engine ACURA RL KA9 1996 Service Owners Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 470 of 1954

Oil Pa n

Remova l

Engine remova l i s no t require d i n thi s procedure .

• Mak e sur e jack s an d safet y stand s ar e place d properl y

(se e sectio n 1 ).

• Appl y th e parkin g brak e an d bloc k th e rea r wheel s s o

th e vehicl e wil l no t rol l of f stand s whil e yo u ar e

workin g unde r it .

CAUTION :

• Us e fende r cover s t o avoi d damagin g painte d sur -

faces .

• Unplu g th e wirin g connector s carefull y whil e holdin g

th e connecto r portio n to avoi d damaging .

• Mar k al l wirin g an d hose s t o avoi d misconnection .

Also , b e sur e tha t the y d o no t contac t othe r wirin g

o r hose s o r interfer e wit h othe r parts .

1 . Loose n th e idle r pulle y cente r nu t an d adjustin g bolt ,

the n remov e th e ai r conditionin g (A/C ) compresso r

bel t (se e pag e 5-7 ).

2 . Disconnec t th e powe r steerin g pressur e (PSP )

switc h connector , the n remov e th e powe r steerin g

pum p bel t an d pum p (se e pag e 5-8 ).

3 . Remov e th e lef t an d righ t sid e exhaus t manifol d

covers (se e pag e 9-4 ).

4 . Rais e th e hois t t o ful l height .

5 . Remov e th e fron t tires/wheel s an d splas h shiel d

(se e pag e 5-8 ).

6 . Remov e th e dampe r fork s (se e sectio n 18 ).

7 . Disconnec t th e suspensio n lowe r ar m bal l joint s

with the specia l tool . Refe r t o sectio n 1 8 fo r th e

prope r procedure .

8 . Remov e th e driveshaft s an d intermediat e shaf t (se e

sectio n 16 ).

9 . Drai n th e differentia l oil . Reinstal l th e drai n plu g usin g

a ne w washe r (se e sectio n 15 ).

10 . Drai n th e engin e oil . Reinstal l th e drai n bol t usin g a

ne w washe r (se e pag e 8-4 ).

11 . Disconnec t th e vehicl e spee d senso r (VSS ) connec -

tor , the n remov e th e VSS/powe r steerin g spee d

senso r (se e pag e 5-9 ).

D o no t disconnec t th e flui d hoses .

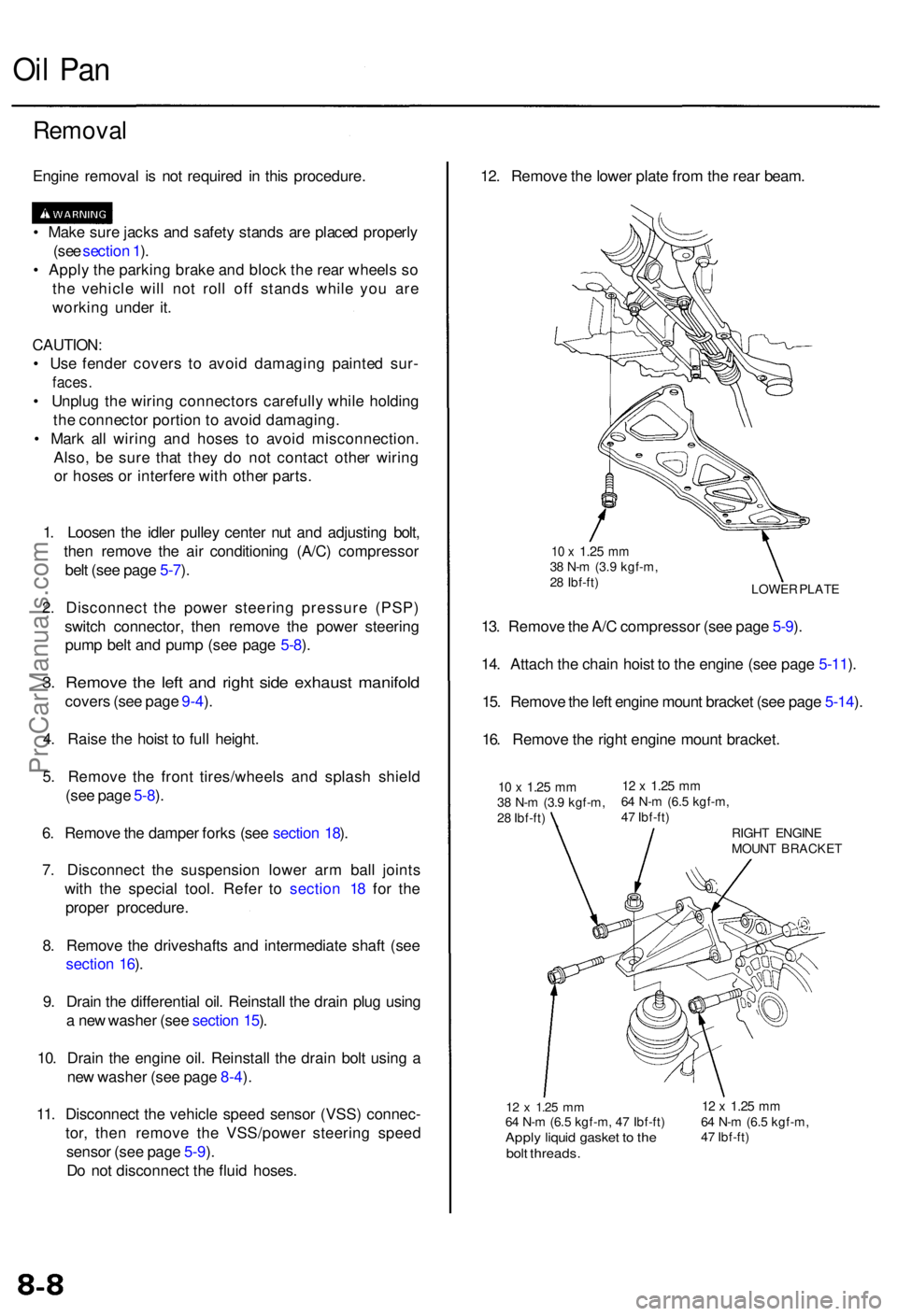

12 x 1.2 5 mm64 N- m (6. 5 kgf-m , 4 7 Ibf-ft )Apply liqui d gaske t t o th ebol t threads .

12 x 1.2 5 mm64 N- m (6. 5 kgf-m ,

4 7 Ibf-ft )

12. Remov e th e lowe r plat e fro m th e rea r beam .

LOWE R PLAT E

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

13. Remov e th e A/ C compresso r (se e pag e 5-9 ).

14 . Attac h th e chai n hois t t o th e engin e (se e pag e 5-11 ).

15 . Remov e th e lef t engin e moun t bracke t (se e pag e 5-14 ).

16 . Remov e th e righ t engin e moun t bracket .

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )12 x 1.2 5 mm64 N- m (6. 5 kgf-m ,

4 7 Ibf-ft )

RIGHT ENGIN E

MOUN T BRACKE T

ProCarManuals.com

Page 472 of 1954

Oil Pan

Installation

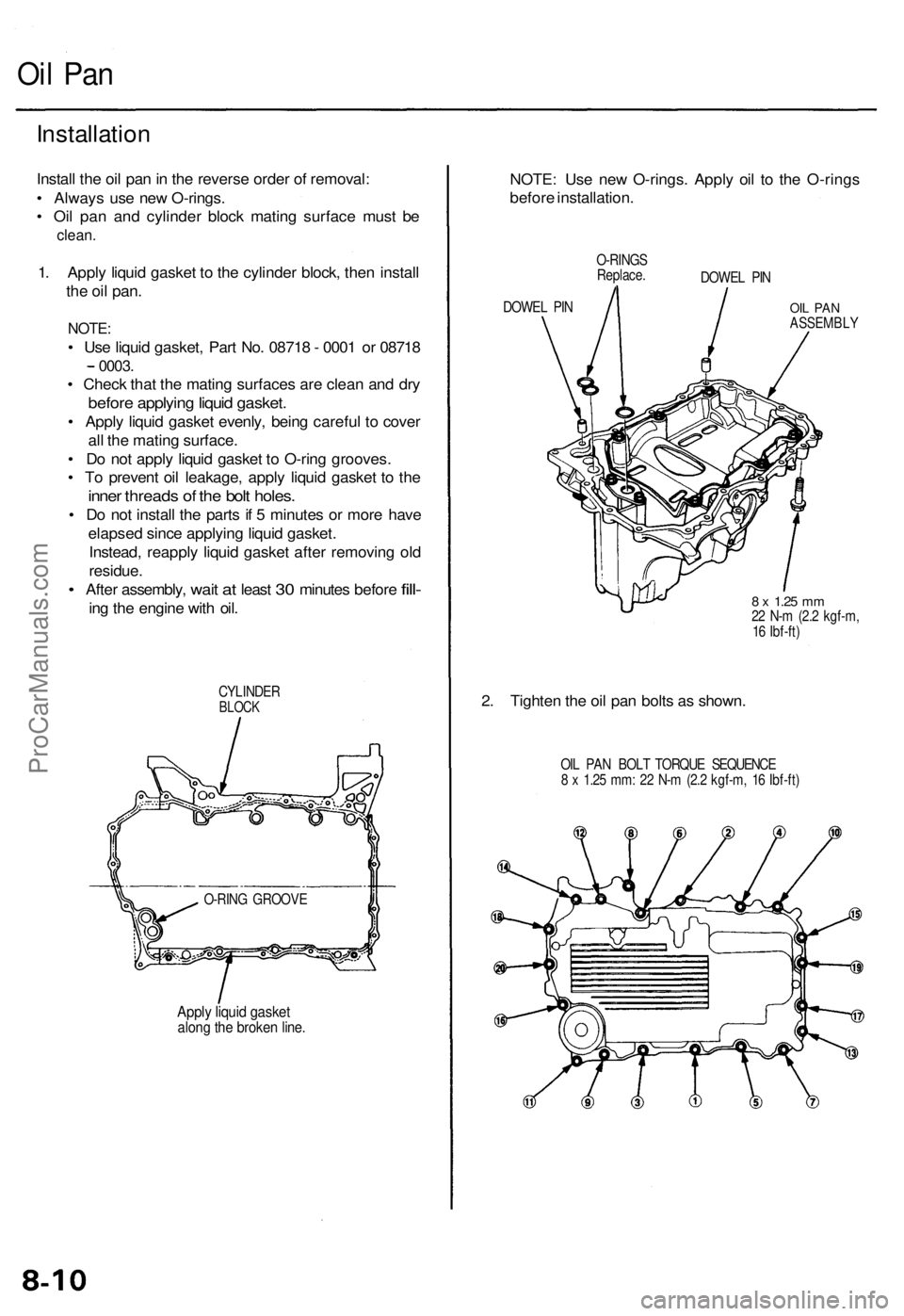

Install the oil pan in the reverse order of removal:

• Always use new O-rings.

• Oil pan and cylinder block mating surface must be

clean.

1. Apply liquid gasket to the cylinder block, then install

the oil

pan.

NOTE:

• Use liquid gasket, Part No. 08718 - 0001 or 08718

0003.

• Check that the mating surfaces are clean and dry

before applying liquid gasket.

• Apply liquid gasket evenly, being careful to cover

all the mating surface.

• Do not apply liquid gasket to O-ring grooves.

• To prevent oil leakage, apply liquid gasket to the

inner threads of the bolt holes.

• Do not install the parts if 5 minutes or more have

elapsed since applying liquid gasket.

Instead, reapply liquid gasket after removing old

residue.

•

After assembly,

wait

at

least

30

minutes before

fill-

ing the engine with oil.

CYLINDER

BLOCK

O-RING GROOVE

Apply liquid gasket

along the broken line.

NOTE: Use new O-rings. Apply oil to the O-rings

before installation.

DOWEL PIN

O-RINGS

Replace.

DOWEL PIN

OIL PAN

ASSEMBLY

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

2. Tighten the oil pan bolts as shown.

OIL PAN BOLT TORQUE SEQUENCE

8 x 1.25 mm: 22 N-m (2.2 kgf-m, 16 Ibf-ft)ProCarManuals.com

Page 473 of 1954

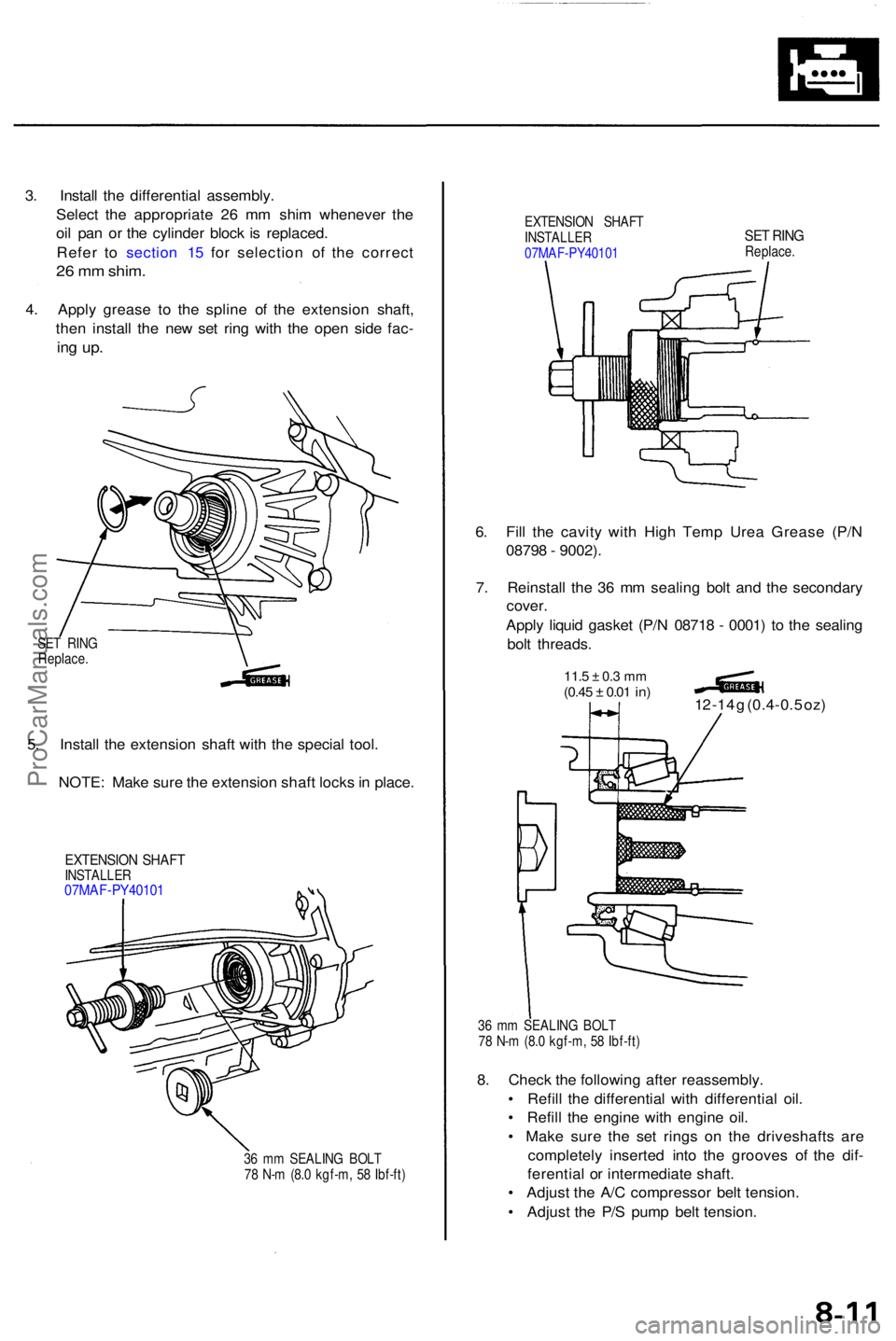

3. Instal l th e differentia l assembly .

Selec t th e appropriat e 2 6 m m shi m wheneve r th e

oi l pa n o r th e cylinde r bloc k i s replaced .

Refe r t o sectio n 1 5 fo r selectio n o f th e correc t

26 m m shim .

4. Appl y greas e t o th e splin e o f th e extensio n shaft ,

the n instal l th e ne w se t rin g wit h th e ope n sid e fac -

ing up .

EXTENSIO N SHAF T

INSTALLE R

07MA F-PY4010 1SET RIN GReplace .

6. Fil l th e cavit y wit h Hig h Tem p Ure a Greas e (P/ N

0879 8 - 9002) .

7 . Reinstal l th e 3 6 m m sealin g bol t an d th e secondar y

cover .

Appl y liqui d gaske t (P/ N 0871 8 - 0001 ) t o th e sealin g

bol t threads .

11.5 ± 0. 3 m m(0.4 5 ± 0.01 in)12 -1 4 g (0.4-0. 5 oz )

36 m m SEALIN G BOL T

7 8 N- m (8. 0 kgf-m , 5 8 Ibf-ft )

8. Chec k th e followin g afte r reassembly .

• Refil l th e differentia l wit h differentia l oil .

• Refil l th e engine with engin e oil .

• Mak e sur e th e se t ring s o n th e driveshaft s ar e

completel y inserte d int o th e groove s o f th e dif -

ferentia l o r intermediat e shaft .

• Adjus t th e A/ C compresso r bel t tension .

• Adjus t th e P/ S pum p bel t tension .

36 m m SEALIN G BOL T

7 8 N- m (8. 0 kgf-m , 5 8 Ibf-ft )

EXTENSIO N SHAF TINSTALLE R07MAF-PY4010 1

5. Instal l th e extensio n shaf t wit h th e specia l tool .

NOTE : Mak e sur e th e extensio n shaf t lock s in place .

SET RIN G

Replace .

ProCarManuals.com

Page 475 of 1954

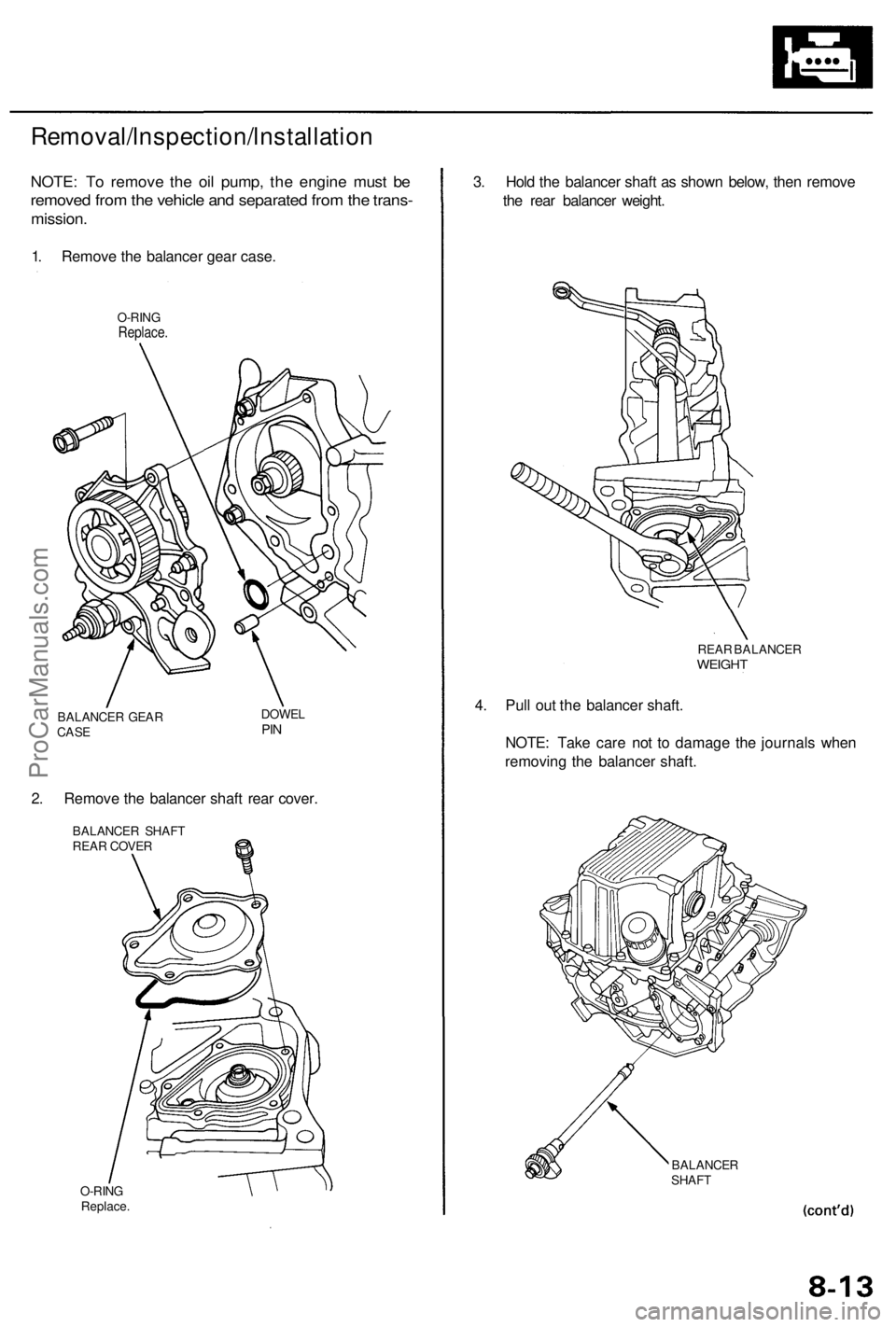

Removal/lnspection/lnstallation

NOTE: To remove the oil pump, the engine must be

removed from the vehicle and separated from the trans-

mission.

1. Remove the balancer gear case.

O-RING

Replace.

BALANCER GEAR

CASE

DOWEL

PIN

2. Remove the balancer shaft rear cover.

BALANCER SHAFT

REAR COVER

O-RING

Replace.

BALANCER

SHAFT

3. Hold the balancer shaft as shown below, then remove

the rear balancer weight.

4. Pull out the balancer shaft.

NOTE: Take care not to damage the journals when

removing the balancer shaft.

REAR BALANCER

WEIGHTProCarManuals.com

Page 487 of 1954

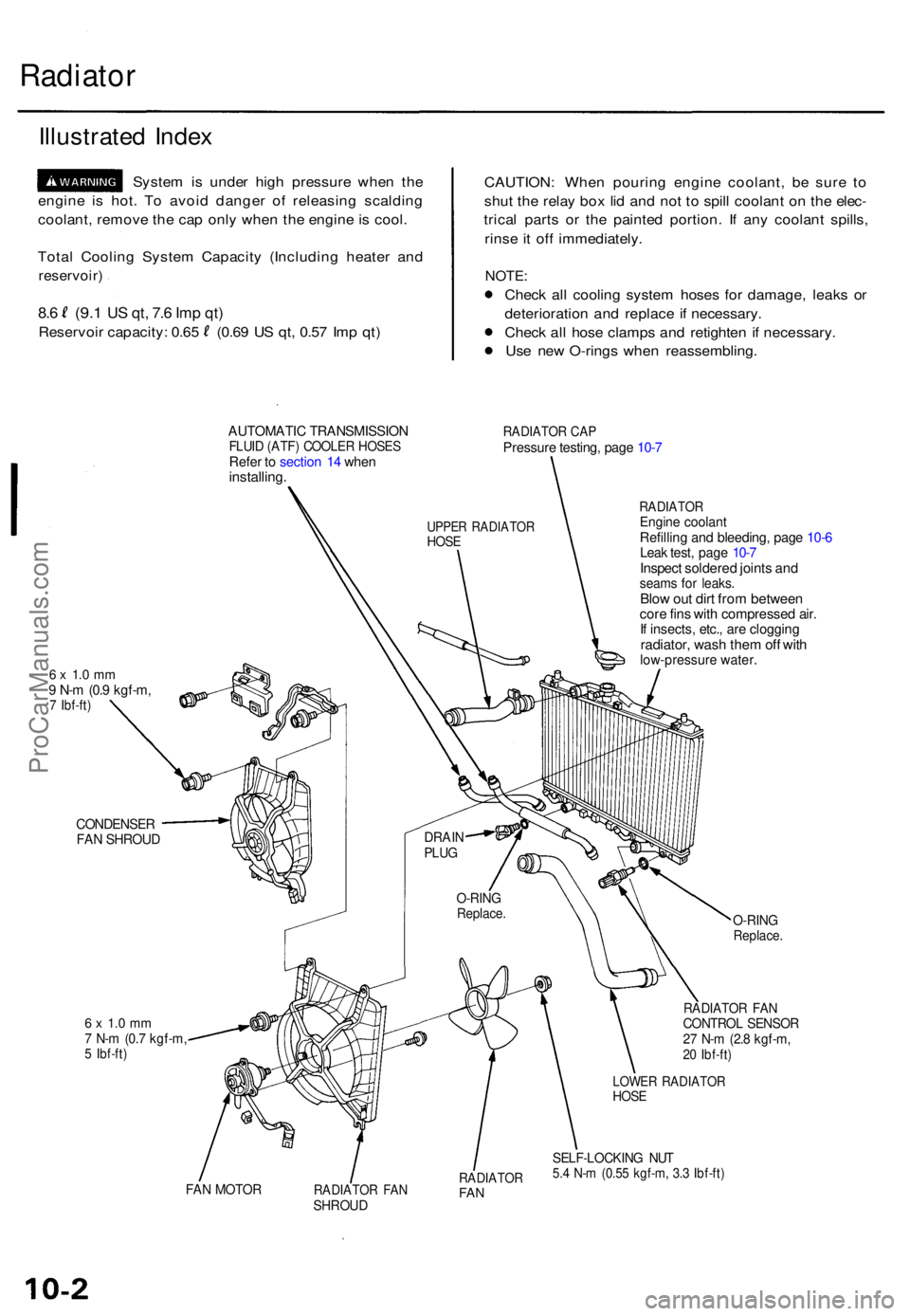

Radiator

Illustrate d Inde x

Syste m is unde r hig h pressur e whe n th e

engin e i s hot . T o avoi d dange r o f releasin g scaldin g

coolant , remov e th e ca p onl y whe n th e engin e is cool .

Tota l Coolin g Syste m Capacit y (Includin g heate r an d

reservoir )

8.6 (9. 1 US qt , 7. 6 Im p qt )

Reservoi r capacity : 0.6 5 (0.6 9 U S qt , 0.5 7 Im p qt ) CAUTION

: Whe n pourin g engin e coolant , b e sur e t o

shu t th e rela y bo x li d an d no t t o spil l coolan t o n th e elec -

trica l part s o r th e painte d portion . I f an y coolan t spills ,

rins e it of f immediately .

NOTE:

Check al l coolin g syste m hose s fo r damage , leak s o r

deterioratio n an d replac e if necessary .

Chec k al l hos e clamp s an d retighte n i f necessary .

Us e ne w O-ring s whe n reassembling .

AUTOMATIC TRANSMISSIO NFLUID (ATF ) COOLE R HOSE SRefer t o sectio n 1 4 whe ninstalling .

RADIATO R CA PPressur e testing , pag e 10-7

6 x 1. 0 m m9 N- m (0. 9 kgf-m ,7 Ibf-ft )

RADIATO REngine coolan tRefilling an d bleeding , pag e 10-6Lea k test , pag e 10-7Inspec t soldere d joint s an dseam s fo r leaks .Blow ou t dir t fro m betwee ncore fin s wit h compresse d air .If insects , etc. , ar e cloggin gradiator, was h the m of f wit hlow-pressur e water .

CONDENSE RFAN SHROU D

6 x 1. 0 m m7 N- m (0. 7 kgf-m ,5 Ibf-ft )

O-RIN GReplace .

RADIATO R FA NCONTRO L SENSO R27 N- m (2. 8 kgf-m ,20 Ibf-ft )

FAN MOTO RRADIATO R FA NSHROU D

RADIATO RFAN

LOWE R RADIATO RHOSE

SELF-LOCKIN G NU T5.4 N- m (0.5 5 kgf-m , 3. 3 Ibf-ft )

O-RIN GReplace .

DRAINPLUG

UPPE R RADIATO RHOSE

ProCarManuals.com

Page 488 of 1954

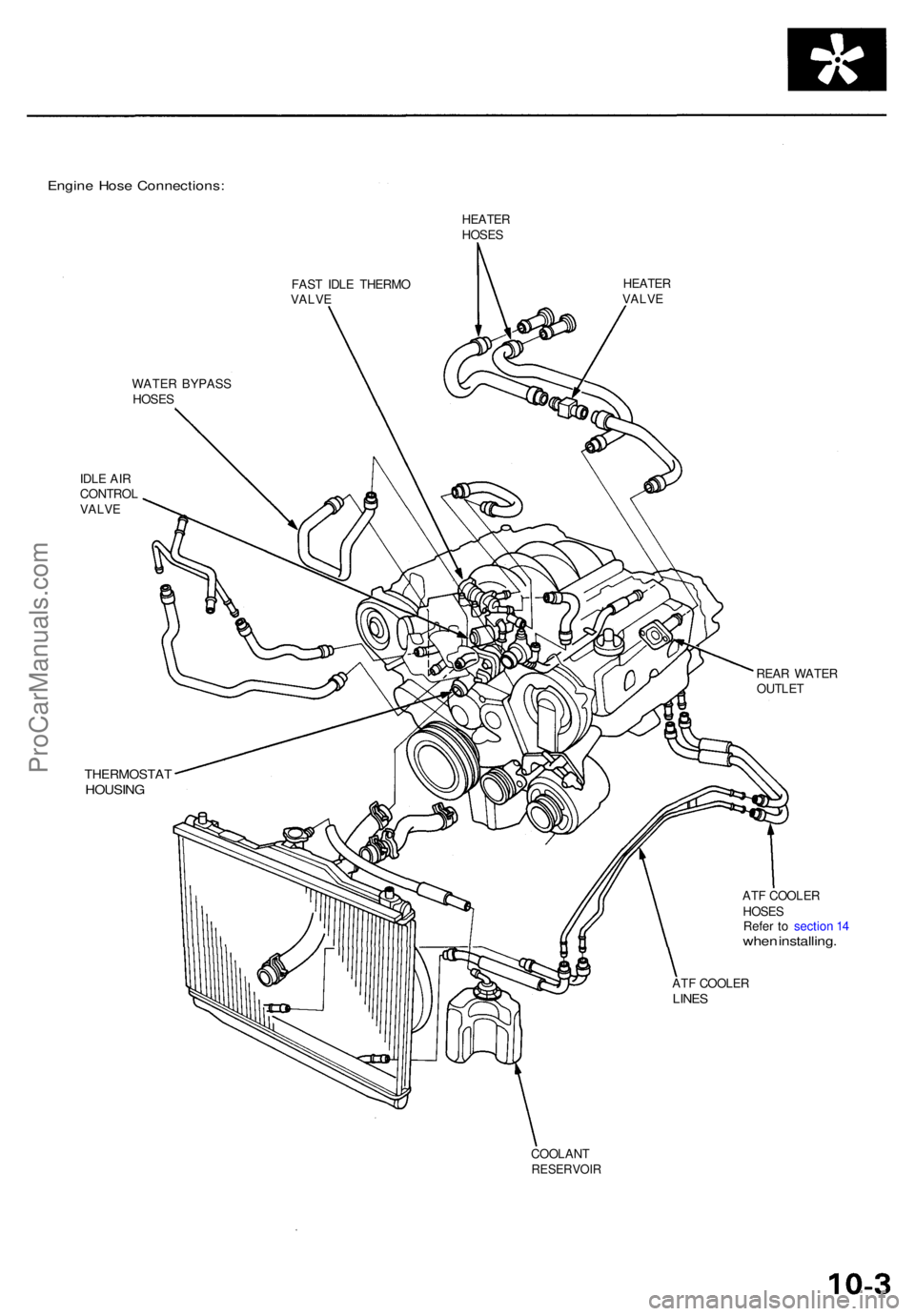

Engine Hos e Connections :

HEATERHOSES

FAS T IDL E THERM O

VALV E

HEATE RVALVE

WATE R BYPAS S

HOSE S

IDL E AI R

CONTRO L

VALV E

THERMOSTA THOUSING

REAR WATE R

OUTLE T

AT F COOLE R

HOSE S

Refe r t o sectio n 1 4

whe n installing .

ATF COOLE RLINES

COOLAN TRESERVOI R

ProCarManuals.com

Page 490 of 1954

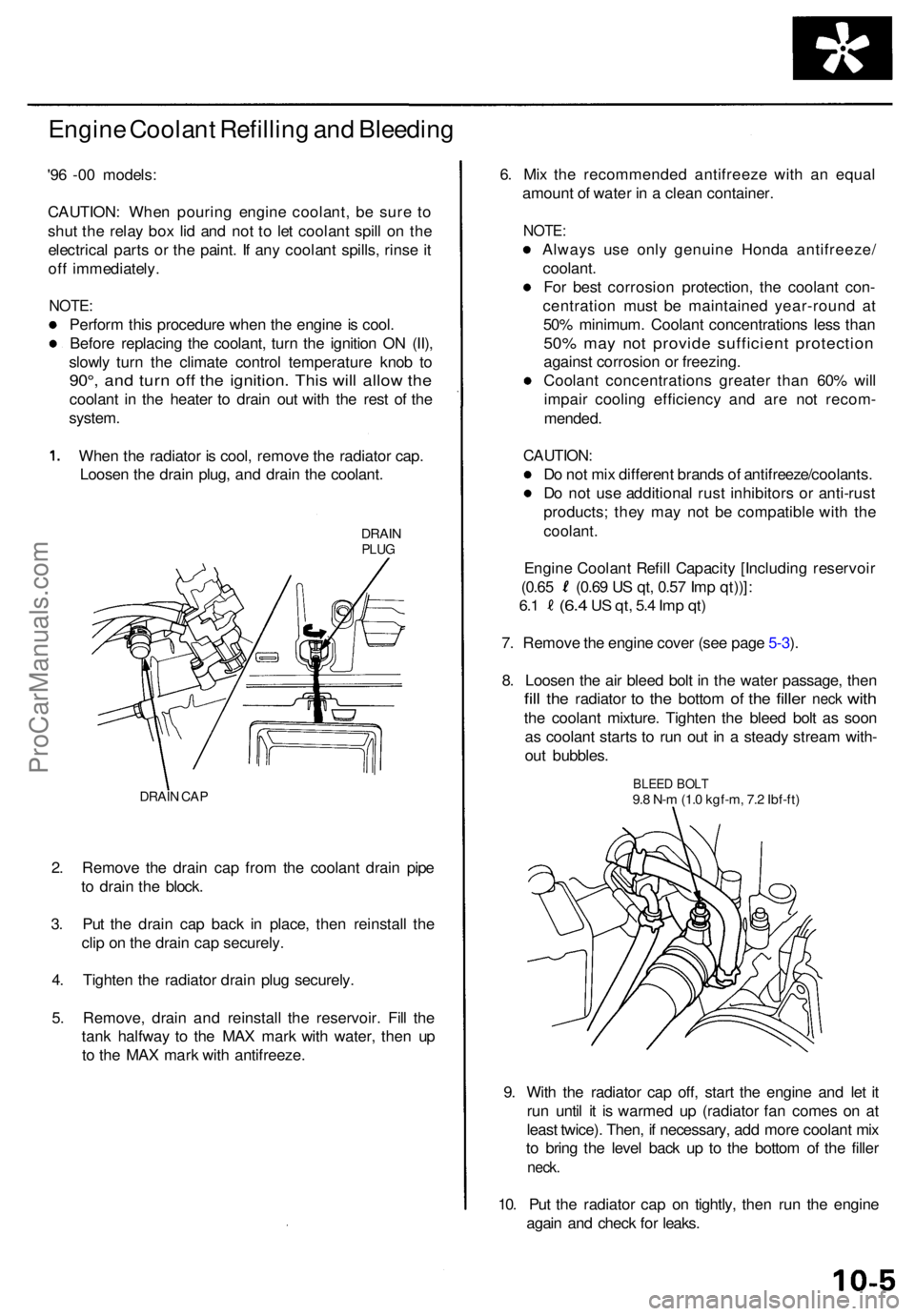

Engine Coolan t Refillin g an d Bleedin g

'96 -0 0 models :

CAUTION : Whe n pourin g engin e coolant , b e sur e t o

shu t th e rela y bo x li d an d no t t o le t coolan t spil l o n th e

electrica l part s o r th e paint . I f an y coolan t spills , rins e it

of f immediately .

NOTE:

Perfor m thi s procedur e whe n th e engin e is cool .

Befor e replacin g th e coolant , tur n th e ignitio n O N (II) ,

slowl y tur n th e climat e contro l temperatur e kno b t o

90° , an d tur n of f th e ignition . Thi s wil l allo w th e

coolan t i n th e heate r t o drai n ou t wit h th e res t o f th e

system .

Whe n th e radiato r i s cool , remov e th e radiato r cap .

Loose n th e drai n plug , an d drai n th e coolant .

DRAINPLUG

DRAI N CA P

2. Remov e th e drai n cap from th e coolan t drai n pip e

t o drai n th e block .

3 . Pu t th e drai n ca p bac k i n place , the n reinstal l th e

cli p o n th e drai n ca p securely .

4 . Tighte n th e radiato r drai n plu g securely .

5 . Remove , drai n an d reinstal l th e reservoir . Fil l th e

tan k halfwa y t o th e MA X mar k wit h water , the n u p

t o th e MA X mar k wit h antifreeze . 6

. Mi x th e recommende d antifreez e wit h a n equa l

amoun t o f wate r i n a clea n container .

NOTE:

Alway s us e onl y genuin e Hond a antifreeze /

coolant .

Fo r bes t corrosio n protection , th e coolan t con -

centratio n mus t b e maintaine d year-roun d a t

50 % minimum . Coolan t concentration s les s tha n

50% ma y no t provid e sufficien t protectio n

against corrosio n o r freezing .

Coolan t concentration s greate r tha n 60 % wil l

impai r coolin g efficienc y an d ar e no t recom -

mended .

CAUTION :

Do no t mi x differen t brand s o f antifreeze/coolants .

D o no t us e additiona l rus t inhibitor s o r anti-rus t

products ; the y ma y no t b e compatibl e wit h th e

coolant .

Engine Coolan t Refil l Capacit y [Includin g reservoi r

(0.65 (0.6 9 U S qt , 0.5 7 Im p qt))] :

6.1 (6. 4 US qt , 5. 4 Im p qt )

7. Remov e th e engin e cove r (se e pag e 5-3 ).

8 . Loose n th e ai r blee d bol t i n th e wate r passage , the n

fill th e radiato r to th e botto m of th e fille r nec k with

the coolan t mixture . Tighte n th e blee d bol t a s soo n

a s coolan t start s t o ru n ou t i n a stead y strea m with -

ou t bubbles .

9 . Wit h th e radiato r ca p off , star t th e engin e an d le t i t

ru n unti l i t i s warme d u p (radiato r fa n come s o n a t

leas t twice) . Then , i f necessary , ad d mor e coolan t mi x

t o brin g th e leve l bac k u p t o th e botto m o f th e fille r

neck .

10. Pu t th e radiato r ca p o n tightly , the n ru n th e engin e

agai n an d chec k fo r leaks .

BLEE D BOL T9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

ProCarManuals.com

Page 491 of 1954

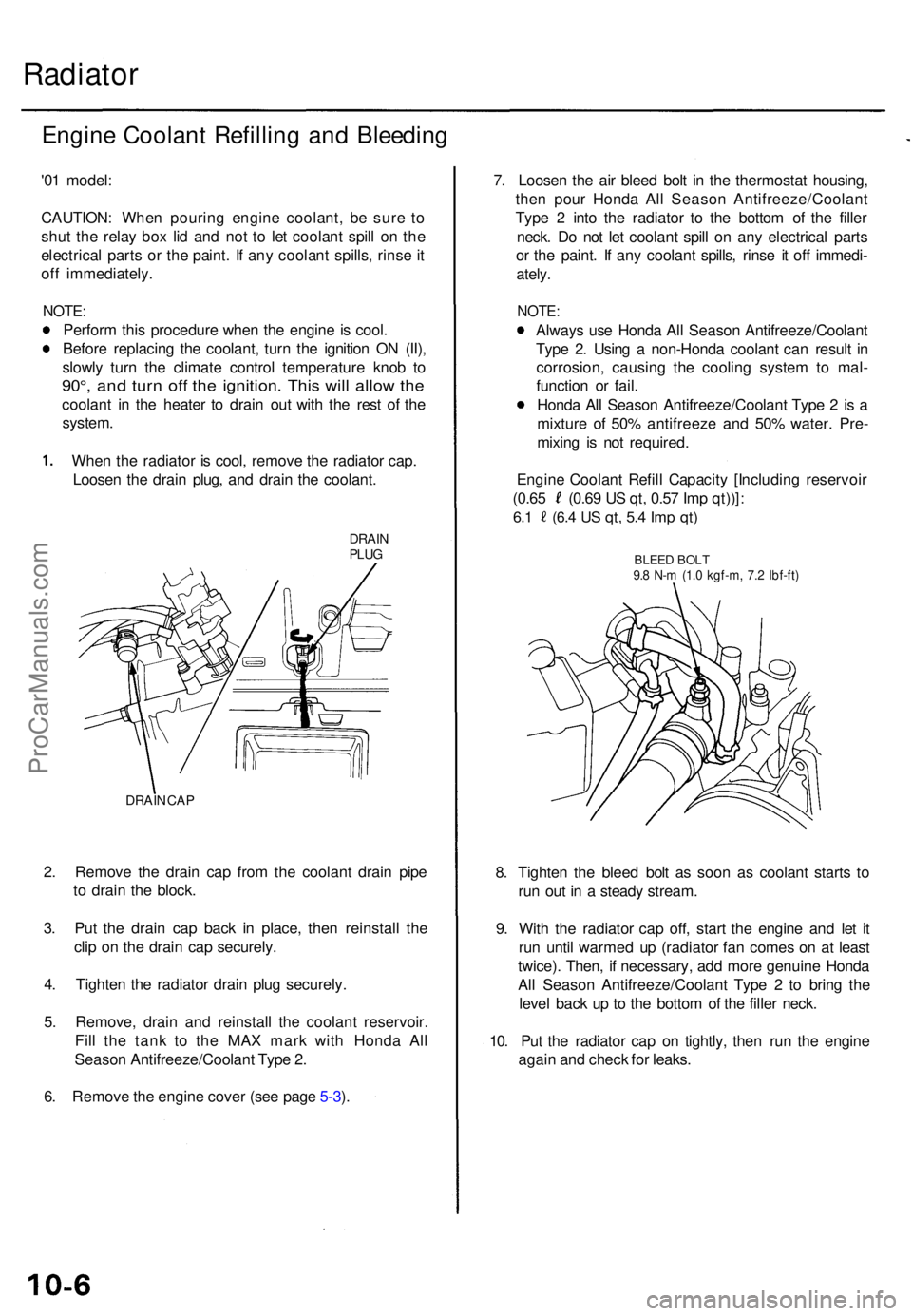

Radiator

Engine Coolan t Refillin g an d Bleedin g

'01 model :

CAUTION : Whe n pourin g engin e coolant , b e sur e t o

shu t th e rela y bo x li d an d no t t o le t coolan t spil l o n th e

electrica l part s o r th e paint . I f an y coolan t spills , rins e it

of f immediately .

NOTE:

Perfor m thi s procedur e whe n th e engin e is cool .

Befor e replacin g th e coolant , tur n th e ignitio n O N (II) ,

slowl y tur n th e climat e contro l temperatur e kno b t o

90° , an d tur n of f th e ignition . Thi s wil l allo w th e

coolan t i n th e heate r t o drai n ou t wit h th e res t o f th e

system .

Whe n th e radiato r i s cool , remov e th e radiato r cap .

Loose n th e drai n plug , an d drai n th e coolant .

DRAINPLUG

DRAI N CA P

2. Remov e th e drai n ca p fro m th e coolan t drai n pip e

t o drai n th e block .

3 . Pu t th e drai n ca p bac k i n place , the n reinstal l th e

cli p o n th e drai n ca p securely .

4 . Tighte n th e radiato r drai n plu g securely .

5 . Remove , drai n an d reinstal l th e coolan t reservoir .

Fil l th e tan k t o th e MA X mar k wit h Hond a Al l

Seaso n Antifreeze/Coolan t Typ e 2 .

6 . Remov e th e engine cover (se e pag e 5-3 ). 7

. Loose n th e ai r blee d bol t i n th e thermosta t housing ,

the n pou r Hond a Al l Seaso n Antifreeze/Coolan t

Typ e 2 int o th e radiato r t o th e botto m o f th e fille r

neck . D o no t le t coolan t spil l o n an y electrica l part s

o r th e paint . I f an y coolan t spills , rins e i t of f immedi -

ately .

NOTE :

Alway s us e Hond a Al l Seaso n Antifreeze/Coolan t

Typ e 2 . Usin g a non-Hond a coolan t ca n resul t i n

corrosion , causin g th e coolin g syste m to mal -

functio n o r fail .

Hond a Al l Seaso n Antifreeze/Coolan t Typ e 2 is a

mixtur e o f 50 % antifreez e an d 50 % water . Pre -

mixin g i s no t required .

8 . Tighte n th e blee d bol t a s soo n a s coolan t start s t o

ru n ou t i n a stead y stream .

9 . Wit h th e radiato r cap off, star t th e engin e an d le t i t

ru n unti l warme d u p (radiato r fa n come s o n a t leas t

twice) . Then , i f necessary , ad d mor e genuin e Hond a

Al l Seaso n Antifreeze/Coolan t Typ e 2 to brin g th e

leve l bac k u p t o th e botto m o f th e fille r neck .

10 . Pu t th e radiato r ca p o n tightly , the n ru n th e engin e

agai n an d chec k fo r leaks .

Engin

e Coolan t Refil l Capacit y [Includin g reservoi r

(0.65 (0.6 9 U S qt , 0.5 7 Im p qt))] :

6.1 (6. 4 US qt , 5. 4 Im p qt )

BLEE D BOL T9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

ProCarManuals.com

Page 492 of 1954

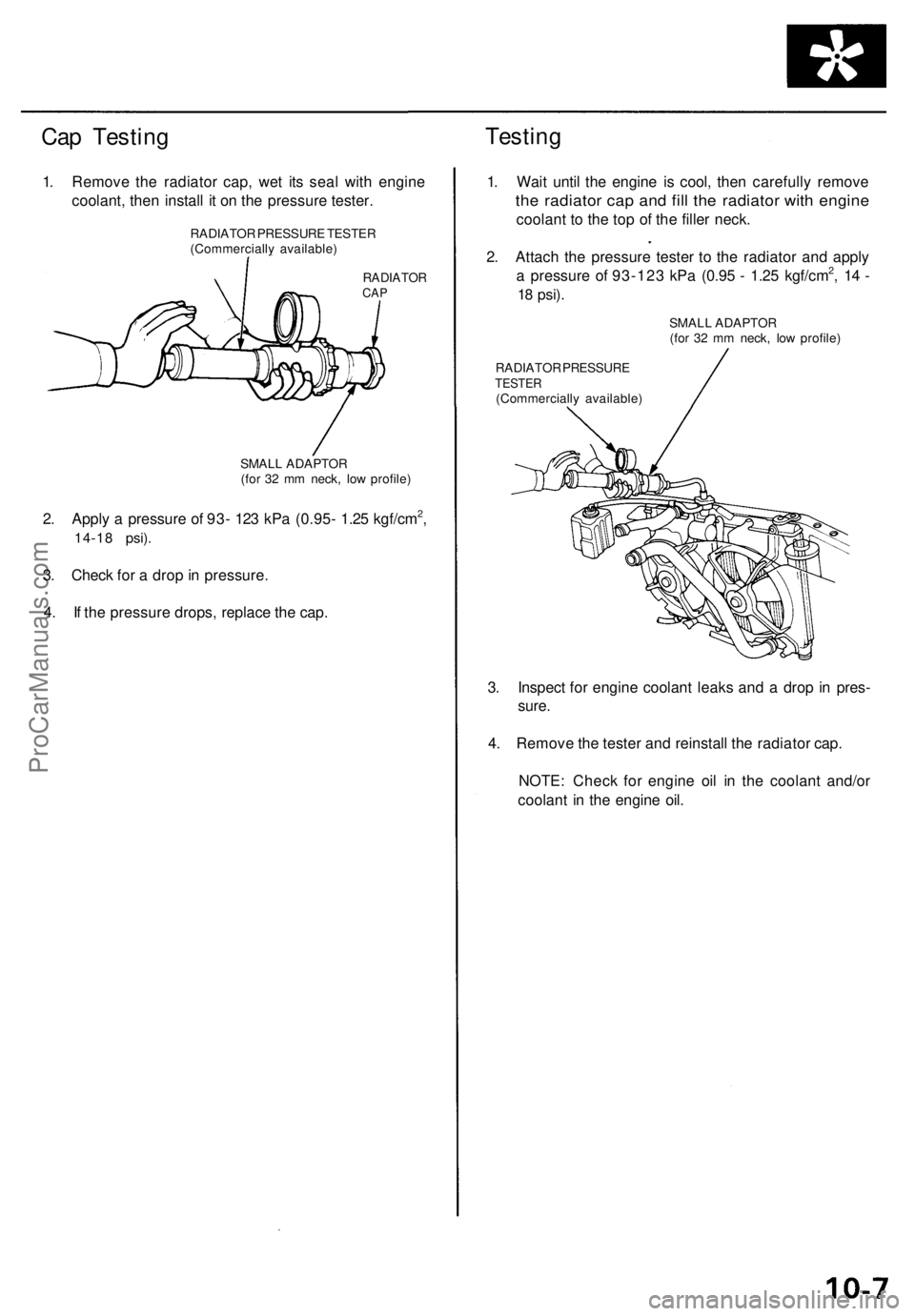

Cap Testing

Testing

1. Remove the radiator cap, wet its seal with engine

coolant, then install it on the pressure tester.

RADIATOR

CAP

2. Apply a pressure of 93- 123 kPa (0.95- 1.25 kgf/cm2,

14-18 psi).

3. Check for a drop in pressure.

4. If the pressure drops, replace the cap.

1. Wait until the engine is cool, then carefully remove

the radiator cap and fill the radiator with engine

coolant to the top of the filler neck.

2. Attach the pressure tester to the radiator and apply

a pressure of 93-123 kPa (0.95 - 1.25 kgf/cm2, 14 -

18

psi).

RADIATOR PRESSURE

TESTER

(Commercially available)

3. Inspect for engine coolant leaks and a drop in pres-

sure.

4. Remove the tester and reinstall the radiator cap.

NOTE: Check for engine oil in the coolant and/or

coolant in the engine oil.

RADIATOR PRESSURE TESTER

(Commercially available)

SMALL ADAPTOR

(for 32 mm neck, low profile)

SMALL ADAPTOR

(for 32 mm neck, low profile)ProCarManuals.com

Page 493 of 1954

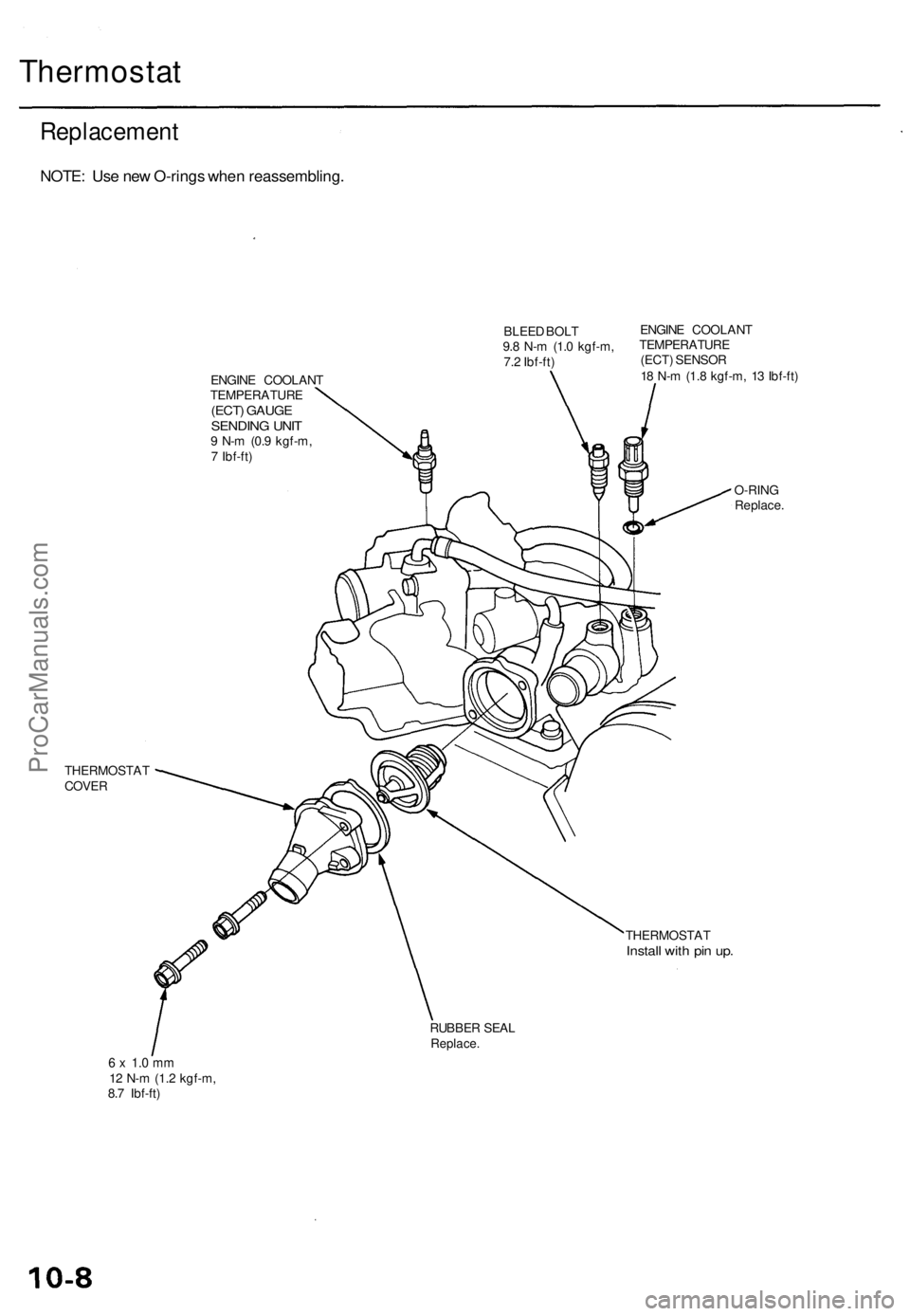

Thermostat

Replacement

NOTE: Use new O-rings when reassembling.

BLEED BOLT

9.8 N-m (1.0 kgf-m,

7.2 Ibf-ft)

ENGINE COOLANT

TEMPERATURE

(ECT) GAUGE

SENDING UNIT

9 N-m (0.9 kgf-m,

7 Ibf-ft)

ENGINE COOLANT

TEMPERATURE

(ECT) SENSOR

18 N-m (1.8 kgf-m, 13 Ibf-ft)

THERMOSTAT

COVER

O-RING

Replace.

THERMOSTAT

Install with pin up.

RUBBER SEAL

Replace.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)ProCarManuals.com