ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1251 of 1771

Inspection and Adjustment

Brake Peda l

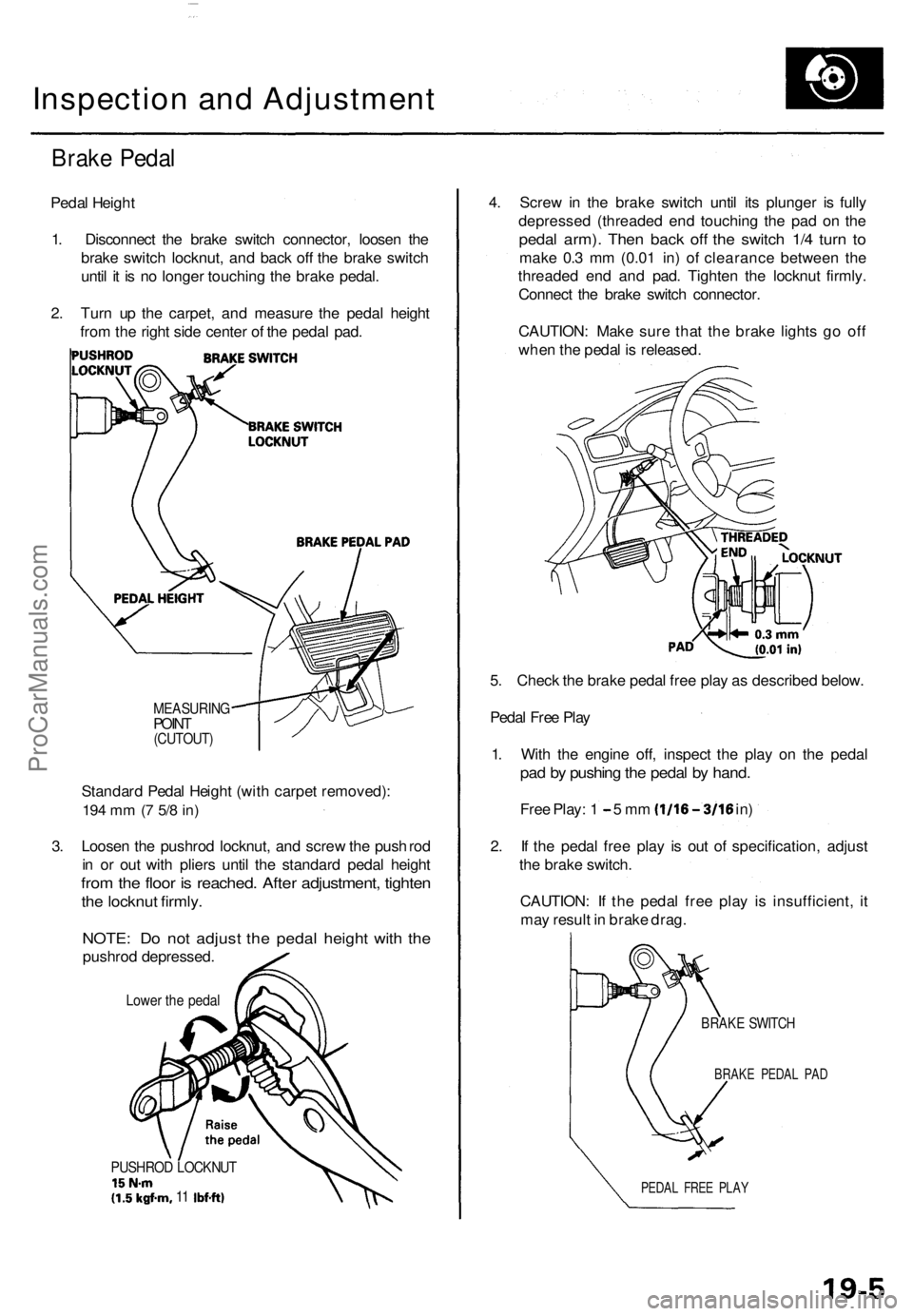

Pedal Heigh t

1 . Disconnec t th e brak e switc h connector , loose n th e

brak e switc h

locknut , and bac k of f th e brak e switc h

unti l i t i s n o longe r touchin g th e brak e pedal .

2 . Tur n u p th e carpet , an d measur e th e peda l heigh t

fro m th e righ t sid e cente r o f th e peda l pad .

MEASURIN GPOINT(CUTOUT )

Standard Peda l Heigh t (wit h carpe t removed) :

194 m m (7 5/ 8 in )

3. Loose n th e pushro d locknut , an d scre w th e pus h rod

i n o r ou t wit h plier s unti l th e standar d peda l heigh t

from th e floo r i s reached . Afte r adjustment , tighte n

the locknu t firmly .

NOTE : D o no t adjus t th e peda l heigh t wit h th e

pushro d depressed .

Lower th e peda l

PUSHRO D LOCKNU T15N-m(1.5kgf-m , 11 Ibf-ft )

4. Scre w in th e brak e switc h unti l it s plunge r i s full y

depresse d (threade d en d touchin g th e pa d o n th e

peda l arm) . The n bac k of f th e switc h 1/ 4 tur n t o

mak e 0. 3 m m (0.0 1 in ) of clearanc e betwee n th e

threade d en d an d pad . Tighte n th e locknu t firmly .

Connec t th e brak e switc h connector .

CAUTION : Mak e sur e tha t th e brak e light s g o of f

whe n th e peda l i s released .

5 . Chec k th e brak e peda l fre e pla y a s describe d below .

Peda l Fre e Pla y

1 . Wit h th e engin e off , inspec t th e pla y o n th e peda l

pad b y pushin g th e peda l b y hand .

Free Play : 1 - 5 m m (1/16-3/1 6 in)

2 . I f th e peda l fre e pla y i s ou t o f specification , adjus t

th e brak e switch .

CAUTION : I f th e peda l fre e pla y i s insufficient , i t

ma y resul t i n brak e drag .

BRAK E SWITC H

BRAKE PEDA L PA D

PEDA L FRE E PLA Y

ProCarManuals.com

Page 1252 of 1771

Inspection an d Adjustmen t

Parking Brak e

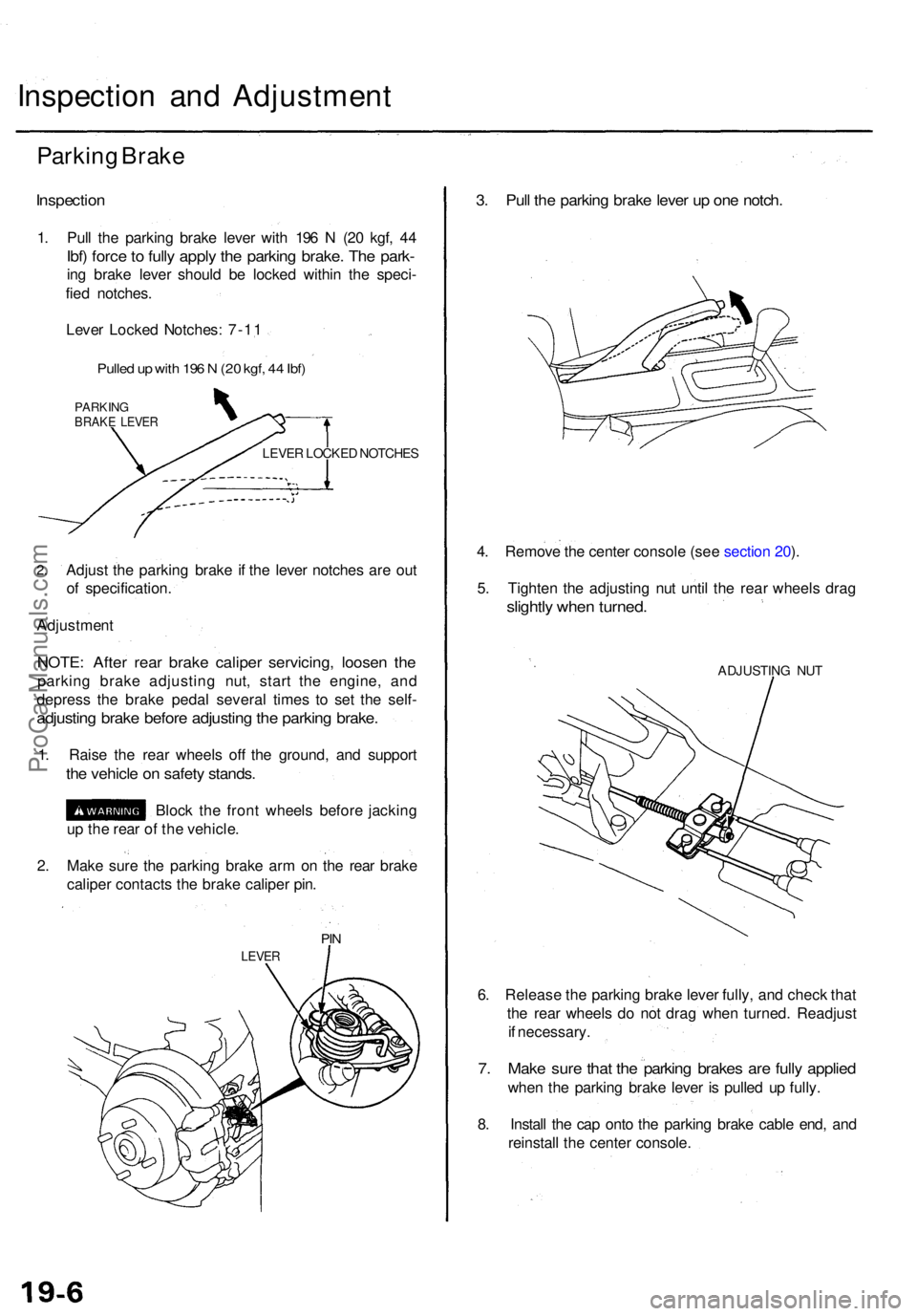

Inspectio n

1. Pul l th e parkin g brak e leve r wit h 19 6 N (2 0 kgf , 4 4

Ibf) forc e to full y appl y th e parkin g brake . Th e park -

ing brak e leve r shoul d b e locke d withi n th e speci -

fie d notches .

Leve r Locke d Notches : 7-1 1

Pulle d u p wit h 19 6 N (2 0 kgf , 4 4 Ibf )

PARKIN GBRAKE LEVE R

LEVER LOCKE D NOTCHE S

2.Adjus t th e parkin g brak e i f th e leve r notche s ar e ou t

o f specification .

Adjustmen t

NOTE: Afte r rea r brak e calipe r servicing , loose n th e

parkin g brak e adjustin g nut , star t th e engine , an d

depres s th e brak e peda l severa l time s t o se t th e self -

adjustin g brak e befor e adjustin g th e parkin g brake .

1. Rais e th e rea r wheel s of f th e ground , an d suppor t

the vehicl e o n safet y stands .

Block th e fron t wheel s befor e jackin g

u p th e rea r o f th e vehicle .

2 . Mak e sur e th e parkin g brak e ar m o n th e rea r brak e

calipe r contact s th e brak e calipe r pin .

PIN

LEVE R

3. Pul l th e parkin g brak e leve r u p on e notch .

4. Remov e th e cente r consol e (se e sectio n 20 ).

5 . Tighte n th e adjustin g nu t unti l th e rea r wheel s dra g

slightl y whe n turned .

ADJUSTIN G NU T

6. Releas e th e parkin g brak e leve r fully , an d chec k tha t

th e rea r wheel s d o no t dra g whe n turned . Readjus t

i f necessary .

7. Mak e sur e tha t th e parkin g brake s ar e full y applie d

when th e parkin g brak e leve r i s pulle d u p fully .

8 . Instal l th e ca p ont o th e parkin g brak e cabl e end , an d

reinstal l th e cente r console .

ProCarManuals.com

Page 1253 of 1771

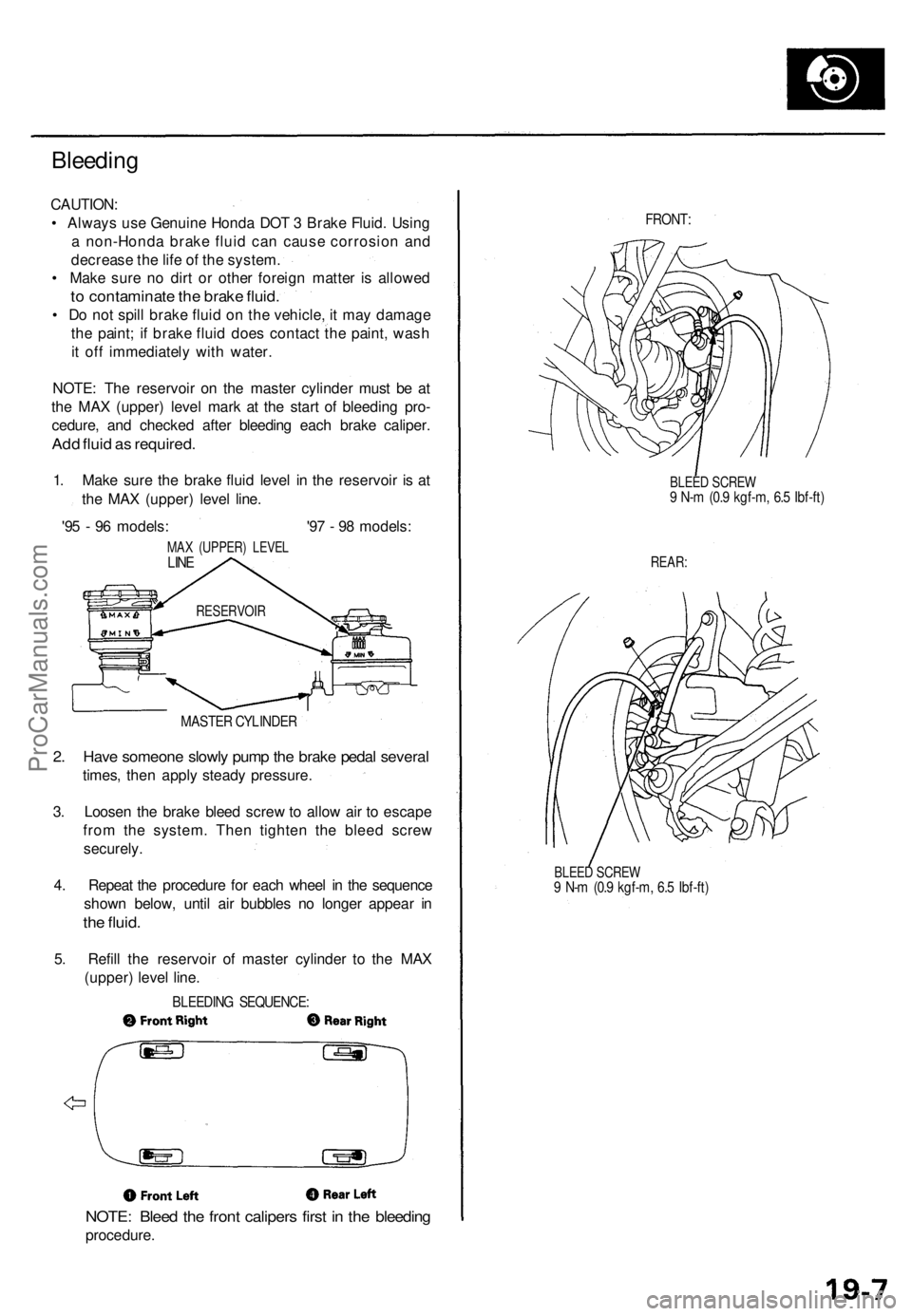

Bleeding

CAUTION:

• Always use Genuine Honda DOT 3 Brake Fluid. Using

a non-Honda brake fluid can cause corrosion and

decrease the life of the system.

• Make sure no dirt or other foreign matter is allowed

to contaminate the brake fluid.

• Do not spill brake fluid on the vehicle, it may damage

the paint; if brake fluid does contact the paint, wash

it off immediately with water.

NOTE: The reservoir on the master cylinder must be at

the MAX (upper) level mark at the start of bleeding pro-

cedure, and checked after bleeding each brake caliper.

Add fluid as required.

1. Make sure the brake fluid level in the reservoir is at

the MAX (upper) level line.

'95 - 96 models: '97 - 98 models:

MAX (UPPER) LEVEL

LINE

MASTER CYLINDER

2. Have someone slowly pump the brake pedal several

times, then apply steady pressure.

3. Loosen the brake bleed screw to allow air to escape

from the system. Then tighten the bleed screw

securely.

4. Repeat the procedure for each wheel in the sequence

shown below, until air bubbles no longer appear in

the fluid.

5. Refill the reservoir of master cylinder to the MAX

(upper) level line.

BLEEDING SEQUENCE:

NOTE: Bleed the front calipers first in the bleeding

procedure.

FRONT:

BLEED SCREW

9 N-m (0.9 kgf-m, 6.5 Ibf-ft)

REAR:

BLEED SCREW

9 N-m (0.9 kgf-m, 6.5 Ibf-ft)

RESERVOIRProCarManuals.com

Page 1254 of 1771

Front Brak e Pad s

Inspectio n an d Replacemen t

• Neve r us e a n ai r hos e o r dr y brus h t o clea n brak e

assemblies .

• Us e a n OSHA-approve d vacuu m cleane r t o avoi d

breathin g brak e dust .

1 . Loose n th e fron t whee l nut s slightly , the n rais e th e

vehicle , an d suppor t i t o n safet y stands . Remov e

the fron t wheels .

2. Remov e th e calipe r bolt , an d pivo t th e calipe r u p

ou t o f th e way .

CALIPE R BOL T CALIPE

R BOD Y

NOTE : Chec k th e hose s an d pi n boot s fo r damag e

and deterioration .

3. Remov e th e pa d shims , pa d retainer s an d pads .

INNER PA D SHIM SCheck fo r weakness .

INNE R PA D

('9 7 -9 8 models )

Chec k fo r wear . OUTE

R PA D

Chec k fo r wear .

('95 , '9 6 models )

OUTER PA D SHI M

Chec k fo r weakness .

4. Usin g vernie r calipers , measur e th e thicknes s o f

eac h brak e pa d lining .

Brak e Pa d Thickness :

Standard: 10.5-11. 5 m m (0.41-0.4 5 in )

Servic e Limit : 1. 6 m m (0.0 6 in )

'95 - 9 6 models : '9 7 - 9 8 models :

BACKIN G PLAT E

NOTE : Measuremen t doe s no t includ e pa d backin g

plat e thickness .

5 . I f th e brak e pa d thicknes s i s les s tha n servic e limit ,

replac e th e fron t pad s a s a set .

6 . Clea n th e calipe r thoroughly ; remov e an y rust , an d

chec k fo r groove s an d cracks .

7 . Chec k th e brak e dis c fo r damag e an d cracks .

8 . Instal l th e pa d retainers .

PAD RETAINER S

PAD RETAINER S

ProCarManuals.com

Page 1255 of 1771

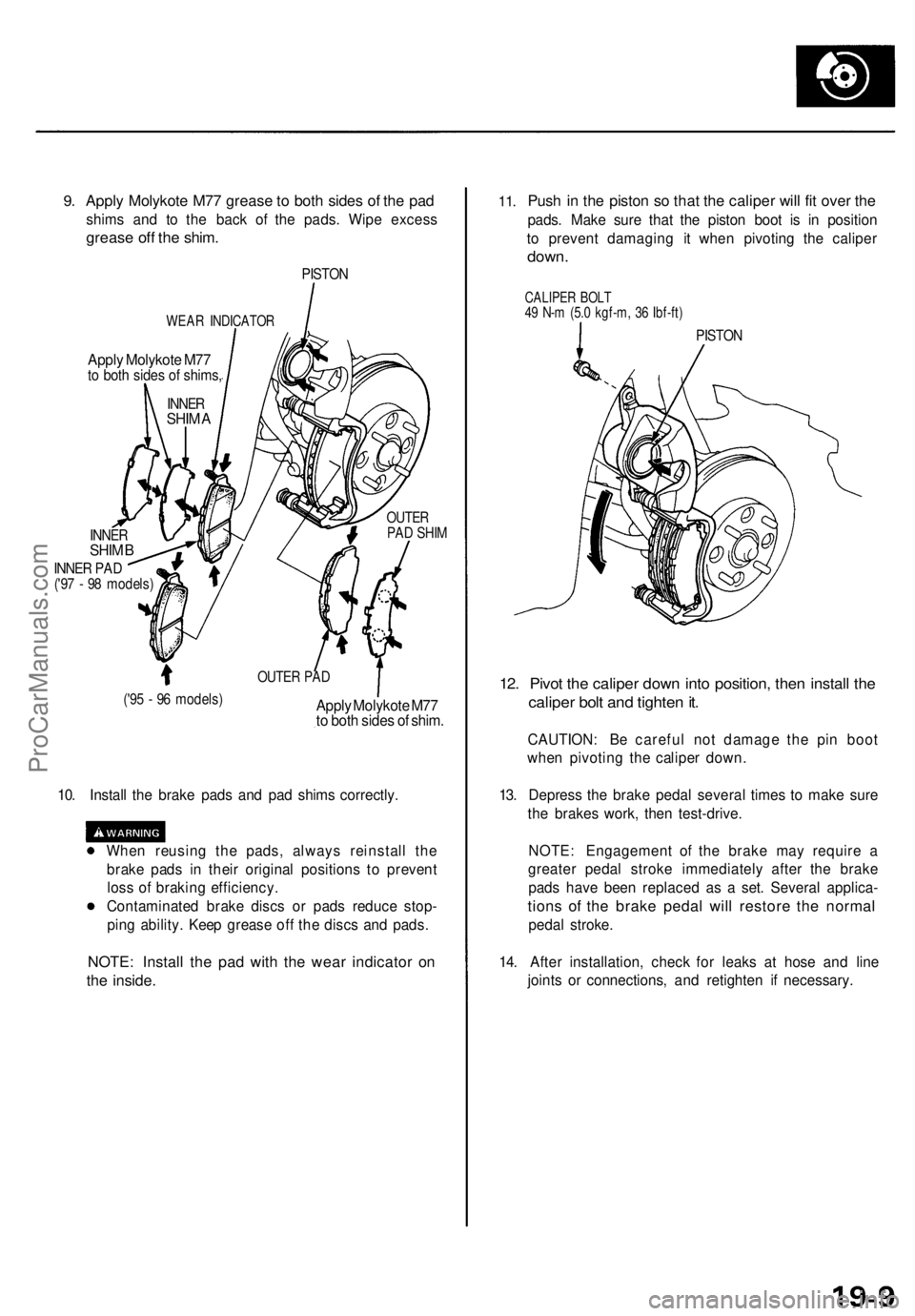

9.

Apply Molykote M77 grease to both sides of the pad

shims and to the back of the pads. Wipe excess

grease off the shim.

PISTON

WEAR INDICATOR

Apply Molykote M77

to both sides of shims,

INNER

SHIM B

INNER PAD

('97 - 98 models)

OUTER

PAD SHIM

('95 - 96 models)

Apply Molykote M77

to both sides of shim.

10. Install the brake pads and pad shims correctly.

When reusing the pads, always reinstall the

brake pads in their original positions to prevent

loss of braking efficiency.

Contaminated brake discs or pads reduce stop-

ping ability. Keep grease off the discs and pads.

NOTE: Install the pad with the wear indicator on

the inside.

11.

Push in the piston so that the caliper will fit over the

pads. Make sure that the piston boot is in position

to prevent damaging it when pivoting the caliper

down.

CALIPER BOLT

49 N-m (5.0 kgf-m, 36 Ibf-ft)

PISTON

12. Pivot the caliper down into position, then install the

caliper bolt and tighten it.

CAUTION: Be careful not damage the pin boot

when pivoting the caliper down.

13. Depress the brake pedal several times to make sure

the brakes work, then test-drive.

NOTE: Engagement of the brake may require a

greater pedal stroke immediately after the brake

pads have been replaced as a set. Several applica-

tions of the brake pedal will restore the normal

pedal stroke.

14. After installation, check for leaks at hose and line

joints or connections, and retighten if necessary.

INNER

SHIM A

OUTER PADProCarManuals.com

Page 1256 of 1771

Front Brak e Dis c

Disc Runou t Inspectio n

1. Loose n th e fron t whee l nut s slightly , the n rais e th e

vehicle , an d suppor t i t o n safet y stands . Remov e

th e fron t wheels .

2 . Remov e th e brak e pad s (se e pag e 19-8 ).

3 . Inspec t th e dis c surfac e fo r damag e an d cracks .

Clea n th e dis c thoroughl y an d remov e al l rust .

4 . Us e whee l nut s an d suitabl e plai n washer s t o hol d

th e dis c securel y agains t th e hub , the n moun t a dia l

indicato r a s shown , an d measur e th e runou t a t

1 0 m m (0. 4 in ) fro m th e oute r edg e o f th e disc .

Brak e Dis c Runout :

Servic e Limit : 0.1 0 m m (0.00 4 in )

WHEE L NU T AN D

PLAI N WASHE R

5. I f th e dis c i s beyon d th e servic e limit, refinis h th e

brak e dis c wit h a n on-ca r brak e lathe . Th e Kwik -

Lath e produce d b y Kwik-wa y manufacturin g Co .

an d th e "Fron t Brak e Dis c Lathe " offere d b y Snap -

o n Tool s Co . ar e approve d fo r thi s operation .

Max . Refinis h Limit : 21. 0 m m (0.8 3 in )

NOTE : A ne w dis c shoul d b e refinishe d i f it s runou t

i s greate r tha n 0.1 0 m m (0.00 4 in )

Dis c Thicknes s an d Parallelis m

Inspection

1. Loose n th e fron t whee l nut s slightly , the n rais e th e

vehicle , an d suppor t i t o n safet y stands . Remov e

th e fron t wheels .

2 . Remov e th e brak e pad s (se e pag e 19-8 ).

3 .

4 .

Usin g a micrometer , measur e dis c thicknes s a t

eigh t points , approximatel y 45 ° apar t an d 1 0 m m

(0. 4 in ) i n fro m th e oute r edg e o f th e disc .

Brak e Dis c Thickness :

Standard: 22. 9 - 23. 1 m m (0.9 0 - 0.9 1 in )

Max . Refinishin g Limit : 21. 0 m m (0.8 3 in )

NOTE : Replac e th e brak e dis c i f th e smalles t mea -

suremen t i s les s tha n th e max . refinishin g limit .

Brak e Dis c Parallelism : 0.01 5 m m (0.000 6 in ) max .

NOTE : Thi s i s th e maximu m allowabl e differenc e

betwee n th e thicknes s measurements .

I f th e dis c i s beyon d th e servic e limi t fo r parallelism ,

refinis h th e brak e dis c wit h a n on-ca r brak e lathe .

Th e Kwik-Lath e produce d b y Kwik-Wa y Manufac -

turin g Co . an d th e "Fron t Brak e Dis c Lathe " offere d

b y Snap-o n Tool s Co . ar e approve d fo r thi s opera -

tion.

NOTE : Se e sectio n 1 8 fo r brak e dis c replacement .

ProCarManuals.com

Page 1257 of 1771

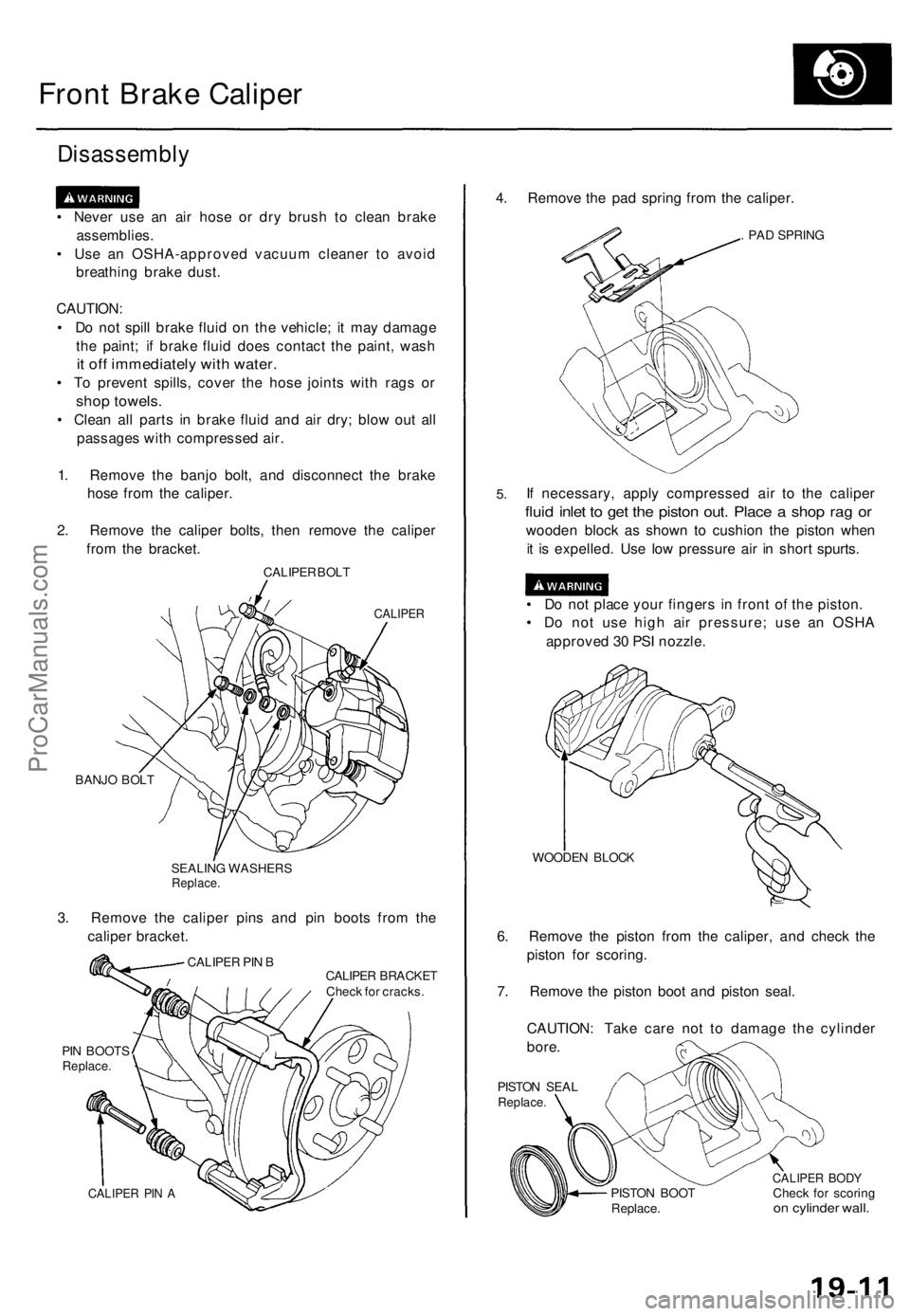

Front Brake Caliper

Disassembly

• Never use an air hose or dry brush to clean brake

assemblies.

• Use an OSHA-approved vacuum cleaner to avoid

breathing brake dust.

CAUTION:

• Do not spill brake fluid on the vehicle; it may damage

the paint; if brake fluid does contact the paint, wash

it off immediately with water.

• To prevent spills, cover the hose joints with rags or

shop towels.

• Clean all parts in brake fluid and air dry; blow out all

passages with compressed air.

1. Remove the banjo bolt, and disconnect the brake

hose from the caliper.

2. Remove the caliper bolts, then remove the caliper

from the bracket.

CALIPER BOLT

CALIPER

BANJO BOLT

SEALING WASHERS

Replace.

3. Remove the caliper pins and pin boots from the

caliper bracket.

CALIPER BRACKET

Check for cracks.

PIN BOOTS

Replace.

CALIPER PIN A

4. Remove the pad spring from the caliper.

. PAD SPRING

5.

If necessary, apply compressed air to the caliper

fluid inlet to get the piston out. Place a shop rag or

wooden block as shown to cushion the piston when

it is expelled. Use low pressure air in short spurts.

• Do not place your fingers in front of the piston.

• Do not use high air pressure; use an OSHA

approved 30 PSI nozzle.

WOODEN BLOCK

6. Remove the piston from the caliper, and check the

piston for scoring.

7. Remove the piston boot and piston seal.

CAUTION: Take care not to damage the cylinder

bore.

PISTON SEAL

Replace.

PISTON BOOT

Replace.

CALIPER BODY

Check for scoring

on cylinder wall.

CALIPER PIN BProCarManuals.com

Page 1258 of 1771

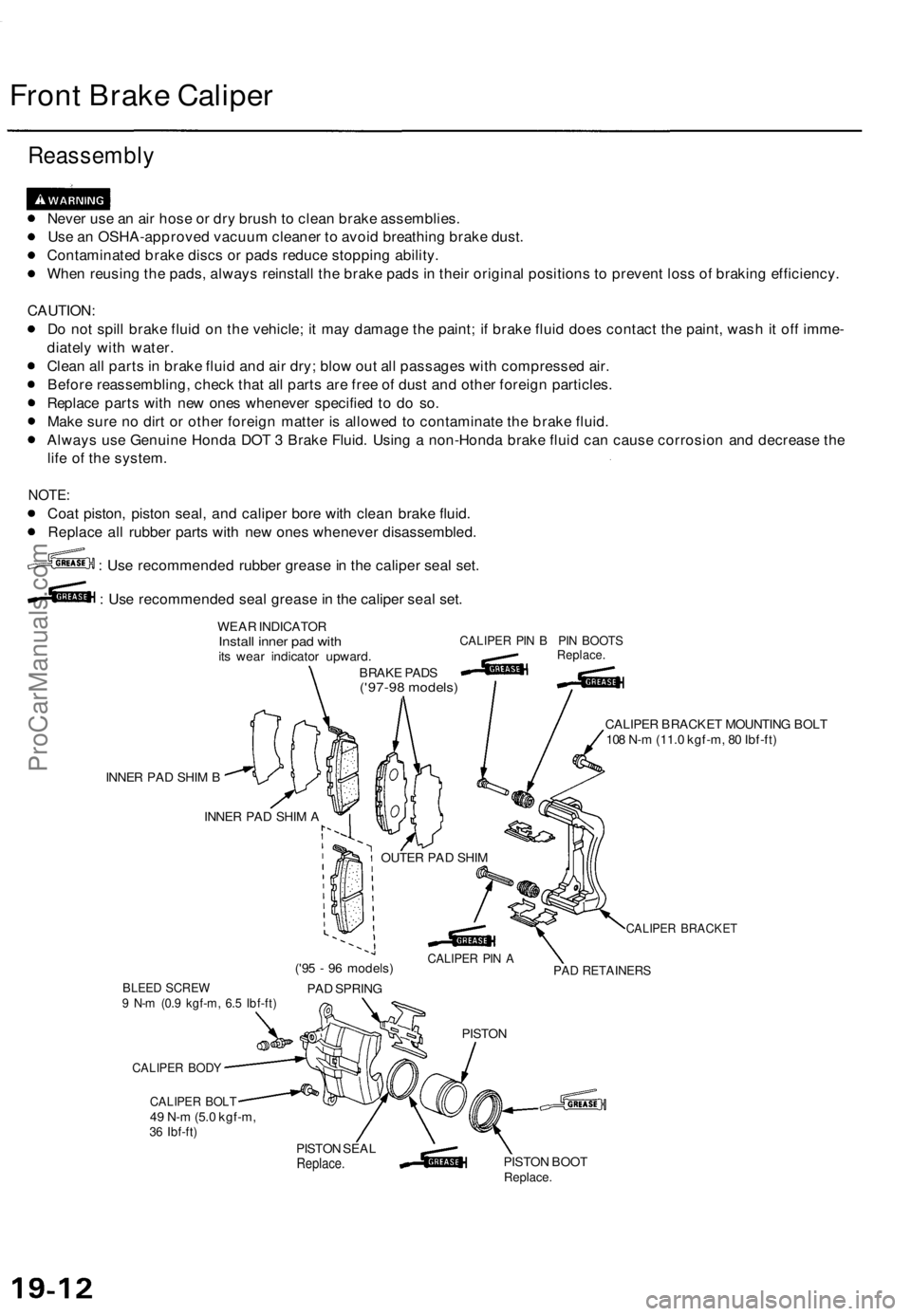

Front Brake Caliper

Reassembly

Never use an air hose or dry brush to clean brake assemblies.

Use an OSHA-approved vacuum cleaner to avoid breathing brake dust.

Contaminated brake discs or pads reduce stopping ability.

When reusing the pads, always reinstall the brake pads in their original positions to prevent loss of braking efficiency.

CAUTION:

Do not spill brake fluid on the vehicle; it may damage the paint; if brake fluid does contact the paint, wash it off imme-

diately with water.

Clean all parts in brake fluid and air dry; blow out all passages with compressed air.

Before reassembling, check that all parts are free of dust and other foreign particles.

Replace parts with new ones whenever specified to do so.

Make sure no dirt or other foreign matter is allowed to contaminate the brake fluid.

Always use Genuine Honda DOT 3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the

life of the system.

NOTE:

Coat piston, piston seal, and caliper bore with clean brake fluid.

Replace all rubber parts with new ones whenever disassembled.

: Use recommended rubber grease in the caliper seal set.

: Use recommended seal grease in the caliper seal set.

WEAR INDICATOR

Install inner pad with

its wear indicator upward.

BRAKE PADS

('97-98 models)

CALIPER PIN B PIN BOOTS

Replace.

INNER PAD SHIM B

CALIPER BRACKET MOUNTING BOLT

108 N-m (11.0 kgf-m, 80 Ibf-ft)

INNER PAD SHIM A

BLEED SCREW

9 N-m (0.9 kgf-m, 6.5 Ibf-ft)

CALIPER BODY

CALIPER BOLT

49 N-m (5.0 kgf-m,

36 Ibf-ft)

('95 - 96 models)

PAD SPRING

CALIPER BRACKET

PAD RETAINERS

PISTON

PISTON SEAL

Replace.

PISTON BOOT

Replace.

OUTER PAD SHIM

CALIPER PIN AProCarManuals.com

Page 1259 of 1771

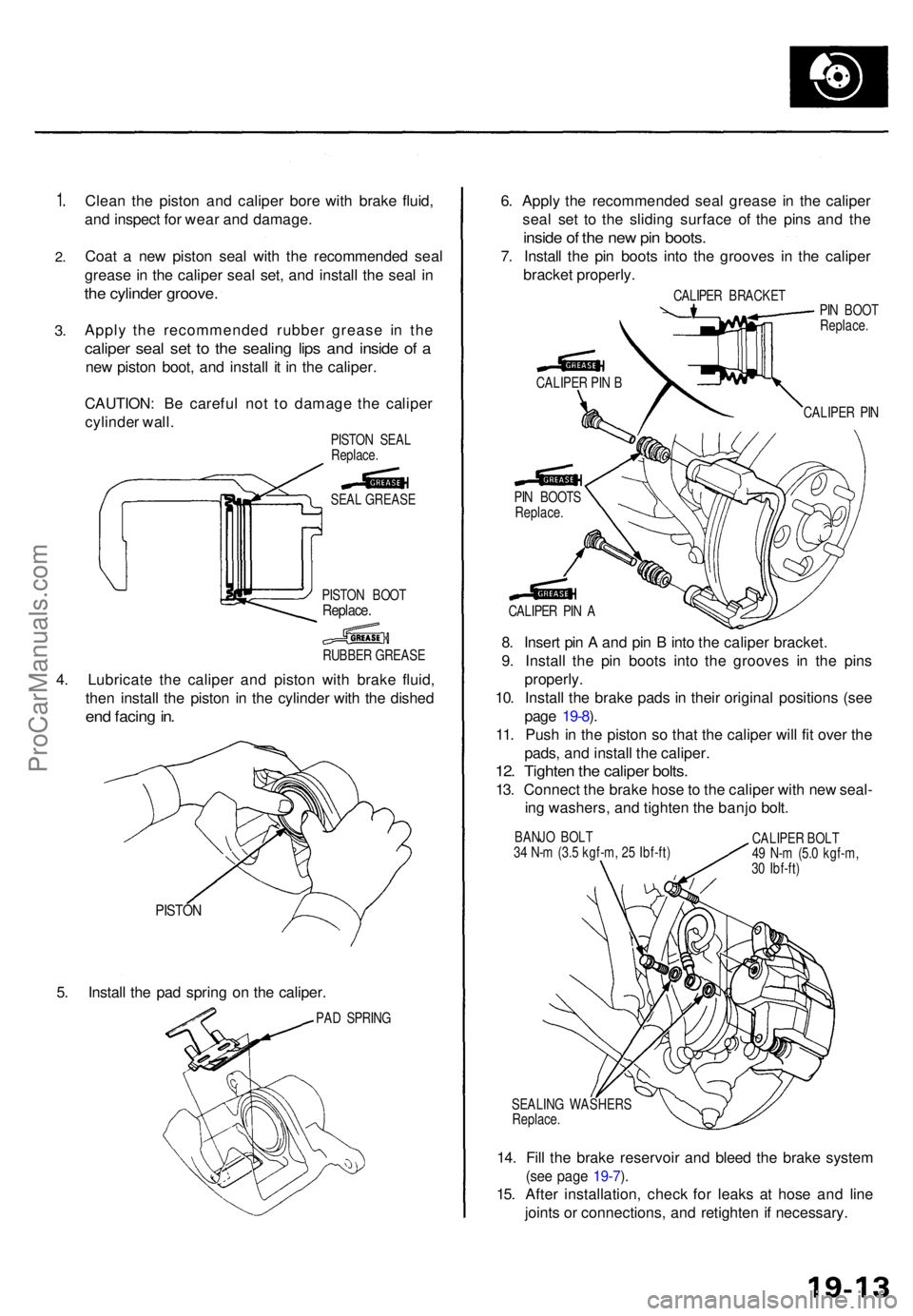

2.

3.

Clea n th e pisto n an d calipe r bor e wit h brak e fluid ,

an d inspec t fo r wea r an d damage .

Coa t a ne w pisto n sea l wit h th e

recommended sea l

greas e in th e calipe r sea l set , an d instal l th e sea l i n

th e cylinde r groove .

Apply th e recommende d rubbe r greas e i n th e

calipe r sea l se t t o th e sealin g lip s an d insid e o f a

ne w pisto n boot , an d instal l i t i n th e caliper .

CAUTION : B e carefu l no t t o damage the calipe r

cylinde r wall .

PISTO N SEA L

Replace .

RUBBE R GREAS E

4. Lubricat e th e calipe r an d pisto n wit h brak e fluid ,

the n instal l th e pisto n i n th e cylinde r wit h th e dishe d

end facin g in .

PISTO N

5. Instal l th e pa d sprin g o n th e caliper .

PAD SPRIN G

6. Appl y th e recommende d sea l greas e i n th e calipe r

sea l se t t o th e slidin g surfac e o f th e pin s an d th e

insid e o f th e ne w pi n boots .

7. Instal l th e pi n boot s int o th e groove s i n th e calipe r

bracke t properly .

CALIPER BRACKE T

PIN BOO T

Replace .

CALIPER PI N

CALIPE R PI N A

8. Inser t pi n A an d pi n B int o th e calipe r bracket .

9 . Instal l th e pi n boot s int o th e groove s i n th e pin s

properly .

10 . Instal l th e brak e pad s i n thei r origina l position s (se e

pag e 19-8 ).

11 . Pus h i n th e pisto n s o tha t th e calipe r wil l fi t ove r th e

pads , an d instal l th e caliper .

12. Tighte n th e calipe r bolts .

13. Connec t th e brak e hos e to th e calipe r wit h ne w seal -

in g washers , an d tighte n th e banj o bolt .

BANJ O BOL T

3 4 N- m (3. 5 kgf-m , 2 5 Ibf-ft ) CALIPE

R BOL T

4 9 N- m (5. 0 kgf-m ,

3 0 Ibf-ft )

SEALIN G WASHER S

Replace .

14. Fil l th e brak e reservoi r an d blee d th e brak e syste m

(see pag e 19-7 ).

15 . Afte r installation , chec k fo r leak s a t hos e an d lin e

joint s o r connections , an d retighte n if necessary .

PISTON BOO TReplace .

SEAL GREAS E CALIPE

R PI N B

PI N BOOT SReplace .

1.

ProCarManuals.com

Page 1260 of 1771

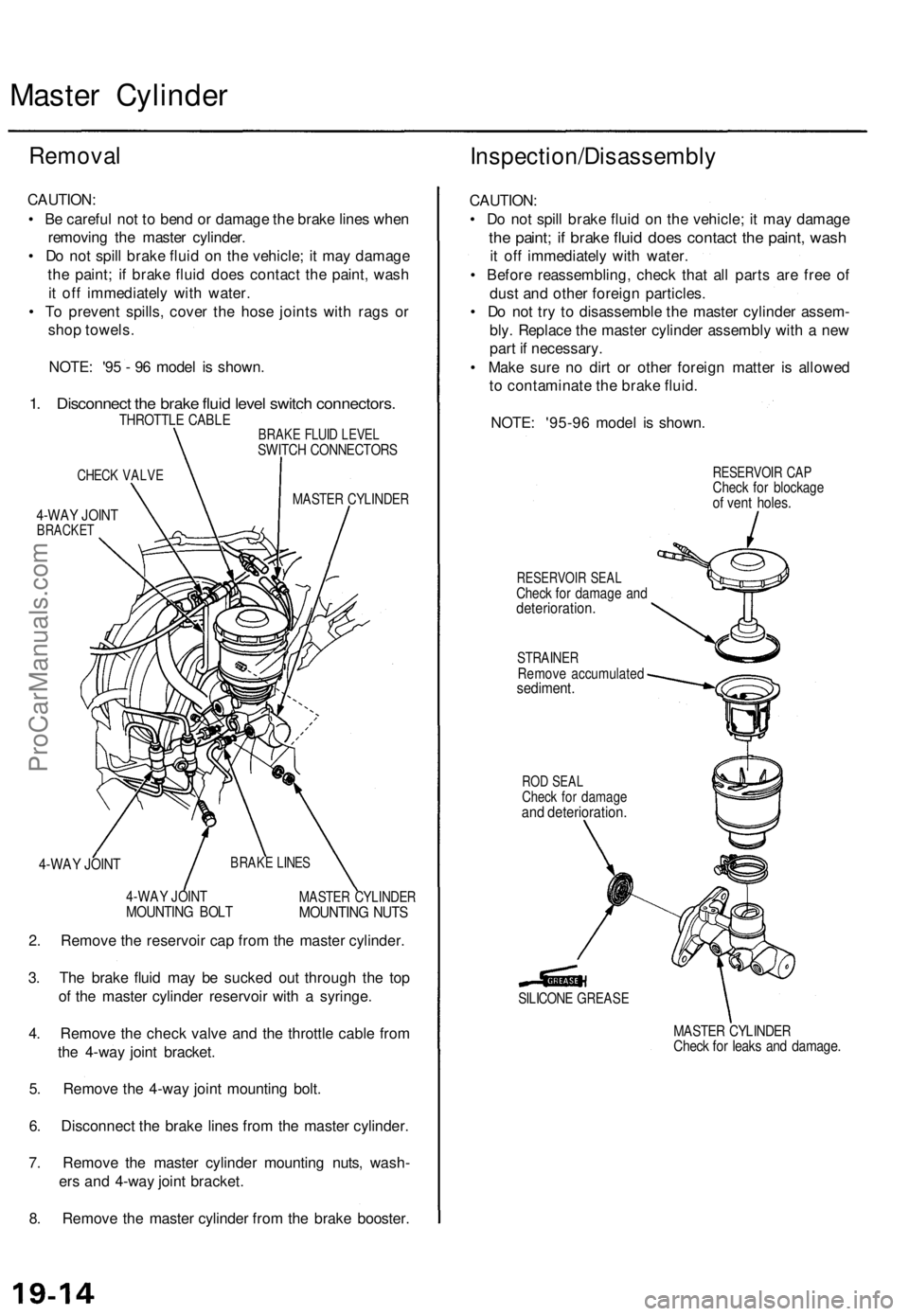

Master Cylinde r

Removal

CAUTION :

• B e carefu l no t t o ben d o r damag e th e brak e line s whe n

removin g th e maste r cylinder .

• D o no t spil l brak e flui d o n th e vehicle ; i t ma y damag e

th e paint ; i f brak e flui d doe s contac t th e paint , was h

i t of f immediatel y wit h water .

• T o preven t spills , cove r th e hos e joint s wit h rag s o r

sho p towels .

NOTE : '9 5 - 9 6 mode l i s shown .

1. Disconnec t th e brak e flui d leve l switc h connectors .THROTTLE CABL EBRAKE FLUI D LEVE LSWITC H CONNECTOR S

CHECK VALV E

MASTE R CYLINDE R4-WAY JOIN TBRACKE T

4-WAY JOIN T

4-WA Y JOIN TMOUNTIN G BOL TMASTE R CYLINDE RMOUNTING NUT S

2. Remov e th e reservoi r ca p fro m th e maste r cylinder .

3 . Th e brak e flui d ma y b e sucke d ou t throug h th e to p

o f th e maste r cylinde r reservoi r wit h a syringe .

4 . Remov e th e chec k valv e an d th e throttl e cabl e fro m

th e 4-wa y join t bracket .

5 . Remov e th e 4-wa y join t mountin g bolt .

6 . Disconnec t th e brak e line s fro m th e maste r cylinder .

7 . Remov e th e maste r cylinde r mountin g nuts , wash -

er s an d 4-wa y join t bracket .

8 . Remov e th e maste r cylinde r fro m th e brak e booster .

Inspection/Disassembl y

CAUTION:

• D o no t spil l brak e flui d o n th e vehicle ; i t ma y damag e

the paint ; i f brak e flui d doe s contac t th e paint , was h

it of f immediatel y wit h water .

• Befor e reassembling , chec k tha t al l part s ar e fre e o f

dus t an d othe r foreig n particles .

• D o no t tr y t o disassembl e th e maste r cylinde r assem -

bly . Replac e th e maste r cylinde r assembl y wit h a ne w

par t i f necessary .

• Mak e sur e n o dir t o r othe r foreig n matte r i s allowe d

t o contaminat e th e brak e fluid .

NOTE : '95-9 6 mode l i s shown .

RESERVOI R SEA LCheck fo r damag e an ddeterioration .

STRAINERRemove accumulate dsediment.

RESERVOI R CA PChec k fo r blockag eof ven t holes .

ROD SEA LCheck fo r damag eand deterioration .

SILICONE GREAS E

MASTER CYLINDE RCheck fo r leak s an d damage .

BRAKE LINE S

ProCarManuals.com