Test ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1562 of 1771

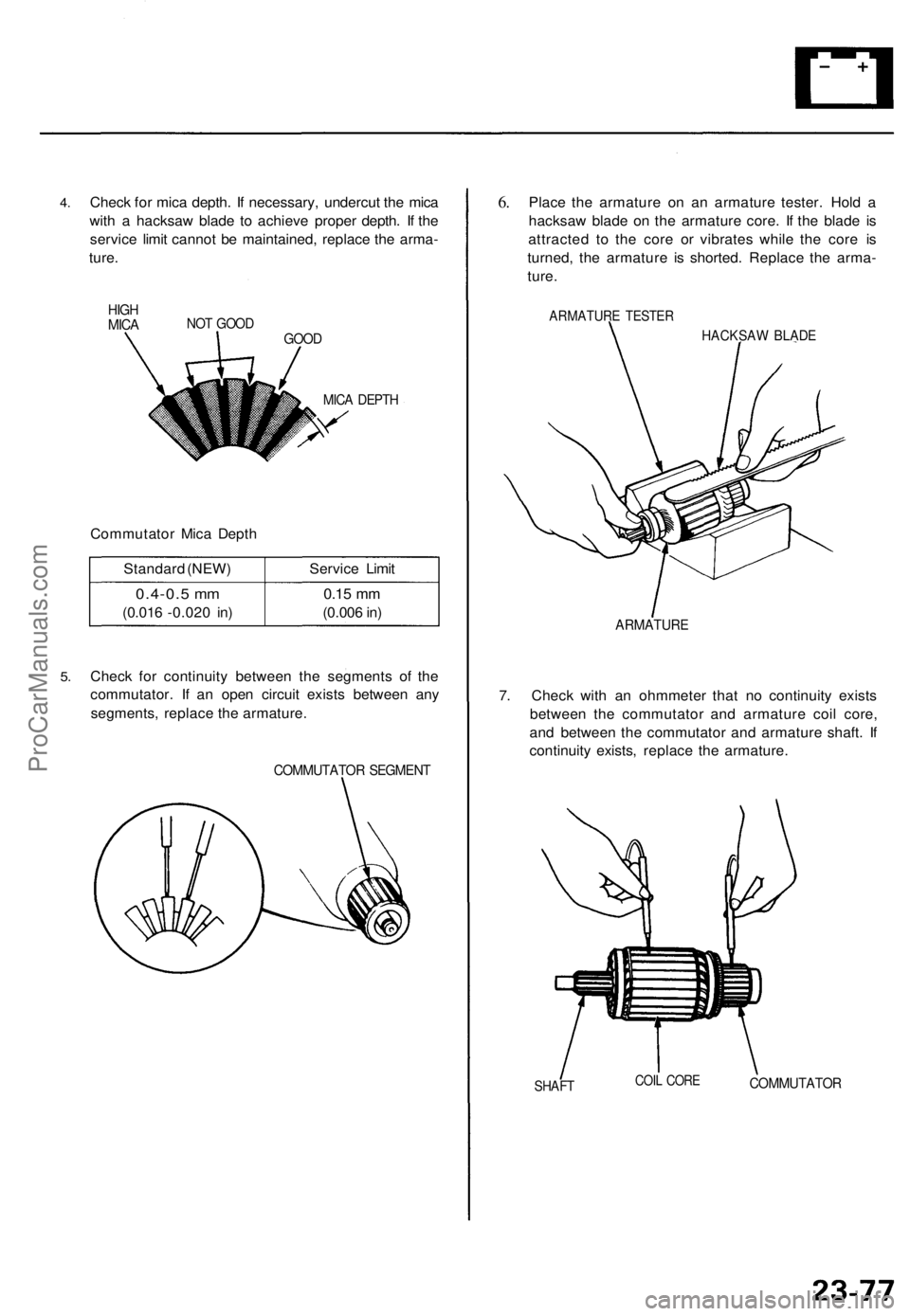

4.

Check for mica depth. If necessary, undercut the mica

with a hacksaw blade to achieve proper depth. If the

service limit cannot be maintained, replace the arma-

ture.

HIGH

MICA

NOT GOOD

GOOD

MICA DEPTH

Commutator Mica Depth

Standard (NEW)

0.4-0.5 mm

(0.016 -0.020 in)

Service Limit

0.15

mm

(0.006 in)

5.

Check for continuity between the segments of the

commutator. If an open circuit exists between any

segments, replace the armature.

COMMUTATOR SEGMENT

6.

Place the armature on an armature tester. Hold a

hacksaw blade on the armature core. If the blade is

attracted to the core or vibrates while the core is

turned, the armature is shorted. Replace the arma-

ture.

ARMATURE TESTER

HACKSAW BLADE

ARMATURE

7. Check with an ohmmeter that no continuity exists

between the commutator and armature coil core,

and between the commutator and armature shaft. If

continuity exists, replace the armature.

SHAFT

COIL CORE

COMMUTATORProCarManuals.com

Page 1565 of 1771

Starting System

Performance Test

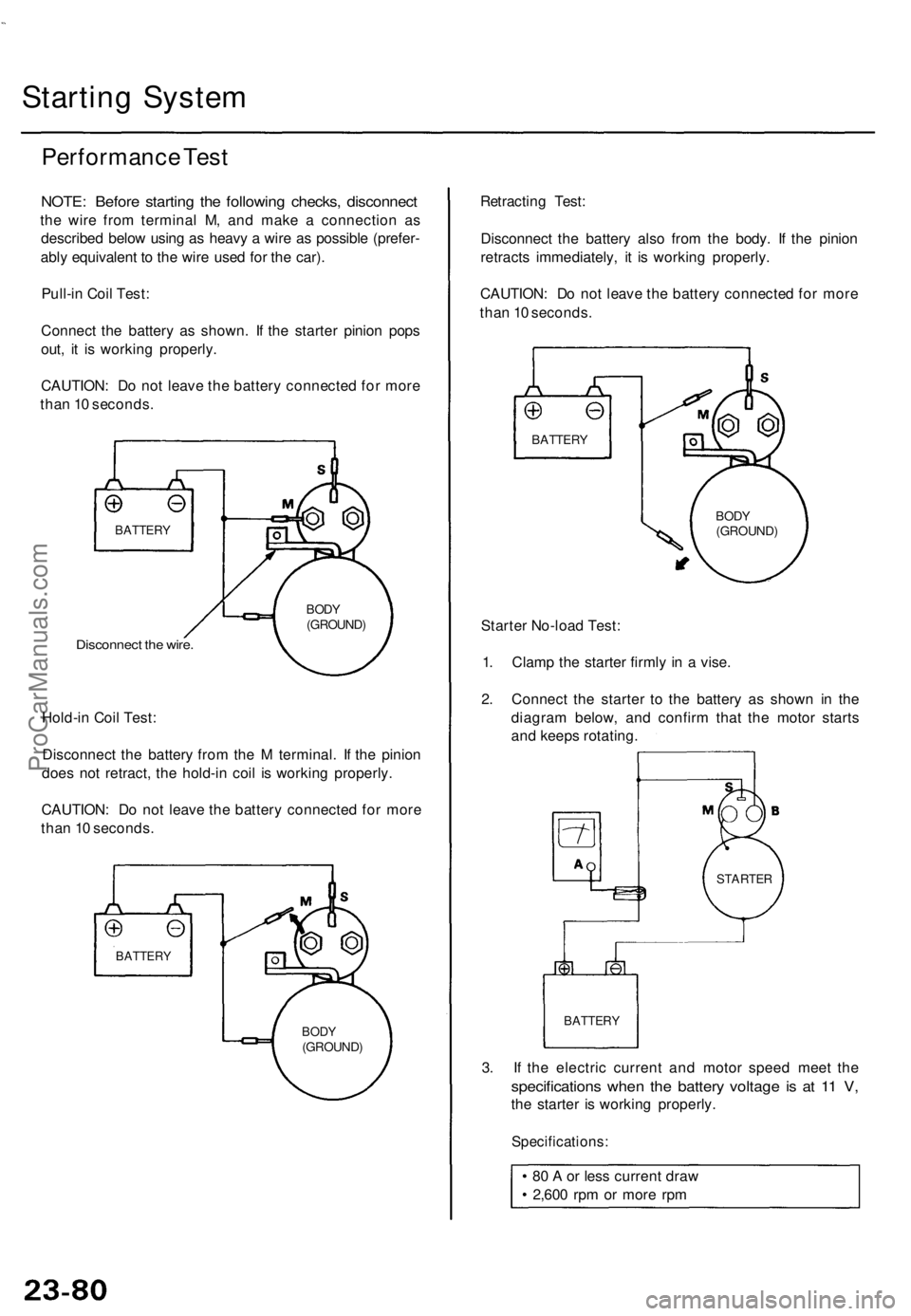

NOTE: Before starting the following checks, disconnect

the wire from terminal M, and make a connection as

described below using as heavy a wire as possible (prefer-

ably equivalent to the wire used for the car).

Pull-in Coil Test:

Connect the battery as shown. If the starter pinion pops

out, it is working properly.

CAUTION: Do not leave the battery connected for more

than 10 seconds.

Disconnect the wire.

Hold-in Coil Test:

Disconnect the battery from the M terminal. If the pinion

does not retract, the hold-in coil is working properly.

CAUTION: Do not leave the battery connected for more

than 10 seconds.

Retracting Test:

Disconnect the battery also from the body. If the pinion

retracts immediately, it is working properly.

CAUTION: Do not leave the battery connected for more

than 10 seconds.

Starter No-load Test:

1. Clamp the starter firmly in a vise.

2. Connect the starter to the battery as shown in the

diagram below, and confirm that the motor starts

and keeps rotating.

3. If the electric current and motor speed meet the

specifications when the battery voltage is at 11 V,

the starter is working properly.

Specifications:

80 A or less current draw

2,600 rpm or more rpm

BATTERY

BODY

(GROUND)

BATTERY

STARTER

BODY

(GROUND)

BATTERY

BODY

(GROUND)

BATTERYProCarManuals.com

Page 1566 of 1771

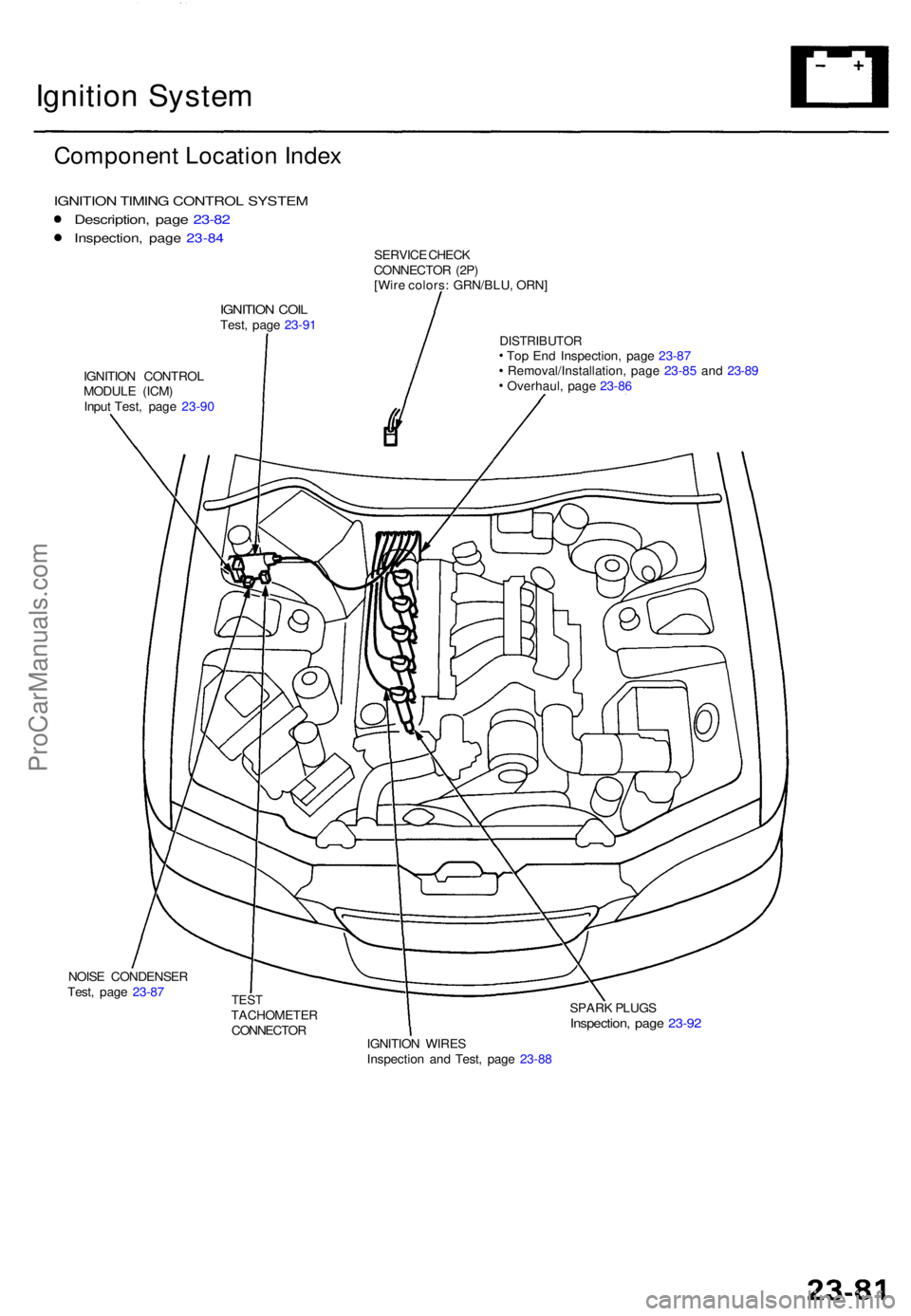

Ignition Syste m

Componen t Locatio n Inde x

IGNITIO N TIMIN G CONTRO L SYSTE M

Description , pag e 23-8 2

Inspection , pag e 23-8 4

IGNITIO N COI LTest , pag e 23-9 1 SERVIC

E CHEC K

CONNECTO R (2P )

[Wir e colors : GRN/BLU , ORN ]

IGNITIO N CONTRO L

MODUL E (ICM )

Inpu t Test , pag e 23-9 0DISTRIBUTO RTop En d Inspection , pag e 23-8 7

Removal/Installation , pag e 23-8 5 an d 23-8 9

Overhaul , pag e 23-8 6

NOIS E CONDENSE R

Test , pag e 23-8 7

TESTTACHOMETE R

CONNECTO R SPAR

K PLUG SInspection , pag e 23-9 2

IGNITIO N WIRE S

Inspectio n an d Test , pag e 23-8 8

ProCarManuals.com

Page 1571 of 1771

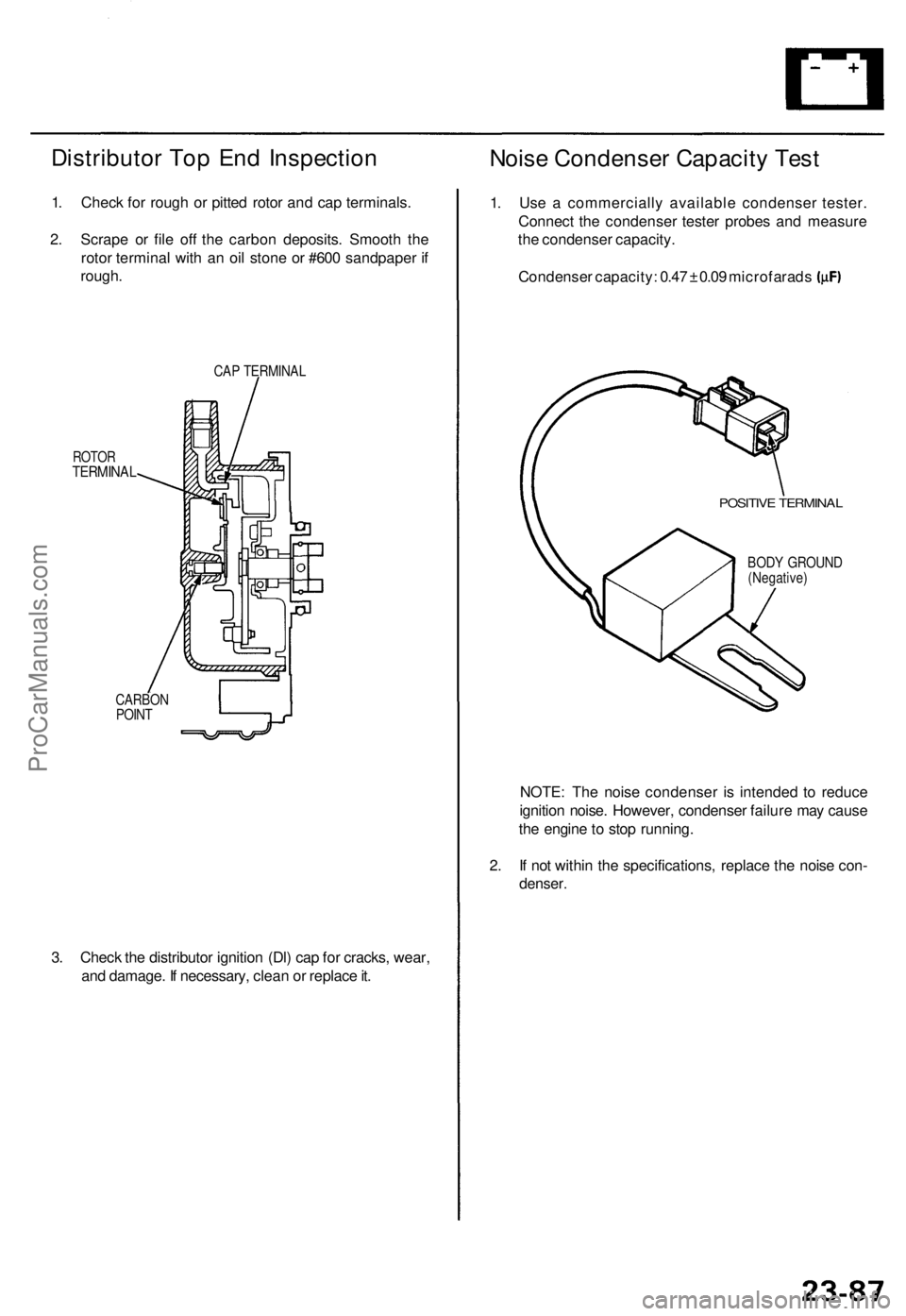

Distributor Top End Inspection

1. Check for rough or pitted rotor and cap terminals.

2. Scrape or file off the carbon deposits. Smooth the

rotor terminal with an oil stone or #600 sandpaper if

rough.

ROTOR

TERMINAL

CAP TERMINAL

CARBON

POINT

3. Check the distributor ignition (Dl) cap for cracks, wear,

and damage. If necessary, clean or replace it.

Noise Condenser Capacity Test

1. Use a commercially available condenser tester.

Connect the condenser tester probes and measure

the condenser capacity.

Condenser capacity: 0.47 ± 0.09 microfarads

POSITIVE TERMINAL

BODY GROUND

(Negative)

NOTE: The noise condenser is intended to reduce

ignition noise. However, condenser failure may cause

the engine to stop running.

2. If not within the specifications, replace the noise con-

denser.ProCarManuals.com

Page 1572 of 1771

Ignition System

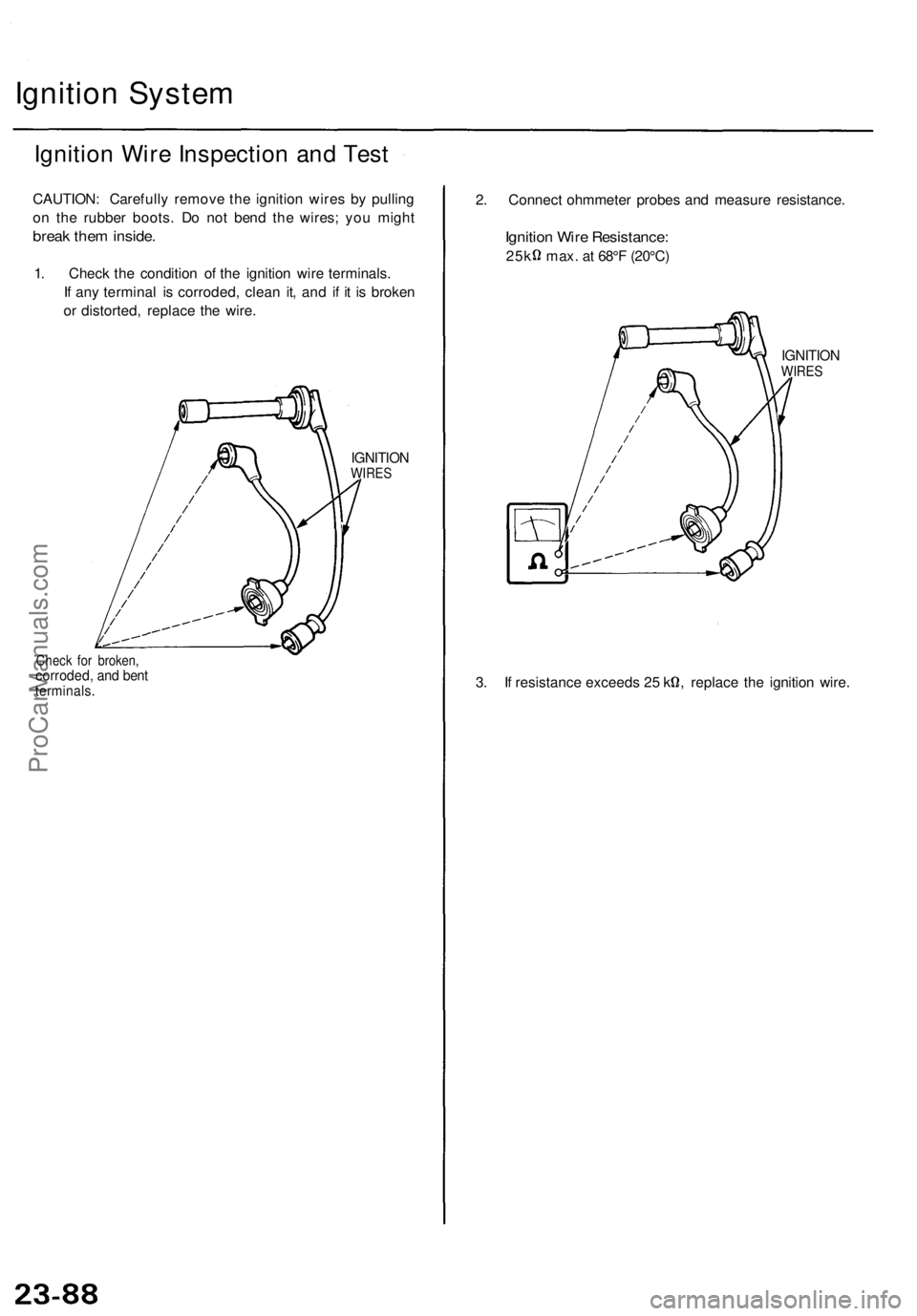

Ignition Wire Inspection and Test

CAUTION: Carefully remove the ignition wires by pulling

on the rubber boots. Do not bend the wires; you might

break them inside.

1. Check the condition of the ignition wire terminals.

If any terminal is corroded, clean it, and if it is broken

or distorted, replace the wire.

Check for broken,

corroded, and bent

terminals.

IGNITION

WIRES

2. Connect ohmmeter probes and measure resistance.

Ignition Wire Resistance:

25k max. at 68°F (20°C)

IGNITION

WIRES

3. If resistance exceeds 25 k , replace the ignition wire.ProCarManuals.com

Page 1574 of 1771

Ignition Syste m

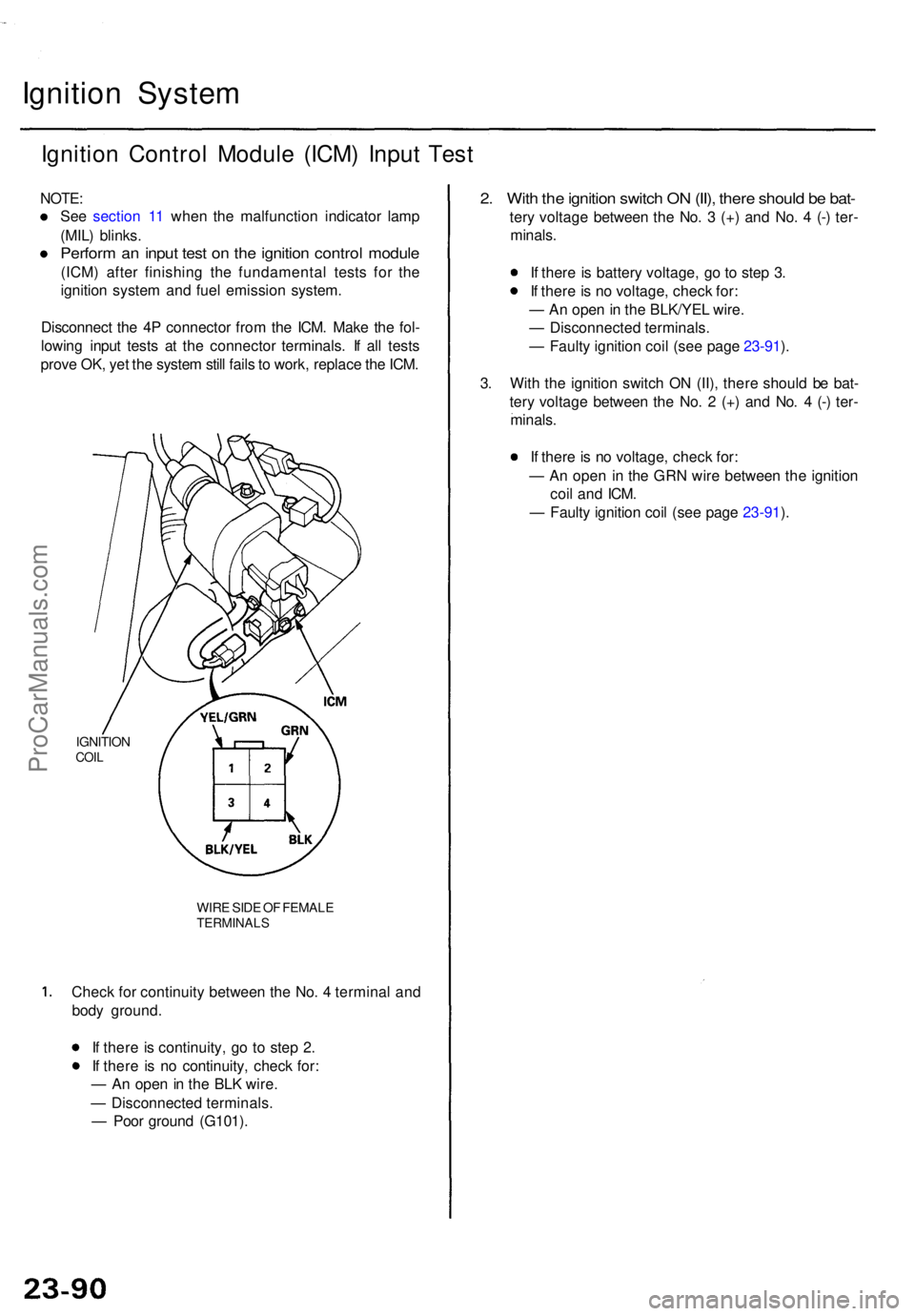

Ignition Contro l Modul e (ICM ) Inpu t Tes t

NOTE :

Se e sectio n 1 1 whe n th e malfunctio n indicator lamp

(MIL ) blinks .

Perform a n inpu t tes t o n th e ignitio n contro l modul e

(ICM) afte r finishin g th e fundamenta l test s fo r th e

ignitio n syste m an d fue l emissio n system .

Disconnec t th e 4 P connecto r fro m th e ICM . Mak e th e fol -

lowin g inpu t test s a t th e connecto r terminals . I f al l test s

prov e OK , ye t th e syste m stil l fail s to work , replac e th e ICM .

IGNITIO NCOIL

WIR E SID E O F FEMAL ETERMINAL S

Check fo r continuit y betwee n th e No . 4 termina l an d

bod y ground .

I f ther e is continuity , g o t o ste p 2 .

I f ther e i s n o continuity , chec k for :

— A n ope n in th e BL K wire .

— Disconnecte d terminals .

— Poo r groun d (G101) .

2. Wit h th e ignitio n switc h O N (II) , ther e shoul d b e bat -

tery voltag e betwee n th e No . 3 (+ ) an d No . 4 (- ) ter -

minals .

I f ther e is batter y voltage , g o t o ste p 3 .

I f ther e is n o voltage , chec k for :

— A n ope n in th e BLK/YE L wire .

— Disconnecte d terminals .

— Fault y ignitio n coi l (se e pag e 23-91 ).

3 . Wit h th e ignitio n switc h O N (II) , ther e shoul d b e bat -

ter y voltag e betwee n th e No . 2 (+ ) an d No . 4 (-) ter -

minals .

I f ther e is n o voltage , chec k for :

— A n ope n i n th e GR N wir e betwee n th e ignitio n

coi l an d ICM .

— Fault y ignitio n coi l (se e pag e 23-91 ).

ProCarManuals.com

Page 1575 of 1771

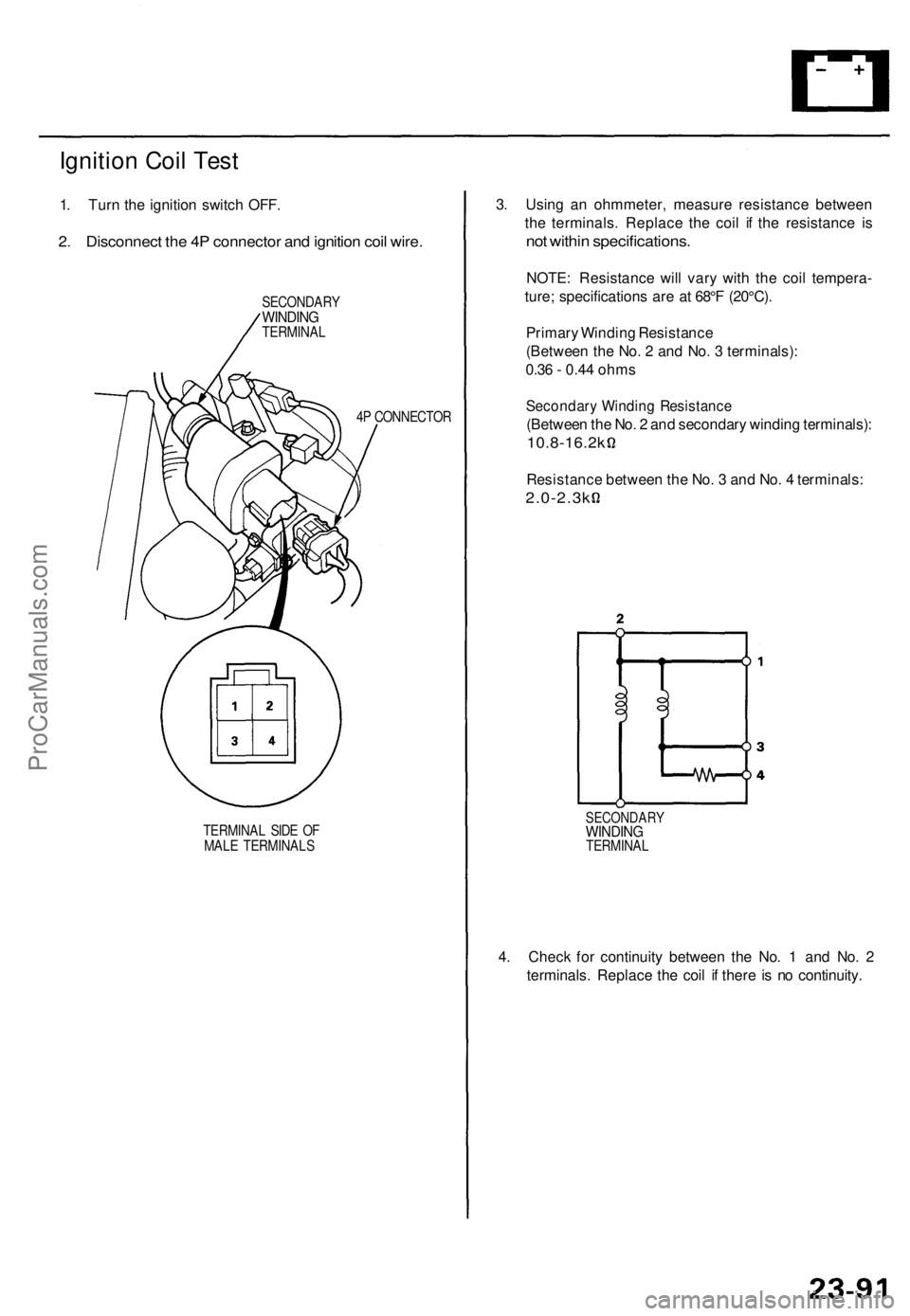

Ignition Coil Test

1. Turn the ignition switch OFF.

2. Disconnect the 4P connector and ignition coil wire.

SECONDARY

WINDING

TERMINAL

4P CONNECTOR

TERMINAL SIDE OF

MALE TERMINALS

3. Using an ohmmeter, measure resistance between

the terminals. Replace the coil if the resistance is

not within specifications.

NOTE: Resistance will vary with the coil tempera-

ture; specifications are at 68°F (20°C).

Primary Winding Resistance

(Between the No. 2 and No. 3 terminals):

0.36 - 0.44 ohms

Secondary Winding Resistance

(Between the No. 2 and secondary winding terminals):

10.8-16.2k

Resistance between the No. 3 and No. 4 terminals:

2.0-2.3k

SECONDARY

WINDING

TERMINAL

4. Check for continuity between the No. 1 and No. 2

terminals. Replace the coil if there is no continuity.ProCarManuals.com

Page 1577 of 1771

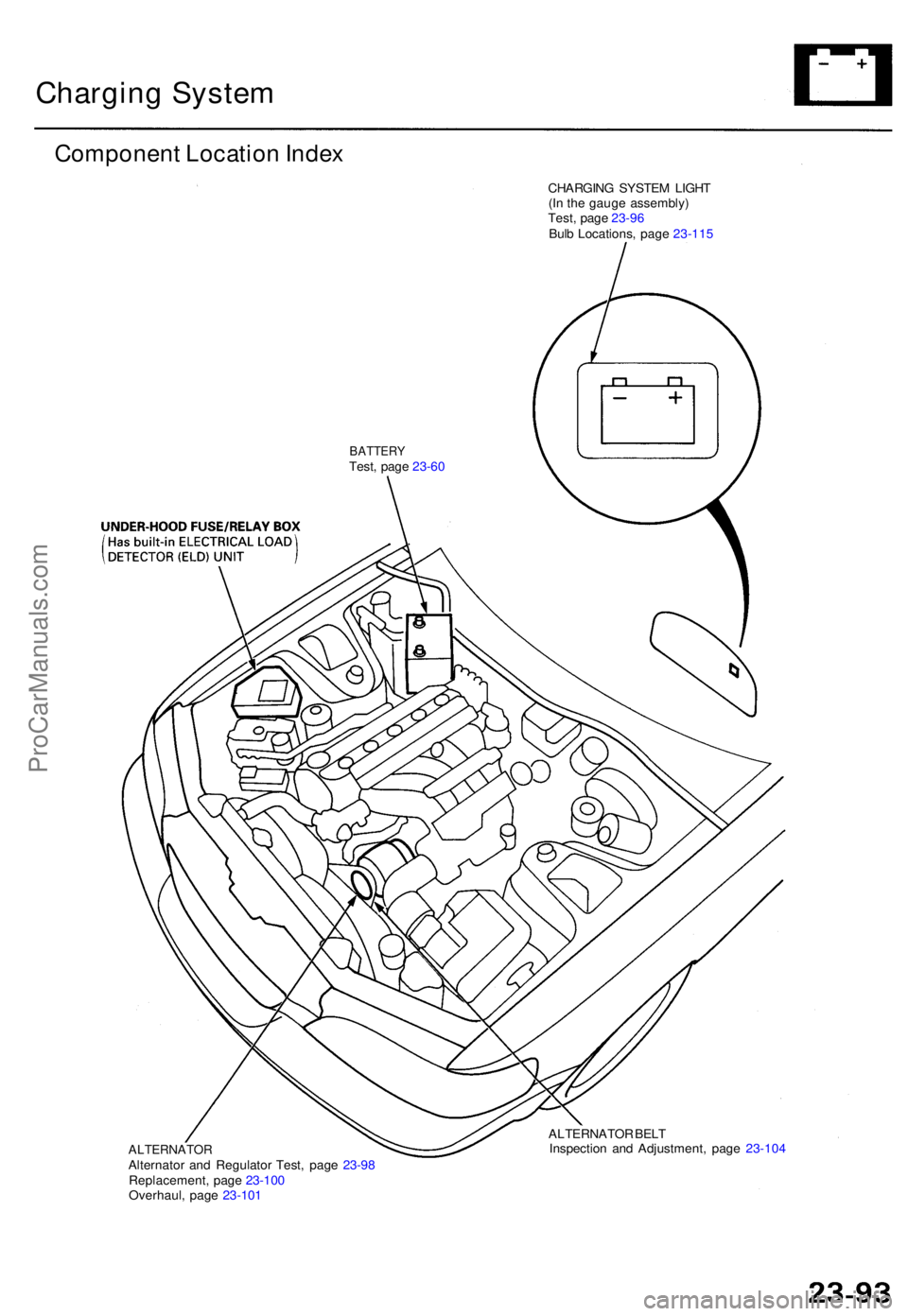

Charging Syste m

Componen t Locatio n Inde x

CHARGIN G SYSTE M LIGH T

(I n th e gaug e assembly )

Test , pag e 23-9 6

Bul b Locations , pag e 23-11 5

BATTER YTest, pag e 23-6 0

ALTERNATO RAlternator an d Regulato r Test , pag e 23-9 8

Replacement , pag e 23-10 0

Overhaul , pag e 23-10 1 ALTERNATO

R BEL T

Inspectio n an d Adjustment , pag e 23-10 4

ProCarManuals.com

Page 1581 of 1771

Charging Syste m

Troubleshootin g (cont'd )

NOTE: B e sur e th e batter y is sufficientl y charge d (se e pag e 23-60 ).

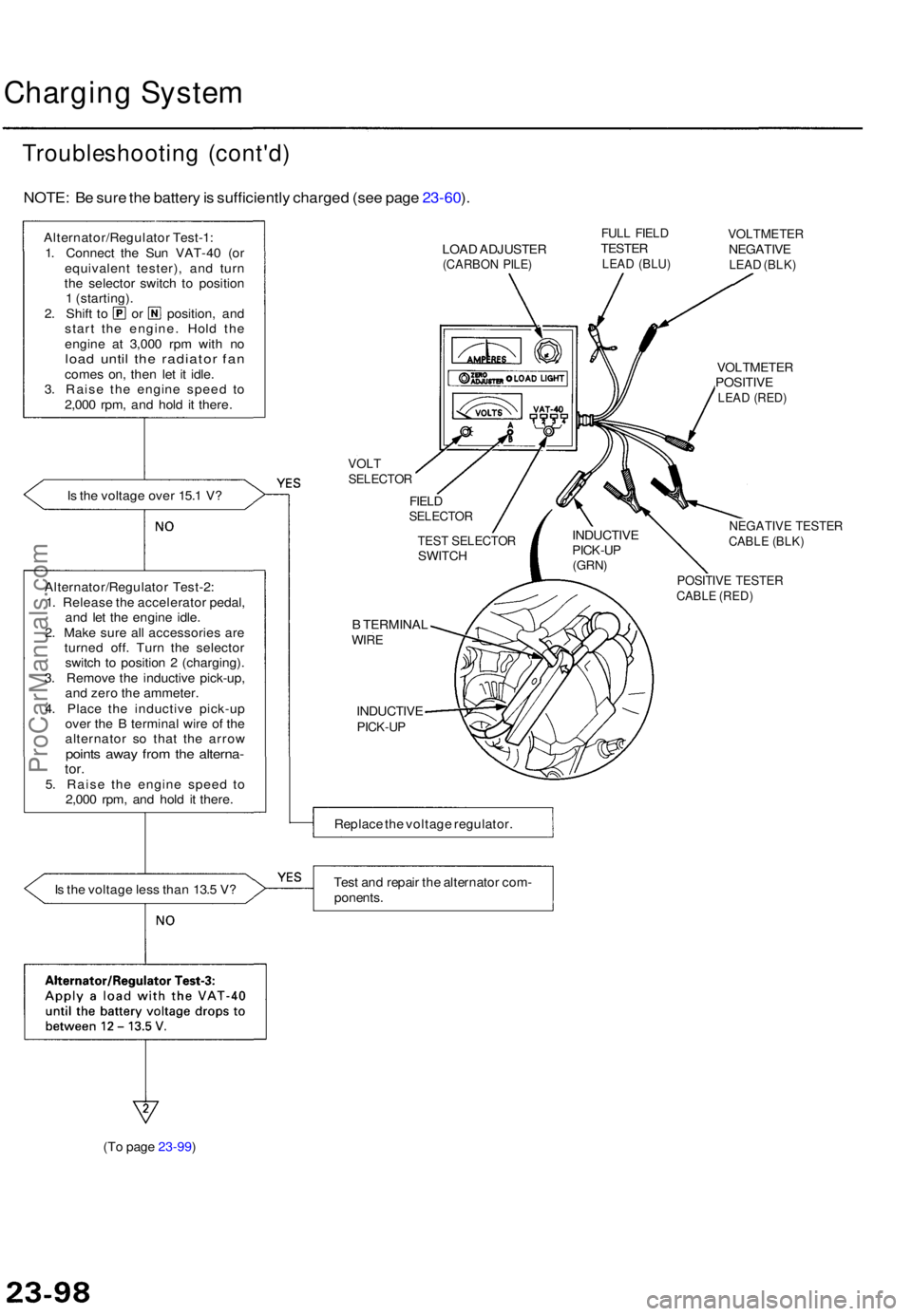

Alternator/Regulato r Test-1 :

1 . Connec t th e Su n VAT-4 0 (o r

equivalen t tester) , an d tur n

th e selecto r switc h t o positio n

1 (starting) .

2. Shif t t o o r position , an d

star t th e engine . Hol d th e

engin e a t 3,00 0 rp m wit h n o

loa d unti l th e radiato r fa ncome s on , the n le t i t idle .

3 . Rais e th e engin e spee d t o

2,00 0 rpm , an d hol d i t there .

I s th e voltag e ove r 15. 1 V ?

I s th e voltag e les s tha n 13. 5 V ? LOA

D ADJUSTE R

(CARBON PILE )

FULL FIEL DTESTE RLEAD (BLU )

VOLTMETE RNEGATIVELEAD (BLK )

VOLTSELECTO R

FIELDSELECTO R

B TERMINA LWIRE

INDUCTIV EPICK-UP

VOLTMETE RPOSITIVELEAD (RED )

NEGATIV E TESTE RCABLE (BLK )

POSITIV E TESTE RCABLE (RED )

Replac e th e voltag e regulator .

Tes t an d repai r th e alternato r com -

ponents .

(T o page 23-99) INDUCTIV

E

PICK-UP(GRN)

TEST SELECTO RSWITCH

Alternator/Regulato r Test-2 :

1 . Releas e th e accelerato r pedal ,

an d le t th e engin e idle .

2 . Mak e sur e al l accessorie s ar e

turne d off . Tur n th e selecto r

switc h t o positio n 2 (charging) .

3 . Remov e th e inductiv e pick-up ,

an d zer o th e ammeter .

4 . Plac e th e inductiv e pick-u p

ove r th e B termina l wire of th e

alternato r s o tha t th e arro w

points awa y fro m th e alterna -tor.5. Rais e th e engin e spee d t o

2,00 0 rpm , an d hol d i t there .

ProCarManuals.com

Page 1582 of 1771

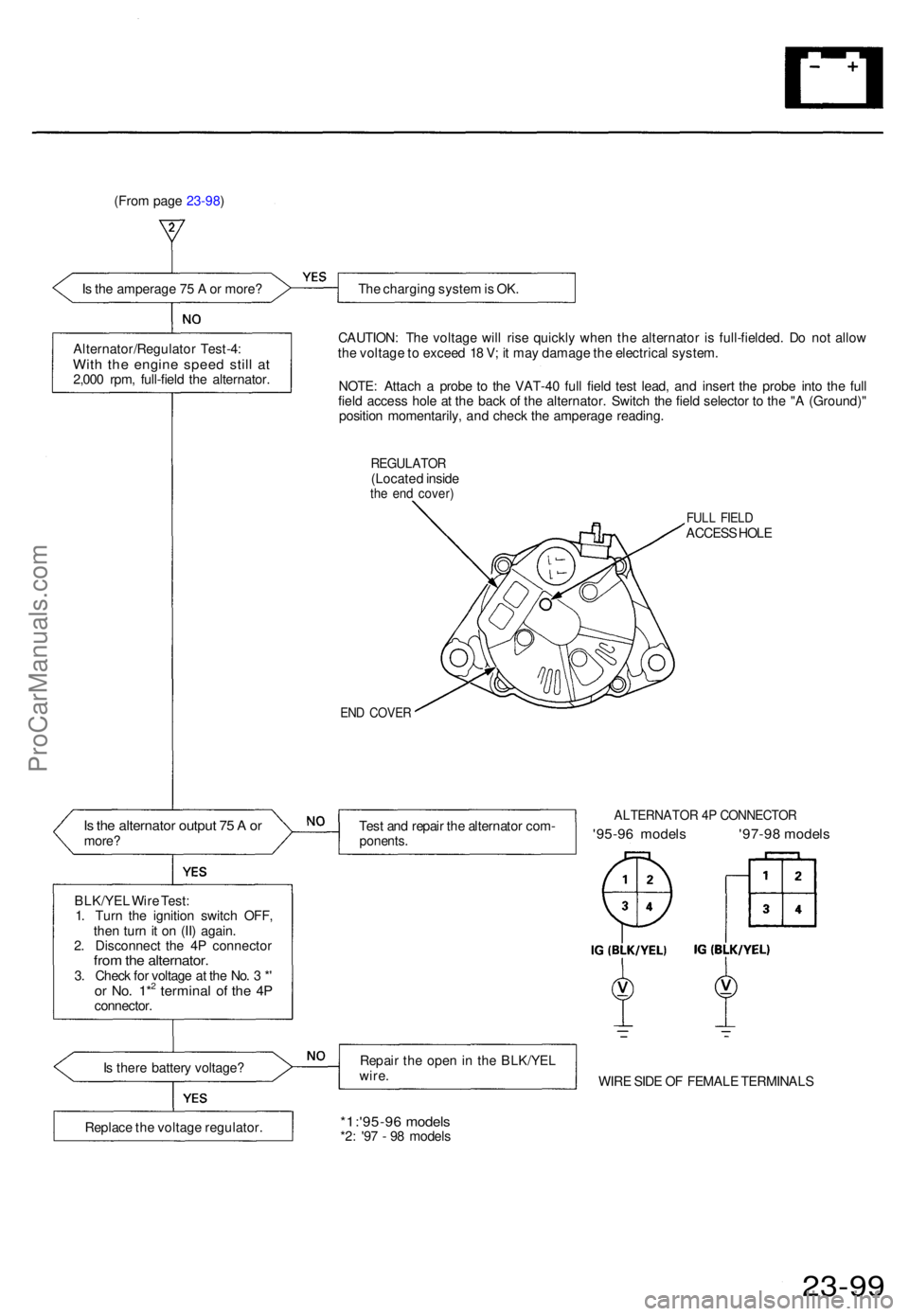

(From page 23-98)

I s th e amperag e 7 5 A or more ? The chargin g syste m is OK .

Alternator/Regulato r Test-4 :

With th e engin e spee d stil l a t2,00 0 rpm , full-fiel d th e alternator . CAUTION

: Th e voltag e wil l ris e quickl y whe n th e alternato r i s full-fielded . D o no t allo w

th e voltag e to excee d 1 8 V ; i t ma y damag e th e electrica l system .

NOTE : Attac h a prob e t o th e VAT-4 0 ful l fiel d tes t lead , an d inser t th e prob e int o th e ful l

fiel d acces s hol e a t th e bac k o f th e alternator . Switc h th e fiel d selecto r t o th e " A (Ground) "

positio n momentarily , an d chec k th e amperag e reading .

END COVE R

Is th e alternato r outpu t 7 5 A ormore ? Tes

t an d repai r th e alternato r com -ponents .

ALTERNATO R 4 P CONNECTO R

'95-96 model s '97-9 8 model s

BLK/YE L Wir e Test :

1 . Tur n th e ignitio n switc h OFF ,

the n tur n i t o n (II ) again .

2 . Disconnec t th e 4 P connecto r

from th e alternator .3. Chec k fo r voltag e a t th e No . 3 *'or No . 1*2 termina l o f th e 4 Pconnector .

I s ther e batter y voltage ? Repai

r th e ope n in th e BLK/YE L

wire .

*1:'95-9 6 model s*2: '9 7 - 9 8 model s

23-99

FULL FIEL DACCES S HOL E

REGULATO R(Located insid ethe en d cover )

WIRE SID E O F FEMAL E TERMINAL S

Replac e th e voltag e regulator .

ProCarManuals.com