ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 141 of 1771

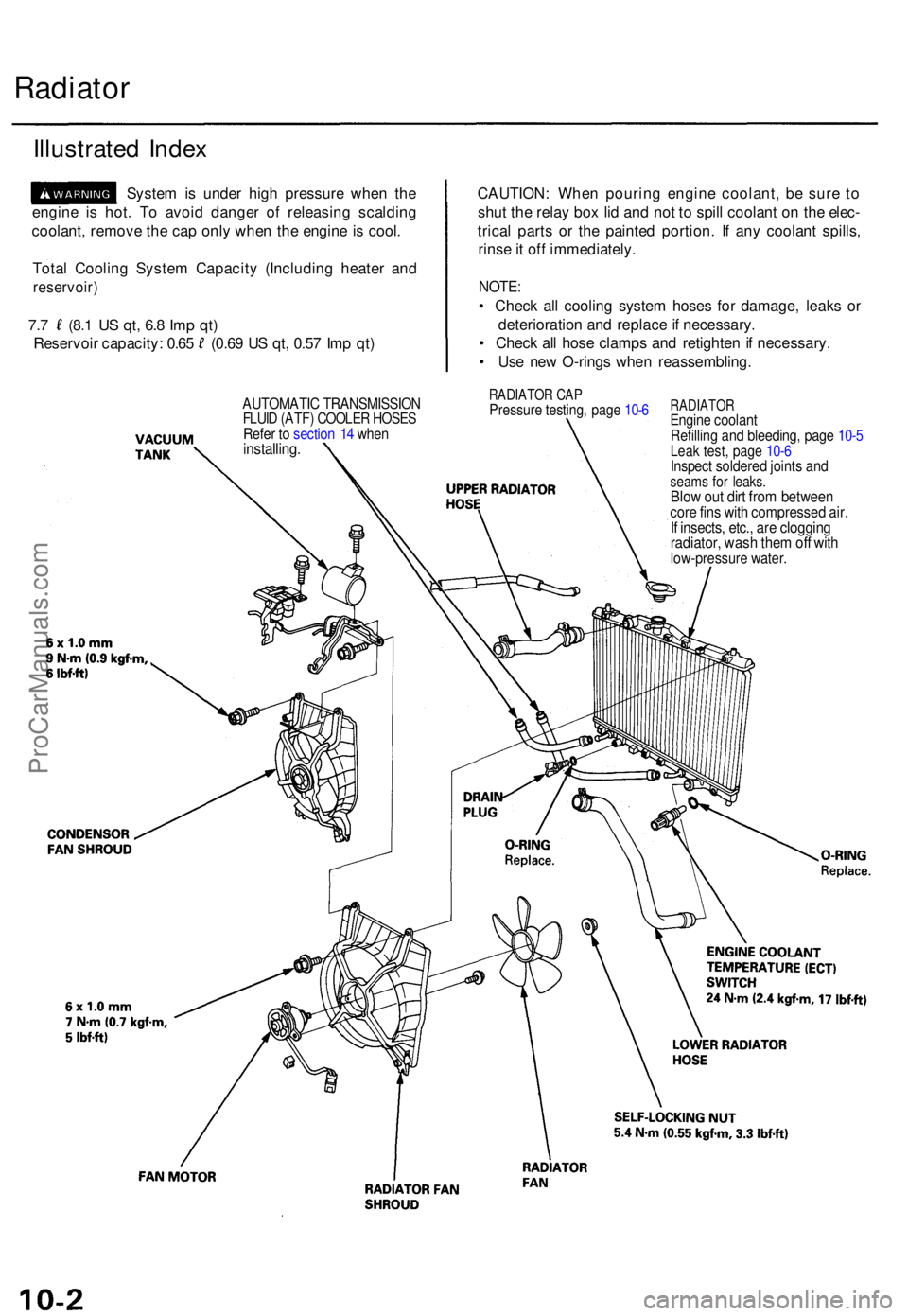

Radiator

Illustrate d Inde x

Syste m is unde r hig h pressur e whe n th e

engin e i s hot . T o avoi d dange r o f releasin g scaldin g

coolant , remov e th e ca p onl y whe n th e engin e is cool .

Tota l Coolin g Syste m Capacit y (Includin g heate r an d

reservoir )

7.7 (8. 1 US qt , 6. 8 Im p qt )

Reservoi r capacity : 0.6 5 (0.6 9 U S qt , 0.5 7 Im p qt ) CAUTION

: Whe n pourin g engin e coolant , b e sur e t o

shu t th e rela y bo x li d an d no t t o spil l coolan t o n th e elec -

trica l part s o r th e painte d portion . I f an y coolan t spills ,

rins e it of f immediately .

NOTE:

• Chec k al l coolin g syste m hose s fo r damage , leak s o r

deterioratio n an d replac e if necessary .

• Chec k al l hos e clamp s an d retighte n if necessary .

• Us e ne w O-ring s whe n reassembling .

RADIATOR CA PPressur e testing , pag e 10- 6RADIATO REngine coolan t

Refillin g an d bleeding , pag e 10- 5

Leak test , pag e 10- 6Inspec t soldere d joint s an dseam s fo r leaks .Blow ou t dir t fro m betwee ncore fin s wit h compresse d air .If insects , etc. , ar e cloggin gradiator , was h the m of f wit hlow-pressur e water .

AUTOMATI C TRANSMISSIO NFLUID (ATF ) COOLE R HOSE SRefer t o sectio n 1 4 whe ninstalling .

ProCarManuals.com

Page 142 of 1771

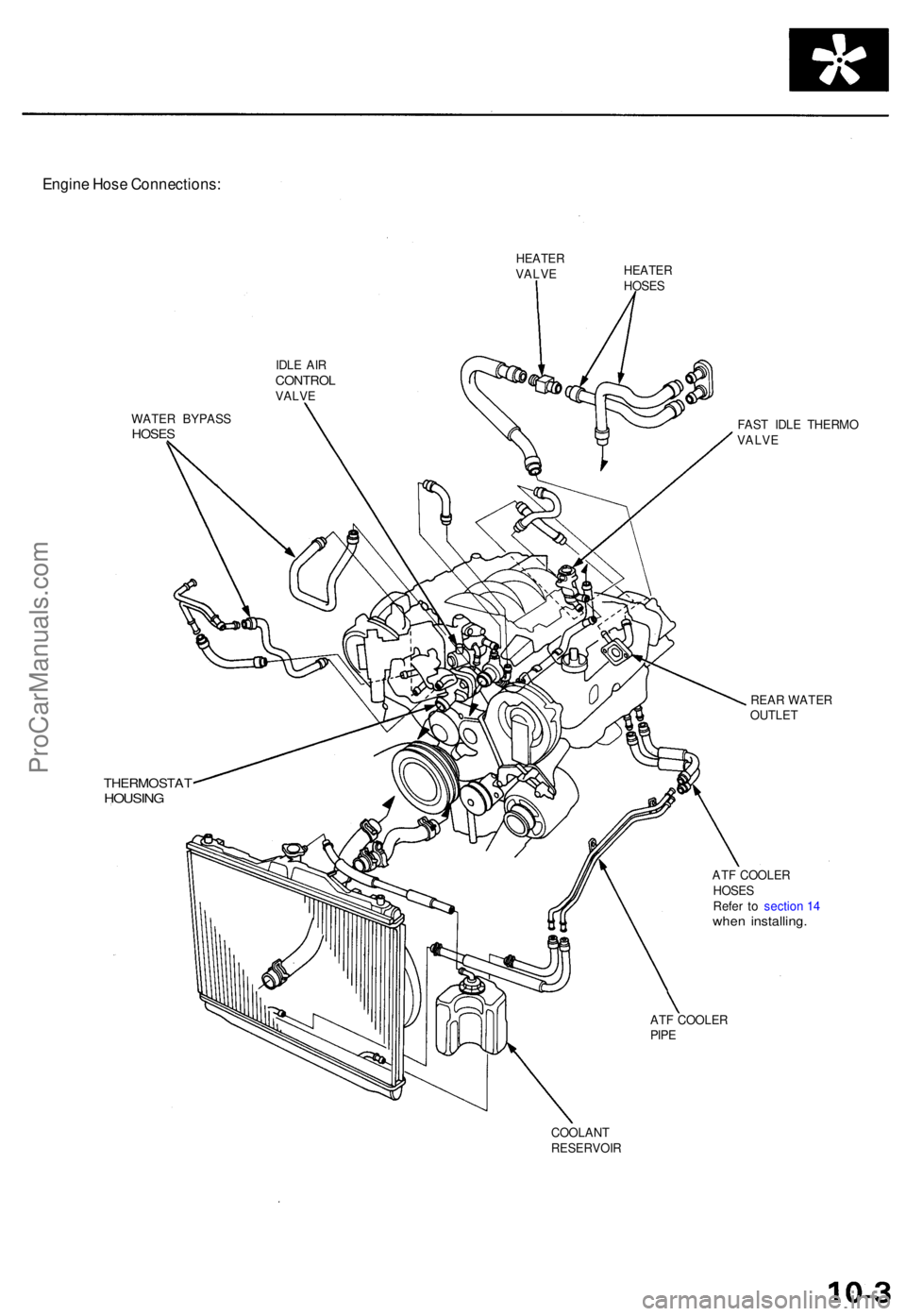

Engine Hos e Connections :

HEATERVALVEHEATE RHOSES

IDL E AI R

CONTRO LVALVE

WATE R BYPAS S

HOSES

THERMOSTA THOUSING

FAST IDL E THERM O

VALV E

REA R WATE R

OUTLE T

AT F COOLE R

HOSE S

Refe r t o sectio n 1 4

whe n installing .

ATF COOLE R

PIP E

COOLAN T

RESERVOI R

ProCarManuals.com

Page 143 of 1771

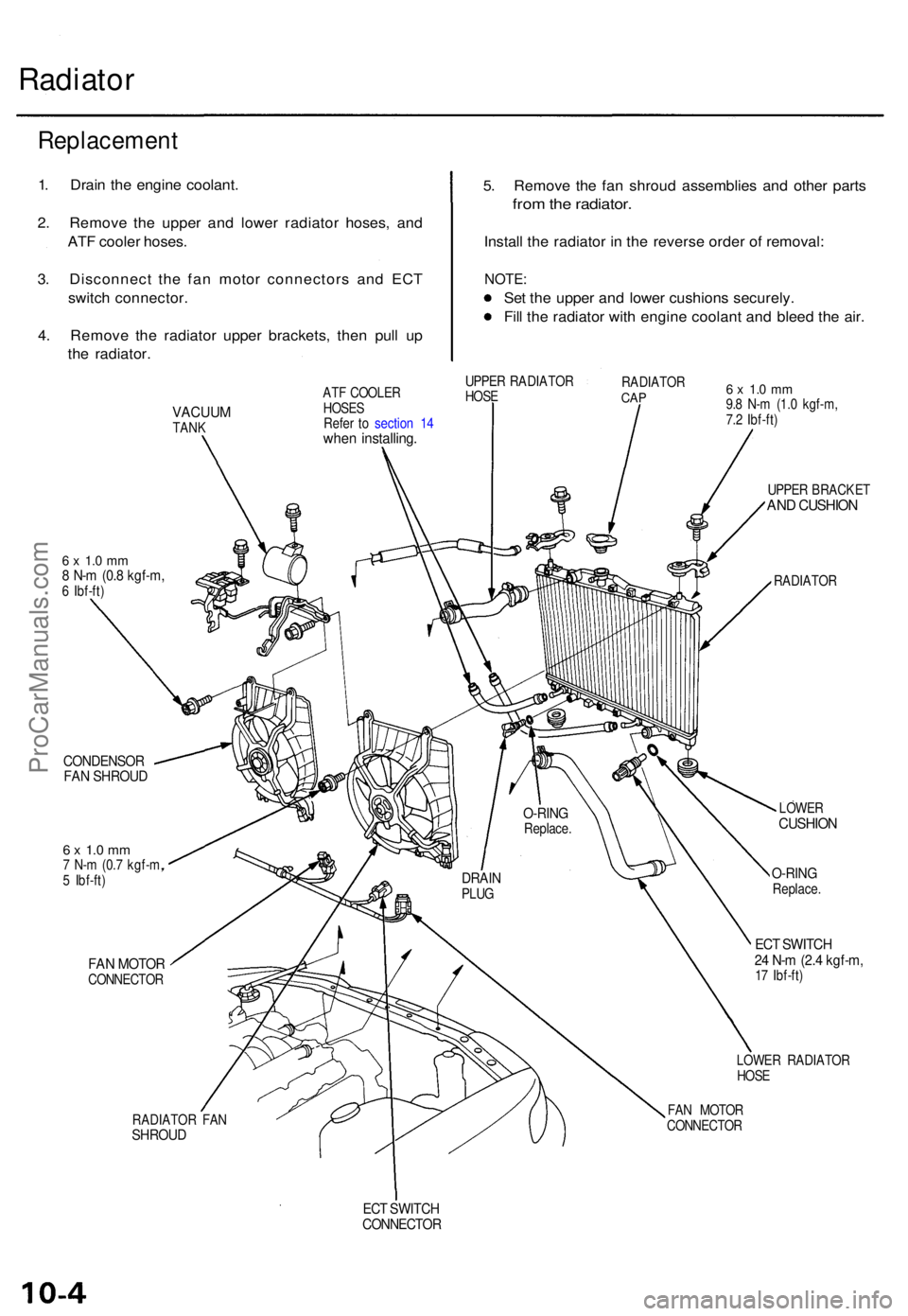

Radiator

5. Remov e th e fa n shrou d assemblie s an d othe r part s

from th e radiator .

Install th e radiato r i n th e revers e orde r o f removal :

NOTE:

Set th e uppe r an d lowe r cushion s securely .

Fil l th e radiato r wit h engin e coolan t an d blee d th e air .

VACUU MTANK

6 x 1. 0 m m8 N- m (0. 8 kgf-m ,6 Ibf-ft )

CONDENSO RFAN SHROU D

6 x 1. 0 m m7 N- m (0. 7 kgf-m ,

5 Ibf-ft )

FAN MOTO RCONNECTO R

RADIATO R FA N

SHROU D

ATF COOLE R

HOSE S

Refe r t o sectio n 1 4

whe n installing .

UPPER RADIATO R

HOS E RADIATO

RCAP6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

UPPE R BRACKE T

AND CUSHIO N

RADIATO R

LOWE R

CUSHIO N

O-RINGReplace .

ECT SWITC H24 N- m (2. 4 kgf-m ,17 Ibf-ft )

LOWE R RADIATO R

HOS E

FA N MOTO R

CONNECTO R

ECT SWITC HCONNECTO R

DRAINPLUG

O-RIN GReplace .

Replacemen t

1. Drai n th e engin e coolant .

2 . Remov e th e uppe r an d lowe r radiato r hoses , an d

AT F coole r hoses .

3 . Disconnec t th e fa n moto r connector s an d EC T

switc h connector .

4 . Remov e th e radiato r uppe r brackets , the n pul l u p

th e radiator .

ProCarManuals.com

Page 144 of 1771

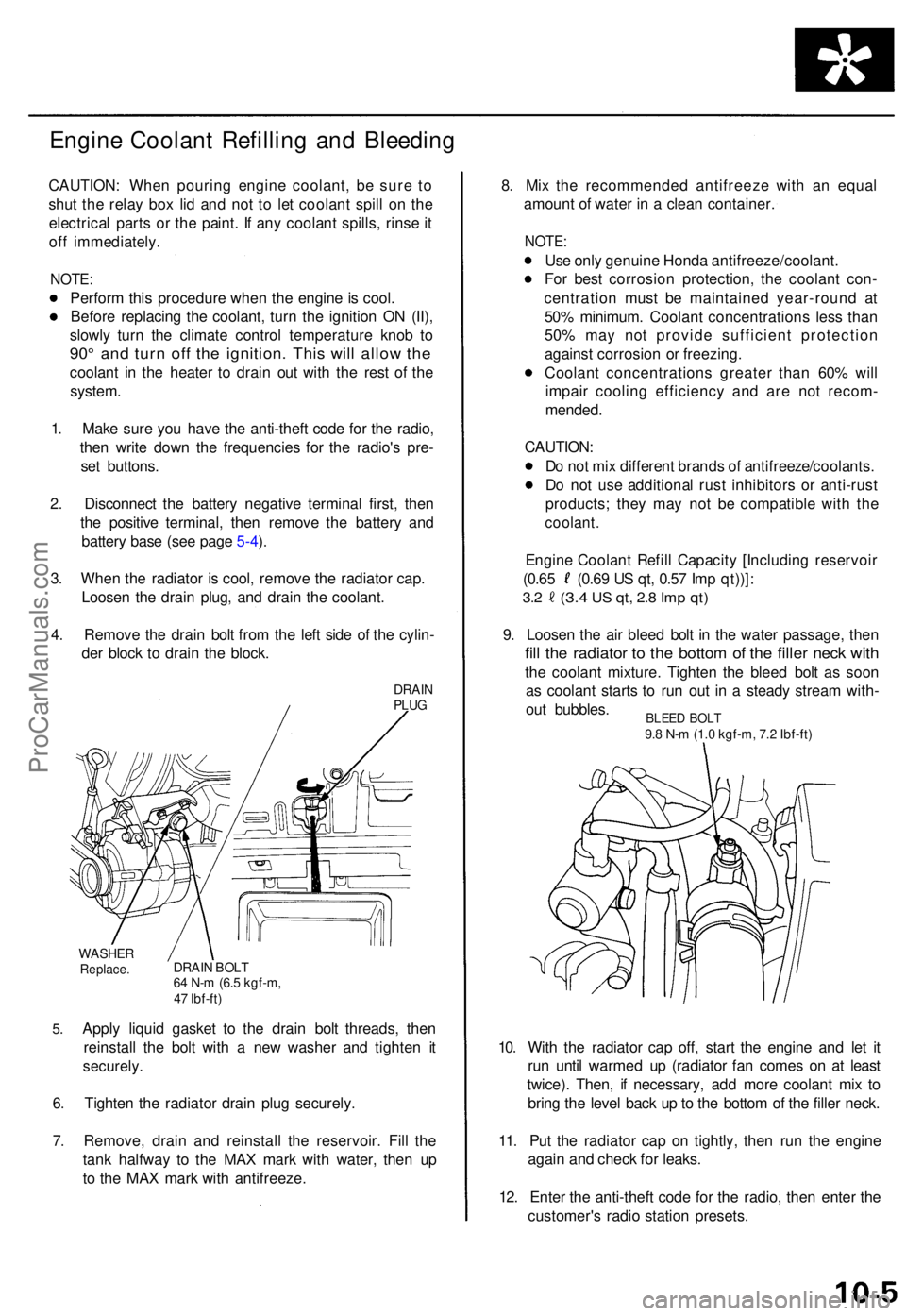

Engine Coolan t Refillin g an d Bleedin g

CAUTION : Whe n pourin g engin e coolant , b e sur e t o

shu t th e rela y bo x li d an d no t t o le t coolan t spil l o n th e

electrica l part s o r th e paint . I f an y coolan t spills , rins e it

of f immediately .

NOTE:

Perfor m thi s procedur e whe n th e engin e is cool .

Befor e replacin g th e coolant , tur n th e ignitio n O N (II) ,

slowl y tur n th e climat e contro l temperatur e kno b t o

90 ° an d tur n of f th e ignition . Thi s wil l allo w th e

coolan t i n th e heate r t o drai n ou t wit h th e res t o f th e

system .

1 . Mak e sur e yo u hav e th e anti-thef t cod e fo r th e radio ,

the n writ e dow n th e frequencie s fo r th e radio' s pre -

se t buttons .

2 . Disconnec t th e batter y negativ e termina l first , the n

th e positiv e terminal , the n remov e th e batter y an d

batter y bas e (se e pag e 5-4 ).

3 . Whe n th e radiato r i s cool , remov e th e radiato r cap .

Loose n th e drai n plug , an d drai n th e coolant .

4 . Remov e th e drai n bol t fro m th e lef t sid e o f th e cylin -

de r bloc k t o drai n th e block .

DRAINPLUG

5.

WASHE RReplace .DRAIN BOL T64 N- m (6. 5 kgf-m ,

4 7 Ibf-ft )

Apply liqui d gaske t t o th e drai n bol t threads , the n

reinstal l th e bol t wit h a ne w washe r an d tighte n i t

securely .

6. Tighte n th e radiato r drai n plu g securely .

7 . Remove , drai n an d reinstal l th e reservoir . Fil l th e

tan k halfwa y t o th e MA X mar k wit h water , the n u p

t o th e MA X mar k wit h antifreeze . 8

. Mi x th e recommende d antifreez e wit h a n equa l

amoun t o f wate r i n a clea n container .

NOTE:

Use onl y genuin e Hond a antifreeze/coolant .

Fo r bes t corrosio n protection , th e coolan t con -

centratio n mus t b e maintaine d year-roun d a t

50 % minimum . Coolan t concentration s les s tha n

50 % ma y no t provid e sufficien t protectio n

agains t corrosio n o r freezing .

Coolan t concentration s greate r tha n 60 % wil l

impai r coolin g efficienc y an d ar e no t recom -

mended .

CAUTION :

D o no t mi x differen t brand s o f antifreeze/coolants .

D o no t us e additiona l rus t inhibitor s o r anti-rus t

products ; the y ma y no t b e compatibl e wit h th e

coolant .

Engine Coolan t Refil l Capacit y [Includin g reservoi r

(0.65 (0.6 9 U S qt , 0.5 7 Im p qt))] :

3.2 (3. 4 US qt , 2. 8 Im p qt )

9. Loose n th e ai r blee d bol t i n th e wate r passage , the n

fill th e radiato r t o th e botto m o f th e fille r nec k wit h

the coolan t mixture . Tighte n th e blee d bol t a s soo n

a s coolan t start s t o ru n ou t i n a stead y strea m with -

ou t bubbles .

10 . Wit h th e radiato r ca p off , star t th e engin e an d le t i t

ru n unti l warme d u p (radiato r fa n come s o n a t leas t

twice) . Then , i f necessary , ad d mor e coolan t mi x t o

brin g th e leve l bac k u p to th e botto m o f th e fille r neck .

11 . Pu t th e radiato r cap on tightly , the n ru n th e engin e

agai n an d chec k fo r leaks .

12 . Ente r th e anti-thef t cod e fo r th e radio , the n ente r th e

customer' s radi o statio n presets .

BLEED BOL T9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

ProCarManuals.com

Page 145 of 1771

Radiator

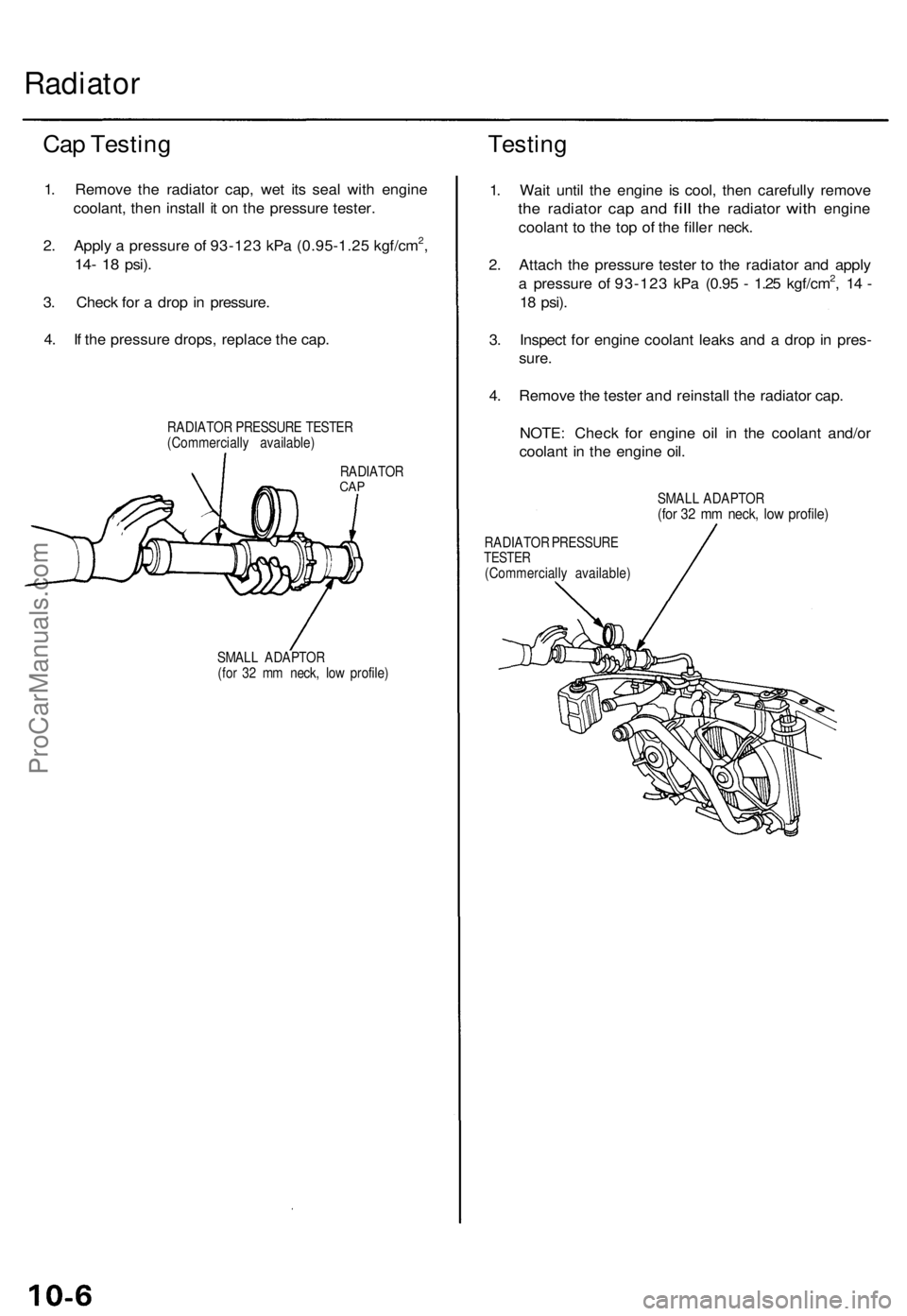

Cap Testing

1. Remove the radiator cap, wet its seal with engine

coolant, then install it on the pressure tester.

2. Apply a pressure of 93-123 kPa (0.95-1.25 kgf/cm2,

14- 18

psi).

3. Check for a drop in pressure.

4. If the pressure drops, replace the cap.

RADIATOR PRESSURE TESTER

(Commercially available)

Testing

RADIATOR

CAP

SMALL ADAPTOR

(for 32 mm neck, low profile)

1. Wait until the engine is cool, then carefully remove

the

radiator

cap and

fill

the

radiator

with

engine

coolant to the top of the filler neck.

2. Attach the pressure tester to the radiator and apply

a pressure of 93-123 kPa (0.95 - 1.25 kgf/cm2, 14 -

18

psi).

3. Inspect for engine coolant leaks and a drop in pres-

sure.

4. Remove the tester and reinstall the radiator cap.

NOTE: Check for engine oil in the coolant and/or

coolant in the engine oil.

SMALL ADAPTOR

(for 32 mm neck, low profile)

RADIATOR PRESSURE

TESTER

(Commercially available)ProCarManuals.com

Page 146 of 1771

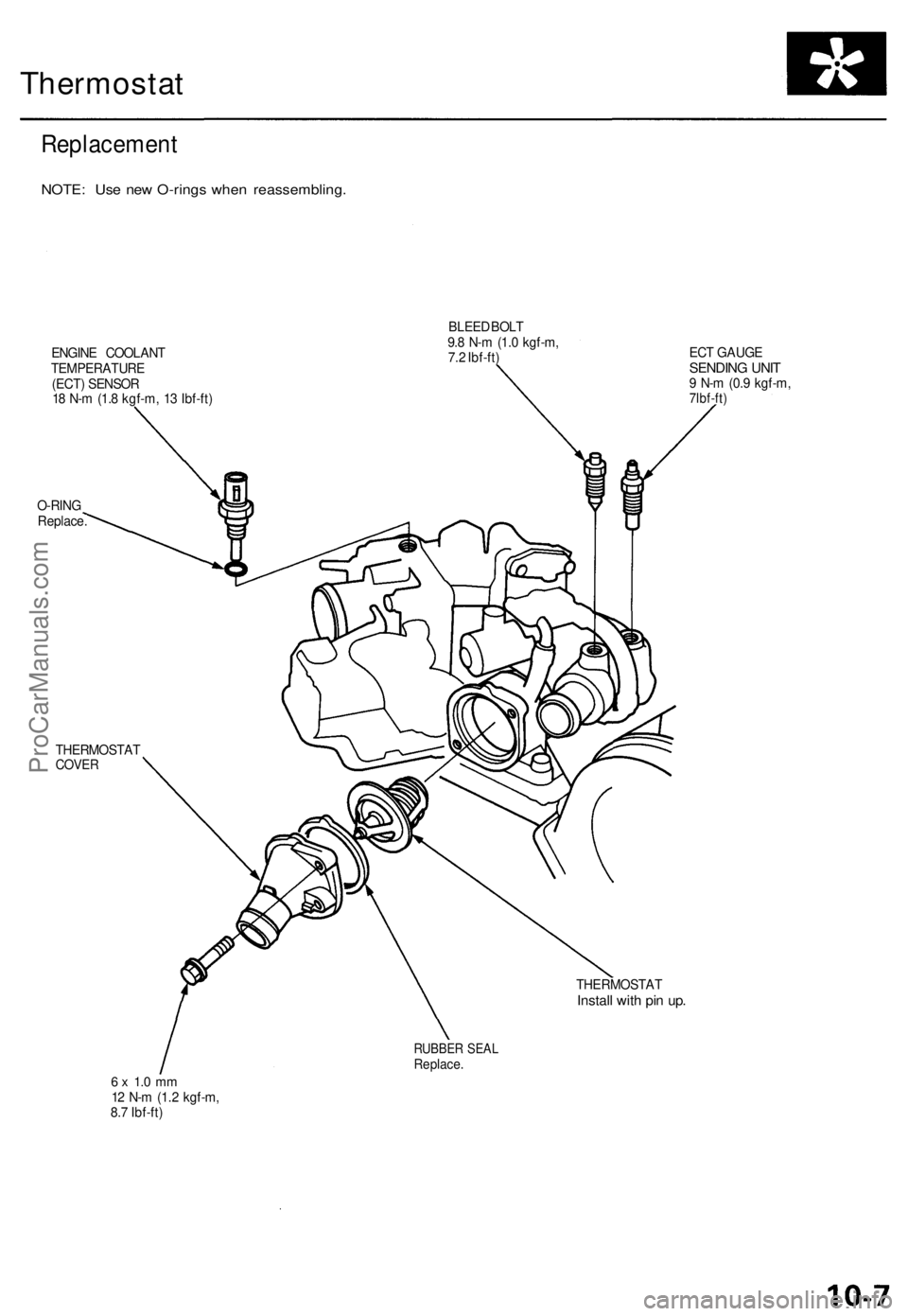

Thermostat

Replacement

NOTE: Use new O-rings when reassembling.

ENGINE COOLANT

TEMPERATURE

(ECT) SENSOR

18 N-m (1.8 kgf-m, 13 Ibf-ft)

BLEED BOLT

9.8 N-m (1.0 kgf-m,

7.2 Ibf-ft)

O-RING

Replace.

ECT GAUGE

SENDING UNIT

9 N-m (0.9 kgf-m,

7lbf-ft)

THERMOSTAT

COVER

THERMOSTAT

Install with pin up.

RUBBER SEAL

Replace.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)ProCarManuals.com

Page 147 of 1771

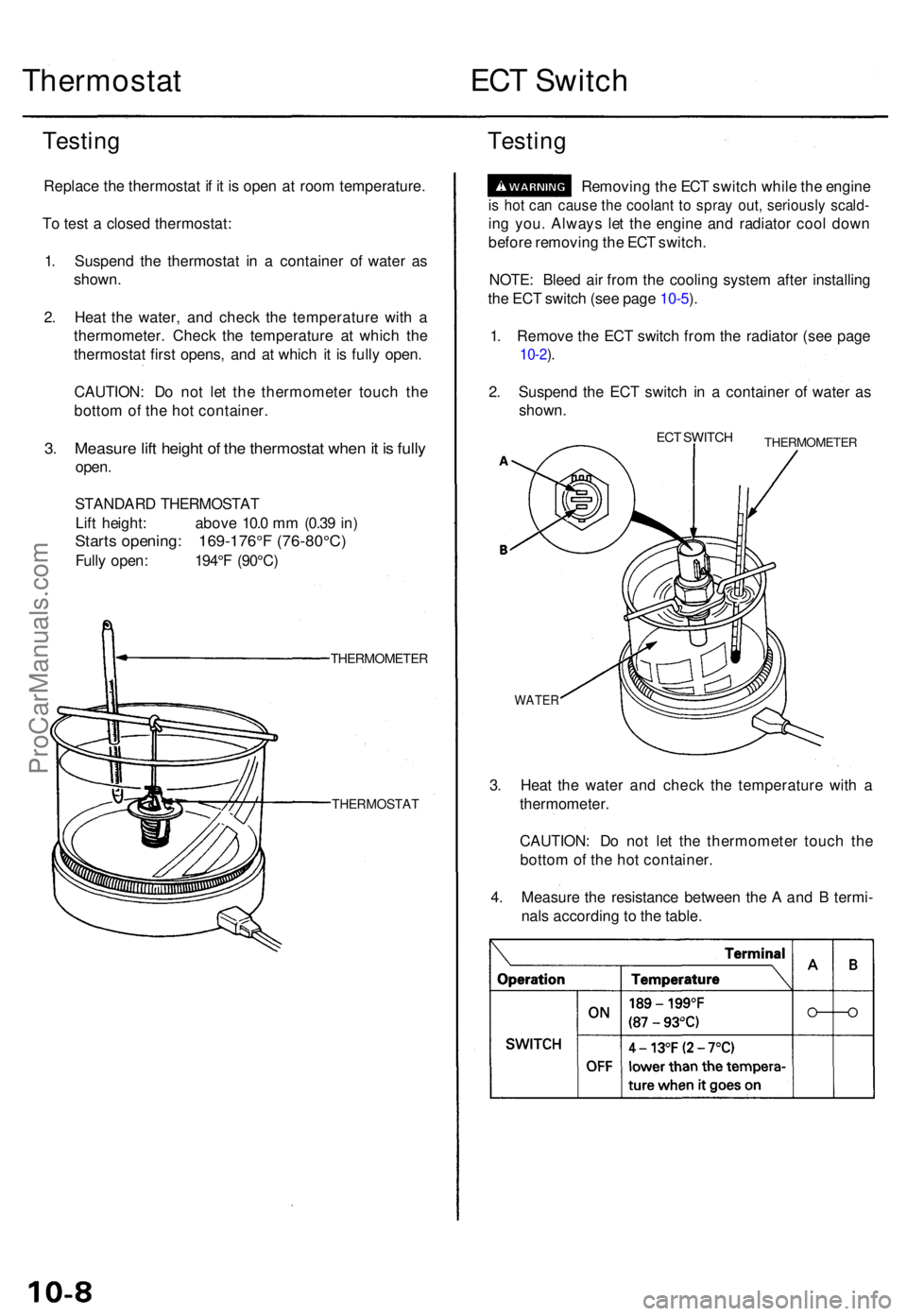

Thermostat ECT Switc h

Testin g

Replac e th e thermosta t i f i t i s ope n a t roo m temperature .

T o tes t a close d thermostat :

1 . Suspen d th e thermosta t i n a containe r o f wate r a s

shown .

2 . Hea t th e water , an d chec k th e temperatur e wit h a

thermometer . Chec k th e temperatur e a t whic h th e

thermosta t firs t opens , an d a t whic h i t i s full y open .

CAUTION : D o no t le t th e thermomete r touc h th e

botto m o f th e ho t container .

3. Measur e lif t heigh t o f th e thermosta t whe n it i s full y

open .

STANDAR D THERMOSTA T

Lif t height : abov e 10. 0 m m (0.3 9 in )

Start s opening : 169-176° F (76-80°C )

Fully open : 194° F (90°C )

THERMOMETE R

THERMOSTAT

Testing

Removin g th e EC T switc h whil e th e engin e

is ho t ca n caus e th e coolan t t o spra y out , seriousl y scald -

ing you . Alway s le t th e engin e an d radiato r coo l dow n

befor e removin g th e EC T switch .

NOTE : Blee d ai r fro m th e coolin g syste m afte r installin g

th e EC T switc h (se e pag e 10-5 ).

1 . Remov e th e EC T switc h fro m th e radiato r (se e pag e

10-2).

2 . Suspen d th e EC T switc h i n a containe r o f wate r a s

shown .

ECT SWITC HTHERMOMETE R

WATER

3. Hea t th e wate r an d chec k th e temperatur e wit h a

thermometer .

CAUTION : D o no t le t th e thermomete r touc h th e

botto m of th e ho t container .

4 . Measur e th e resistanc e betwee n th e A an d B termi -

nal s accordin g t o th e table .

ProCarManuals.com

Page 148 of 1771

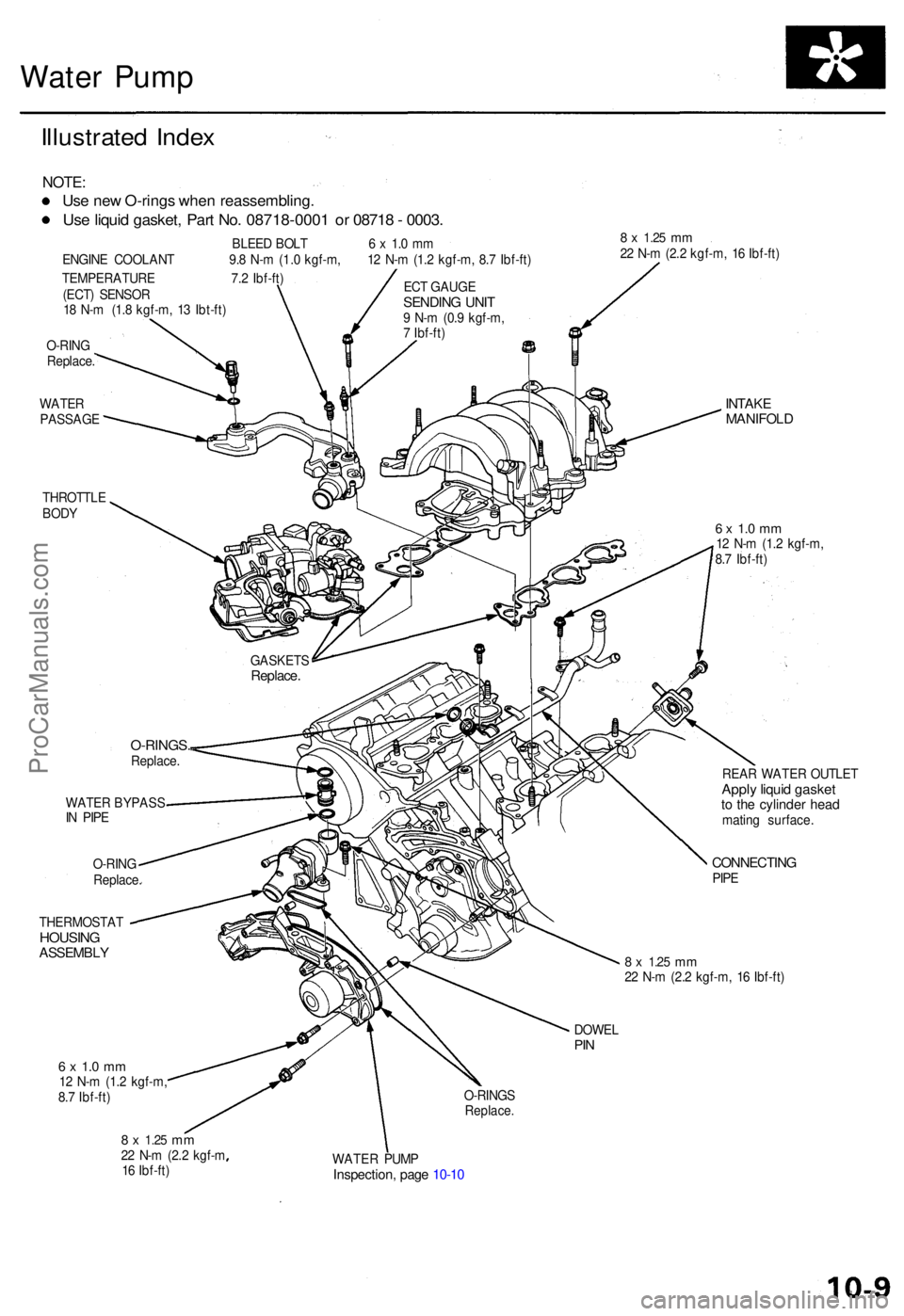

Water Pum p

Illustrate d Inde x

NOTE :

Use ne w O-ring s whe n reassembling .

Use liqui d gasket , Par t No . 08718-000 1 o r 0871 8 - 0003 .

BLEE D BOL T 6 x 1. 0 m m

ENGIN E COOLAN T 9. 8 N- m (1. 0 kgf-m , 1 2 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

TEMPERATUR E 7. 2 Ibf-ft )

(ECT ) SENSO R

1 8 N- m (1. 8 kgf-m , 1 3 Ibt-ft )

O-RIN G

Replace .

WATE R

PASSAG E

THROTTL E

BOD Y8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

WATE R BYPAS S

I N PIP E

O-RIN G

Replace .

THERMOSTA T

HOUSINGASSEMBL Y

INTAKEMANIFOL D

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

REA R WATE R OUTLE T

Apply liqui d gaske tto th e cylinde r hea dmatin g surface .

CONNECTIN GPIPE

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

DOWE L

PIN

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft ) O-RING

S

Replace .

8 x 1.2 5 mm22 N- m (2. 2 kgf- m

1 6 Ibf-ft ) WATE

R PUM P

Inspection , pag e 10-1 0

GASKET SReplace.

O-RINGS .Replace. EC

T GAUG E

SENDIN G UNI T9 N- m (0. 9 kgf-m ,

7 Ibf-ft )

ProCarManuals.com

Page 149 of 1771

Water Pum p

Inspectio n

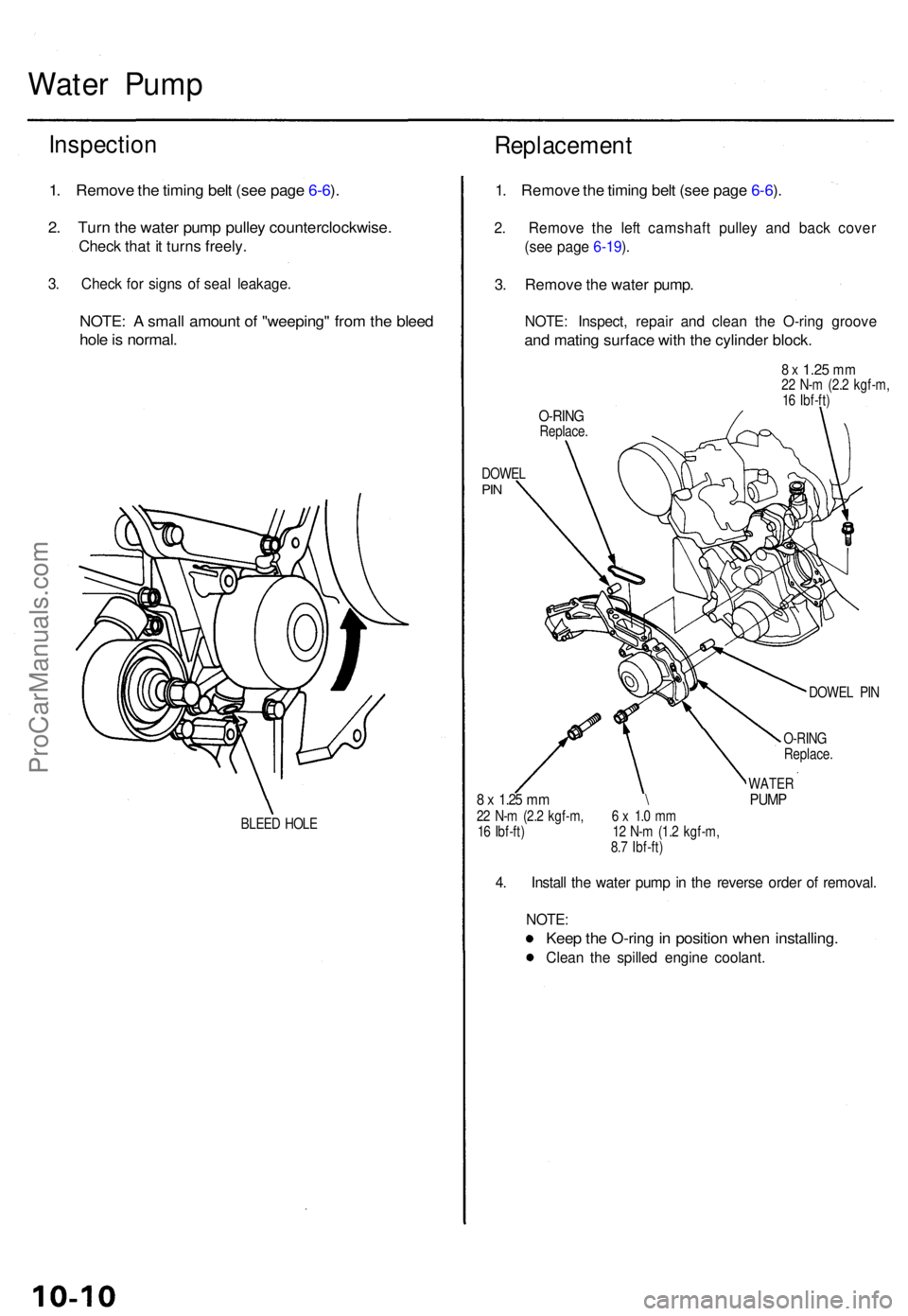

1. Remov e th e timin g bel t (se e pag e 6-6 ).

2 . Tur n th e wate r pum p pulle y counterclockwise .

Check tha t i t turn s freely .

3. Chec k fo r sign s o f sea l leakage .

NOTE: A smal l amoun t o f "weeping " fro m th e blee d

hole is normal .

BLEED HOL E

Replacemen t

1. Remov e th e timin g bel t (se e pag e 6-6 ).

2 . Remov e th e lef t camshaf t pulle y an d bac k cove r

(se e pag e 6-19 ).

3 . Remov e th e wate r pump .

NOTE: Inspect , repai r an d clea n th e O-rin g groov e

and matin g surfac e wit h th e cylinde r block .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

O-RIN GReplace .

DOWE L

PIN

DOWE L PI N

O-RIN G

Replace .

WATER8 x 1.2 5 m m \ PUM P22 N- m (2. 2 kgf-m , 6 x 1. 0 m m

1 6 Ibf-ft ) 1 2 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

4. Instal l th e wate r pum p in th e revers e orde r o f removal .

NOTE :

Keep th e O-rin g in positio n whe n installing .

Clean th e spille d engin e coolant .

ProCarManuals.com

Page 150 of 1771

Special Tool s

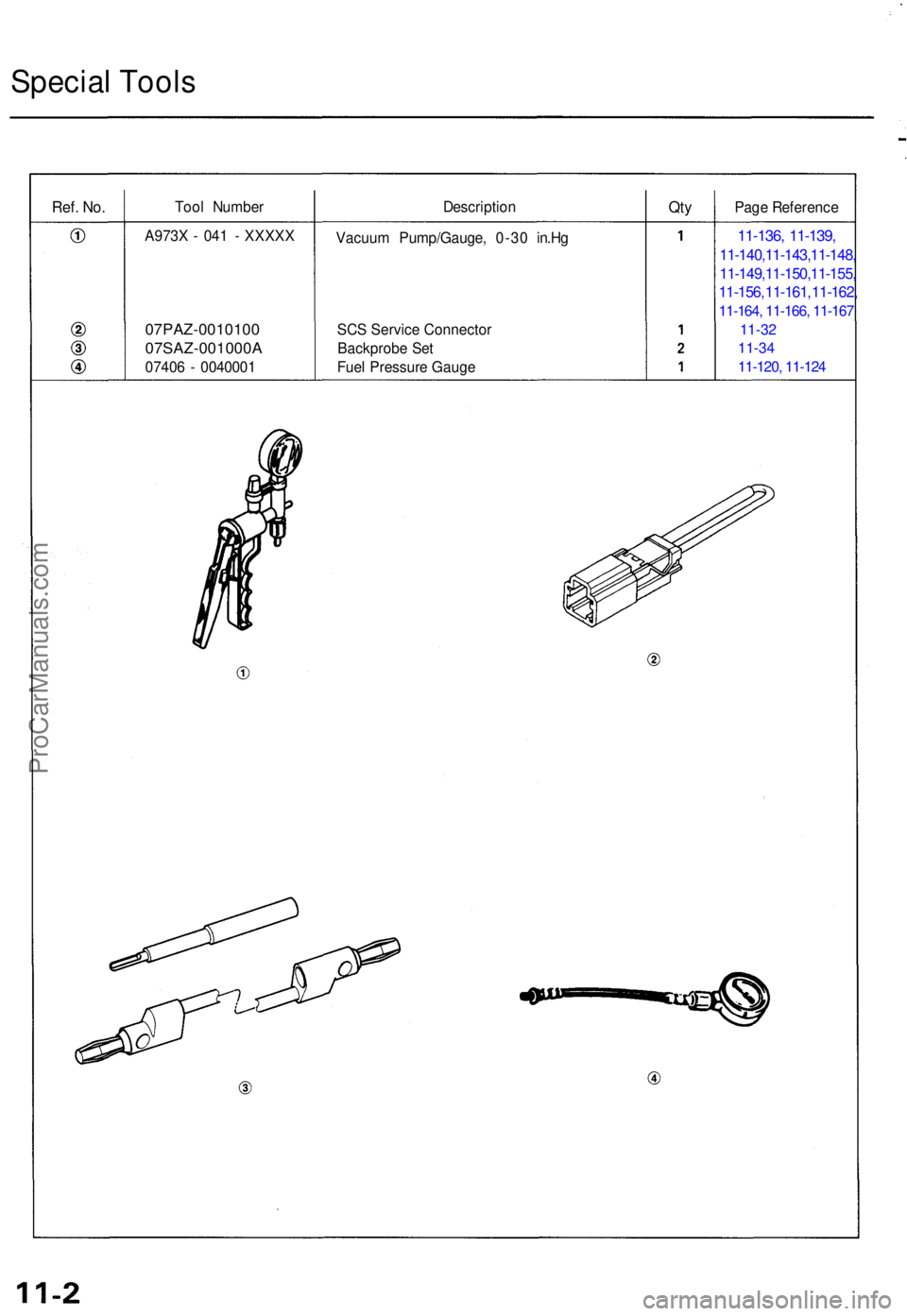

Ref. No.Too l Numbe r DescriptionQtyPag e Referenc e

A973 X - 04 1 - XXXX X

07PAZ-001010 0

07SAZ-001000 A

07406 - 004000 1 Vacuu

m Pump/Gauge , 0-3 0 in.H g

SC S Servic e Connecto r

Backprob e Se t

Fue l Pressur e Gaug e

11-136 , 11-139 ,

11-140,11-143,11-148,

11-149,11-150,11-155,

11-156, 11-161, 11-162,

11-164, 11-166, 11-167

11-32

11-34

11-120, 11-124

ProCarManuals.com