ACURA TL 1995 Service Owners Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 91 of 1771

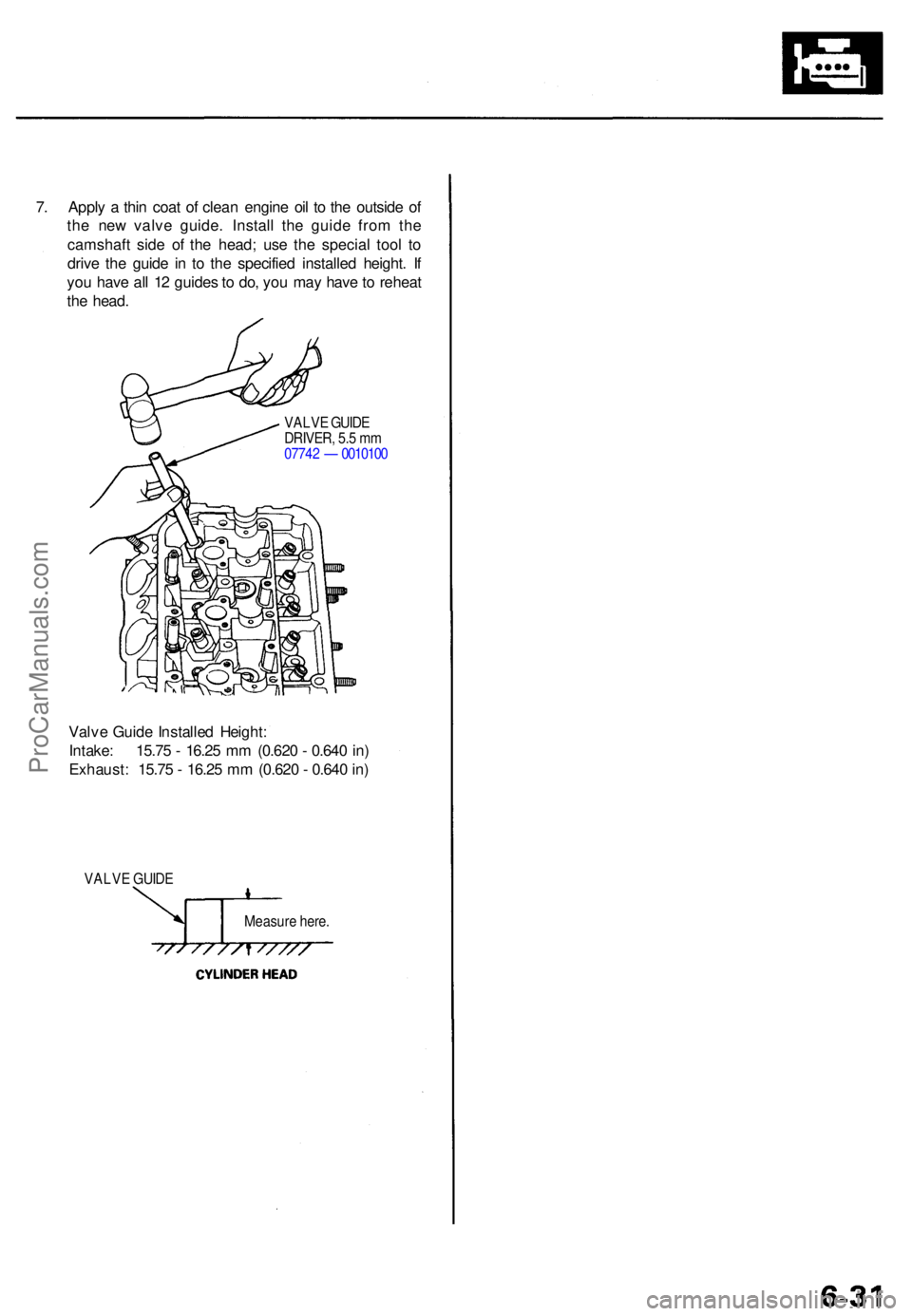

7. Appl y a thi n coa t o f clea n engin e oi l t o th e outsid e o f

th e ne w valv e guide . Instal l th e guid e fro m th e

camshaf t sid e o f th e head ; us e th e specia l too l t o

driv e th e guid e i n t o th e specifie d installe d height . I f

yo u hav e al l 1 2 guide s to do , yo u ma y hav e to rehea t

th e head .

VALV E GUID E

DRIVER , 5. 5 m m

0774 2 — 001010 0

Valve Guid e Installe d Height :

Intake : 15.7 5 - 16.2 5 m m (0.62 0 - 0.64 0 in )

Exhaust : 15.7 5 - 16.2 5 m m (0.62 0 - 0.64 0 in )

VALV E GUID E

Measure here .

ProCarManuals.com

Page 92 of 1771

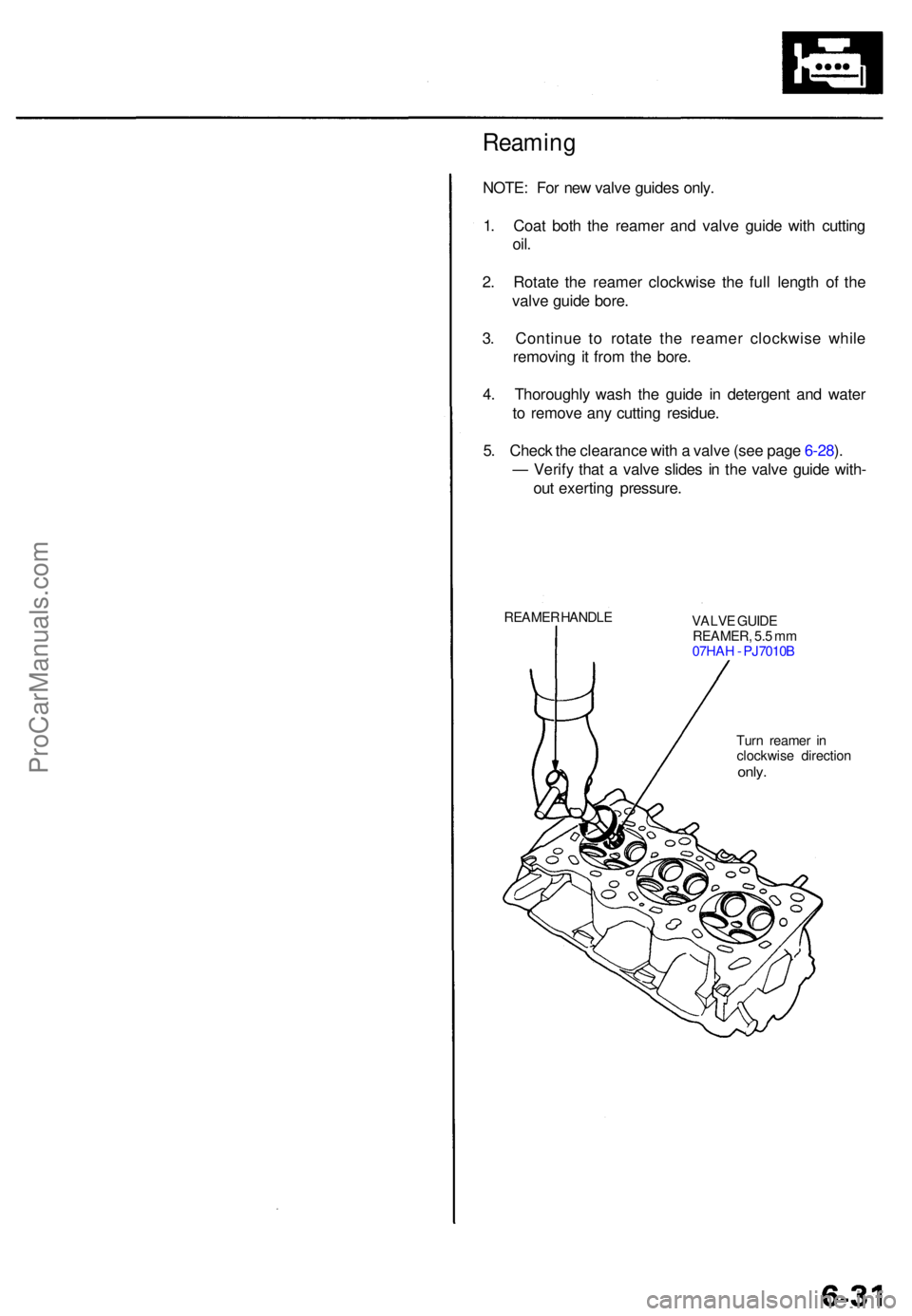

Reaming

NOTE: Fo r ne w valv e guide s only .

1 . Coa t bot h th e reame r an d valv e guid e wit h cuttin g

oil.

2. Rotat e th e reame r clockwis e th e ful l lengt h o f th e

valv e guid e bore .

3 . Continu e t o rotat e th e reame r clockwis e whil e

removin g i t fro m th e bore .

4 . Thoroughl y was h th e guid e i n detergen t an d wate r

t o remov e an y cuttin g residue .

5 . Chec k th e clearanc e wit h a valv e (se e pag e 6-28 ).

— Verif y tha t a valv e slide s i n th e valv e guid e with -

ou t exertin g pressure .

REAMER HANDL E

VALVE GUID E

REAMER , 5. 5 m m

07HA H - PJ7010 B

Tur n reame r i n

clockwis e directio n

only.

ProCarManuals.com

Page 93 of 1771

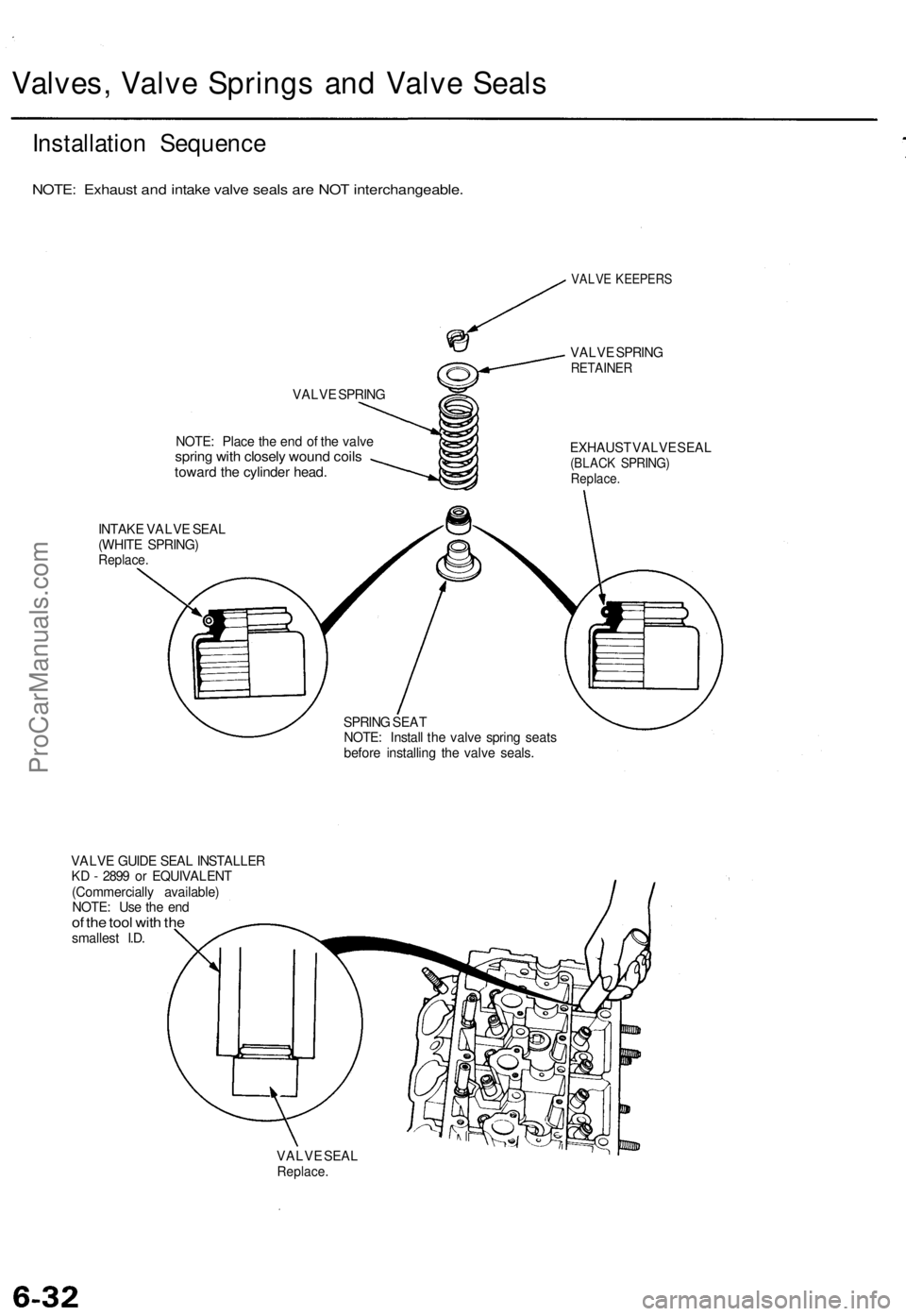

Valves, Valve Springs and Valve Seals

Installation Sequence

NOTE: Exhaust and intake valve seals are NOT interchangeable.

VALVE SPRING

NOTE: Place the end of the valve

spring with closely wound coils

toward the cylinder head.

INTAKE VALVE SEAL

(WHITE SPRING)

Replace.

VALVE KEEPERS

VALVE SPRING

RETAINER

EXHAUST VALVE SEAL

(BLACK SPRING)

Replace.

SPRING SEAT

NOTE: Install the valve spring seats

before installing the valve seals.

VALVE GUIDE SEAL INSTALLER

KD - 2899 or EQUIVALENT

(Commercially available)

NOTE: Use the end

of the tool with the

smallest I.D.

VALVE SEAL

Replace.ProCarManuals.com

Page 94 of 1771

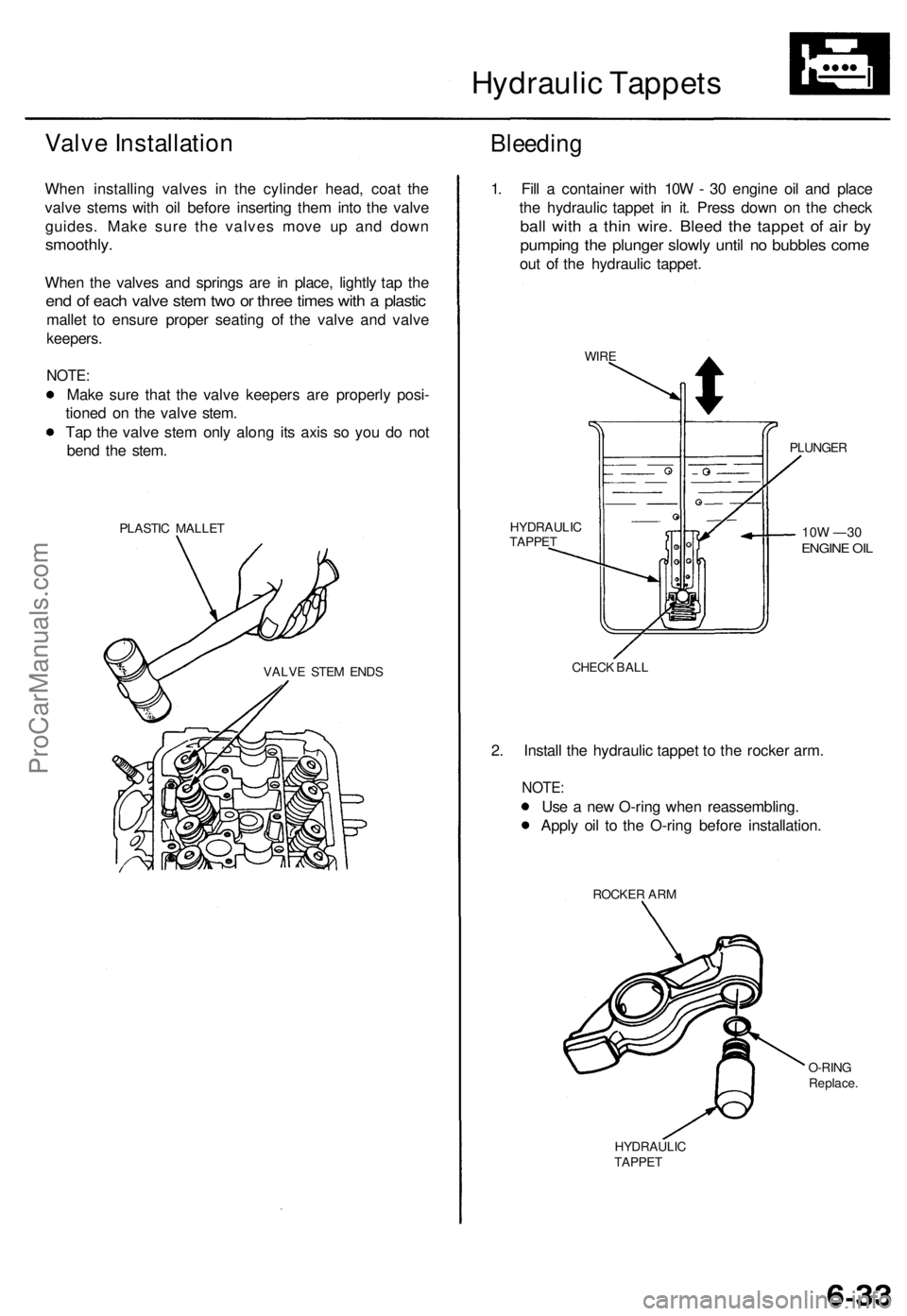

Hydraulic Tappets

Valve Installation

When installing valves in the cylinder head, coat the

valve stems with oil before inserting them into the valve

guides. Make sure the valves move up and down

smoothly.

When the valves and springs are in place, lightly tap the

end of each valve stem two or three times with a plastic

mallet to ensure proper seating of the valve and valve

keepers.

NOTE:

Make sure that the valve keepers are properly posi-

tioned on the valve stem.

Tap the valve stem only along its axis so you do not

bend the stem.

PLASTIC MALLET

Bleeding

VALVE STEM ENDS

1. Fill a container with 10W - 30 engine oil and place

the hydraulic tappet in it. Press down on the check

ball with a thin wire. Bleed the tappet of air by

pumping the plunger slowly until no bubbles come

out of the hydraulic tappet.

WIRE

PLUNGER

10W —30

ENGINE OIL

HYDRAULIC

TAPPET

CHECK BALL

2. Install the hydraulic tappet to the rocker arm.

NOTE:

Use a new O-ring when reassembling.

Apply oil to the O-ring before installation.

ROCKER ARM

O-RING

Replace.

HYDRAULIC

TAPPETProCarManuals.com

Page 95 of 1771

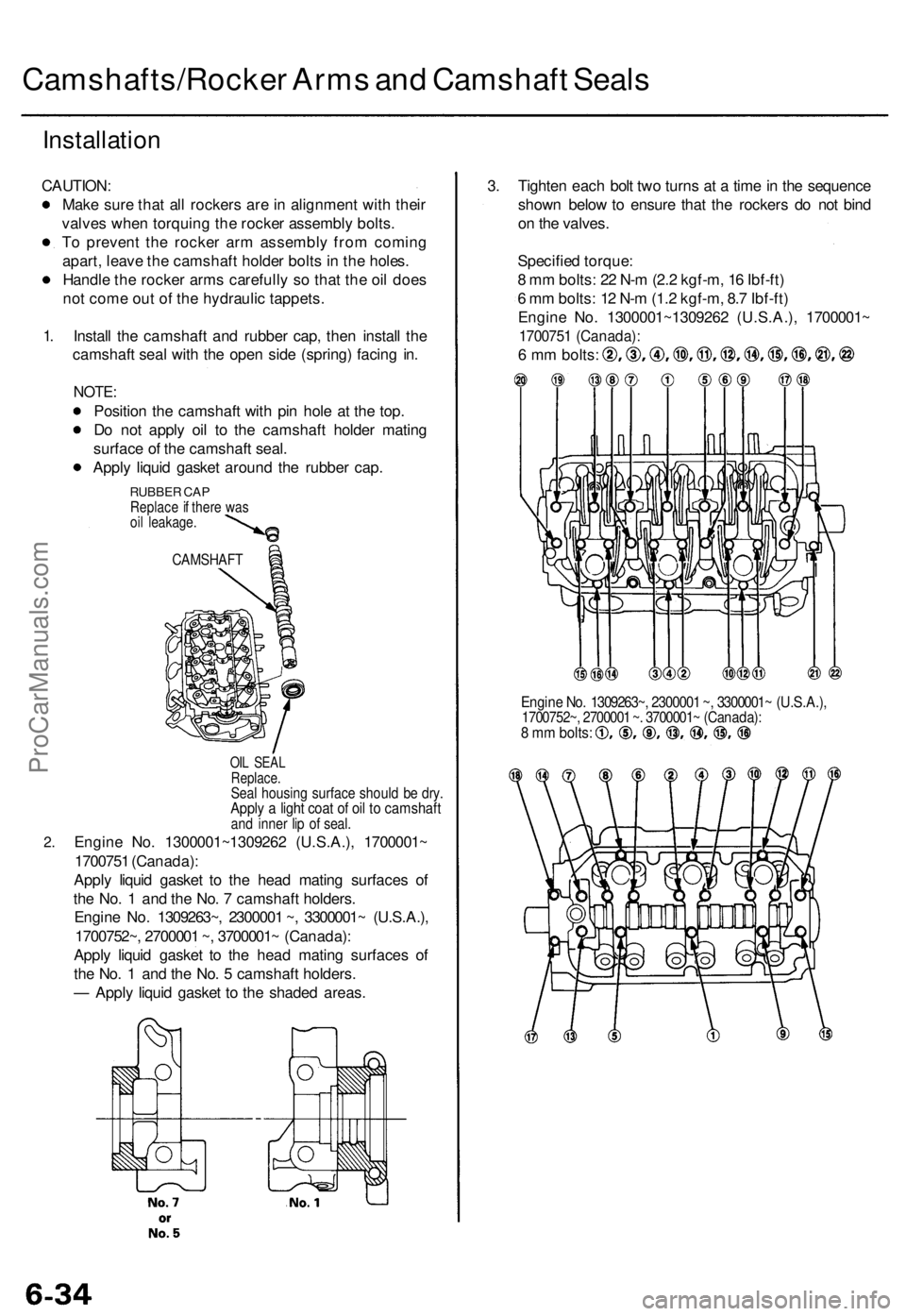

Camshafts/Rocker Arms and Camshaft Seals

Installation

CAUTION:

Make sure that all rockers are in alignment with their

valves when torquing the rocker assembly bolts.

To prevent the rocker arm assembly from coming

apart, leave the camshaft holder bolts in the holes.

Handle the rocker arms carefully so that the oil does

not come out of the hydraulic tappets.

1.

2.

Install the camshaft and rubber cap, then install the

camshaft seal with the open side (spring) facing in.

NOTE:

Position the camshaft with pin hole at the top.

Do not apply oil to the camshaft holder mating

surface of the camshaft seal.

Apply liquid gasket around the rubber cap.

RUBBER CAP

Replace if there was

oil leakage.

CAMSHAFT

OIL SEAL

Replace.

Seal housing surface should be dry.

Apply a light coat of oil to camshaft

and inner lip of seal.

Engine No. 1300001~1309262 (U.S.A.), 1700001~

1700751 (Canada):

Apply liquid gasket to the head mating surfaces of

the No. 1 and the No. 7 camshaft holders.

Engine No. 1309263~, 2300001 ~, 3300001~ (U.S.A.),

1700752~, 2700001 ~, 3700001~ (Canada):

Apply liquid gasket to the head mating surfaces of

the No. 1 and the No. 5 camshaft holders.

— Apply liquid gasket to the shaded areas.

3. Tighten each bolt two turns at a time in the sequence

shown below to ensure that the rockers do not bind

on the valves.

Specified torque:

8 mm bolts: 22 N-m (2.2 kgf-m, 16 Ibf-ft)

6 mm bolts: 12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

Engine No. 1300001~1309262 (U.S.A.), 1700001~

1700751 (Canada):

6 mm bolts:

Engine No. 1309263~, 2300001 ~, 3300001~ (U.S.A.),

1700752~, 2700001 ~. 3700001~ (Canada):

8 mm bolts:ProCarManuals.com

Page 96 of 1771

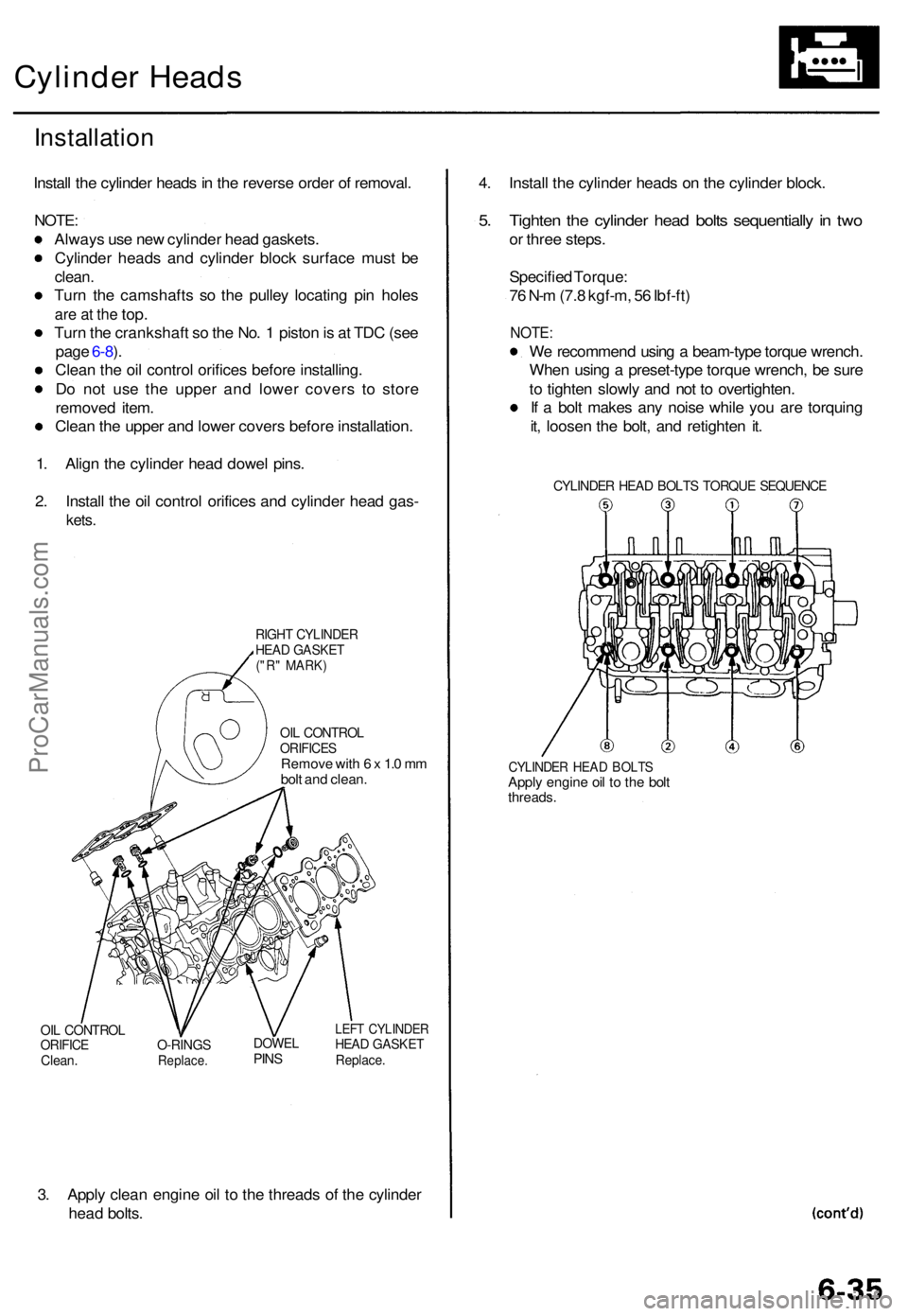

Cylinder Heads

Installation

Install th e cylinde r head s in th e revers e orde r o f removal .

NOTE:

Alway s us e ne w cylinde r hea d gaskets .

Cylinde r head s an d cylinde r bloc k surfac e mus t b e

clean .

Turn th e camshaft s s o th e pulle y locatin g pi n hole s

are a t th e top .

Turn th e crankshaf t s o th e No . 1 pisto n is a t TD C (se e

pag e 6-8 ).

Clea n th e oi l contro l orifice s befor e installing .

D o no t us e th e uppe r an d lowe r cover s t o stor e

remove d item .

Clea n th e uppe r an d lowe r cover s befor e installation .

1 . Alig n th e cylinde r hea d dowe l pins .

2 . Instal l th e oi l contro l orifice s an d cylinde r hea d gas -

kets.

RIGH T CYLINDE RHEAD GASKE T("R" MARK )

OIL CONTRO LORIFICESRemove wit h 6 x 1. 0 m m

bol t an d clean .

OIL CONTRO LORIFICEClean.O-RING SReplace .

DOWELPINS

LEF T CYLINDE RHEAD GASKE TReplace.

3. Appl y clea n engin e oi l t o th e thread s o f th e cylinde r

hea d bolts . 4

. Instal l th e cylinde r head s o n th e cylinde r block .

5. Tighte n th e cylinde r hea d bolt s sequentiall y in tw o

or thre e steps .

Specifie d Torque :

7 6 N- m (7. 8 kgf-m , 5 6 Ibf-ft )

NOTE :

We recommen d usin g a beam-typ e torqu e wrench .

Whe n usin g a preset-typ e torqu e wrench , b e sur e

t o tighte n slowl y an d no t t o overtighten .

I f a bol t make s an y nois e whil e yo u ar e torquin g

it , loose n th e bolt , an d retighte n it .

CYLINDE R HEA D BOLT S TORQU E SEQUENC E

CYLINDER HEA D BOLT SApply engin e oi l t o th e bol tthreads .

ProCarManuals.com

Page 97 of 1771

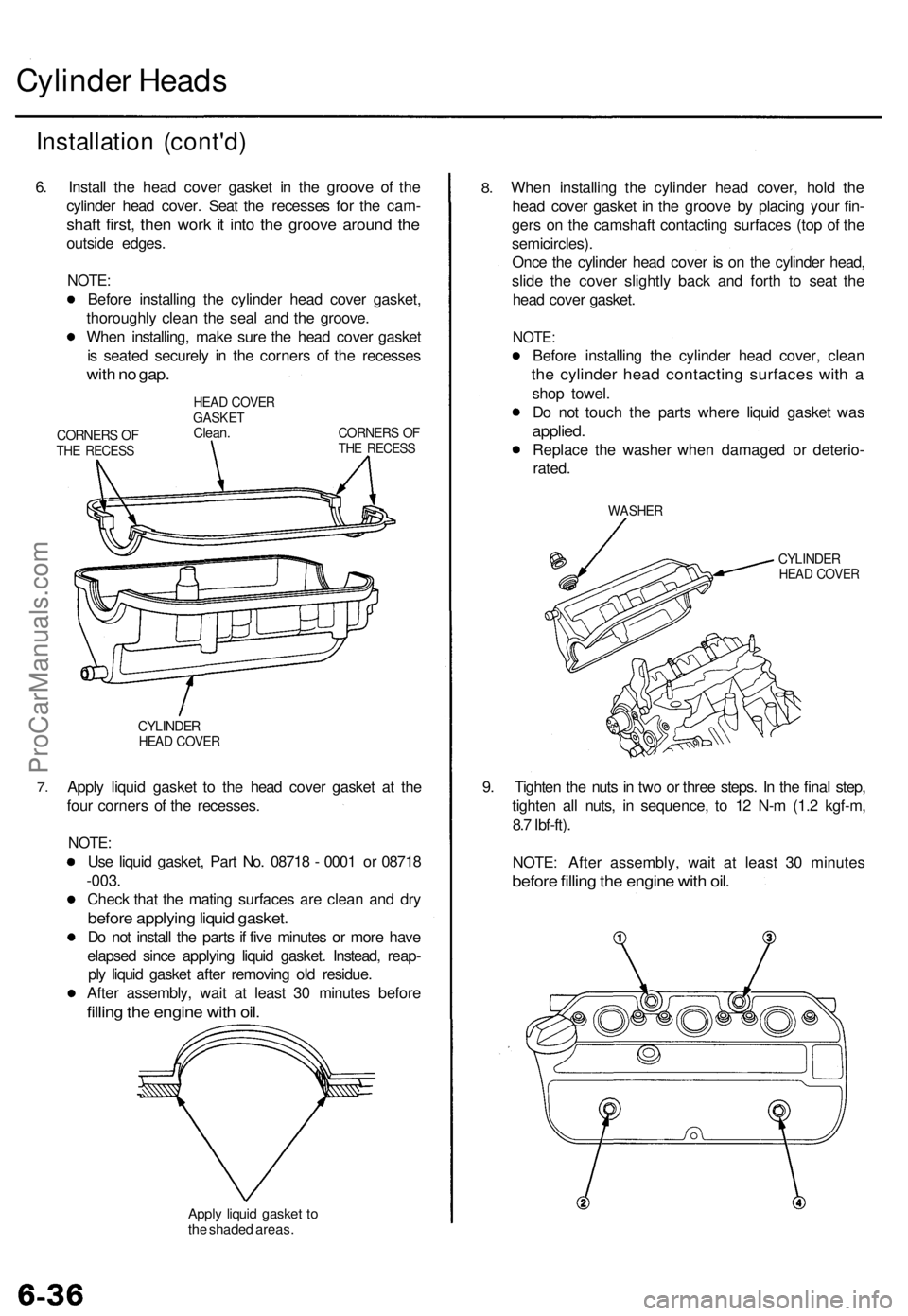

Cylinder Heads

Installation (cont'd)

6. Install the head cover gasket in the groove of the

cylinder head cover. Seat the recesses for the cam-

shaft first, then work it into the groove around the

outside edges.

NOTE:

Before installing the cylinder head cover gasket,

thoroughly clean the seal and the groove.

When installing, make sure the head cover gasket

is seated securely in the corners of the recesses

with no gap.

CORNERS OF

THE RECESS

HEAD COVER

GASKET

Clean.

CORNERS OF

THE RECESS

7.

CYLINDER

HEAD COVER

Apply liquid gasket to the head cover gasket at the

four corners of the recesses.

NOTE:

Use liquid gasket, Part No. 08718 - 0001 or 08718

-003.

Check that the mating surfaces are clean and dry

before applying liquid gasket.

Do not install the parts if five minutes or more have

elapsed since applying liquid gasket. Instead, reap-

ply liquid gasket after removing old residue.

After assembly, wait at least 30 minutes before

filling the engine with oil.

Apply liquid gasket to

the shaded areas.

8.

When installing the cylinder head cover, hold the

head cover gasket in the groove by placing your fin-

gers on the camshaft contacting surfaces (top of the

semicircles).

Once the cylinder head cover is on the cylinder head,

slide the cover slightly back and forth to seat the

head cover gasket.

NOTE:

Before installing the cylinder head cover, clean

the cylinder head contacting surfaces with a

shop towel.

Do not touch the parts where liquid gasket was

applied.

Replace the washer when damaged or deterio-

rated.

WASHER

CYLINDER

HEAD COVER

9. Tighten the nuts in two or three steps. In the final step,

tighten all nuts, in sequence, to 12 N-m (1.2 kgf-m,

8.7 Ibf-ft).

NOTE: After assembly, wait at least 30 minutes

before filling the engine with oil.ProCarManuals.com

Page 98 of 1771

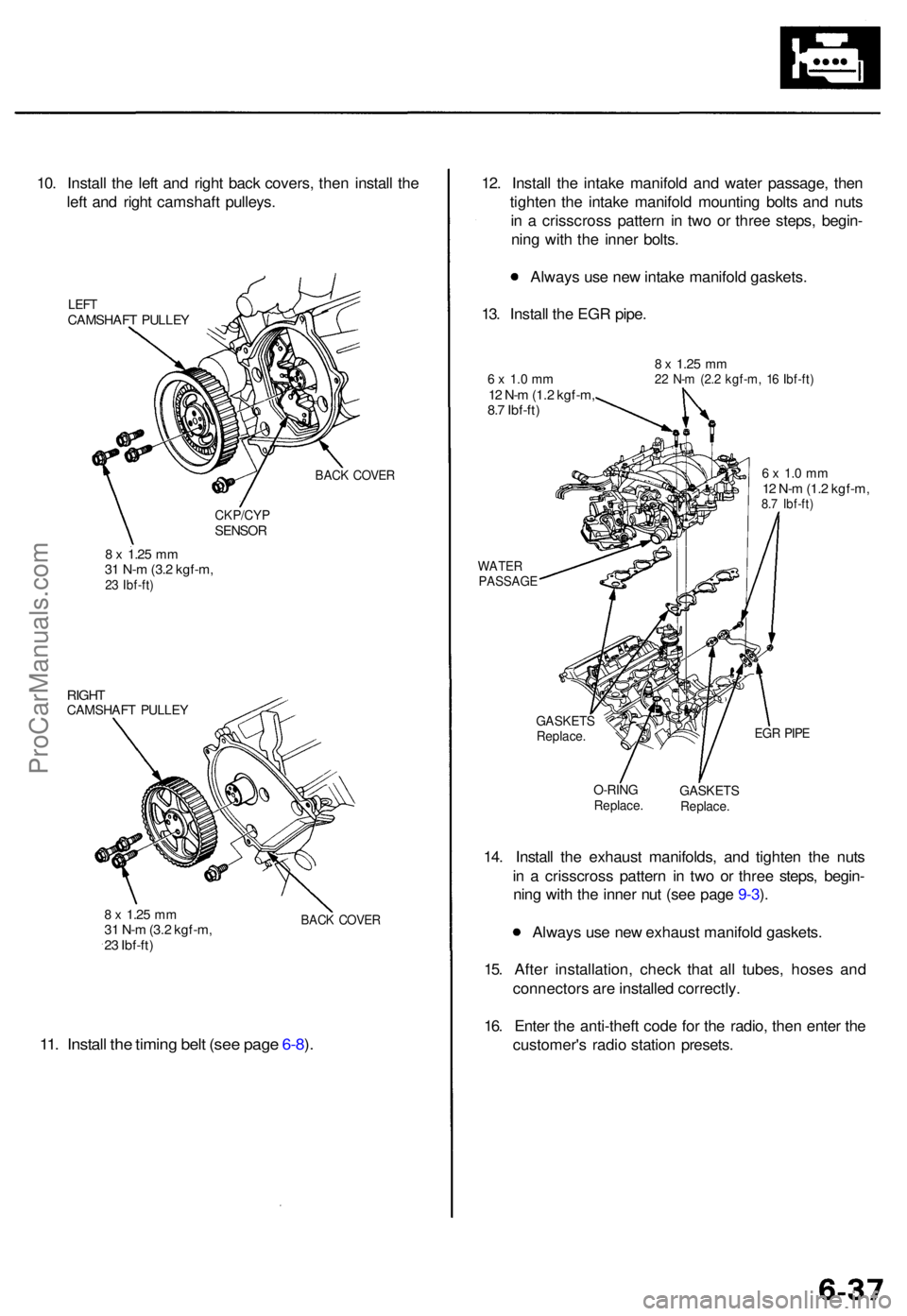

10. Instal l th e lef t an d righ t bac k covers , the n instal l th e

lef t an d righ t camshaf t pulleys .

LEFTCAMSHAF T PULLE Y

BACK COVE R

CKP/CY PSENSOR

8 x 1.2 5 mm31 N- m (3. 2 kgf-m ,23 Ibf-ft )

RIGHTCAMSHAF T PULLE Y

8 x 1.2 5 mm31 N- m (3. 2 kgf-m ,

2 3 Ibf-ft )BACK COVE R

11. Instal l th e timin g bel t (se e pag e 6-8 ).

12 . Instal l th e intak e manifol d an d wate r passage , the n

tighte n th e intak e manifol d mountin g bolt s an d nut s

i n a crisscros s patter n i n tw o o r thre e steps , begin -

nin g wit h th e inne r bolts .

Alway s us e ne w intak e manifol d gaskets .

13 . Instal l th e EG R pipe .

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

WATE RPASSAG E

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )

GASKET SReplace.EGR PIP E

O-RIN GReplace .GASKET SReplace.

14. Instal l th e exhaus t manifolds , an d tighte n th e nut s

i n a crisscros s patter n i n tw o o r thre e steps , begin -

nin g wit h th e inne r nu t (se e pag e 9-3 ).

Alway s us e ne w exhaus t manifol d gaskets .

15 . Afte r installation , chec k tha t al l tubes , hose s an d

connector s ar e installe d correctly .

16 . Ente r th e anti-thef t cod e fo r th e radio , the n ente r th e

customer' s radi o statio n presets .

ProCarManuals.com

Page 99 of 1771

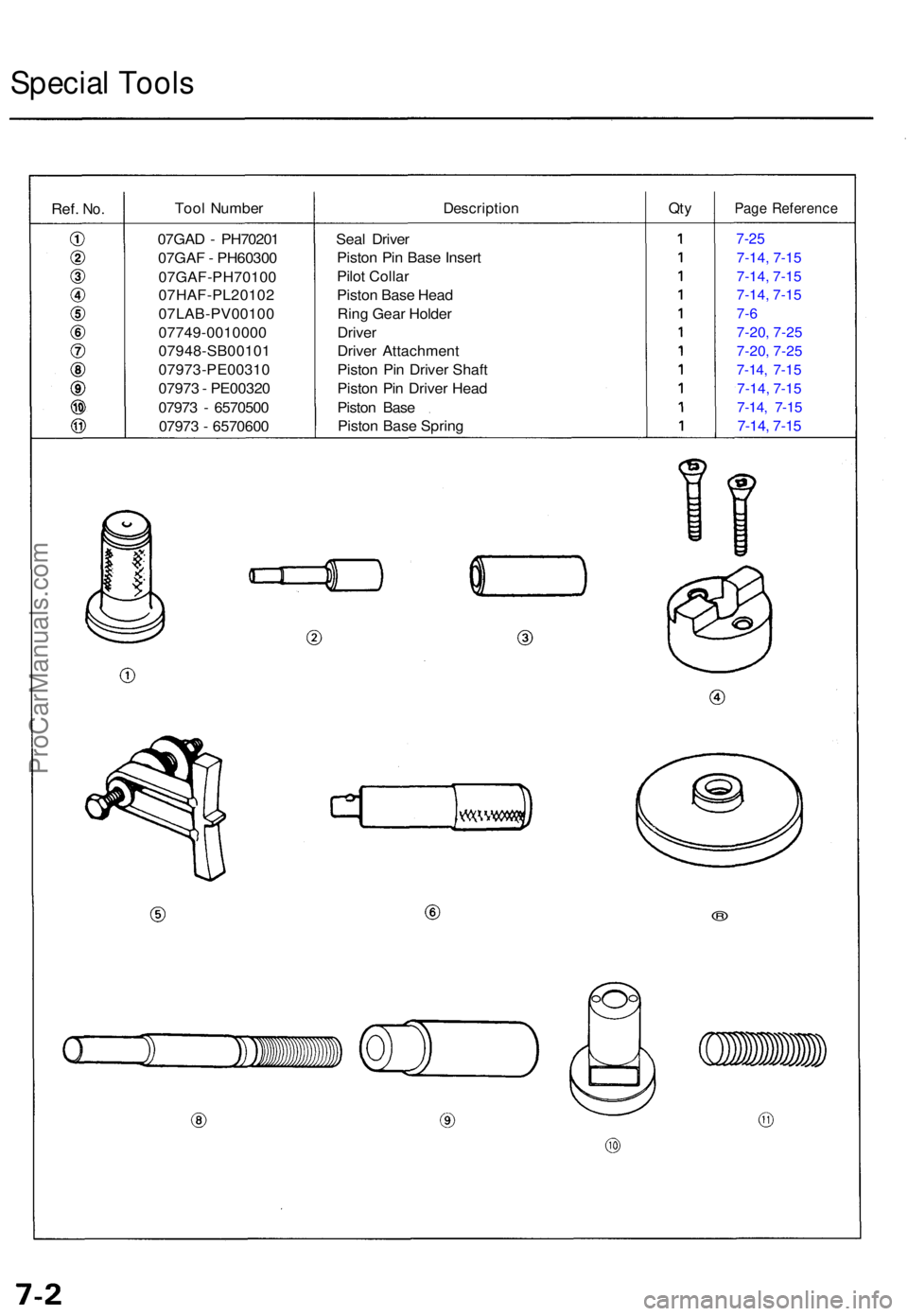

Special Tool s

Ref. No.Too l Numbe rDescriptio nQtyPag e Referenc e

Seal Drive r

Pisto n Pi n Bas e Inser t

Pilo t Colla r

Pisto n Bas e Hea d

Rin g Gea r Holde r

Drive r

Drive r Attachmen t

Pisto n Pi n Drive r Shaf t

Pisto n Pi n Drive r Hea d

Pisto n Bas e

Pisto n Bas e Sprin g7-25

7-14 , 7-1 5

7-14 , 7-1 5

7-14 , 7-1 5

7-6

7-20, 7-25

7-20, 7-25

7-14 , 7-1 5

7-14 , 7-1 5

7-14 , 7-1 5

7-14, 7-15

®

07GA D - PH7020 1

07GA F - PH6030 0

07GAF-PH7010 0

07HAF-PL2010 2

07LAB-PV0010 0

07749-001000 0

07948-SB0010 1

07973-PE0031 0

0797 3 - PE0032 0

0797 3 - 657050 0

0797 3 - 657060 0

ProCarManuals.com

Page 100 of 1771

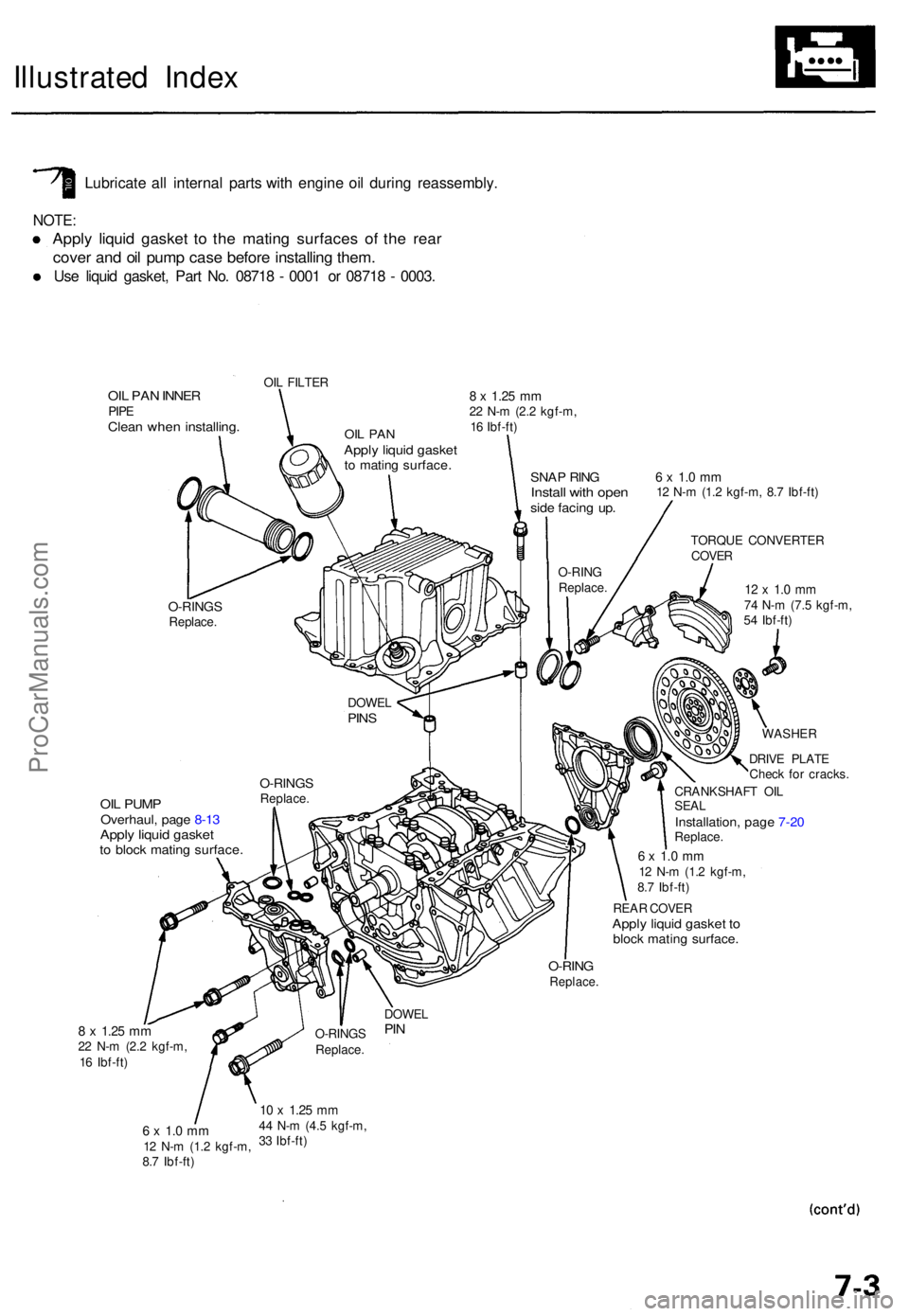

Illustrated Inde x

Lubricat e al l interna l part s wit h engin e oi l durin g reassembly .

NOTE:

Apply liqui d gaske t t o th e matin g surface s o f th e rea r

cove r an d oi l pum p cas e befor e installin g them .

Use liqui d gasket , Par t No . 0871 8 - 000 1 o r 0871 8 - 0003 .

OIL PA N INNE RPIPEClea n whe n installing .

OIL FILTE R8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

TORQU E CONVERTE R

COVE R

12 x 1. 0 m m74 N- m (7. 5 kgf-m ,

5 4 Ibf-ft )

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft ) WASHE

R

OIL PUM POverhaul , pag e 8-1 3Appl y liqui d gaske tto bloc k matin g surface .

DRIVE PLAT E

Chec k fo r cracks .

CRANKSHAF T OI L

SEA L

Installation , pag e 7-2 0Replace .

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

REA R COVE R

Apply liqui d gaske t t obloc k matin g surface .

O-RINGReplace .

10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )O-RING

S

Replace .DOWE

L

PIN

O-RING SReplace .DOWE

L

PINS

O-RING SReplace . O-RIN

G

Replace .

SNAP RIN GInstal l wit h ope nside facin g up .

OIL PA NAppl y liqui d gaske tto matin g surface .

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

ProCarManuals.com