engine ACURA RL KA9 1996 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 1144 of 1954

Modulator Uni t

High-Pressur e Brak e Flui d Replacement/Bleedin g

Replacement

1. Reliev e syste m pressur e (se e pag e 19-97 ). Leav e th e

tub e an d wrenc h o n th e maintenanc e bleeder , an d

leav e th e tub e in th e container .

2 . Star t th e engin e t o operat e th e pum p motor .

NOTE:

If th e pum p moto r operate s fo r 4 0 second s o r

more , th e AB S indicato r ligh t come s on , an d th e

pum p moto r stops . Sto p an d restar t th e engin e t o

operat e th e pum p moto r again .

I f th e AB S indicator light come s on , remov e th e

AB S B 2 (1 5 A ) fus e fo r 3 second s o r mor e t o

eras e th e DT C afte r servicing .

3 . Repea t step s 1 an d 2 to drai n th e res t o f th e brak e

fluid fro m th e modulato r unit .

NOTE : Th e modulato r ha s a capacit y o f approxi -

mately 15 0 (5. 0 fl-oz , 5. 3 Imp-oz) . Approximatel y

35 - 4 5 (1. 2 - 1. 5 fl-oz , 1. 2 - 1. 6 Imp-oz ) o f th e flui d

i s draine d eac h tim e yo u reliev e syste m pressure .

4 . Remov e th e cap , an d refil l th e reservoi r t o th e MA X

(upper ) leve l wit h fres h brak e fluid .

NOTE : Pou r th e brak e flui d slowl y s o tha t i t doe s

not foam , an d wai t fo r a fe w minutes .

5. Repea t step s 1 an d 2 twice , an d refil l th e reservoi r

t o th e MA X (upper ) leve l wit h fres h brak e fluid .

6 . Tighte n th e maintenanc e bleede r t o th e specifie d

torque .

7 . Star t th e engine , an d mak e sur e tha t th e AB S indica -

tor ligh t goe s off .

Bleedin g

Whe n th e brak e flui d i s completel y draine d fro m th e

reservoi r (ai r enter s th e modulato r unit) , blee d th e ai r

from th e modulato r a s follows :

1 . Fil l th e reservoi r t o th e MA X (upper ) leve l wit h fres h

brake fluid .

2. Connec t a tub e t o th e maintenanc e bleede r o n th e

modulato r unit , an d se t th e othe r en d o f th e tub e in a

suitabl e containe r (se e pag e 19-97 ).

3 . Loose n th e bleeder , an d star t th e engin e t o operat e

th e pum p motor .

4 . Tighte n th e bleede r whe n th e flui d start s t o flo w ou t

o f th e bleeder .

NOTE : Tak e car e no t t o spil l th e brak e flui d fro m

th e container .

5 . Sto p th e engin e afte r th e pum p moto r stops .

NOTE : I f th e AB S indicato r ligh t come s o n an d th e

pum p moto r stops , restar t th e engin e an d repea t step s

3 throug h 5 above .

19-98ProCarManuals.com

Page 1154 of 1954

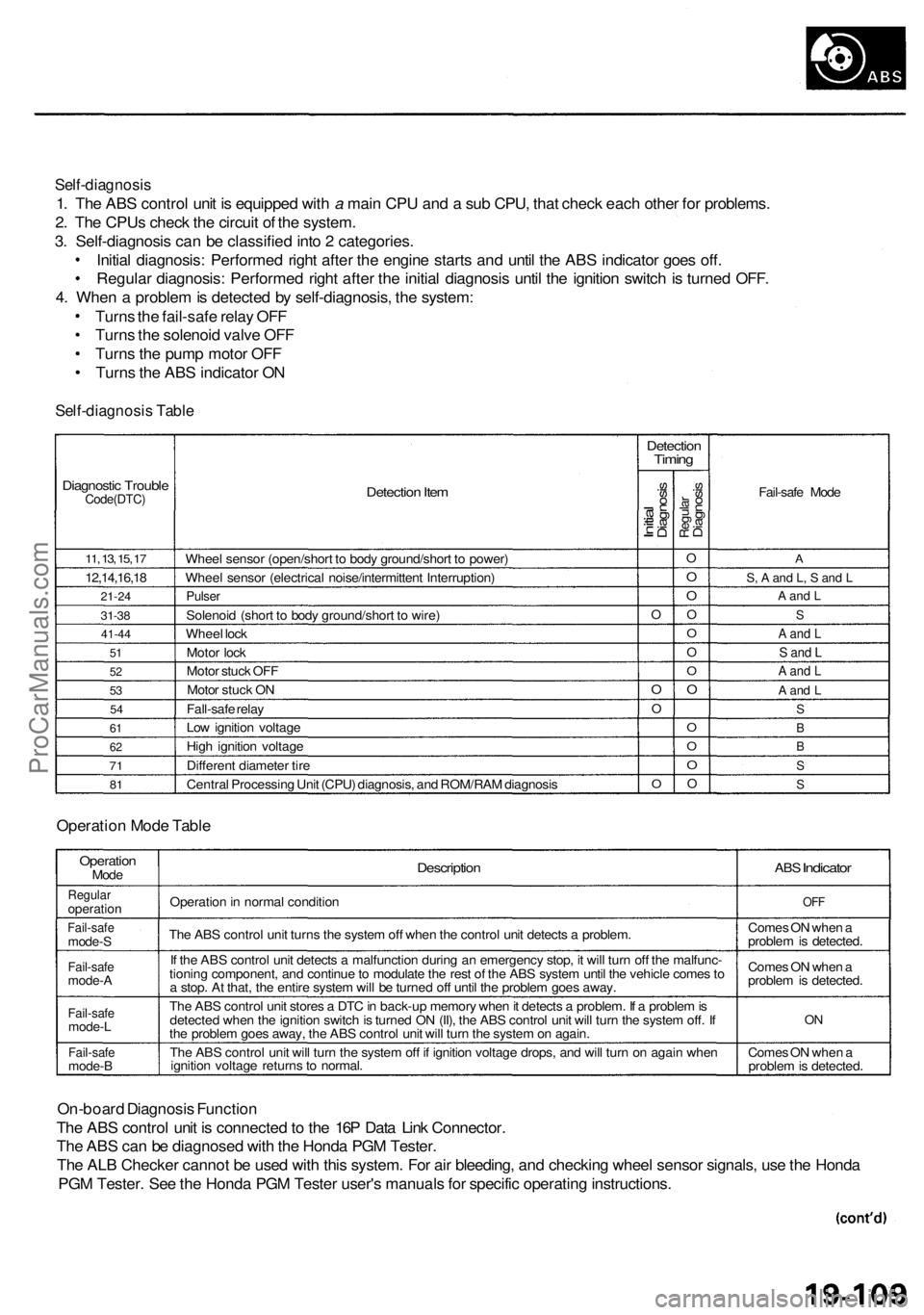

Self-diagnosis

1. The ABS control unit is equipped with a main CPU and a sub CPU, that check each other for problems.

2. The CPUs check the circuit of the system.

3. Self-diagnosis can be classified into 2 categories.

Initial diagnosis: Performed right after the engine starts and until the ABS indicator goes off.

Regular diagnosis: Performed right after the initial diagnosis until the ignition switch is turned OFF.

4. When a problem is detected by self-diagnosis, the system:

Turns the fail-safe relay OFF

Turns the solenoid valve OFF

Turns the pump motor OFF

Turns the ABS indicator ON

Self-diagnosis Table

Diagnostic Trouble

Code(DTC)

11, 13, 15, 17

12,14,16,18

21-24

31-38

41-44

51

52

53

54

61

62

71

81

Detection Item

Wheel sensor (open/short to body ground/short to power)

Wheel sensor (electrical noise/intermittent Interruption)

Pulser

Solenoid (short to body ground/short to wire)

Wheel lock

Motor lock

Motor stuck OFF

Motor stuck ON

Fall-safe relay

Low ignition voltage

High ignition voltage

Different diameter tire

Central Processing Unit (CPU) diagnosis, and ROM/RAM diagnosis

Detection

Timing

Initial

Diagnosis

O

O

O

O

Regular

Diagnosis

O

O

O

O

O

O

O

O

O

O

O

O

Fail-safe Mode

A

S, A and L, S and L

A and L

S

A and L

S and L

A and L

A and L

S

B

B

S

S

Operation Mode Table

Operation

Mode

Regular

operation

Fail-safe

mode-S

Fail-safe

mode-A

Fail-safe

mode-L

Fail-safe

mode-B

Description

Operation in normal condition

The ABS control unit turns the system off when the control unit detects a problem.

If the ABS control unit detects a malfunction during an emergency stop, it will turn off the malfunc-

tioning component, and continue to modulate the rest of the ABS system until the vehicle comes to

a stop. At that, the entire system will be turned off until the problem goes away.

The ABS control unit stores a DTC in back-up memory when it detects a problem. If a problem is

detected when the ignition switch is turned ON (II), the ABS control unit will turn the system off. If

the problem goes away, the ABS control unit will turn the system on again.

The ABS control unit will turn the system off if ignition voltage drops, and will turn on again when

ignition voltage returns to normal.

ABS

Indicator

OFF

Comes ON when a

problem is detected.

Comes ON when a

problem is detected.

ON

Comes ON when a

problem is detected.

On-board Diagnosis Function

The ABS control unit is connected to the 16P Data Link Connector.

The ABS can be diagnosed with the Honda PGM Tester.

The ALB Checker cannot be used with this system. For air bleeding, and checking wheel sensor signals, use the Honda

PGM Tester. See the Honda PGM Tester user's manuals for specific operating instructions.

ProCarManuals.com

Page 1160 of 1954

Troubleshooting Precautions

ABS Indicator

1. If the system is OK, the ABS indicator goes off 2 seconds after turning the ignition switch ON (II) without starting the

engine, and then comes on again and goes off after 2 seconds. This occurs because the ABS control unit is turned on

by the IG2 power source.

2. The ABS indicator comes on when the ABS control unit detects a problem in the system. However, even though the

system is operating properly, the ABS indicator will come on, under the following conditions.

Only drive wheels rotate

One drive wheel is stuck

Vehicle spin

ABS continues to operate for a long time

Signal disturbance

To determine the actual cause of problem, question the customer about the problem, taking these conditions into con-

sideration.

3. When a problem is detected and the ABS indicator comes on, there are cases when the indicator stays on until the igni-

tion switch is turned OFF, and cases when the indicator goes off automatically when the system returns to normal. For

DTCs 61 and 62, the indicator goes off automatically when the system returns to normal. For all other codes, the indica-

tor stays on until the ignition switch is turned OFF.

4. For DTCs 12, 14, 16, 18, 21, 22, 23, 24, 51, 52 and 53, the indicator goes off when the vehicle is driven again and the sys-

tem is OK after the ignition switch is turned from OFF to ON (II). However, if the DTC is erased, the CPU is reset and the

indicator goes off right after the engine is started if the system is OK.

Diagnostic Trouble Code (DTC)

1. If the CPU cannot be activated and the indicator comes on, the DTC is not memorized.

2. The memory can hold any number of DTCs. However, when the same DTC is detected more than once, the later one is

written over the old one. Therefore, when the same problem is detected repeatedly, it is memorized as 1 DTC.

3. The DTCs are indicated in the order of ascending number, not in the order they occur.

4. The DTCs are memorized in the EEPROM (non-volatile memory). Therefore, the memorized DTCs cannot be canceled

by disconnecting the battery. Perform the specified procedures to erase the DTCs.

Self-diagnosis

1. Self-diagnosis can be classified into 2 categories.

• Initial diagnosis: Performed right after the engine starts and until the ABS indicator goes off.

• Regular diagnosis: Performed right after the initial diagnosis until the ignition switch is turned OFF.

2. When a problem is detected by self-diagnosis, the system.

Turns the fail-safe relay OFF

Turns the solenoid valve OFF

Turns the pump motor OFF

Turns the ABS indicator ONProCarManuals.com

Page 1169 of 1954

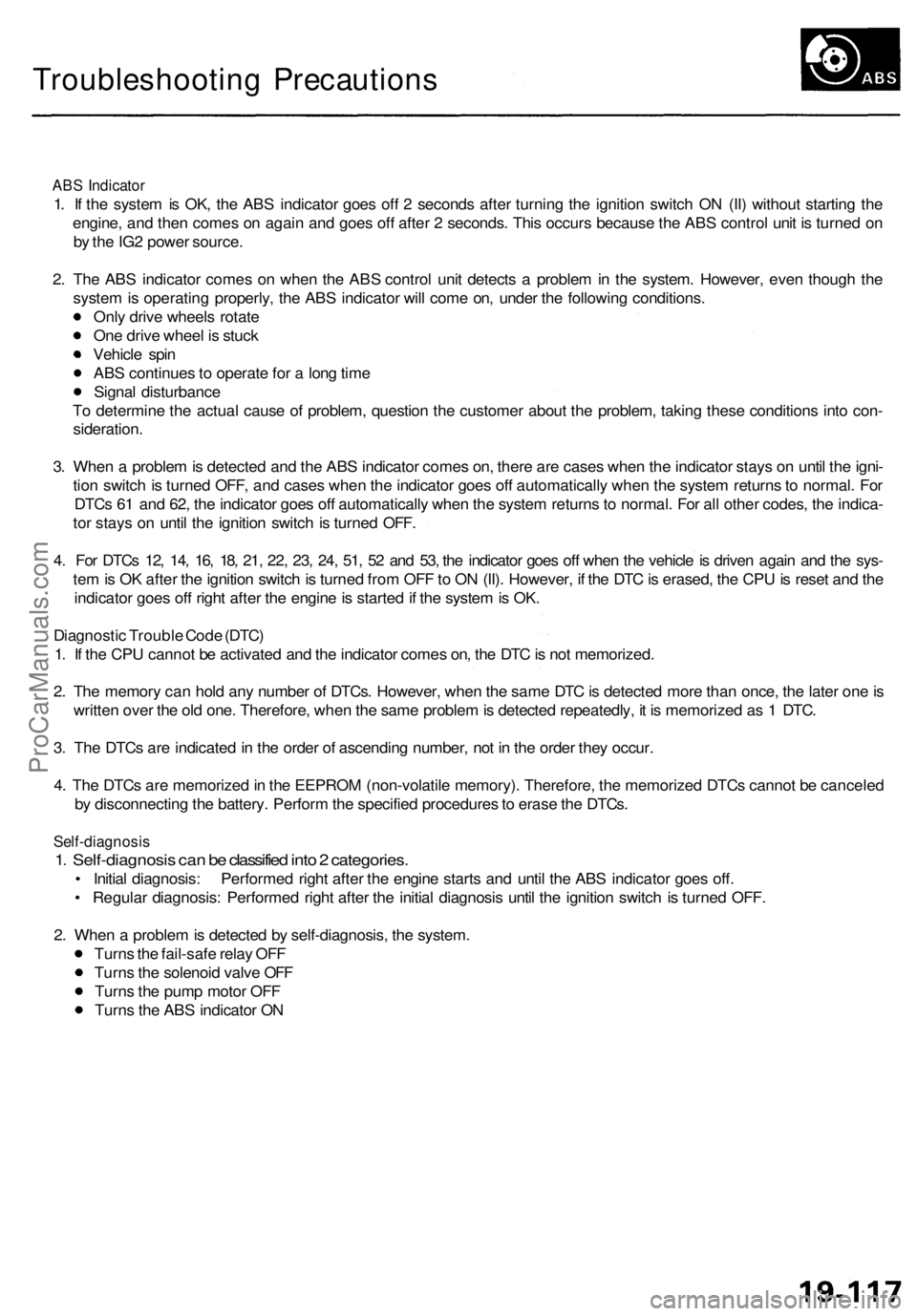

Troubleshooting

DTC 11 , 13 , 15 , 17 : Whee l Senso r (Open/Shor t t o Bod y Ground/Shor t t o Power )

With th e ignitio n switc h O N

(II) , th e AB S indicato r doe s

not g o off .With th e SC S servic e connec -

to r connecte d (se e pag e

19-119 ), DTC s 11 , 13 , 15 , 1 7 ar e

indicated .

Chec k fo r a shor t t o powe r i n th e

whee l senso r circuit :

1 . Disconnec t th e AB S contro l

unit 22 P connector .2. Star t th e engine .

3 . Measur e th e voltag e betwee n

th e appropriat e whee l senso r

(+) circui t termina l an d bod ygroun d (se e table) .

DTC

11 (Right-front )

13 (Left-front )

15 (Right-rear )

17 (Left-rear )

Appropriat e Termina l

(+) Sid e

No. 9 : FR W (+)

No . 7 : FL W (+ )

No . 19 : RR W (+ )

No . 17:RLW(+ )

(-) Sid e

No. 8 : FR W (-)

No . 6 : FL W (-)

No . 20 : RR W (-)

No . 18 : RL W (-)

Is ther e 2 V or more ?

NOTE : Judgemen t valu e fo r shor t t o

powe r i s 2 V . Repai

r shor t t o powe r i n th e (+ )

circui t wir e betwee n th e AB S

contro l uni t an d th e appropriat e

whee l sensor .

Chec k fo r a shor t t o bod y groun d

i n th e whee l senso r circuit :

Check fo r continuit y betwee n th eappropriat e whee l senso r (+ ) cir -cuit termina l an d bod y groun d(see table) .

I s ther e continuity ?

Chec k fo r a n ope n i n th e whee l

senso r circuit :

Chec k th e resistanc e betwee n th e

appropriat e whee l senso r (+ ) an d

(-) circui t terminal s (se e table) .

Is th e resistanc e OK ?Front/Rear : 45 0 - 2,05 0

(a t 20°C , 68°F) .

Check fo r loos e AB S contro l uni tconnectors , i f necessary , substi -tute a known-goo d AB S contro lunit an d recheck . Repai

r shor t t o bod y groun d in

th e (+ ) o r (- ) circui t wir e betwee n

the AB S contro l uni t an d th eappropriat e whee l sensor .

Replac e th e appropriat e whee l

sensor .

Repair ope n i n the (+) o r (- )

circui t wire , o r shor t t o th e (+ )

circui t wir e i n th e (- ) circui t

wir e betwee n th e AB S contro l

uni t an d th e appropriat e whee l

sensor .

Replac e th e appropriat e whee l

sensor . AB

S CONTRO L UNI T 22 P CONNECTO R

Wir e sid e o f femal e terminal s

ProCarManuals.com

Page 1179 of 1954

Troubleshooting

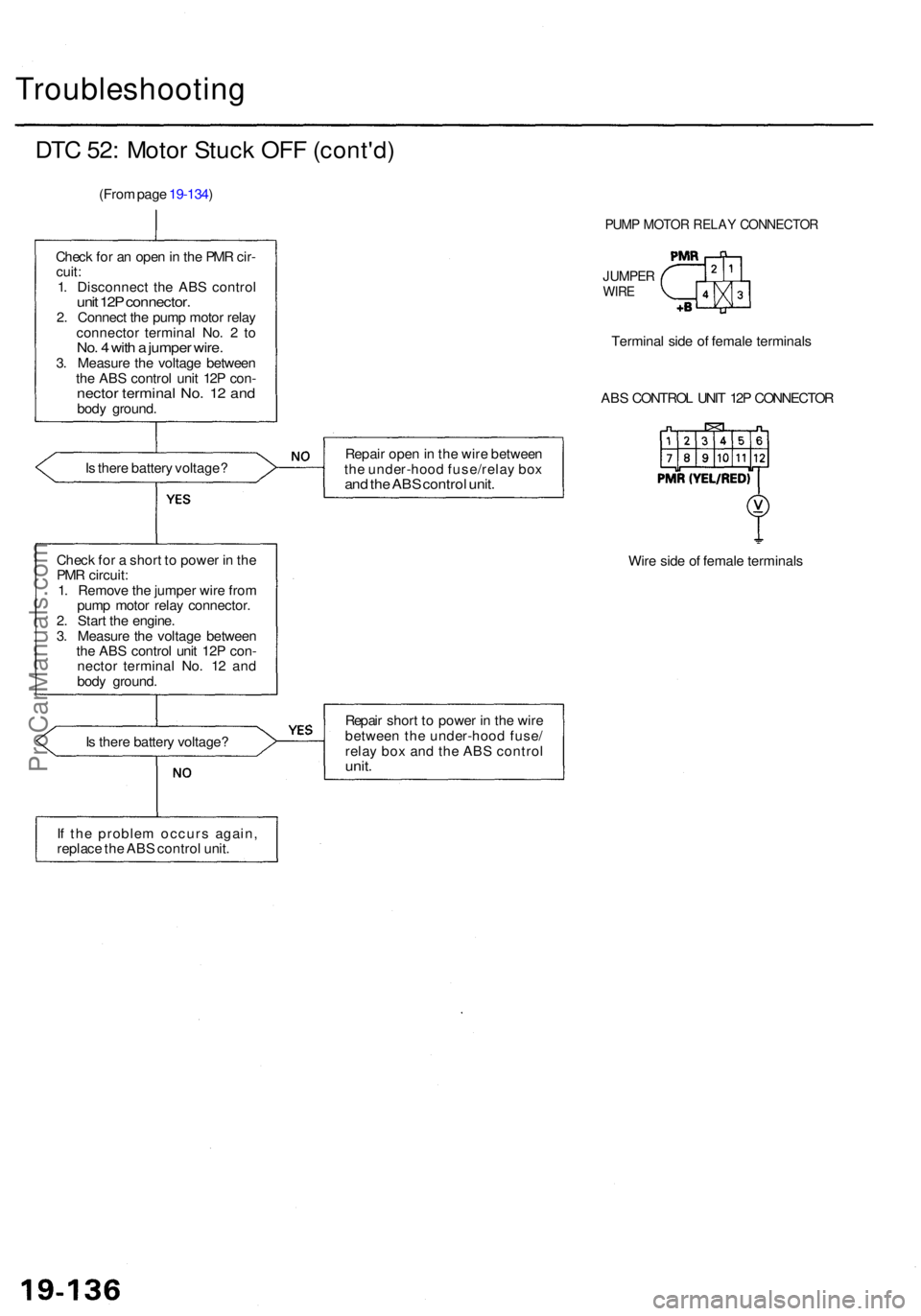

DTC 52 : Moto r Stuc k OF F (cont'd )

(From pag e 19-134 )

Chec k fo r a n ope n in th e PM R cir -

cuit :

1 . Disconnec t th e AB S contro l

unit 12 P connector .2. Connec t th e pum p moto r rela y

connecto r termina l No . 2 to

No . 4 wit h a jumpe r wire .3. Measur e th e voltag e betwee n

th e AB S contro l uni t 12 P con -

necto r termina l No . 1 2 an dbod y ground .

I s ther e batter y voltage ?

Chec k fo r a shor t t o powe r i n th e

PM R circuit :

1 . Remov e th e jumpe r wir e fro m

pum p moto r rela y connector .

2 . Star t th e engine .

3 . Measur e th e voltag e betwee n

th e AB S contro l uni t 12 P con -

necto r termina l No . 1 2 an d

bod y ground . Repai

r ope n in th e wir e betwee n

th e under-hoo d fuse/rela y bo x

and th e AB S contro l unit .

Wire sid e o f femal e terminal s

I s ther e batter y voltage ? Repai

r shor t t o powe r i n th e wir e

betwee n th e under-hoo d fuse /

rela y bo x an d th e AB S contro l

unit.

If th e proble m occur s again ,

replac e th e AB S contro l unit .

PUM P MOTO R RELA Y CONNECTO R

JUMPERWIRE

Termina l sid e o f femal e terminal s

AB S CONTRO L UNI T 12 P CONNECTO R

ProCarManuals.com

Page 1186 of 1954

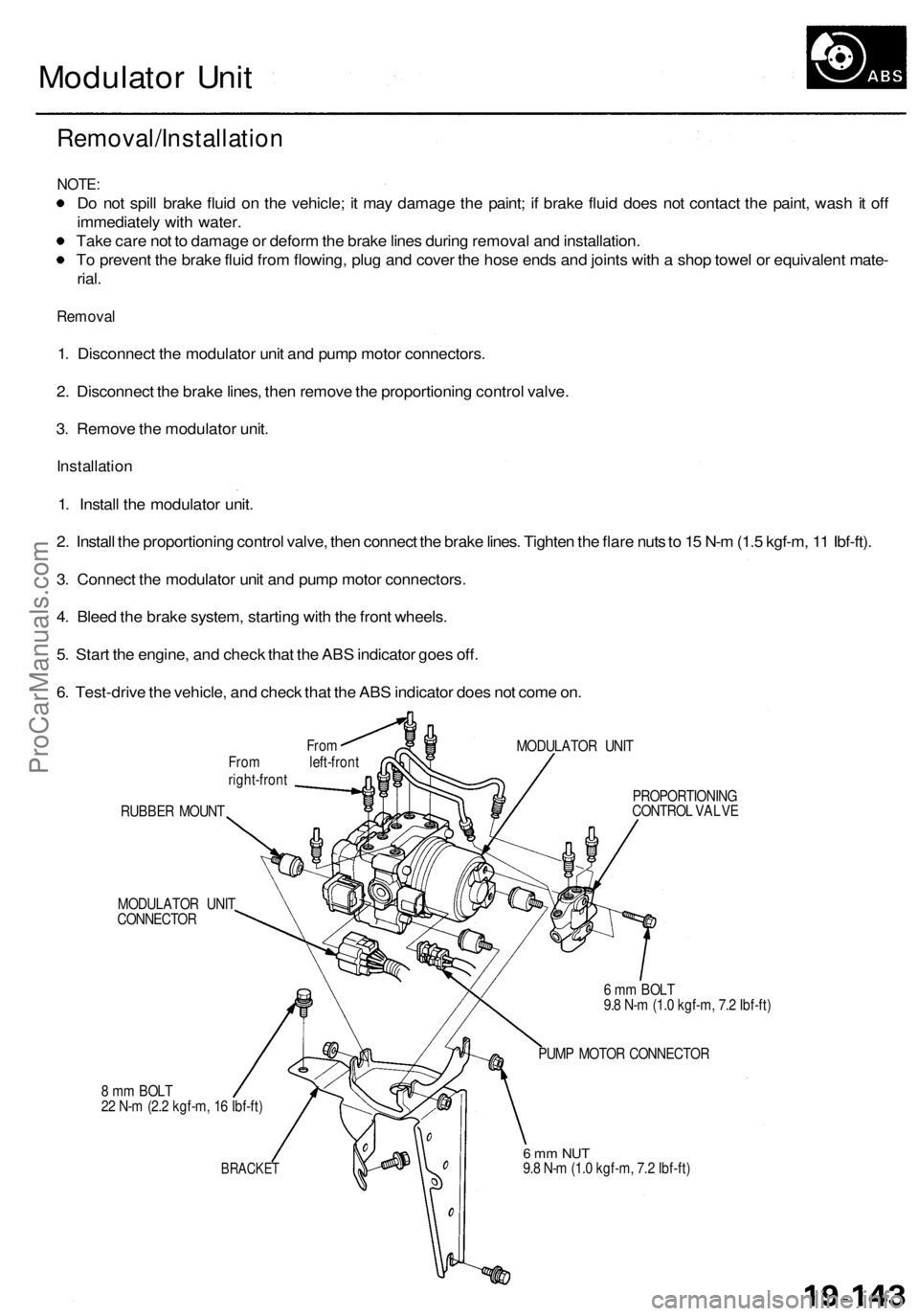

Modulator Unit

Removal/Installation

NOTE:

Do not spill brake fluid on the vehicle; it may damage the paint; if brake fluid does not contact the paint, wash it off

immediately with water.

Take care not to damage or deform the brake lines during removal and installation.

To prevent the brake fluid from flowing, plug and cover the hose ends and joints with a shop towel or equivalent mate-

rial.

Removal

1. Disconnect the modulator unit and pump motor connectors.

2. Disconnect the brake lines, then remove the proportioning control valve.

3. Remove the modulator unit.

Installation

1. Install the modulator unit.

2. Install the proportioning control valve, then connect the brake lines. Tighten the flare nuts to 15 N-m (1.5 kgf-m, 11 Ibf-ft).

3. Connect the modulator unit and pump motor connectors.

4. Bleed the brake system, starting with the front wheels.

5. Start the engine, and check that the ABS indicator goes off.

6. Test-drive the vehicle, and check that the ABS indicator does not come on.

From

From left-front

right-front

MODULATOR UNIT

RUBBER MOUNT

MODULATOR UNIT

CONNECTOR

8 mm BOLT

22 N-m (2.2 kgf-m, 16 Ibf-ft)

BRACKET

PROPORTIONING

CONTROL VALVE

6 mm BOLT

9.8 N-m (1.0 kgf-m, 7.2 Ibf-ft)

PUMP MOTOR CONNECTOR

6 mm NUT

9.8 N-m (1.0 kgf-m, 7.2 Ibf-ft)ProCarManuals.com

Page 1191 of 1954

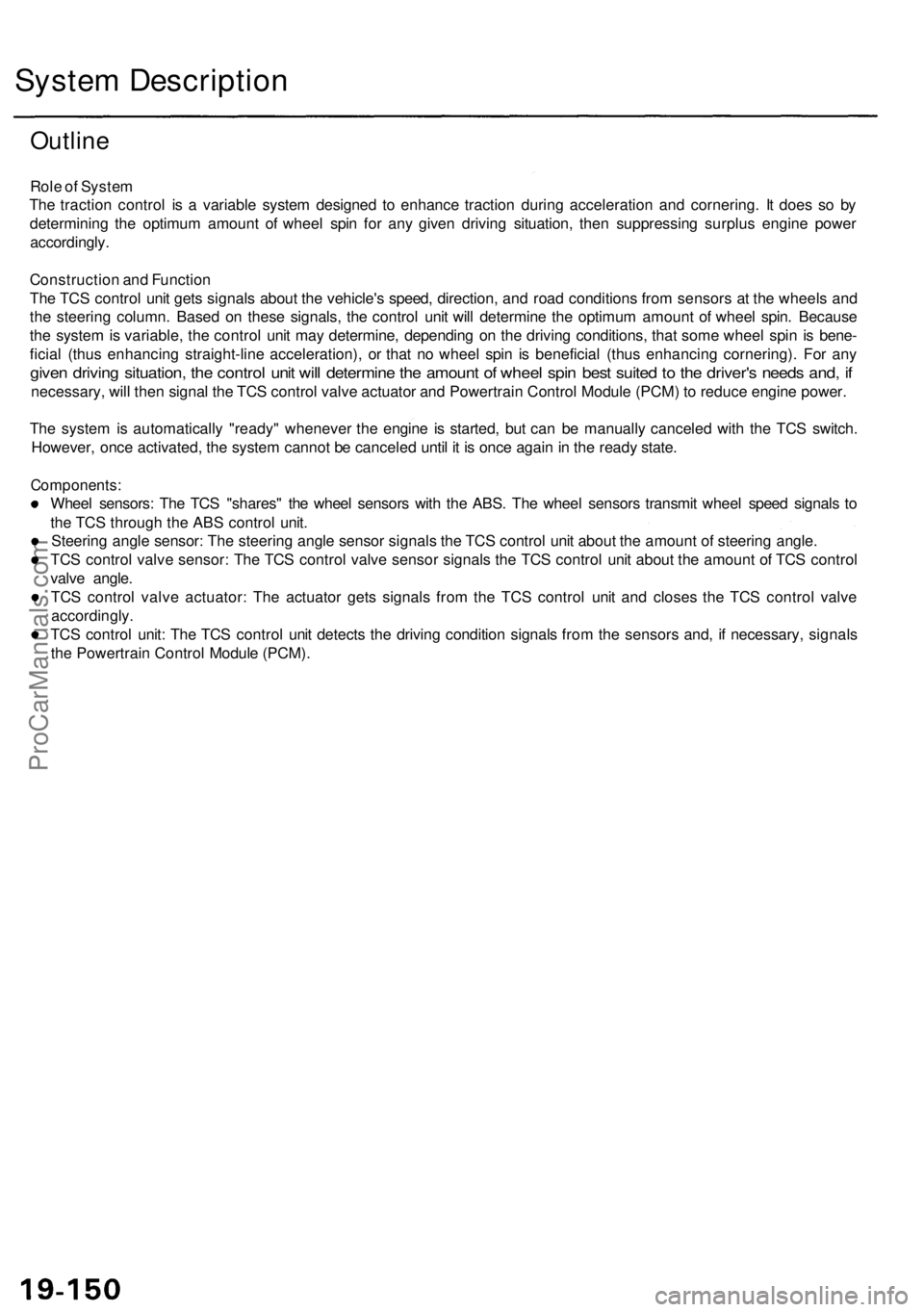

System Description

Outline

Role of System

The traction control is a variable system designed to enhance traction during acceleration and cornering. It does so by

determining the optimum amount of wheel spin for any given driving situation, then suppressing surplus engine power

accordingly.

Construction and Function

The TCS control unit gets signals about the vehicle's speed, direction, and road conditions from sensors at the wheels and

the steering column. Based on these signals, the control unit will determine the optimum amount of wheel spin. Because

the system is variable, the control unit may determine, depending on the driving conditions, that some wheel spin is bene-

ficial (thus enhancing straight-line acceleration), or that no wheel spin is beneficial (thus enhancing cornering). For any

given driving situation, the control unit will determine the amount of wheel spin best suited to the driver's needs and, if

necessary, will then signal the TCS control valve actuator and Powertrain Control Module (PCM) to reduce engine power.

The system is automatically "ready" whenever the engine is started, but can be manually canceled with the TCS switch.

However, once activated, the system cannot be canceled until it is once again in the ready state.

Components:

Wheel sensors: The TCS "shares" the wheel sensors with the ABS. The wheel sensors transmit wheel speed signals to

the TCS through the ABS control unit.

Steering angle sensor: The steering angle sensor signals the TCS control unit about the amount of steering angle.

TCS control valve sensor: The TCS control valve sensor signals the TCS control unit about the amount of TCS control

valve angle.

TCS control valve actuator: The actuator gets signals from the TCS control unit and closes the TCS control valve

accordingly.

TCS control unit: The TCS control unit detects the driving condition signals from the sensors and, if necessary, signals

the Powertrain Control Module (PCM).ProCarManuals.com

Page 1192 of 1954

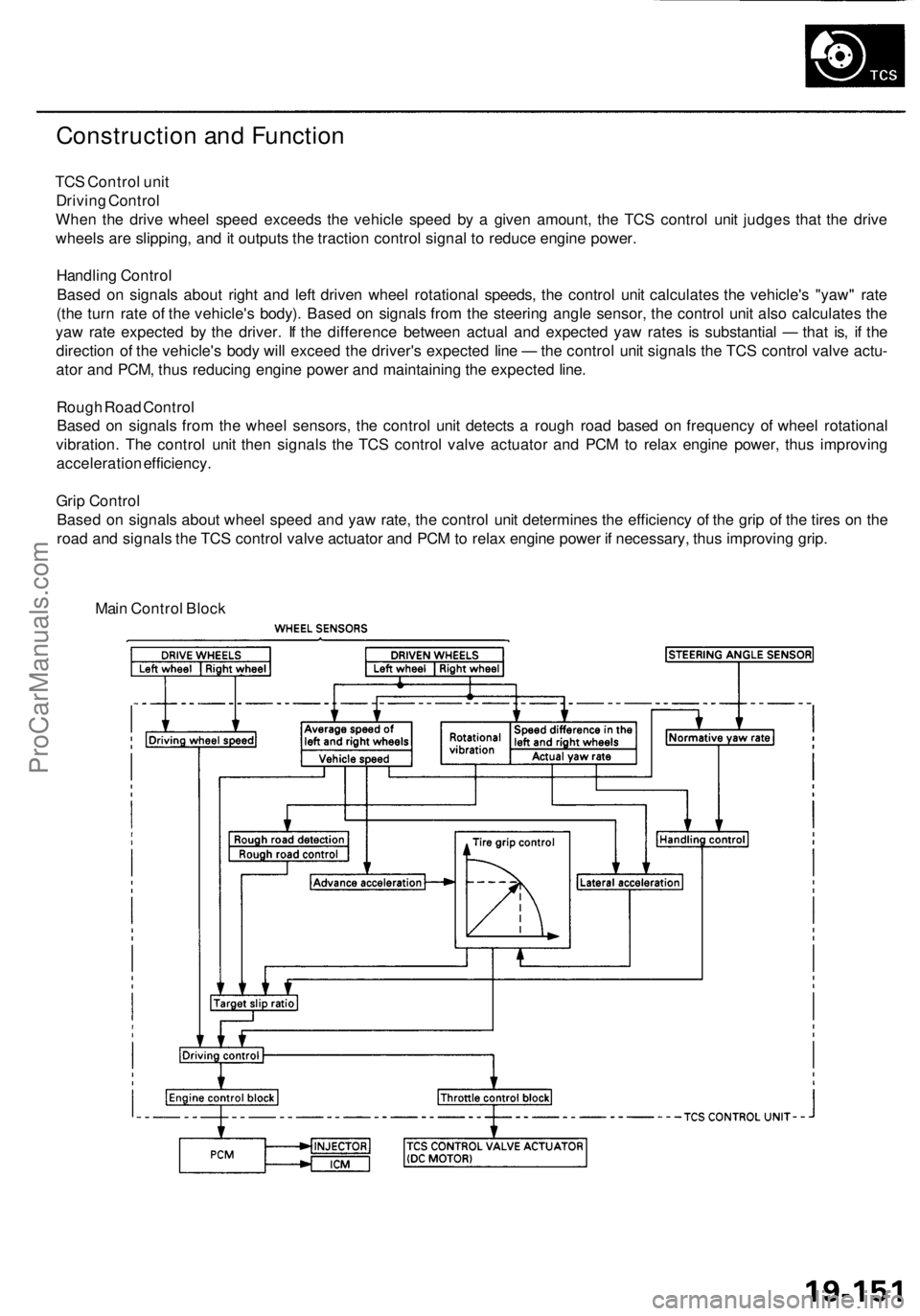

Construction and Function

TCS Control unit

Driving Control

When the drive wheel speed exceeds the vehicle speed by a given amount, the TCS control unit judges that the drive

wheels are slipping, and it outputs the traction control signal to reduce engine power.

Handling Control

Based on signals about right and left driven wheel rotational speeds, the control unit calculates the vehicle's "yaw" rate

(the turn rate of the vehicle's body). Based on signals from the steering angle sensor, the control unit also calculates the

yaw rate expected by the driver. If the difference between actual and expected yaw rates is substantial — that is, if the

direction of the vehicle's body will exceed the driver's expected line — the control unit signals the TCS control valve actu-

ator and PCM, thus reducing engine power and maintaining the expected line.

Rough Road Control

Based on signals from the wheel sensors, the control unit detects a rough road based on frequency of wheel rotational

vibration. The control unit then signals the TCS control valve actuator and PCM to relax engine power, thus improving

acceleration efficiency.

Grip Control

Based on signals about wheel speed and yaw rate, the control unit determines the efficiency of the grip of the tires on the

road and signals the TCS control valve actuator and PCM to relax engine power if necessary, thus improving grip.

Main Control BlockProCarManuals.com

Page 1194 of 1954

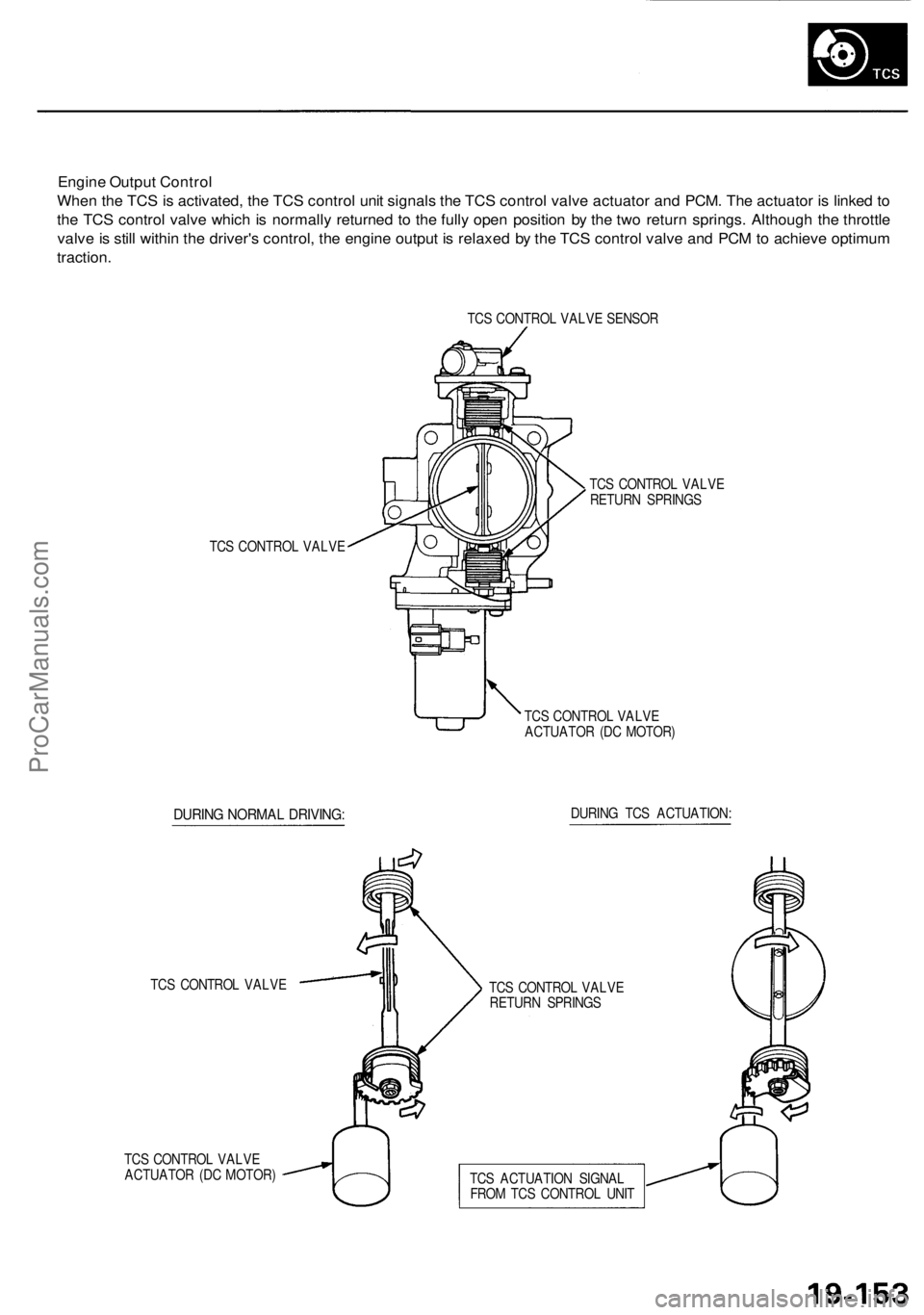

Engine Output Control

When the TCS is activated, the TCS control unit signals the TCS control valve actuator and PCM. The actuator is linked to

the TCS control valve which is normally returned to the fully open position by the two return springs. Although the throttle

valve is still within the driver's control, the engine output is relaxed by the TCS control valve and PCM to achieve optimum

traction.

TCS CONTROL VALVE SENSOR

TCS CONTROL VALVE

TCS CONTROL VALVE

RETURN SPRINGS

TCS CONTROL VALVE

ACTUATOR (DC MOTOR)

DURING NORMAL DRIVING:

DURING TCS ACTUATION:

TCS CONTROL VALVE

TCS CONTROL VALVE

ACTUATOR (DC MOTOR)

TCS CONTROL VALVE

RETURN SPRINGS

TCS ACTUATION SIGNAL

FROM TCS CONTROL UNITProCarManuals.com

Page 1196 of 1954

TCS CONTROL UNIT 20P CONNECTOR

Wire side of female terminals

VB: Battery Voltage

Terminal

number

1

2

4

5

6

9

10

11

12

13

14

15

16

17

20

Wire

color

BLK/YEL

GRN/RED

BLU

PNK/BLU

BLK/WHT

BLK

BRN/WHT

GRN/WHT

BLU

GRN/ORN

BLK/ORN

BRN/BLK

WHT/BLU

BLU/GRY

GRN

BRN

Terminal sign

(Terminal name)

IG1

(Ignition 1)

PARK

(Parking)

SCS

(Service check

signal)

STR-GND

(Steering ground)

AT-SHIFT

(AT shift)

FSR

(Fail-safe relay)

PMG

(Power motor

Ground)

VPM

(Voltage power

motor)

STOP

(Stop)

NEP (Engine

speed pulse)

BARO

(Barometric)

TC-FC

(Traction control

fuel cut)

LG2

(Logic ground 2)

STR-VCC (Steer-

ing power supply)

WARN2

(Warning 2)

SH-MOT

(Shield motor)

MOT +

(Motor +)

MOT-

(Motor -)

Description

Detects ignition switch

IG1 signal

Detects parking brake

switch signal

Detects service check

connector signal

(Diagnostic trouble

code indication)

Ground for the steering

angle sensor

Detects A/T shift posi-

tion signal

Drives fail-safe relay

Power ground for the

TCS control valve

actuator motor

Power source for the

TCS control valve

actuator motor

Detects brake pedal

position switch signal

Detects engine speed

signal

Detects barometric

sensor signal

TCS Fl, Fuel cut

(torque down) signal

Ground for the logic

circuit

Power source for the

steering angle sensor

Drives TCS indicator light

(The indicator light comes

on by the self-bias)

Shield for the TCS con-

trol valve actuator motor

Drives TCS control

valve actuator motor

Drives TCS control

valve actuator motor

Measurement

terminals

1-GND

2

3-GND

4-GND

5-GND

6-GND

9-GND

10-GND

11-GND

12-GND

13-GND

14-GND

15-GND

16-GND

17-GND

19-20

20-19

Voltage

Conditions

(Ignition Switch ON (II))

Depress the parking

brake pedal.

Release the parking

brake pedal.

SCS service connector

connected.

SCS service connector

disconnected.

Shift the transmission

to position, then

start the engine.

Start the engine.

Start the engine.

Brake pedal depressed.

Brake pedal released.

Engine idling

TCS is functioning,

(maximum fuel cut)

TCS is not functioning.

Indicator light ON

Indicator light OFF

TCS is functioning.

TCS is not functioning.

TCS is functioning.

TCS is not functioning.

Output

voltage

VB

Below 0.6 V

VB

0V

5V

Below 0.3V

About 4V

(5V 0V)

VB

1.5V

Below 0.3 V

0V

VB

VB

0V

About 6V

(12V

0V)

About 3 V

About 1.5V

About 4.5 V

(5 V,

PWM)

Below 0.3V

About 5 V

About 2 V

VB

VB

0V

VB

0VProCarManuals.com