Test ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1507 of 1771

Heater Valve

Test

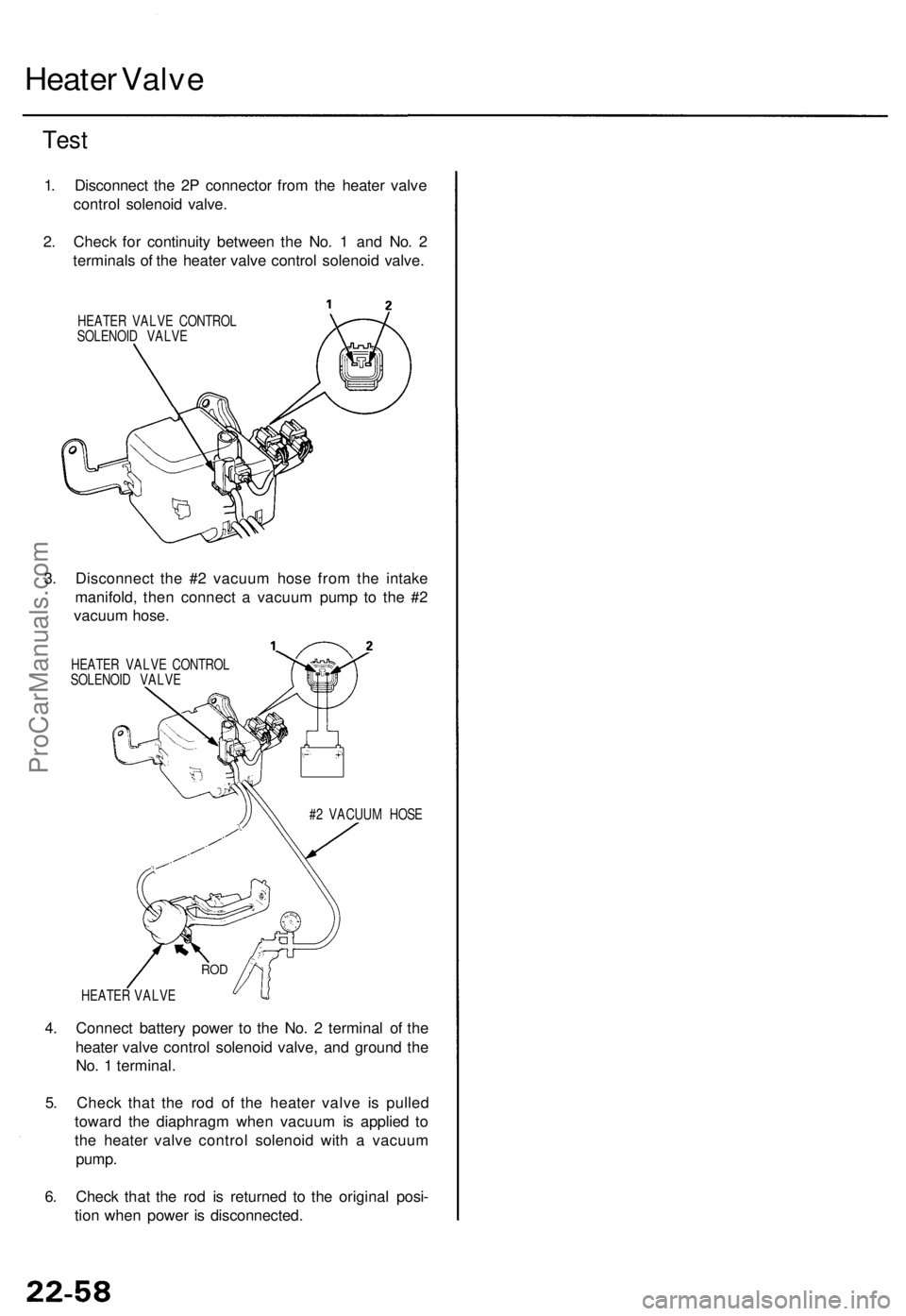

1. Disconnect the 2P connector from the heater valve

control solenoid valve.

2. Check for continuity between the No. 1 and No. 2

terminals of the heater valve control solenoid valve.

HEATER VALVE CONTROL

SOLENOID VALVE

3. Disconnect the #2 vacuum hose from the intake

manifold, then connect a vacuum pump to the #2

vacuum hose.

HEATER VALVE CONTROL

SOLENOID VALVE

#2 VACUUM HOSE

HEATER VALVE

4. Connect battery power to the No. 2 terminal of the

heater valve control solenoid valve, and ground the

No. 1 terminal.

5. Check that the rod of the heater valve is pulled

toward the diaphragm when vacuum is applied to

the heater valve control solenoid with a vacuum

pump.

6. Check that the rod is returned to the original posi-

tion when power is disconnected.

RODProCarManuals.com

Page 1510 of 1771

Evaporator

Overhaul

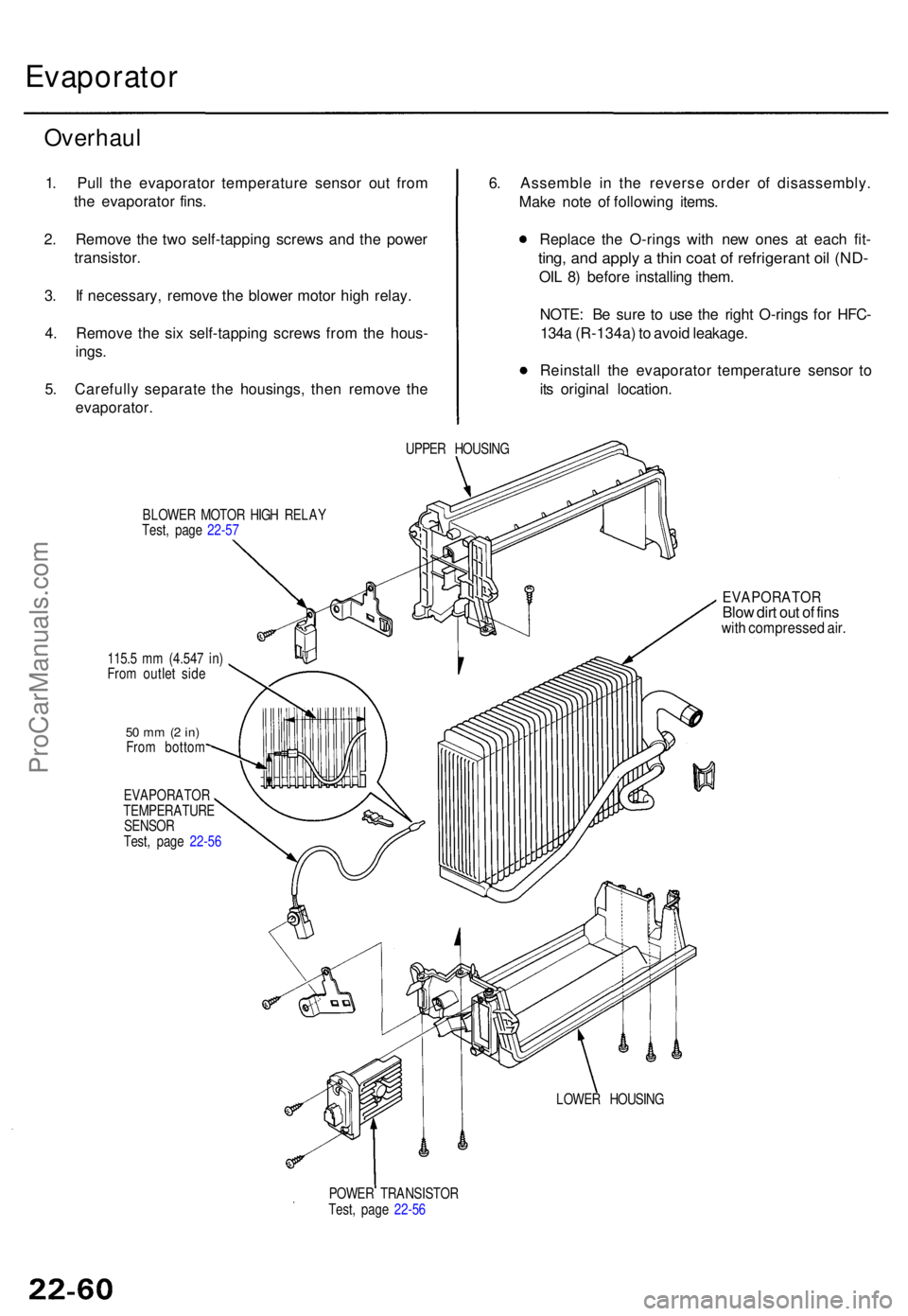

1. Pul l th e evaporato r temperatur e senso r ou t fro m

th e evaporato r fins .

2 . Remov e th e tw o self-tappin g screw s an d th e powe r

transistor .

3 . I f necessary , remov e th e blowe r moto r hig h relay .

4 . Remov e th e si x self-tappin g screw s fro m th e hous -

ings .

5 . Carefull y separat e th e housings , the n remov e th e

evaporator .

6. Assembl e i n th e revers e orde r o f disassembly .

Mak e not e o f followin g items .

Replac e th e O-ring s wit h ne w one s a t eac h fit -

ting , an d appl y a thi n coa t o f refrigeran t oi l (ND -

OIL 8 ) befor e installin g them .

NOTE : B e sur e t o us e th e righ t O-ring s fo r HFC -

134 a (R-134a ) t o avoi d leakage .

Reinstal l th e evaporato r temperatur e senso r t o

it s origina l location .

UPPER HOUSIN G

BLOWE R MOTO R HIG H RELA Y

Test , pag e 22-5 7

115. 5 m m (4.54 7 in )

Fro m outle t sid e

50 m m (2 in )Fro m botto m

EVAPORATO R

TEMPERATUR E

SENSO R

Test , pag e 22-5 6

EVAPORATO RBlow dir t ou t o f fin swit h compresse d air .

LOWE R HOUSIN G

POWE R TRANSISTO R

Test , pag e 22-5 6

ProCarManuals.com

Page 1516 of 1771

A/C Servic e Tip s an d Precaution s

The ai r conditione r syste m use s HFC-134 a (R-134a) refrigeran t and polyalkyleneglyco l (PAG ) refrigeran t oil*, whic h are no t

compatibl e wit h CFC-1 2 (R-12 ) refrigeran t an d minera l oil . D o no t us e R-1 2 refrigeran t o r minera l oi l i n thi s system , an d d o

no t attemp t t o us e R-1 2 servicin g equipment ; damag e t o th e ai r conditione r syste m o r you r servicin g equipmen t wil l result .

* DENS O ND-OIL8 :

P/N 3889 7 - PR 7 - A01AH : 12 0 ( 4 fl-oz , 4. 2 Imp-oz )

P/N 3889 9 - PR 7 - A01 : 4 0 ( 1 1/ 3 fl-oz , 1. 4 Imp-oz )

Us e onl y servic e equipmen t tha t i s U.L.-liste d an d i s certifie d t o mee t th e requirement s o f SA E J221 0 t o remov e R-134 a

fro m th e ai r conditione r system .

CAUTION : Exposur e t o ai r conditione r refrigeran t an d lubrican t vapo r o r mis t ca n irritat e eyes , nos e an d throat . Avoi d

breathin g th e ai r conditione r refrigeran t an d lubrican t vapo r o r mist .

I f accidenta l syste m discharg e occurs , ventilat e wor k are a befor e resumin g service .

R-134 a servic e equipmen t o r vehicl e ai r conditione r system s shoul d no t b e pressur e teste d o r lea k teste d wit h compresse d air .

Som e mixture s o f ai r an d R-134 a hav e bee n show n to b e combustibl e a t elevate d pressure s an d ca n resul t

i n fir e o r explosio n causin g injur y o r propert y damage . Neve r us e compresse d ai r t o pressur e tes t R-134 a servic e equip -

men t o r vehicl e ai r conditione r systems .

Additiona l healt h an d safet y informatio n ma y b e obtaine d fro m th e refrigeran t an d lubrican t manufacturers .

1 . Alway s disconnec t th e negativ e cabl e fro m th e batter y wheneve r replacin g ai r conditionin g parts .

2 . Kee p moistur e an d dus t ou t o f th e system . Whe n disconnectin g an y lines , plu g o r ca p th e fitting s immediately ; don' t

remov e th e cap s o r plug s unti l jus t befor e yo u reconnec t eac h line .

3 . Befor e connecting any hos e o r line , appl y a fe w drop s o f refrigeran t oi l t o th e O-ring .

4 . Whe n tightenin g o r loosenin g a fitting , us e a secon d wrenc h t o suppor t th e matchin g fitting .

5 . Whe n dischargin g th e system , us e a R-134 a refrigeran t Recovery/Recycling/Chargin g System ; don' t releas e refriger -

an t int o th e atmosphere .

6 . Ad d refrigeran t oi l afte r replacin g th e followin g parts :

NOTE :

To avoi d contamination , d o no t retur n th e oi l t o th e containe r onc e dispensed , an d neve r mi x i t wit h othe r refriger -

ant oils .

Immediatel y afte r usin g th e oil , replac e th e ca p o n th e container , an d sea l i t t o avoi d moistur e absorption .

D o no t spil l th e refrigeran t oi l o n th e vehicle ; i t ma y damag e th e paint ; i f th e refrigeran t oi l contact s th e paint , was h

i t of f immediately .

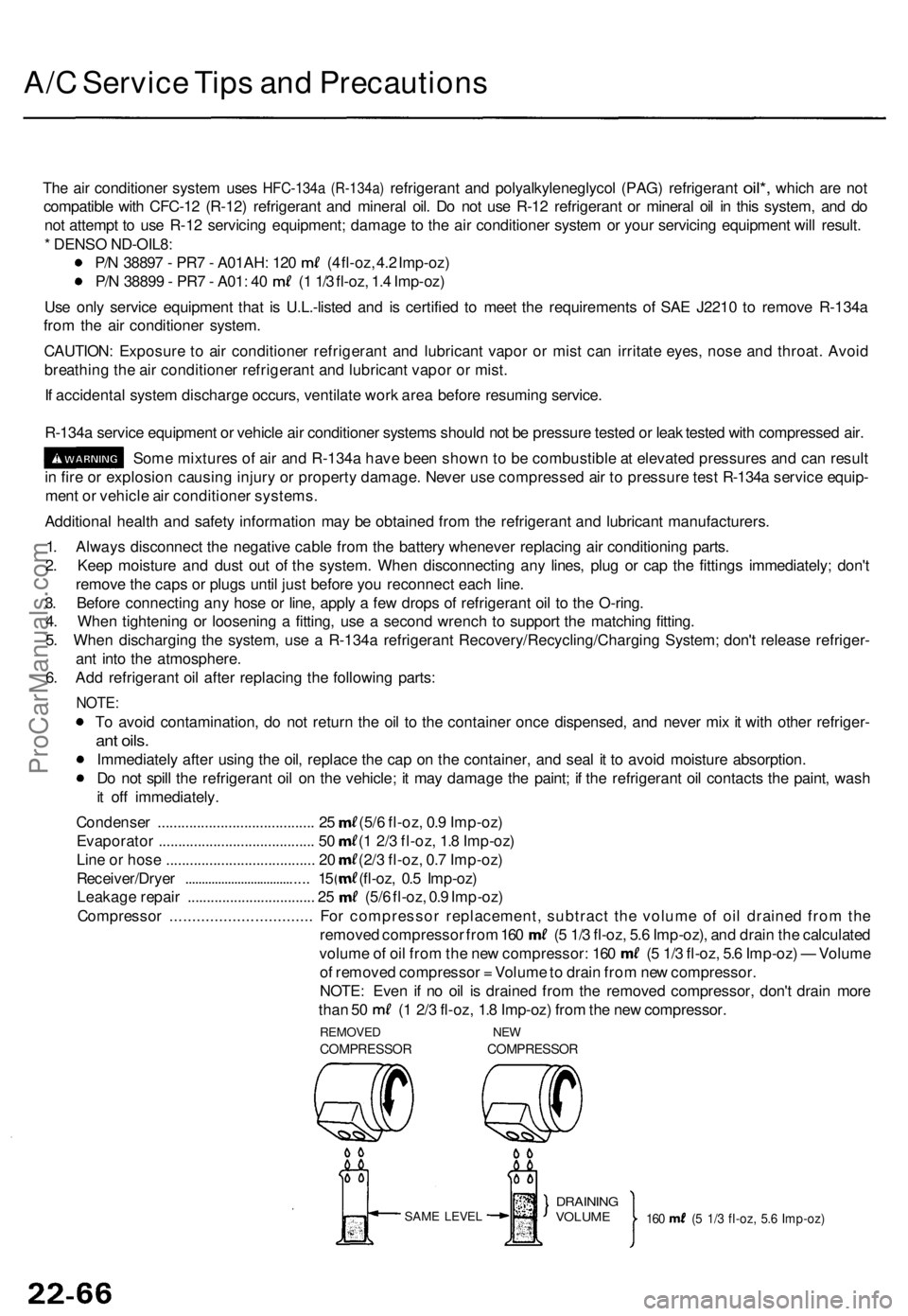

Condense r ....................................... . 2 5 (5/ 6 fl-oz , 0. 9 Imp-oz )

Evaporato r ....................................... . 5 0 ( 1 2/ 3 fl-oz , 1. 8 Imp-oz )

Lin e o r hos e ..................................... . 2 0 (2/ 3 fl-oz , 0. 7 Imp-oz )

Receiver/Drye r ................................ ..... 15(1/ 2(fl-oz , 0. 5 Imp-oz )

Leakag e repai r ................................ . 2 5 (5/ 6 fl-oz , 0. 9 Imp-oz )

Compresso r ............................... . Fo r compresso r replacement , subtrac t th e volum e o f oi l draine d fro m th e

remove d compresso r fro m 16 0 ( 5 1/ 3 fl-oz , 5. 6 Imp-oz) , an d drai n th e calculate d

volume o f oi l fro m th e ne w compressor : 16 0 ( 5 1/ 3 fl-oz , 5. 6 Imp-oz ) — Volum e

o f remove d compresso r = Volum e to drai n fro m ne w compressor .

NOTE : Eve n i f n o oi l i s draine d fro m th e remove d compressor , don' t drai n mor e

than 5 0 ( 1 2/ 3 fl-oz , 1. 8 Imp-oz ) fro m th e ne w compressor .

REMOVED NE W

COMPRESSOR COMPRESSO R

SAME LEVE LDRAININ GVOLUME160 ( 5 1/ 3 fl-oz , 5. 6 Imp-oz )

ProCarManuals.com

Page 1518 of 1771

A/C Syste m Servic e

Performanc e Tes t

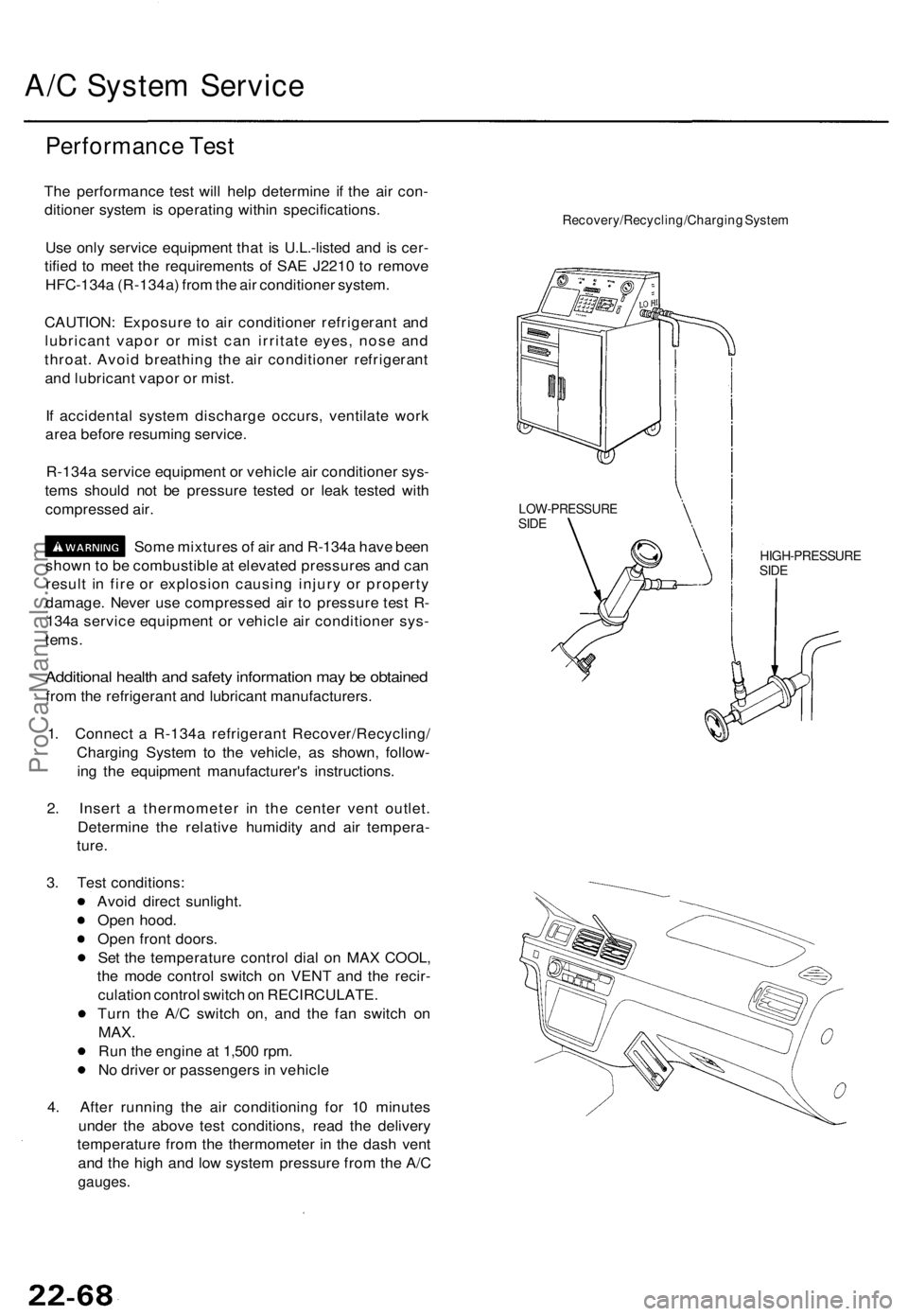

The performanc e tes t wil l hel p determin e i f th e ai r con -

ditione r syste m is operatin g withi n specifications .

Us e onl y servic e equipmen t tha t i s U.L.-liste d an d is cer -

tifie d t o mee t th e requirement s o f SA E J221 0 t o remov e

HFC-134 a (R-134a ) fro m th e ai r conditione r system .

CAUTION : Exposur e t o ai r conditione r refrigeran t an d

lubrican t vapo r o r mis t ca n irritat e eyes , nos e an d

throat . Avoi d breathin g th e ai r conditione r refrigeran t

an d lubrican t vapo r o r mist .

I f accidenta l syste m discharg e occurs , ventilat e wor k

are a befor e resumin g service .

R-134 a servic e equipmen t o r vehicl e ai r conditione r sys -

tem s shoul d no t b e pressur e teste d o r lea k teste d wit h

compresse d air .

Som e mixture s o f ai r an d R-134 a hav e bee n

show n to b e combustibl e a t elevate d pressure s an d ca n

resul t i n fir e o r explosio n causin g injur y o r propert y

damage . Neve r us e compresse d ai r t o pressur e tes t R -

134 a servic e equipmen t o r vehicl e ai r conditione r sys -

tems .

Additiona l healt h an d safet y informatio n ma y b e obtaine d

from th e refrigeran t an d lubrican t manufacturers .

1 . Connec t a R-134 a refrigeran t Recover/Recycling /

Chargin g Syste m to th e vehicle , a s shown , follow -

in g th e equipmen t manufacturer' s instructions .

2 . Inser t a thermomete r i n th e cente r ven t outlet .

Determin e th e relativ e humidit y an d ai r tempera -

ture .

Recovery/Recycling/Chargin g Syste m

HIGH-PRESSUR ESIDE

3. Tes t conditions :

Avoi d direc t sunlight .

Ope n hood .

Ope n fron t doors .

Se t th e temperatur e contro l dia l o n MA X COOL ,

th e mod e contro l switc h o n VEN T an d th e recir -

culatio n contro l switc h o n RECIRCULATE .

Tur n th e A/ C switc h on , an d th e fa n switc h o n

MAX .

Run th e engin e a t 1,50 0 rpm .

N o drive r o r passenger s in vehicl e

4 . Afte r runnin g th e ai r conditionin g fo r 1 0 minute s

unde r th e abov e tes t conditions , rea d th e deliver y

temperatur e fro m th e thermomete r i n th e das h ven t

an d th e hig h an d lo w syste m pressur e fro m th e A/ C

gauges .

LOW-PRESSUR ESIDE

ProCarManuals.com

Page 1519 of 1771

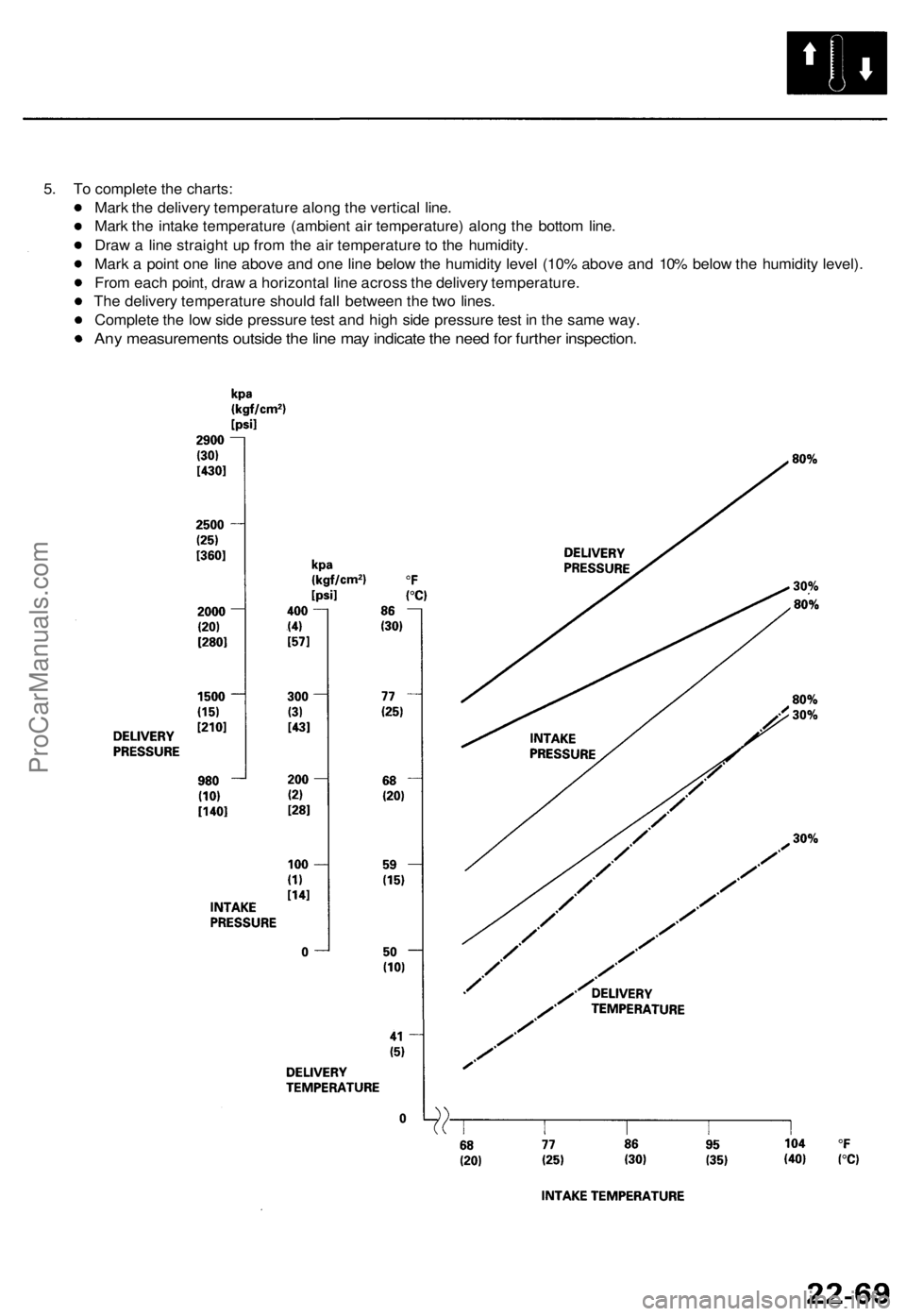

5. To complete the charts:

Mark the delivery temperature along the vertical line.

Mark the intake temperature (ambient air temperature) along the bottom line.

Draw a line straight up from the air temperature to the humidity.

Mark a point one line above and one line below the humidity level (10% above and 10% below the humidity level).

From each point, draw a horizontal line across the delivery temperature.

The delivery temperature should fall between the two lines.

Complete the low side pressure test and high side pressure test in the same way.

Any measurements outside the line may indicate the need for further inspection.ProCarManuals.com

Page 1520 of 1771

A/C Syste m Servic e

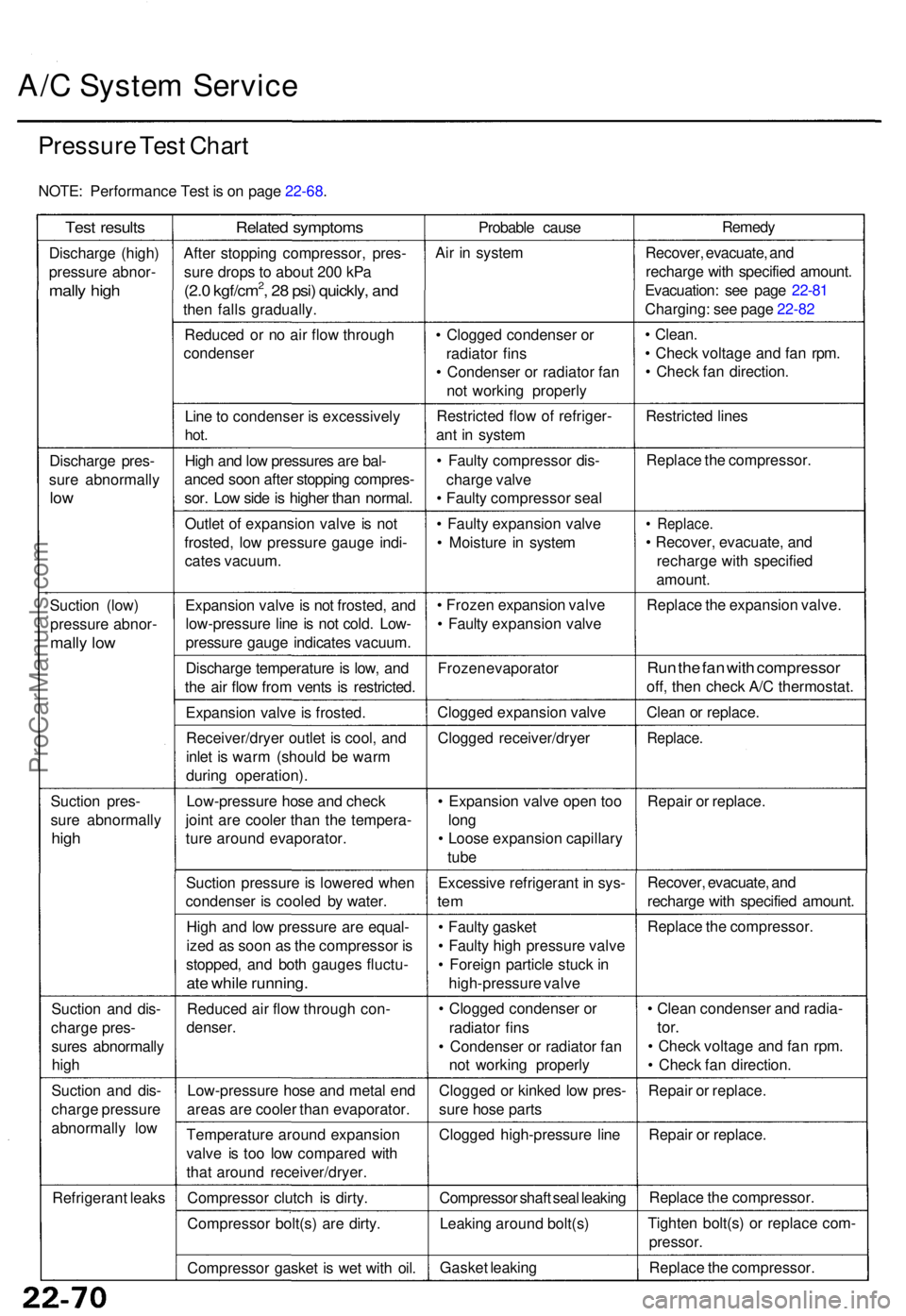

Pressur e Tes t Char t

NOTE : Performanc e Tes t i s o n pag e 22-68 .

Test result s

Discharg e (high )

pressur e abnor -

mally hig h

Discharg e pres -

sur e abnormall y

low

Suctio n (low )

pressur e abnor -

mally lo w

Suctio n pres -

sur e abnormall y

high

Suctio n an d dis -

charg e pres -

sure s abnormall y

hig h

Suctio n an d dis -

charg e pressur e

abnormall y lo w

Refrigeran t leak s

Relate d symptom s

After stoppin g compressor, pres-

sur e drop s t o abou t 20 0 kP a

(2.0 kgf/cm2, 2 8 psi ) quickly , an d

the n fall s gradually .

Reduce d o r n o ai r flo w throug h

condense r

Lin e to condense r i s excessivel y

hot.

Hig h an d lo w pressure s ar e bal -

ance d soo n afte r stoppin g compres -

sor . Lo w sid e is highe r tha n normal .

Outle t o f expansio n valv e is no t

frosted , lo w pressur e gaug e indi -

cate s vacuum .

Expansio n valv e is no t frosted , an d

low-pressur e lin e is no t cold . Low -

pressur e gaug e indicate s vacuum .

Discharg e temperatur e is low , an d

th e ai r flo w fro m vent s i s restricted .

Expansio n valv e is frosted .

Receiver/drye r outle t i s cool , an d

inle t i s war m (shoul d b e war m

durin g operation) .

Low-pressur e hos e an d chec k

join t ar e coole r tha n th e tempera -

tur e aroun d evaporator .

Suctio n pressur e is lowere d whe n

condense r i s coole d b y water .

Hig h an d lo w pressur e ar e equal -

ize d a s soo n a s th e compresso r i s

stopped , an d bot h gauge s fluctu -

ate whil e running .

Reduced ai r flo w throug h con -

denser .

Low-pressur e hos e an d meta l en d

area s ar e coole r tha n evaporator .

Temperatur e aroun d expansio n

valv e i s to o lo w compare d wit h

tha t aroun d receiver/dryer .

Compresso r clutc h i s dirty .

Compresso r bolt(s ) ar e dirty .

Compresso r gaske t i s we t wit h oil . Probabl

e caus e

Ai r i n syste m

• Clogge d condense r o r

radiato r fin s

• Condense r o r radiato r fa n

no t workin g properl y

Restricte d flo w o f refriger -

an t i n syste m

• Fault y compresso r dis -

charg e valv e

• Fault y compresso r sea l

• Fault y expansio n valv e

• Moistur e i n syste m

• Froze n expansio n valv e

• Fault y expansio n valv e

Froze n evaporato r

Clogge d expansio n valv e

Clogge d receiver/drye r

• Expansio n valv e ope n to o

lon g

• Loos e expansio n capillar y

tub e

Excessiv e refrigeran t i n sys -

tem

• Fault y gaske t

• Fault y hig h pressur e valv e

• Foreig n particl e stuc k in

high-pressur e valv e

• Clogge d condense r o r

radiato r fin s

• Condense r o r radiato r fa n

no t workin g properl y

Clogge d o r kinke d lo w pres -

sur e hos e part s

Clogge d high-pressur e lin e

Compresso r shaf t sea l leakin g

Leakin g aroun d bolt(s )

Gaske t leakin g Remed

y

Recover , evacuate , an d

recharg e wit h specifie d amount .

Evacuation : se e pag e 22-8 1

Charging : se e pag e 22-8 2

• Clean .

• Chec k voltag e an d fa n rpm .

• Chec k fa n direction .

Restricte d line s

Replac e th e compressor .

• Replace .

• Recover , evacuate , an d

recharg e wit h specifie d

amount .

Replac e th e expansio n valve .

Run th e fa n wit h compresso r

off, the n chec k A/ C thermostat .

Clea n o r replace .

Replace .

Repair o r replace .

Recover , evacuate , an d

recharg e wit h specifie d amount .

Replac e th e compressor .

• Clea n condense r an d radia -

tor.

• Chec k voltag e an d fa n rpm .

• Chec k fa n direction .

Repai r o r replace .

Repai r o r replace .

Replac e th e compressor .

Tighte n bolt(s ) o r replac e com -

pressor .

Replac e th e compressor .

ProCarManuals.com

Page 1521 of 1771

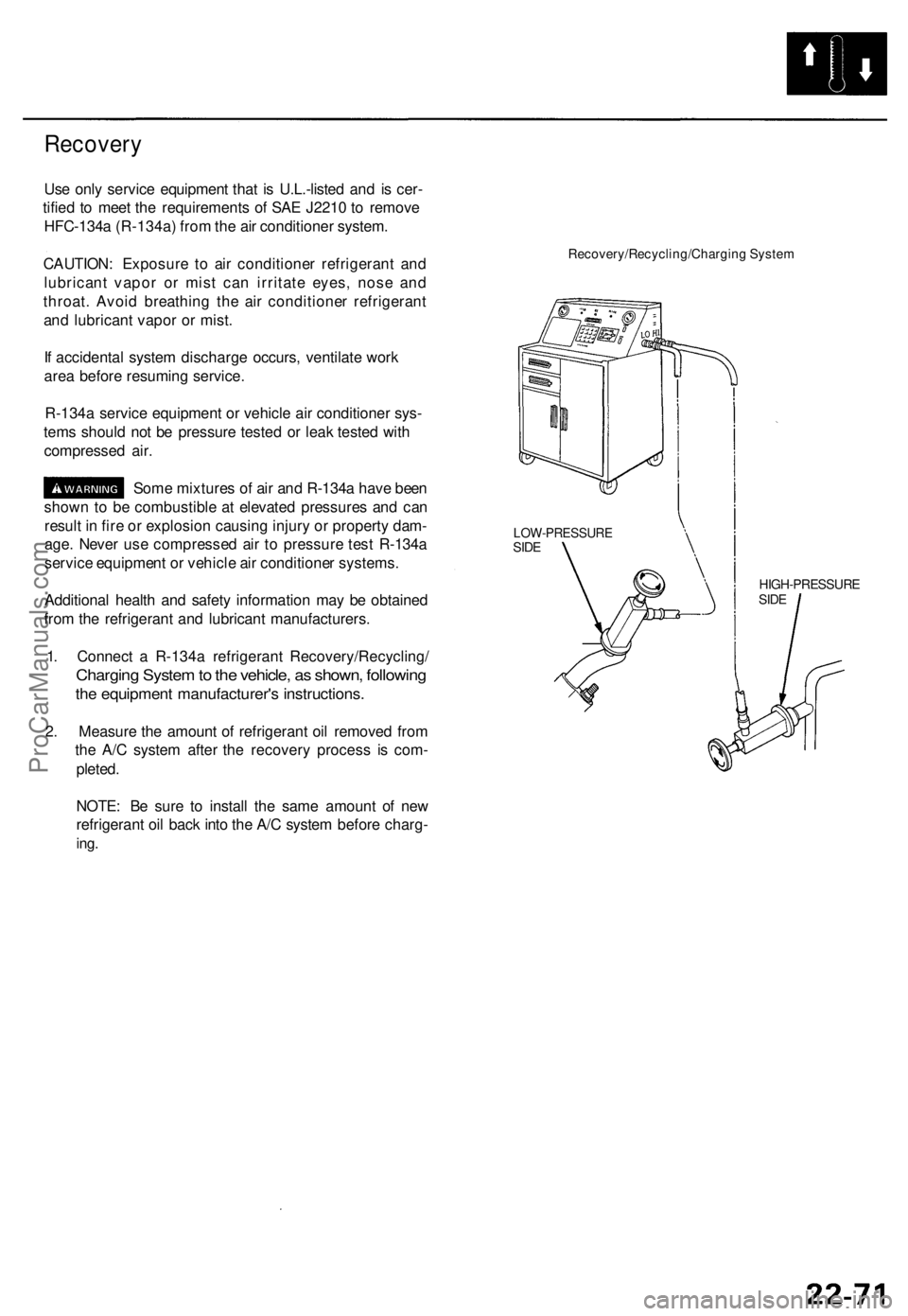

Recovery

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner refrigerant and

lubricant vapor or mist can irritate eyes, nose and

throat. Avoid breathing the air conditioner refrigerant

and lubricant vapor or mist.

If accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

compressed air.

Some mixtures of air and R-134a have been

shown to be combustible at elevated pressures and can

result in fire or explosion causing injury or property dam-

age. Never use compressed air to pressure test R-134a

service equipment or vehicle air conditioner systems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

1. Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the vehicle, as shown, following

the equipment manufacturer's instructions.

2. Measure the amount of refrigerant oil removed from

the A/C system after the recovery process is com-

pleted.

NOTE: Be sure to install the same amount of new

refrigerant oil back into the A/C system before charg-

ing.

Recovery/Recycling/Charging System

HIGH-PRESSURE

SIDE

LOW-PRESSURE

SIDEProCarManuals.com

Page 1532 of 1771

A/C System Service

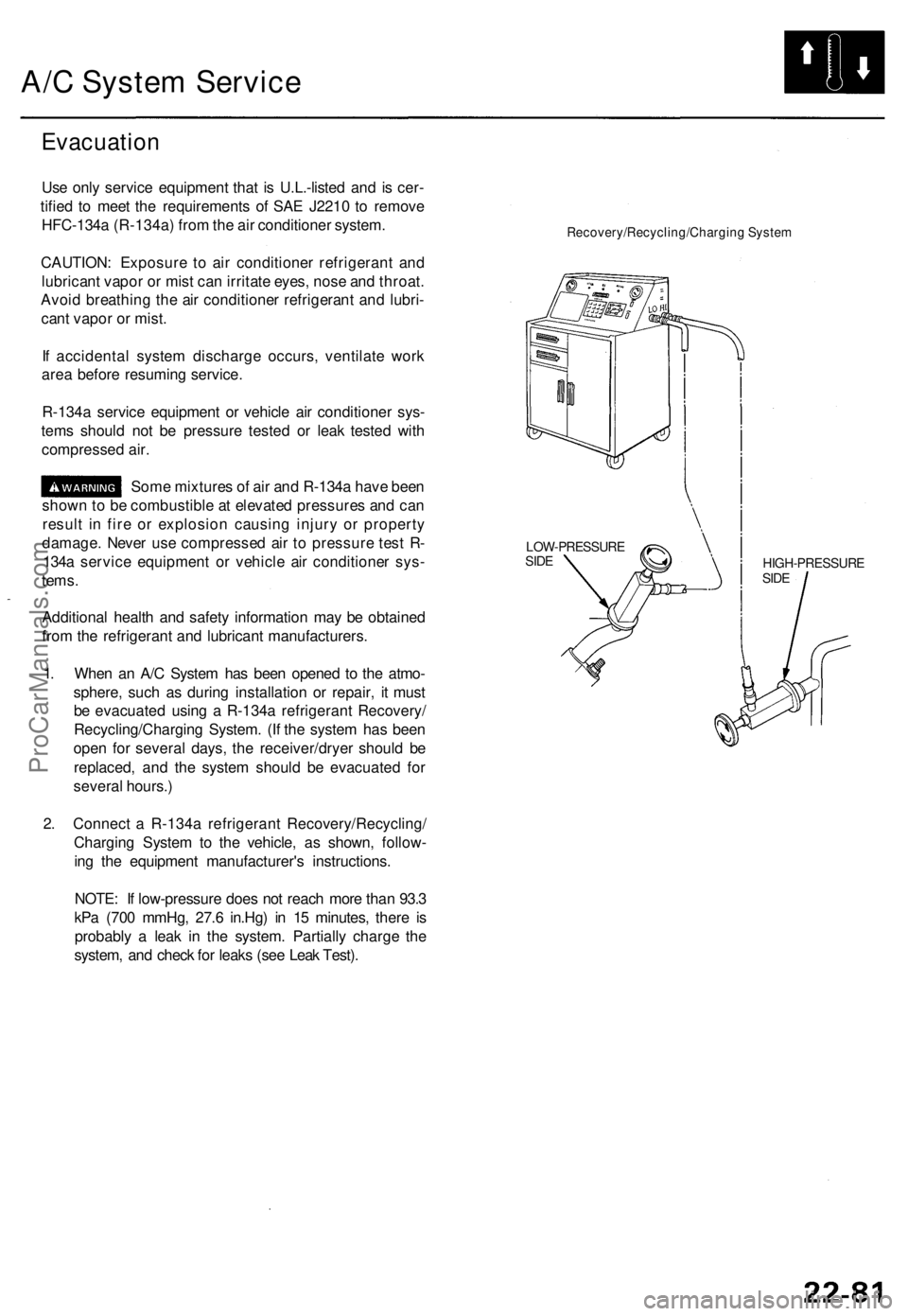

Evacuation

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner refrigerant and

lubricant vapor or mist can irritate eyes, nose and throat.

Avoid breathing the air conditioner refrigerant and lubri-

cant vapor or mist.

If accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

compressed air.

Some mixtures of air and R-134a have been

shown to be combustible at elevated pressures and can

result in fire or explosion causing injury or property

damage. Never use compressed air to pressure test R-

134a service equipment or vehicle air conditioner sys-

tems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

1. When an A/C System has been opened to the atmo-

sphere, such as during installation or repair, it must

be evacuated using a R-134a refrigerant Recovery/

Recycling/Charging System. (If the system has been

open for several days, the receiver/dryer should be

replaced, and the system should be evacuated for

several hours.)

2. Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the vehicle, as shown, follow-

ing the equipment manufacturer's instructions.

NOTE: If low-pressure does not reach more than 93.3

kPa (700 mmHg, 27.6 in.Hg) in 15 minutes, there is

probably a leak in the system. Partially charge the

system, and check for leaks (see Leak Test).

Recovery/Recycling/Charging System

HIGH-PRESSURE

SIDE

LOW-PRESSURE

SIDEProCarManuals.com

Page 1534 of 1771

Leak Tes t

Use onl y servic e equipmen t tha t i s U.L.-liste d an d i s cer -

tified to mee t th e requirement s o f SA E J221 0 to remov e

HFC-134 a (R-134a ) fro m th e ai r conditione r system .

CAUTION : Exposur e t o ai r conditione r refrigeran t an d

lubrican t vapo r o r mis t ca n irritat e eyes , nos e an d throat .

Avoi d breathin g th e ai r conditione r refrigeran t an d lubri -

can t vapo r o r mist .

I f accidenta l syste m discharg e occurs , ventilat e wor k

are a befor e resumin g service .

R-134 a servic e equipmen t o r vehicl e ai r conditione r sys -

tem s shoul d no t b e pressur e teste d o r lea k teste d wit h

compresse d air .

Som e mixture s o f ai r an d R-134 a hav e

bee n show n t o b e combustibl e a t elevate d pressure s

an d ca n resul t i n fir e o r explosio n causin g injur y o r

propert y damage . Neve r us e compresse d ai r t o pressur e

tes t R-134 a servic e equipmen t o r vehicl e ai r conditione r

systems.

Additiona l healt h an d safet y informatio n ma y b e obtaine d

fro m th e refrigeran t an d lubrican t manufacturers .

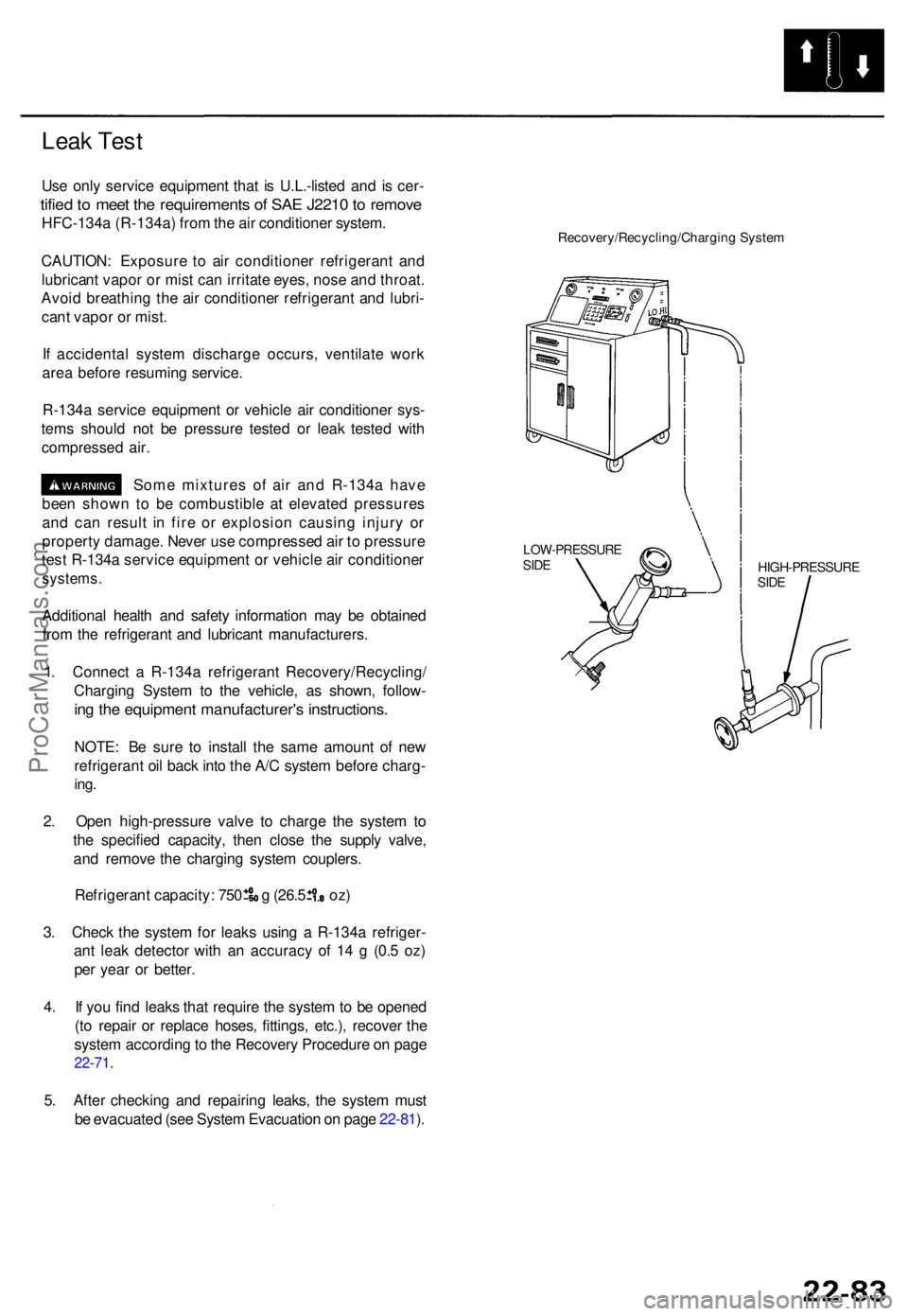

1 . Connec t a R-134 a refrigeran t Recovery/Recycling /

Chargin g Syste m to th e vehicle , a s shown , follow -

ing th e equipmen t manufacturer' s instructions .

NOTE: B e sur e t o instal l th e sam e amoun t o f ne w

refrigeran t oi l bac k int o th e A/ C syste m befor e charg -

ing.

2. Ope n high-pressur e valv e t o charg e th e syste m to

th e specifie d capacity , the n clos e th e suppl y valve ,

an d remov e th e chargin g syste m couplers .

Refrigeran t capacity : 75 0 g (26.5 oz )

3 . Chec k th e syste m fo r leak s usin g a R-134 a refriger -

an t lea k detecto r wit h a n accurac y o f 1 4 g (0. 5 oz )

pe r yea r o r better .

4 . I f yo u fin d leak s tha t requir e th e syste m to b e opene d

(t o repai r o r replac e hoses , fittings , etc.) , recove r th e

syste m accordin g to th e Recover y Procedur e o n pag e

22-71 .

Recovery/Recycling/Chargin g Syste m

HIGH-PRESSUR ESIDE

5. Afte r checkin g an d repairin g leaks , th e syste m mus t

b e evacuate d (se e Syste m Evacuatio n o n pag e 22-81 ).

LOW-PRESSUR ESIDE

ProCarManuals.com

Page 1537 of 1771

Troubleshooting

Tips and Precautions (cont'd)

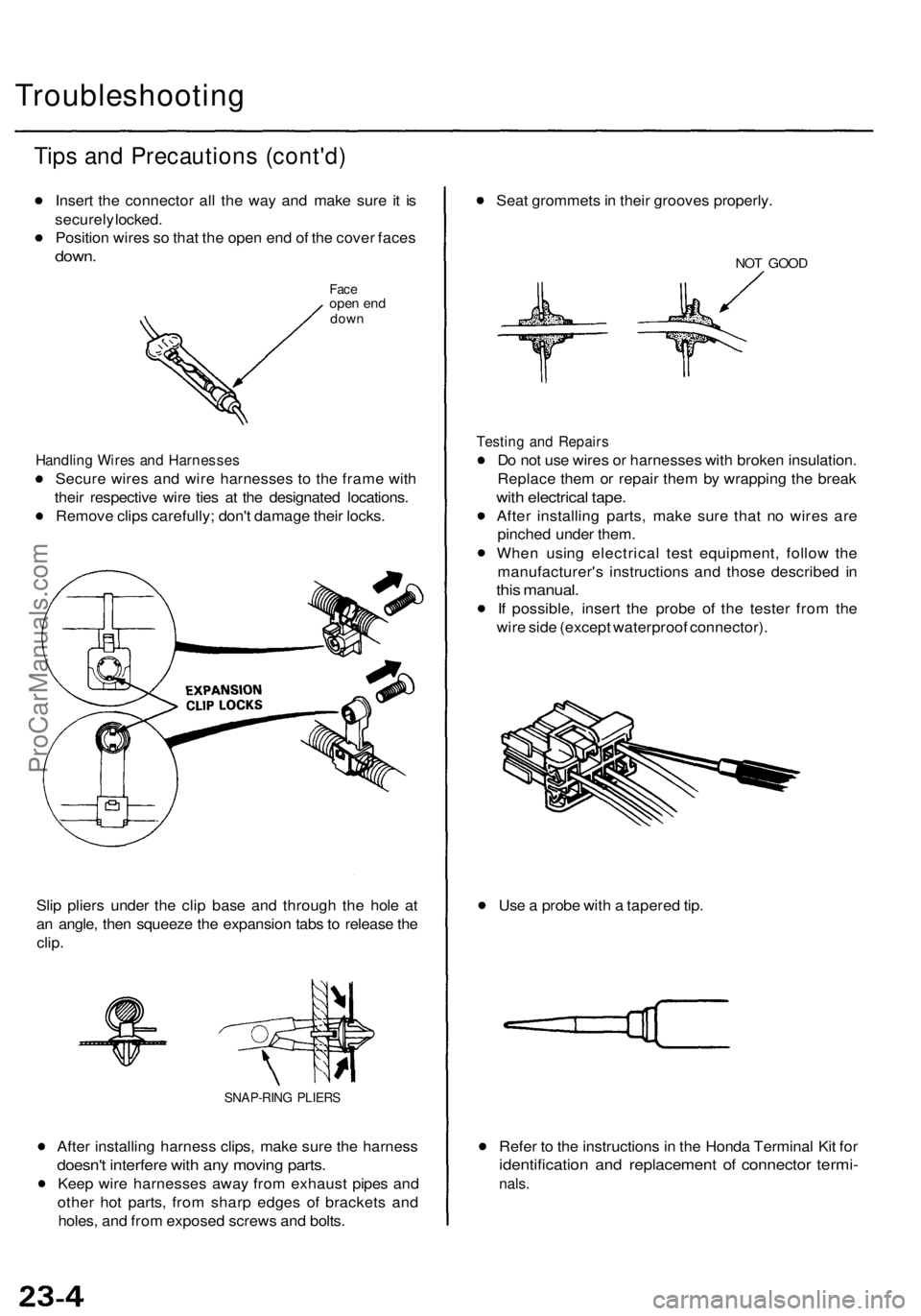

Insert the connector all the way and make sure it is

securely locked.

Position wires so that the open end of the cover faces

down.

Face

open end

down

Handling Wires and Harnesses

Secure wires and wire harnesses to the frame with

their respective wire ties at the designated locations.

Remove clips carefully; don't damage their locks.

Slip pliers under the clip base and through the hole at

an angle, then squeeze the expansion tabs to release the

clip.

SNAP-RING PLIERS

After installing harness clips, make sure the harness

doesn't interfere with any moving parts.

Keep wire harnesses away from exhaust pipes and

other hot parts, from sharp edges of brackets and

holes, and from exposed screws and bolts.

Seat grommets in their grooves properly.

NOT GOOD

Testing and Repairs

Do not use wires or harnesses with broken insulation.

Replace them or repair them by wrapping the break

with electrical tape.

After installing parts, make sure that no wires are

pinched under them.

When using electrical test equipment, follow the

manufacturer's instructions and those described in

this manual.

If possible, insert the probe of the tester from the

wire side (except waterproof connector).

Use a probe with a tapered tip.

Refer to the instructions in the Honda Terminal Kit for

identification and replacement of connector termi-

nals.ProCarManuals.com