Test ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1538 of 1771

Five-step Troubleshooting

1. Verify The Complaint

Turn on all the components in the problem circuit to

verify the customer complaint. Note the symptoms.

Do not begin disassembly or testing until you have

narrowed down the problem area.

2. Analyze The Schematic

Look up the schematic for the problem circuit.

Determine how the circuit is supposed to work by

tracing the current paths from the power feed

through the circuit components to ground. If several

circuits fail at the same time, the fuse or ground is a

likely cause.

Based on the symptoms and your understanding of

the circuit operation, identify one or more possible

causes of the problem.

3. Isolate The Problem By Testing The Circuit

Make circuit tests to check the diagnosis you made

in step 2. Keep in mind that a logical, simple proce-

dure is the key to efficient troubleshooting. Test for

the most likely cause of failure first. Try to make

tests at points that are easily accessible.

4. Fix The Problem

Once the specific problem is identified, make the

repair. Be sure to use proper tools and safe proce-

dures.

5. Make Sure The Circuit Works

Turn on all components in the repaired circuit in all

modes to make sure you've fixed the entire prob-

lem. If the problem was a blown fuse, be sure to

test all of the circuits on the fuse. Make sure no new

problems turn up and the original problem does not

recur.

Wire Color Codes

The following abbreviations are used to identify wire

colors in the circuit schematics:

WHT .............................White

YEL ............................... Yellow

BLK .............................. Black

BLU

..............................

Blue

GRN ............................. Green

RED

..............................

Red

ORN ............................. Orange

PNK.............................. Pink

BRN .............................. Brown

GRY.............................. Gray

PUR .............................. Purple

LT BLU ......................... Light Blue

LT GRN ........................ Light Green

The wire insulation has one color or one color with

another color stripe. The second color is the stripe.

WHT/BLK

NOTE: Different wires with the same color in the same

system have been given number suffixes to distinguish

them (for example, YEL1 and YEL2 are not the same).ProCarManuals.com

Page 1545 of 1771

Battery

Test

Battery fluid (electrolyte) contains sulfuric acid. It may cause severe burns if it gets on your skin or in your eyes. Wear

protective clothing and a face shield.

— If electrolyte gets on your skin or clothes, rinse it off with water immediately.

— If electrolyte gets in your eyes, flush it out by splashing water in your eyes for at least 15 minutes; call a physician

immediately.

A battery gives off hydrogen gas. If ignited, the hydrogen will explode and could crack the battery case and splatter

acid on you. Keep sparks, flames, and cigarettes away from the battery.

Overcharging will raise the temperature of the electrolyte. This may force electrolyte to spray out of the battery vents.

Follow the charger manufacturer's instructions, and charge the battery at a proper rate.

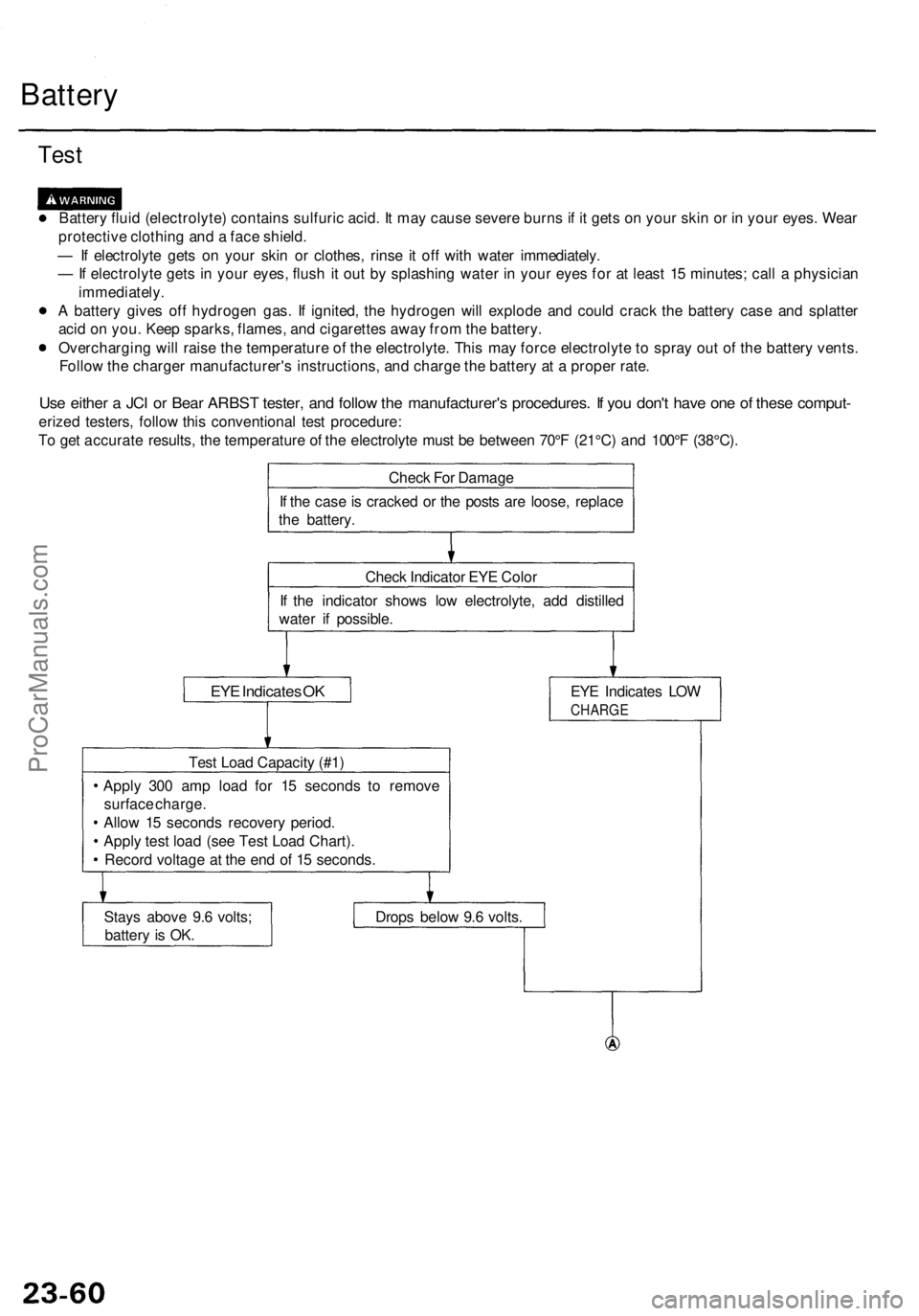

Use either a JCI or Bear ARBST tester, and follow the manufacturer's procedures. If you don't have one of these comput-

erized testers, follow this conventional test procedure:

To get accurate results, the temperature of the electrolyte must be between 70°F (21°C) and 100°F (38°C).

Check For Damage

If the case is cracked or the posts are loose, replace

the battery.

Check Indicator EYE Color

If the indicator shows low electrolyte, add distilled

water if possible.

EYE Indicates OK

EYE Indicates LOW

CHARGE

Test Load Capacity (#1)

Apply 300 amp load for 15 seconds to remove

surface charge.

Allow 15 seconds recovery period.

Apply test load (see Test Load Chart).

Record voltage at the end of 15 seconds.

Stays above 9.6 volts;

battery is OK.

Drops below 9.6 volts.ProCarManuals.com

Page 1546 of 1771

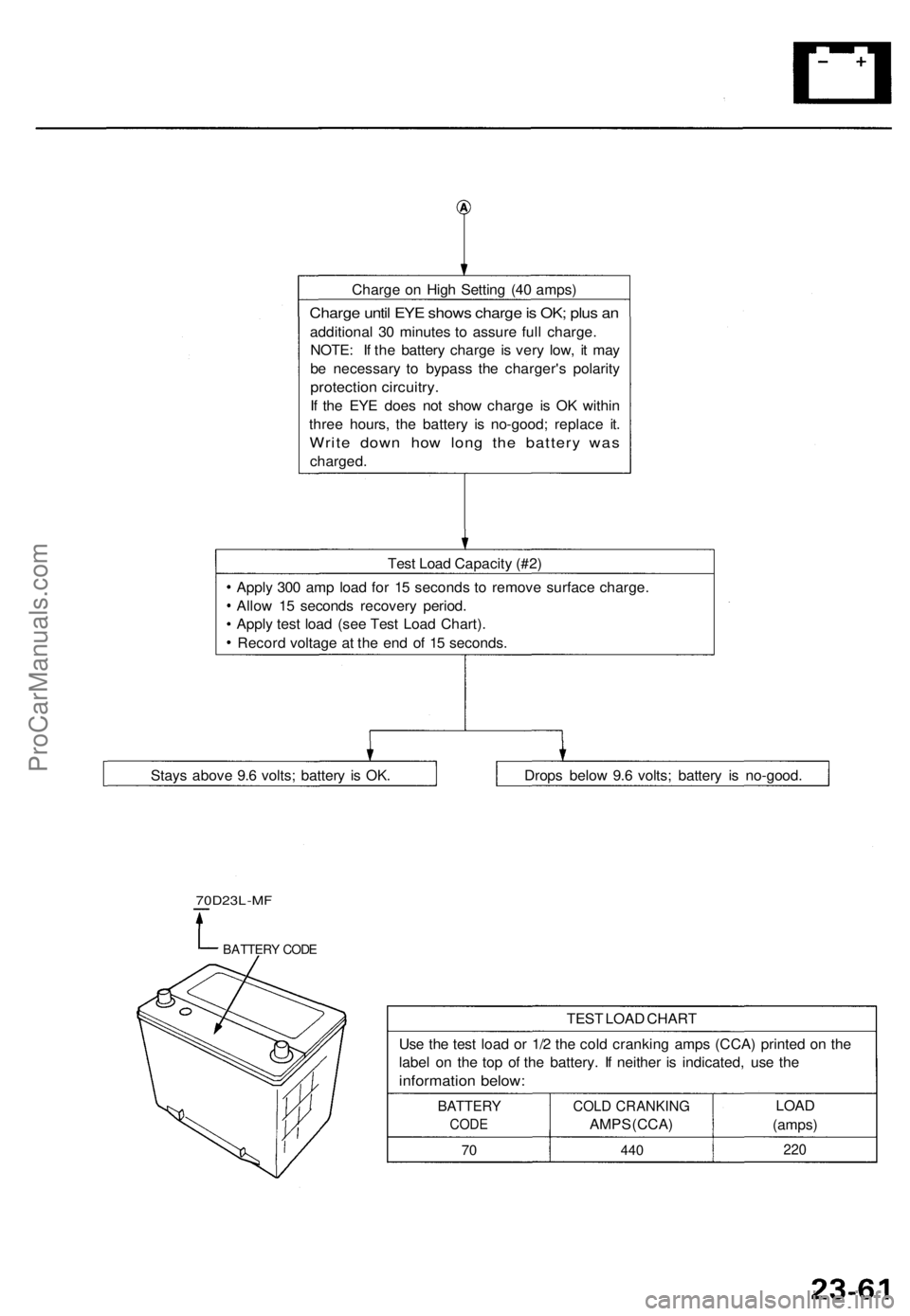

Charge on High Setting (40 amps)

Charge until EYE shows charge is OK; plus an

additional 30 minutes to assure full charge.

NOTE: If the battery charge is very low, it may

be necessary to bypass the charger's polarity

protection circuitry.

If the EYE does not show charge is OK within

three hours, the battery is no-good; replace it.

Write down how long the battery was

charged.

Test Load Capacity (#2)

Apply 300 amp load for 15 seconds to remove surface charge.

Allow 15 seconds recovery period.

Apply test load (see Test Load Chart).

Record voltage at the end of 15 seconds.

70D23L-MF

BATTERY CODE

TEST LOAD CHART

Use the test load or 1/2 the cold cranking amps (CCA) printed on the

label on the top of the battery. If neither is indicated, use the

information below:

BATTERY

CODE

70

COLD CRANKING

AMPS (CCA)

440

LOAD

(amps)

220

Drops below 9.6 volts; battery is no-good.

Stays above 9.6 volts; battery is OK.ProCarManuals.com

Page 1547 of 1771

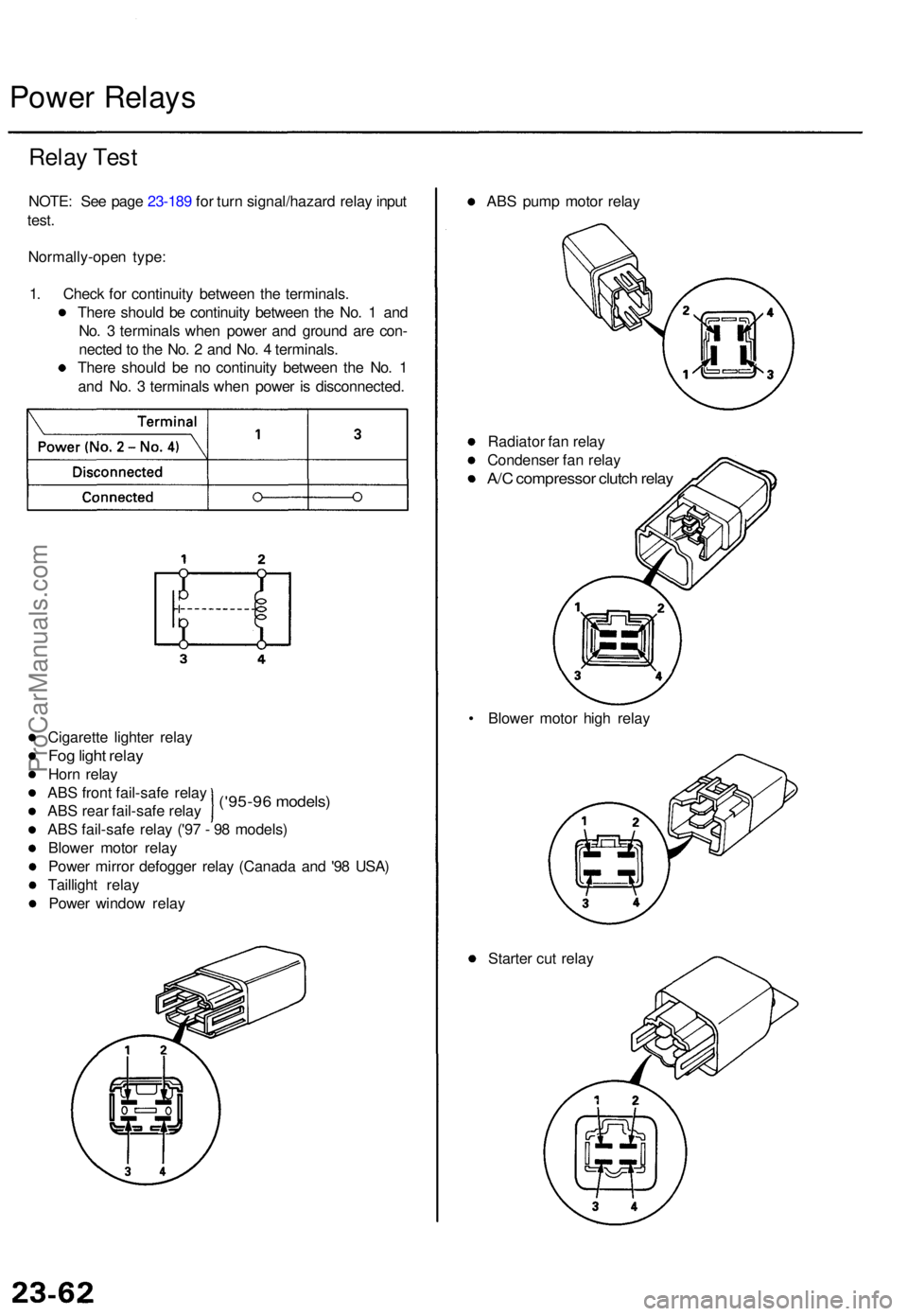

Power Relay s

Relay Tes t

NOTE : Se e pag e 23-18 9 fo r tur n signal/hazar d rela y inpu t

test .

Normally-ope n type :

1 . Chec k fo r continuit y betwee n th e terminals .

Ther e shoul d b e continuit y betwee n th e No . 1 an d

No . 3 terminal s whe n powe r an d groun d ar e con -

necte d to th e No . 2 an d No . 4 terminals .

Ther e shoul d b e n o continuit y betwee n th e No . 1

an d No . 3 terminal s whe n powe r i s disconnected .

('95-96 models )

Cigarett e lighte r rela y

Fog ligh t rela y

Horn rela y

AB S fron t fail-saf e rela y

AB S rea r fail-saf e rela y

AB S fail-saf e rela y ('9 7 - 9 8 models )

Blowe r moto r rela y

Powe r mirro r defogge r rela y (Canad a an d '9 8 USA )

Tailligh t rela y

Powe r windo w rela y AB

S pum p moto r rela y

Radiato r fa n rela y

Condense r fa n rela y

A/C compresso r clutc h rela y

• Blowe r moto r hig h rela y

Starte r cu t rela y

ProCarManuals.com

Page 1551 of 1771

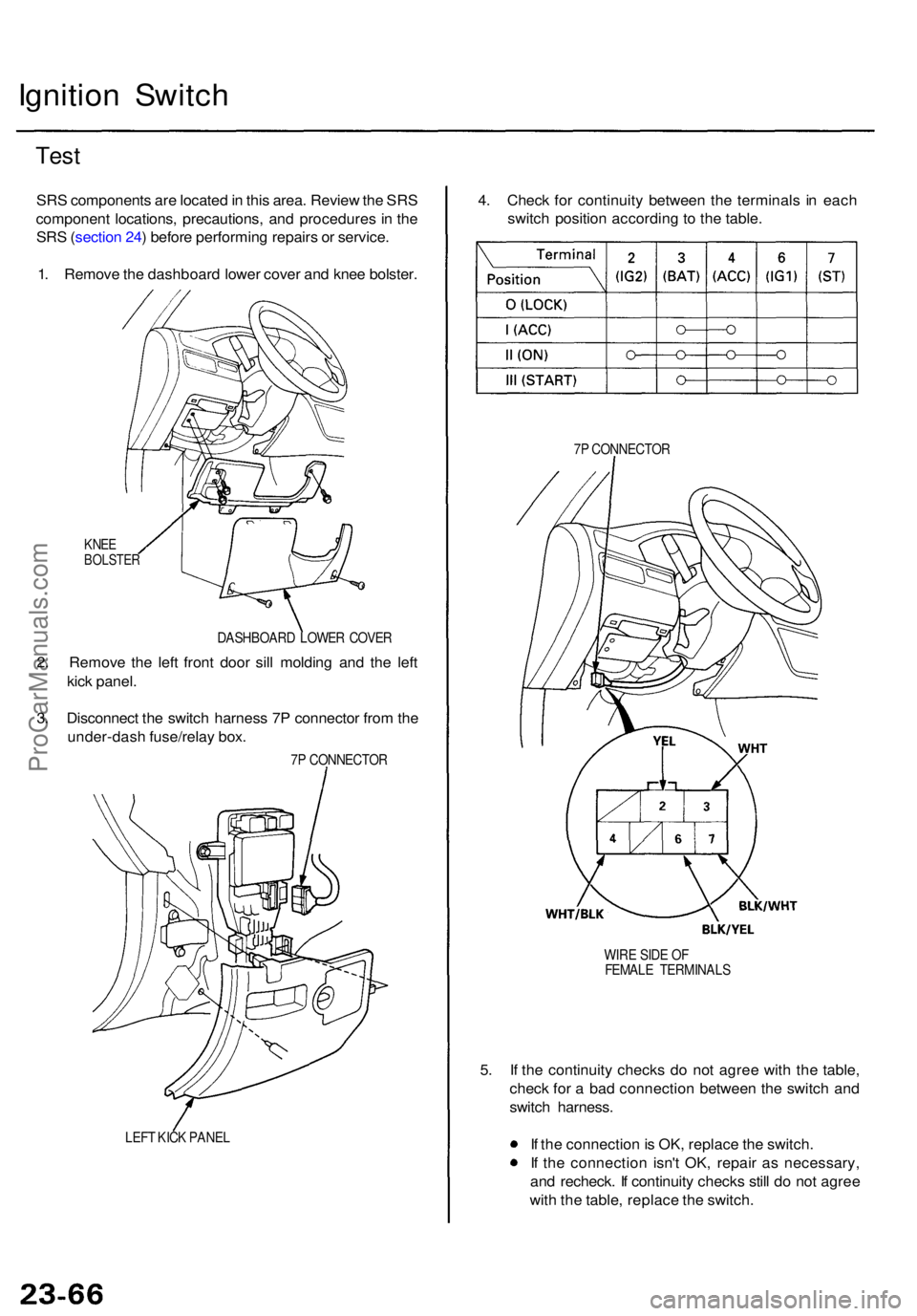

Ignition Switc h

Test

SRS component s ar e locate d in thi s area . Revie w th e SR S

componen t locations , precautions , an d procedure s i n th e

SR S (sectio n 24 ) befor e performin g repair s o r service .

1 . Remov e th e dashboar d lowe r cove r an d kne e bolster .

KNEEBOLSTE R

DASHBOAR D LOWE R COVE R

2. Remov e th e lef t fron t doo r sil l moldin g an d th e lef t

kic k panel .

3 . Disconnec t th e switc h harnes s 7 P connecto r fro m th e

under-das h fuse/rela y box .

7P CONNECTO R

LEF T KIC K PANE L

4. Chec k fo r continuit y betwee n th e terminal s i n eac h

switc h positio n accordin g t o th e table .

7P CONNECTO R

WIR E SID E O F

FEMAL E TERMINAL S

5. I f th e continuit y check s d o no t agre e wit h th e table ,

chec k fo r a ba d connectio n betwee n th e switc h an d

switc h harness .

I f th e connectio n is OK , replac e th e switch .

I f th e connectio n isn' t OK , repai r a s necessary ,

an d recheck . I f continuit y check s stil l d o no t agre e

wit h th e table , replac e th e switch .

ProCarManuals.com

Page 1555 of 1771

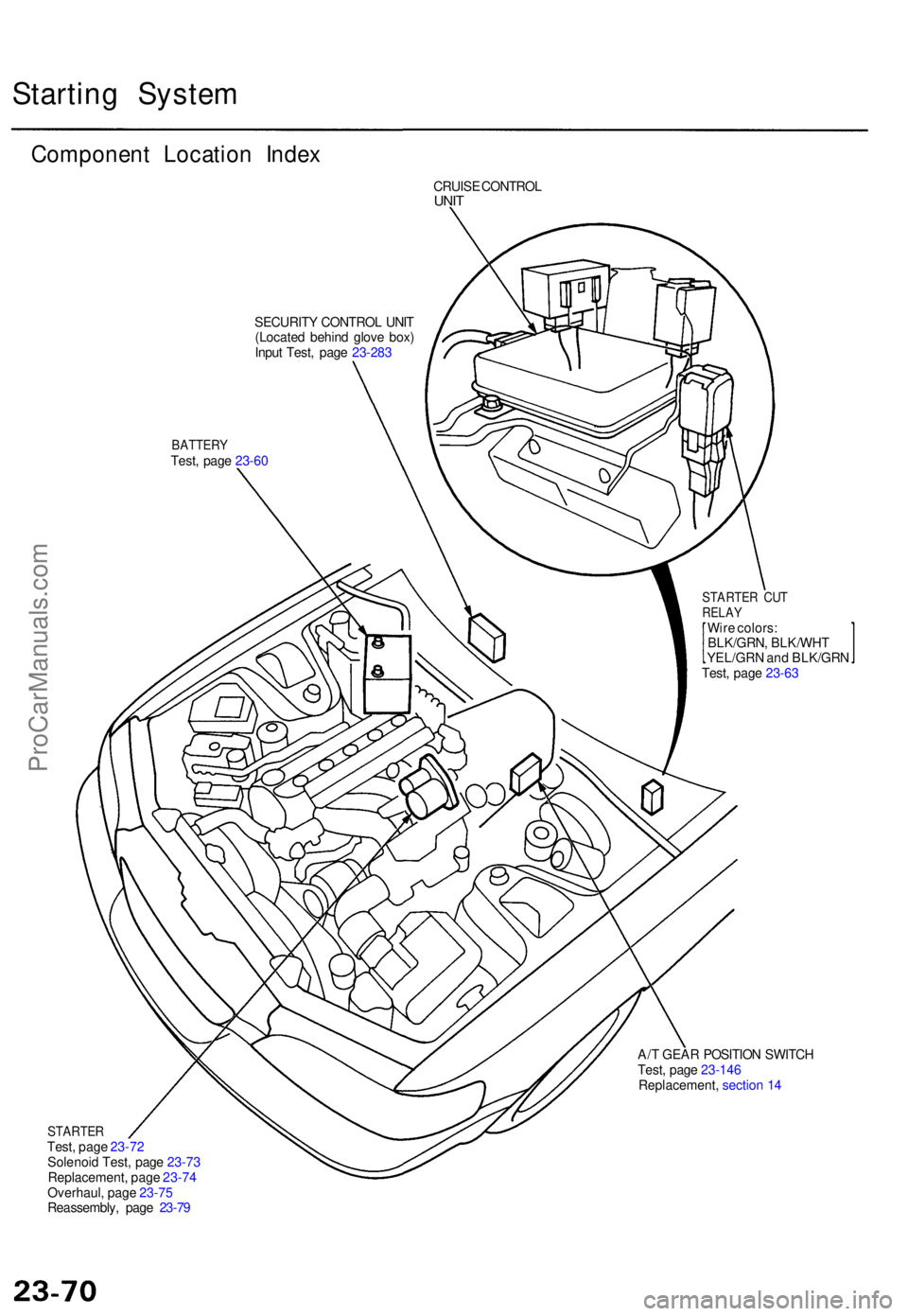

Starting Syste m

Componen t Locatio n Inde x

CRUIS E CONTRO LUNIT

SECURIT Y CONTRO L UNI T

(Locate d behin d glov e box )

Inpu t Test , pag e 23-28 3

BATTER YTest, pag e 23-6 0

STARTE R CU TRELA YWire colors :

BLK/GRN , BLK/WH T

YEL/GR N an d BLK/GR N

Test , pag e 23-6 3

A/ T GEA R POSITIO N SWITC H

Test , pag e 23-14 6

Replacement , sectio n 1 4

STARTE RTest, pag e 23-7 2

Solenoi d Test , pag e 23-7 3

Replacement , pag e 23-7 4

Overhaul , pag e 23-7 5

Reassembly , pag e 23-7 9

ProCarManuals.com

Page 1556 of 1771

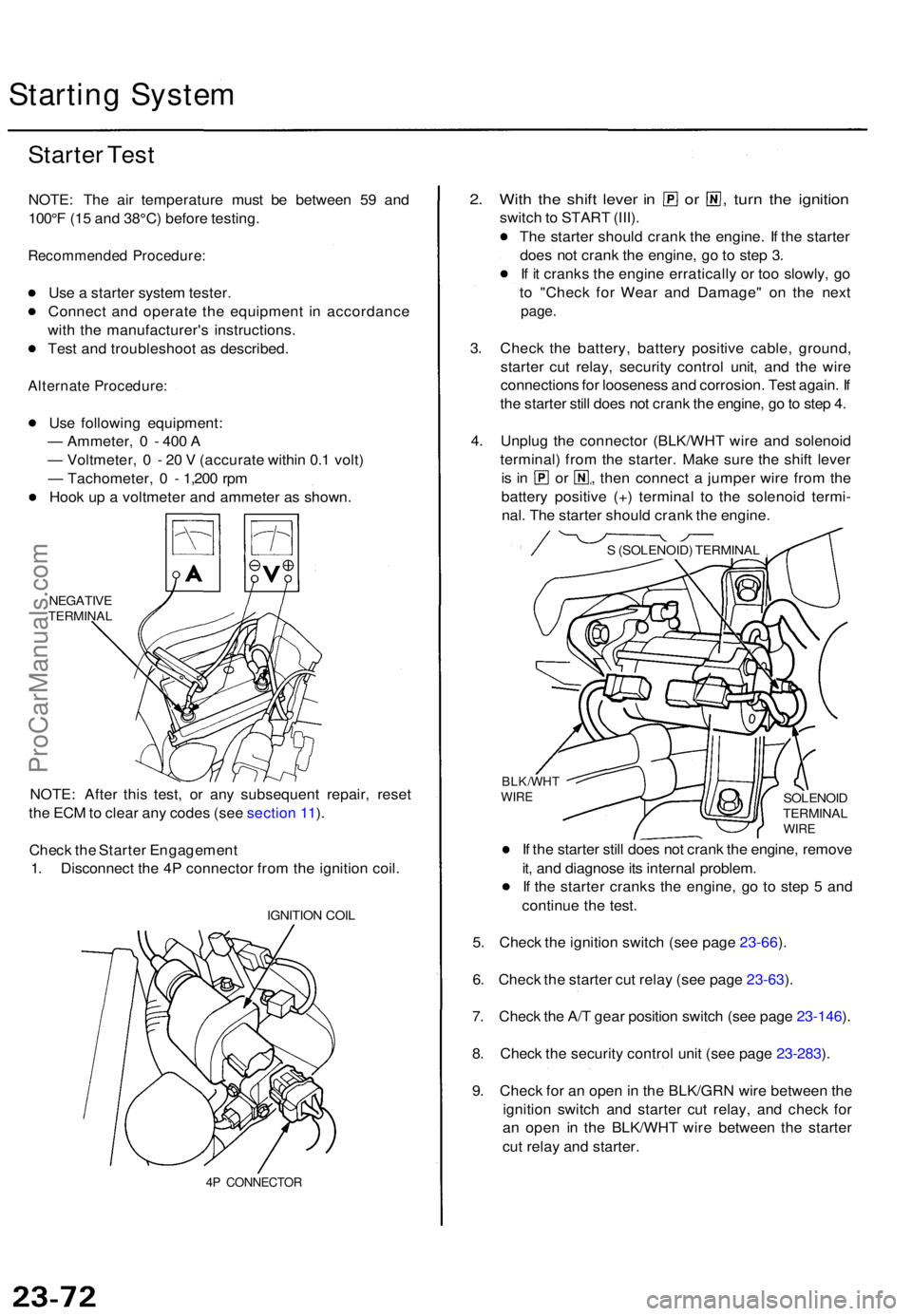

Starting Syste m

Starter Tes t

NOTE : Th e ai r temperatur e mus t b e betwee n 5 9 an d

100° F (1 5 an d 38°C ) befor e testing .

Recommende d Procedure :

Use a starte r syste m tester .

Connec t an d operat e th e equipmen t i n accordanc e

wit h th e manufacturer' s instructions .

Tes t an d troubleshoo t a s described .

Alternate Procedure :

Use followin g equipment :

— Ammeter , 0 - 400 A

— Voltmeter , 0 - 20 V (accurat e withi n 0. 1 volt )

— Tachometer , 0 - 1,20 0 rp m

Hoo k u p a voltmete r an d ammete r a s shown .

NEGATIV ETERMINA L

NOTE: Afte r thi s test , o r an y subsequen t repair , rese t

th e EC M to clea r an y code s (se e sectio n 11 ).

Chec k th e Starte r Engagemen t

1 . Disconnec t th e 4 P connecto r fro m th e ignitio n coil .

IGNITIO N COI L

4P CONNECTO R

2. Wit h th e shif t leve r i n o r , turn th e ignitio n

switch to STAR T (III) .

Th e starte r shoul d cran k th e engine . I f th e starte r

doe s no t cran k th e engine , g o to ste p 3 .

I f i t crank s th e engin e erraticall y o r to o slowly , g o

t o "Chec k fo r Wea r an d Damage " o n th e nex t

page .

3. Chec k th e battery , batter y positiv e cable , ground ,

starte r cu t relay , securit y contro l unit , an d th e wir e

connection s fo r loosenes s an d corrosion . Tes t again . I f

th e starte r stil l doe s no t cran k th e engine , g o to ste p 4 .

4 . Unplu g th e connecto r (BLK/WH T wir e an d solenoi d

terminal ) fro m th e starter . Mak e sur e th e shif t leve r

is i n o r , then connec t a jumpe r wir e fro m th e

batter y positiv e (+ ) termina l t o th e solenoi d termi -

nal . Th e starte r shoul d cran k th e engine .

I f th e starte r stil l doe s no t cran k th e engine , remov e

it , an d diagnos e it s interna l problem .

I f th e starte r crank s th e engine , g o t o ste p 5 an d

continu e th e test .

5 . Chec k th e ignitio n switc h (se e pag e 23-66 ).

6 . Chec k th e starte r cu t rela y (se e pag e 23-63 ).

7 . Chec k th e A/ T gea r positio n switc h (se e pag e 23-146 ).

8 . Chec k th e securit y contro l uni t (se e pag e 23-283 ).

9 . Chec k fo r a n ope n in th e BLK/GR N wir e betwee n th e

ignitio n switc h an d starte r cu t relay , an d chec k fo r

a n ope n i n th e BLK/WH T wir e betwee n th e starte r

cu t rela y an d starter .

SOLENOI DTERMINA LWIRE

BLK/WH TWIRE

S (SOLENOID ) TERMINA L

ProCarManuals.com

Page 1558 of 1771

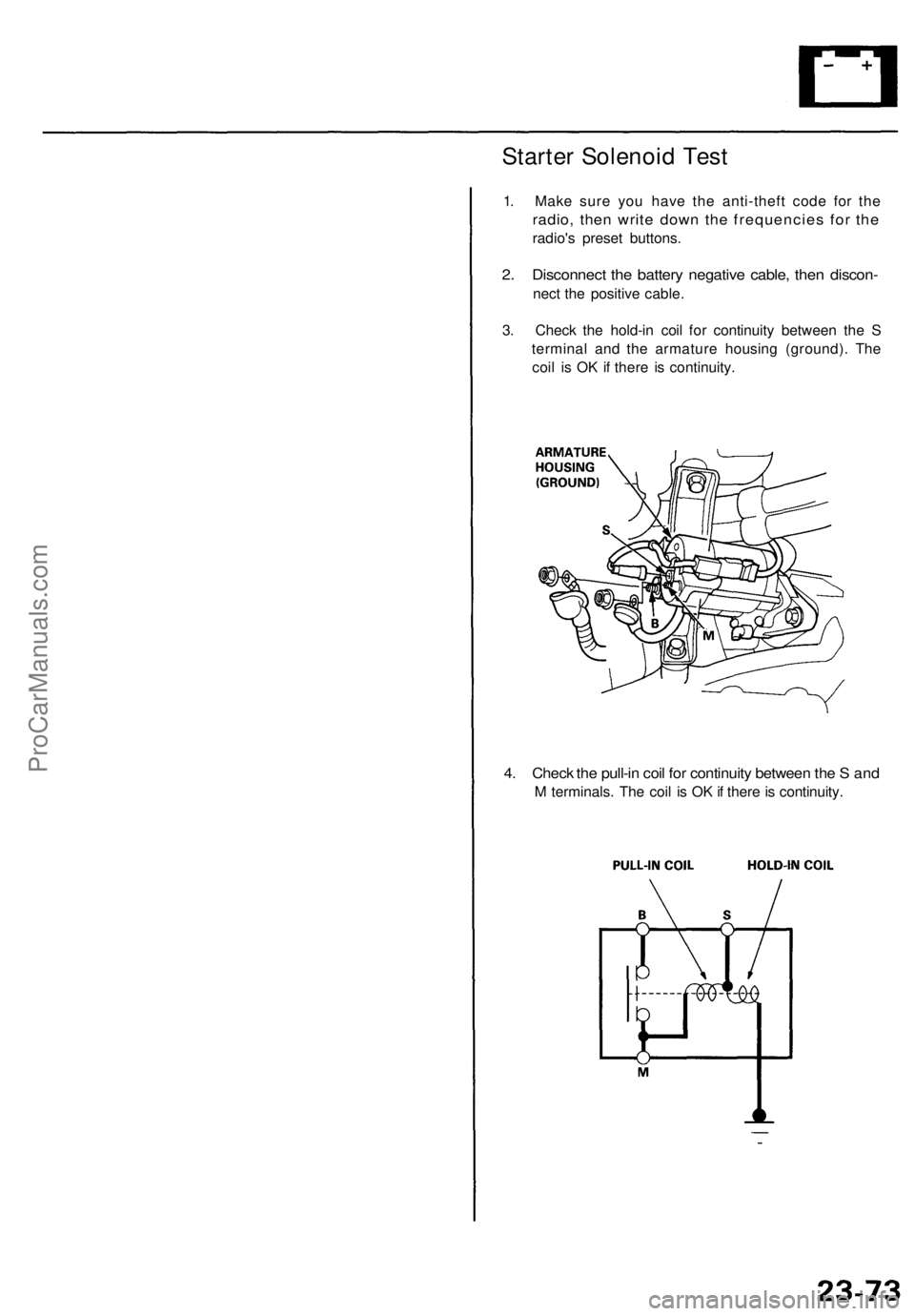

Starter Solenoid Test

1. Make sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's preset buttons.

2. Disconnect the battery negative cable, then discon-

nect the positive cable.

3. Check the hold-in coil for continuity between the S

terminal and the armature housing (ground). The

coil is OK if there is continuity.

4. Check the pull-in coil for continuity between the S and

M terminals. The coil is OK if there is continuity.ProCarManuals.com

Page 1560 of 1771

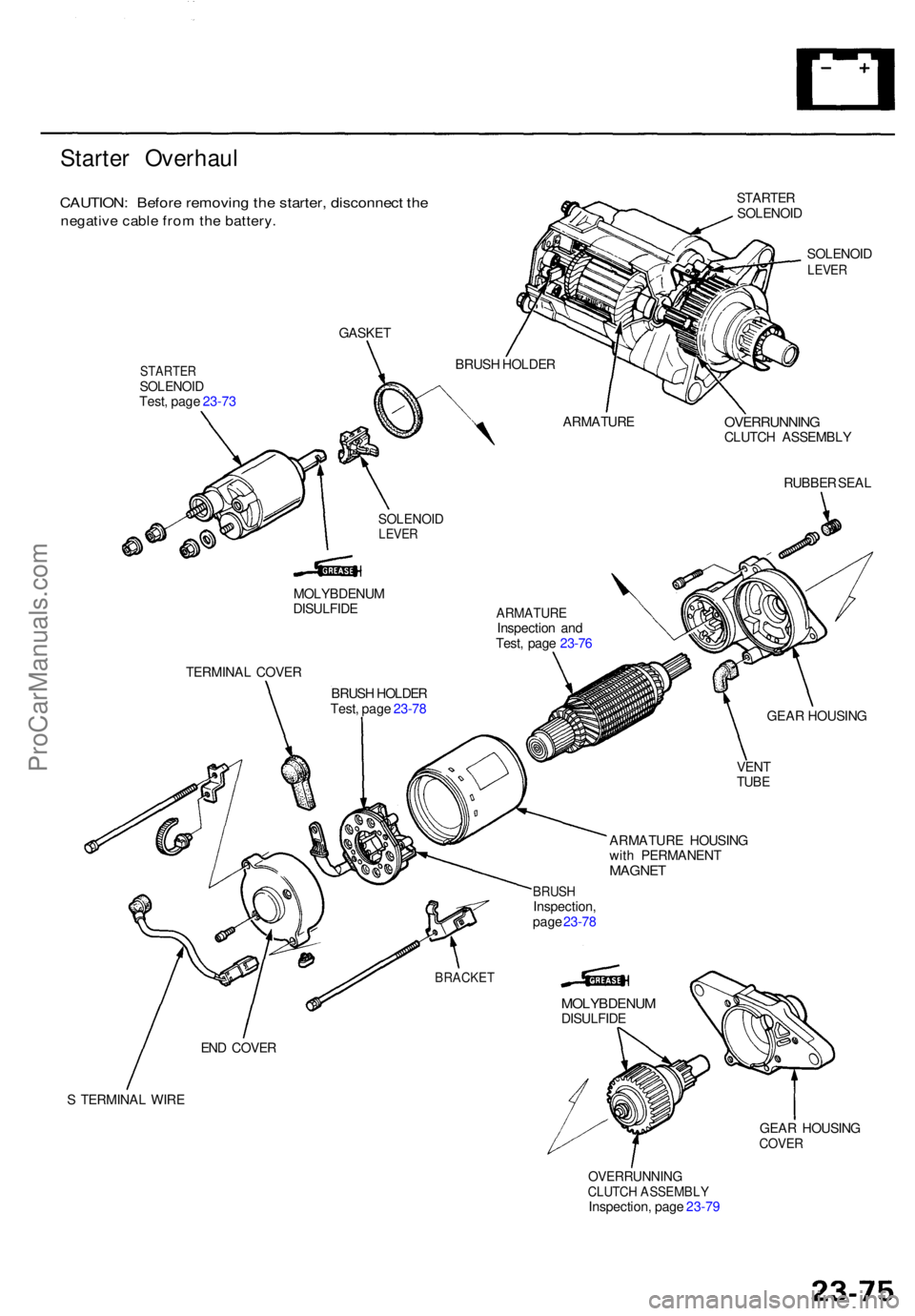

Starter Overhau l

CAUTION: Befor e removin g th e starter , disconnec t th e

negativ e cabl e fro m th e battery .

STARTE R

SOLENOI D

SOLENOI D

LEVER

STARTE RSOLENOI DTest, pag e 23-7 3

OVERRUNNIN GCLUTCH ASSEMBL Y

RUBBE R SEA L

MOLYBDENU M

DISULFID E

TERMINA L COVE R

BRUSH HOLDE R

Test , pag e 23-7 8

ARMATUR EInspection an d

Test , pag e 23-7 6

ARMATUR E HOUSIN G

wit h PERMANEN T

MAGNET

GEAR HOUSIN G

VEN T

TUBE

S TERMINA L WIR E

GEAR HOUSIN G

COVER

OVERRUNNIN GCLUTCH ASSEMBL YInspection, pag e 23-7 9

GASKE

T

BRUSH HOLDE R

ARMATUR E

SOLENOIDLEVER

BRUS HInspection ,

pag e 23-7 8

BRACKE T

END COVE R

MOLYBDENU MDISULFIDE

ProCarManuals.com

Page 1561 of 1771

Starting System

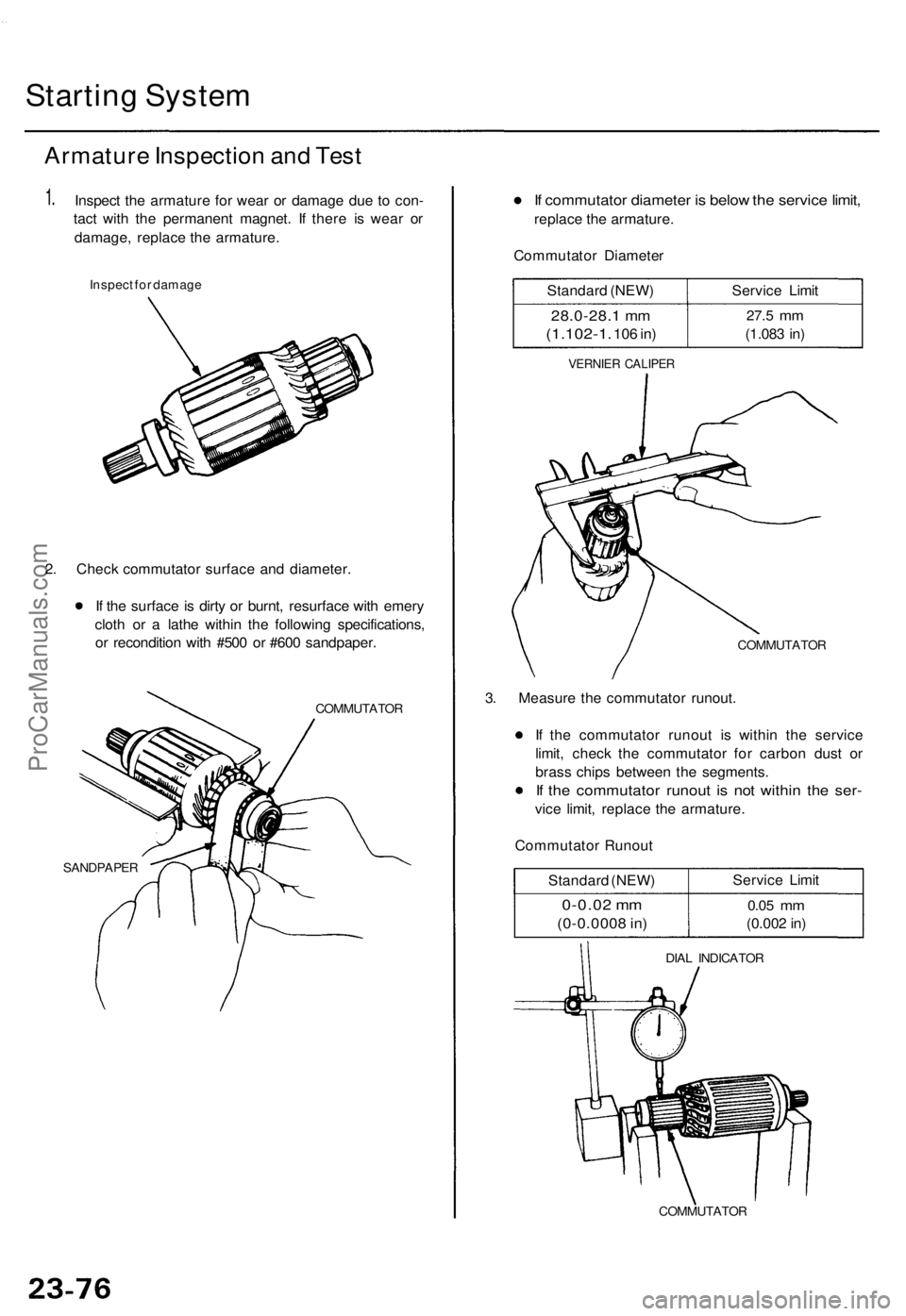

Armature Inspection and Test

1.

Inspect the armature for wear or damage due to con-

tact with the permanent magnet. If there is wear or

damage, replace the armature.

Inspect for damage

2. Check commutator surface and diameter.

If the surface is dirty or burnt, resurface with emery

cloth or a lathe within the following specifications,

or recondition with #500 or #600 sandpaper.

COMMUTATOR

SANDPAPER

If commutator diameter is below the service limit,

replace the armature.

Commutator Diameter

Standard (NEW)

28.0-28.1 mm

(1.102-1.

106 in)

Service Limit

27.5

mm

(1.083 in)

VERNIER CALIPER

COMMUTATOR

3. Measure the commutator runout.

If the commutator runout is within the service

limit, check the commutator for carbon dust or

brass chips between the segments.

If the commutator runout is not within the ser-

vice limit, replace the armature.

Commutator Runout

Standard (NEW)

0-0.02 mm

(0-0.0008 in)

Service Limit

0.05

mm

(0.002 in)

DIAL INDICATOR

COMMUTATORProCarManuals.com