ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997,

Model line: NSX,

Model: ACURA NSX 1997

Pages: 1503, PDF Size: 57.08 MB

ACURA NSX 1997 Service Repair Manual

NSX 1997

ACURA

ACURA

https://www.carmanualsonline.info/img/32/56989/w960_56989-0.png

ACURA NSX 1997 Service Repair Manual

Trending: sport mode, maintenance schedule, buttons, automatic transmission fluid, child lock, fuel pressure, height

Page 821 of 1503

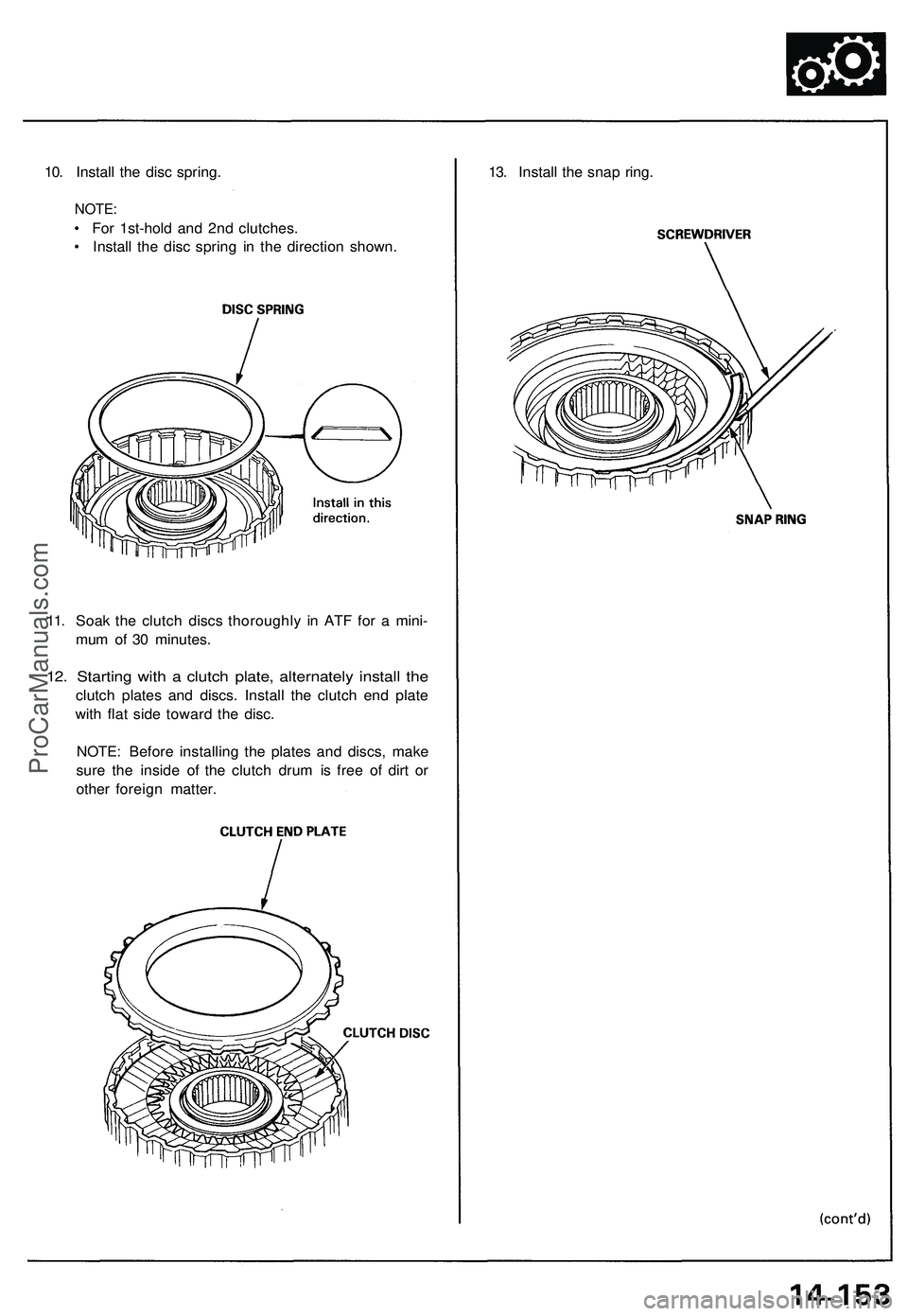

10. Install the disc spring.

NOTE:

• For 1st-hold and 2nd clutches.

• Install the disc spring in the direction shown.

13. Install the snap ring.

11. Soak the clutch discs thoroughly in ATF for a mini-

mum of 30 minutes.

12. Starting with a clutch plate, alternately install the

clutch plates and discs. Install the clutch end plate

with flat side toward the disc.

NOTE: Before installing the plates and discs, make

sure the inside of the clutch drum is free of dirt or

other foreign matter.ProCarManuals.com

Page 822 of 1503

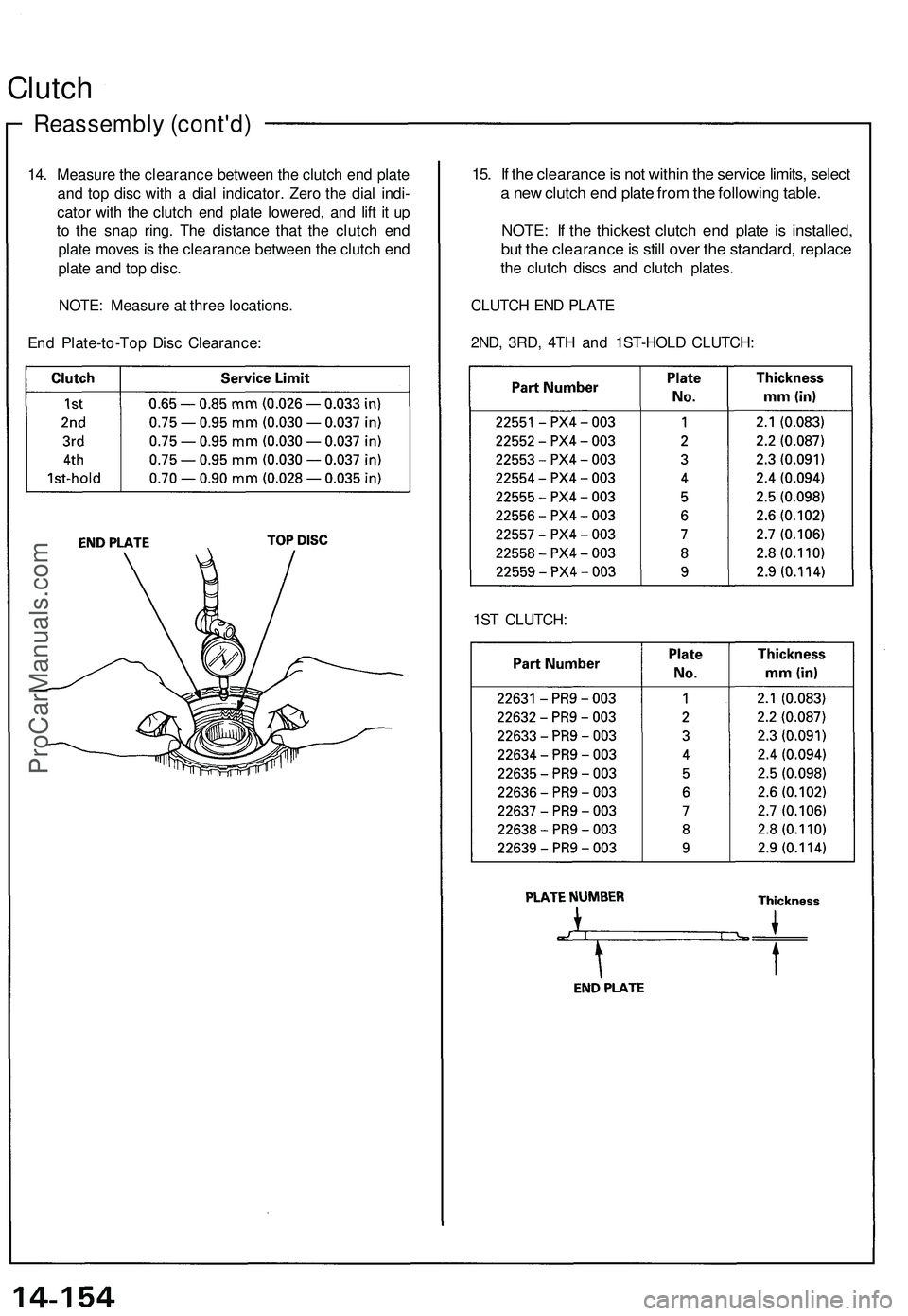

14. Measure the clearance between the clutch end plate

and top disc with a dial indicator. Zero the dial indi-

cator with the clutch end plate lowered, and lift it up

to the snap ring. The distance that the clutch end

plate moves is the clearance between the clutch end

plate and top disc.

NOTE: Measure at three locations.

End Plate-to-Top Disc Clearance:

Reassembly (cont'd)

Clutch

15. If the clearance is not within the service limits, select

a new clutch end plate from the following table.

NOTE: If the thickest clutch end plate is installed,

but the clearance is still over the standard, replace

the clutch discs and clutch plates.

CLUTCH END PLATE

2ND, 3RD, 4TH and 1ST-HOLD CLUTCH:

1ST CLUTCH:ProCarManuals.com

Page 823 of 1503

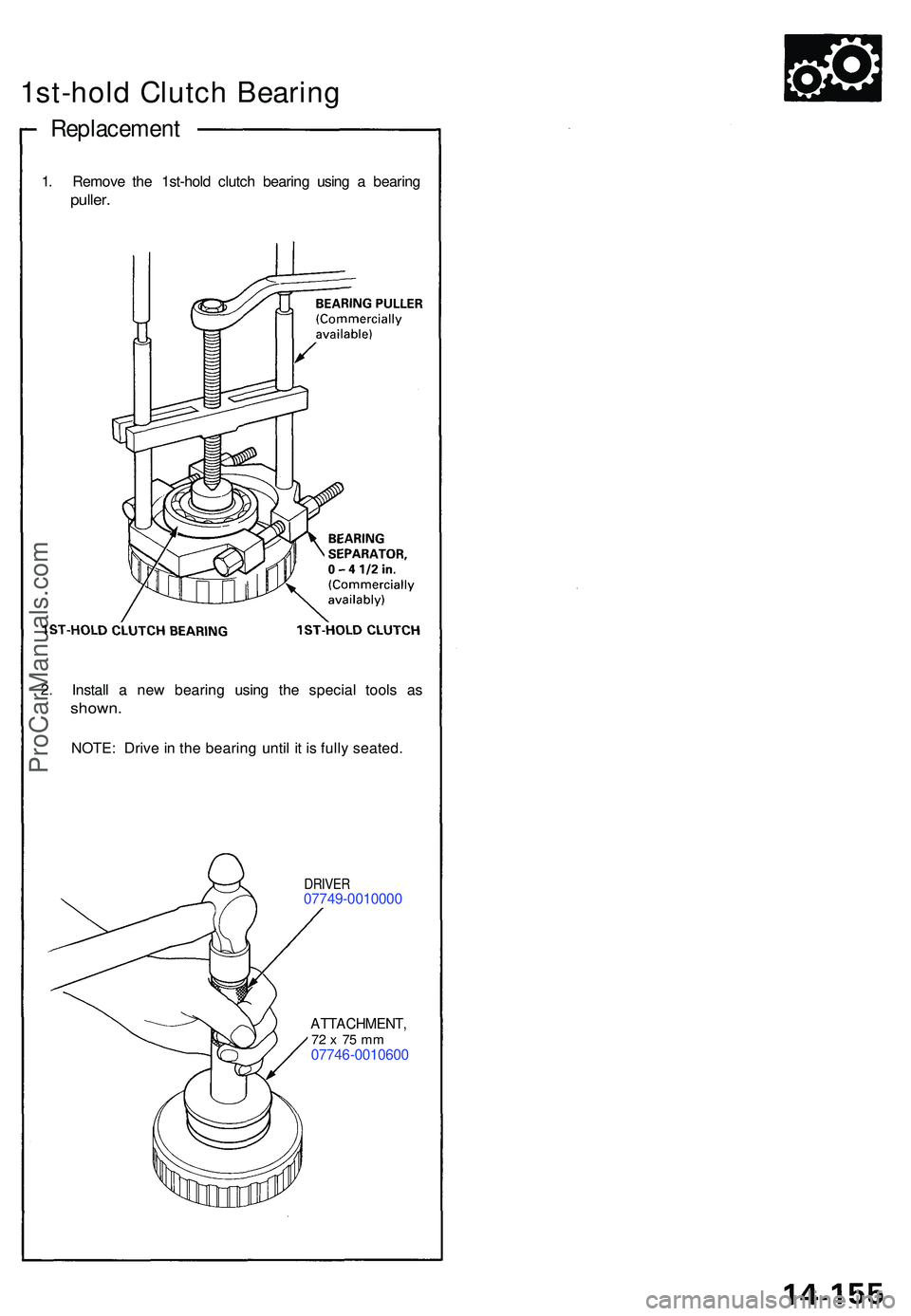

1st-hold Clutc h Bearin g

Replacemen t

1. Remov e th e 1st-hol d clutc h bearin g usin g a bearin g

puller.

2. Instal l a ne w bearin g usin g th e specia l tool s a s

shown .

NOTE: Driv e in th e bearin g unti l i t i s full y seated .

DRIVER07749-001000 0

ATTACHMENT ,72 x 7 5 m m07746-001060 0

ProCarManuals.com

Page 824 of 1503

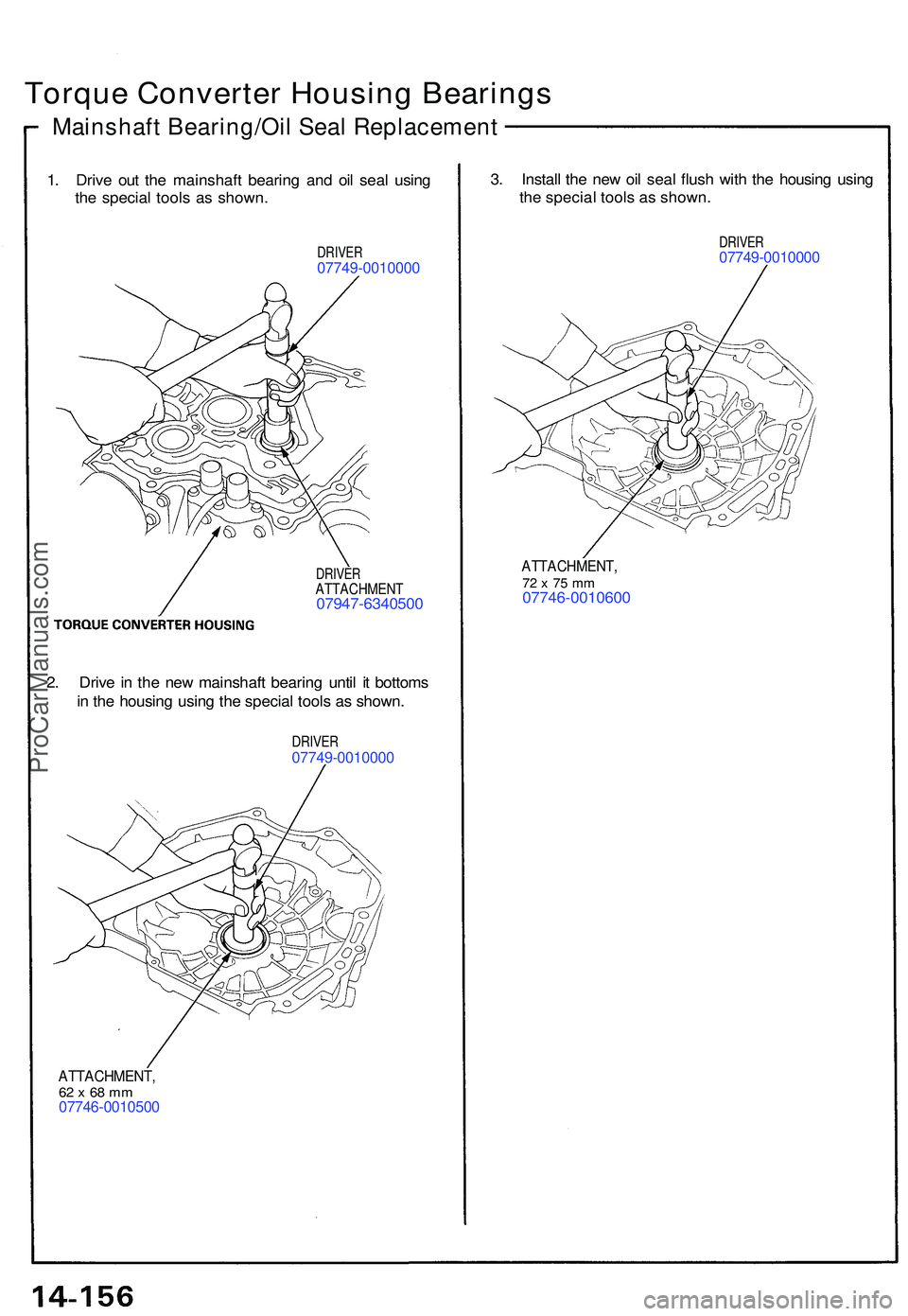

Torque Converter Housing Bearings

Mainshaft Bearing/Oil Seal Replacement

1. Driv e ou t th e mainshaf t bearin g an d oi l sea l usin g

th e specia l tool s a s shown .

DRIVER07749-001000 0

3. Instal l th e ne w oi l sea l flus h wit h th e housin g usin g

th e specia l tool s a s shown .

DRIVER07749-001000 0

DRIVERATTACHMEN T07947-634050 0

ATTACHMENT ,72 x 7 5 m m07746-001060 0

2 . Driv e in th e ne w mainshaf t bearin g unti l i t bottom s

i n th e housin g usin g th e specia l tool s a s shown .

DRIVER07749-001000 0

ATTACHMENT ,62 x 68 m m07746-001050 0

ProCarManuals.com

Page 825 of 1503

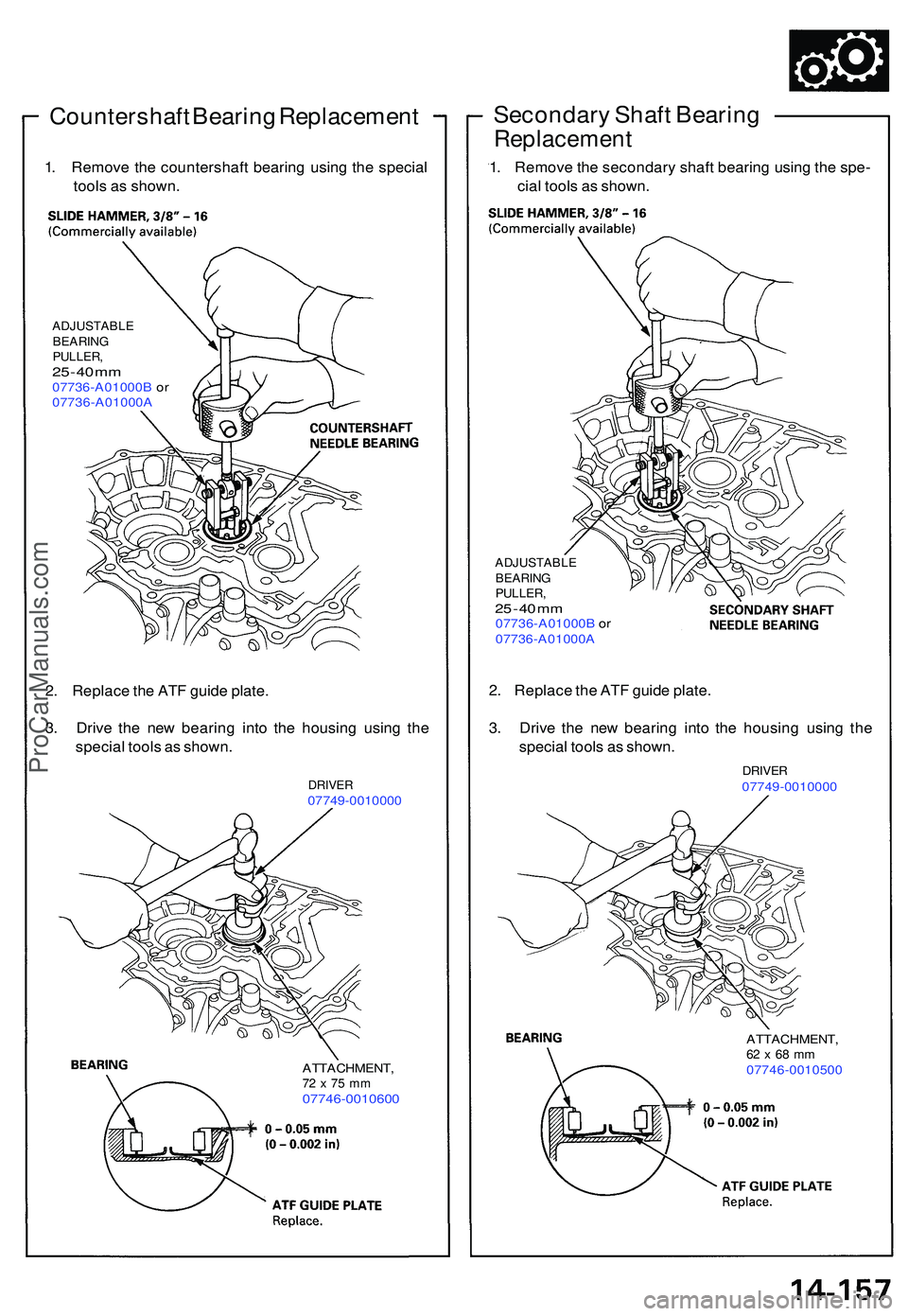

Countershaft Bearin g Replacemen t

1. Remov e th e countershaf t bearin g usin g th e specia l

tool s a s shown .

ADJUSTABL E

BEARIN G

PULLER ,

25 - 4 0 m m07736-A01000 B o r

07736-A01000 A

Secondary Shaf t Bearin g

Replacemen t

1. Remov e th e secondar y shaf t bearin g usin g th e spe -

cia l tool s a s shown .

ADJUSTABL E

BEARIN G

PULLER ,

25 - 4 0 m m07736-A01000 B o r

07736-A01000 A

2. Replac e th e AT F guid e plate .

3 . Driv e th e ne w bearin g int o th e housin g usin g th e

specia l tool s a s shown .

DRIVER07749-001000 0

2. Replac e th e AT F guid e plate .

3 . Driv e th e ne w bearin g int o th e housin g usin g th e

specia l tool s a s shown .

DRIVER07749-001000 0

ATTACHMENT ,72 x 75 m m07746-001060 0

ATTACHMENT ,62 x 68 m m07746-001050 0

ProCarManuals.com

Page 826 of 1503

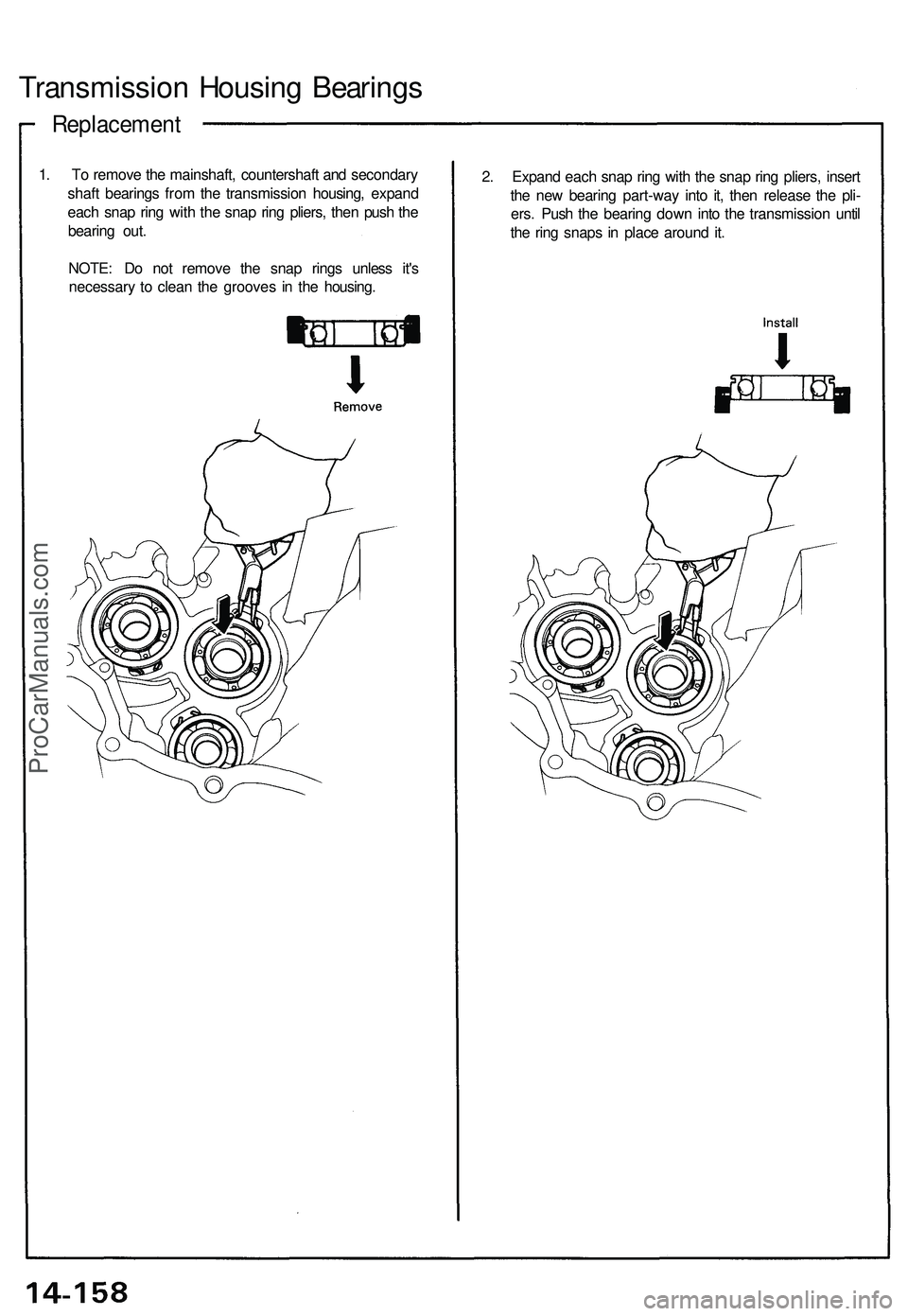

Replacement

Transmission Housin g Bearing s

1. T o remov e th e mainshaft , countershaf t an d secondar y

shaf t bearing s fro m th e transmissio n housing , expan d

eac h sna p rin g wit h th e sna p rin g pliers , the n pus h th e

bearin g out .

NOTE : D o no t remov e th e sna p ring s unles s it' s

necessar y t o clea n th e groove s i n th e housing . 2

. Expan d eac h sna p rin g wit h th e sna p rin g pliers , inser t

th e ne w bearin g part-wa y int o it , the n releas e th e pli -

ers . Pus h th e bearin g dow n int o th e transmissio n unti l

th e rin g snap s i n plac e aroun d it .

ProCarManuals.com

Page 827 of 1503

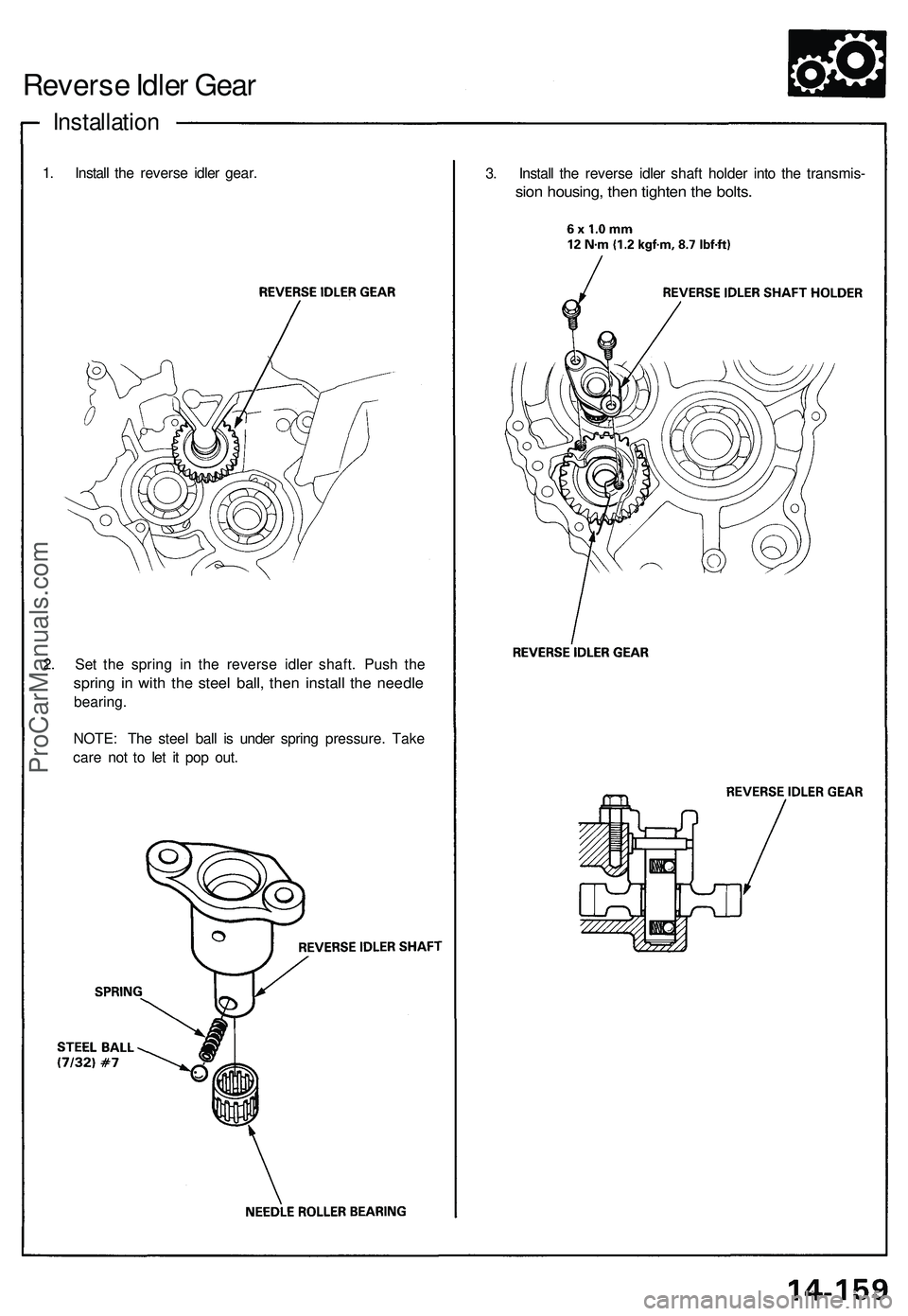

Reverse Idler Gear

Installation

1. Install the reverse idler gear.

3. Install the reverse idler shaft holder into the transmis-

sion housing, then tighten the bolts.

2. Set the spring in the reverse idler shaft. Push the

spring in with the steel ball, then install the needle

bearing.

NOTE: The steel ball is under spring pressure. Take

care not to let it pop out.ProCarManuals.com

Page 828 of 1503

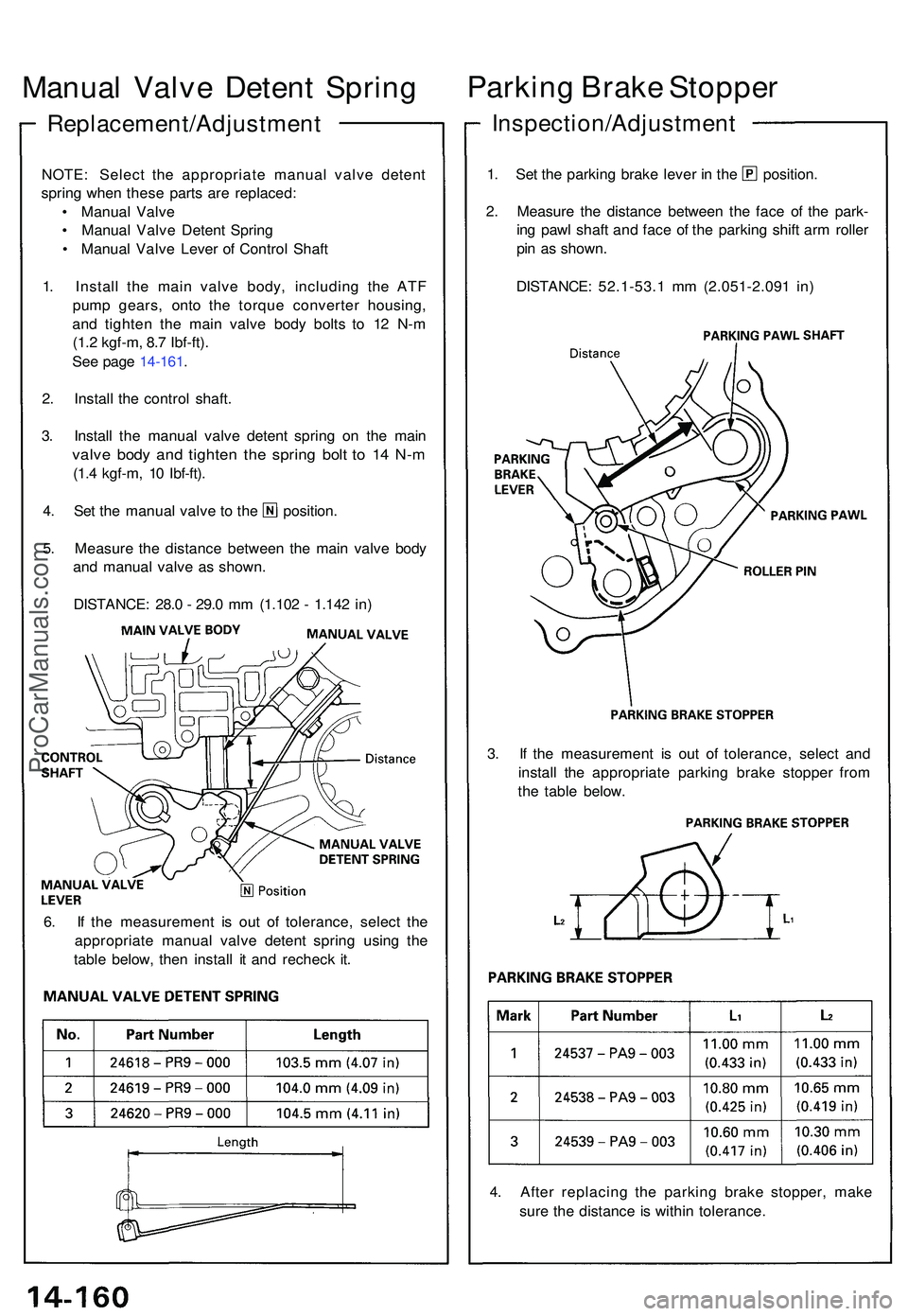

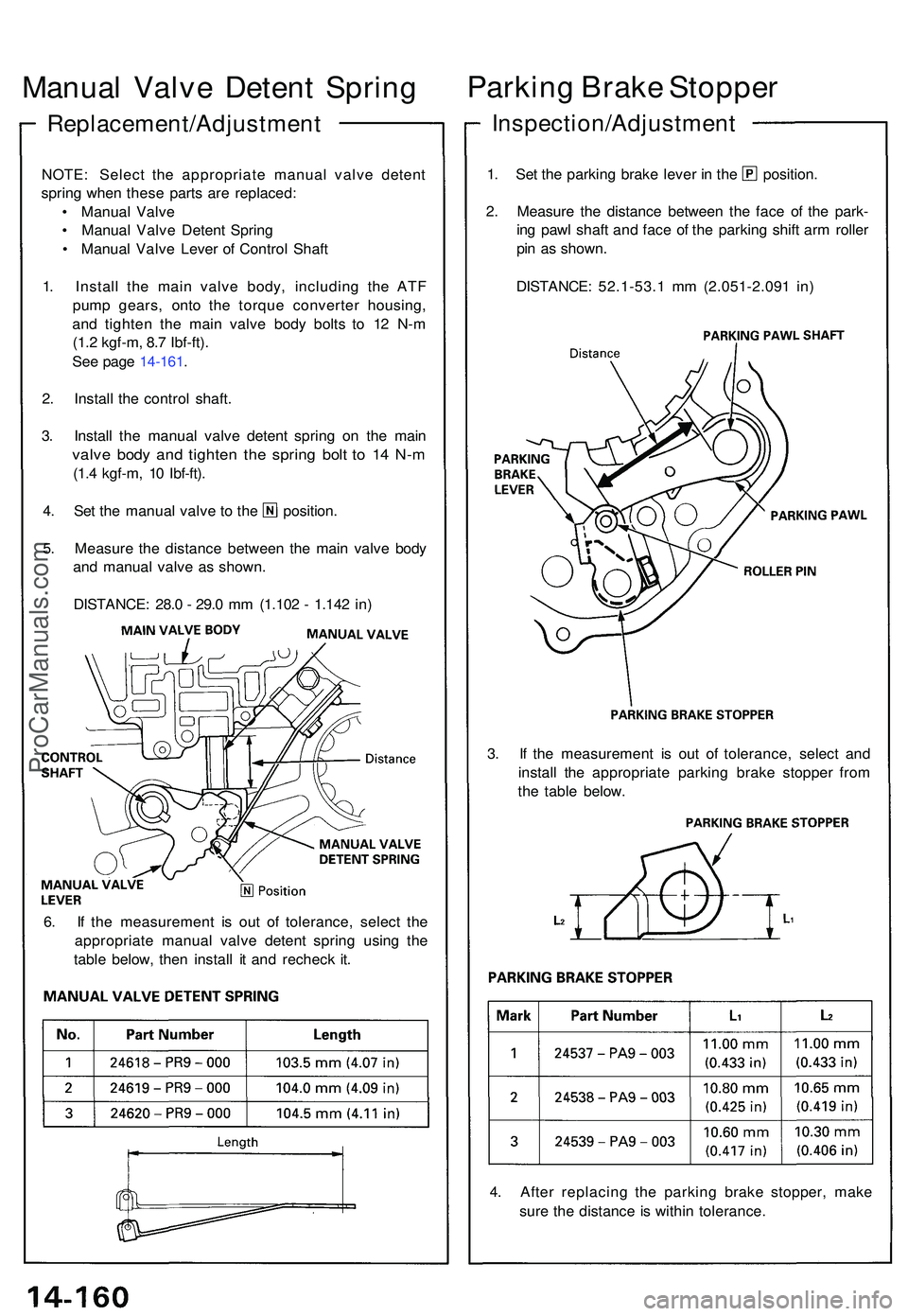

Replacement/Adjustment

Manual Valv e Deten t Sprin gParkin

g Brak e Stoppe r

Inspection/Adjustmen t

NOTE: Selec t th e appropriat e manua l valv e deten t

sprin g whe n thes e part s ar e replaced :

• Manua l Valv e

• Manua l Valv e Deten t Sprin g

• Manua l Valv e Leve r o f Contro l Shaf t

1 . Instal l th e mai n valv e body , includin g th e AT F

pum p gears , ont o th e torqu e converte r housing ,

an d tighte n th e mai n valv e bod y bolt s t o 1 2 N- m

(1. 2 kgf-m , 8. 7 Ibf-ft) .

Se e pag e 14-161 .

2 . Instal l th e contro l shaft .

3 . Instal l th e manua l valv e deten t sprin g o n th e mai n

valve bod y an d tighte n th e sprin g bol t t o 1 4 N- m

(1.4 kgf-m , 1 0 Ibf-ft) .

4. Se t th e manua l valv e t o th e position .

5 . Measur e th e distanc e betwee n th e mai n valv e bod y

an d manua l valv e a s shown .

DISTANCE : 28. 0 - 29. 0 m m (1.10 2 - 1.14 2 in )

1. Se t th e parkin g brak e leve r i n th e position .

2 . Measur e th e distanc e betwee n th e fac e o f th e park -

in g paw l shaf t an d fac e o f th e parkin g shif t ar m rolle r

pi n a s shown .

DISTANCE : 52.1-53. 1 m m (2.051-2.09 1 in )

6 . I f th e measuremen t i s ou t o f tolerance , selec t th e

appropriat e manua l valv e deten t sprin g usin g th e

tabl e below , the n instal l i t an d rechec k it . 3

. I f th e measuremen t i s ou t o f tolerance , selec t an d

instal l th e appropriat e parkin g brak e stoppe r fro m

th e tabl e below .

4 . Afte r replacin g th e parkin g brak e stopper , mak e

sur e th e distanc e i s withi n tolerance .

ProCarManuals.com

Page 829 of 1503

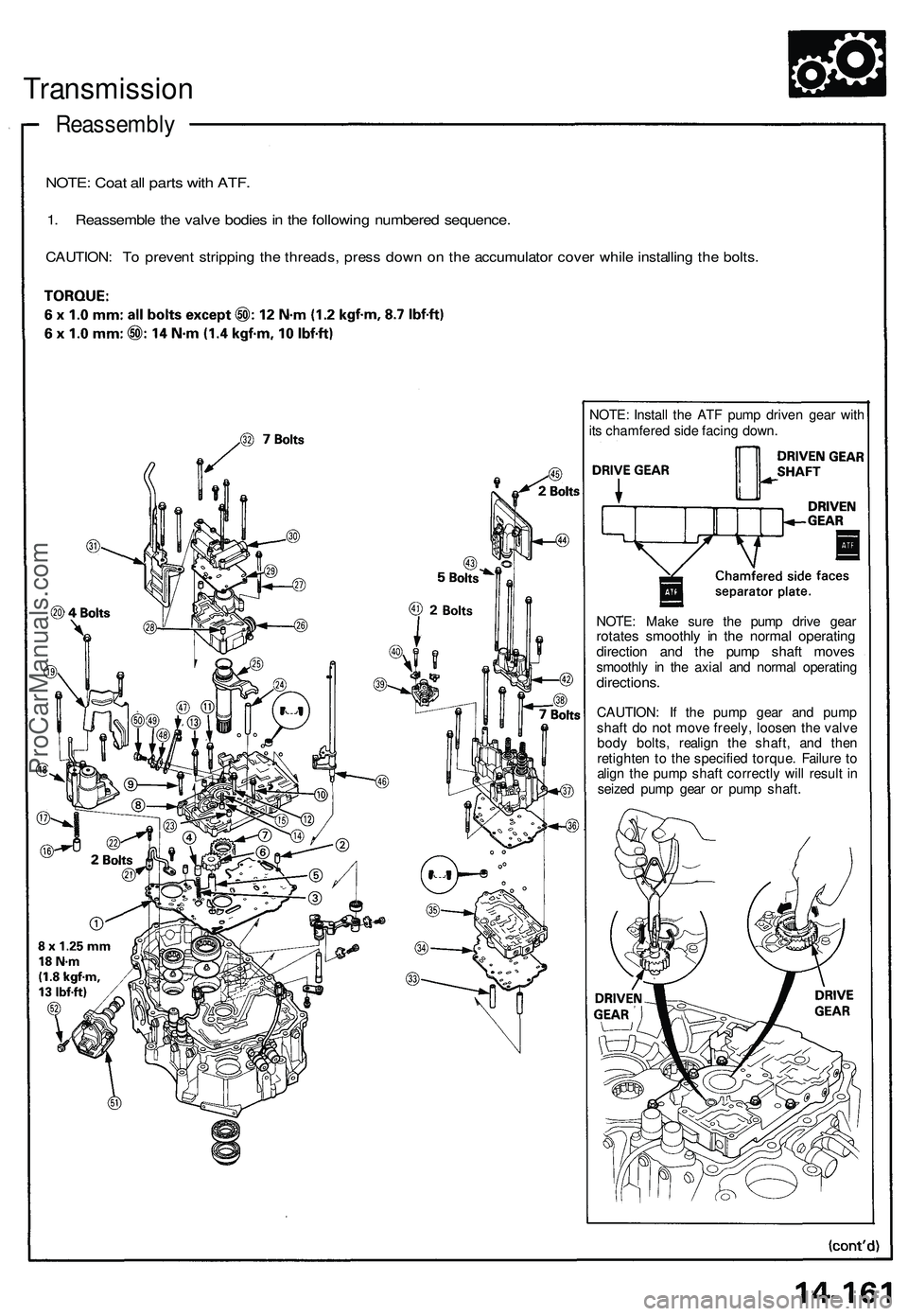

Reassembly

Transmissio n

NOTE: Coa t al l part s wit h ATF .

1. Reassembl e th e valv e bodie s in th e followin g numbere d sequence .

CAUTION: T o preven t strippin g th e threads , pres s dow n o n th e accumulato r cove r whil e installin g th e bolts .

NOTE : Instal l th e AT F pum p drive n gea r wit h

it s chamfere d sid e facin g down .

NOTE : Mak e sur e th e pum p driv e gea r

rotate s smoothl y i n th e norma l operatin gdirection an d th e pum p shaf t move ssmoothl y i n th e axia l an d norma l operatin gdirections .

CAUTION : I f th e pum p gea r an d pum p

shaf t d o no t mov e freely , loose n th e valv e

bod y bolts , realig n th e shaft , an d the n

retighte n t o th e specifie d torque . Failur e t o

alig n th e pum p shaf t correctl y wil l resul t i n

seize d pum p gea r o r pum p shaft .

ProCarManuals.com

Page 830 of 1503

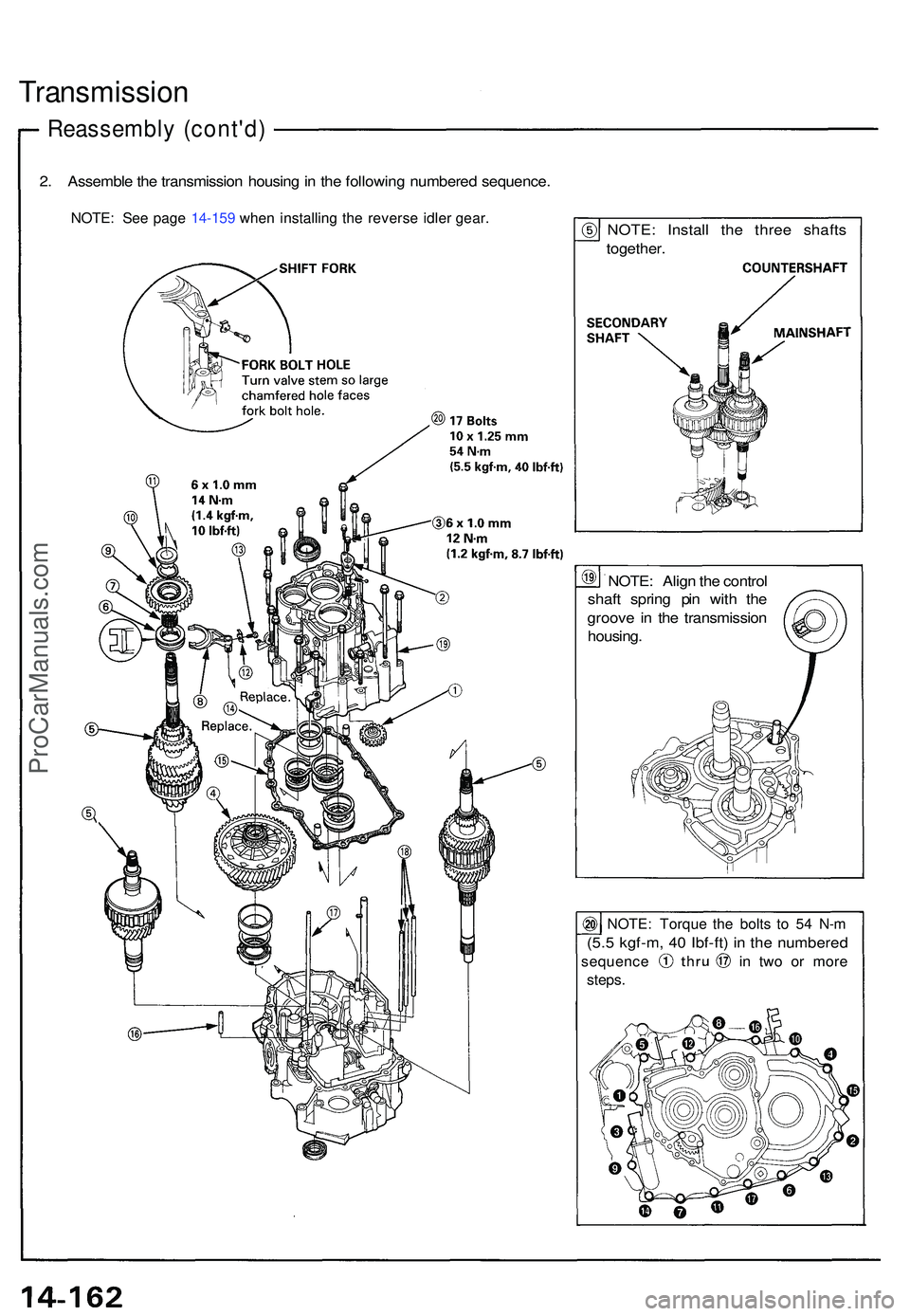

Reassembly (cont'd )

Transmissio n

2. Assembl e th e transmissio n housin g in th e followin g numbere d sequence .

NOTE: Se e pag e 14-15 9 whe n installin g th e revers e idle r gear .NOTE : Instal l th e thre e shaft s

together .

NOTE : Alig n th e contro l

shaf t sprin g pi n wit h th e

groov e i n th e transmissio n

housing .

NOTE: Torqu e th e bolt s t o 5 4 N- m

(5.5 kgf-m , 4 0 Ibf-ft ) i n th e numbere d

sequence i n tw o o r mor e

steps.

ProCarManuals.com

Trending: towing, mirror, Brake pedal assembly, odometer, headrest, ECO mode, driver seat adjustment