ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 131 of 1771

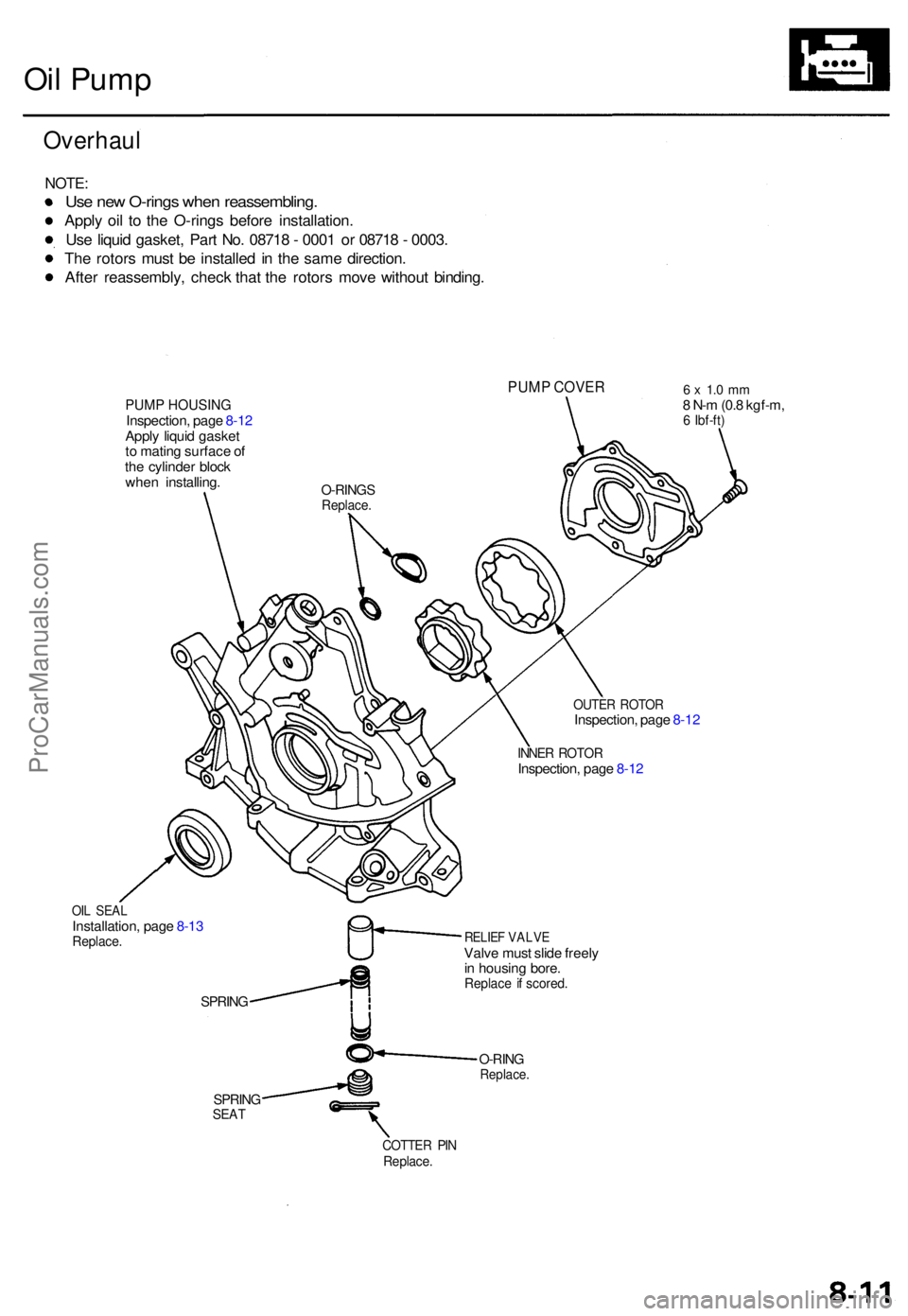

Oil Pum p

Overhau l

NOTE:

Use ne w O-ring s whe n reassembling .

Apply oi l t o th e O-ring s befor e installation .

Us e liqui d gasket , Par t No . 0871 8 - 000 1 o r 0871 8 - 0003 .

Th e rotor s mus t b e installe d in th e sam e direction .

Afte r reassembly , chec k tha t th e rotor s mov e withou t binding .

PUMP COVE R

PUMP HOUSINGInspection , pag e 8-1 2

Appl y liqui d gaske t

t o matin g surfac e o f

th e cylinde r bloc k

whe n installing .

6 x 1. 0 m m8 N- m (0. 8 kgf-m ,6 Ibf-ft )

OUTE R ROTO RInspection , pag e 8-1 2

INNE R ROTO RInspection , pag e 8-1 2

OIL SEA LInstallation , pag e 8-1 3Replace .

SPRING

SPRINGSEAT

RELIE F VALV EValve mus t slid e freel y

i n housin g bore .

Replac e i f scored .

O-RINGReplace .

COTTER PI NReplace .

O-RINGSReplace .

ProCarManuals.com

Page 132 of 1771

Oil Pum p

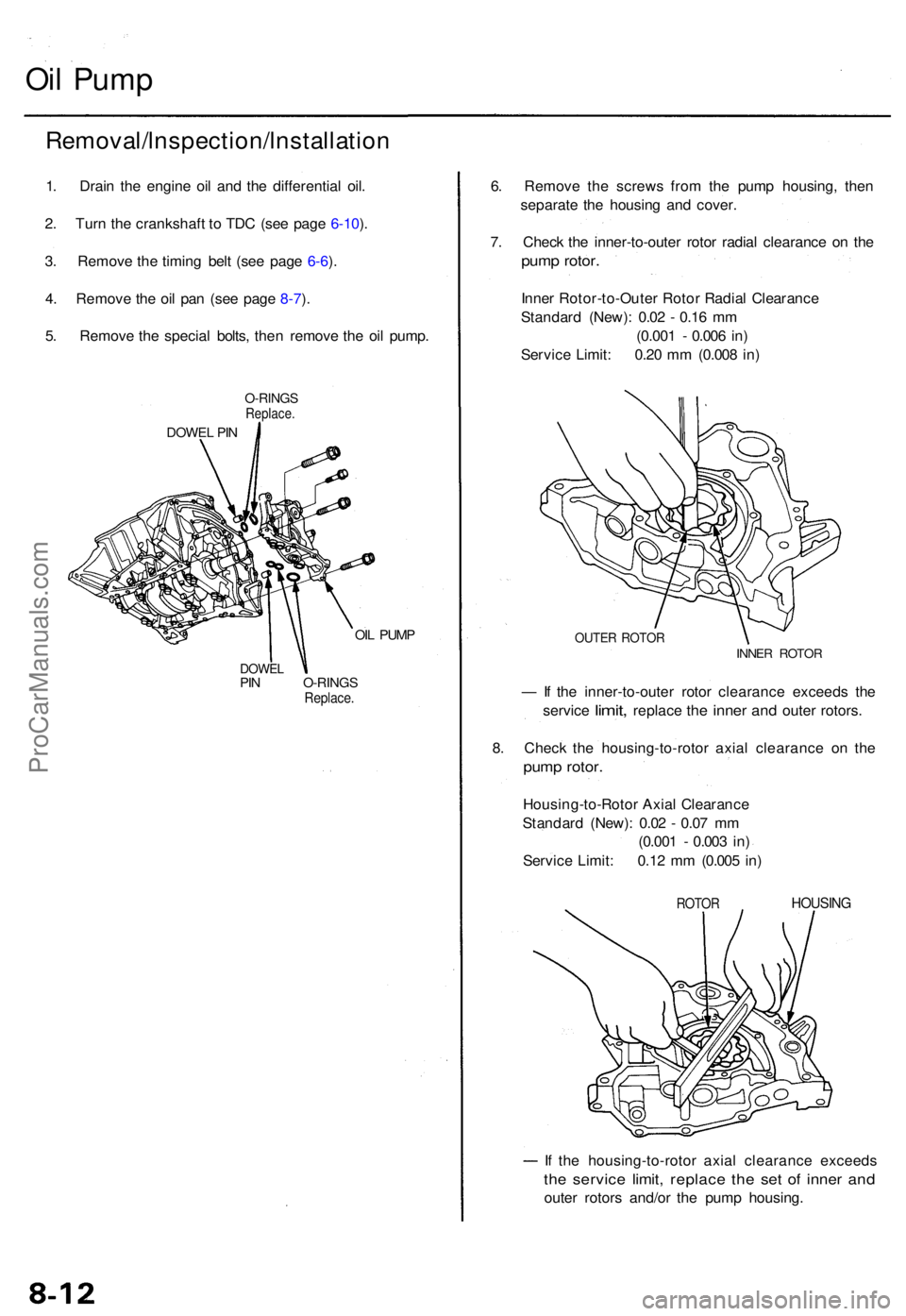

Removal/lnspection/lnstallatio n

1. Drai n th e engin e oi l an d th e differentia l oil .

2 . Tur n th e crankshaf t t o TD C (se e pag e 6-10 ).

3 . Remov e th e timin g bel t (se e pag e 6-6 ).

4 . Remov e th e oi l pa n (se e pag e 8-7 ).

5 . Remov e th e specia l bolts , the n remov e th e oi l pump .

O-RING SReplace .

DOWEL PI N

OIL PUM P

DOWE LPIN O-RING SReplace.

6. Remov e th e screw s fro m th e pum p housing , the n

separat e th e housin g an d cover .

7 . Chec k th e inner-to-oute r roto r radia l clearanc e o n th e

pum p rotor .

Inner Rotor-to-Oute r Roto r Radia l Clearanc e

Standar d (New) : 0.0 2 - 0.1 6 m m

(0.00 1 - 0.00 6 in )

Servic e Limit : 0.2 0 m m (0.00 8 in )

OUTE R ROTO RINNER ROTO R

— If th e inner-to-oute r roto r clearanc e exceed s th e

servic e

limit, replac e the inne r and oute r rotors .

8 . Chec k th e housing-to-roto r axia l clearanc e o n th e

pum p rotor .

Housing-to-Roto r Axia l Clearanc e

Standar d (New) : 0.0 2 - 0.0 7 m m

(0.00 1 - 0.00 3 in )

Servic e Limit : 0.1 2 m m (0.00 5 in )

ROTO RHOUSIN G

If th e housing-to-roto r axia l clearanc e exceed s

the servic e limit , replac e th e se t of inne r an d

oute r rotor s and/o r th e pum p housing .

ProCarManuals.com

Page 133 of 1771

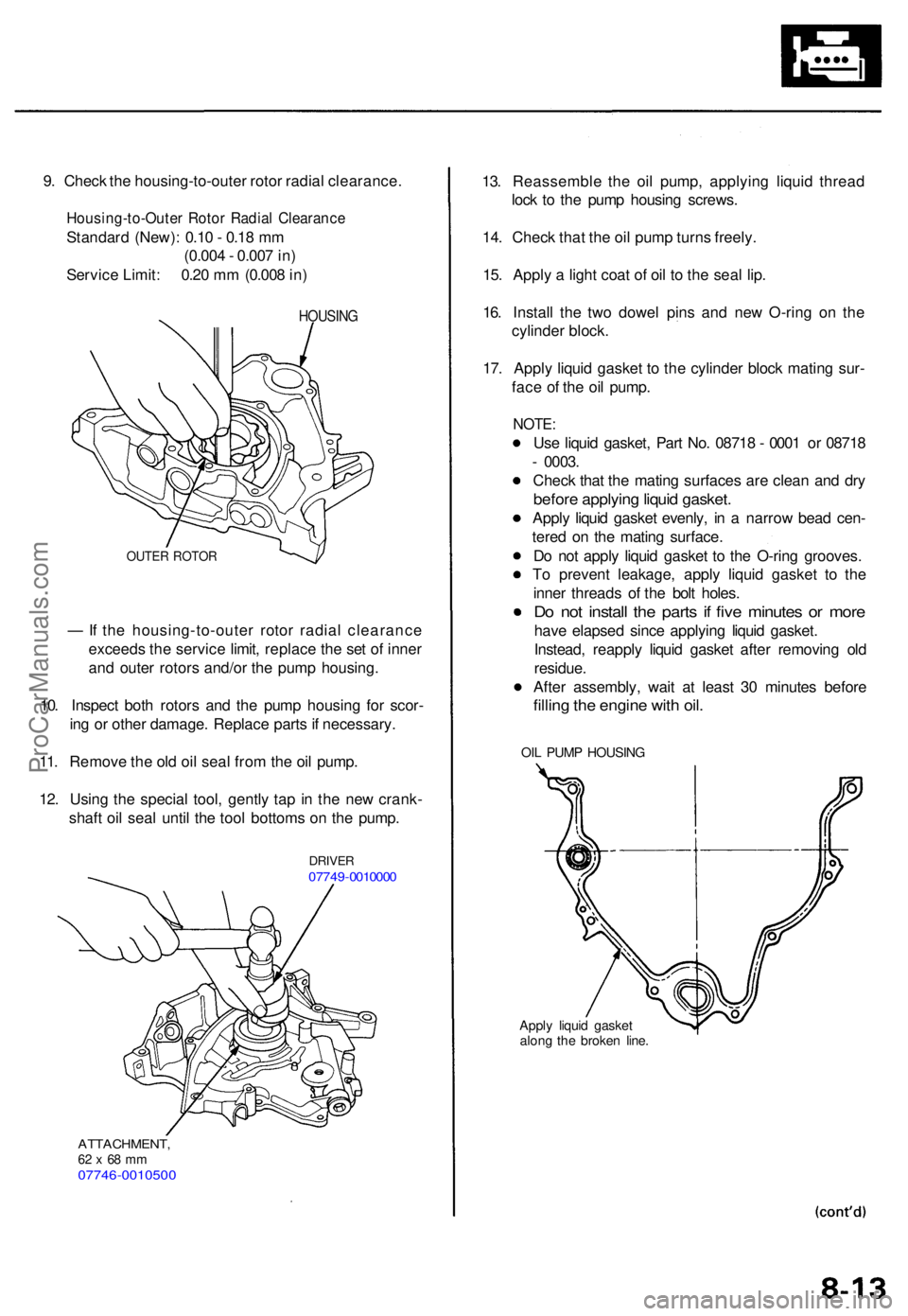

9. Chec k th e housing-to-oute r roto r radia l clearance .

Housing-to-Oute r Roto r Radia l Clearanc e

Standard (New) : 0.1 0 - 0.1 8 m m

(0.00 4 - 0.00 7 in )

Servic e Limit : 0.2 0 m m (0.00 8 in )

HOUSIN G

OUTER ROTO R

— If th e housing-to-oute r roto r radia l clearanc e

exceed s th e servic e limit , replac e th e se t o f inne r

an d oute r rotor s and/o r th e pum p housing .

10 . Inspec t bot h rotor s an d th e pum p housin g fo r scor -

in g o r othe r damage . Replac e part s if necessary .

11 . Remov e th e ol d oi l sea l fro m th e oi l pump .

12 . Usin g th e specia l tool , gentl y ta p i n th e ne w crank -

shaf t oi l sea l unti l th e too l bottom s o n th e pump .

DRIVE R07749-001000 0

ATTACHMENT ,62 x 68 m m07746-001050 0

13. Reassembl e th e oi l pump , applyin g liqui d threa d

loc k t o th e pum p housin g screws .

14 . Chec k tha t th e oi l pum p turn s freely .

15 . Appl y a ligh t coa t o f oi l t o th e sea l lip .

16 . Instal l th e tw o dowe l pin s an d ne w O-rin g o n th e

cylinde r block .

17 . Appl y liqui d gaske t t o th e cylinde r bloc k matin g sur -

fac e o f th e oi l pump .

NOTE:

Use liqui d gasket , Par t No . 0871 8 - 000 1 o r 0871 8

- 0003 .

Chec k tha t th e matin g surface s ar e clea n an d dr y

befor e applyin g liqui d gasket .

Apply liqui d gaske t evenly , i n a narro w bea d cen -

tere d o n th e matin g surface .

D o no t appl y liqui d gaske t t o th e O-rin g grooves .

T o preven t leakage , appl y liqui d gaske t t o th e

inne r thread s o f th e bol t holes .

Do no t instal l th e part s i f fiv e minute s o r mor e

have elapse d sinc e applyin g liqui d gasket .

Instead , reappl y liqui d gaske t afte r removin g ol d

residue .

Afte r assembly , wai t a t leas t 3 0 minute s befor e

filling th e engin e wit h oil .

OIL PUM P HOUSIN G

Apply liqui d gaske t

alon g th e broke n line .

ProCarManuals.com

Page 134 of 1771

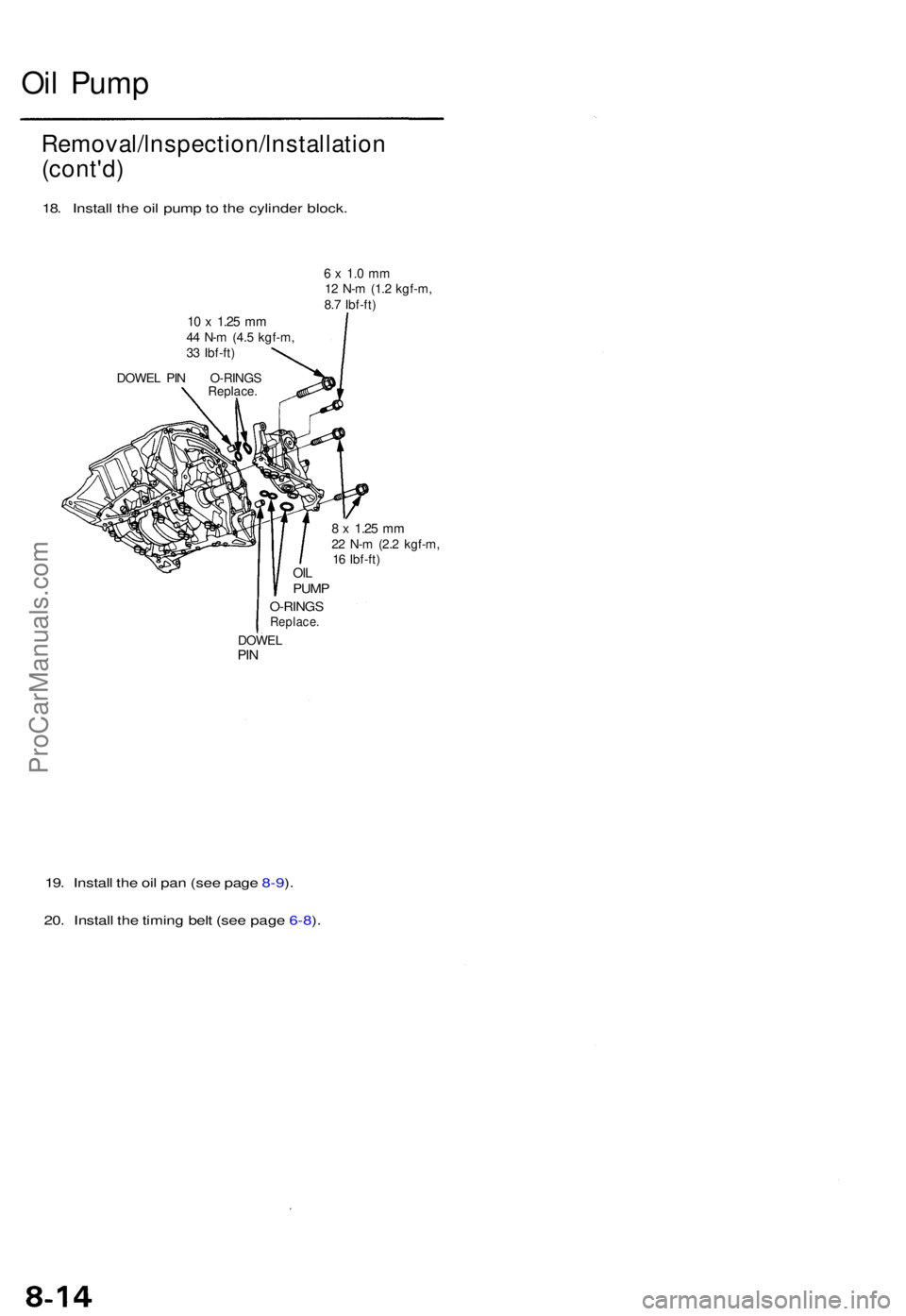

Oil Pum p

10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

DOWE L PI N O-RING S

Replace.

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

OILPUM P

O-RING SReplace .

DOWELPIN

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

19. Instal l th e oi l pa n (se e pag e 8-9 ).

20 . Instal l th e timin g bel t (se e pag e 6-8 ).

Removal/lnspection/lnstallatio n

(cont'd )

18. Instal l th e oi l pum p to th e cylinde r block .

ProCarManuals.com

Page 135 of 1771

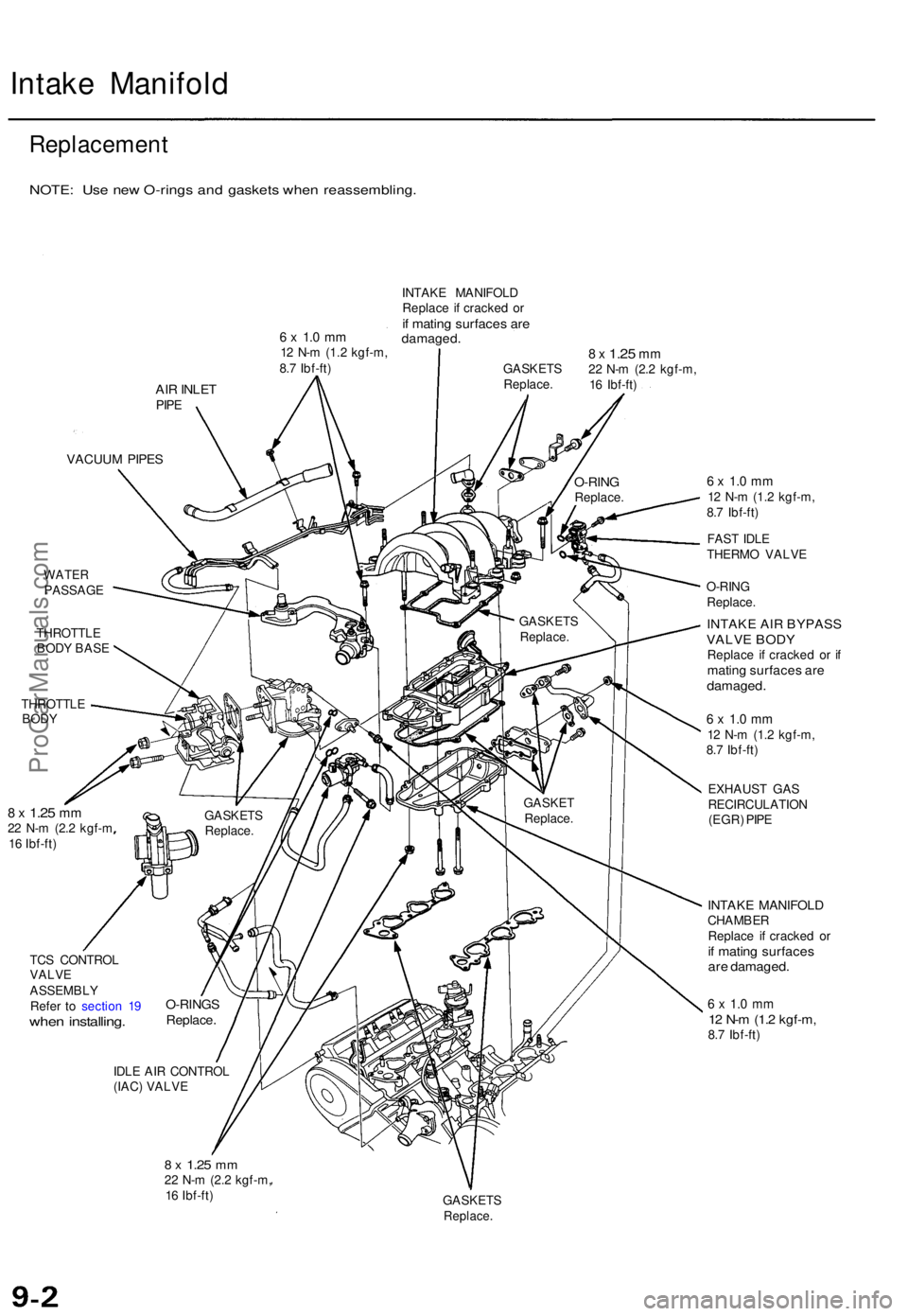

Intake Manifol d

Replacemen t

NOTE: Us e ne w O-ring s an d gasket s whe n reassembling .

6 x 1. 0 m m12 N- m (1.2 kgf-m ,

8. 7 Ibf-ft ) INTAK

E MANIFOL D

Replac e i f cracke d o r

if matin g surface s ar edamaged .

AIR INLE TPIPE

GASKET S

Replace .8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

VACUU M PIPE S

WATE RPASSAG E

THROTTL E

BOD Y BAS E

THROTTL E

BODY

8 x 1.2 5 mm22 N- m (2. 2 kgf- m

1 6 Ibf-ft )

TC S CONTRO L

VALV E

ASSEMBL Y

Refe r t o sectio n 1 9

whe n installing .

IDLE AI R CONTRO L

(IAC ) VALV E

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

FAS T IDL E

THERM O VALV E

O-RIN G

Replace .

INTAKE AIR BYPASSVALVE BODYReplace i f cracke d o r i fmatin g surface s ar edamaged .

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

EXHAUS T GA S

RECIRCULATIO N

(EGR ) PIP E

INTAK E MANIFOL DCHAMBER

Replac e i f cracke d o r

if matin g surface sare damaged .

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )

GASKET S

Replace.

O-RINGSReplace .

GASKETReplace .

GASKET

S

Replace . GASKET

S

Replace.

O-RINGReplace .

ProCarManuals.com

Page 136 of 1771

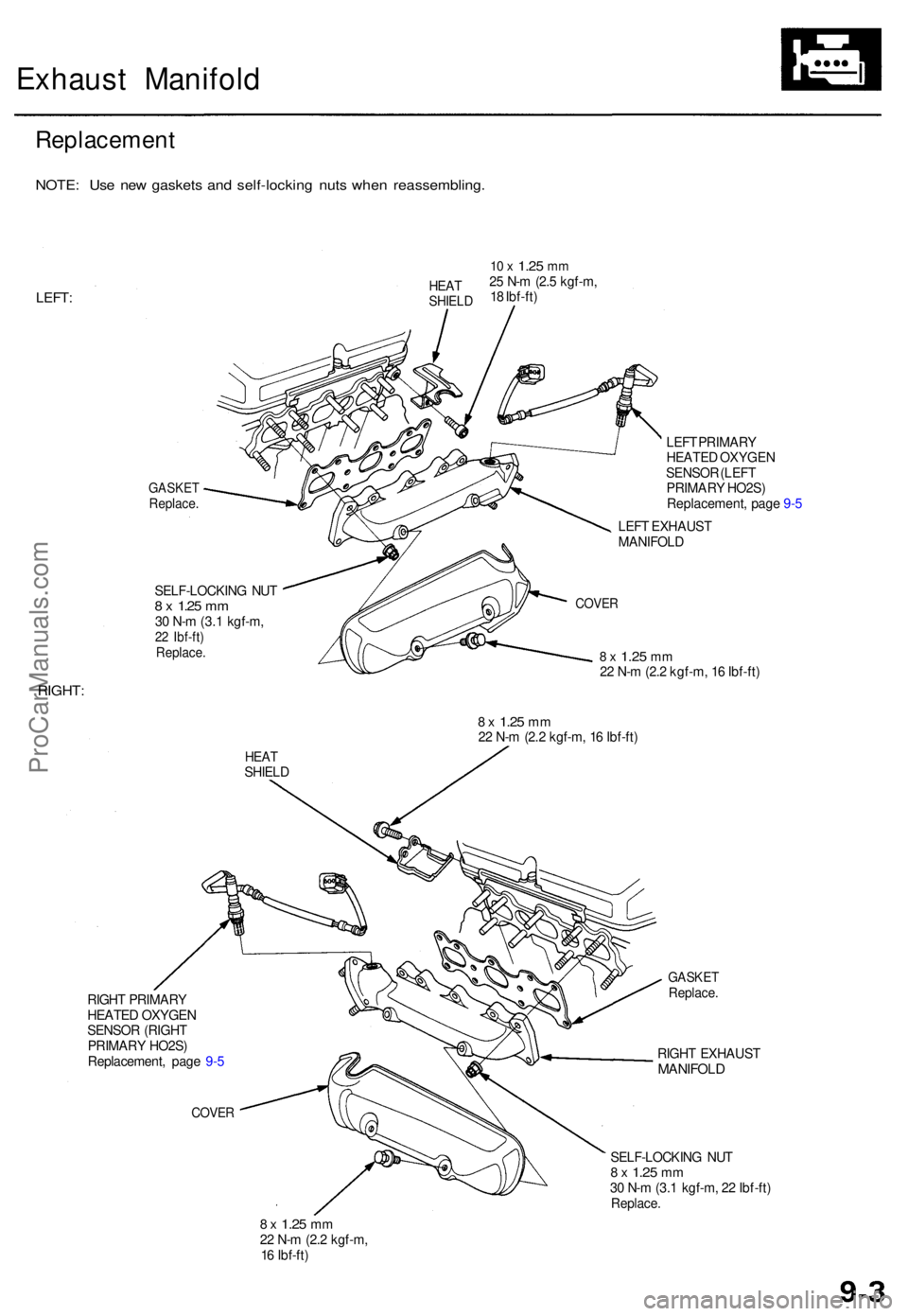

Exhaust Manifol d

Replacemen t

NOTE: Us e ne w gasket s an d self-lockin g nut s whe n reassembling .

LEFT:

10 x 1.2 5 mm25 N- m (2. 5 kgf-m ,

1 8 Ibf-ft )

GASKE TReplace .

SELF-LOCKIN G NU T8 x 1.2 5 mm30 N- m (3. 1 kgf-m ,22 Ibf-ft )Replace .

LEFT PRIMAR Y

HEATE D OXYGE N

SENSO R (LEF T

PRIMAR Y HO2S )

Replacement , pag e 9- 5

LEF T EXHAUS T

MANIFOL D

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

RIGHT :

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

HEATSHIEL D

RIGH T PRIMAR Y

HEATED OXYGE NSENSOR (RIGH T

PRIMAR Y HO2S )

Replacement , pag e 9- 5

COVE R

GASKE TReplace .

RIGHT EXHAUS TMANIFOLD

SELF-LOCKIN G NU T8 x 1.2 5 mm30 N- m (3. 1 kgf-m , 2 2 Ibf-ft )Replace .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

COVE R

HEATSHIEL D

ProCarManuals.com

Page 137 of 1771

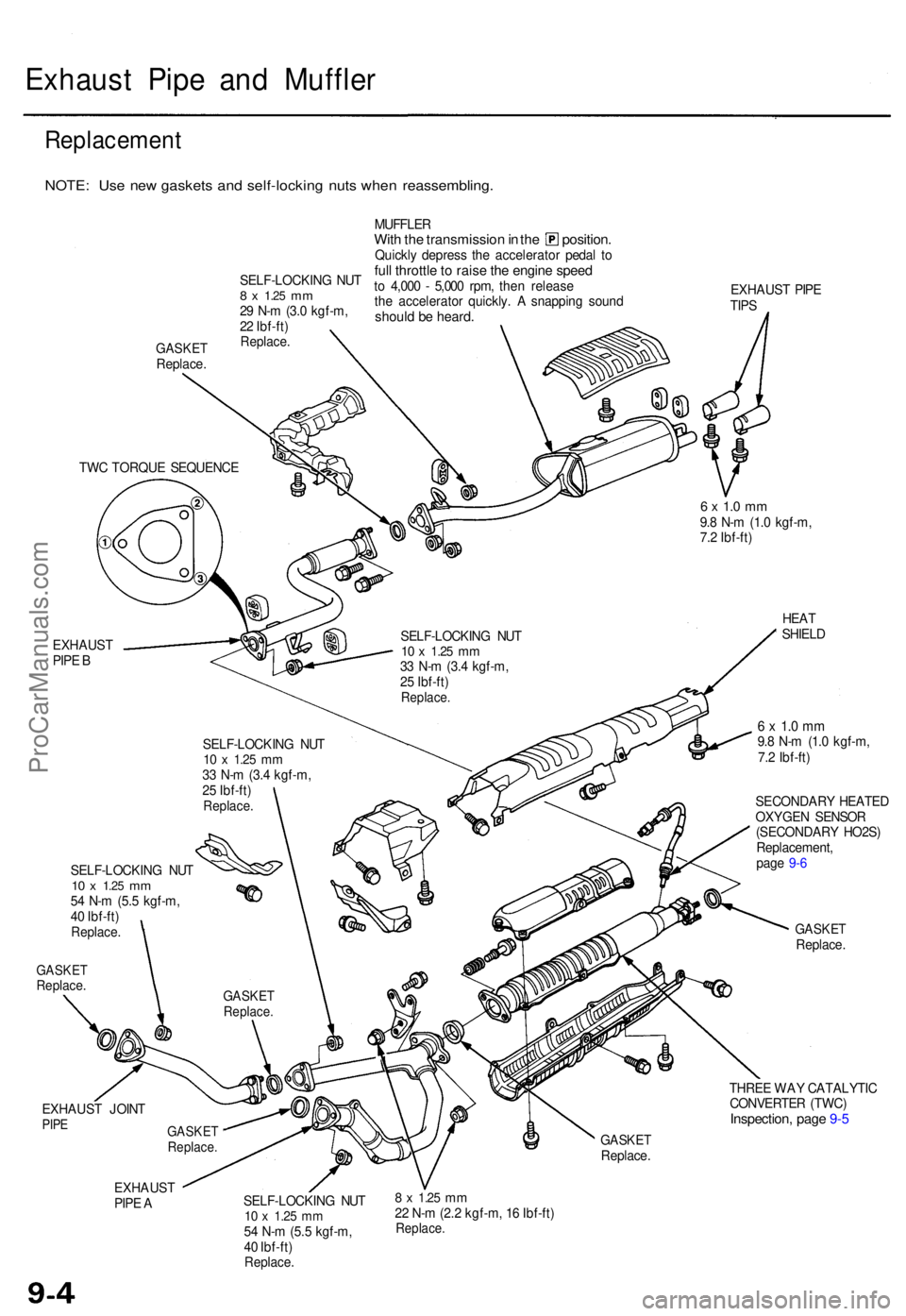

Exhaust Pip e an d Muffle r

Replacemen t

NOTE: Us e ne w gasket s an d self-lockin g nut s whe n reassembling .

GASKETReplace . MUFFLE

R

With th e transmissio n in th e position .Quickly depres s th e accelerato r peda l t oful l throttl e to rais e th e engin e spee dto 4,00 0 - 5,00 0 rpm , the n releas e

th e accelerato r quickly . A snappin g soun d

should b e heard .

EXHAUS T PIP E

TIP S

EXHAUS T

PIP E B

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

HEAT

SHIEL D

GASKE TReplace .

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

SECONDAR Y HEATE D

OXYGE N SENSO R

(SECONDAR Y HO2S )

Replacement ,

pag e 9- 6

GASKE TReplace .

EXHAUS T JOIN T

PIPE

THRE E WA Y CATALYTI C

CONVERTE R (TWC )

Inspection , pag e 9- 5

GASKE TReplace .

EXHAUS T

PIP E A SELF-LOCKIN

G NU T

10 x 1.2 5 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

Replace .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )Replace .

TWC TORQU E SEQUENC E

SELF-LOCKING NU T

10 x 1.2 5 mm33 N- m (3. 4 kgf-m ,

2 5 Ibf-ft )

Replace .

SELF-LOCKIN G NU T10 x 1.2 5 mm33 N- m (3. 4 kgf-m ,

2 5 Ibf-ft )

Replace .

SELF-LOCKIN G NU T10 x 1.2 5 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

Replace .

GASKETReplace .

GASKETReplace .

SELF-LOCKIN G NU T8 x 1.2 5 mm29 N- m (3. 0 kgf-m ,

2 2 Ibf-ft )

Replace .

ProCarManuals.com

Page 138 of 1771

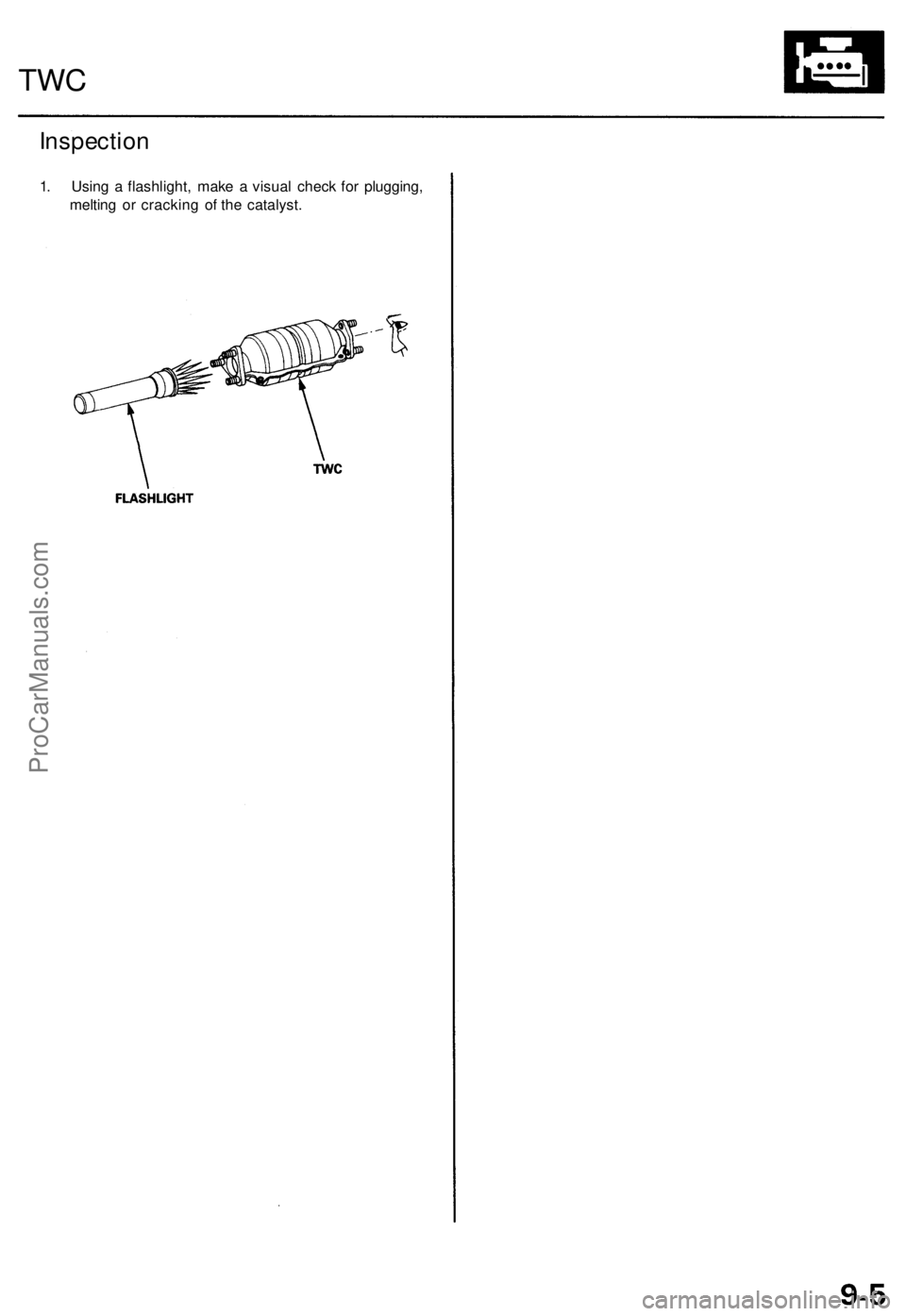

Inspection

1. Using a flashlight, make a visual check for plugging,

melting or cracking of the catalyst.

TWCProCarManuals.com

Page 139 of 1771

Replacement

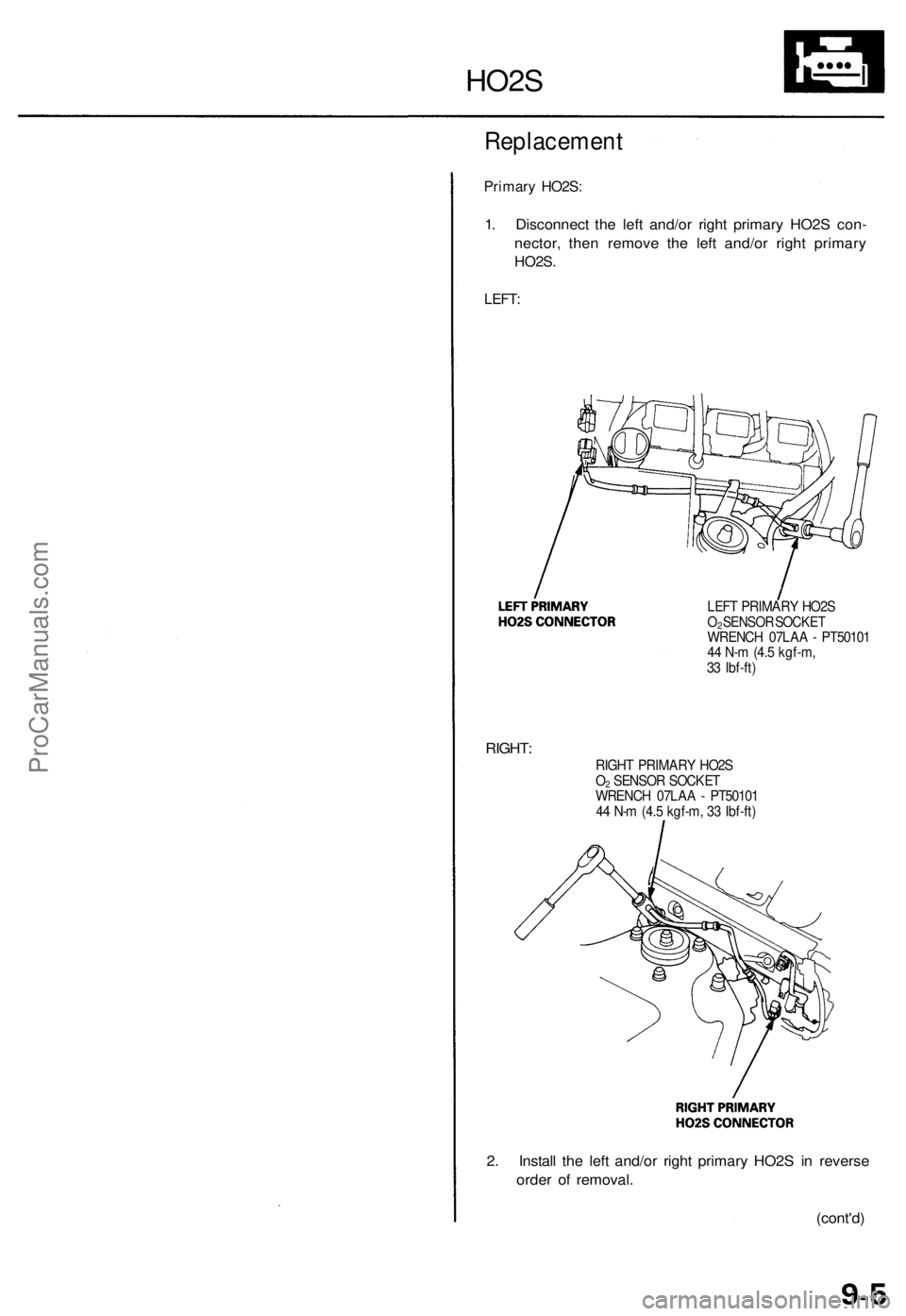

Primary HO2S:

1. Disconnect the left and/or right primary HO2S con-

nector, then remove the left and/or right primary

HO2S.

LEFT:

HO2S

LEFT PRIMARY HO2S

O2 SENSOR SOCKET

WRENCH 07LAA - PT50101

44 N-m (4.5 kgf-m,

33 Ibf-ft)

RIGHT:

RIGHT PRIMARY HO2S

O2 SENSOR SOCKET

WRENCH 07LAA - PT50101

44 N-m (4.5 kgf-m, 33 Ibf-ft)

2. Install the left and/or right primary HO2S in reverse

order of removal.

(cont'd)ProCarManuals.com

Page 140 of 1771

HO2S

Replacement (cont'd)

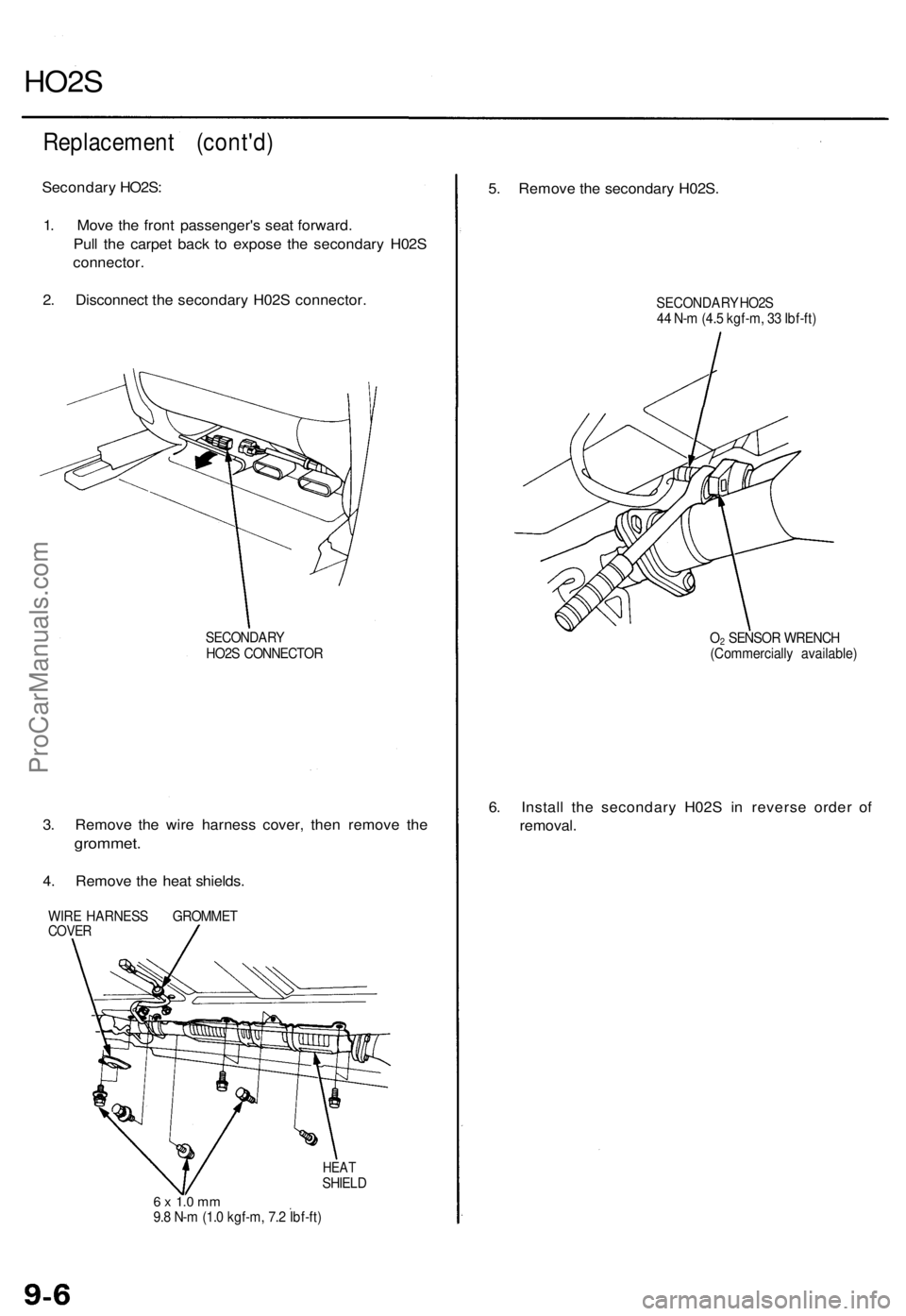

Secondary HO2S:

1. Move the front passenger's seat forward.

Pull the carpet back to expose the secondary H02S

connector.

2. Disconnect the secondary H02S connector.

SECONDARY

HO2S CONNECTOR

3. Remove the wire harness cover, then remove the

grommet.

4. Remove the heat shields.

WIRE HARNESS GROMMET

COVER

HEAT

SHIELD

6 x 1.0 mm

9.8 N-m (1.0 kgf-m, 7.2 Ibf-ft)

5. Remove the secondary H02S.

SECONDARY HO2S

44 N-m (4.5 kgf-m, 33 Ibf-ft)

O2 SENSOR WRENCH

(Commercially available)

6. Install the secondary H02S in reverse order of

removal.ProCarManuals.com