sensor ACURA RL KA9 1996 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 1478 of 1954

Evaporator Temperatur e

Sensor Powe r Transisto r

Test

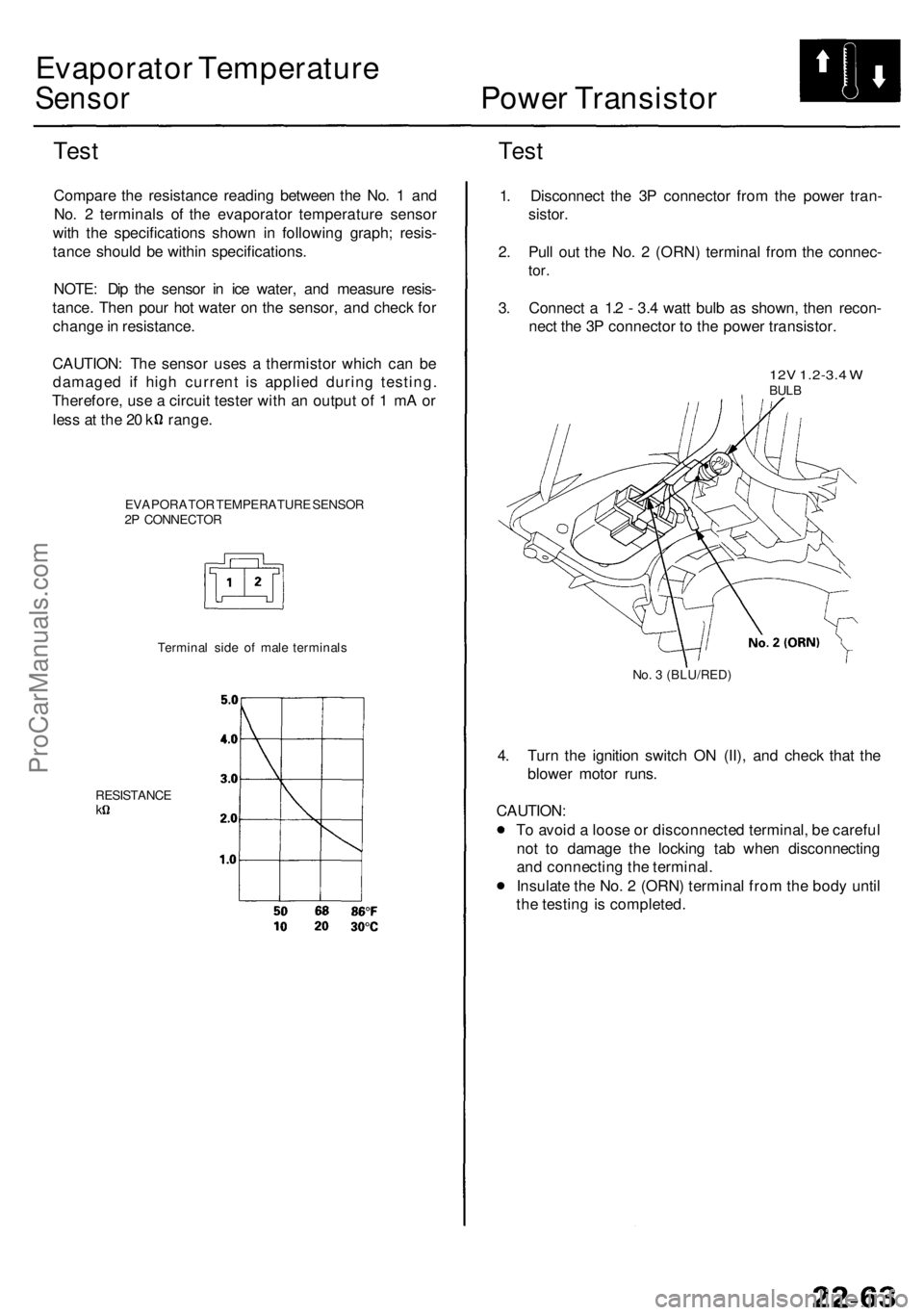

Compar e th e resistanc e readin g betwee n th e No . 1 an d

No . 2 terminal s o f th e evaporato r temperatur e senso r

wit h th e specification s show n i n followin g graph ; resis -

tanc e shoul d b e withi n specifications .

NOTE : Di p th e senso r i n ic e water , an d measur e resis -

tance . The n pou r ho t wate r o n th e sensor , an d chec k fo r

chang e in resistance .

CAUTION : Th e senso r use s a thermisto r whic h ca n b e

damage d i f hig h curren t i s applie d durin g testing .

Therefore , us e a circui t teste r wit h a n outpu t o f 1 m A o r

les s a t th e 2 0 k range .

EVAPORATO R TEMPERATUR E SENSO R

2 P CONNECTO R

Test

Termina l sid e o f mal e terminal s

RESISTANC E

k

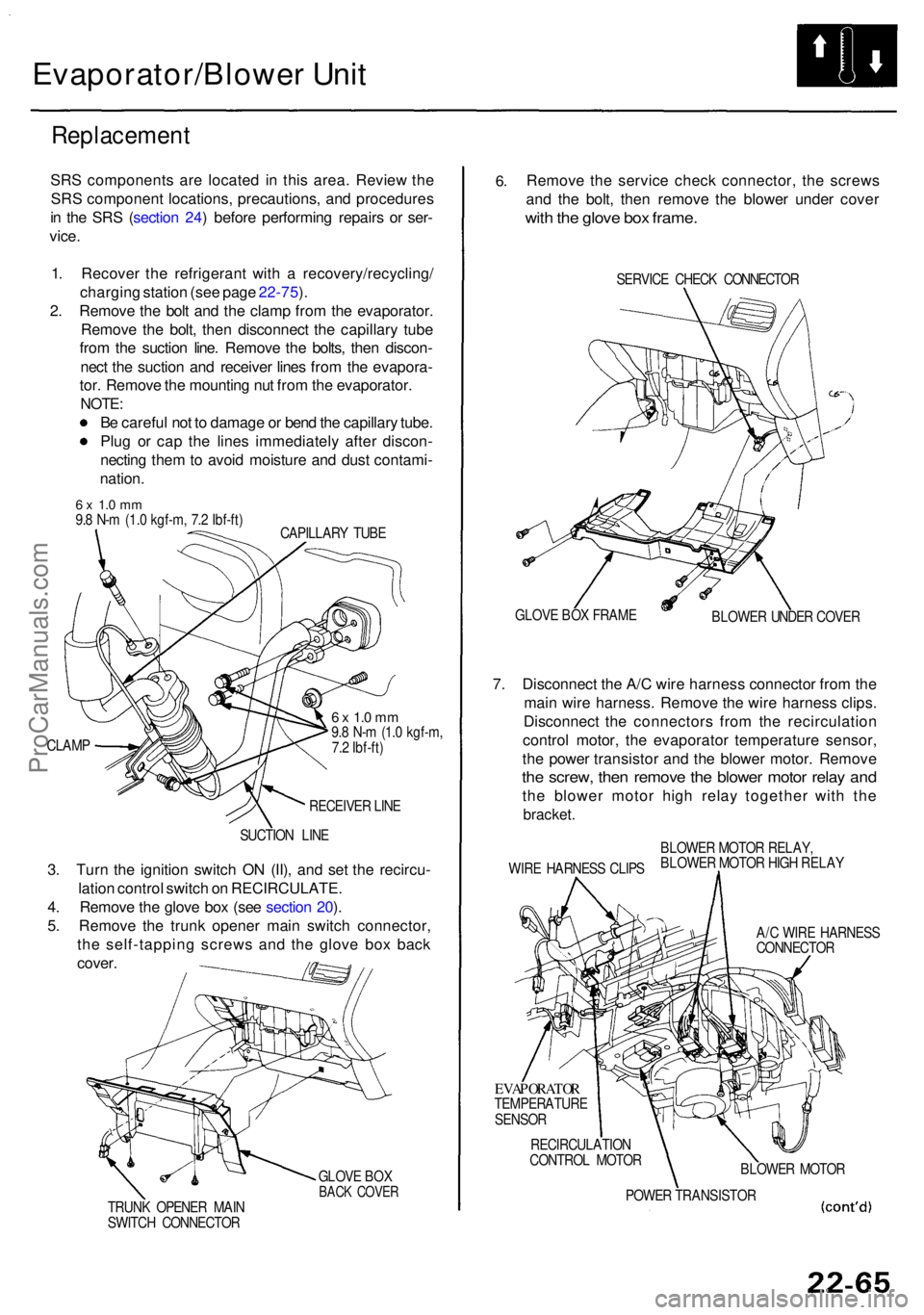

1. Disconnec t th e 3 P connecto r fro m th e powe r tran -

sistor .

2 . Pul l ou t th e No . 2 (ORN ) termina l fro m th e connec -

tor.

3. Connec t a 1. 2 - 3. 4 wat t bul b a s shown , the n recon -

nec t th e 3 P connecto r t o th e powe r transistor .

12V 1.2-3. 4 WBUL B

No. 3 (BLU/RED )

4. Tur n th e ignitio n switc h O N (II) , an d chec k tha t th e

blowe r moto r runs .

CAUTION :

T o avoi d a loos e o r disconnecte d terminal , b e carefu l

no t t o damag e th e lockin g ta b whe n disconnectin g

an d connectin g th e terminal .

Insulat e th e No . 2 (ORN ) termina l fro m th e bod y unti l

th e testin g is completed .

ProCarManuals.com

Page 1480 of 1954

Evaporator/Blower Uni t

Replacemen t

SRS component s ar e locate d i n thi s area . Revie w th e

SR S componen t locations , precautions , an d procedure s

i n th e SR S (sectio n 24 ) befor e performin g repair s o r ser -

vice .

1 . Recove r th e refrigeran t wit h a recovery/recycling /

chargin g statio n (se e pag e 22-75 ).

2 . Remov e th e bol t an d th e clam p fro m th e evaporator .

Remov e th e bolt , the n disconnec t th e capillar y tub e

fro m th e suctio n line . Remov e th e bolts , the n discon -

nec t th e suctio n an d receive r line s fro m th e evapora -

tor . Remov e th e mountin g nu t fro m th e evaporator .

NOTE:

Be carefu l no t t o damag e o r ben d th e capillar y tube .

Plu g o r ca p th e line s immediatel y afte r discon -

nectin g the m to avoi d moistur e an d dus t contami -

nation .

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

CAPILLAR Y TUB E

CLAM P

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

RECEIVE R LIN E

SUCTIO N LIN E

3. Tur n th e ignitio n switc h O N (II) , an d se t th e recircu -

latio n contro l switc h o n RECIRCULATE .

4 . Remov e th e glov e bo x (se e sectio n 20 ).

5 . Remov e th e trun k opene r mai n switc h connector ,

th e self-tappin g screw s an d th e glov e bo x bac k

cover .

GLOV E BO XBAC K COVE RTRUNK OPENE R MAI N

SWITC H CONNECTO R

6.Remov e th e servic e chec k connector , th e screw s

an d th e bolt , the n remov e th e blowe r unde r cove r

with th e glov e bo x frame .

SERVIC E CHEC K CONNECTO R

GLOV E BO X FRAM E

BLOWER UNDE R COVE R

7. Disconnec t th e A/ C wir e harnes s connecto r fro m th e

mai n wir e harness . Remov e th e wir e harnes s clips .

Disconnec t th e connector s fro m th e recirculatio n

contro l motor , th e evaporato r temperatur e sensor ,

th e powe r transisto r an d th e blowe r motor . Remov e

the screw , the n remov e th e blowe r moto r rela y an d

the blowe r moto r hig h rela y togethe r wit h th e

bracket .

WIRE HARNES S CLIP SBLOWE

R MOTO R RELAY ,

BLOWE R MOTO R HIG H RELA Y

A/ C WIR E HARNES S

CONNECTO R

EVAPORATO RTEMPERATUR E

SENSO R

RECIRCULATIO N

CONTRO L MOTO R

BLOWER MOTO R

POWE R TRANSISTO R

ProCarManuals.com

Page 1482 of 1954

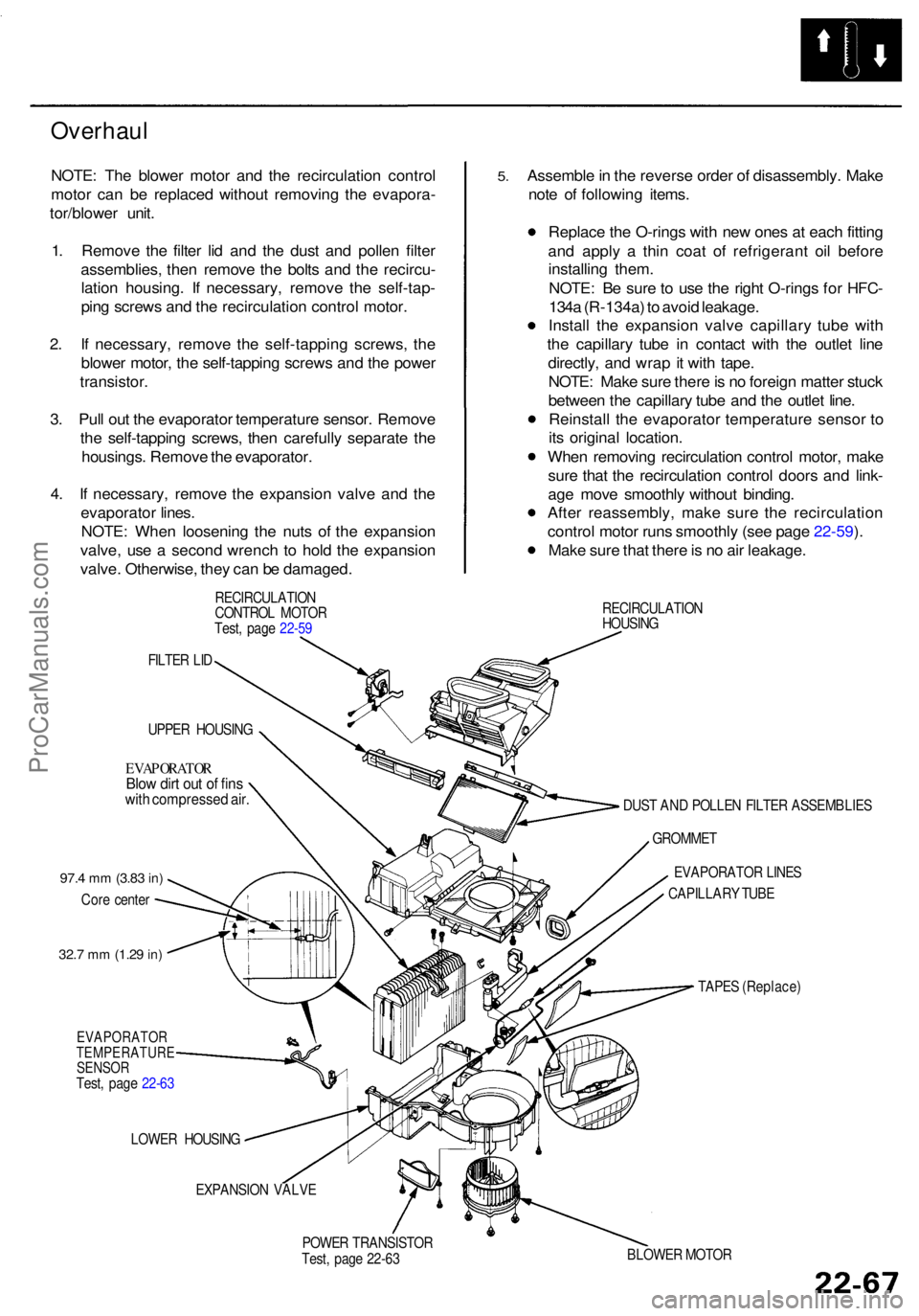

Overhaul

NOTE: Th e blowe r moto r an d th e recirculatio n contro l

moto r ca n b e replace d withou t removin g th e evapora -

tor/blowe r unit .

1 . Remov e th e filte r li d an d th e dus t an d polle n filte r

assemblies , the n remov e th e bolt s an d th e recircu -

latio n housing . I f necessary , remov e th e self-tap -

pin g screw s an d th e recirculatio n contro l motor .

2 . I f necessary , remov e th e self-tappin g screws , th e

blowe r motor , th e self-tappin g screw s an d th e powe r

transistor .

3 . Pul l ou t th e evaporato r temperatur e sensor . Remov e

th e self-tappin g screws , the n carefull y separat e th e

housings . Remov e th e evaporator .

4 . I f necessary , remov e th e expansio n valv e an d th e

evaporato r lines .

NOTE : Whe n loosenin g th e nut s o f th e expansio n

valve , us e a secon d wrenc h t o hol d th e expansio n

valve . Otherwise , the y ca n b e damaged .

RECIRCULATIO N

CONTRO L MOTO R

Test , pag e 22-5 9

FILTE R LI D

UPPE R HOUSIN G

EVAPORATO RBlow dir t ou t o f fin swith compresse d air .

97. 4 mm (3.8 3 in)

Cor e cente r

32.7 mm (1.2 9 in)

EVAPORATO R

TEMPERATUR E

SENSO R

Test, pag e 22-6 3

LOWE R HOUSIN G

EXPANSIO N VALV E

POWE R TRANSISTO R

Test , pag e 22-6 3

5.Assembl e in th e revers e orde r o f disassembly . Mak e

not e o f followin g items .

Replac e th e O-ring s wit h ne w one s a t eac h fittin g

an d appl y a thi n coa t of refrigeran t oi l befor e

installin g them .

NOTE : B e sur e to us e th e righ t O-ring s fo r HFC -

134 a (R-134a ) t o avoi d leakage .

Instal l th e expansio n valv e capillar y tub e wit h

th e capillar y tub e i n contac t wit h th e outle t lin e

directly , an d wra p it wit h tape .

NOTE : Mak e sur e ther e is n o foreig n matte r stuc k

betwee n th e capillar y tub e an d th e outle t line .

Reinstal l th e evaporato r temperatur e senso r t o

it s origina l location .

Whe n removin g recirculatio n contro l motor , mak e

sur e tha t th e recirculatio n contro l door s an d link -

ag e mov e smoothl y withou t binding .

Afte r reassembly , mak e sur e th e recirculatio n

contro l moto r run s smoothl y (se e pag e 22-59 ).

Mak e sur e tha t ther e is n o ai r leakage .

RECIRCULATIO N

HOUSIN G

DUS T AN D POLLE N FILTE R ASSEMBLIE S

GROMME T

EVAPORATO R LINE S

CAPILLAR Y TUB E

TAPE S (Replace )

BLOWE R MOTO R

ProCarManuals.com

Page 1493 of 1954

A/C Syste m Servic e

Pressur e Tes t Char t

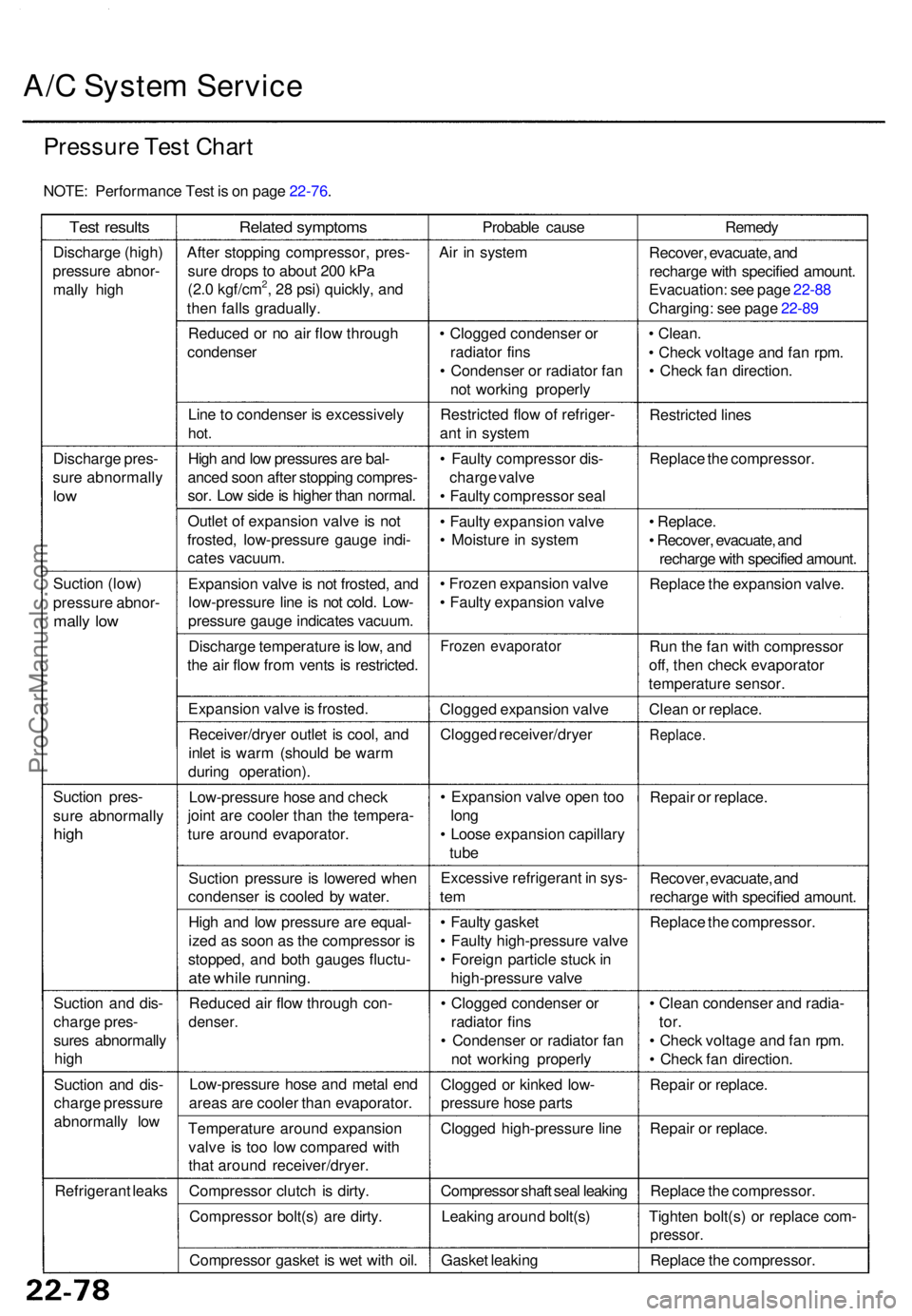

NOTE : Performanc e Tes t i s o n pag e 22-76 .

Test result s

Discharg e (high )

pressur e abnor -

mall y hig h

Discharg e pres -

sur e abnormall y

low

Suctio n (low )

pressur e abnor -

mally lo w

Suctio n pres -

sur e abnormall y

high

Suctio n an d dis -

charg e pres -

sure s abnormall y

hig h

Suctio n an d dis -

charg e pressur e

abnormall y lo w

Refrigeran t leak s

Relate d symptom s

After stoppin g compressor , pres -

sur e drop s t o abou t 20 0 kP a

(2. 0 kgf/cm

2, 2 8 psi ) quickly , an d

the n fall s gradually .

Reduce d o r n o ai r flo w throug h

condense r

Lin e to condense r i s excessivel y

hot.

Hig h an d lo w pressure s ar e bal -

ance d soo n afte r stoppin g compres -

sor . Lo w sid e is highe r tha n normal .

Outle t o f expansio n valv e is no t

frosted , low-pressur e gaug e indi -

cate s vacuum .

Expansio n valv e is no t frosted , an d

low-pressur e lin e is no t cold . Low -

pressur e gaug e indicate s vacuum .

Discharg e temperatur e is low , an d

th e ai r flo w fro m vent s i s restricted .

Expansio n valv e is frosted .

Receiver/drye r outle t i s cool , an d

inle t i s war m (shoul d b e war m

durin g operation) .

Low-pressur e hos e an d chec k

join t ar e coole r tha n th e tempera -

tur e aroun d evaporator .

Suctio n pressur e is lowere d whe n

condense r i s coole d b y water .

Hig h an d lo w pressur e ar e equal -

ize d a s soo n a s th e compresso r i s

stopped , an d bot h gauge s fluctu -

ate whil e running .

Reduce d ai r flo w throug h con -

denser .

Low-pressur e hos e an d meta l en d

area s ar e coole r tha n evaporator .

Temperatur e aroun d expansio n

valv e i s to o lo w compare d wit h

tha t aroun d receiver/dryer .

Compresso r clutc h i s dirty .

Compresso r bolt(s ) ar e dirty .

Compresso r gaske t i s we t wit h oil . Probabl

e caus e

Ai r i n syste m

• Clogge d condense r o r

radiato r fin s

• Condense r o r radiato r fa n

no t workin g properl y

Restricte d flo w o f refriger -

an t i n syste m

• Fault y compresso r dis -

charg e valv e

• Fault y compresso r sea l

• Fault y expansio n valv e

• Moistur e in syste m

• Froze n expansio n valv e

• Fault y expansio n valv e

Froze n evaporato r

Clogged expansio n valv e

Clogge d receiver/drye r

• Expansio n valv e ope n to o

lon g

• Loos e expansio n capillar y

tub e

Excessiv e refrigeran t i n sys -

tem

• Fault y gaske t

• Fault y high-pressur e valv e

• Foreig n particl e stuc k in

high-pressur e valv e

• Clogge d condense r o r

radiato r fin s

• Condense r o r radiato r fa n

no t workin g properl y

Clogge d o r kinke d low -

pressur e hos e part s

Clogge d high-pressur e lin e

Compresso r shaf t sea l leakin g

Leakin g aroun d bolt(s )

Gaske t leakin g Remed

y

Recover , evacuate , an d

recharg e wit h specifie d amount .

Evacuation : se e pag e 22-8 8

Charging : se e pag e 22-8 9

• Clean .

• Chec k voltag e an d fa n rpm .

• Chec k fa n direction .

Restricte d line s

Replac e th e compressor .

• Replace .

• Recover , evacuate , an d

recharg e wit h specifie d amount .

Replac e th e expansio n valve .

Ru n th e fa n wit h compresso r

off , the n chec k evaporato r

temperatur e sensor .

Clea n o r replace .

Replace .

Repair o r replace .

Recover , evacuate , an d

recharg e wit h specifie d amount .

Replac e th e compressor .

• Clea n condense r an d radia -

tor.

• Chec k voltag e an d fa n rpm .

• Chec k fa n direction .

Repai r o r replace .

Repai r o r replace .

Replac e th e compressor .

Tighte n bolt(s ) o r replac e com -

pressor .

Replace th e compressor .

ProCarManuals.com

Page 1524 of 1954

*: Yo u ca n als o tes t th e switc h b y usin g th e self-diagnosi s functio n (mod e 2) . (Se e pag e 23-252 .)

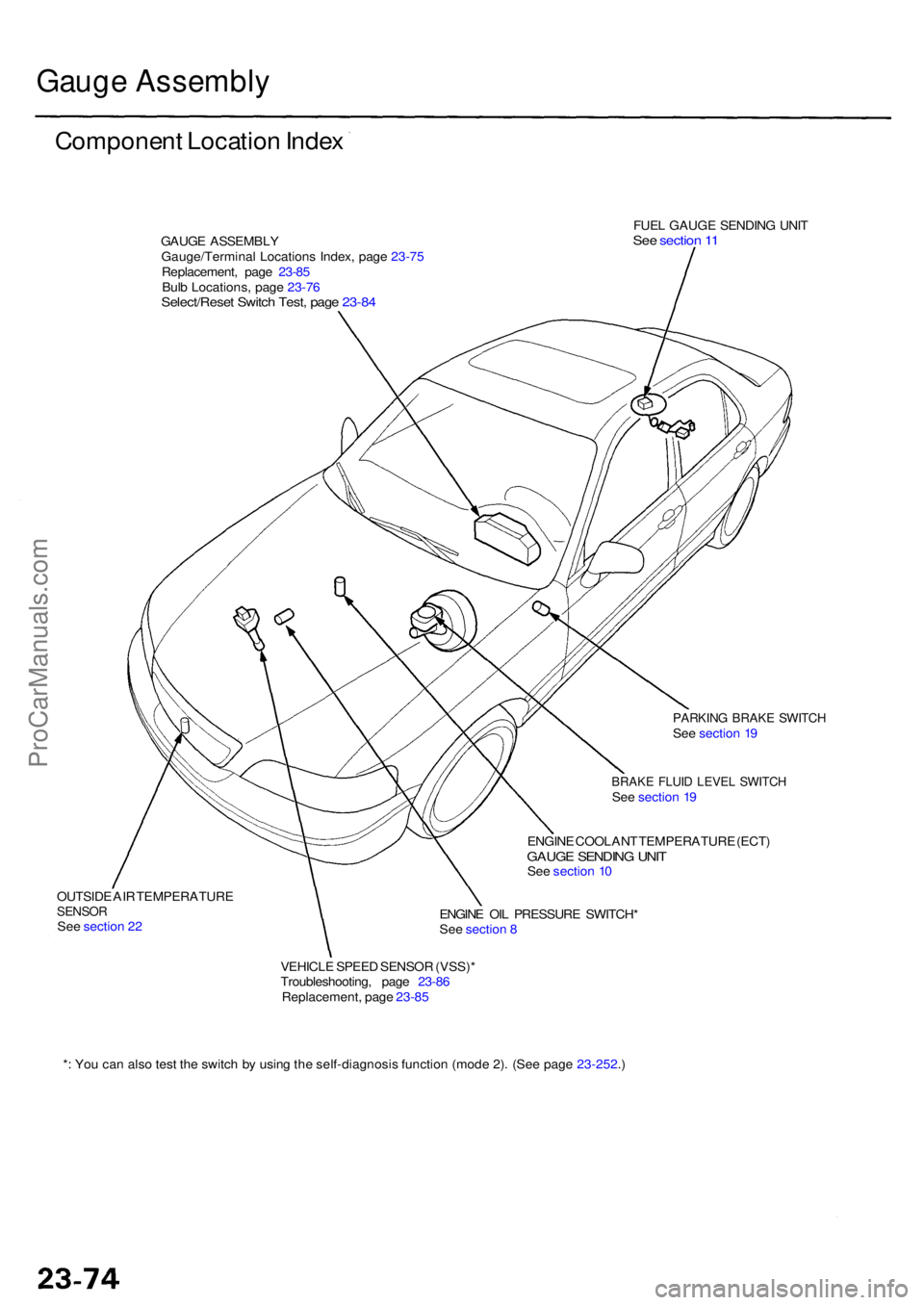

Gaug e Assembl y

Componen t Locatio n Inde x

GAUG E ASSEMBL Y

Gauge/Termina l Location s Index , pag e 23-7 5

Replacement , pag e 23-8 5

Bul b Locations , pag e 23-7 6

Select/Rese t Switc h Test , pag e 23-8 4

FUEL GAUG E SENDIN G UNI TSee sectio n 1 1

PARKIN G BRAK E SWITC HSee sectio n 1 9

BRAK E FLUI D LEVE L SWITC HSee sectio n 1 9

ENGIN E COOLAN T TEMPERATUR E (ECT )

GAUG E SENDIN G UNI TSee sectio n 1 0

ENGIN E OI L PRESSUR E SWITCH *

Se e sectio n 8

VEHICL E SPEE D SENSO R (VSS) *

Troubleshooting , pag e 23-8 6

Replacement , pag e 23-8 5

OUTSID

E AI R TEMPERATUR E

SENSORSee sectio n 2 2

ProCarManuals.com

Page 1525 of 1954

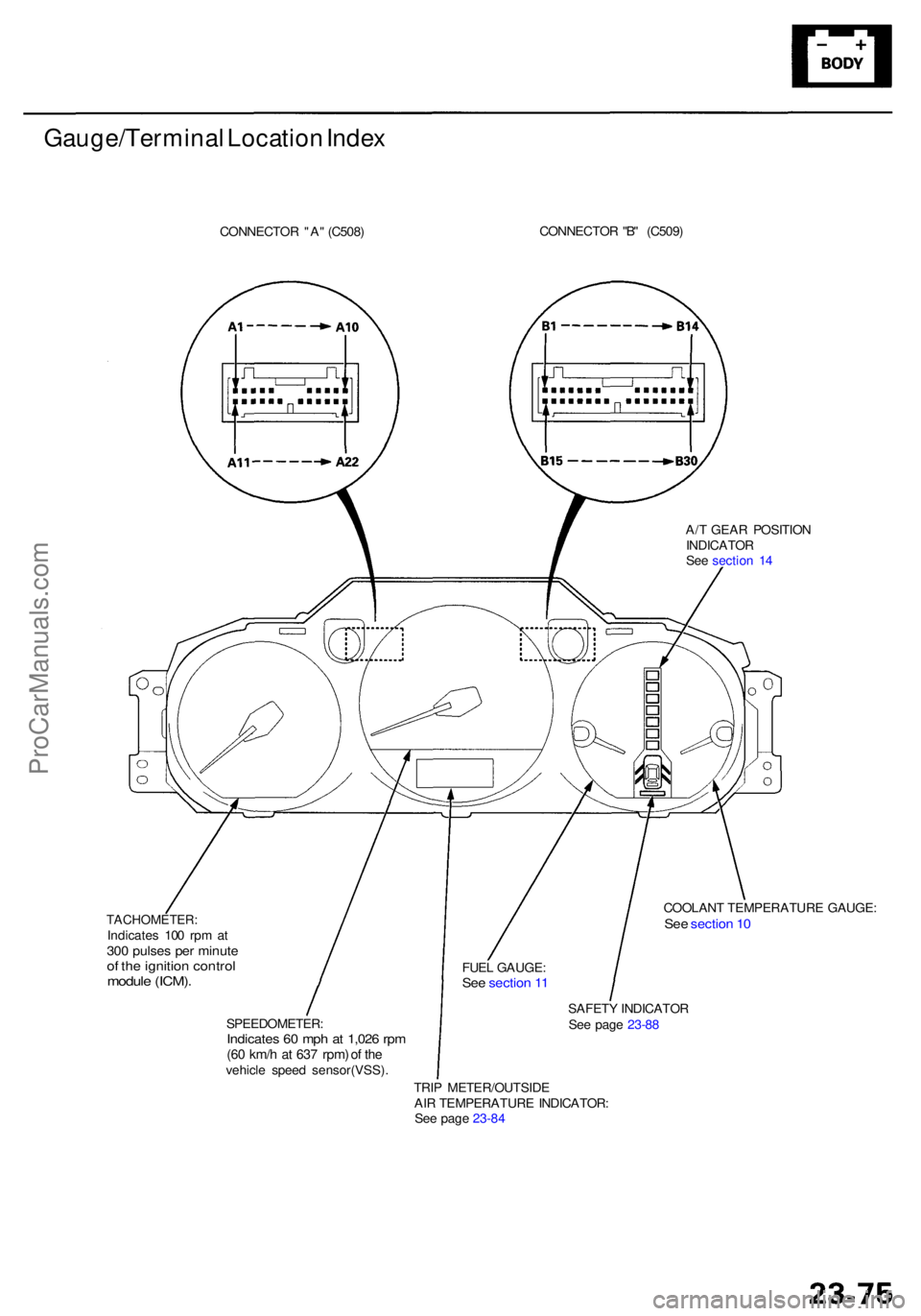

Gauge/Terminal Locatio n Inde x

CONNECTO R "A " (C508 ) CONNECTO

R "B " (C509 )

A/ T GEA R POSITIO N

INDICATO R

Se e sectio n 1 4

COOLAN T TEMPERATUR E GAUGE :

See sectio n 1 0

SAFET Y INDICATO R

Se e pag e 23-8 8

FUE

L GAUGE :

See sectio n 1 1

TRI P METER/OUTSID E

AI R TEMPERATUR E INDICATOR :

Se e pag e 23-8 4

SPEEDOMETER

:

Indicates 6 0 mp h a t 1,02 6 rp m(60 km/ h at 63 7 rpm ) of th evehicl e spee d sensor(VSS) .

TACHOMETER :Indicates 10 0 rp m a t30 0 pulse s pe r minut eof th e ignitio n controlmodul e (ICM) .

ProCarManuals.com

Page 1527 of 1954

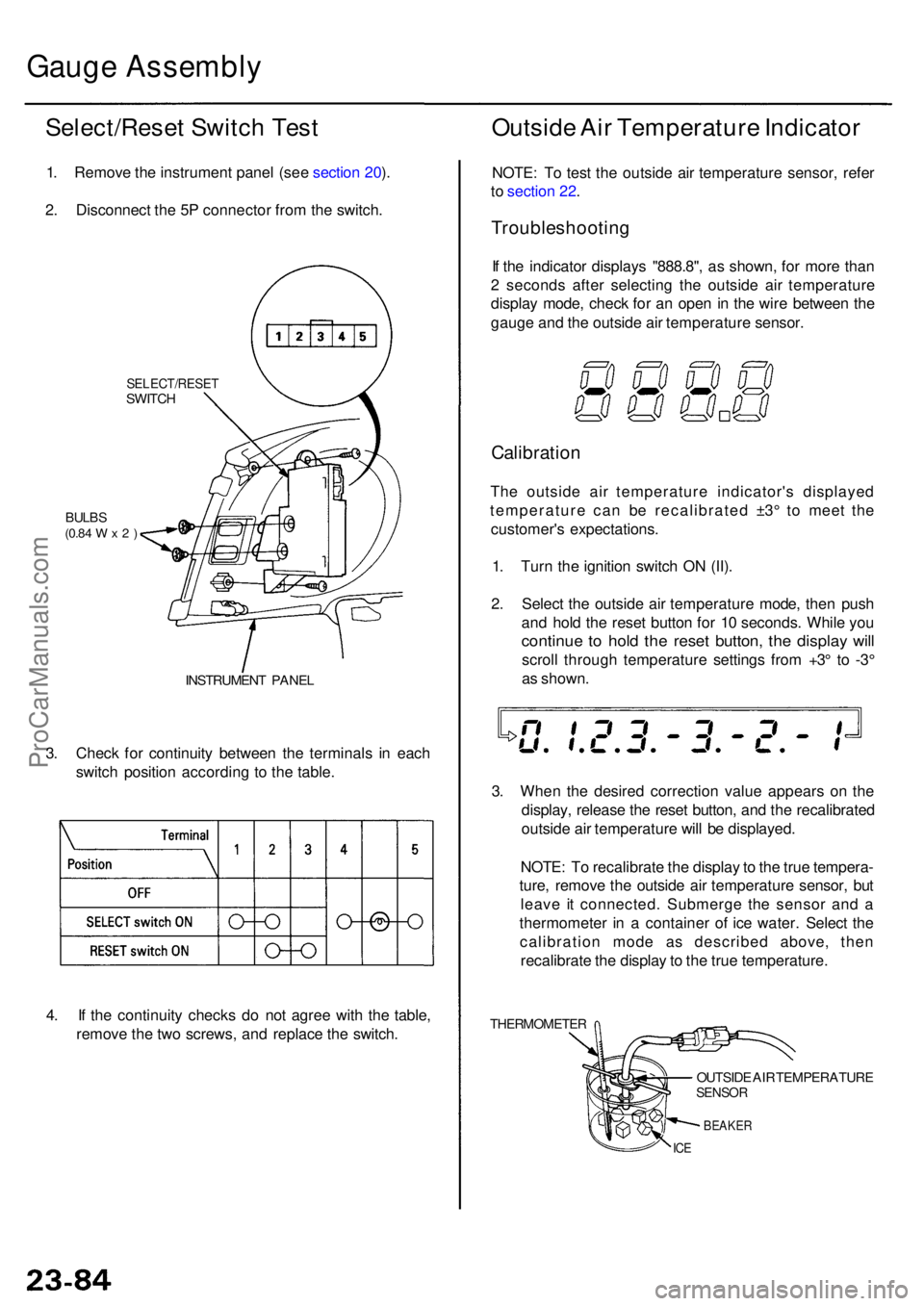

Gauge Assembl y

Select/Rese t Switc h Tes t

1. Remov e th e instrumen t pane l (se e sectio n 20 ).

2 . Disconnec t th e 5 P connecto r fro m th e switch .

SELECT/RESE TSWITCH

BULBS(0.84 W x 2 )

INSTRUMEN T PANE L

3. Chec k fo r continuit y betwee n th e terminal s i n eac h

switc h positio n accordin g t o th e table .

Outsid e Ai r Temperatur e Indicato r

NOTE: T o tes t th e outsid e ai r temperatur e sensor , refe r

t o sectio n 22 .

Troubleshootin g

If th e indicato r display s "888.8" , a s shown , fo r mor e tha n

2 second s afte r selectin g th e outsid e ai r temperatur e

displa y mode , chec k fo r a n ope n in th e wir e betwee n th e

gaug e an d th e outsid e ai r temperatur e sensor .

Calibratio n

The outsid e ai r temperatur e indicator' s displaye d

temperatur e ca n b e recalibrate d ±3 ° t o mee t th e

customer' s expectations .

1 . Tur n th e ignitio n switc h O N (II) .

2 . Selec t th e outsid e ai r temperatur e mode , the n pus h

an d hol d th e rese t butto n fo r 1 0 seconds . Whil e yo u

continu e t o hol d th e rese t button , th e displa y wil l

scrol l throug h temperatur e setting s fro m +3 ° t o -3 °

a s shown .

3 . Whe n th e desire d correctio n valu e appear s o n th e

display , releas e th e rese t button , an d th e recalibrate d

outsid e ai r temperatur e wil l b e displayed .

NOTE : T o recalibrat e th e displa y to th e tru e tempera -

ture , remov e th e outsid e ai r temperatur e sensor , bu t

leav e i t connected . Submerg e th e senso r an d a

thermomete r i n a containe r o f ic e water . Selec t th e

calibratio n mod e a s describe d above , the n

recalibrat e th e displa y to th e tru e temperature .

THERMOMETE R

OUTSIDE AI R TEMPERATUR ESENSOR

BEAKE R

ICE

4. I f th e continuit y check s d o no t agre e wit h th e table ,

remov e th e tw o screws , an d replac e th e switch .

ProCarManuals.com

Page 1529 of 1954

(To page 23-87) GR

N TES T HARNES S CLI P

TES

T HARNES S

07LA J-PT3020 A

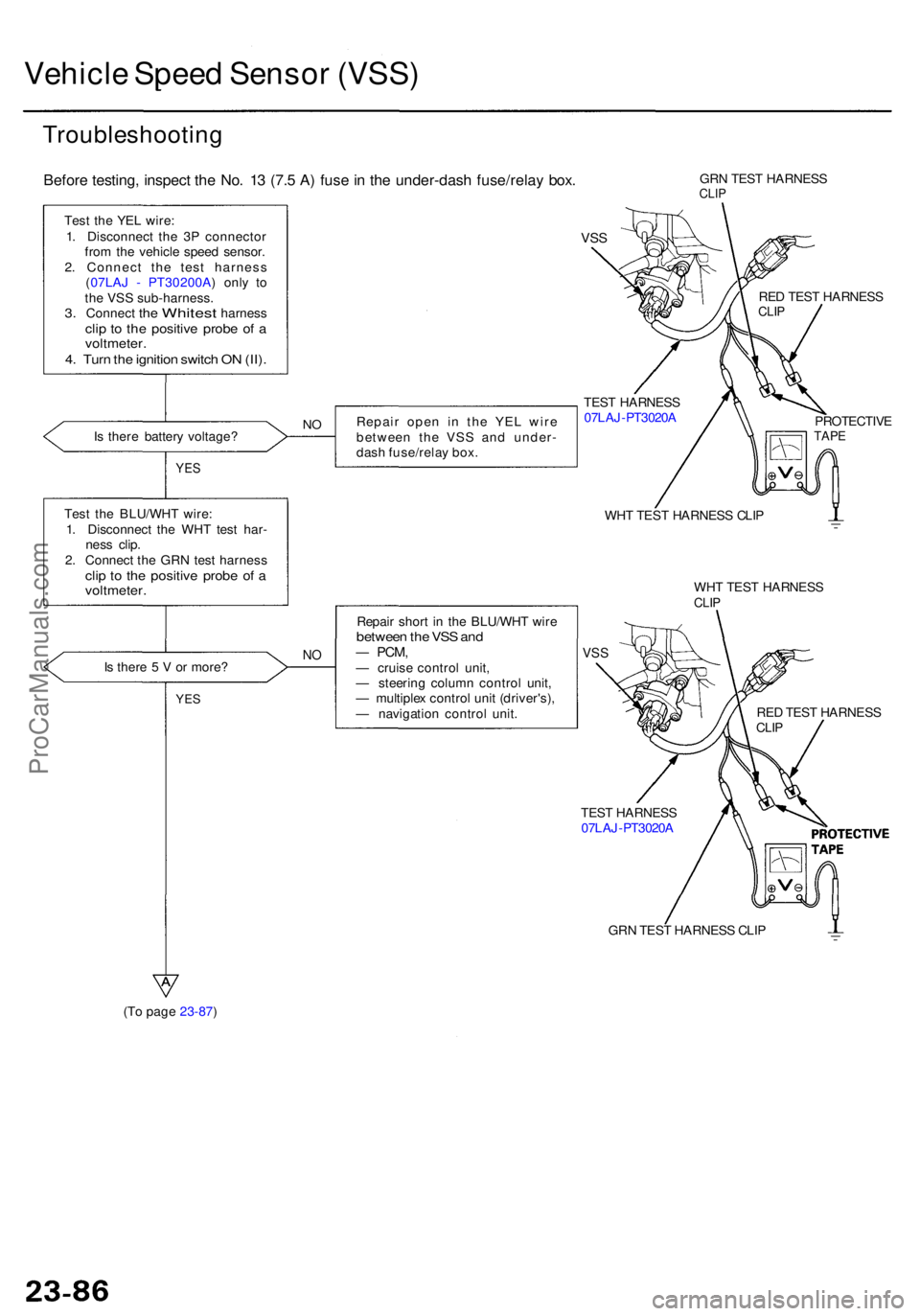

Vehicle Spee d Senso r (VSS )

Troubleshootin g

Before testing , inspec t th e No . 1 3 (7. 5 A ) fus e in th e under-das h fuse/rela y box .

Test th e YE L wire :

1 . Disconnec t th e 3 P connecto r

fro m th e vehicl e spee d sensor .

2 . Connec t th e tes t harnes s

( 07LA J - PT30200A ) onl y t o

th e VS S sub-harness .

3. Connec t the Whites t harnes sclip t o th e positiv e prob e o f avoltmeter .4. Tur n th e ignitio n switc h O N (II) .

Is ther e batter y voltage ? Repai

r ope n i n th e YE L wir e

betwee n th e VS S an d under -

das h fuse/rela y box .NO

YE S

Tes t th e BLU/WH T wire :

1 . Disconnec t th e WH T tes t har -

nes s clip .

2 . Connec t th e GR N tes t harnes s

clip t o th e positiv e prob e o f avoltmeter .

Is ther e 5 V or more ?NO

Repai r shor t i n th e BLU/WH T wir ebetwee n th e VS S an d— PCM ,— cruis e contro l unit ,

— steerin g colum n contro l unit ,

— multiple x contro l uni t (driver's) ,

— navigatio n contro l unit .

YES

GR N TES T HARNES SCLIP

VSS

TES T HARNES S

07LA J-PT3020 A RE

D TES T HARNES S

CLIP

PROTECTIV ETAPE

WHT TES T HARNES S CLI P

WH T TES T HARNES S

CLIP

VSS

RE D TES T HARNES SCLIP

ProCarManuals.com

Page 1534 of 1954

Safety Indicato r Syste m

Brake Ligh t Failur e Senso r Tes t

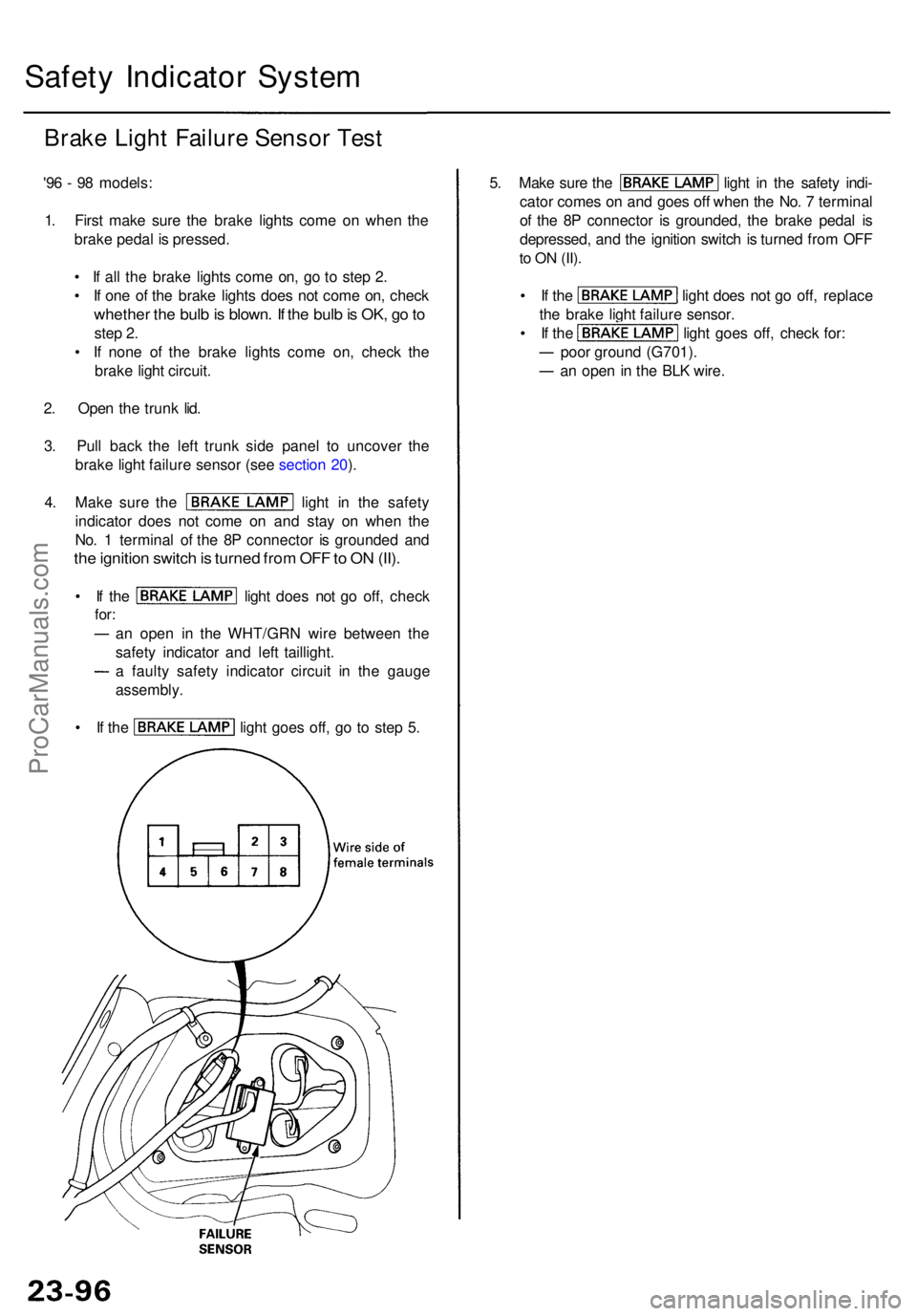

'96 - 9 8 models :

1 . Firs t mak e sur e th e brak e light s com e o n whe n th e

brak e peda l i s pressed .

• I f al l th e brak e light s com e on , g o t o ste p 2 .

• I f on e o f th e brak e light s doe s no t com e on , chec k

whethe r th e bul b is blown . I f th e bul b is OK , g o to

ste p 2 .

• I f non e o f th e brak e light s com e on , chec k th e

brak e ligh t circui t.

2 . Ope n th e trun k lid .

3 . Pul l bac k th e lef t trun k sid e pane l t o uncove r th e

brak e ligh t failur e senso r (se e sectio n 20 ).

4 . Mak e sur e th e ligh t i n th e safet y

indicato r doe s no t com e o n an d sta y o n whe n th e

No . 1 termina l o f th e 8 P connecto r i s grounde d an d

the ignitio n switc h is turne d fro m OF F to O N (II) .

• I f th e ligh t doe s no t g o off , chec k

for:

an ope n i n th e WHT/GR N wir e betwee n th e

safet y indicato r an d lef t taillight .

a fault y safet y indicato r circui t i n th e gaug e

assembly .

• I f th e ligh t goe s off , g o t o ste p 5 .

5. Mak e sur e th e ligh t i n th e safet y indi -

cato r come s o n an d goe s of f whe n th e No . 7 termina l

o f th e 8 P connecto r i s grounded , th e brak e peda l i s

depressed , an d th e ignitio n switc h is turne d fro m OF F

to O N (II) .

• I f th e ligh t doe s no t g o off , replac e

th e brak e ligh t failur e sensor .

• I f th e ligh t goe s off , chec k for :

poo r groun d (G701) .

an ope n i n th e BL K wire .

ProCarManuals.com

Page 1535 of 1954

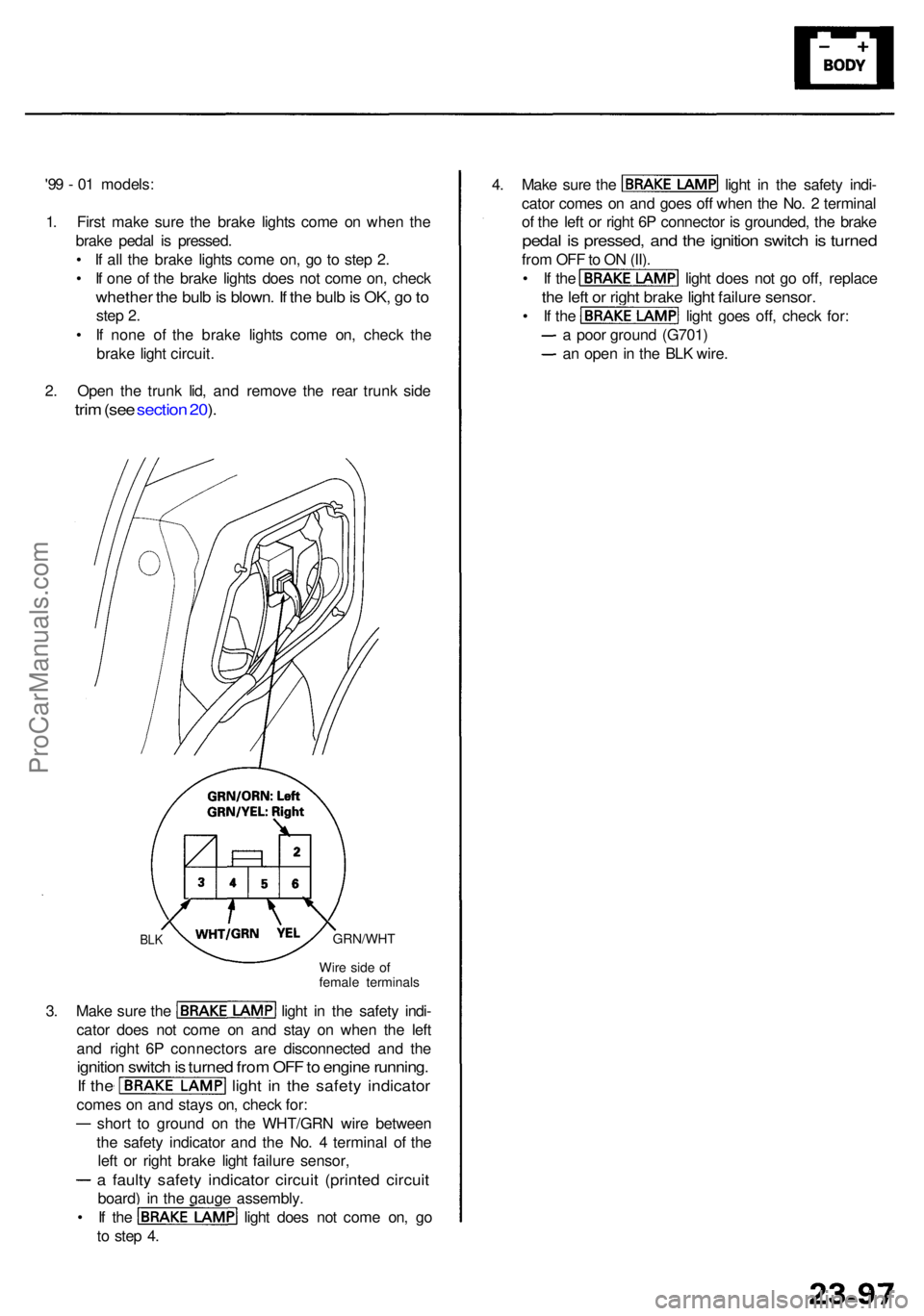

'99 - 0 1 models :

1 . Firs t mak e sur e th e brak e light s com e o n whe n th e

brak e peda l i s pressed .

• I f al l th e brak e light s com e on , g o t o ste p 2 .

• I f on e o f th e brak e light s doe s no t com e on , chec k

whethe r th e bul b is blown . I f th e bul b is OK , g o to

ste p 2 .

• I f non e o f th e brak e light s com e on , chec k th e

brak e ligh t circui t.

2 . Ope n th e trunk lid, an d remov e th e rea r trunk side

trim (se e sectio n 20 ).

4 . Mak e sur e th e ligh t i n th e safet y indi -

cato r come s o n an d goe s of f whe n th e No . 2 termina l

o f th e lef t o r righ t 6 P connecto r i s grounded , th e brak e

pedal i s pressed , an d th e ignitio n switc h is turne d

from OF F to O N (II) .

• I f th e ligh t doe s no t g o off , replac e

the lef t o r righ t brak e ligh t failur e sensor .

• I f th e ligh t goe s off , chec k for :

a poo r groun d (G701 )

an ope n in th e BL K wire .

Wire sid e o f

femal e terminal s

GRN/WH TBLK

3. Mak e sur e th e ligh t i n th e safet y indi -

cato r doe s no t com e o n an d sta y o n whe n th e lef t

an d righ t 6 P connector s ar e disconnecte d an d th e

ignitio n switc h is turne d fro m OF F to engin e running .

If th e ligh t i n th e safet y indicato r

comes o n an d stay s on , chec k for :

shor t t o groun d o n th e WHT/GR N wir e betwee n

th e safet y indicato r an d th e No . 4 termina l o f th e

lef t o r righ t brak e ligh t failur e sensor ,

a fault y safet y indicato r circui t (printe d circui t

board) i n th e gaug e assembly .

• I f th e ligh t doe s no t com e on , g o

t o ste p 4 .

ProCarManuals.com