check engine ACURA RL KA9 1996 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 466 of 1954

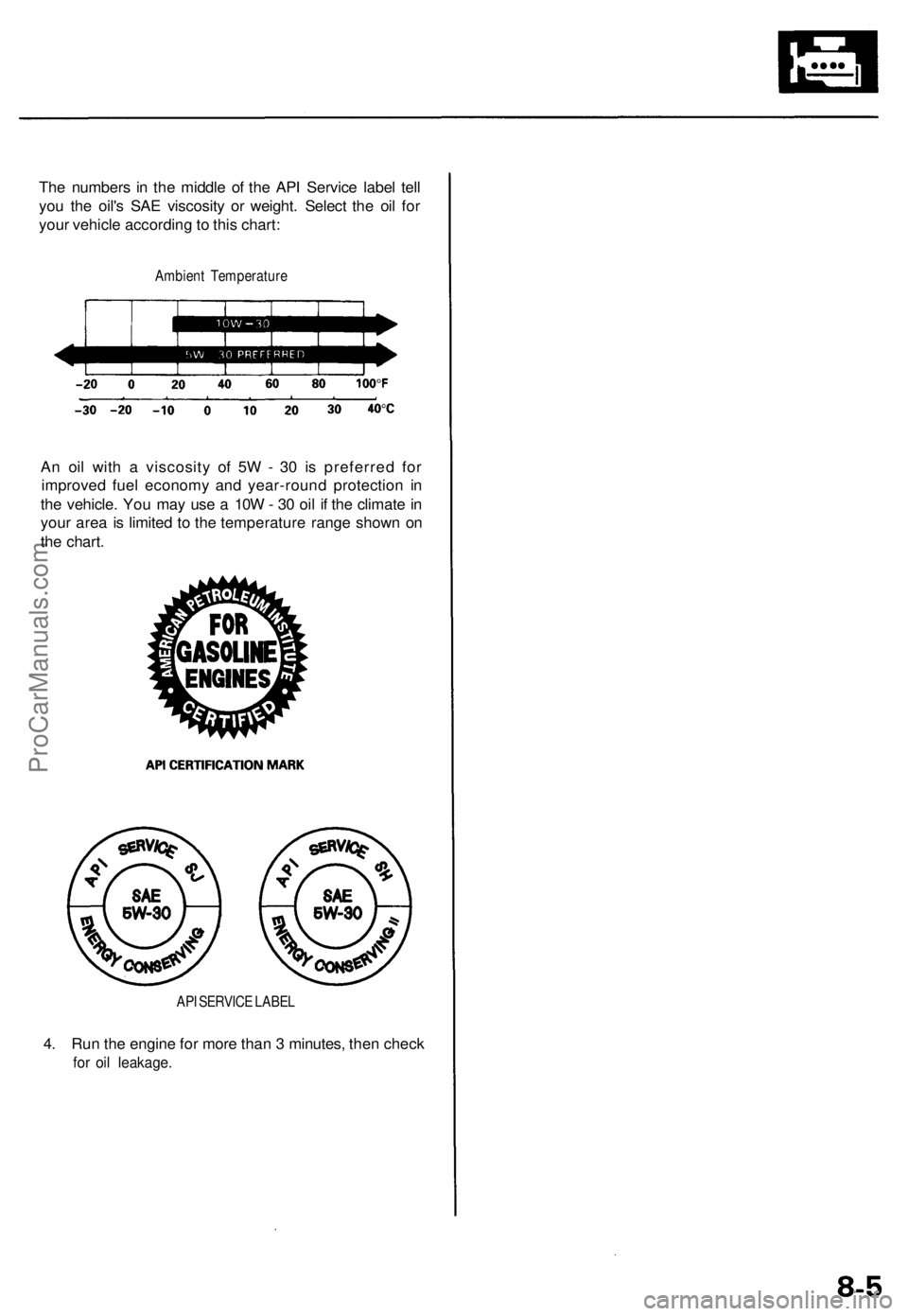

The numbers in the middle of the API Service label tell

you the oil's SAE viscosity or weight. Select the oil for

your vehicle according to this chart:

Ambient Temperature

An oil with a viscosity of 5W - 30 is preferred for

improved fuel economy and year-round protection in

the vehicle. You may use a 10W - 30 oil if the climate in

your area is limited to the temperature range shown on

the chart.

API SERVICE LABEL

4. Run the engine for more than 3 minutes, then check

for oil leakage.ProCarManuals.com

Page 472 of 1954

Oil Pan

Installation

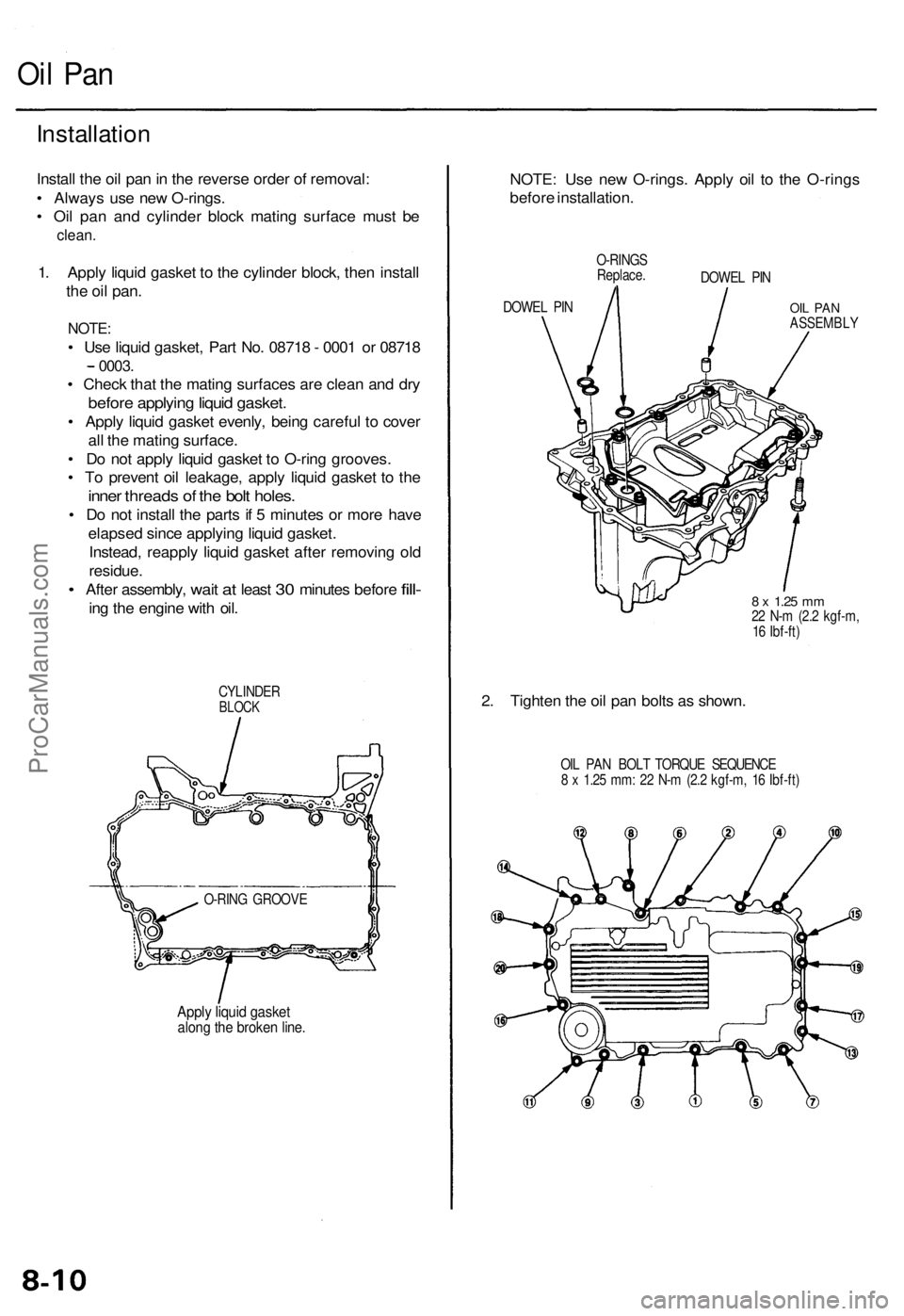

Install the oil pan in the reverse order of removal:

• Always use new O-rings.

• Oil pan and cylinder block mating surface must be

clean.

1. Apply liquid gasket to the cylinder block, then install

the oil

pan.

NOTE:

• Use liquid gasket, Part No. 08718 - 0001 or 08718

0003.

• Check that the mating surfaces are clean and dry

before applying liquid gasket.

• Apply liquid gasket evenly, being careful to cover

all the mating surface.

• Do not apply liquid gasket to O-ring grooves.

• To prevent oil leakage, apply liquid gasket to the

inner threads of the bolt holes.

• Do not install the parts if 5 minutes or more have

elapsed since applying liquid gasket.

Instead, reapply liquid gasket after removing old

residue.

•

After assembly,

wait

at

least

30

minutes before

fill-

ing the engine with oil.

CYLINDER

BLOCK

O-RING GROOVE

Apply liquid gasket

along the broken line.

NOTE: Use new O-rings. Apply oil to the O-rings

before installation.

DOWEL PIN

O-RINGS

Replace.

DOWEL PIN

OIL PAN

ASSEMBLY

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

2. Tighten the oil pan bolts as shown.

OIL PAN BOLT TORQUE SEQUENCE

8 x 1.25 mm: 22 N-m (2.2 kgf-m, 16 Ibf-ft)ProCarManuals.com

Page 487 of 1954

Radiator

Illustrate d Inde x

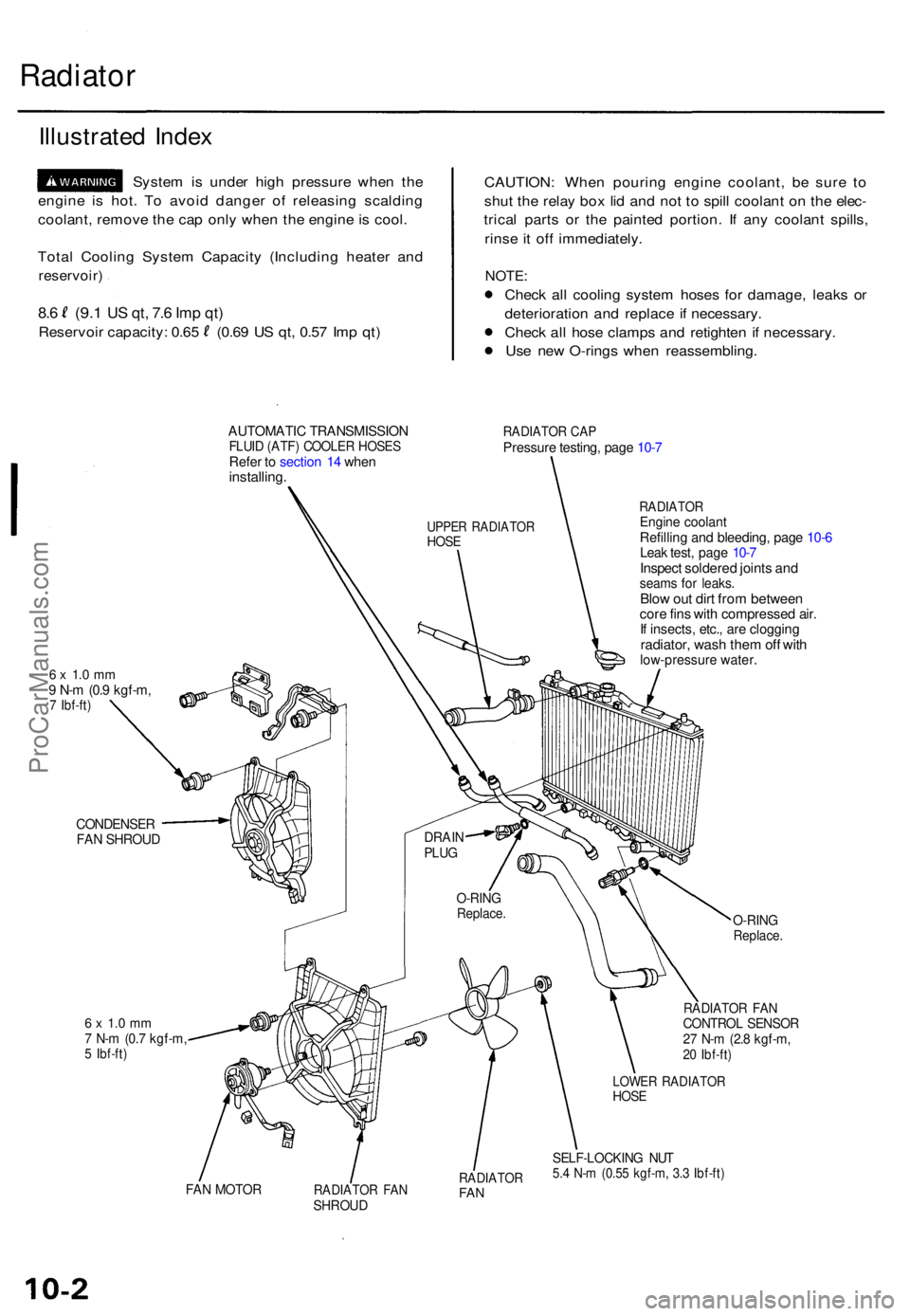

Syste m is unde r hig h pressur e whe n th e

engin e i s hot . T o avoi d dange r o f releasin g scaldin g

coolant , remov e th e ca p onl y whe n th e engin e is cool .

Tota l Coolin g Syste m Capacit y (Includin g heate r an d

reservoir )

8.6 (9. 1 US qt , 7. 6 Im p qt )

Reservoi r capacity : 0.6 5 (0.6 9 U S qt , 0.5 7 Im p qt ) CAUTION

: Whe n pourin g engin e coolant , b e sur e t o

shu t th e rela y bo x li d an d no t t o spil l coolan t o n th e elec -

trica l part s o r th e painte d portion . I f an y coolan t spills ,

rins e it of f immediately .

NOTE:

Check al l coolin g syste m hose s fo r damage , leak s o r

deterioratio n an d replac e if necessary .

Chec k al l hos e clamp s an d retighte n i f necessary .

Us e ne w O-ring s whe n reassembling .

AUTOMATIC TRANSMISSIO NFLUID (ATF ) COOLE R HOSE SRefer t o sectio n 1 4 whe ninstalling .

RADIATO R CA PPressur e testing , pag e 10-7

6 x 1. 0 m m9 N- m (0. 9 kgf-m ,7 Ibf-ft )

RADIATO REngine coolan tRefilling an d bleeding , pag e 10-6Lea k test , pag e 10-7Inspec t soldere d joint s an dseam s fo r leaks .Blow ou t dir t fro m betwee ncore fin s wit h compresse d air .If insects , etc. , ar e cloggin gradiator, was h the m of f wit hlow-pressur e water .

CONDENSE RFAN SHROU D

6 x 1. 0 m m7 N- m (0. 7 kgf-m ,5 Ibf-ft )

O-RIN GReplace .

RADIATO R FA NCONTRO L SENSO R27 N- m (2. 8 kgf-m ,20 Ibf-ft )

FAN MOTO RRADIATO R FA NSHROU D

RADIATO RFAN

LOWE R RADIATO RHOSE

SELF-LOCKIN G NU T5.4 N- m (0.5 5 kgf-m , 3. 3 Ibf-ft )

O-RIN GReplace .

DRAINPLUG

UPPE R RADIATO RHOSE

ProCarManuals.com

Page 492 of 1954

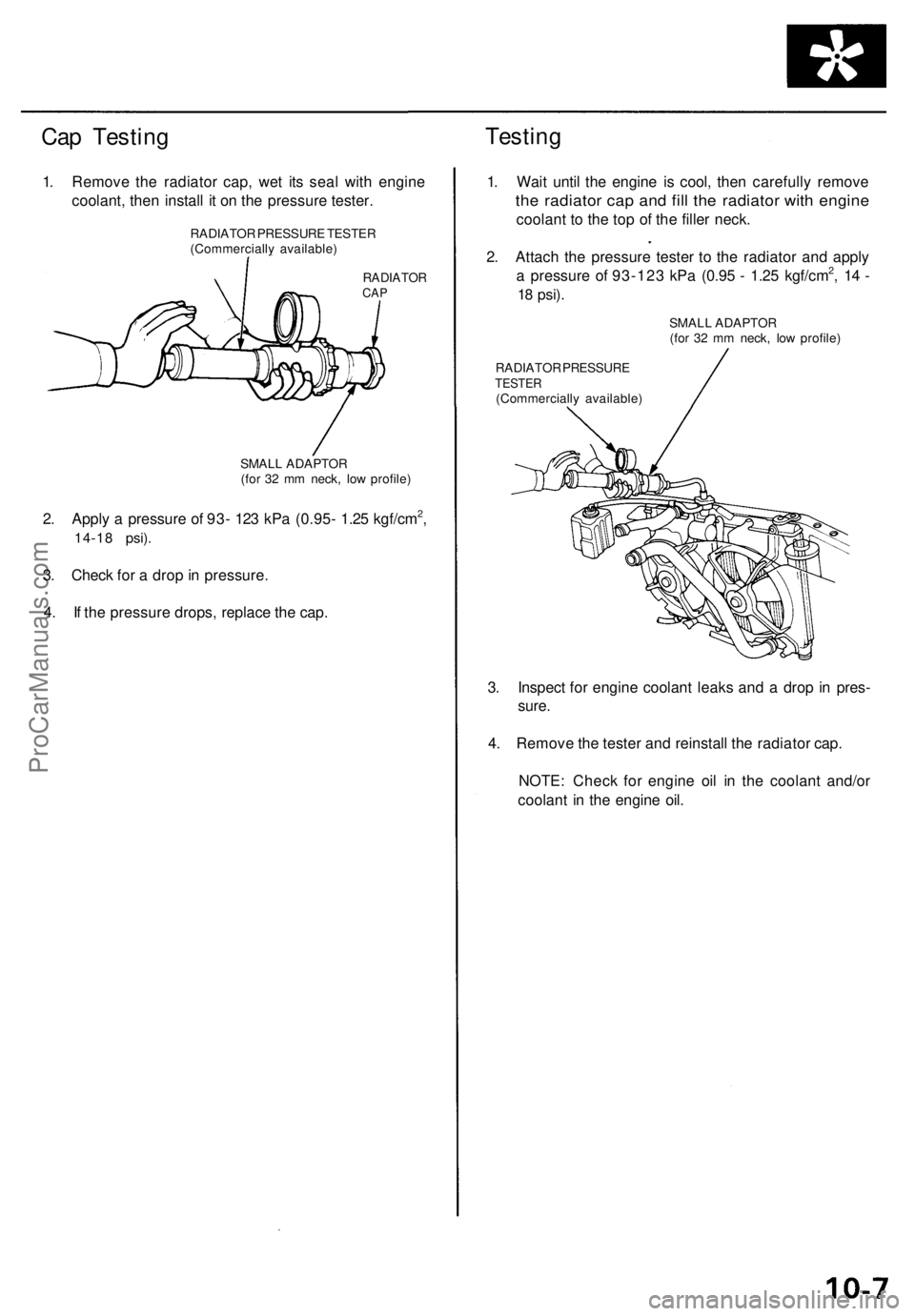

Cap Testing

Testing

1. Remove the radiator cap, wet its seal with engine

coolant, then install it on the pressure tester.

RADIATOR

CAP

2. Apply a pressure of 93- 123 kPa (0.95- 1.25 kgf/cm2,

14-18 psi).

3. Check for a drop in pressure.

4. If the pressure drops, replace the cap.

1. Wait until the engine is cool, then carefully remove

the radiator cap and fill the radiator with engine

coolant to the top of the filler neck.

2. Attach the pressure tester to the radiator and apply

a pressure of 93-123 kPa (0.95 - 1.25 kgf/cm2, 14 -

18

psi).

RADIATOR PRESSURE

TESTER

(Commercially available)

3. Inspect for engine coolant leaks and a drop in pres-

sure.

4. Remove the tester and reinstall the radiator cap.

NOTE: Check for engine oil in the coolant and/or

coolant in the engine oil.

RADIATOR PRESSURE TESTER

(Commercially available)

SMALL ADAPTOR

(for 32 mm neck, low profile)

SMALL ADAPTOR

(for 32 mm neck, low profile)ProCarManuals.com

Page 512 of 1954

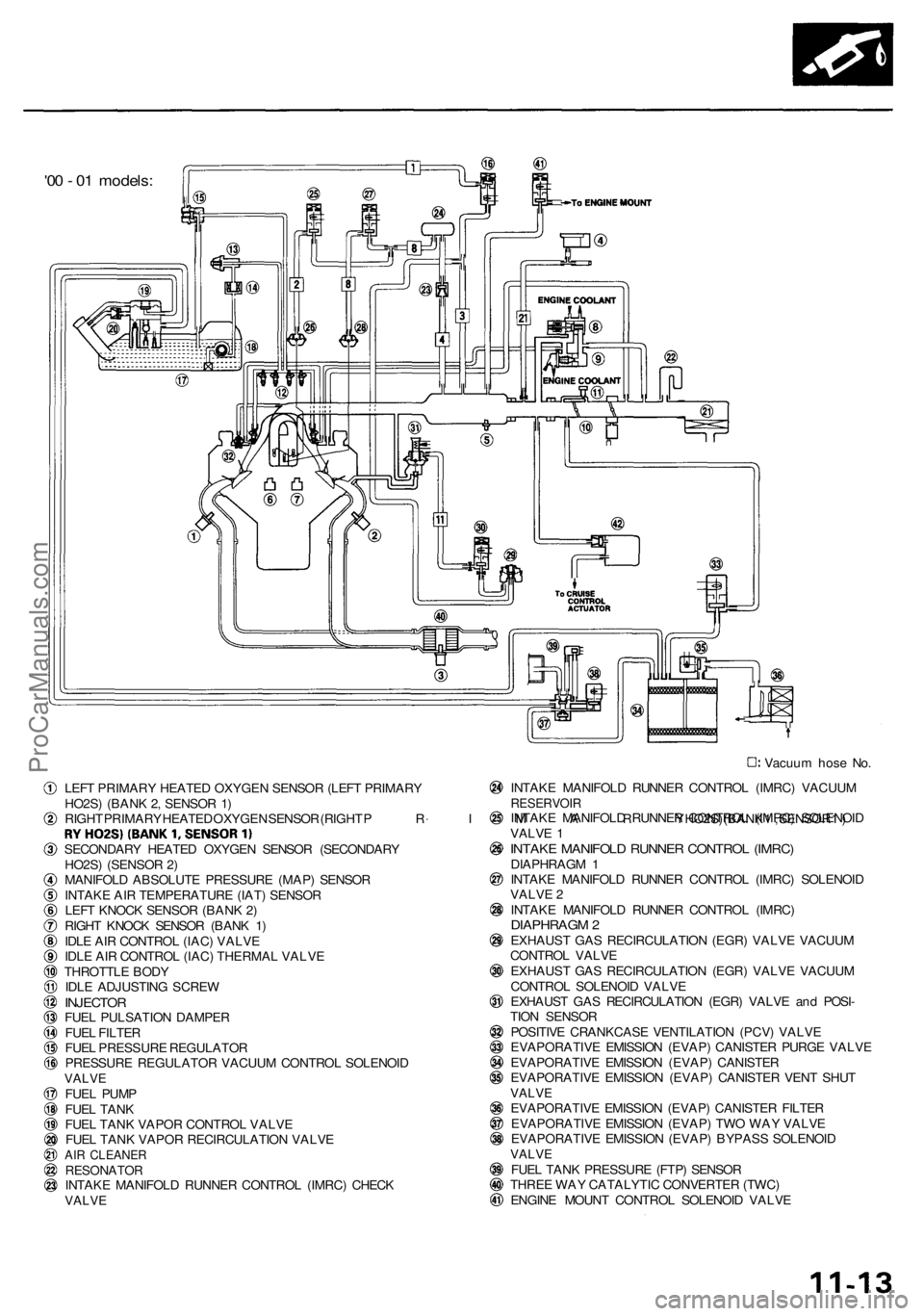

'00 - 01 models:

Vacuum hose No.

LEFT PRIMARY HEATED OXYGEN SENSOR (LEFT PRIMARY

HO2S) (BANK 2, SENSOR 1)

RIGHT PRIMARY HEATED OXYGEN SENSOR (RIGHT

PRIMARY

HO2S) (BANK

1,

SENSOR

1)

SECONDARY HEATED OXYGEN SENSOR (SECONDARY

HO2S) (SENSOR 2)

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

INTAKE AIR TEMPERATURE (IAT) SENSOR

LEFT KNOCK SENSOR (BANK 2)

RIGHT KNOCK SENSOR (BANK 1)

IDLE AIR CONTROL (IAC) VALVE

IDLE AIR CONTROL (IAC) THERMAL VALVE

THROTTLE BODY

IDLE ADJUSTING SCREW

INJECTOR

FUEL PULSATION DAMPER

FUEL FILTER

FUEL PRESSURE REGULATOR

PRESSURE REGULATOR VACUUM CONTROL SOLENOID

VALVE

FUEL PUMP

FUEL TANK

FUEL TANK VAPOR CONTROL VALVE

FUEL TANK VAPOR RECIRCULATION VALVE

AIR CLEANER

RESONATOR

INTAKE MANIFOLD RUNNER CONTROL (IMRC) CHECK

VALVE

INTAKE MANIFOLD RUNNER CONTROL (IMRC) VACUUM

RESERVOIR

INTAKE MANIFOLD RUNNER CONTROL (IMRC) SOLENOID

VALVE 1

INTAKE MANIFOLD RUNNER CONTROL (IMRC)

DIAPHRAGM 1

INTAKE MANIFOLD RUNNER CONTROL (IMRC) SOLENOID

VALVE 2

INTAKE MANIFOLD RUNNER CONTROL (IMRC)

DIAPHRAGM 2

EXHAUST GAS RECIRCULATION (EGR) VALVE VACUUM

CONTROL VALVE

EXHAUST GAS RECIRCULATION (EGR) VALVE VACUUM

CONTROL SOLENOID VALVE

EXHAUST GAS RECIRCULATION (EGR) VALVE and POSI-

TION SENSOR

POSITIVE CRANKCASE VENTILATION (PCV) VALVE

EVAPORATIVE EMISSION (EVAP) CANISTER PURGE VALVE

EVAPORATIVE EMISSION (EVAP) CANISTER

EVAPORATIVE EMISSION (EVAP) CANISTER VENT SHUT

VALVE

EVAPORATIVE EMISSION (EVAP) CANISTER FILTER

EVAPORATIVE EMISSION (EVAP) TWO WAY VALVE

EVAPORATIVE EMISSION (EVAP) BYPASS SOLENOID

VALVE

FUEL TANK PRESSURE (FTP) SENSOR

THREE WAY CATALYTIC CONVERTER (TWC)

ENGINE MOUNT CONTROL SOLENOID VALVEProCarManuals.com

Page 541 of 1954

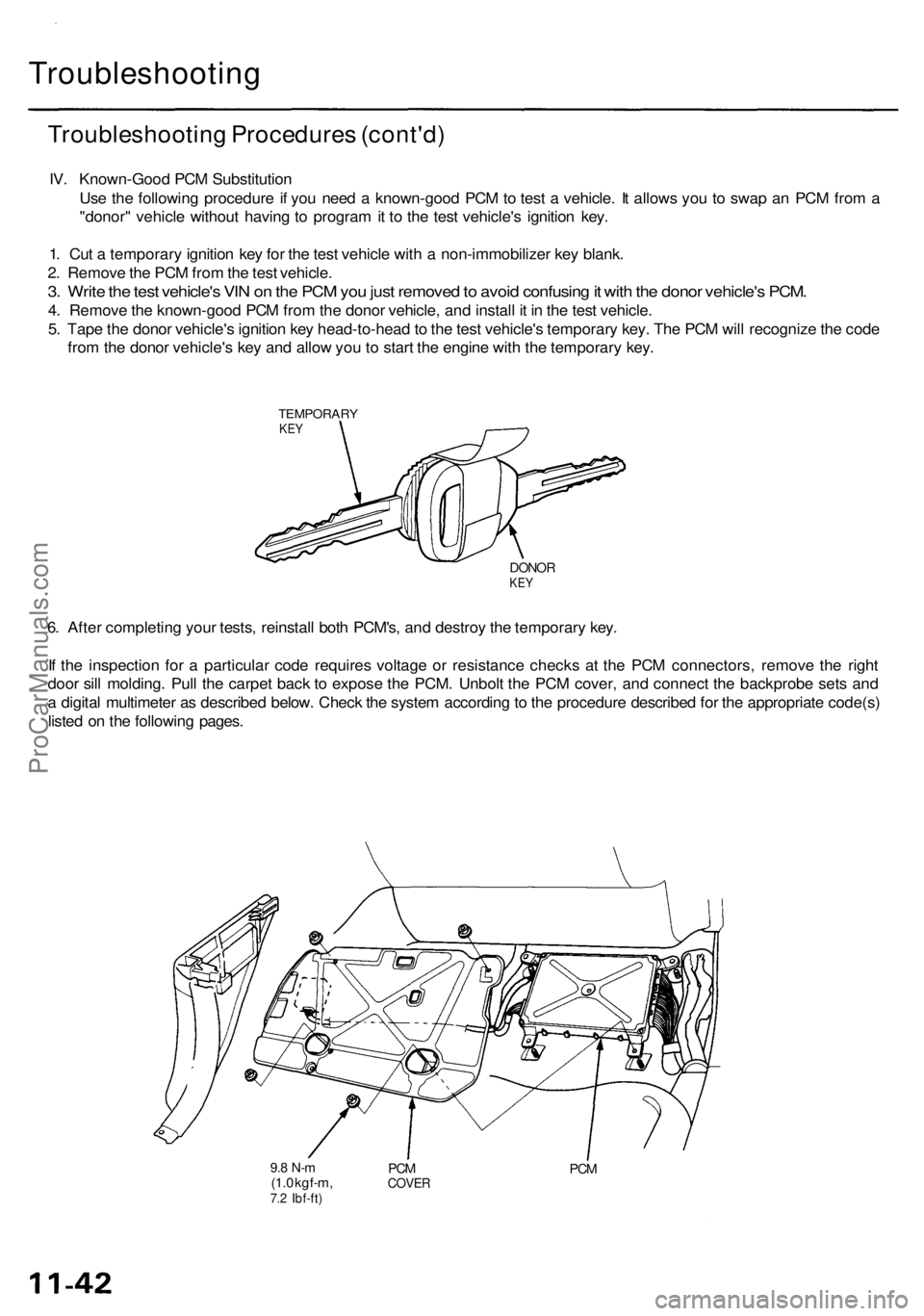

PCM

PCM

COVER

9.8 N-m

(1.0 kgf-m,

7.2 Ibf-ft)

6. After completing your tests, reinstall both PCM's, and destroy the temporary key.

If the inspection for a particular code requires voltage or resistance checks at the PCM connectors, remove the right

door sill molding. Pull the carpet back to expose the PCM. Unbolt the PCM cover, and connect the backprobe sets and

a digital multimeter as described below. Check the system according to the procedure described for the appropriate code(s)

listed on the following pages.

DONOR

KEY

TEMPORARY

KEY

Troubleshooting

Troubleshooting Procedures (cont'd)

IV. Known-Good PCM Substitution

Use the following procedure if you need a known-good PCM to test a vehicle. It allows you to swap an PCM from a

"donor" vehicle without having to program it to the test vehicle's ignition key.

1. Cut a temporary ignition key for the test vehicle with a non-immobilizer key blank.

2. Remove the PCM from the test vehicle.

3. Write the test vehicle's VIN on the PCM you just removed to avoid confusing it with the donor vehicle's PCM.

4. Remove the known-good PCM from the donor vehicle, and install it in the test vehicle.

5. Tape the donor vehicle's ignition key head-to-head to the test vehicle's temporary key. The PCM will recognize the code

from the donor vehicle's key and allow you to start the engine with the temporary key.ProCarManuals.com

Page 560 of 1954

How to Set Readiness Codes

Catalytic Converter

NOTE:

• Do not turn the ignition switch OFF.

• When the battery negative cable is disconnected, all

readiness codes are cleared.

Required condition ('96 - 97 models):

• Ambient temperature between 32 - 95°F (0 - 35°C).

• Altitude below 2,400 m (7,874 ft.).

Required condition ('98 - 01 models):

Ambient temperature between 20 - 95°F (-7 - 35°C).

1. Connect the scan tool to the Data Link Connector

(DLC).

2. Start the engine. Hold it at 3,000 rpm with no load

(in Park or neutral) until the radiator fan comes on.

3. Drive for about 10 minutes without stopping on a

highway or freeway. Your speed can vary.

4. '96 - 97 models:

With the transmission in D4 position, drive at a

steady speed between 33 - 37 mph (53 - 59 km/h)

for 30 seconds.

'98 - 01 models:

With the A/T in D4 position, drive at a steady speed

between 50 - 62 mph (80 - 100 km/h) for 30 sec-

onds.

5. Do step 4 three times. Between each repetition,

close the throttle completely for 1 - 2 seconds. If the

engine is stopped during this part of the procedure,

go to step 3 and do the procedure again.

6. Check for the readiness code with the scan tool.

EGR Monitor

NOTE:

• Do not turn the ignition switch OFF.

• When the battery negative cable is disconnected, all

readiness codes are cleared.

Required condition ('96 - 97 models):

Altitude below 2,400 m (7,874 ft.).

1. Connect the scan tool to the Data Link Connector

(DLC).

2. Start the engine, and hold it at 3,000 rpm with no

load (in Park or neutral) until the radiator fan comes

on.

3. Drive at a steady speed with the transmission in D4

position, between 50 - 62 mph (80 - 100 km/h) for

more than 10 seconds.

4. With the A/T in D4 position, decelerate from 62 mph

(100 km/h) by completely releasing the throttle for

at least 5 seconds. If the engine is stopped during

this procedure, go to step 3 and do the procedure

again.

5. Check for the readiness code with the scan tool.

EVAP Leak Monitor

NOTE:

• When the battery negative cable is disconnected, all

readiness codes are cleared.

• If the engine is stopped while doing the procedure

between stops 6 and 16, do this procedure from step

1 again.

1. Make sure the gasoline level is 60 - 90% of fuel tank

capacity (not full).

2. Turn the ignition switch OFF.

3. Let the vehicle sit more than 8 hours.

4. '96 - 97 models:

Make sure the outside temperature is 32 - 95°F (0 -

35°C).

'98 - 01 models:

Make sure the outside temperature is 20 - 95°F (-7 -

35°C).

5. Connect the scan tool to the Data Link Connector

(DLC).

6. Start the engine and drive for about 15 minutes.

7. '96 - 97 models:

Keep the vehicle at a steady speed between 50 - 62

mph (80 - 100 km/h), without moving the accelera-

tor pedal, for about 1 minute.

'98 - 01 models:

Keep the vehicle at a steady speed between 50 - 70

mph (80 - 114 km/h), without moving the accelera-

tor pedal, for about 1 minute.

8. Stop the vehicle (do not stop engine).

9. Repeat steps 7 and 8 two more times.

10. Check for the readiness code with the scan tool. If

the readiness code does not set, go to step 11.

11. When ambient temperature is less than 32°F (0°C),

hold the engine at 3,000 rpm with no load (in Park

or neutral) until the radiator fan comes on.

12. When ambient temperature is more than 86°F

(30°C), remove the fuel fill cap, then install the fuel

fill cap.

13. After step 12, drive for about 20 minutes on a free-

way.

14. '96 - 97 models:

Keep the vehicle at a steady speed between 50 - 62

mph (80 - 100 km/h), without moving the accelera-

tor pedal, for about 1 minute.

'98 - 01 models:

Keep the vehicle at a steady speed between 50 - 70

mph (80 - 114 km/h), without moving the accelera-

tor pedal, for about 1 minute.

15. Stop the vehicle (do not stop the engine).

16. Repeat steps 14 and 15 two more times.

17. Check for the readiness code with the scan tool.ProCarManuals.com

Page 561 of 1954

PGM-FI System

How to Set Readiness Codes (cont'd)

HO2S Monitor

NOTE:

• Do not turn the ignition switch OFF.

• When the battery negative cable is disconnected, all

readiness codes are cleared.

Required condition ('96 - 97 models):

• Ambient temperature between 32 - 95°F (0 - 35°C).

• Altitude below 2,400 m (7,874 ft.).

Required condition ('98 - 01 models):

Ambient temperature between 20 - 95°F (-7 - 35°C).

1. Connect the scan tool to the Data Link Connector

(DLC).

2. Start the engine, and hold it at 3,000 rpm with no

load (in Park or neutral) until the radiator fan comes

on.

3. Let the engine idle for 5 seconds.

4. Drive at a steady speed between 50 - 62 mph (80 -

100 km/h) for about 2 minutes.

5. With the A/T in D4 position, decelerate from 62 mph

(100 km/h) by completely releasing the throttle for

at least 5 seconds. If the engine is stopped during

this procedure, go to step 4 and do the procedure

again.

6. Check for the readiness code with the scan tool.

HO2S Heater Monitor

NOTE: When the battery negative cable is disconnected,

all readiness codes are cleared.

1. Connect the scan tool to the Data Link Connector

(DLC).

2. Start the engine, and let the engine idle for 10 min-

utes.

3. Check for the readiness code with the scan tool.ProCarManuals.com

Page 562 of 1954

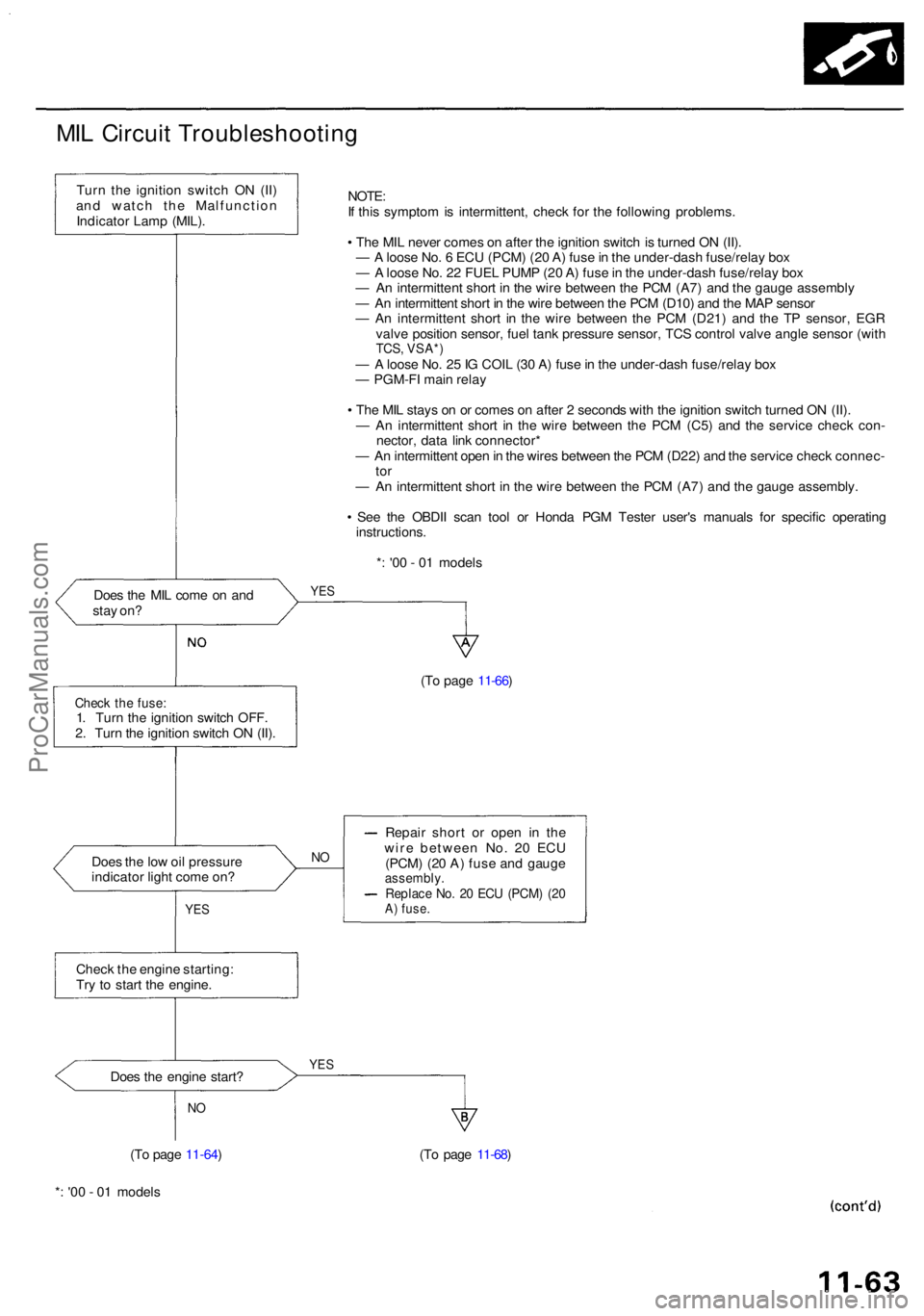

MIL Circui t Troubleshootin g

Turn th e ignitio n switc h O N (II )

an d watc h th e Malfunctio n

Indicato r Lam p (MIL) . NOTE

:

I f thi s sympto m is intermittent , chec k fo r th e followin g problems .

• Th e MI L neve r come s o n afte r th e ignitio n switc h is turne d O N (II) .

— A loos e No . 6 EC U (PCM ) (2 0 A ) fus e in th e under-das h fuse/rela y bo x

— A loos e No . 2 2 FUE L PUM P (2 0 A ) fus e in th e under-das h fuse/rela y bo x

— A n intermitten t shor t i n th e wir e betwee n th e PC M (A7 ) an d th e gaug e assembl y

— A n intermitten t shor t i n th e wir e betwee n th e PC M (D10 ) an d th e MA P senso r

— A n intermitten t shor t i n th e wir e betwee n th e PC M (D21 ) an d th e T P sensor , EG R

valv e positio n sensor , fue l tan k pressur e sensor , TC S contro l valv e angl e senso r (wit h

TCS , VSA* )— A loos e No . 2 5 IG COI L (3 0 A ) fus e in th e under-das h fuse/rela y bo x

— PGM-F I mai n rela y

• Th e MI L stay s o n o r come s o n afte r 2 second s wit h th e ignitio n switc h turne d O N (II) .

— A n intermitten t shor t i n th e wir e betwee n th e PC M (C5 ) an d th e servic e chec k con -

nector , dat a lin k connector *

— A n intermitten t ope n in th e wire s betwee n th e PC M (D22 ) an d th e servic e chec k connec -

tor— A n intermitten t shor t i n th e wir e betwee n th e PC M (A7 ) an d th e gaug e assembly .

• Se e th e OBDI I sca n too l o r Hond a PG M Teste r user' s manual s fo r specifi c operatin g

instructions .

Doe s th e MI L com e o n an d

sta y on ?

YE S

(To pag e 11-66 )

Doe s th e lo w oi l pressur e

indicato r ligh t com e on ?

NO

YE S

Repai r shor t o r ope n i n th e

wir e betwee n No . 2 0 EC U

(PCM ) (2 0 A ) fus e an d gaug e

assembly .Replace No . 2 0 EC U (PCM ) (2 0A) fuse .

Check th e engin e starting :

Tr y t o star t th e engine .

Doe s th e engin e start ?

YES

(To pag e 11-68 )

* : '0 0 - 0 1 model s

(T

o pag e 11-64 )

NO

Chec k th e fuse :1. Tur n th e ignitio n switc h OFF .

2 . Tur n th e ignitio n switc h O N (II) . *

: '0 0 - 0 1 model s

ProCarManuals.com

Page 568 of 1954

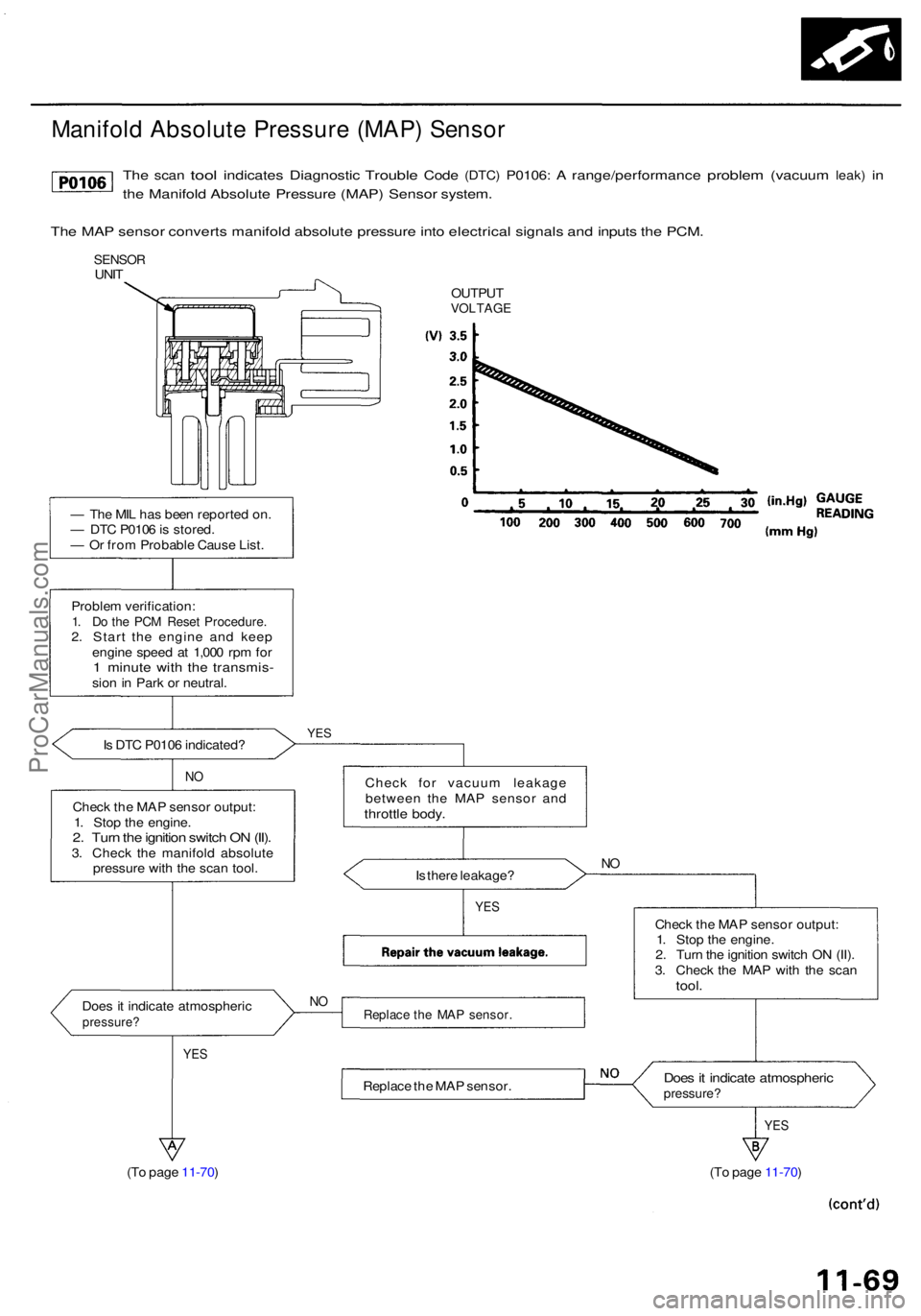

Manifold Absolut e Pressur e (MAP ) Senso r

The sca n tool indicate s Diagnosti c Trouble Code (DTC ) P0106 : A range/performanc e problem (vacuu m leak) in

th e Manifol d Absolut e Pressur e (MAP ) Senso r system .

The MA P senso r convert s manifol d absolut e pressur e int o electrica l signal s an d input s th e PCM .

SENSO RUNIT

— Th e MI L ha s bee n reporte d on .

— DT C P010 6 is stored .

— O r fro m Probabl e Caus e List .

Proble m verification :

1. D o th e PC M Rese t Procedure .2. Star t th e engin e an d kee p

engin e spee d a t 1,00 0 rp m fo r

1 minut e wit h th e transmis -sion in Par k o r neutral .

I s DT C P010 6 indicated ?

NO

Chec k th e MA P senso r output :

1 . Sto p th e engine .

2. Tur n th e ignitio n switc h O N (II) .3. Chec k th e manifol d absolut e

pressur e wit h th e sca n tool .

Doe s i t indicat e atmospheri c

pressure?

YES

(To pag e 11-70 ) OUTPU

T

VOLTAG E

YES

Chec k fo r vacuu m leakag e

betwee n th e MA P senso r an d

throttl e body .

Is ther e leakage ?NO

Replac e th e MA P sensor .

Check th e MA P senso r output :

1 . Sto p th e engine .

2 . Tur n th e ignitio n switc h O N (II) .

3 . Chec k th e MA P wit h th e sca n

tool.

Replac e th e MA P sensor .Does it indicat e atmospheri cpressure?

YES

(To pag e 11-70 )

YES

NO

ProCarManuals.com