t

End Pla y

Connectin g Ro d En d Play :

Standar d (New) : 0.15—0.3 0 m m

(0.006-0.01 2 in )

Servic e Limit : 0.4 0 m m (0.01 6 in )

CONNECTIN G RO D CRANKSHAF T

• I f out-of-tolerance , instal l a ne w connectin g rod .

• I f stil l out-of-tolerance , replac e th e crankshaf t

(se e page s 7-9 , 7-1 0 an d 7-1 8 to 7-21 ).

Pus h th e crankshaf t firml y awa y fro m th e dia l indicator ,

an d zer o th e dia l agains t th e en d o f th e crankshaft . The n

pul l th e crankshaf t firml y bac k towar d th e indicator ; dia l

readin g shoul d no t excee d servic e limit .

SCREWDRIVE R

Crankshaft En d Play :

Standar d (New) :

0.10-0.3 5 mm

(0.004-0.01 4 in )

Servic e Limit : 0.4 5 m m (0.01 8 in )

• I f en d pla y i s excessive , inspec t th e thrus t

washer s an d thrus t surfac e o n th e crankshaft .

Replac e part s a s necessary .

NOTE : Thrus t washe r thicknes s i s fixe d an d mus t

no t b e change d eithe r b y grindin g o r shimming .

Thrus t washer s ar e installe d wit h groove d sid e fac -

in g outward .

ProCarManuals.com