engine ACURA RL KA9 1996 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 802 of 1954

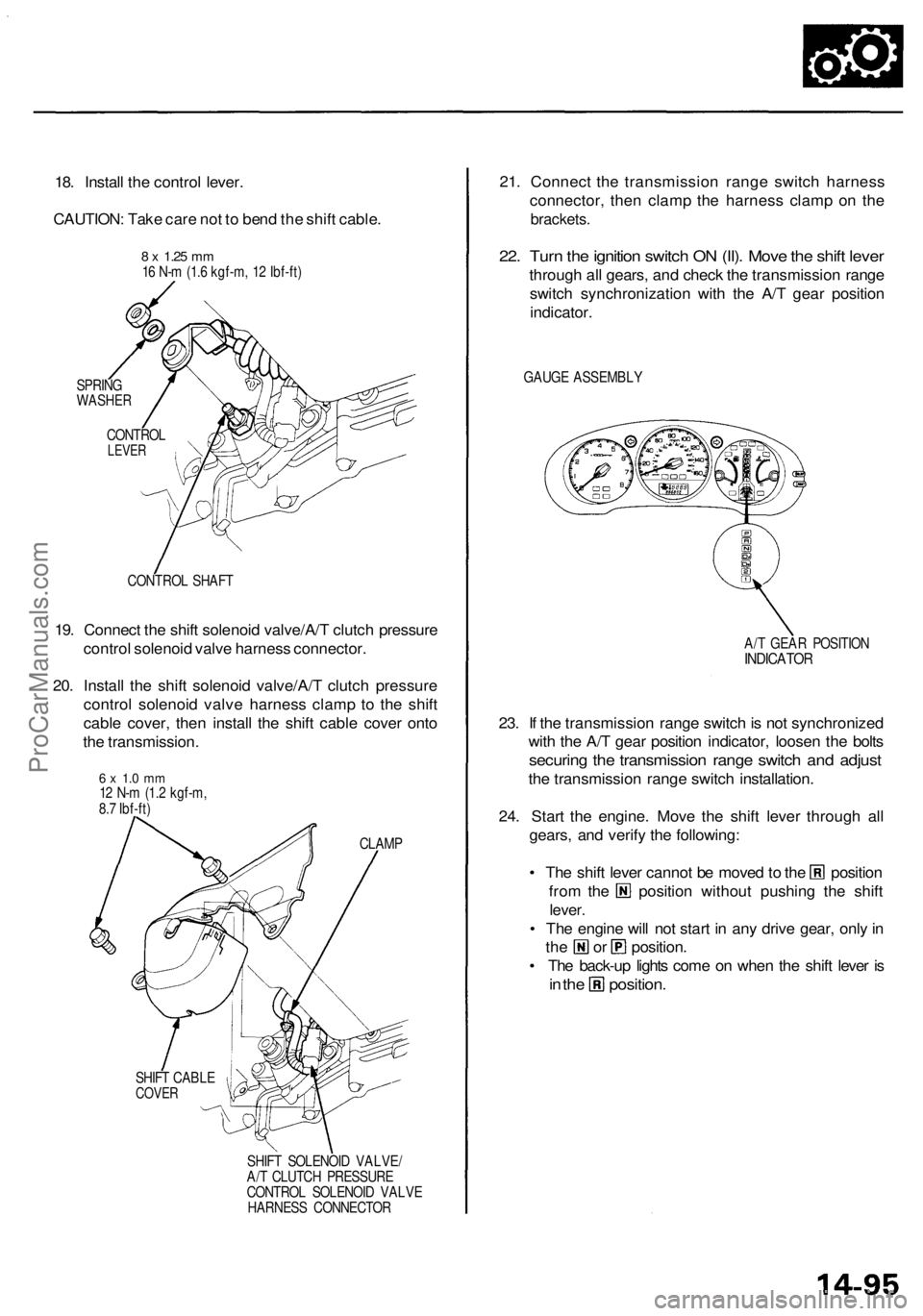

18. Install the control lever.

CAUTION: Take care not to bend the shift cable.

SPRING

WASHER

CONTROL SHAFT

19. Connect the shift solenoid valve/A/T clutch pressure

control solenoid valve harness connector.

20. Install the shift solenoid valve/A/T clutch pressure

control solenoid valve harness clamp to the shift

cable cover, then install the shift cable cover onto

the transmission.

CLAMP

SHIFT CABLE

COVER

SHIFT SOLENOID VALVE/

A/T CLUTCH PRESSURE

CONTROL SOLENOID VALVE

HARNESS CONNECTOR

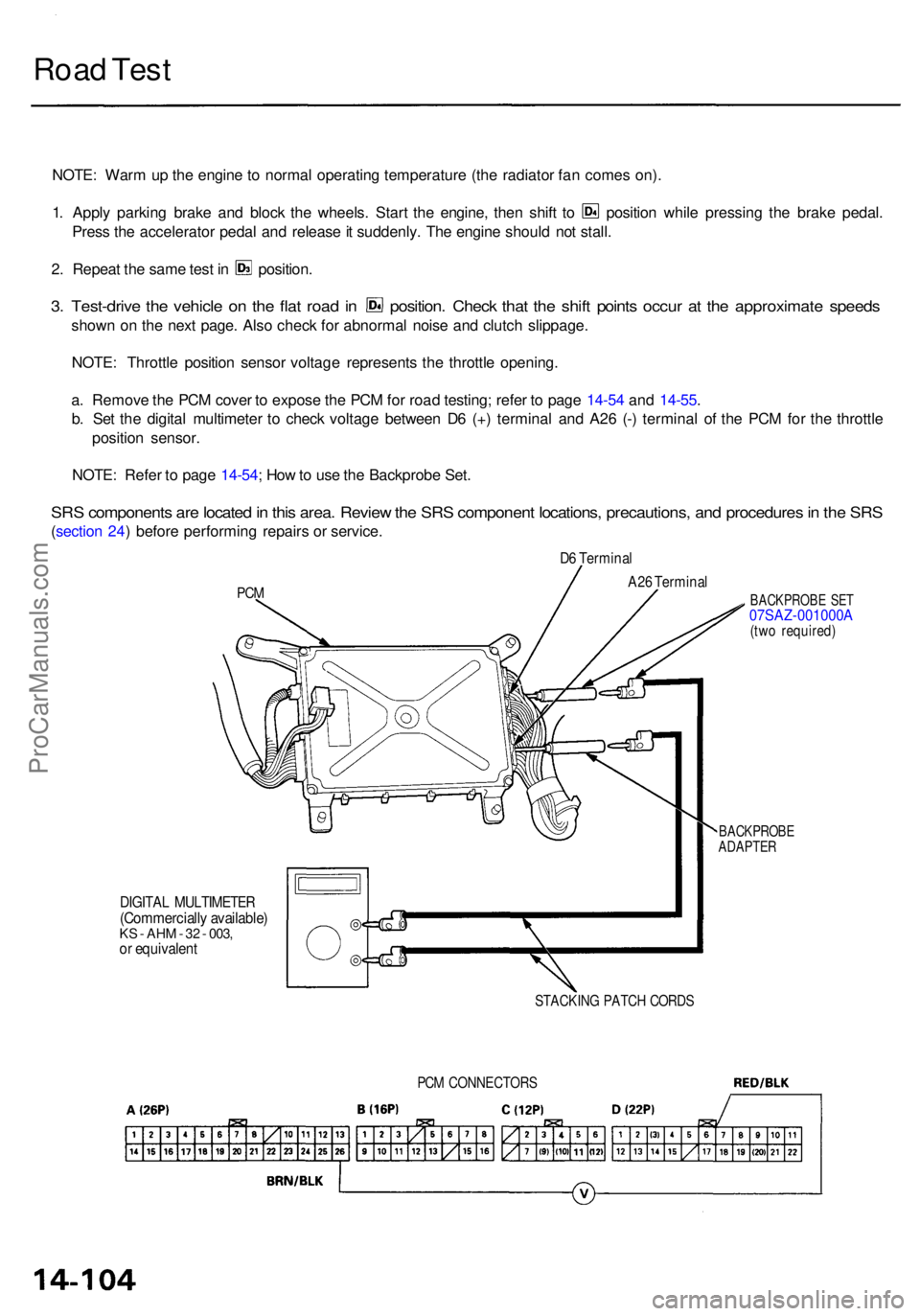

21. Connect the transmission range switch harness

connector, then clamp the harness clamp on the

brackets.

22. Turn the ignition switch ON (II). Move the shift lever

through all gears, and check the transmission range

switch synchronization with the A/T gear position

indicator.

GAUGE ASSEMBLY

A/T GEAR POSITION

INDICATOR

23. If the transmission range switch is not synchronized

with the A/T gear position indicator, loosen the bolts

securing the transmission range switch and adjust

the transmission range switch installation.

24. Start the engine. Move the shift lever through all

gears, and verify the following:

• The shift lever cannot be moved to the position

from the position without pushing the shift

lever.

• The engine will not start in any drive gear, only in

the or position.

• The back-up lights come on when the shift lever is

in the position.

8 x

1.25

mm

16 N-m (1.6 kgf-m, 12 Ibf-ft)

CONTROL

LEVER

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)ProCarManuals.com

Page 811 of 1954

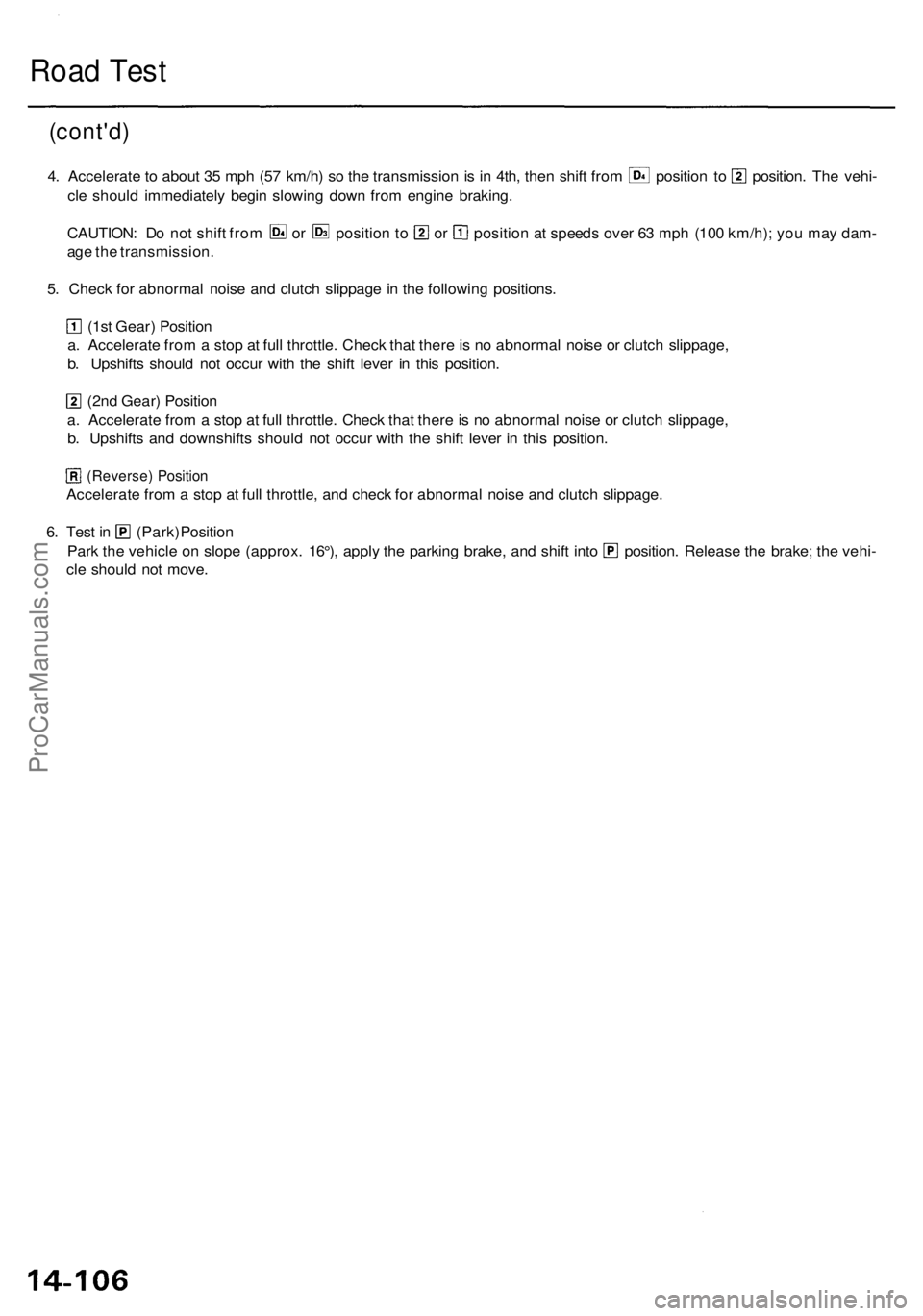

Road Tes t

NOTE : War m u p th e engin e to norma l operatin g temperatur e (th e radiato r fa n come s on) .

1. Appl y parkin g brak e an d bloc k th e wheels . Star t th e engine , the n shif t t o positio n whil e pressin g th e brak e pedal .

Pres s th e accelerato r peda l an d releas e it suddenly . Th e engin e shoul d no t stall .

2. Repea t th e sam e tes t i n position .

3. Test-driv e th e vehicl e o n th e fla t roa d in position . Chec k tha t th e shif t point s occu r a t th e approximat e speed s

shown o n th e nex t page . Als o chec k fo r abnorma l nois e an d clutc h slippage .

NOTE : Throttl e positio n senso r voltag e represent s th e throttl e opening .

a . Remov e th e PC M cove r t o expos e th e PC M fo r roa d testing ; refe r t o pag e 14-5 4 an d 14-55 .

b . Se t th e digita l multimete r t o chec k voltag e betwee n D 6 (+ ) termina l an d A2 6 (- ) termina l o f th e PC M fo r th e throttl e

positio n sensor .

NOTE : Refe r t o pag e 14-54 ; Ho w to us e th e Backprob e Set .

SRS component s ar e locate d in thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s in th e SR S

(sectio n 24 ) befor e performin g repair s o r service .

PCM

D6 Termina l

DIGITAL MULTIMETE R(Commercially available )KS - AH M - 3 2 - 003 ,or equivalen t

BACKPROB E SE T07SAZ-001000A(two required )

BACKPROB EADAPTER

STACKIN G PATC H CORD S

A26 Termina l

PCM CONNECTOR S

ProCarManuals.com

Page 813 of 1954

Road Tes t

(cont'd )

4. Accelerat e to abou t 3 5 mp h (5 7 km/h ) s o th e transmissio n is i n 4th , the n shif t fro m positio n t o position . Th e vehi -

cl e shoul d immediatel y begi n slowin g dow n fro m engine braking .

CAUTION : D o no t shif t fro m o r positio n to o r positio n a t speed s ove r 6 3 mp h (10 0 km/h) ; yo u ma y dam -

ag e th e transmission .

5 . Chec k fo r abnorma l nois e an d clutc h slippag e in th e followin g positions .

(1st Gear ) Positio n

a . Accelerat e fro m a sto p a t ful l throttle . Chec k tha t ther e is n o abnorma l nois e o r clutc h slippage ,

b . Upshift s shoul d no t occu r wit h th e shif t leve r i n thi s position .

(2nd Gear ) Positio n

a . Accelerat e fro m a sto p a t ful l throttle . Chec k tha t ther e is n o abnorma l nois e o r clutc h slippage ,

b . Upshift s an d downshift s shoul d no t occu r wit h th e shif t leve r i n thi s position .

(Reverse ) Positio n

Accelerat e fro m a sto p a t ful l throttle , an d chec k fo r abnorma l nois e an d clutc h slippage .

6. Tes t i n (Park ) Positio n

Park th e vehicl e o n slop e (approx . 16°) , appl y th e parkin g brake , an d shif t int o position . Releas e th e brake ; th e vehi -

cl e shoul d no t move .

ProCarManuals.com

Page 814 of 1954

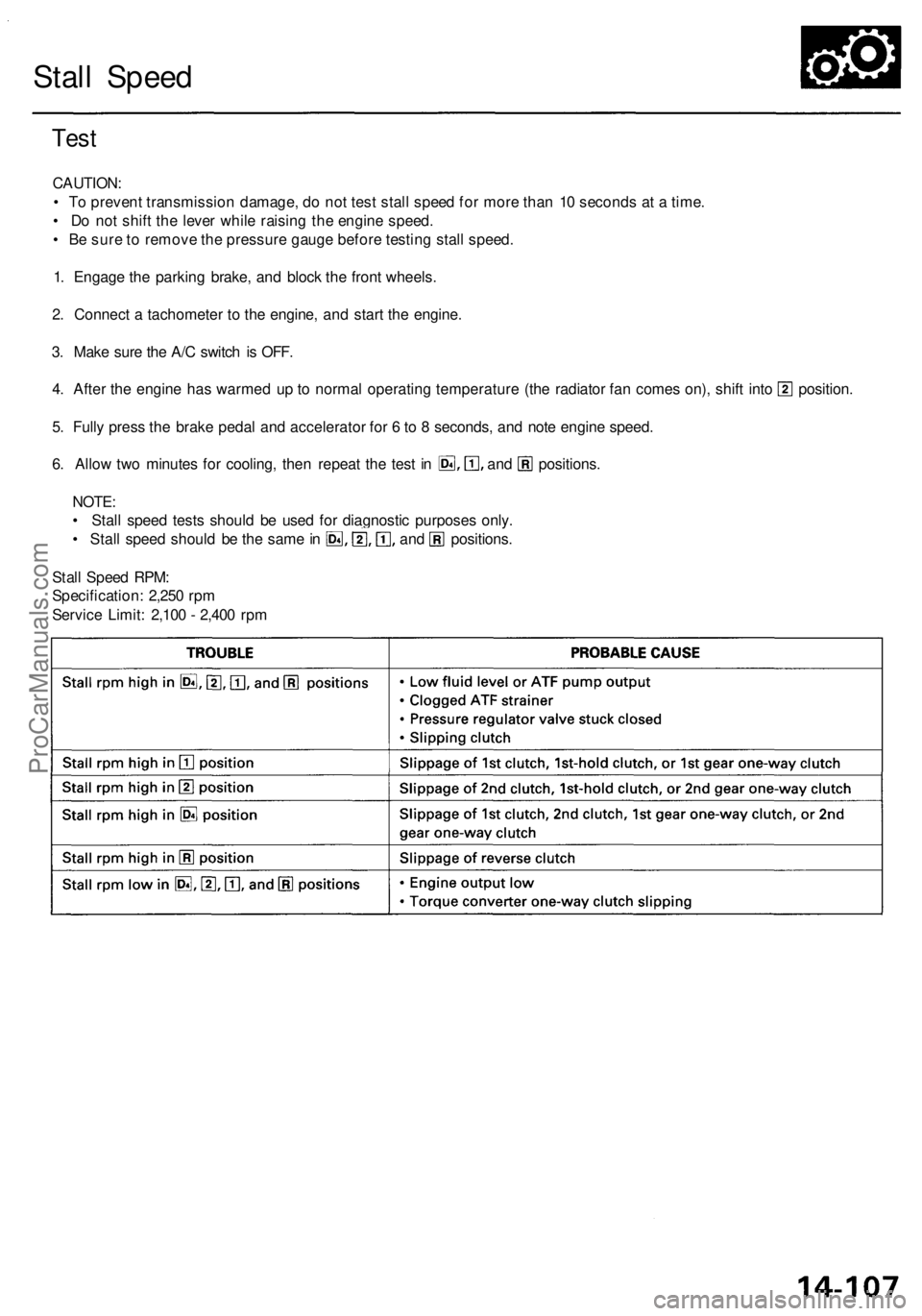

Stall Speed

Test

CAUTION:

• To prevent transmission damage, do not test stall speed for more than 10 seconds at a time.

• Do not shift the lever while raising the engine speed.

• Be sure to remove the pressure gauge before testing stall speed.

1. Engage the parking brake, and block the front wheels.

2. Connect a tachometer to the engine, and start the engine.

3. Make sure the A/C switch is OFF.

4. After the engine has warmed up to normal operating temperature (the radiator fan comes on), shift into position.

5. Fully press the brake pedal and accelerator for 6 to 8 seconds, and note engine speed.

6. Allow two minutes for cooling, then repeat the test in and positions.

NOTE:

• Stall speed tests should be used for diagnostic purposes only.

• Stall speed should be the same in and positions.

Stall Speed RPM:

Specification: 2,250 rpm

Service Limit: 2,100 - 2,400 rpmProCarManuals.com

Page 815 of 1954

Fluid Leve l

Checking/Changin g

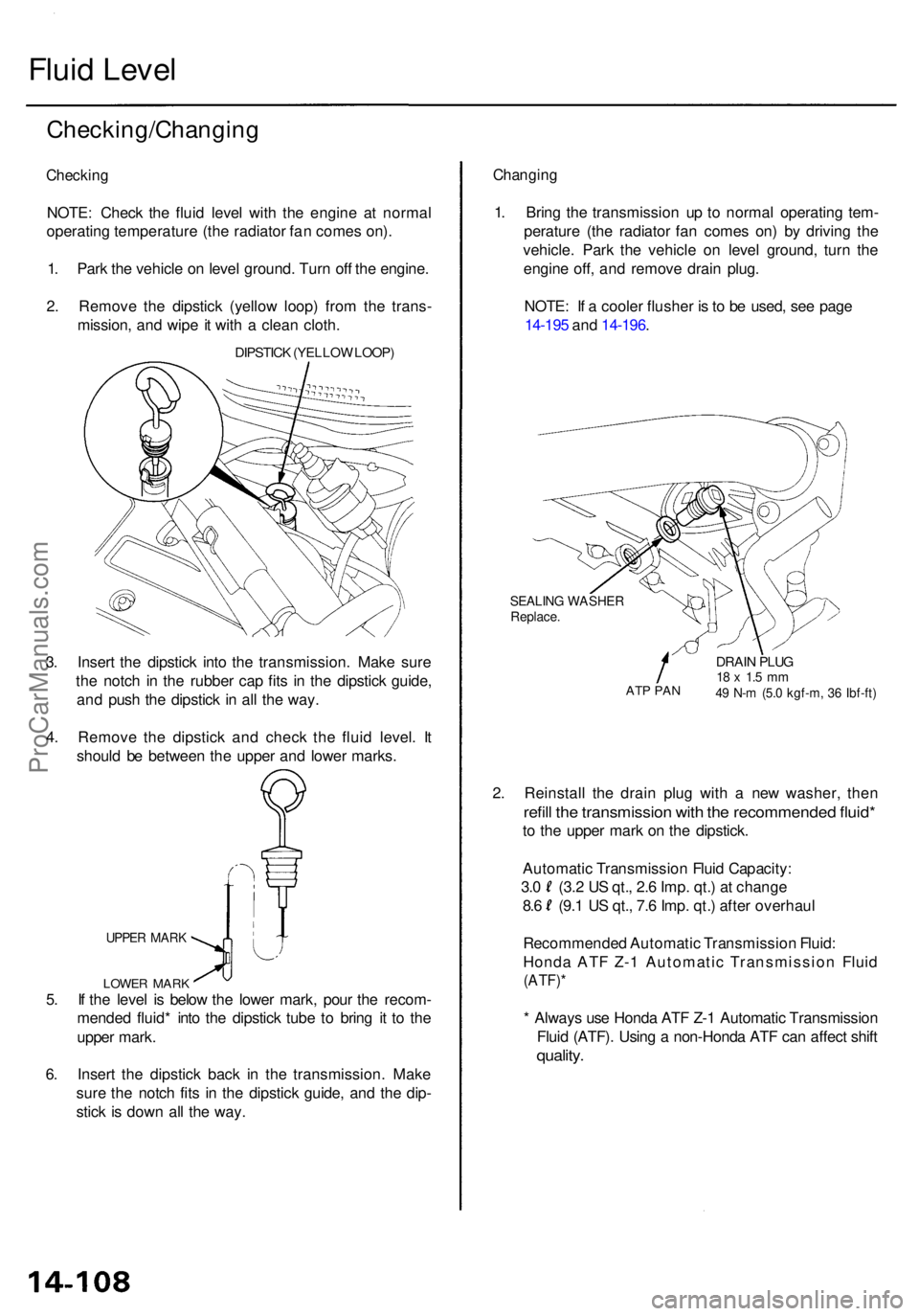

Checking

NOTE: Chec k th e flui d leve l wit h th e engin e a t norma l

operatin g temperatur e (th e radiato r fa n come s on) .

1 . Par k th e vehicl e o n leve l ground . Tur n of f th e engine .

2 . Remov e th e dipstic k (yello w loop ) fro m th e trans -

mission , an d wip e it wit h a clea n cloth .

DIPSTIC K (YELLO W LOOP )

3. Inser t th e dipstic k int o th e transmission . Mak e sur e

th e notc h i n th e rubbe r ca p fit s i n th e dipstic k guide ,

an d pus h th e dipstic k i n al l th e way .

4 . Remov e th e dipstic k an d chec k th e flui d level . I t

shoul d b e betwee n th e uppe r an d lowe r marks .

UPPER MAR K

5. I f th e leve l i s belo w th e lowe r mark , pou r th e recom -

mende d fluid * int o th e dipstic k tub e t o brin g i t t o th e

uppe r mark .

6 . Inser t th e dipstic k bac k i n th e transmission . Mak e

sur e th e notc h fit s i n th e dipstic k guide , an d th e dip -

stic k i s dow n al l th e way .

Changin g

1. Brin g th e transmissio n u p t o norma l operatin g tem -

peratur e (th e radiato r fa n come s on ) b y drivin g th e

vehicle . Par k th e vehicl e o n leve l ground , tur n th e

engin e off , an d remov e drai n plug .

NOTE : I f a coole r flushe r i s to b e used , se e pag e

14-19 5 an d 14-196 .

SEALIN G WASHE RReplace.

ATP PA N

DRAI N PLU G18 x 1. 5 m m49 N- m (5. 0 kgf-m , 3 6 Ibf-ft )

2. Reinstal l th e drai n plu g wit h a ne w washer , the n

refill th e transmissio n wit h th e recommende d fluid *

to th e uppe r mar k o n th e dipstick .

Automati c Transmissio n Flui d Capacity :

3.0 (3. 2 U S qt. , 2. 6 Imp . qt. ) a t chang e

8.6 (9. 1 U S qt. , 7. 6 Imp . qt. ) afte r overhau l

Recommende d Automati c Transmissio n Fluid :

Hond a AT F Z- 1 Automati c Transmissio n Flui d

(ATF) *

* Alway s us e Hond a AT F Z- 1 Automati c Transmissio n

Flui d (ATF) . Usin g a non-Hond a AT F ca n affec t shif t

quality .

LOWE R MAR K

ProCarManuals.com

Page 817 of 1954

Pressure Testing

(cont'd)

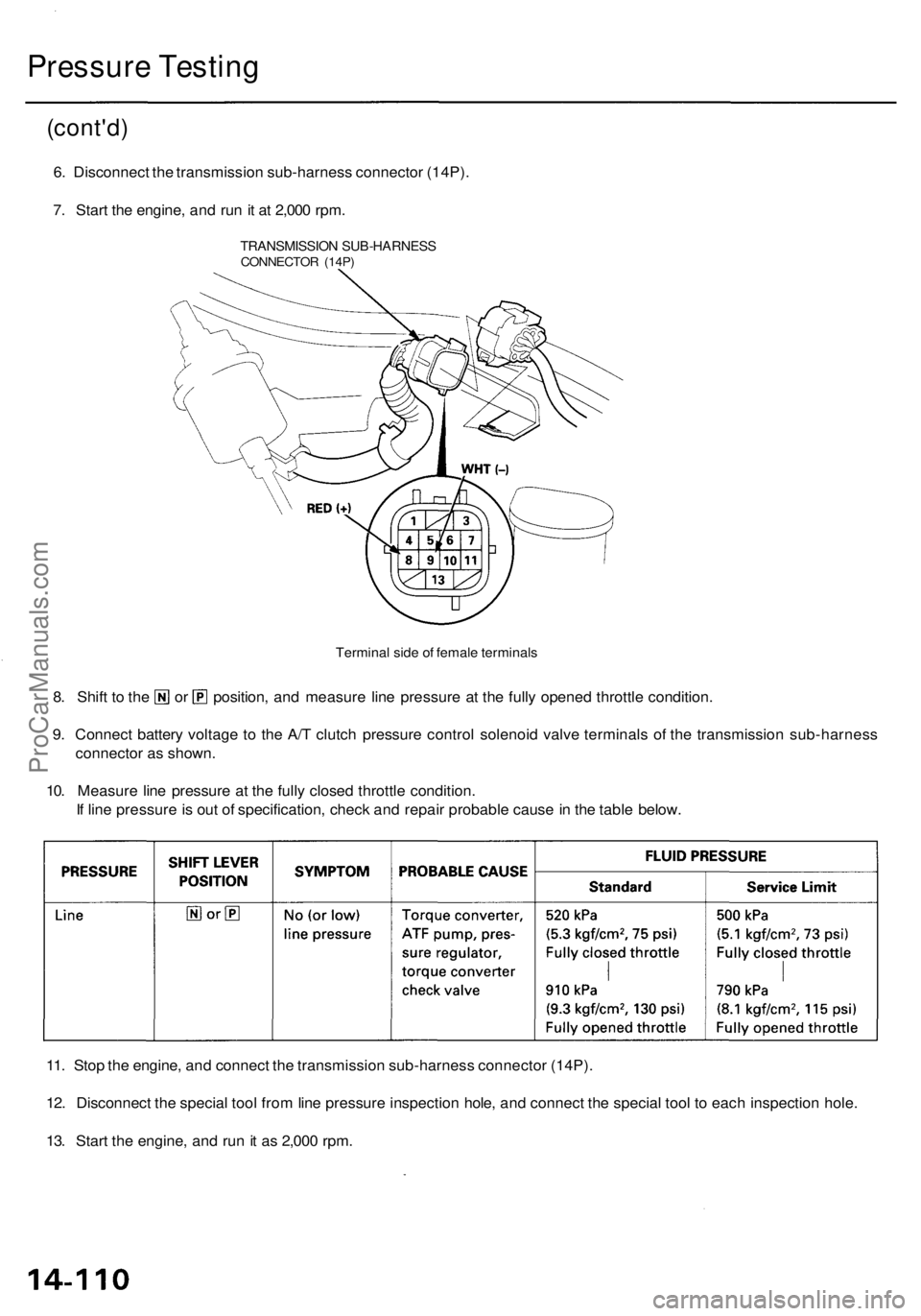

6. Disconnect the transmission sub-harness connector (14P).

7. Start the engine, and run it at 2,000 rpm.

Terminal side of female terminals

8. Shift to the or position, and measure line pressure at the fully opened throttle condition.

9. Connect battery voltage to the A/T clutch pressure control solenoid valve terminals of the transmission sub-harness

connector as shown.

10. Measure line pressure at the fully closed throttle condition.

If line pressure is out of specification, check and repair probable cause in the table below.

11. Stop the engine, and connect the transmission sub-harness connector (14P).

12. Disconnect the special tool from line pressure inspection hole, and connect the special tool to each inspection hole.

13. Start the engine, and run it as 2,000 rpm.

TRANSMISSION SUB-HARNESS

CONNECTOR (14P)ProCarManuals.com

Page 826 of 1954

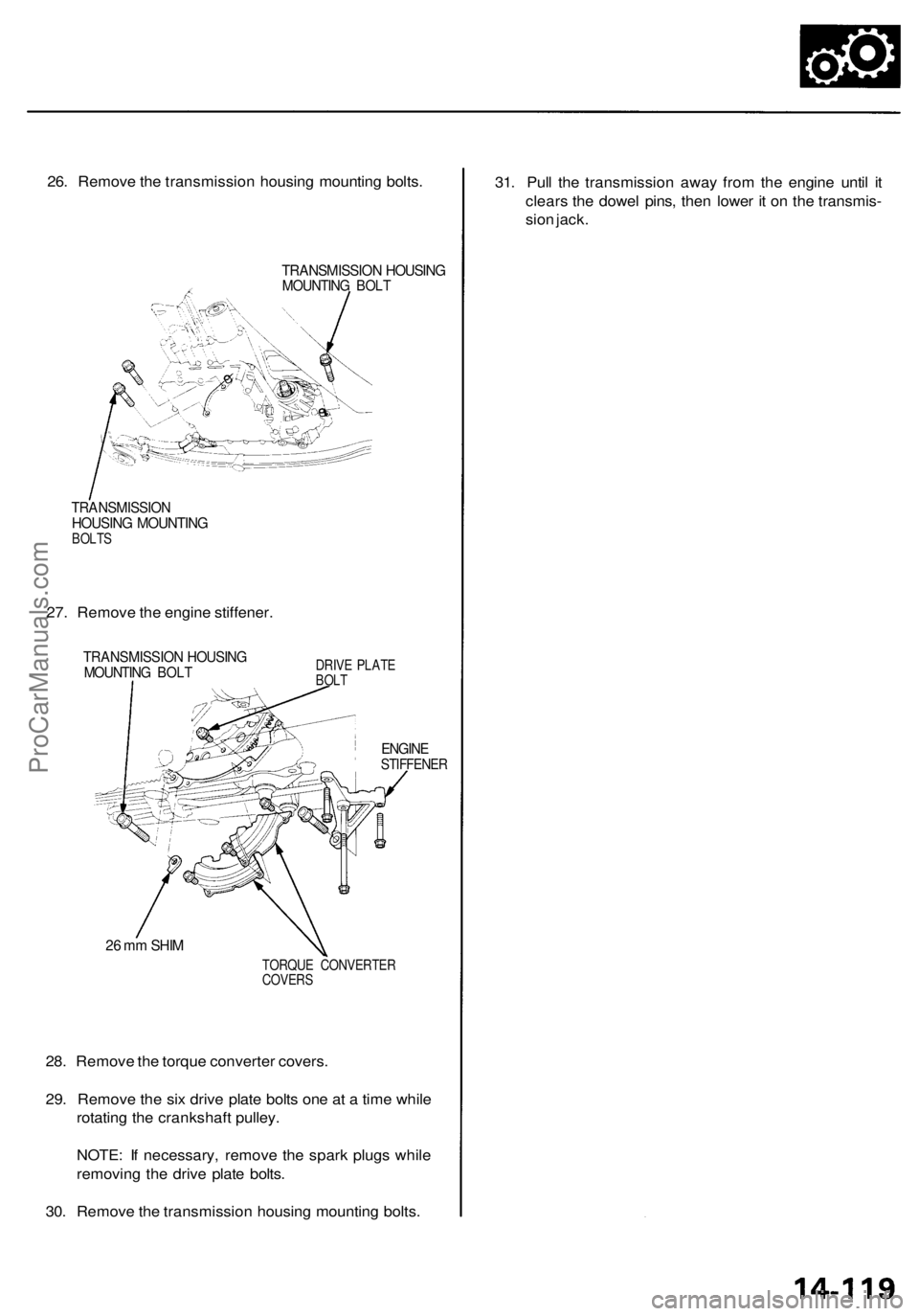

26. Remove the transmission housing mounting bolts.

TRANSMISSION HOUSING

MOUNTING BOLT

TRANSMISSION

HOUSING MOUNTING

BOLTS

27. Remove the engine stiffener.

TRANSMISSION HOUSING

MOUNTING BOLT

DRIVE PLATE

BOLT

ENGINE

STIFFENER

26 mm SHIM

TORQUE CONVERTER

COVERS

28. Remove the torque converter covers.

29. Remove the six drive plate bolts one at a time while

rotating the crankshaft pulley.

NOTE: If necessary, remove the spark plugs while

removing the drive plate bolts.

30. Remove the transmission housing mounting bolts.

31. Pull the transmission away from the engine until it

clears the dowel pins, then lower it on the transmis-

sion jack.ProCarManuals.com

Page 898 of 1954

Transmission

Installation

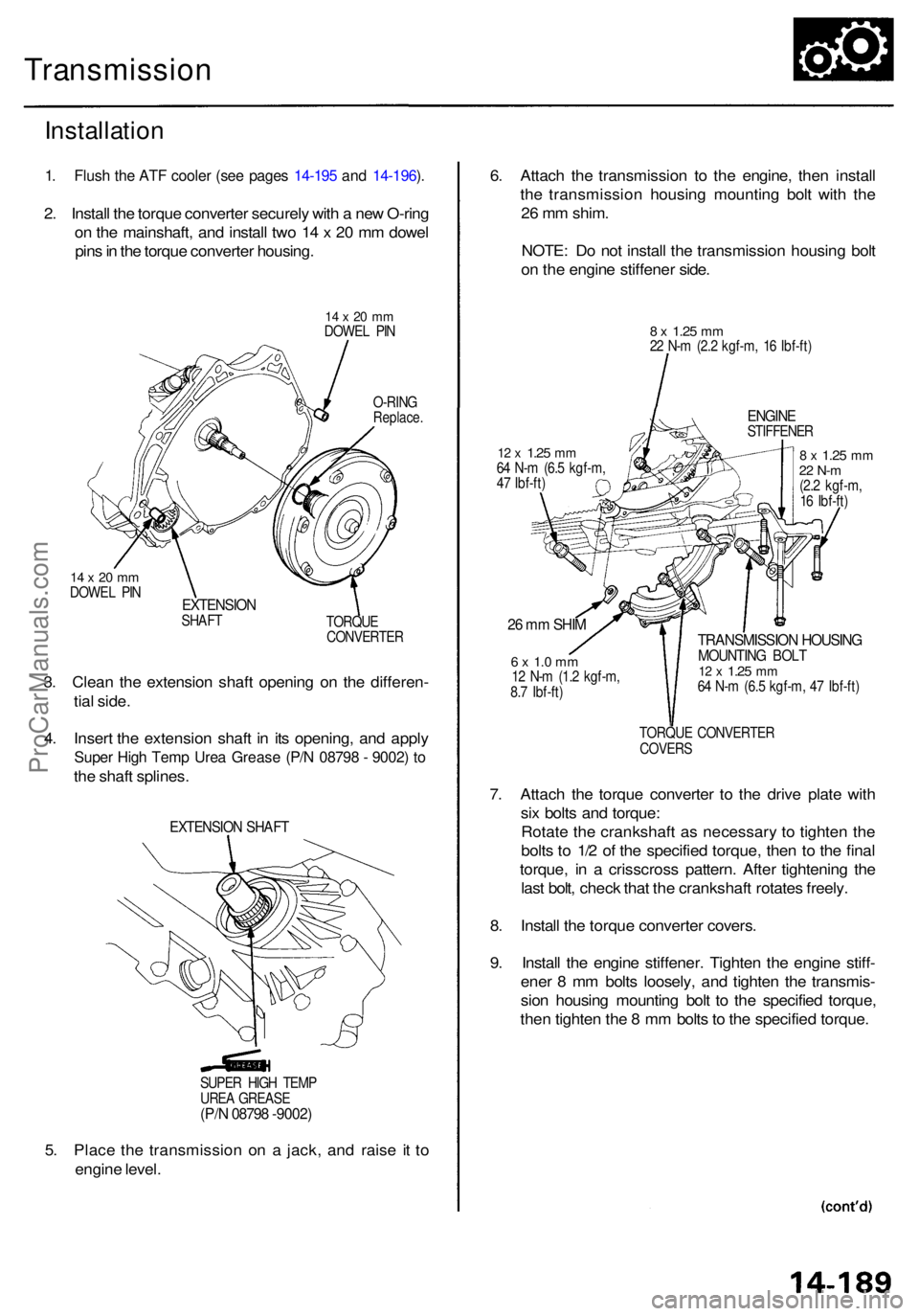

1. Flus h th e AT F coole r (se e page s 14-19 5 an d 14-196 ).

2 . Instal l th e torqu e converte r securel y wit h a ne w O-rin g

o n th e mainshaft , an d instal l tw o 1 4 x 2 0 m m dowe l

pin s in th e torqu e converte r housing .

14 x 20 m mDOWE L PI N

O-RIN G

Replace .

14 x 20 m mDOWE L PI NEXTENSIO NSHAFT

TORQUE

CONVERTE R

3. Clea n th e extensio n shaf t openin g o n th e differen -

tia l side .

4 . Inser t th e extensio n shaf t i n it s opening , an d appl y

Supe r Hig h Tem p Ure a Greas e (P/ N 0879 8 - 9002 ) t o

th e shaf t splines .

EXTENSIO N SHAF T

5. Plac e th e transmissio n o n a jack , an d rais e i t t o

engin e level . 6

. Attac h th e transmissio n t o th e engine , the n instal l

th e transmissio n housin g mountin g bol t wit h th e

2 6 m m shim .

NOTE : D o no t instal l th e transmissio n housin g bol t

o n th e engin e stiffene r side .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

ENGIN ESTIFFENE R

12 x 1.2 5 mm64 N- m (6. 5 kgf-m ,

4 7 Ibf-ft )8 x 1.2 5 mm22 N- m(2.2 kgf-m ,

1 6 Ibf-ft )

26 m m SHI M

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

TRANSMISSIO N HOUSIN GMOUNTIN G BOL T12 x 1.2 5 mm64 N- m (6. 5 kgf-m , 4 7 Ibf-ft )

TORQU E CONVERTE R

COVER S

7. Attac h th e torqu e converte r t o th e driv e plat e wit h

si x bolt s an d torque :

Rotat e th e crankshaf t a s necessar y t o tighte n th e

bolt s t o 1/ 2 o f th e specifie d torque , the n t o th e fina l

torque , i n a crisscros s pattern . Afte r tightenin g th e

las t bolt , chec k tha t th e crankshaf t rotate s freely .

8 . Instal l th e torqu e converte r covers .

9 . Instal l th e engin e stiffener . Tighte n th e engin e stiff -

ene r 8 m m bolt s loosely , an d tighte n th e transmis -

sio n housin g mountin g bol t t o th e specifie d torque ,

the n tighte n th e 8 m m bolt s t o th e specifie d torque .

SUPER HIG H TEM P

URE A GREAS E

(P/N 0879 8 -9002 )

ProCarManuals.com

Page 903 of 1954

Transmission

Installation (cont'd )

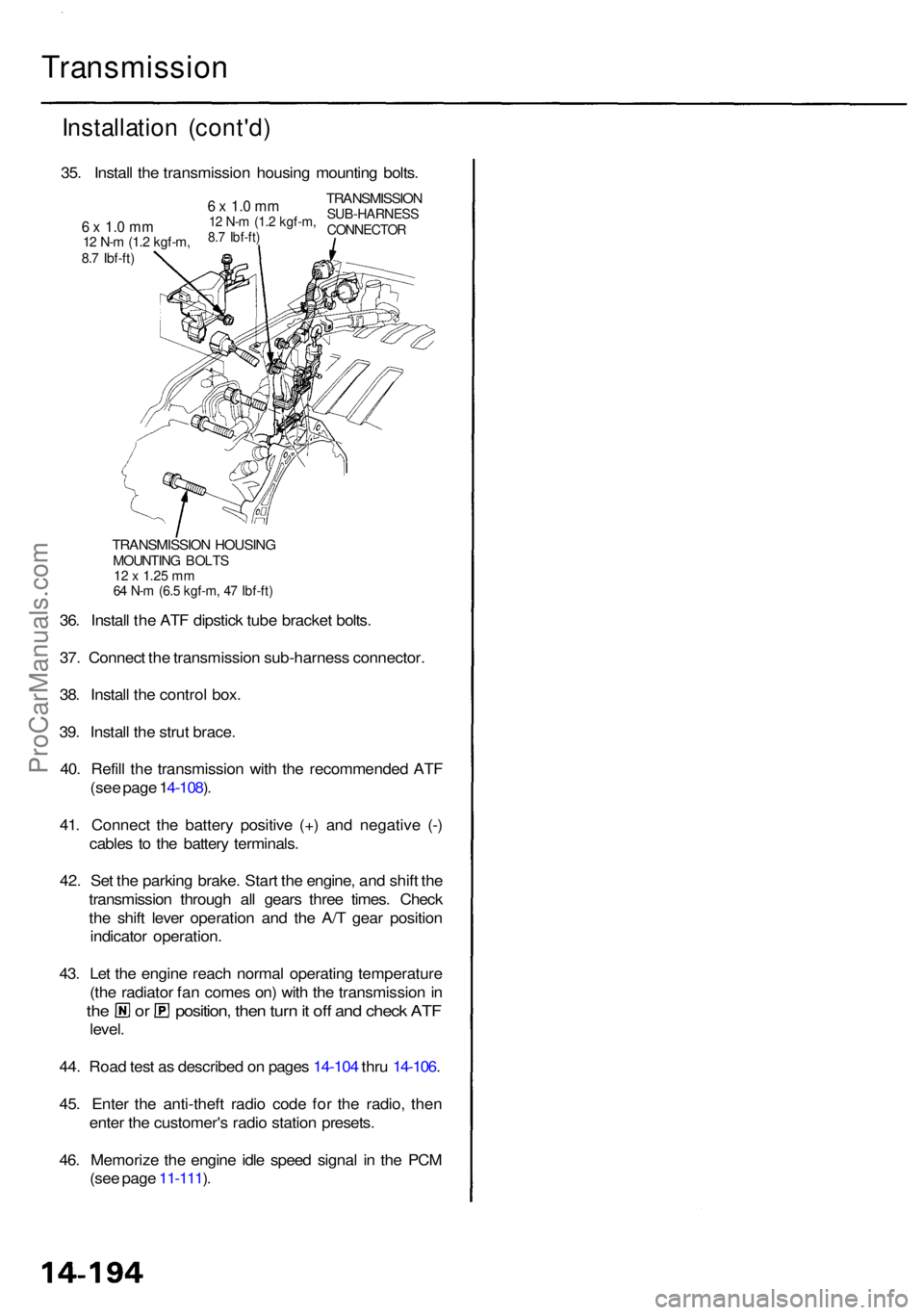

TRANSMISSIO N HOUSIN GMOUNTIN G BOLT S12 x 1.2 5 m m64 N- m (6. 5 kgf-m , 4 7 Ibf-ft )

36. Instal l th e AT F dipstic k tub e bracke t bolts .

37 . Connec t th e transmissio n sub-harnes s connector .

38 . Instal l th e contro l box .

39 . Instal l th e stru t brace .

40 . Refil l th e transmissio n wit h th e recommende d AT F

(se e pag e 1 4-108 ).

41 . Connec t th e batter y positiv e (+ ) an d negativ e (- )

cable s t o th e batter y terminals .

42 . Se t th e parkin g brake . Star t th e engine , an d shif t th e

transmissio n throug h al l gear s thre e times . Chec k

th e shif t leve r operatio n an d th e A/ T gea r positio n

indicato r operation .

43 . Le t th e engin e reac h norma l operatin g temperatur e

(th e radiato r fa n come s on ) wit h th e transmissio n in

th e o r position , the n tur n it of f an d chec k AT F

level .

44 . Roa d tes t a s describe d o n page s 14-10 4 thr u 14-106 .

45 . Ente r th e anti-thef t radi o cod e fo r th e radio , the n

ente r th e customer' s radi o statio n presets .

46 . Memoriz e th e engin e idl e spee d signa l i n th e PC M

(se e pag e 11-111 ).

35

. Instal l th e transmissio n housin g mountin g bolts .

TRANSMISSIO NSUB-HARNES SCONNECTOR

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )

ProCarManuals.com

Page 909 of 1954

Link Adjustmen t

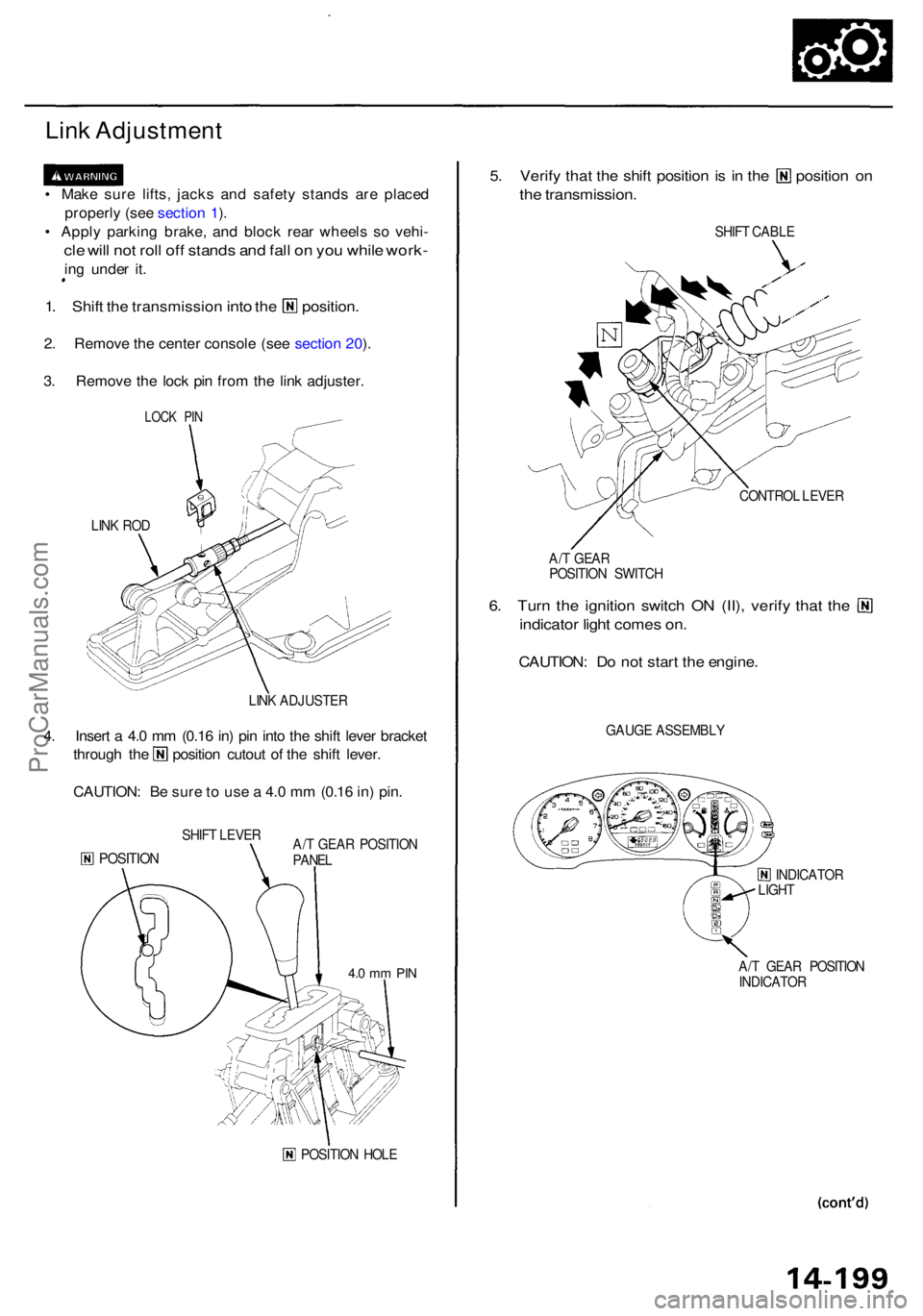

• Mak e sur e lifts , jack s an d safet y stand s ar e place d

properl y (se e sectio n 1 ).

• Appl y parkin g

brake, and bloc k rea r wheel s s o vehi -

cle wil l no t rol l of f stand s an d fal l o n yo u whil e work -

ing unde r it .

1. Shif t the transmissio n into the position .

2. Remov e th e cente r consol e (se e sectio n 20 ).

3 . Remov e th e loc k pi n fro m th e lin k adjuster .

LINK RO D

LINK ADJUSTE R

4. Inser t a 4. 0 m m (0.1 6 in ) pi n int o th e shif t leve r bracke t

through th e positio n cutou t o f th e shif t lever .

CAUTION : B e sur e t o us e a 4. 0 m m (0.1 6 in ) pin .

SHIF T LEVE R

POSITIO NA/T GEA R POSITIO N

PANE L

POSITIO N HOL E

5. Verif y tha t th e shif t positio n is i n th e positio n o n

the transmission .

SHIFT CABL E

CONTRO L LEVE R

A/ T GEA R

POSITIO N SWITC H

6. Tur n th e ignitio n switc h O N (II) , verif y tha t th e

indicato r ligh t come s on .

CAUTION : D o no t star t th e engine .

GAUGE ASSEMBL Y

INDICATOR

LIGH T

A/ T GEA R POSITIO N

INDICATO R

LOCK PI N

4.0 m m PI N

ProCarManuals.com