engine ACURA RL KA9 1996 Service Manual PDF

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 375 of 1954

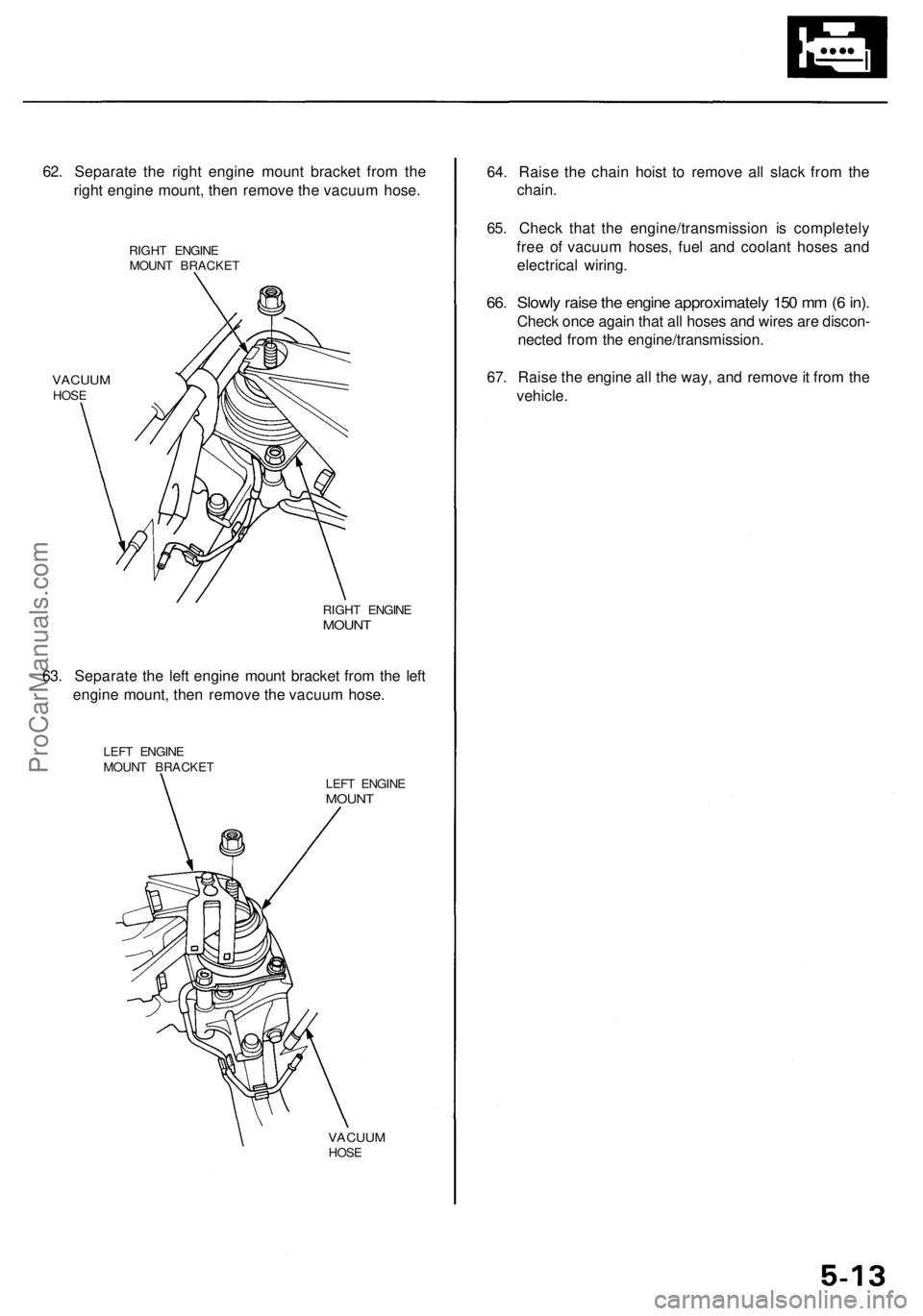

62. Separate the right engine mount bracket from the

right engine mount, then remove the vacuum hose.

RIGHT ENGINE

MOUNT BRACKET

VACUUM

HOSE

RIGHT ENGINE

MOUNT

63. Separate the left engine mount bracket from the left

engine mount, then remove the vacuum hose.

LEFT ENGINE

MOUNT BRACKET

LEFT ENGINE

MOUNT

VACUUM

HOSE

64. Raise the chain hoist to remove all slack from the

chain.

65. Check that the engine/transmission is completely

free of vacuum hoses, fuel and coolant hoses and

electrical wiring.

66. Slowly raise the engine approximately 150 mm (6 in).

Check once again that all hoses and wires are discon-

nected from the engine/transmission.

67. Raise the engine all the way, and remove it from the

vehicle.ProCarManuals.com

Page 376 of 1954

Engine Removal/Installatio n

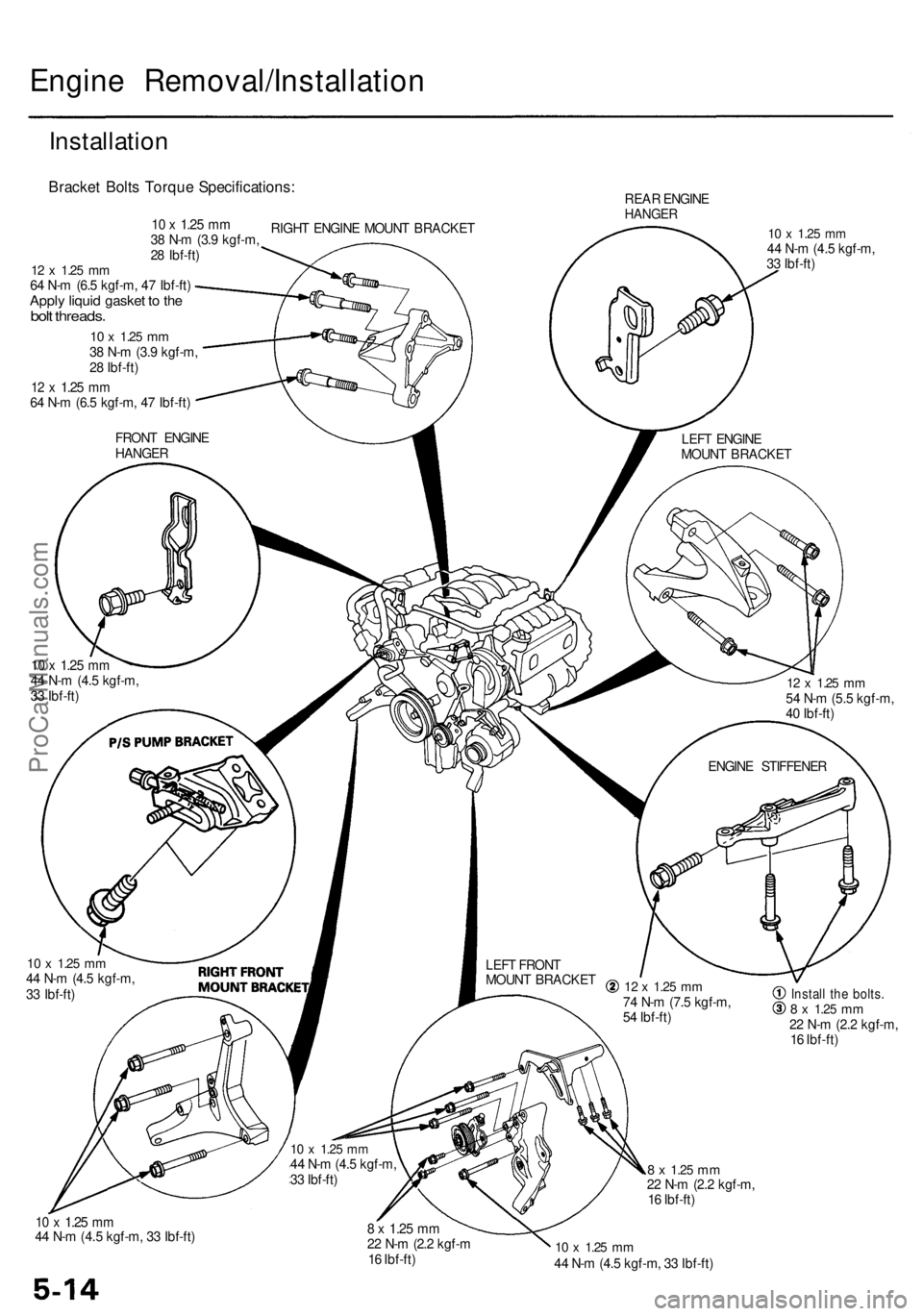

Installation

Bracket Bolt s Torqu e Specifications :

RIGHT ENGIN E MOUN T BRACKE T REA

R ENGIN EHANGE R

10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )Instal l th e bolts .8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

10 x 1.2 5 mm44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )8 x 1.2 5 mm22 N- m (2. 2 kgf- m

1 6 Ibf-ft )10 x 1.2 5 mm44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

12 x 1.2 5 mm74 N- m (7. 5 kgf-m ,

5 4 Ibf-ft )

LEF

T FRON T

MOUN T BRACKE T ENGIN

E STIFFENE R

12 x 1.2 5 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

LEF

T ENGIN E

MOUN T BRACKE T

FRON

T ENGIN E

HANGE R

12 x 1.2 5 mm64 N- m (6. 5 kgf-m , 4 7 Ibf-ft )

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

12 x 1.2 5 mm64 N- m (6. 5 kgf-m , 4 7 Ibf-ft )Apply liqui d gaske t t o th ebol t threads .

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

10 x 1.2 5 m m44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

ProCarManuals.com

Page 377 of 1954

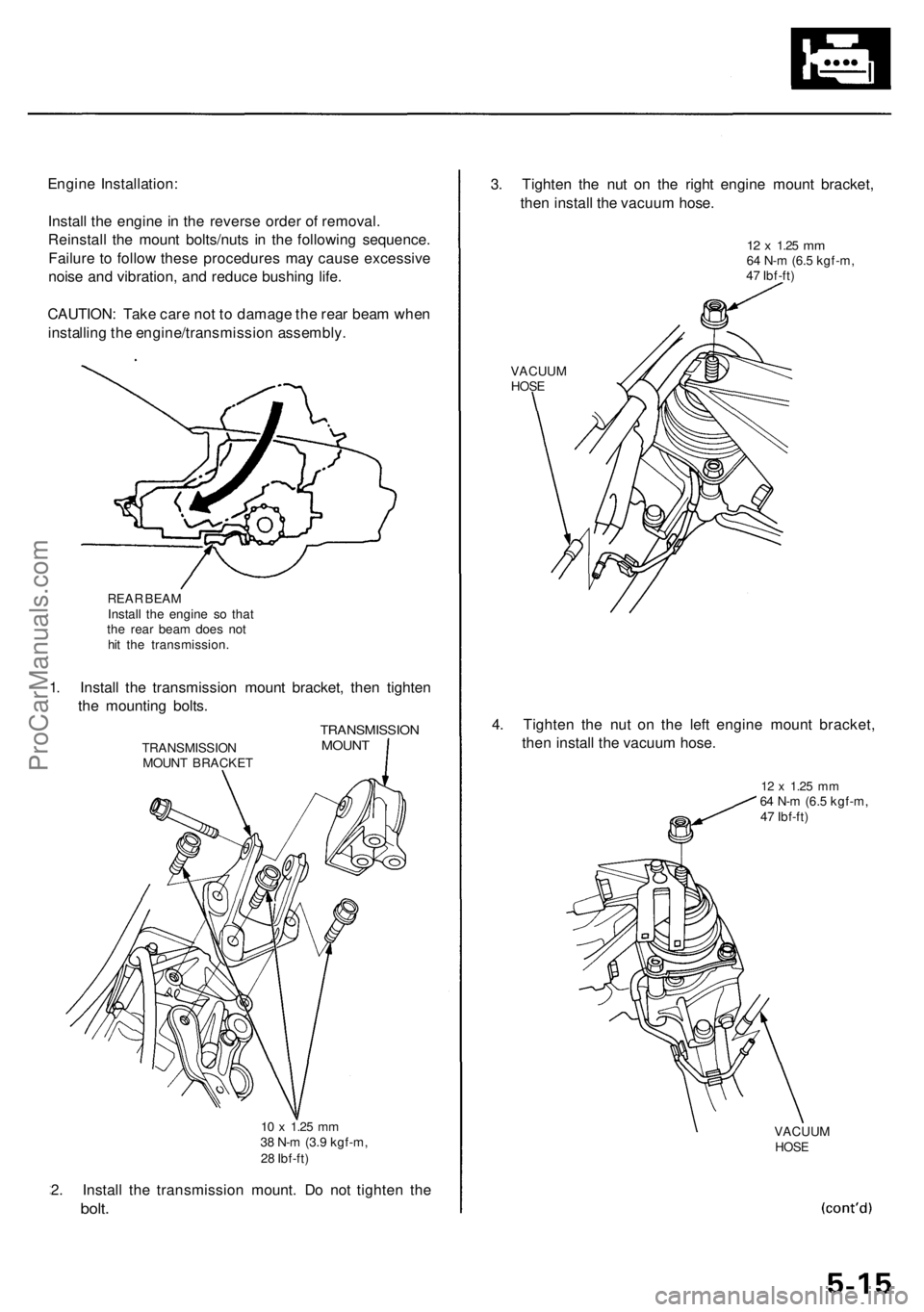

Engine Installation :

Instal l th e engin e in th e revers e orde r o f removal .

Reinstal l th e moun t bolts/nut s i n th e followin g sequence .

Failur e t o follo w thes e procedure s ma y caus e excessiv e

nois e an d vibration , an d reduc e bushin g life .

CAUTION : Tak e car e no t t o damag e th e rea r bea m whe n

installin g th e engine/transmissio n assembly .

REAR BEA M

Instal l th e engin e s o tha t

th e rea r bea m doe s no t

hi t th e transmission .

1. Instal l th e transmissio n moun t bracket , the n tighte n

th e mountin g bolts .

TRANSMISSIO N

MOUN T BRACKE T

TRANSMISSIO NMOUNT

2. Instal l th e transmissio n mount . D o no t tighte n th e

bolt .

3. Tighte n th e nu t o n th e righ t engin e moun t bracket ,

the n instal l th e vacuu m hose .

12 x 1.2 5 mm64 N- m (6. 5 kgf-m ,

4 7 Ibf-ft )

VACUU M

HOSE

4. Tighte n th e nu t o n th e lef t engin e moun t bracket ,

the n instal l th e vacuu m hose .

12 x 1.2 5 mm64 N- m (6. 5 kgf-m ,

4 7 Ibf-ft )

VACUU M

HOSE

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

ProCarManuals.com

Page 378 of 1954

Engine Removal/Installatio n

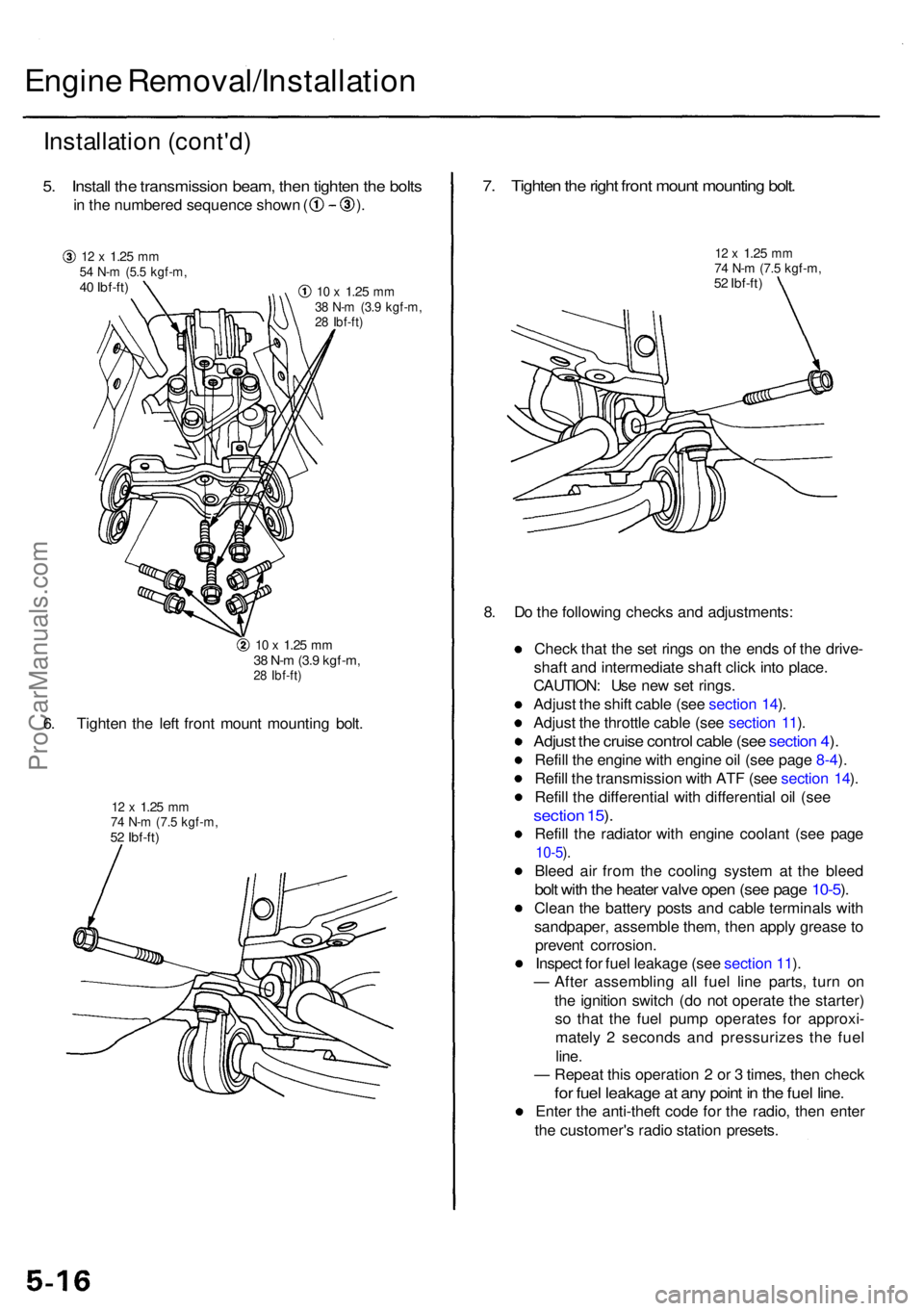

Installation (cont'd )

5. Instal l th e transmissio n beam , the n tighte n th e bolt s

in th e numbere d sequenc e show n ( ) .

12 x 1.2 5 mm54 N- m (5. 5 kgf-m ,40 Ibf-ft )10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,28 Ibf-ft )

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,28 Ibf-ft )

6. Tighte n th e lef t fron t moun t mountin g bolt .

12 x 1.2 5 mm74 N- m (7. 5 kgf-m ,52 Ibf-ft )

7. Tighte n th e righ t fron t moun t mountin g bolt .

12 x 1.2 5 mm74 N- m (7. 5 kgf-m ,52 Ibf-ft )

8. D o th e followin g check s an d adjustments :

Chec k tha t th e se t ring s o n th e end s o f th e drive -

shaf t an d intermediat e shaf t clic k int o place .

CAUTION : Us e ne w se t rings .

Adjus t th e shif t cabl e (se e sectio n 14 ).

Adjus t th e throttl e cabl e (se e sectio n 11 ).

Adjus t th e cruis e contro l cabl e (se e sectio n 4 ).

Refil l th e engin e wit h engin e oi l (se e pag e 8-4 ).

Refil l th e transmissio n wit h AT F (se e sectio n 14 ).

Refil l th e differentia l wit h differentia l oi l (se e

sectio n 15 ).

Refil l th e radiato r wit h engin e coolan t (se e pag e

10-5).

Blee d ai r fro m th e coolin g syste m a t th e blee d

bolt wit h th e heate r valv e ope n (se e pag e 10-5 ).

Clea n th e batter y post s an d cabl e terminal s wit h

sandpaper , assembl e them , the n appl y greas e to

preven t corrosion .

Inspec t fo r fue l leakag e (se e sectio n 11 ).

— Afte r assemblin g al l fue l lin e parts , tur n o n

th e ignitio n switc h (d o no t operat e th e starter )

s o tha t th e fue l pum p operate s fo r approxi -

matel y 2 second s an d pressurize s th e fue l

line .

— Repea t thi s operatio n 2 or 3 times , the n chec k

for fue l leakag e a t an y poin t i n th e fue l line .

Ente r th e anti-thef t cod e fo r th e radio , the n ente r

th e customer' s radi o statio n presets .

ProCarManuals.com

Page 379 of 1954

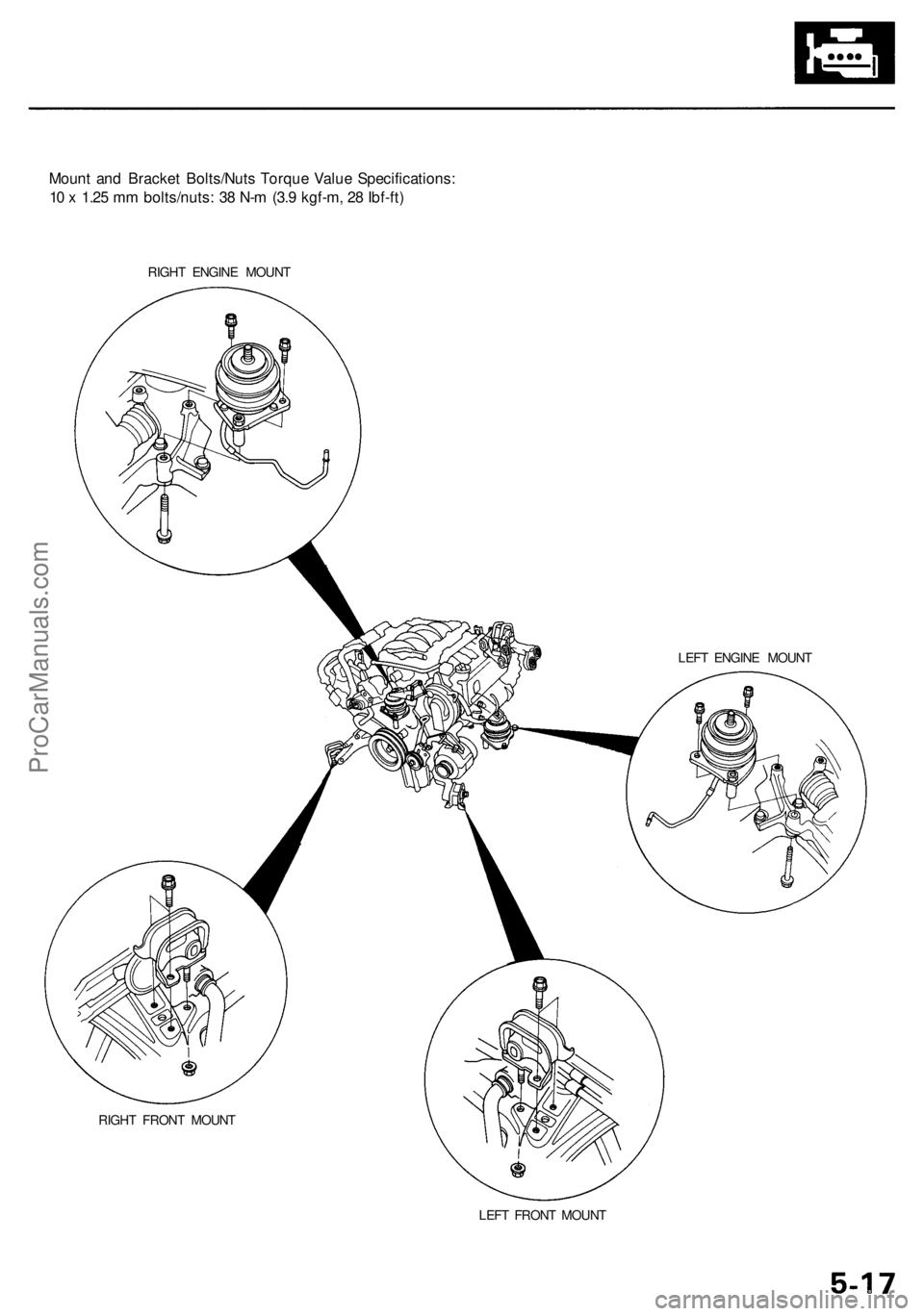

Mount and Bracket Bolts/Nuts Torque Value Specifications:

10 x 1.25 mm bolts/nuts: 38 N-m (3.9 kgf-m, 28 Ibf-ft)

RIGHT ENGINE MOUNT

LEFT ENGINE MOUNT

RIGHT FRONT MOUNT

LEFT FRONT MOUNTProCarManuals.com

Page 380 of 1954

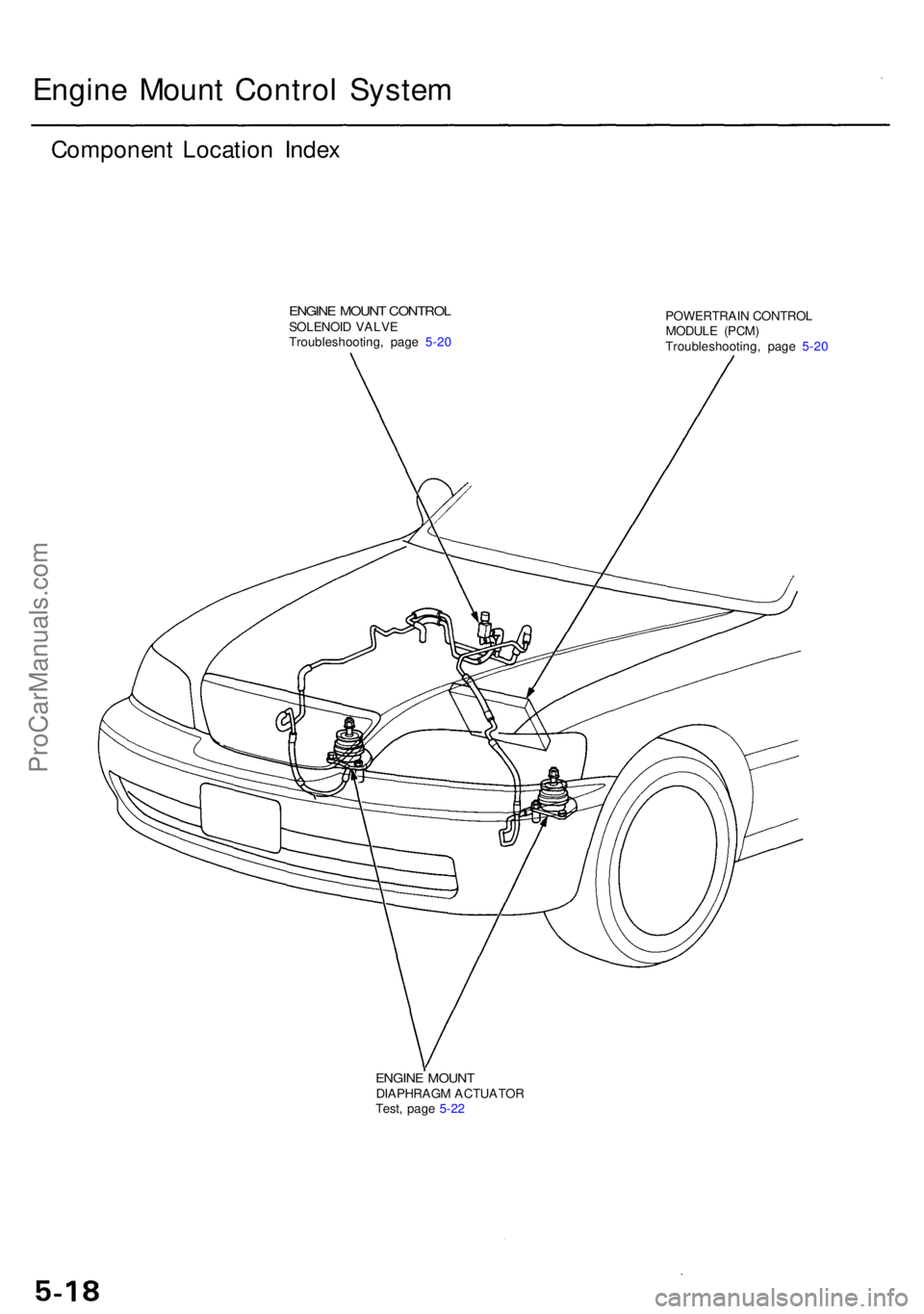

Engine Moun t Contro l Syste m

Componen t Locatio n Inde x

ENGIN E MOUN T CONTRO LSOLENOI D VALV E

Troubleshooting , pag e 5-2 0 POWERTRAI

N CONTRO L

MODUL E (PCM )

Troubleshooting , pag e 5-2 0

ENGIN E MOUN TDIAPHRAG M ACTUATO R

Test , pag e 5-2 2

ProCarManuals.com

Page 381 of 1954

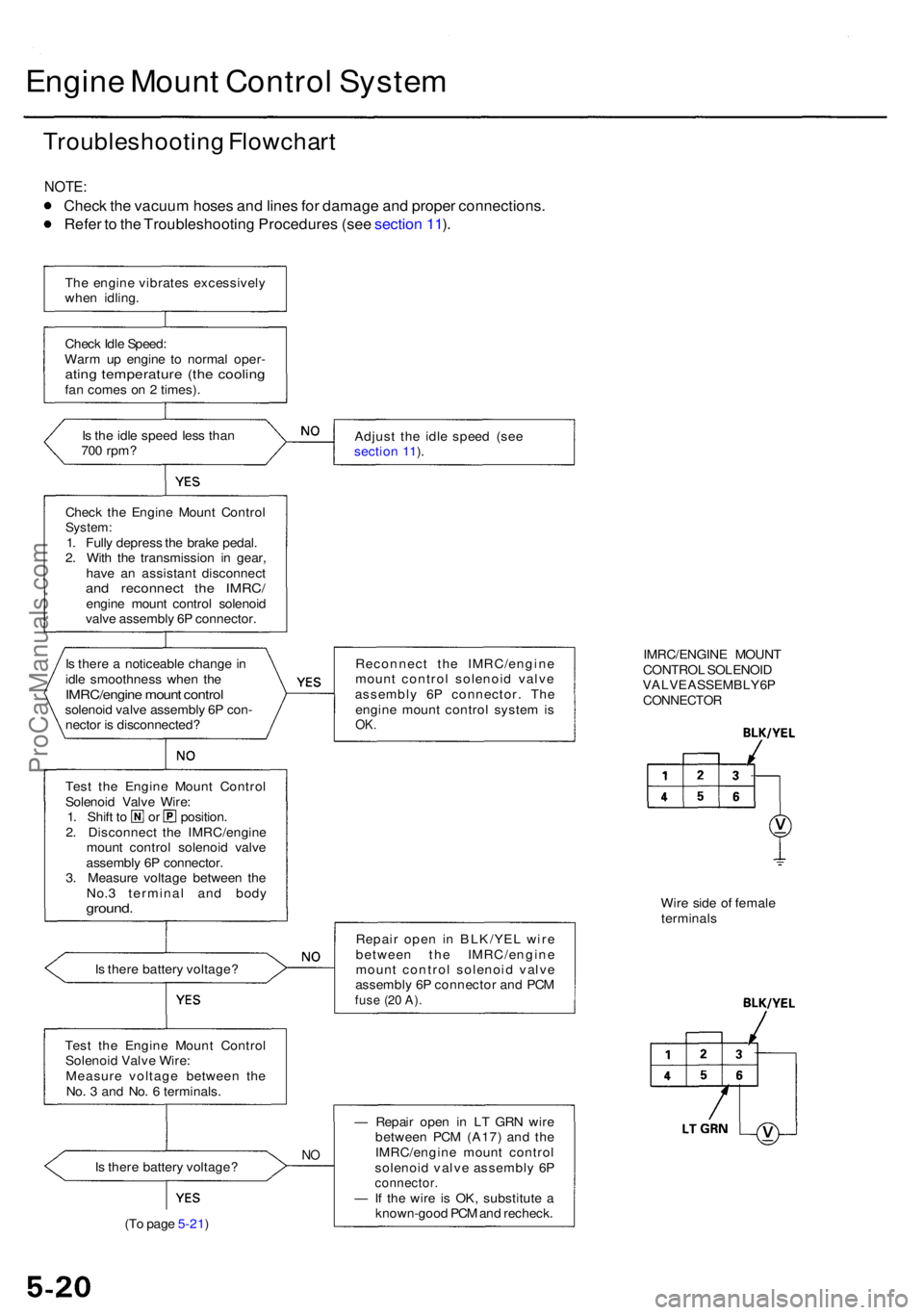

Engine Moun t Contro l Syste m

Troubleshootin g Flowchar t

NOTE:

Check th e vacuu m hose s an d line s fo r damag e an d prope r connections .

Refe r t o th e Troubleshootin g Procedure s (se e sectio n 11 ).

Th e engin e vibrate s excessivel y

whe n idling .

Chec k Idl e Speed :

War m u p engin e t o norma l oper -

ating temperatur e (th e coolin gfan come s o n 2 times) .

I s th e idl e spee d les s tha n

70 0 rpm ? Adjus

t th e idl e spee d (se e

sectio n 11 ).

Chec k th e Engin e Moun t Contro l

System:1. Full y depres s th e brak e pedal .

2 . Wit h th e transmissio n i n gear ,

hav e a n assistan t disconnec t

and reconnec t th e IMRC /engine moun t contro l solenoi d

valv e assembl y 6 P connector .

I s ther e a noticeabl e chang e in

idl e smoothnes s whe n th e

IMRC/engin e moun t contro lsolenoi d valv e assembl y 6 P con -

necto r i s disconnected ? Reconnec

t th e IMRC/engin e

moun t contro l solenoi d valv e

assembl y 6 P connector . Th e

engin e moun t contro l syste m isOK .

IMRC/ENGIN E MOUN T

CONTRO L SOLENOI D

VALV E ASSEMBL Y 6P

CONNECTO R

Test th e Engin e Moun t Contro l

Solenoi d Valv e Wire :

1. Shif t t o o r position .

2 . Disconnec t th e IMRC/engin e

moun t contro l solenoi d valv e

assembl y 6 P connector .

3 . Measur e voltag e betwee n th e

No. 3 termina l an d bod y

ground .

Is ther e batter y voltage ? Repai

r ope n i n BLK/YE L wir e

betwee n th e IMRC/engin e

moun t contro l solenoi d valv e

assembl y 6 P connecto r an d PC M

fuse (2 0 A) .

Wir e sid e o f femal e

terminal s

Tes t th e Engin e Moun t Contro l

Solenoi d Valv e Wire :

Measur e voltag e betwee n th e

No . 3 an d No . 6 terminals .

I s ther e batter y voltage ?

NO

(T o pag e 5-21 ) —

Repai r ope n i n L T GR N wir e

betwee n PC M (A17 ) an d th e

IMRC/engin e moun t contro l

solenoi d valv e assembl y 6 P

connector .— If th e wir e i s OK , substitut e a

known-goo d PC M an d recheck .

ProCarManuals.com

Page 383 of 1954

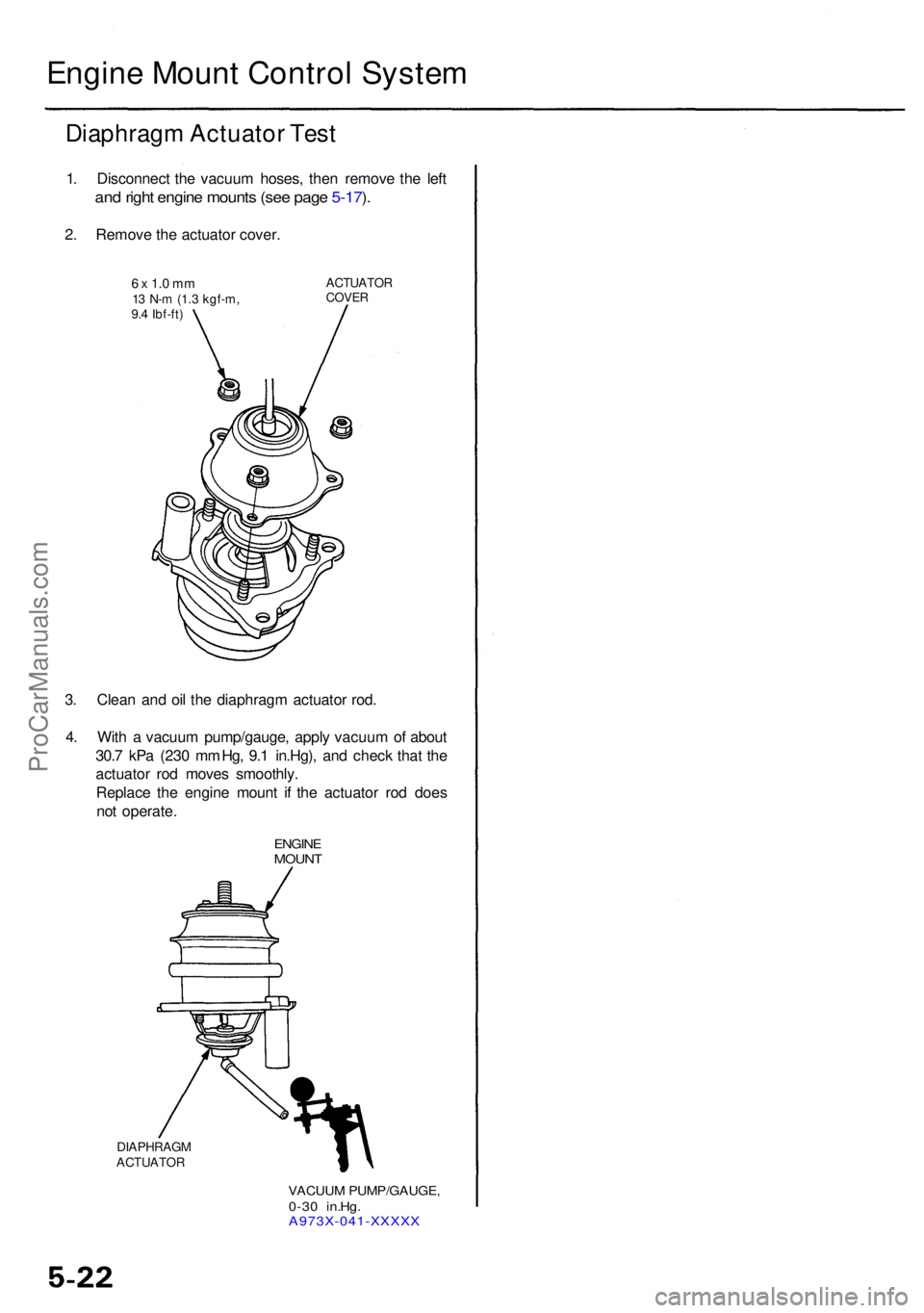

Engine Moun t Contro l Syste m

Diaphrag m Actuato r Tes t

1. Disconnec t th e vacuu m hoses , the n remov e th e lef t

and righ t engin e mount s (se e pag e 5-17 ).

2 . Remov e th e actuato r cover .

6 x 1. 0 m m13 N- m (1. 3 kgf-m ,

9. 4 Ibf-ft ) ACTUATO

RCOVER

3. Clea n an d oi l th e diaphrag m actuato r rod .

4 . Wit h a vacuu m pump/gauge , appl y vacuu m o f abou t

30. 7 kP a (23 0 m m Hg , 9. 1 in.Hg) , an d chec k tha t th e

actuato r ro d move s smoothly .

Replac e th e engin e moun t i f th e actuato r ro d doe s

no t operate .

DIAPHRAG M

ACTUATO R

VACUUM PUMP/GAUGE ,0-30 in.Hg .A973X-041-XXXX X

ENGINEMOUN T

ProCarManuals.com

Page 399 of 1954

Cylinder Heads

Illustrated Index (cont'd)

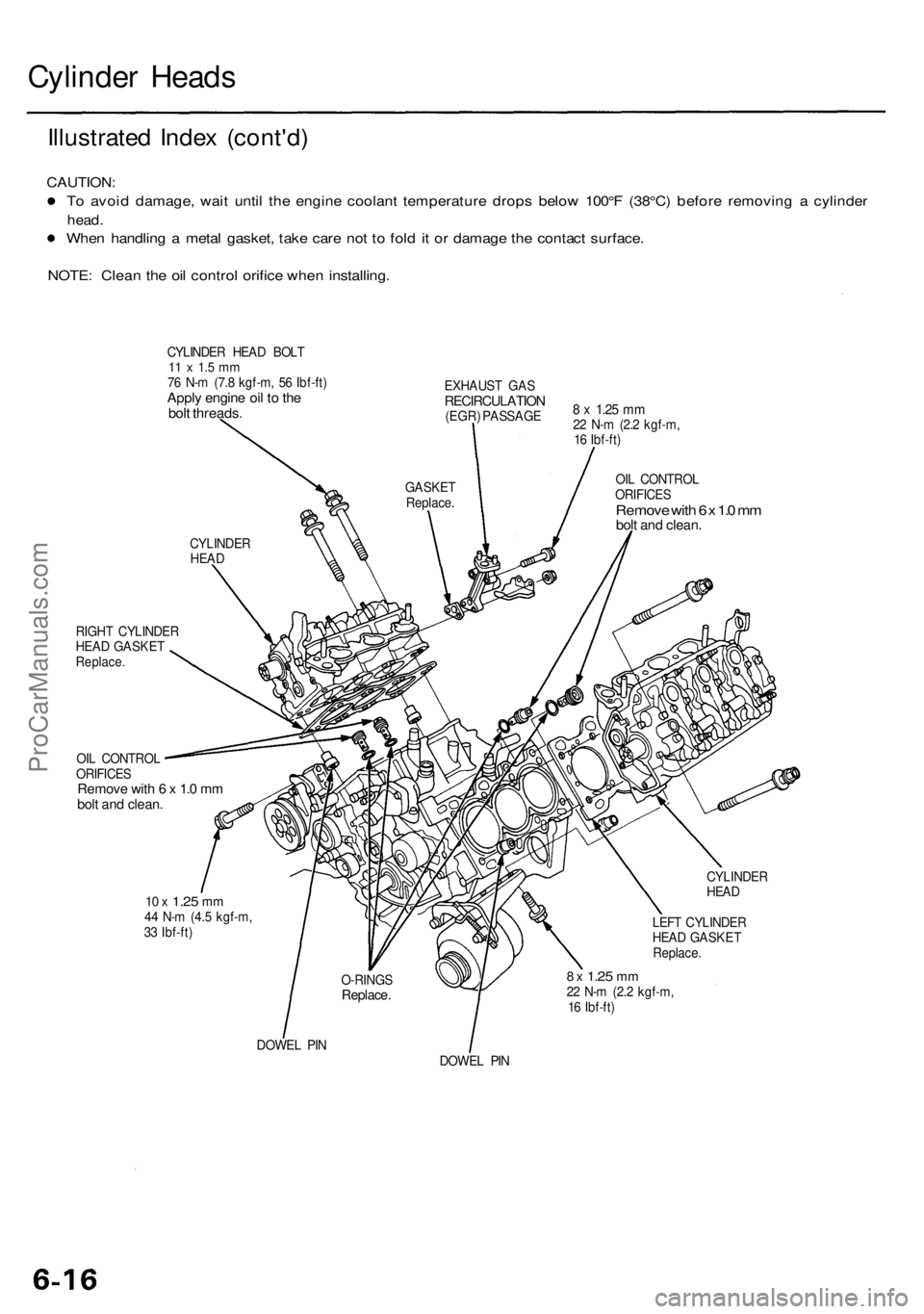

CAUTION:

To avoid damage, wait until the engine coolant temperature drops below 100°F (38°C) before removing a cylinder

head.

When handling a metal gasket, take care not to fold it or damage the contact surface.

NOTE: Clean the oil control orifice when installing.

CYLINDER HEAD BOLT

11 x 1.5 mm

76 N-m (7.8 kgf-m, 56 Ibf-ft)

Apply engine oil to the

bolt threads.

EXHAUST GAS

RECIRCULATION

(EGR) PASSAGE

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

OIL CONTROL

ORIFICES

Remove with 6 x 1.0 mm

bolt and clean.

RIGHT CYLINDER

HEAD GASKET

Replace.

OIL CONTROL

ORIFICES

Remove with 6 x 1.0 mm

bolt and clean.

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

LEFT CYLINDER

HEAD GASKET

Replace.

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

DOWEL PIN

DOWEL PIN

GASKET

Replace.

CYLINDER

HEAD

O-RINGS

Replace.

CYLINDER

HEADProCarManuals.com

Page 401 of 1954

Cylinder Head s

Remova l

Make sur e jack s an d safet y stand s ar e

place d properl y an d hois t bracket s ar e attache d t o th e

correc t position s o n th e engine .

CAUTION :

Us e fende r cover s t o avoi d damagin g painte d sur -

faces .

Unplu g th e wirin g connector s carefull y whil e holdin g

th e connecto r portio n to avoi d damage .

T o avoi d damagin g th e cylinde r head , wai t unti l th e

engin e coolan t temperatur e drop s belo w 100° F (38°C )

befor e loosenin g th e retainin g bolts .

NOTE :

Unspecifie d item s ar e common .

Mar k al l wirin g an d hose s t o avoi d misconnection .

Also , b e sur e tha t the y d o no t contac t othe r wirin g o r

hose s o r interfer e wit h othe r parts .

Inspec t th e timin g bel t befor e removin g th e cylinde r

head.

Turn th e crankshaf t pulle y s o tha t th e No . 1 pisto n i s

a t to p dea d cente r (TDC) .

D o th e PC M Memor y Settin g afte r reconnectin g th e

batter y (se e sectio n 11 ).

1 . Remov e th e suppor t strut s fro m th e hood . Fi x th e

hoo d i n a vertica l position , the n reinstal l th e sup -

por t strut s b y usin g 6 x 1. 0 m m bolt s (se e pag e 5-3 ).

2 . Mak e sur e yo u hav e th e anti-thef t cod e fo r th e radio ,

the n writ e dow n th e frequencie s fo r th e radio' s pre -

set buttons .

3. Disconnec t th e batter y negativ e termina l first , the n

th e positiv e terminal .

4 . Drai n th e engin e coolan t (se e pag e 10-5 ).

5 . Remov e th e stru t brac e (se e pag e 5-3 ).

6 . Remov e th e engine cover (se e pag e 5-3 ).

7 . Remov e th e intak e ai r duc t an d ai r cleane r housin g

assembl y (se e pag e 5-4 ). 8

. Remov e th e throttl e cove r (se e pag e 5-4 ).

9 . Remov e th e throttl e cabl e an d cruis e contro l cabl e

b y loosenin g th e locknuts , the n sli p th e cabl e end s

ou t o f th e accelerato r linkag e (se e pag e 5-4 ).

NOTE :

Take car e no t t o ben d th e cabl e whe n removin g

it . Alway s replac e an y kinke d cabl e wit h a ne w

one .

Adjus t th e throttl e cabl e whe n installin g (se e

sectio n 11 ).

Adjus t th e cruis e contro l cabl e whe n installin g

(se e sectio n 23 ).

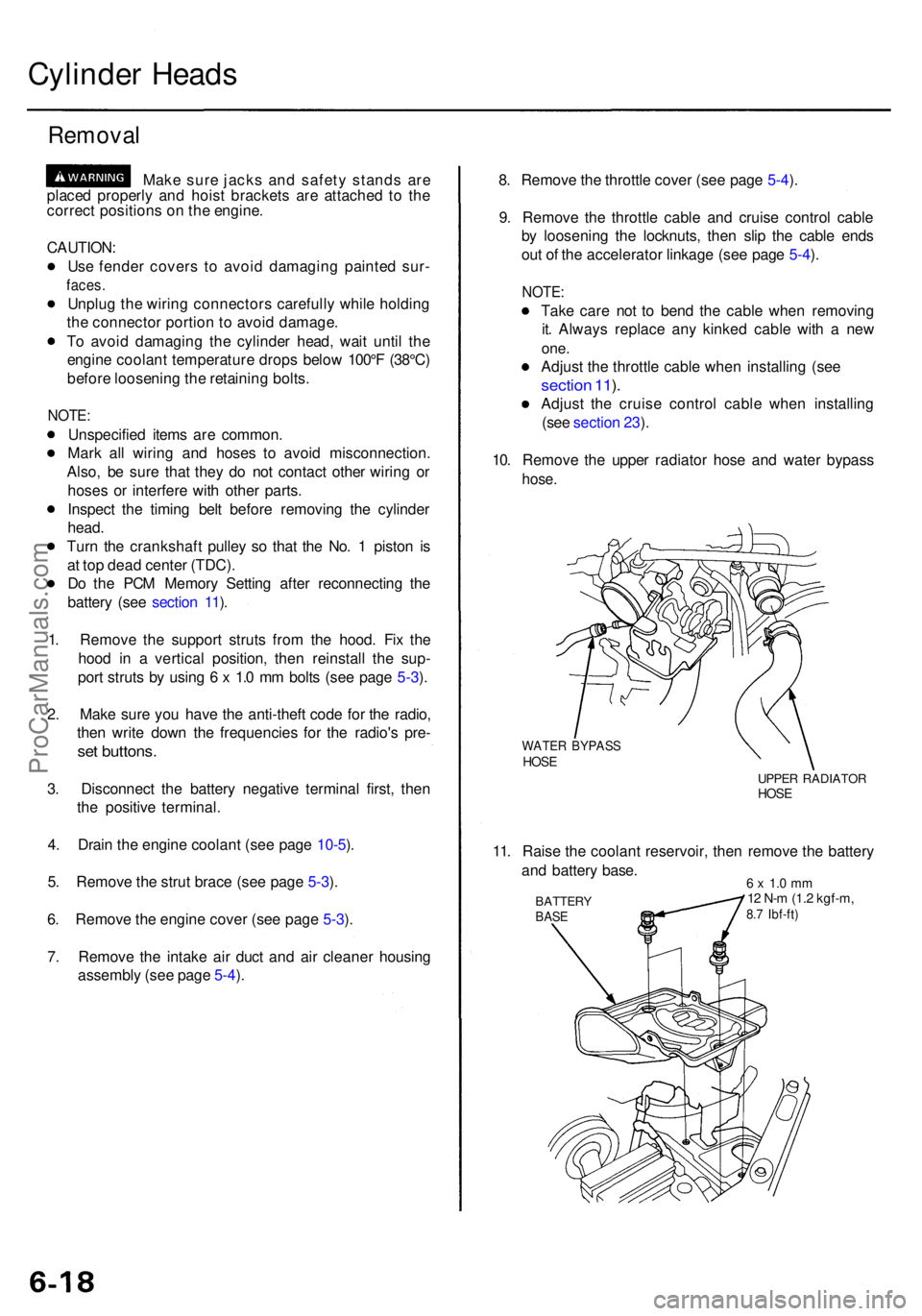

10 . Remov e th e uppe r radiato r hos e an d wate r bypas s

hose.

WATE R BYPAS SHOSEUPPE R RADIATO RHOSE

11. Rais e th e coolan t reservoir , the n remov e th e batter y

an d batter y base .

BATTER YBASE

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )

ProCarManuals.com