engine ACURA NSX 1991 Service Manual PDF

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 231 of 1640

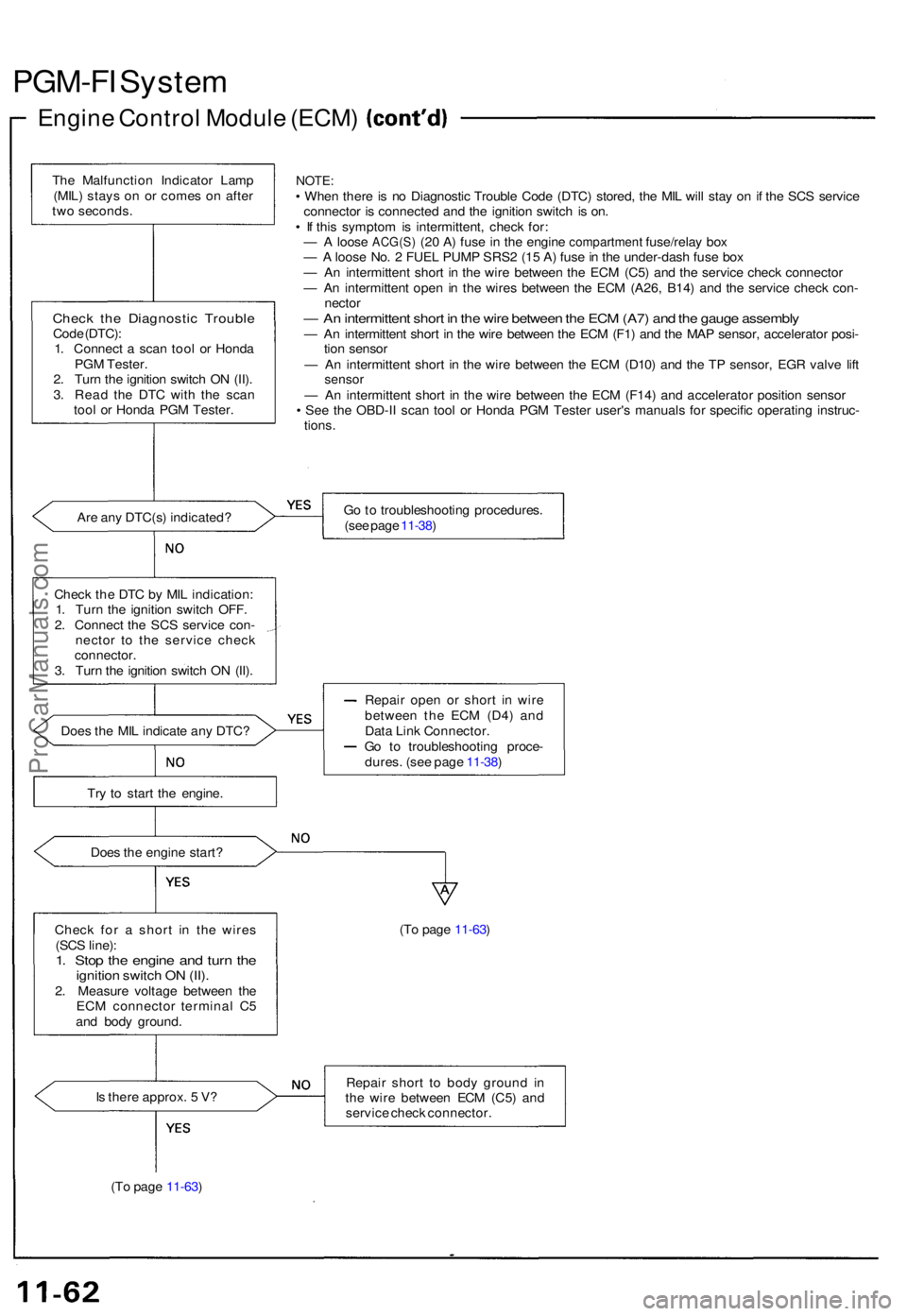

PGM-FI Syste m

Engine Contro l Modul e (ECM )

The Malfunctio n Indicato r Lam p

(MIL ) stay s o n o r come s o n afte r

tw o seconds .

Check th e Diagnosti c Troubl eCode (DTC) :

1 . Connec t a sca n too l o r Hond a

PG M Tester .

2 . Tur n th e ignitio n switc h O N (II) .

3 . Rea d th e DT C wit h th e sca n

too l o r Hond a PG M Tester .

NOTE:• Whe n ther e is n o Diagnosti c Troubl e Cod e (DTC ) stored , th e MI L wil l sta y o n i f th e SC S servic e

connecto r i s connecte d an d th e ignitio n switc h i s on .

• I f thi s sympto m is intermittent , chec k for :

— A loos e ACG(S ) (20 A ) fus e in th e engin e compartment fuse/rela y box— A loos e No . 2 FUE L PUM P SRS 2 (1 5 A ) fus e in th e under-das h fus e bo x

— A n intermitten t shor t i n th e wir e betwee n th e EC M (C5 ) an d th e servic e chec k connecto r

— A n intermitten t ope n i n th e wire s betwee n th e EC M (A26 , B14 ) an d th e servic e chec k con -

necto r

— A n intermitten t shor t i n th e wir e betwee n th e EC M (A7 ) an d th e gaug e assembl y— A n intermitten t shor t i n th e wir e betwee n th e EC M (F1 ) an d th e MA P sensor , accelerato r posi -

tio n senso r

— A n intermitten t shor t i n th e wir e betwee n th e EC M (D10 ) an d th e T P sensor , EG R valv e lif t

senso r— A n intermitten t shor t i n th e wir e betwee n th e EC M (F14 ) an d accelerato r positio n senso r

• Se e th e OBD-I I sca n too l o r Hond a PG M Teste r user' s manual s fo r specifi c operatin g instruc -

tions .

Ar e an y DTC(s ) indicated ? G

o to troubleshootin g procedures .

(se e pag e 11-38 )

Chec k th e DT C b y MI L indication :

1 . Tur n th e ignitio n switc h OFF .

2 . Connec t th e SC S servic e con -

necto r t o th e servic e chec k

connector .

3 . Tur n th e ignitio n switc h O N (II) .

Doe s th e MI L indicat e an y DTC ? Repai

r ope n o r shor t i n wir e

betwee n th e EC M (D4 ) an d

Dat a Lin k Connector .

G o t o troubleshootin g proce -

dures . (se e pag e 11-38 )

Tr y t o star t th e engine .

Doe s th e engin e start ?

Chec k fo r a shor t i n th e wire s

(SC S line) :

1. Sto p th e engin e an d tur n th eignitio n switc h O N (II) .2. Measur e voltag e betwee n th e

EC M connecto r termina l C 5

an d bod y ground . (T

o pag e 11-63 )

I s ther e approx . 5 V ?

(T o pag e 11-63 ) Repai

r shor t t o bod y groun d i n

th e wir e betwee n EC M (C5 ) an d

servic e chec k connector .

ProCarManuals.com

Page 233 of 1640

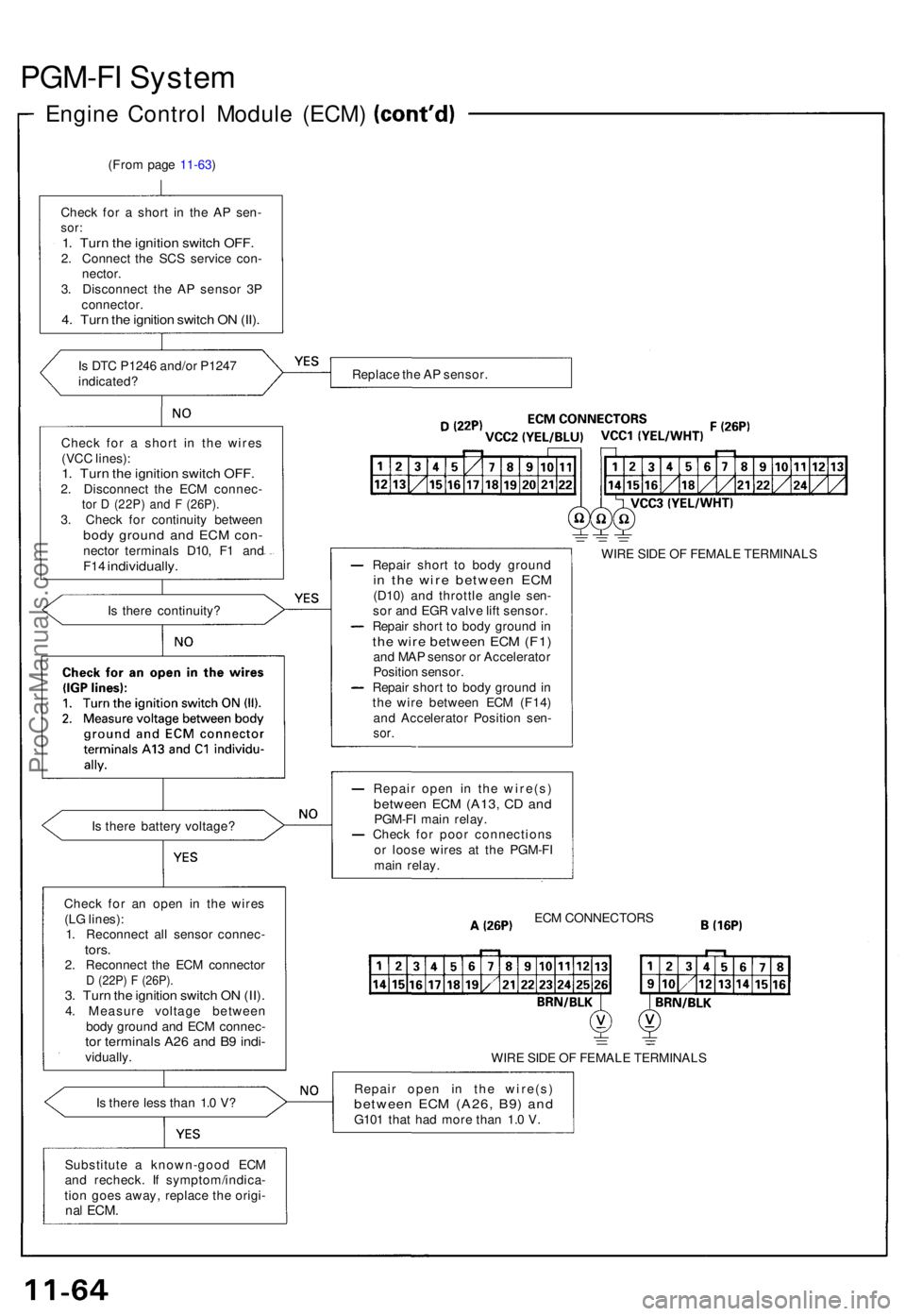

PGM-FI Syste m

Engine Contro l Modul e (ECM )

(From pag e 11-63 )

Chec k fo r a shor t i n th e A P sen -

sor:1. Tur n th e ignitio n switc h OFF .2. Connec t th e SC S servic e con -

nector .

3 . Disconnec t th e A P senso r 3 P

connector .

4. Tur n th e ignitio n switc h O N (II) .

Is DT C P124 6 and/o r P124 7

indicated ?

Chec k fo r a shor t i n th e wire s

(VC C lines) :

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e EC M connec -tor D (22P ) an d F (26P) .3. Chec k fo r continuit y betwee nbody groun d an d EC M con -necto r terminal s D10 , F 1 an dF14 individually .

Is ther e continuity ?

I s ther e batter y voltage ?

Chec k fo r a n ope n i n th e wire s

(L G lines) :

1 . Reconnec t al l senso r connec -

tors.2. Reconnec t th e EC M connecto rD (22P ) F (26P) .3. Tur n th e ignitio n switc h O N (II) .4. Measur e voltag e betwee n

bod y groun d an d EC M connec -

tor terminal s A2 6 an d B 9 indi -vidually .

I s ther e les s tha n 1. 0 V ?

Substitut e a known-goo d EC M

an d recheck . I f symptom/indica -

tio n goe s away , replac e th e origi -

nal ECM .

Replac e th e A P sensor .

Repai r shor t t o bod y groun d

in th e wir e betwee n EC M(D10 ) an d throttl e angl e sen -

so r an d EG R valv e lif t sensor .

Repai r shor t t o bod y groun d in

th e wir e betwee n EC M (F1 )and MA P senso r o r Accelerato r

Positio n sensor .

Repai r shor t t o bod y groun d in

th e wir e betwee n EC M (F14 )

an d Accelerato r Positio n sen -

sor.

WIR E SID E O F FEMAL E TERMINAL S

Repai r ope n i n th e wire(s )

between EC M (A13 , C D an dPGM-F I mai n relay .

Chec k fo r poo r connection s

o r loos e wire s a t th e PGM-F I

mai n relay .

ECM CONNECTOR S

WIR E SID E O F FEMAL E TERMINAL S

Repai r ope n i n th e wire(s )

between EC M (A26 , B9 ) an dG10 1 tha t ha d mor e tha n 1. 0 V .

ProCarManuals.com

Page 234 of 1640

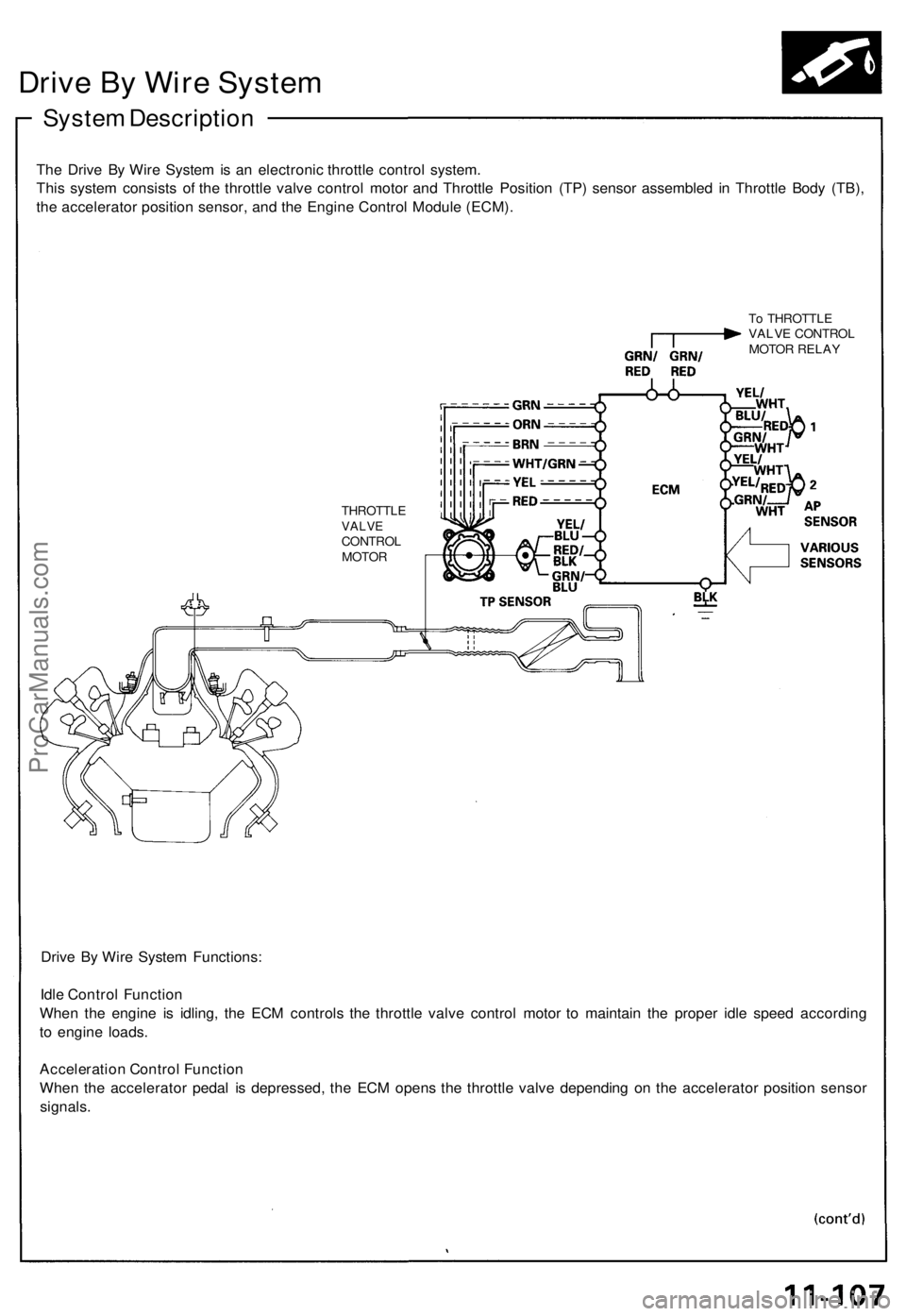

Drive By Wire System

System Description

The Drive By Wire System is an electronic throttle control system.

This system consists of the throttle valve control motor and Throttle Position (TP) sensor assembled in Throttle Body (TB),

the accelerator position sensor, and the Engine Control Module (ECM).

To THROTTLE

VALVE CONTROL

MOTOR RELAY

THROTTLE

VALVE

CONTROL

MOTOR

Drive By Wire System Functions:

Idle Control Function

When the engine is idling, the ECM controls the throttle valve control motor to maintain the proper idle speed according

to engine loads.

Acceleration Control Function

When the accelerator pedal is depressed, the ECM opens the throttle valve depending on the accelerator position sensor

signals.ProCarManuals.com

Page 237 of 1640

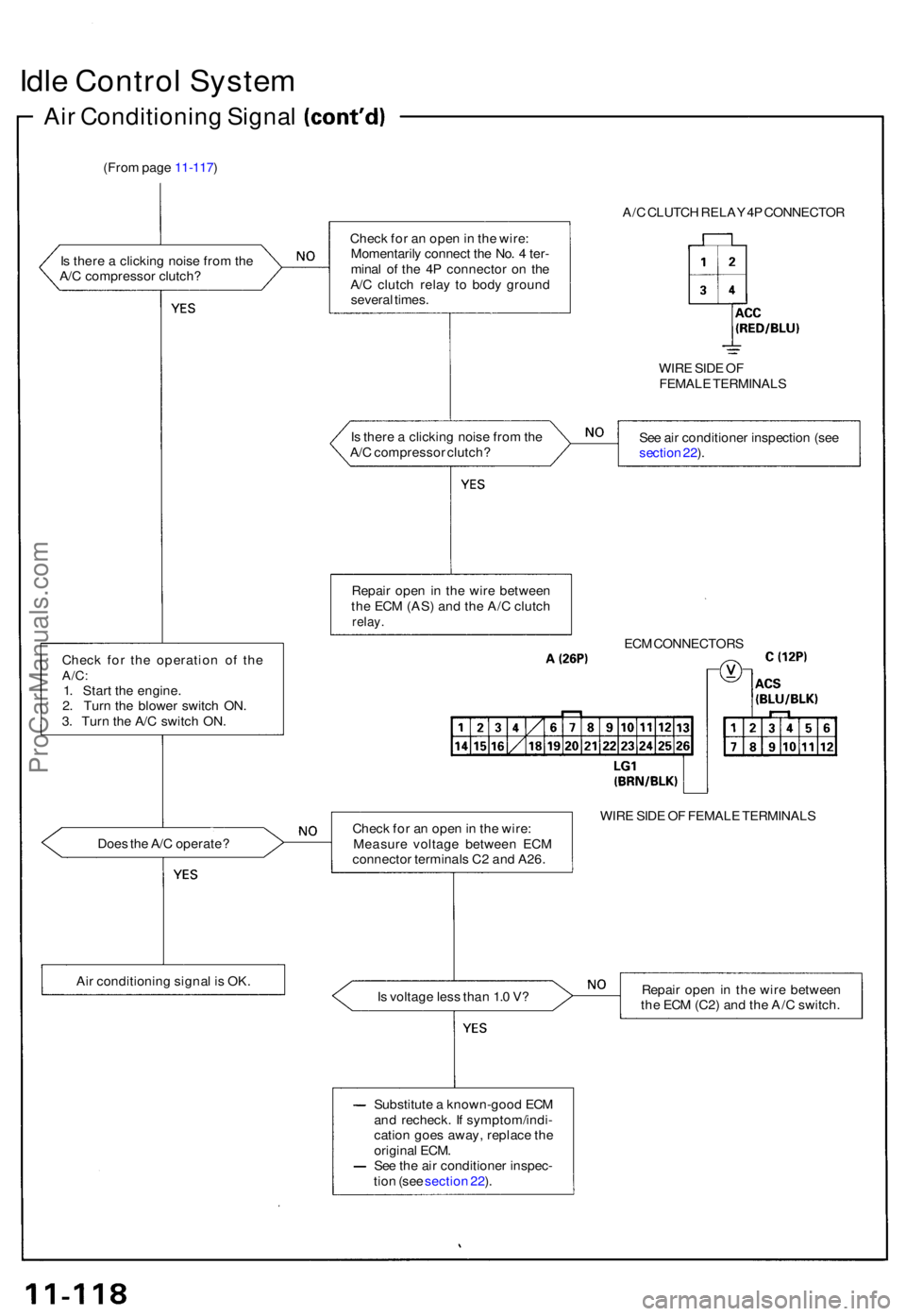

Idle Contro l Syste m

Air Conditionin g Signa l

(From pag e 11-117 )

I s ther e a clickin g nois e fro m th e

A/ C compresso r clutch ?

Chec k fo r th e operatio n o f th e

A/C :1. Star t th e engine .

2 . Tur n th e blowe r switc h ON .

3 . Tur n th e A/ C switc h ON .

Doe s th e A/ C operate ?

Ai r conditionin g signa l i s OK . A/

C CLUTC H RELA Y 4P CONNECTO R

Chec k fo r a n ope n in th e wire :

Momentaril y connec t th e No . 4 ter -

mina l o f th e 4 P connecto r o n th e

A/ C clutc h rela y t o bod y groun d

severa l times .

WIRE SID E O F

FEMAL E TERMINAL S

I s ther e a clickin g nois e fro m th e

A/ C compresso r clutch ? Se

e ai r conditione r inspectio n (se e

sectio n 22 ).

Repai r ope n in th e wir e betwee n

th e EC M (AS ) an d th e A/ C clutc h

relay.

ECM CONNECTOR S

Chec k fo r a n ope n in th e wire :

Measur e voltag e betwee n EC M

connecto r terminal s C 2 an d A26 . WIR

E SID E O F FEMAL E TERMINAL S

I s voltag e les s tha n 1. 0 V ? Repai

r ope n in th e wir e betwee n

th e EC M (C2 ) an d th e A/ C switch .

Substitut e a known-goo d EC M

an d recheck . I f symptom/indi -

catio n goe s away , replac e th e

origina l ECM .

Se e th e ai r conditione r inspec -

tio n (se e sectio n 22 ).

ProCarManuals.com

Page 238 of 1640

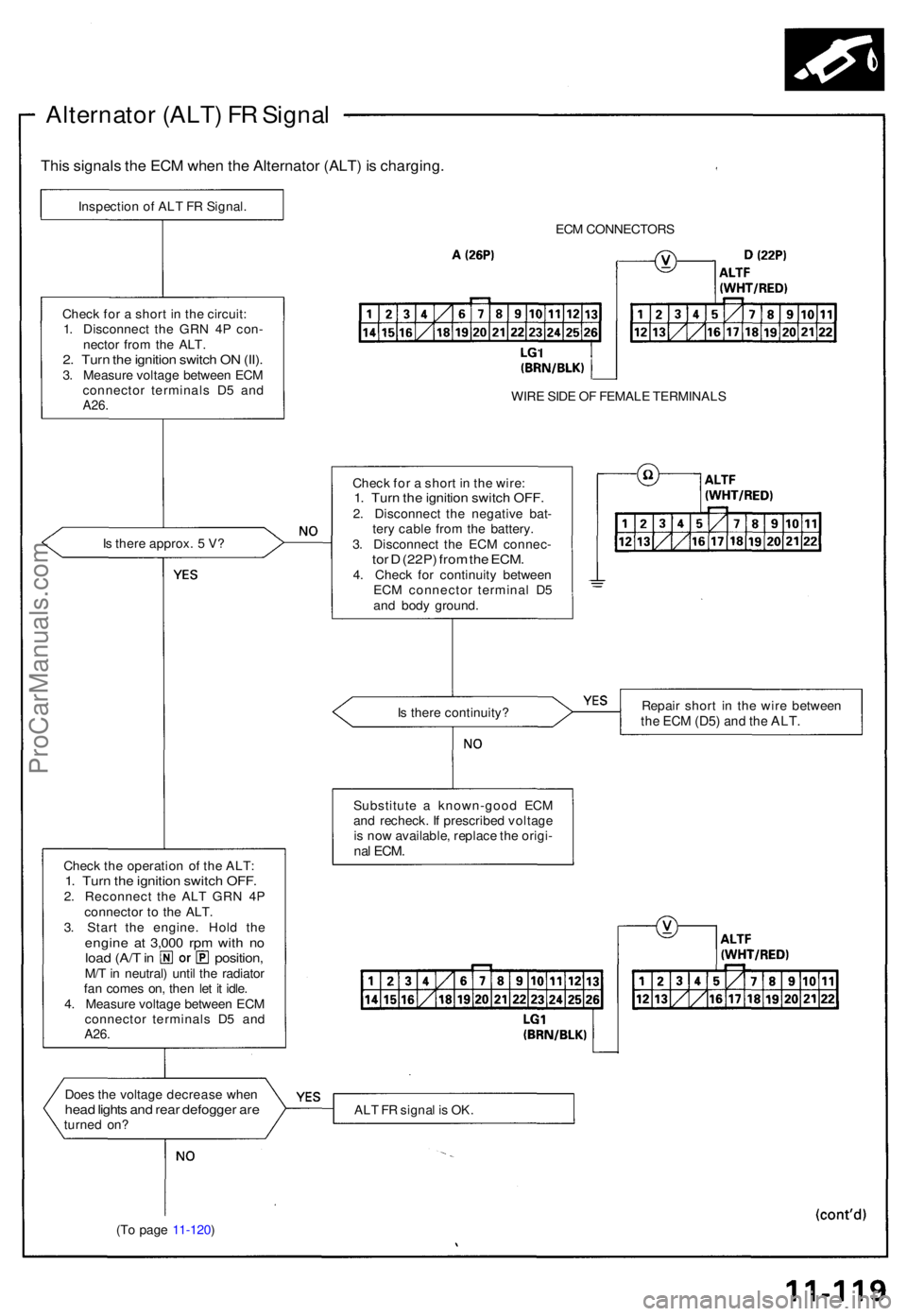

Alternator (ALT ) F R Signa l

This signal s th e EC M whe n th e Alternato r (ALT ) i s charging .

Inspection o f AL T F R Signal .

ECM CONNECTOR S

WIR E SID E O F FEMAL E TERMINAL S

Chec k fo r a shor t i n th e wire :

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e negativ e bat -

ter y cabl e fro m th e battery .

3 . Disconnec t th e EC M connec -

tor D (22P ) fro m th e ECM .4. Chec k fo r continuit y betwee n

EC M connecto r termina l D 5

an d bod y ground .

I

s ther e approx . 5 V ?

Chec

k fo r a shor t i n th e circuit :

1 . Disconnec t th e GR N 4 P con -

necto r fro m th e ALT .

2. Tur n th e ignitio n switc h O N (II) .3. Measur e voltag e betwee n EC M

connecto r terminal s D 5 an d

A26 .

Is ther e continuity ? Repai

r shor t i n th e wir e betwee nthe EC M (D5 ) and th e ALT .

Substitut e a known-goo d EC M

an d recheck . I f prescribe d voltag e

i s no w available , replac e th e origi -

nal ECM .Chec k th e operatio n o f th e ALT :1. Tur n th e ignitio n switc h OFF .2. Reconnec t th e AL T GR N 4 P

connecto r t o th e ALT .

3 . Star t th e engine . Hol d th e

engin e a t 3,00 0 rp m wit h n oloa d (A/ T in position ,M/T in neutral ) unti l th e radiato r

fa n come s on , the n le t i t idle .

4 . Measur e voltag e betwee n EC M

connecto r terminal s D 5 an d

A26.

Doe s th e voltag e decreas e whe nhead light s an d rea r defogge r ar eturne d on ? AL

T F R signa l i s OK .

(T o pag e 11-120 )

ProCarManuals.com

Page 241 of 1640

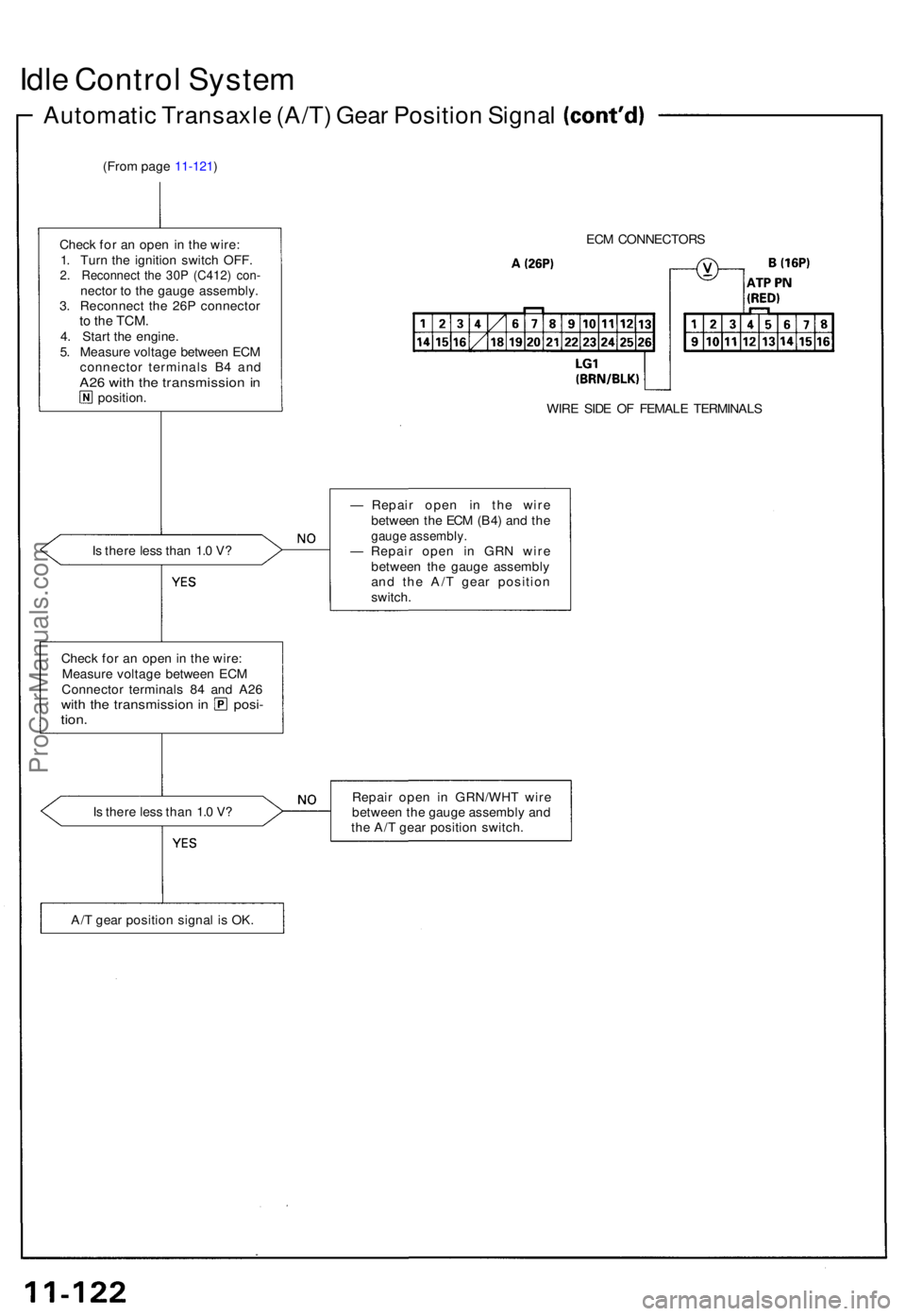

Idle Contro l Syste m

Automati c Transaxl e (A/T ) Gea r Positio n Signa l

(From pag e 11-121 )

Chec k fo r a n ope n in th e wire :

1 . Tur n th e ignitio n switc h OFF .

2. Reconnec t th e 30 P (C412 ) con -necto r t o th e gaug e assembly .

3 . Reconnec t th e 26 P connecto r

to th e TCM .4. Star t th e engine .

5 . Measur e voltag e betwee n EC M

connecto r terminal s B 4 an d

A26 wit h th e transmissio n i nposition . EC

M CONNECTOR S

WIR E SID E O F FEMAL E TERMINAL S

I s ther e les s tha n 1. 0 V ? —

Repai r ope n i n th e wir e

betwee n th e EC M (B4 ) an d th e

gaug e assembly .— Repai r ope n i n GR N wir e

betwee n th e gaug e assembl y

an d th e A/ T gea r positio n

switch .

Chec k fo r a n ope n in th e wire :

Measur e voltag e betwee n EC M

Connecto r terminal s 8 4 an d A2 6

with th e transmissio n i n posi -tion.

Is ther e les s tha n 1. 0 V ? Repai

r ope n i n GRN/WH T wir e

betwee n th e gaug e assembl y an d

th e A/ T gea r positio n switch .

A/ T gea r positio n signa l i s OK .

ProCarManuals.com

Page 242 of 1640

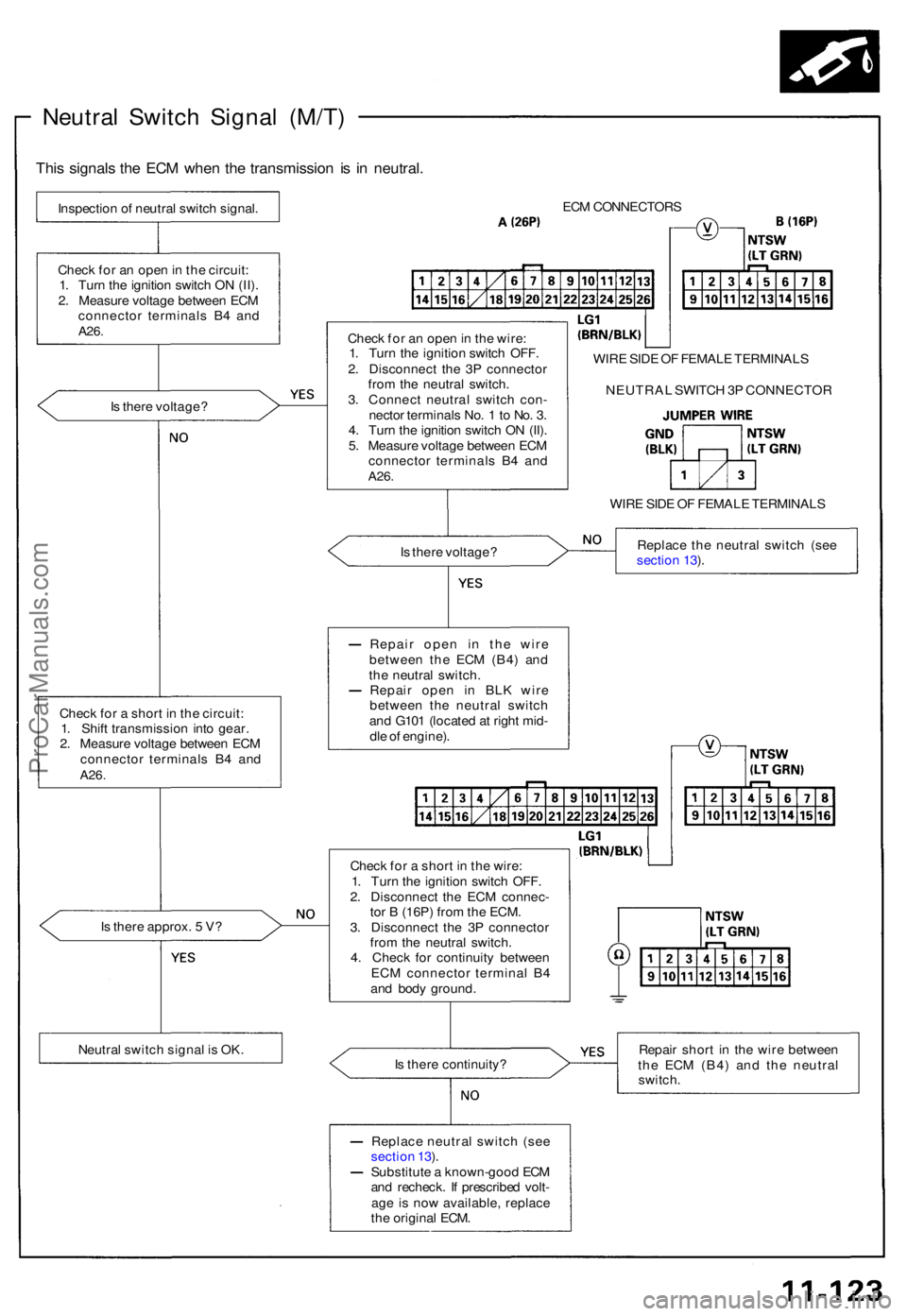

Neutral Switc h Signa l (M/T )

This signal s th e EC M whe n th e transmissio n i s i n neutral .

Inspectio n o f neutra l switc h signal .

Chec k fo r a n ope n in th e circuit :

1 . Tur n th e ignitio n switc h O N (II) .

2 . Measur e voltag e betwee n EC M

connecto r terminal s B 4 an d

A26 .

Is ther e voltage ?

Chec k fo r a shor t i n th e circuit :

1 . Shif t transmissio n int o gear .

2 . Measur e voltag e betwee n EC M

connecto r terminal s B 4 an d

A26 .

Is ther e approx . 5 V ?

Neutra l switc h signa l i s OK . EC

M CONNECTOR S

Chec k fo r a n ope n in th e wire :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e 3 P connecto r

fro m th e neutra l switch .

3 . Connec t neutra l switc h con -

necto r terminal s No . 1 to No . 3 .

4 . Tur n th e ignitio n switc h O N (II) .

5 . Measur e voltag e betwee n EC M

connecto r terminal s B 4 an d

A26 .

WIR E SID E O F FEMAL E TERMINAL S

WIR E SID E O F FEMAL E TERMINAL S

I s ther e voltage ? Replac

e th e neutra l switc h (se e

sectio n 13 ).

Repai r ope n i n th e wir e

betwee n th e EC M (B4 ) an d

th e neutra l switch .

Repai r ope n i n BL K wir e

betwee n th e neutra l switc h

an d G10 1 (locate d a t righ t mid -

dl e o f engine) .

Chec k fo r a shor t i n th e wire :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e EC M connec -

to r B (16P ) fro m th e ECM .

3 . Disconnec t th e 3 P connecto r

fro m th e neutra l switch .

4 . Chec k fo r continuit y betwee n

EC M connecto r termina l B 4

an d bod y ground .

I s ther e continuity ? Repai

r shor t i n th e wir e betwee n

th e EC M (B4 ) an d th e neutra l

switch .

Replac e neutra l switc h (se e

sectio n 13 ).

Substitut e a known-goo d EC M

an d recheck . I f prescribe d volt -

ag e i s no w available , replac e

th e origina l ECM . NEUTRA

L SWITC H 3 P CONNECTO R

ProCarManuals.com

Page 246 of 1640

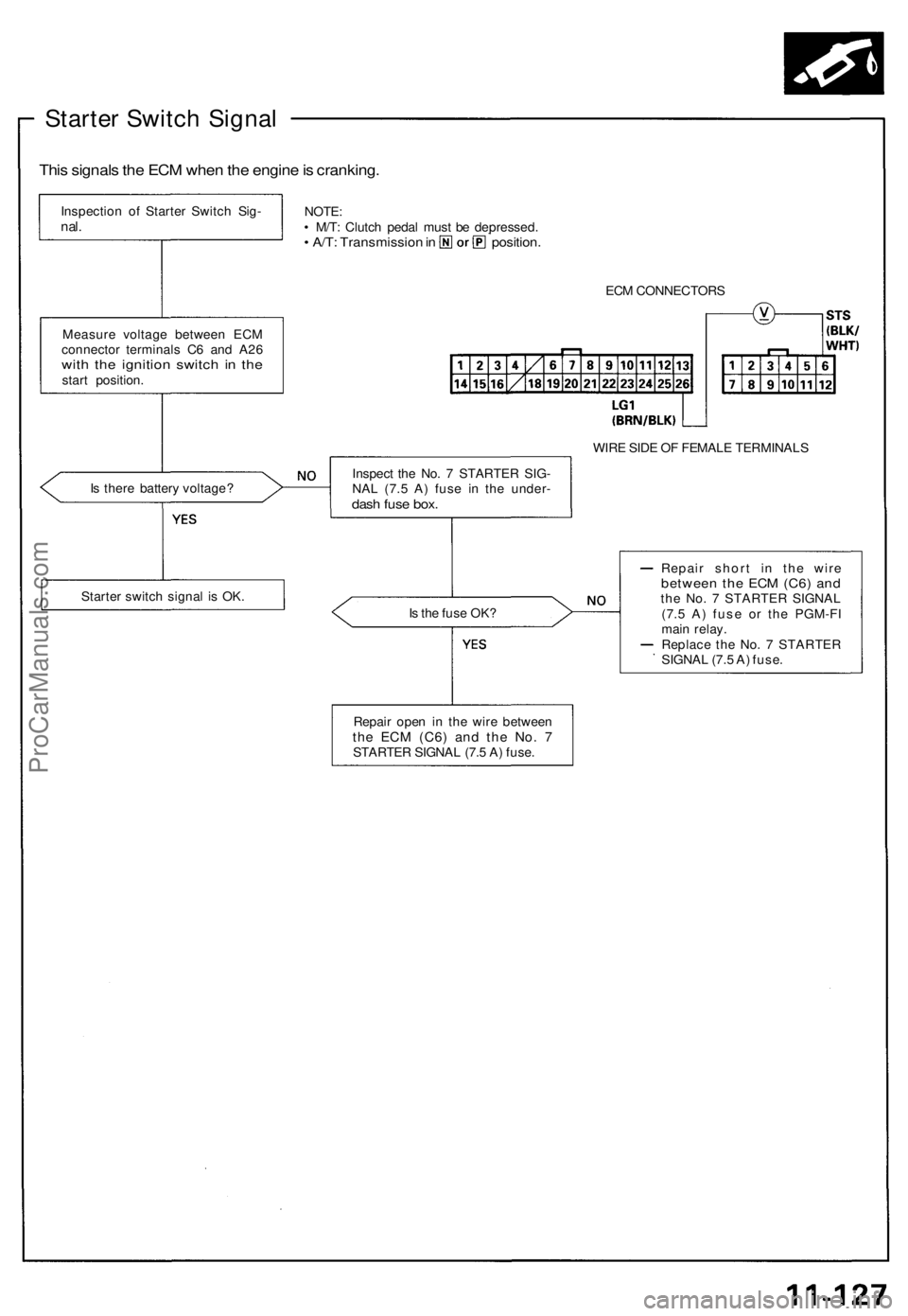

Starter Switch Signal

This signals the ECM when the engine is cranking.

Inspection of Starter Switch Sig-

nal.

NOTE:

• M/T: Clutch pedal must be depressed.

• A/T: Transmission in position.

ECM CONNECTORS

Measure voltage between ECM

connector terminals C6 and A26

with the ignition switch in the

start position.

WIRE SIDE OF FEMALE TERMINALS

Is there battery voltage?

Is the fuse OK?

Repair short in the wire

between the ECM (C6) and

the No. 7 STARTER SIGNAL

(7.5 A) fuse or the PGM-FI

main relay.

Replace the No. 7 STARTER

SIGNAL (7.5 A) fuse.

Starter switch signal is OK.

Repair open in the wire between

the ECM

(C6)

and the No. 7

STARTER SIGNAL (7.5 A) fuse.

Inspect the No. 7 STARTER SIG-

NAL (7.5 A) fuse in the under-

dash fuse box.ProCarManuals.com

Page 247 of 1640

Idle Contro l Syste m

Idle Spee d Settin g

Inspection/Adjustmen t

NOTE: Befor e settin g th e idl e speed , chec k th e followin g

items :

— Th e Chec k Engin e ligh t ha s no t bee n reporte d on .

— Ignitio n timin g

— Spar k plug s

— Ai r cleane r

— PC V syste m

1 . Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (A/ T in position , M/ T in neutral ) unti l

th e radiato r fa n come s on , the n tur n th e ignitio n

switc h OFF .

2 . Connec t th e SC S servic e connecto r t o servic e chec k

connector .

3. Connec t a OBDI I sca n too l (se e pag e 11-38 ) o r

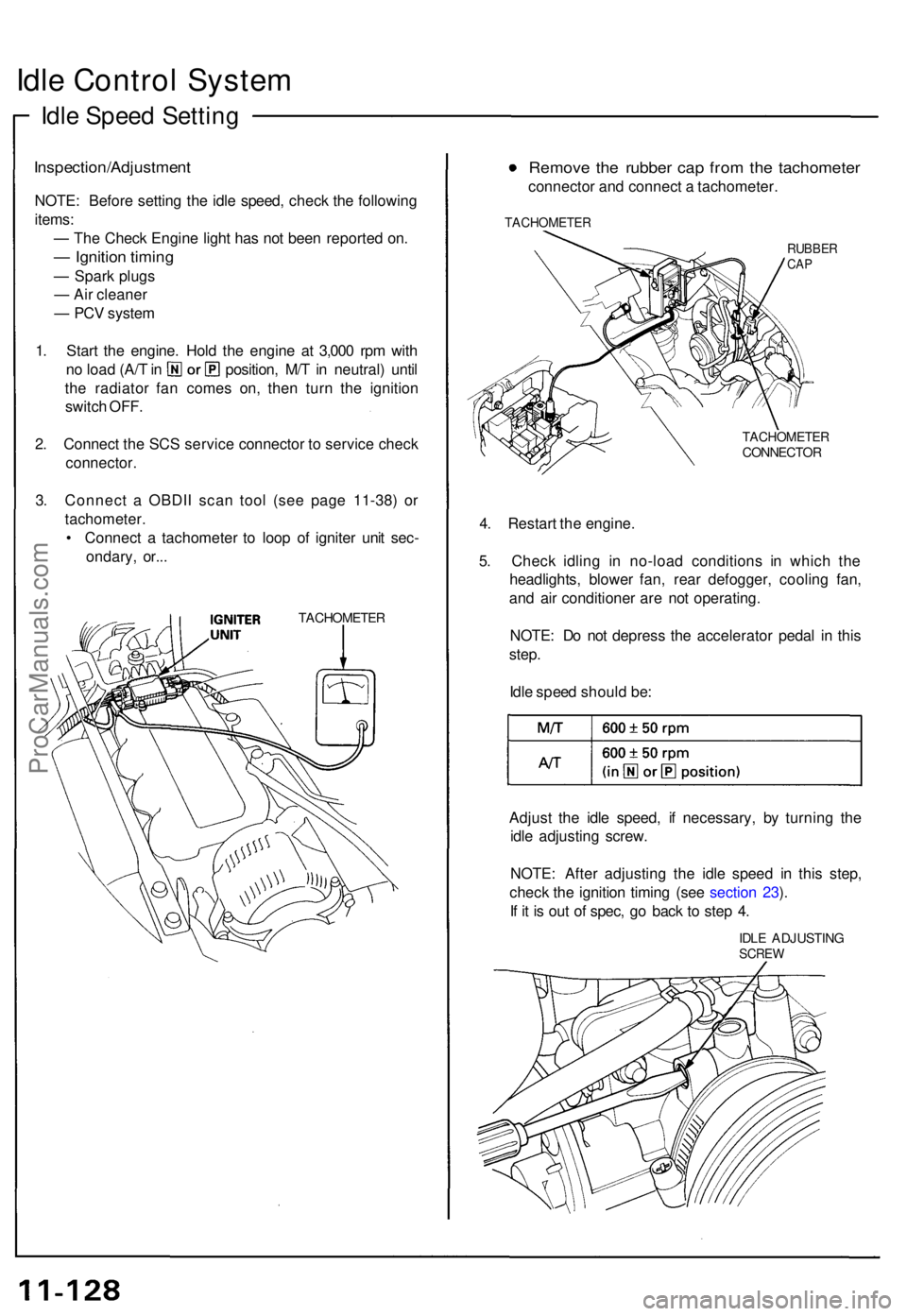

tachometer .

• Connec t a tachomete r t o loo p o f ignite r uni t sec -

ondary , or.. .

TACHOMETE R

Remove th e rubbe r ca p fro m th e tachomete r

connector an d connec t a tachometer .

TACHOMETE R

RUBBERCAP

TACHOMETE RCONNECTOR

4. Restar t th e engine .

5 . Chec k idlin g i n no-loa d condition s i n whic h th e

headlights , blowe r fan , rea r defogger , coolin g fan ,

an d ai r conditione r ar e no t operating .

NOTE : D o no t depres s th e accelerato r peda l i n thi s

step .

Idl e spee d shoul d be :

Adjus t th e idl e speed , i f necessary , b y turnin g th e

idl e adjustin g screw .

NOTE : Afte r adjustin g th e idl e spee d i n thi s step ,

chec k th e ignitio n timin g (se e sectio n 23 ).

I f i t i s ou t o f spec , g o bac k t o ste p 4 .

IDL E ADJUSTIN GSCREW

ProCarManuals.com

Page 248 of 1640

6. Disconnect the SCS service connector.

7. Depress the accelerator pedal and stabilize the

engine speed at 1,000 rpm, then slowly release the

pedal until the engine idles, then check the idle

speed.

Idle speed should be:ProCarManuals.com