engine ACURA RL KA9 1996 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 910 of 1954

Shift Leve r

Link Adjustmen t (cont'd)

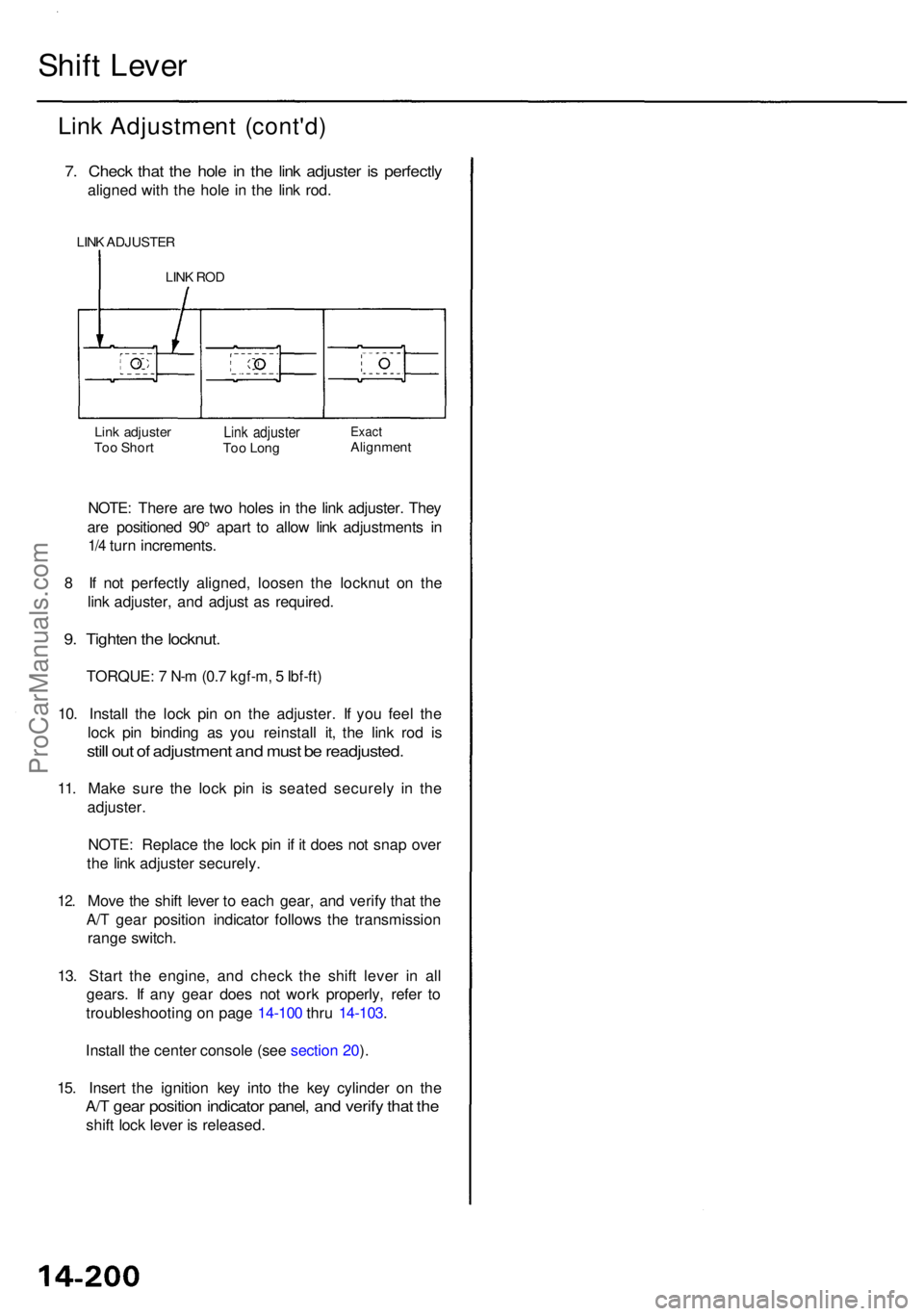

7. Chec k tha t th e hol e i n th e lin k adjuste r i s perfectl y

aligned wit h th e hol e i n th e lin k rod .

LINK ADJUSTE R

Lin k adjuste r

Too Shor tLink adjuste rToo Lon gExac tAlignmen t

NOTE: Ther e ar e tw o hole s i n th e lin k adjuster . The y

ar e positione d 90 ° apar t t o allo w lin k adjustment s i n

1/ 4 tur n increments .

8 I f no t perfectl y aligned , loose n th e locknu t o n th e

lin k adjuster , an d adjus t a s required .

9. Tighte n th e locknut .

TORQUE : 7 N- m (0. 7 kgf-m , 5 Ibf-ft)

10. Instal l th e loc k pi n o n th e adjuster . I f yo u fee l th e

loc k pi n bindin g a s yo u reinstal l it , th e lin k ro d i s

stil l ou t o f adjustmen t an d mus t b e readjusted .

11. Mak e sur e th e loc k pi n i s seate d securel y i n th e

adjuster .

NOTE : Replac e th e loc k pi n i f i t doe s no t sna p ove r

th e lin k adjuste r securely .

12. Mov e th e shif t leve r t o eac h gear , an d verif y tha t th e

A/T gea r positio n indicato r follow s th e transmissio n

rang e switch .

13 . Star t th e engine , an d chec k th e shif t leve r i n al l

gears . I f an y gea r doe s no t wor k properly , refe r t o

troubleshootin g o n pag e 14-10 0 thru 14-103 .

14. Instal l th e cente r consol e (se e sectio n 20 ).

15 . Inser t th e ignitio n ke y int o th e ke y cylinde r o n th e

A/T gea r positio n indicato r panel , an d verif y tha t th e

shif t loc k leve r i s released .

LINK RO D

ProCarManuals.com

Page 915 of 1954

Maintenance

Differential Oil

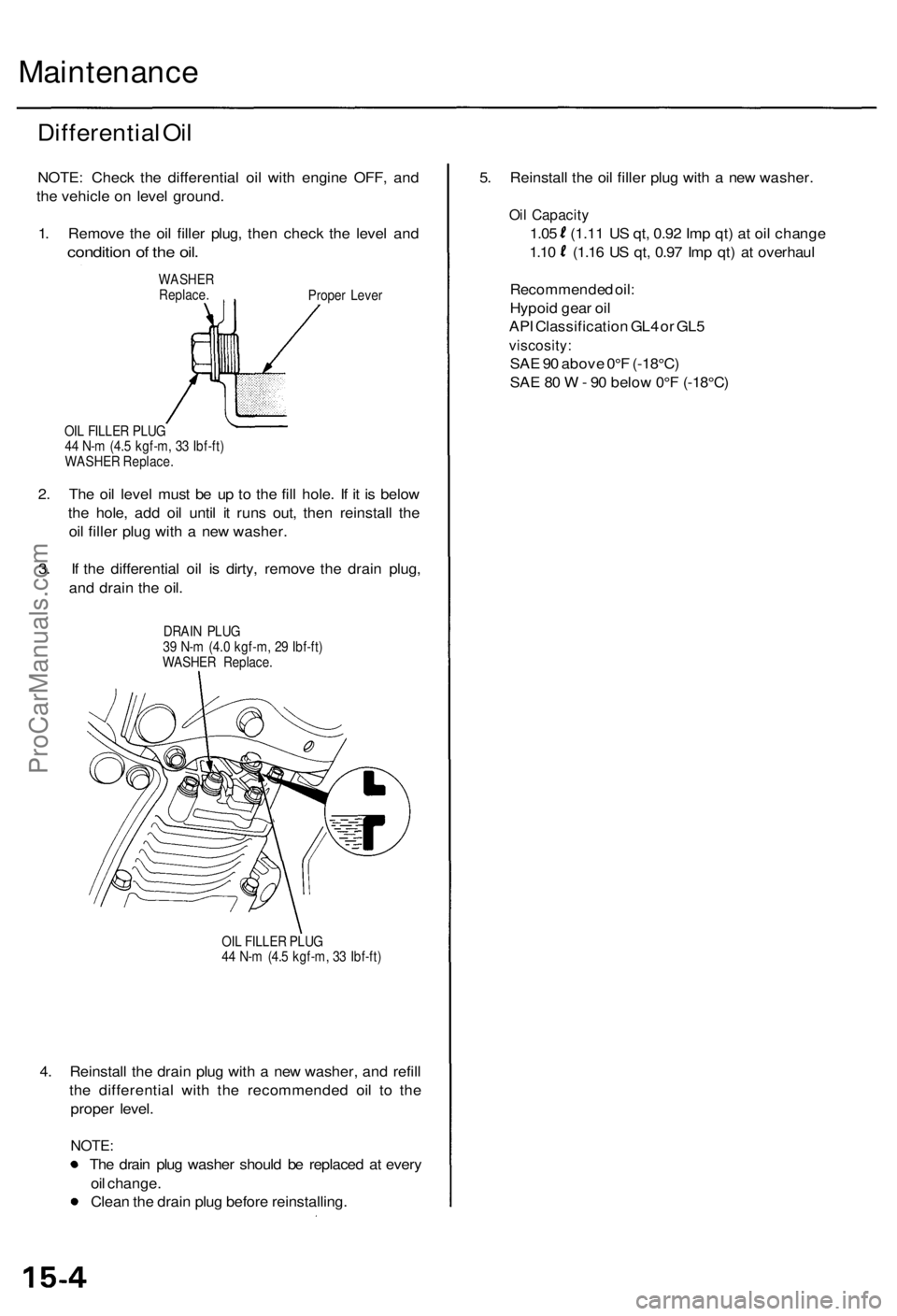

NOTE: Check the differential oil with engine OFF, and

the vehicle on level ground.

1. Remove the oil filler plug, then check the level and

condition of the oil.

WASHER

Replace.

Proper Lever

OIL FILLER PLUG

44 N-m (4.5 kgf-m, 33 Ibf-ft)

WASHER Replace.

2. The oil level must be up to the fill hole. If it is below

the hole, add oil until it runs out, then reinstall the

oil filler plug with a new washer.

3. If the differential oil is dirty, remove the drain plug,

and drain the oil.

DRAIN PLUG

39 N-m (4.0 kgf-m, 29 Ibf-ft)

WASHER Replace.

OIL FILLER PLUG

44 N-m (4.5 kgf-m, 33 Ibf-ft)

4. Reinstall the drain plug with a new washer, and refill

the differential with the recommended oil to the

proper level.

NOTE:

The drain plug washer should be replaced at every

oil change.

Clean the drain plug before reinstalling.

5. Reinstall the oil filler plug with a new washer.

Oil Capacity

1.05 (1.11 US qt, 0.92 Imp qt) at oil change

1.10 (1.16 US qt, 0.97 Imp qt) at overhaul

Recommended oil:

Hypoid gear oil

API Classification GL4 or GL5

viscosity:

SAE 90 above 0°F (-18°C)

SAE 80 W - 90 below 0°F (-18°C)ProCarManuals.com

Page 916 of 1954

Differential Assembly

Removal

Make sur e jack s an d safet y stand s ar e place d properly ,

an d hois t bracket s ar e attache d to correc t position s o n

th e engine .

Appl y parkin g brak e an d bloc k rea r wheel s s o th e

vehicl e wil l no t rol l of f stand s an d fal l o n yo u whil e

workin g unde r it .

CAUTION : Us e fende r cover s to avoi d damagin g painte d

surfaces .

1. Remov e th e drai n plug , an d drai n th e differentia l oi l

(se e pag e 15-4 ).

2 . Remov e th e cotte r pin s an d castl e nuts , tha n sepa -

rat e th e bal l joint s fro m th e lowe r ar m usin g th e

specia l too l (se e sectio n 18 ).

3 . Remov e th e righ t dampe r pinc h bolt , the n separat e

th e dampe r for k an d dampe r (se e sectio n 18 ).

4 . Pr y th e driveshaft s ou t o f th e differentia l an d inter -

mediat e shaf t (se e sectio n 16 ).

CAUTION :

D o no t pul l o n th e driveshaft , a s th e inboar d

join t ma y com e apart .

Us e car e whe n pryin g ou t th e assembly , an d pul l

i t straigh t t o avoi d damagin g th e differentia l oi l

sea l o r th e intermediat e shaf t oute r seal .

5 . Pul l o n th e inboar d join t t o remov e th e righ t drive -

shaf t fro m th e differentia l an d t o remov e th e lef t

driveshaft from the intermediate shaft (see

section 16 ).

6 . Remov e th e intermediat e shaf t assembl y fro m th e

oi l pa n (se e sectio n 16 ).

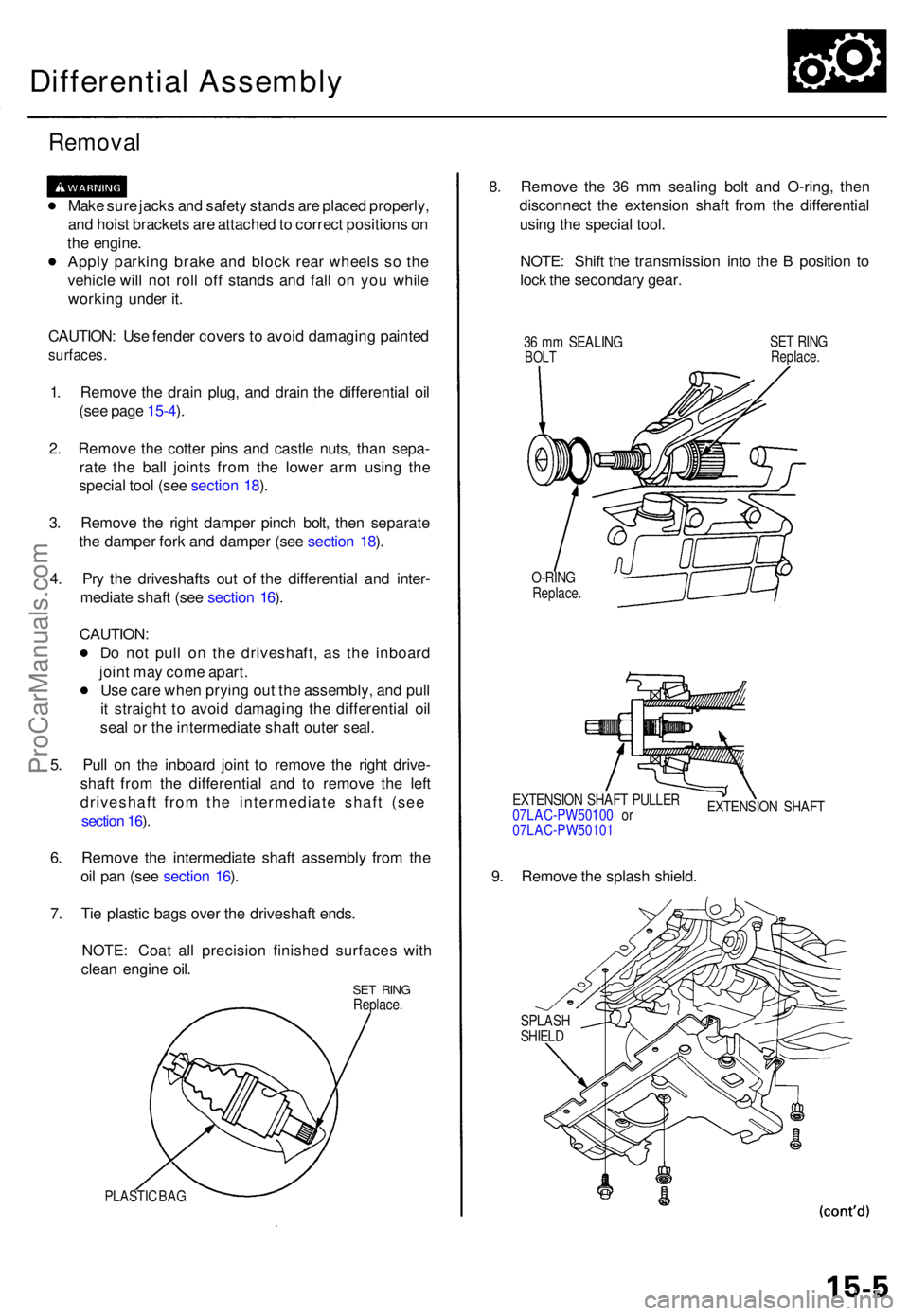

7 . Ti e plasti c bag s ove r th e driveshaf t ends .

NOTE : Coa t al l precisio n finishe d surface s wit h

clea n engin e oil .

SE T RIN GReplace .

PLASTIC BA G

8. Remov e th e 3 6 m m sealin g bol t an d O-ring , the n

disconnec t th e extensio n shaf t fro m th e differentia l

usin g th e specia l tool .

NOTE : Shif t th e transmissio n int o th e B positio n t o

loc k th e secondar y gear .

36 m m SEALIN GBOLTSET RIN GReplace .

O-RINGReplace .

EXTENSIO N SHAF T PULLE R

07LAC-PW5010 0 o r

07LAC-PW5010 1 EXTENSIO

N SHAF T

9. Remov e th e splas h shield .

SPLAS HSHIELD

ProCarManuals.com

Page 918 of 1954

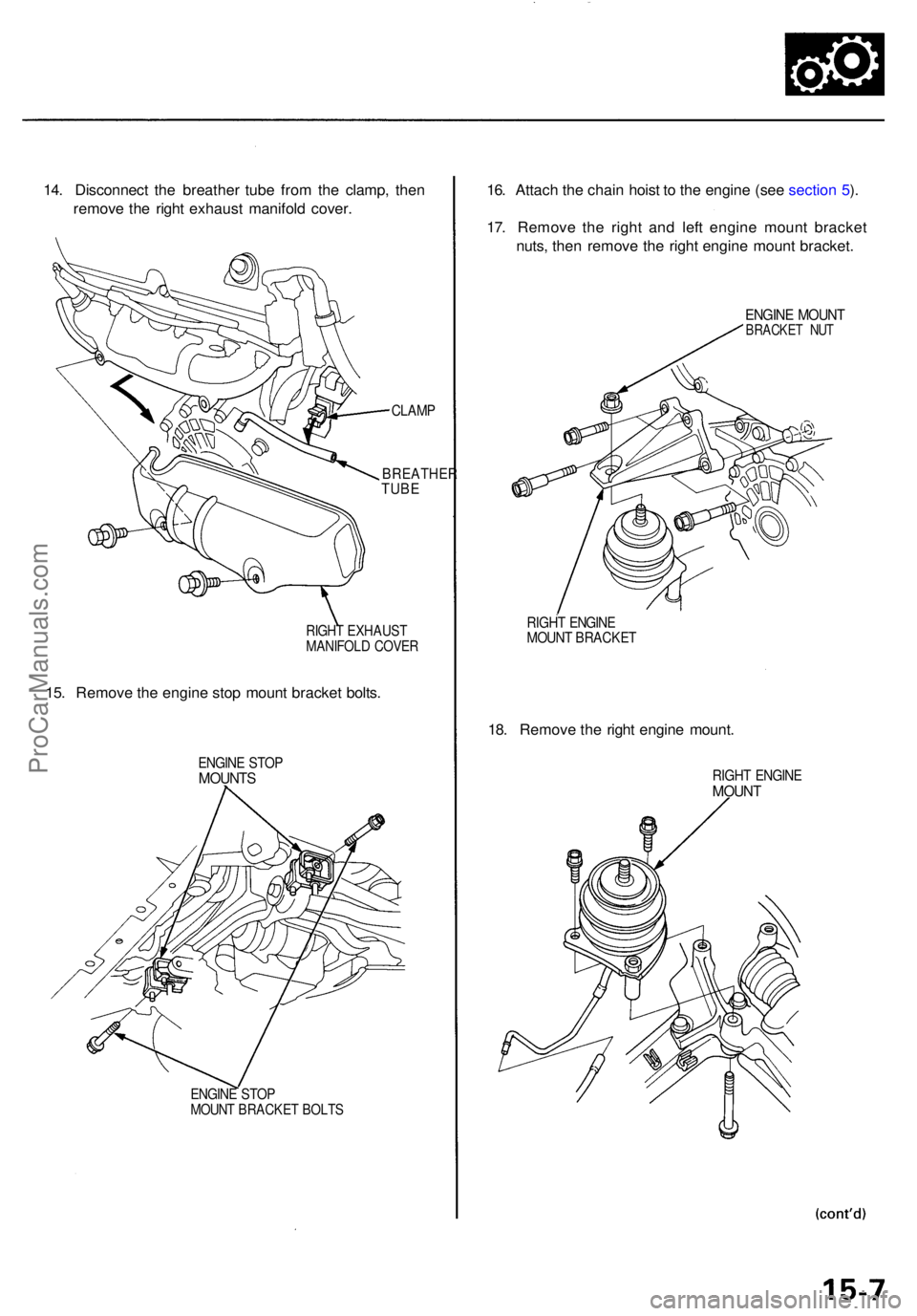

14. Disconnec t th e breathe r tub e fro m th e clamp , the n

remov e th e righ t exhaus t manifol d cover .

CLAMP

BREATHE RTUBE

RIGH T EXHAUS TMANIFOLD COVE R

15. Remov e th e engin e sto p moun t bracke t bolts .

ENGIN E STO PMOUNT S

ENGINE STO PMOUN T BRACKE T BOLT S

16. Attac h th e chai n hois t t o th e engin e (se e sectio n 5 ).

17 . Remov e th e righ t an d lef t engin e moun t bracke t

nuts , the n remov e th e righ t engin e moun t bracket .

ENGINE MOUN TBRACKE T NU T

RIGH T ENGIN EMOUNT BRACKE T

18. Remov e th e righ t engin e mount .

RIGHT ENGIN EMOUNT

ProCarManuals.com

Page 938 of 1954

Differential Assembl y

Installation

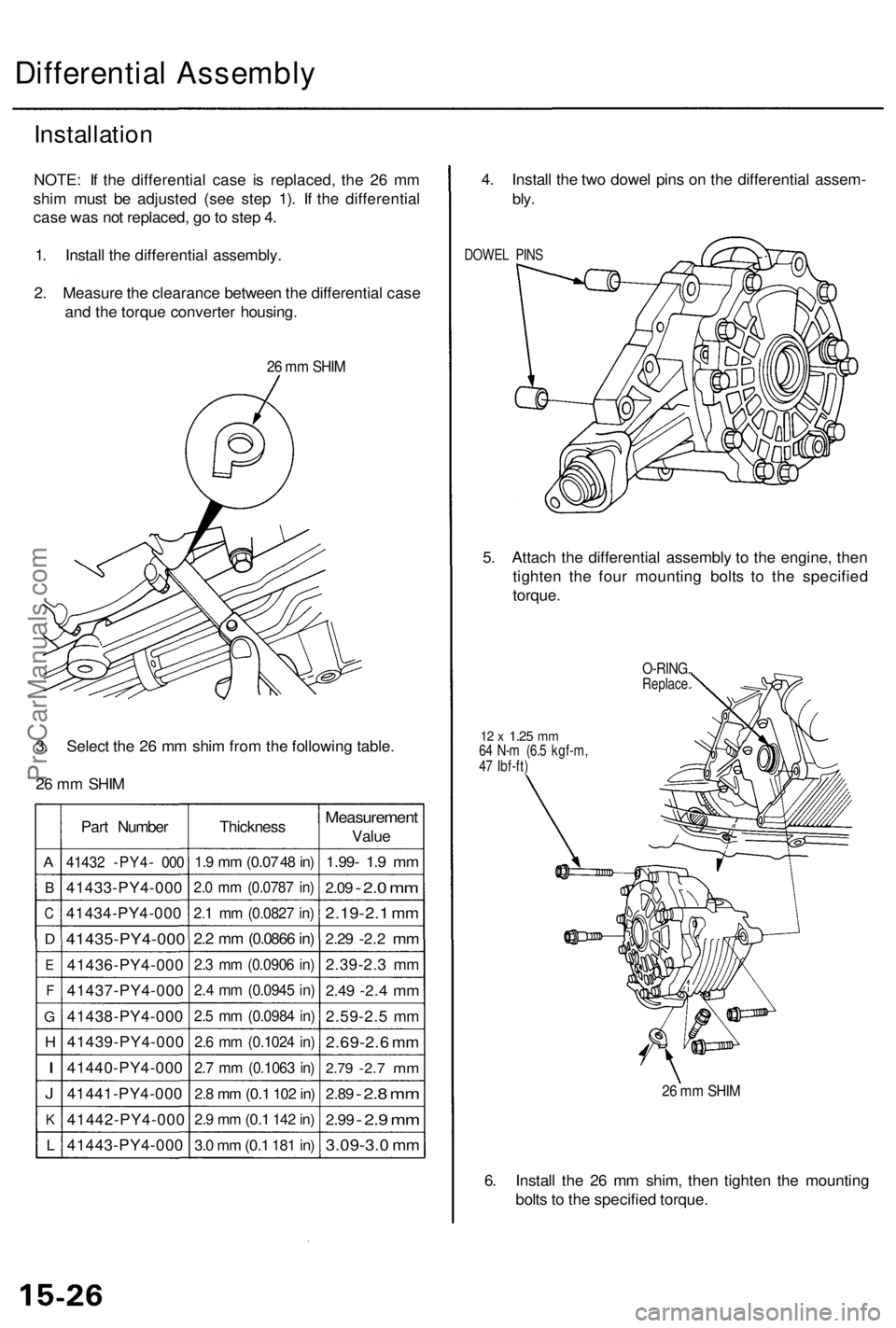

NOTE: I f th e differentia l cas e i s replaced , th e 2 6 m m

shi m mus t b e adjuste d (se e ste p 1) . I f th e differentia l

cas e wa s no t replaced , g o to ste p 4 .

1 . Instal l th e differentia l assembly .

2 . Measur e th e clearanc e betwee n th e differentia l cas e

an d th e torqu e converte r housing .

26 m m SHI M

3. Selec t th e 2 6 m m shi m fro m th e followin g table .

2 6 m m SHI M

A

B

C

D

E

F

G

H

I

J

K

L

Part Numbe r

41432 -PY4 - 00 0

41433-PY4-00 0

41434-PY4-00 0

41435-PY4-000

41436-PY4-00 0

41437-PY4-00 0

41438-PY4-00 0

41439-PY4-00 0

41440-PY4-00 0

41441-PY4-00 0

41442-PY4-00 0

41443-PY4-00 0Thicknes

s

1.9 m m (0.0 7 48 in )

2.0 m m (0.078 7 in )

2.1 m m (0.082 7 in )

2.2 m m (0.086 6 in )

2.3 m m (0.090 6 in )

2.4 m m (0.094 5 in )

2.5 m m (0.098 4 in )

2.6 m m (0.102 4 in )

2.7 m m (0.106 3 in )

2.8 m m (0. 1 102 in )

2.9 m m (0. 1 142 in )

3.0 m m (0. 1 181 in )

Measuremen t

Value

1.99- 1.9 m m

2.0 9 - 2.0 m m

2.19-2. 1 m m

2.2 9 -2. 2 mm

2.39-2. 3 m m

2.4 9 -2. 4 mm

2.59-2. 5 m m

2.69-2. 6 m m

2.7 9 -2. 7 mm

2.89 - 2.8 m m

2.9 9 - 2.9 m m

3.09-3. 0 m m

4. Instal l th e tw o dowe l pin s o n th e differentia l assem -

bly.

DOWE L PIN S

5. Attac h th e differentia l assembl y t o th e engine , the n

tighte n th e fou r mountin g bolt s t o th e specifie d

torque .

O-RING .Replace .

12 x 1.2 5 mm64 N- m (6. 5 kgf-m ,

4 7 Ibf-ft )

26 m m SHI M

6. Instal l th e 2 6 m m shim , the n tighte n th e mountin g

bolt s t o th e specifie d torque .

ProCarManuals.com

Page 977 of 1954

Inspection an d Adjustmen t

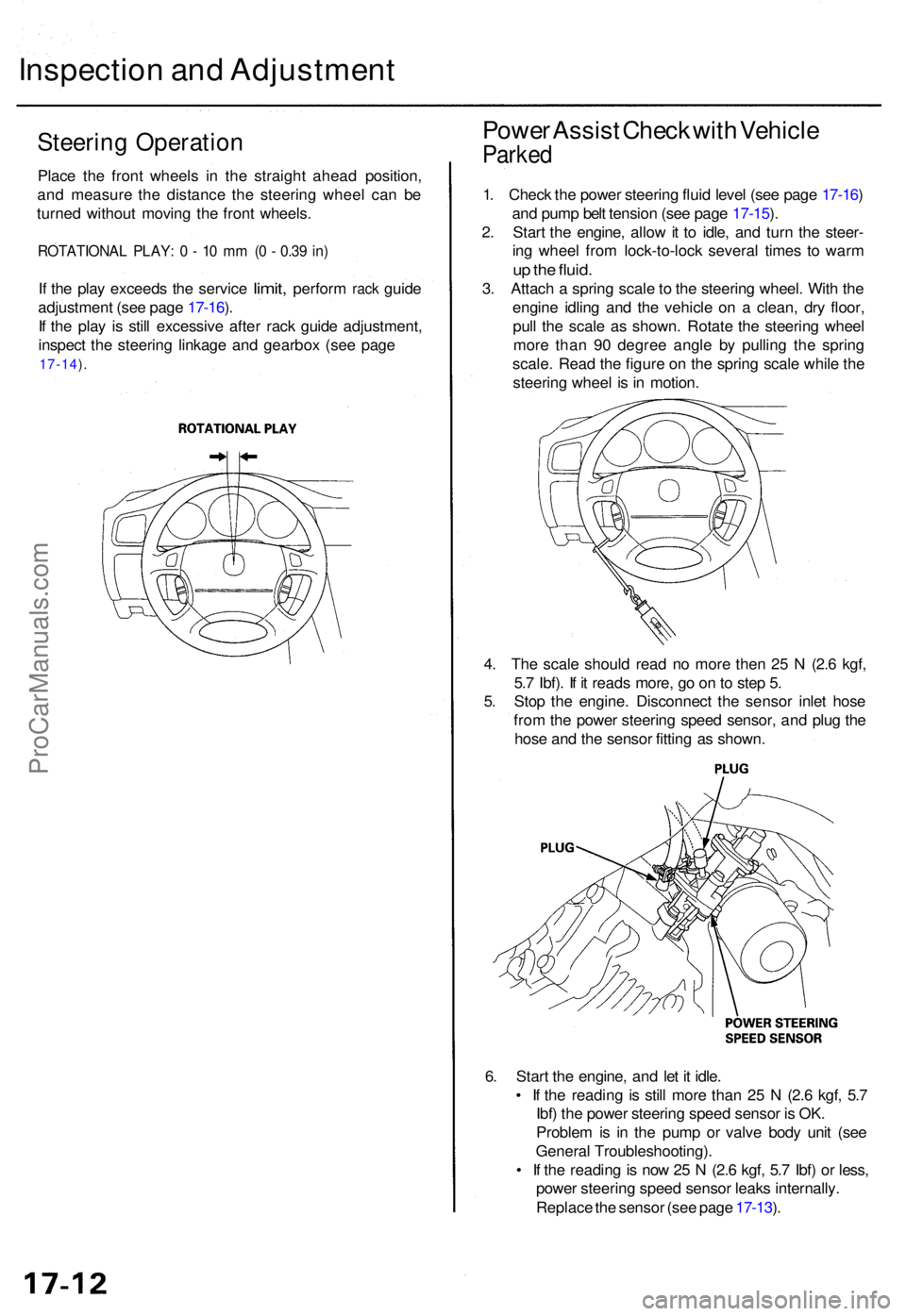

Steering Operatio n

Place th e fron t wheel s i n th e straigh t ahea d position ,

an d measur e th e distanc e th e steerin g whee l ca n b e

turne d withou t movin g th e fron t wheels .

ROTATIONA L PLAY : 0 - 1 0 m m (0 - 0.3 9 in )

If th e pla y exceed s th e servic e limit, perfor m rack guid e

adjustmen t (se e pag e 17-16 ).

I f th e pla y i s stil l excessiv e afte r rac k guid e adjustment ,

inspec t th e steerin g linkag e an d gearbo x (se e pag e

17-14 ).

Powe r Assis t Chec k wit h Vehicl e

Parked

1. Chec k th e powe r steerin g flui d leve l (se e pag e 17-16 )

an d pum p bel t tensio n (se e pag e 17-15 ).

2 . Star t th e engine , allo w it t o idle , an d tur n th e steer -

in g whee l fro m lock-to-loc k severa l time s t o war m

up th e fluid .

3. Attac h a sprin g scal e to th e steerin g wheel . Wit h th e

engin e idlin g an d th e vehicl e o n a clean , dr y floor ,

pul l th e scal e a s shown . Rotat e th e steerin g whee l

mor e tha n 9 0 degre e angl e b y pullin g th e sprin g

scale . Rea d th e figur e o n th e sprin g scal e whil e th e

steerin g whee l i s in motion .

4 . Th e scal e shoul d rea d n o mor e the n 2 5 N (2. 6 kgf ,

5. 7 Ibf) . I f i t read s more , g o o n to ste p 5 .

5 . Sto p th e engine . Disconnec t th e senso r inle t hos e

fro m th e powe r steerin g spee d sensor , an d plu g th e

hos e an d th e senso r fittin g a s shown .

6 . Star t th e engine , an d le t i t idle .

• I f th e readin g i s stil l mor e tha n 2 5 N (2. 6 kgf , 5. 7

Ibf ) th e powe r steerin g spee d senso r i s OK .

Proble m is i n th e pum p o r valv e bod y uni t (se e

Genera l Troubleshooting) .

• I f th e readin g is no w 2 5 N (2. 6 kgf , 5. 7 Ibf ) o r less ,

powe r steerin g spee d senso r leak s internally .

Replac e th e senso r (se e pag e 17-13 ).

ProCarManuals.com

Page 978 of 1954

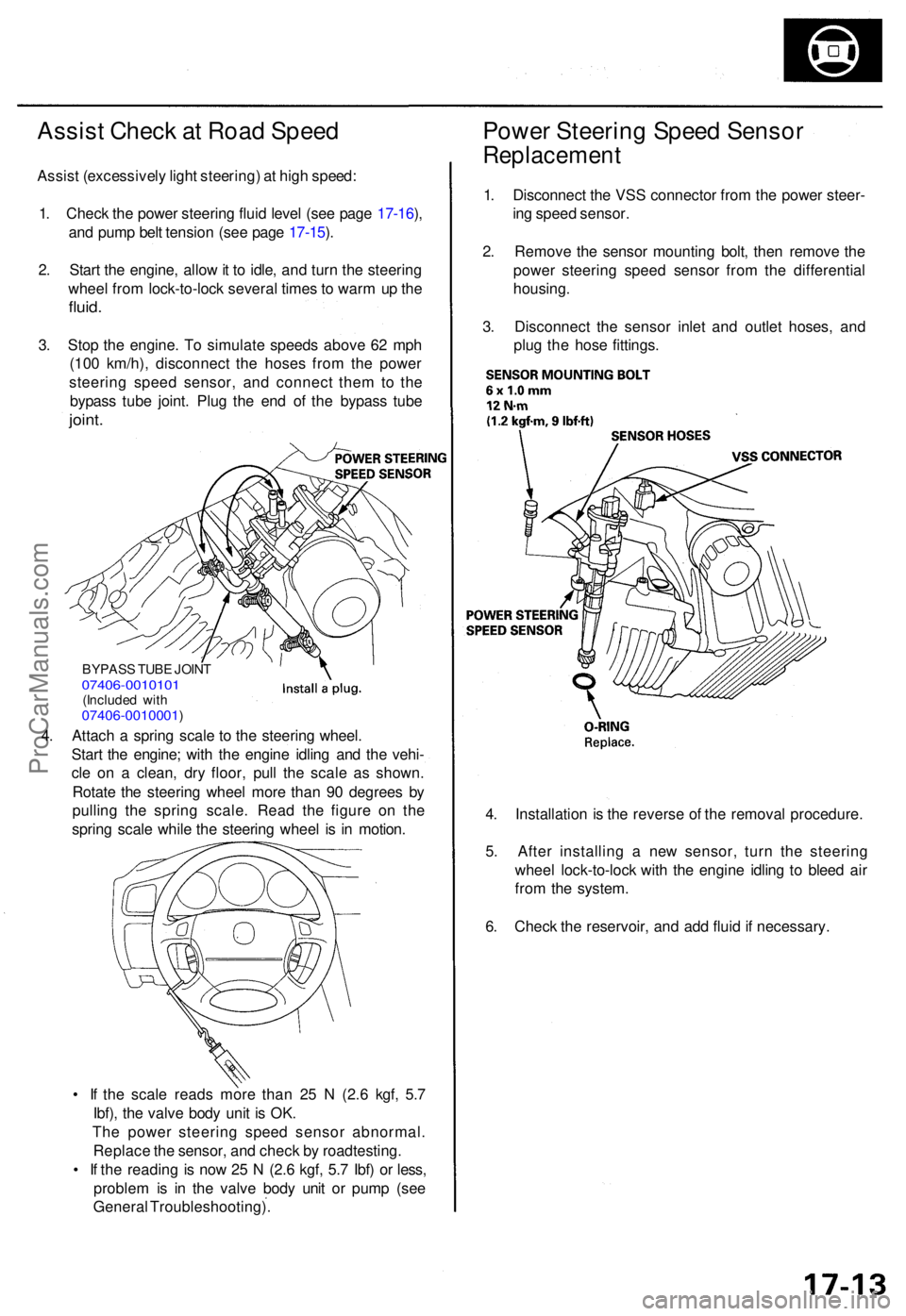

Assist Chec k a t Roa d Spee d

Assist (excessivel y ligh t steering ) a t hig h speed :

1 . Chec k th e powe r steerin g flui d leve l (se e pag e 17-16 ),

an d pum p bel t tensio n (se e pag e 17-15 ).

2 . Star t th e engine , allo w it t o idle , an d tur n th e steerin g

whee l fro m lock-to-loc k severa l time s t o war m u p th e

fluid .

3. Sto p th e engine . T o simulat e speed s abov e 6 2 mp h

(10 0 km/h) , disconnec t th e hose s fro m th e powe r

steerin g spee d sensor , an d connec t the m to th e

bypas s tub e joint . Plu g th e en d o f th e bypas s tub e

joint .

Powe r Steerin g Spee d Senso r

Replacemen t

1. Disconnec t th e VS S connecto r fro m th e powe r steer -

in g spee d sensor .

2 . Remov e th e senso r mountin g bolt , the n remov e th e

powe r steerin g spee d senso r fro m th e differentia l

housing .

3 . Disconnec t th e senso r inle t an d outle t hoses , an d

plu g th e hos e fittings .

4 . Installatio n is th e revers e o f th e remova l procedure .

5 . Afte r installin g a ne w sensor , tur n th e steerin g

whee l lock-to-loc k wit h th e engine idling t o blee d ai r

fro m th e system .

6 . Chec k th e reservoir , an d ad d flui d if necessary .

BYPASS TUB E JOIN T07406-001010 1(Included wit h07406-0010001 )

4. Attac h a sprin g scal e to th e steerin g wheel .

Star t th e engine ; wit h th e engin e idlin g an d th e vehi -

cl e o n a clean , dr y floor , pul l th e scal e a s shown .

Rotat e th e steerin g whee l mor e tha n 9 0 degree s b y

pullin g th e sprin g scale . Rea d th e figur e o n th e

sprin g scal e whil e th e steerin g whee l i s i n motion .

• I f th e scal e read s mor e tha n 2 5 N (2. 6 kgf , 5. 7

Ibf) , th e valv e bod y uni t i s OK .

Th e powe r steerin g spee d senso r abnormal .

Replac e th e sensor , an d chec k b y roadtesting .

• I f th e readin g is no w 2 5 N (2. 6 kgf , 5. 7 Ibf ) o r less ,

proble m is i n th e valv e bod y uni t o r pum p (se e

Genera l Troubleshooting) .

ProCarManuals.com

Page 981 of 1954

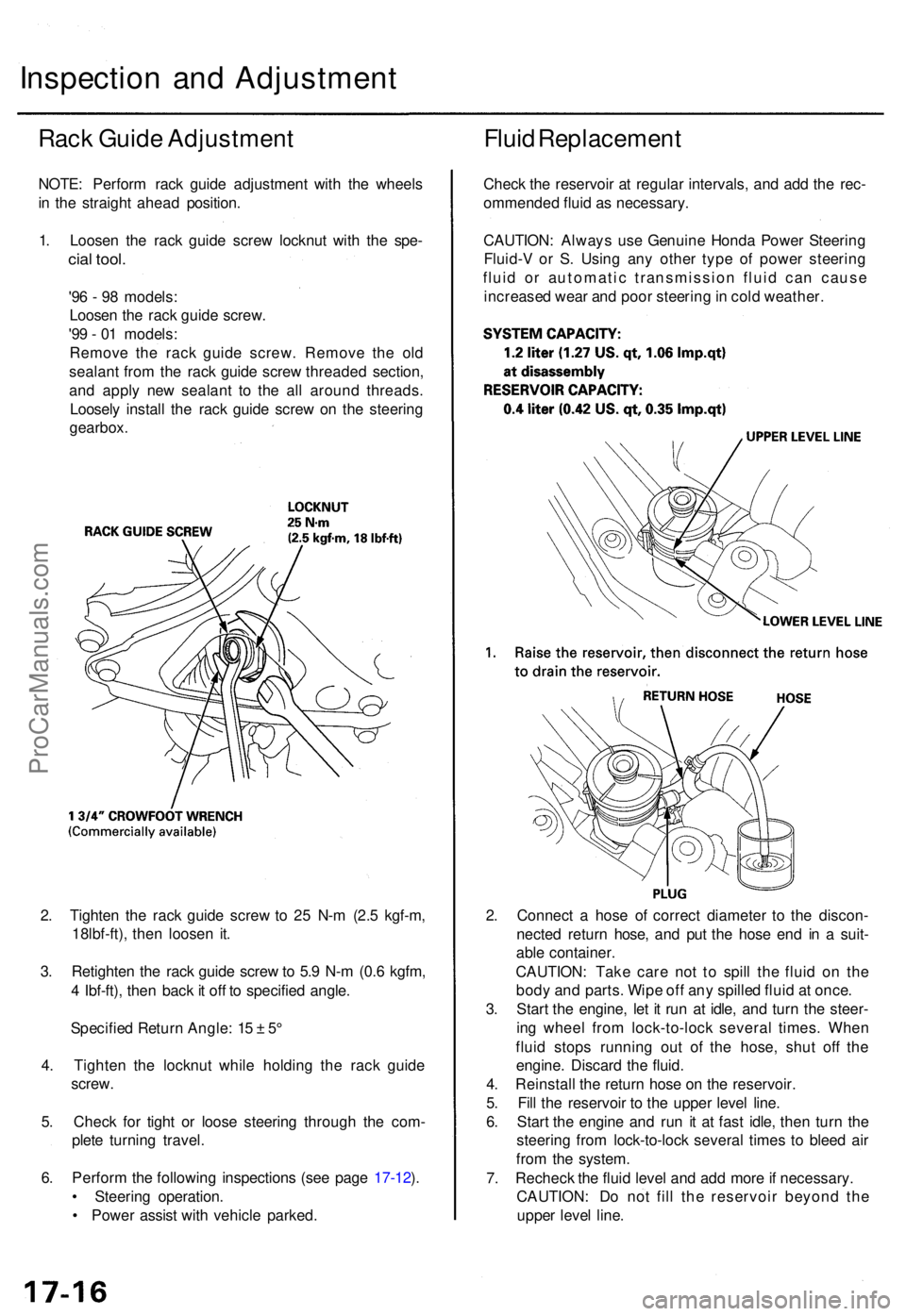

2. Tighte n th e rac k guid e scre w to 2 5 N- m (2. 5 kgf-m ,

18lbf-ft) , the n loose n it .

3 . Retighte n th e rac k guid e scre w to 5. 9 N- m (0. 6 kgfm ,

4 Ibf-ft) , the n bac k it of f t o specifie d angle .

Specifie d Retur n Angle : 1 5 ± 5°

4 . Tighte n th e locknu t whil e holdin g th e rac k guid e

screw .

5 . Chec k fo r tigh t o r loos e steerin g throug h th e com -

plet e turnin g travel .

6 . Perfor m th e followin g inspection s (se e pag e 17-12 ).

• Steerin g operation .

• Powe r assis t wit h vehicl e parked . 2

. Connec t a hos e o f correc t diamete r t o th e discon -

necte d retur n hose , an d pu t th e hos e en d i n a suit -

abl e container .

CAUTION : Tak e car e no t t o spil l th e flui d o n th e

bod y an d parts . Wip e of f an y spille d flui d a t once .

3 . Star t th e engine , le t i t ru n a t idle , an d tur n th e steer -

in g whee l fro m lock-to-loc k severa l times . Whe n

flui d stop s runnin g ou t of the hose , shu t of f th e

engine . Discar d th e fluid .

4 . Reinstal l th e retur n hos e o n th e reservoir .

5 . Fil l th e reservoi r t o th e uppe r leve l line .

6 . Star t th e engin e an d ru n i t a t fas t idle , the n tur n th e

steerin g fro m lock-to-loc k severa l time s t o blee d ai r

fro m th e system .

7 . Rechec k th e flui d leve l an d ad d mor e if necessary .

CAUTION : D o no t fil l th e reservoi r beyon d th e

uppe r leve l line .

Inspectio n an d Adjustmen t

Rack Guid e Adjustmen t

NOTE: Perfor m rac k guid e adjustmen t wit h th e wheel s

i n th e straigh t ahea d position .

1 . Loose n th e rac k guid e scre w locknu t wit h th e spe -

cial tool .

'96 - 9 8 models :

Loose n th e rac k guid e screw .

'9 9 - 0 1 models :

Remov e th e rac k guid e screw . Remov e th e ol d

sealan t fro m th e rac k guid e scre w threade d section ,

an d appl y ne w sealan t t o th e al l aroun d threads .

Loosel y instal l th e rac k guid e scre w o n th e steerin g

gearbox .

Fluid Replacemen t

Check th e reservoi r a t regula r intervals , an d ad d th e rec -

ommende d flui d a s necessary .

CAUTION : Alway s us e Genuin e Hond a Powe r Steerin g

Fluid- V o r S . Usin g an y othe r typ e o f powe r steerin g

flui d o r automati c transmissio n flui d ca n caus e

increase d wea r an d poo r steerin g in col d weather .

ProCarManuals.com

Page 1022 of 1954

12. Instal l th e fron t wheels .

13 . Fil l th e syste m wit h th e recommende d powe r steer -

in g fluid , an d blee d ai r fro m th e syste m (se e pag e

17-16 ).

14 . Afte r installation , perfor m th e followin g checks .

• Star t th e engine , allo w it t o idle , an d tur n th e steer -

in g whee l fro m lock-to-loc k severa l time s t o war m

u p th e fluid . Chec k th e gearbo x fo r leak s (se e pag e

17-23 ).

• Adjus t th e fron t to e (se e sectio n 18 ).

• Chec k th e steerin g whee l spok e angle . Adjus t b y

turnin g th e righ t an d lef t tie-rods , i f necessary .

NOTE : Tur n th e righ t an d lef t tie-rod s equally .

11

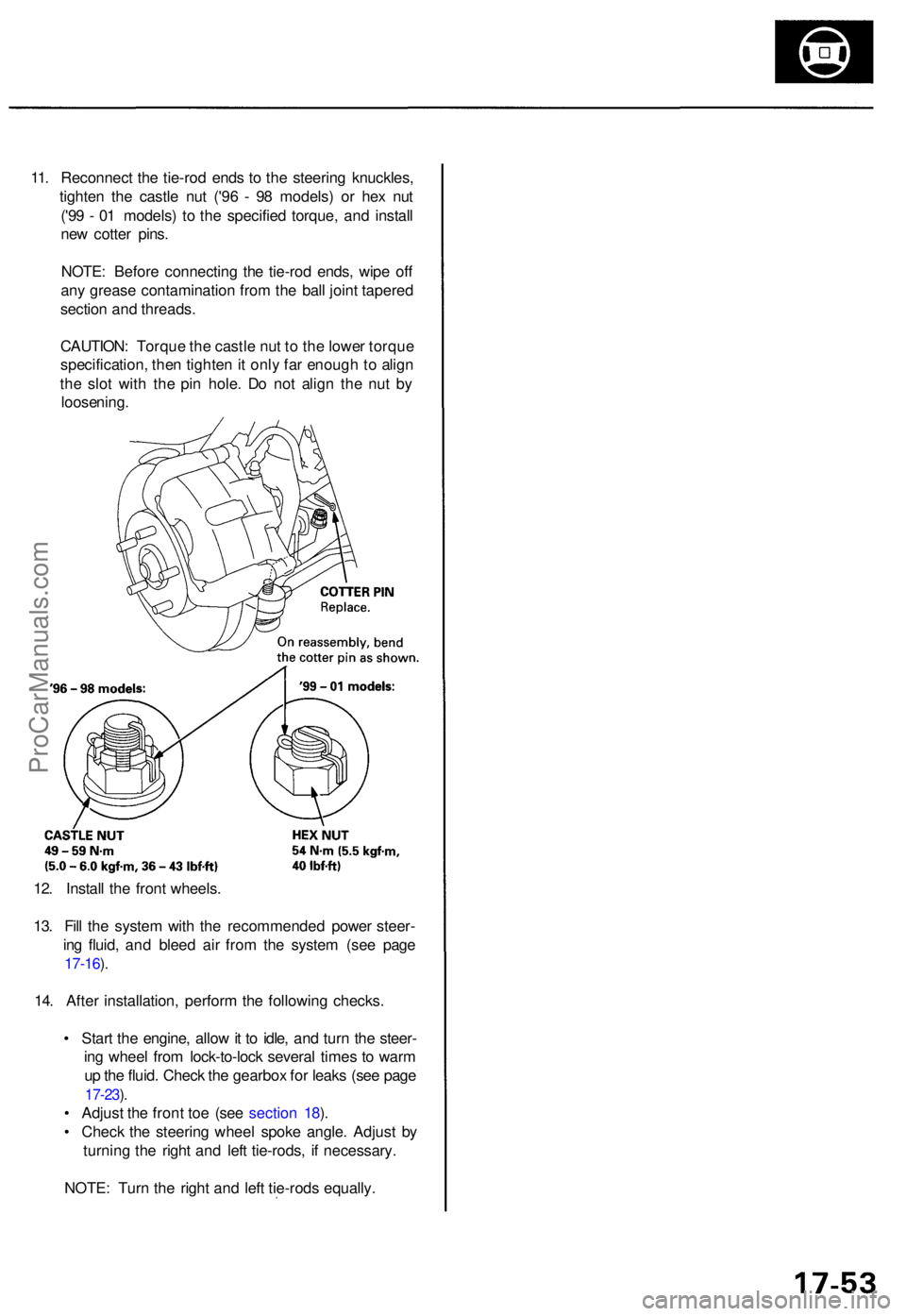

. Reconnec t th e tie-ro d end s t o th e steerin g knuckles ,

tighte n th e castl e nu t ('9 6 - 9 8 models ) o r he x nu t

('9 9 - 0 1 models ) t o th e specifie d torque , an d instal l

ne w cotte r pins .

NOTE : Befor e connectin g th e tie-ro d ends , wip e of f

an y greas e contaminatio n fro m th e bal l join t tapere d

sectio n an d threads .

CAUTION : Torqu e th e castl e nu t t o th e lowe r torqu e

specification , the n tighte n it onl y fa r enoug h to alig n

th e slo t wit h th e pi n hole . D o no t alig n th e nu t b y

loosening .

ProCarManuals.com

Page 1030 of 1954

Front Suspensio n

Knuckle/Hub Replacemen t

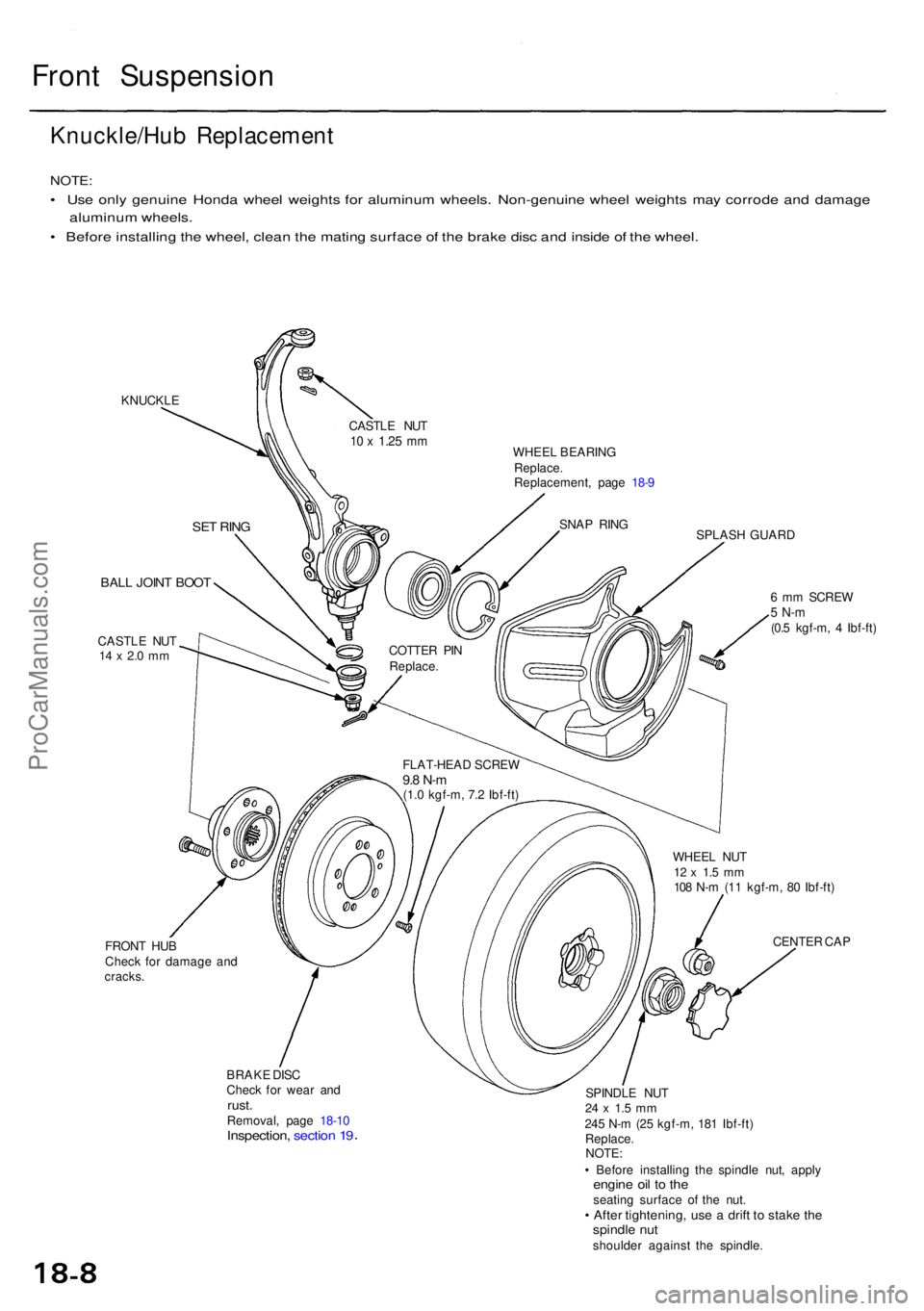

NOTE:

• Us e onl y genuin e Hond a whee l weight s fo r aluminu m wheels . Non-genuin e whee l weight s ma y corrod e an d damag e

aluminu m wheels .

• Befor e installin g th e wheel , clea n th e matin g surfac e o f th e brak e dis c an d insid e o f th e wheel .

KNUCKL E

WHEEL BEARIN G

Replace .

Replacement , pag e 18- 9

SPLASH GUAR D

BALL JOIN T BOO T

CASTL E NU T14 x 2. 0 m m

FRON T HU B

Chec k fo r damag e an d

cracks .

BRAKE DIS C

Chec k fo r wea r an d

rust .Removal , pag e 18-1 0Inspection , sectio n 1 9

6 m m SCRE W5 N- m(0.5 kgf-m , 4 Ibf-ft )

WHEE L NU T

12 x 1. 5 m m108 N- m (1 1 kgf-m , 8 0 Ibf-ft )

CENTE R CA P

SPINDL E NU T

24 x 1. 5 m m245 N- m (2 5 kgf-m , 18 1 Ibf-ft )

Replace .

NOTE :

• Befor e installin g th e spindl e nut , appl y

engine oi l t o th eseatin g surfac e o f th e nut .• Afte r tightening , us e a drif t t o stak e th espindl e nu tshoulde r agains t th e spindle .

FLAT-HEA

D SCRE W

9.8 N- m(1.0 kgf-m , 7. 2 Ibf-ft )

COTTE

R PI N

Replace .

SNAP RIN G

CASTL

E NU T

10 x 1.2 5 mm

SE T RIN G

ProCarManuals.com