ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 761 of 1771

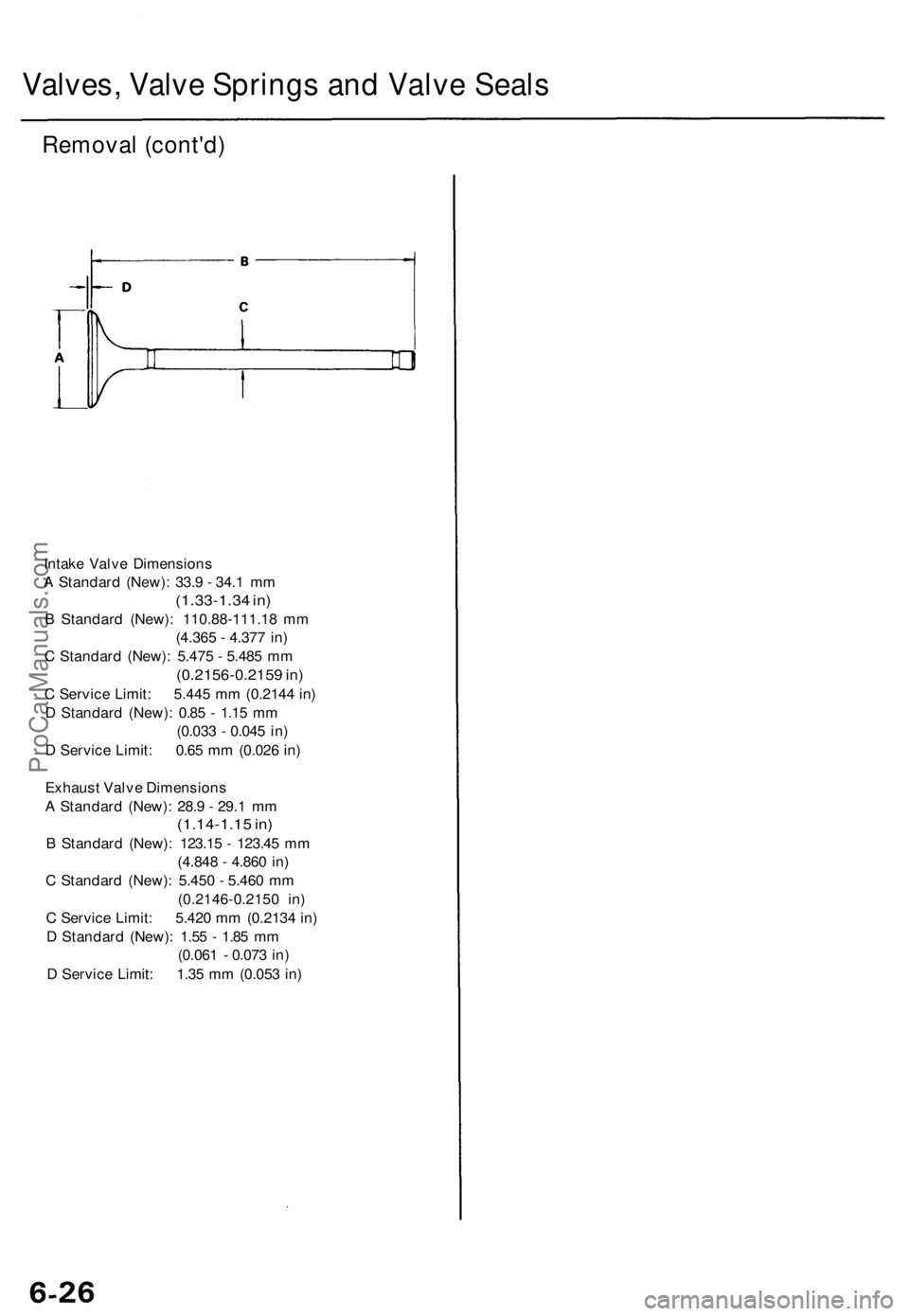

Valves, Valve Springs and Valv e Seal s

Remova l (cont'd )

Intake Valv e Dimension s

A Standar d (New) : 33. 9 - 34. 1 m m

(1.33-1.3 4 in )

B Standar d (New) : 110.88-111.1 8 m m

(4.36 5 - 4.37 7 in )

C Standar d (New) : 5.47 5 - 5.48 5 m m

(0.2156-0.215 9 in )

C Servic e Limit : 5.44 5 m m (0.214 4 in )

D Standar d (New) : 0.8 5 - 1.1 5 m m

(0.03 3 - 0.04 5 in )

D Servic e Limit : 0.6 5 m m (0.02 6 in )

Exhaus t Valv e Dimension s

A Standar d (New) : 28. 9 - 29. 1 m m

(1.14-1.1 5 in )

B Standar d (New) : 123.1 5 - 123.4 5 m m

(4.84 8 - 4.86 0 in )

C Standar d (New) : 5.45 0 - 5.46 0 m m

(0.2146-0.215 0 in )

C Servic e Limit : 5.42 0 m m (0.213 4 in )

D Standar d (New) : 1.5 5 - 1.8 5 m m

(0.06 1 - 0.07 3 in )

D Servic e Limit : 1.3 5 m m (0.05 3 in )

ProCarManuals.com

Page 762 of 1771

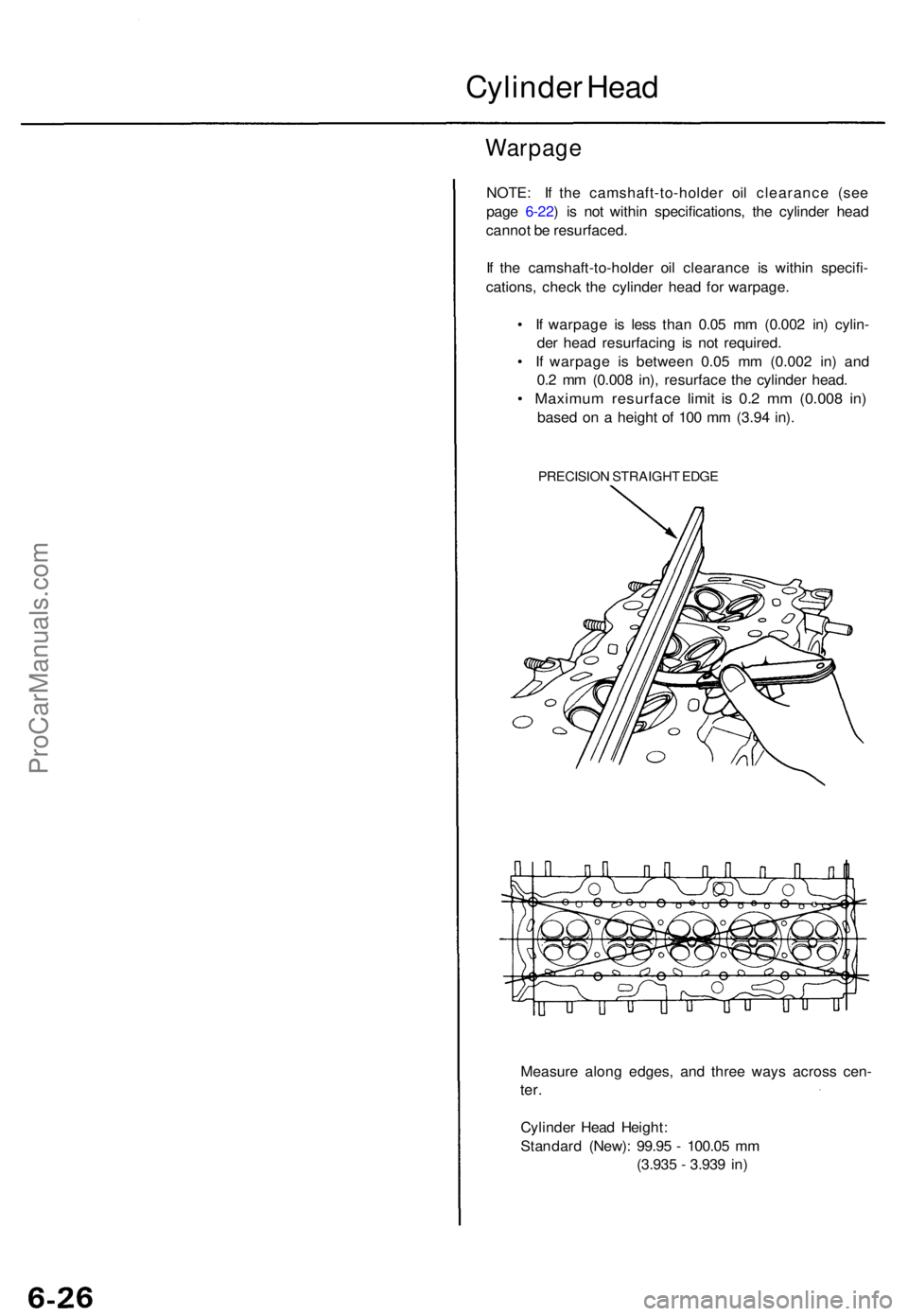

Cylinder Hea d

Warpag e

NOTE: I f th e camshaft-to-holde r oi l clearanc e (se e

pag e 6-22 ) i s no t withi n specifications , th e cylinde r hea d

canno t b e resurfaced .

I f th e camshaft-to-holde r oi l clearanc e i s withi n specifi -

cations , chec k th e cylinde r hea d fo r warpage .

• I f warpag e i s les s tha n 0.0 5 m m (0.00 2 in ) cylin -

de r hea d resurfacin g i s no t required .

• I f warpag e i s betwee n 0.0 5 m m (0.00 2 in ) an d

0. 2 m m (0.00 8 in) , resurfac e th e cylinde r head .

• Maximu m resurfac e limi t i s 0. 2 m m (0.00 8 in )

base d o n a heigh t o f 10 0 m m (3.9 4 in) .

PRECISIO N STRAIGH T EDG E

Measur e alon g edges , an d thre e way s acros s cen -

ter.

Cylinde r Hea d Height :

Standar d (New) : 99.9 5 - 100.0 5 m m

(3.93 5 - 3.93 9 in )

ProCarManuals.com

Page 763 of 1771

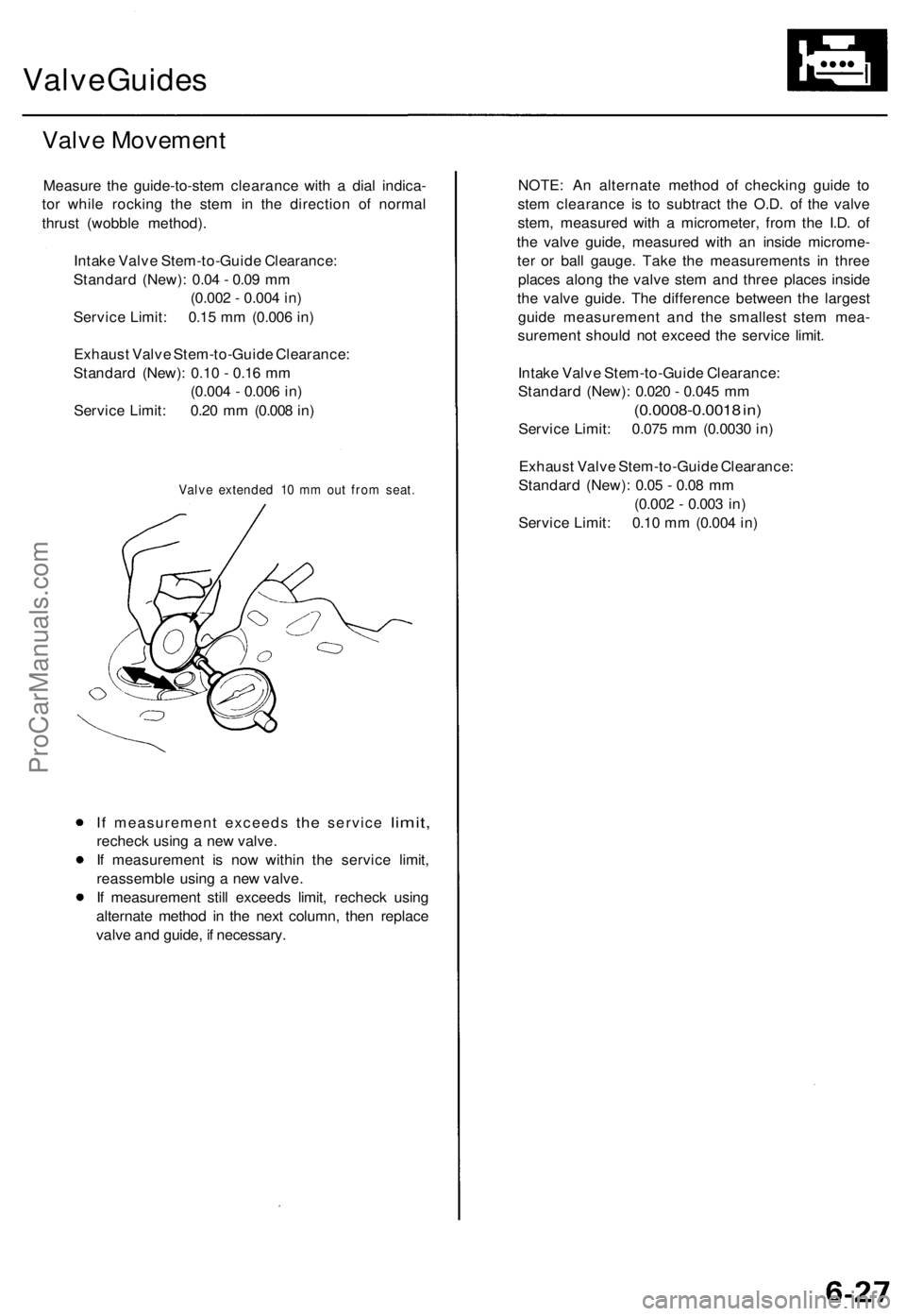

Valve Guides

Valve Movement

Measure the guide-to-stem clearance with a dial indica-

tor while rocking the stem in the direction of normal

thrust (wobble method).

Intake Valve Stem-to-Guide Clearance:

Standard (New): 0.04 - 0.09 mm

(0.002 - 0.004 in)

Service Limit: 0.15 mm (0.006 in)

Exhaust Valve Stem-to-Guide Clearance:

Standard (New): 0.10 - 0.16 mm

(0.004 - 0.006 in)

Service Limit: 0.20 mm (0.008 in)

Valve extended 10 mm out from seat.

If

measurement exceeds

the

service

limit,

recheck using a new valve.

If measurement is now within the service limit,

reassemble using a new valve.

If measurement still exceeds limit, recheck using

alternate method in the next column, then replace

valve and guide, if necessary.

NOTE: An alternate method of checking guide to

stem clearance is to subtract the O.D. of the valve

stem, measured with a micrometer, from the I.D. of

the valve guide, measured with an inside microme-

ter or ball gauge. Take the measurements in three

places along the valve stem and three places inside

the valve guide. The difference between the largest

guide measurement and the smallest stem mea-

surement should not exceed the service limit.

Intake Valve Stem-to-Guide Clearance:

Standard (New): 0.020 - 0.045 mm

(0.0008-0.0018 in)

Service Limit: 0.075 mm (0.0030 in)

Exhaust Valve Stem-to-Guide Clearance:

Standard (New): 0.05 - 0.08 mm

(0.002 - 0.003 in)

Service Limit: 0.10 mm (0.004 in)ProCarManuals.com

Page 764 of 1771

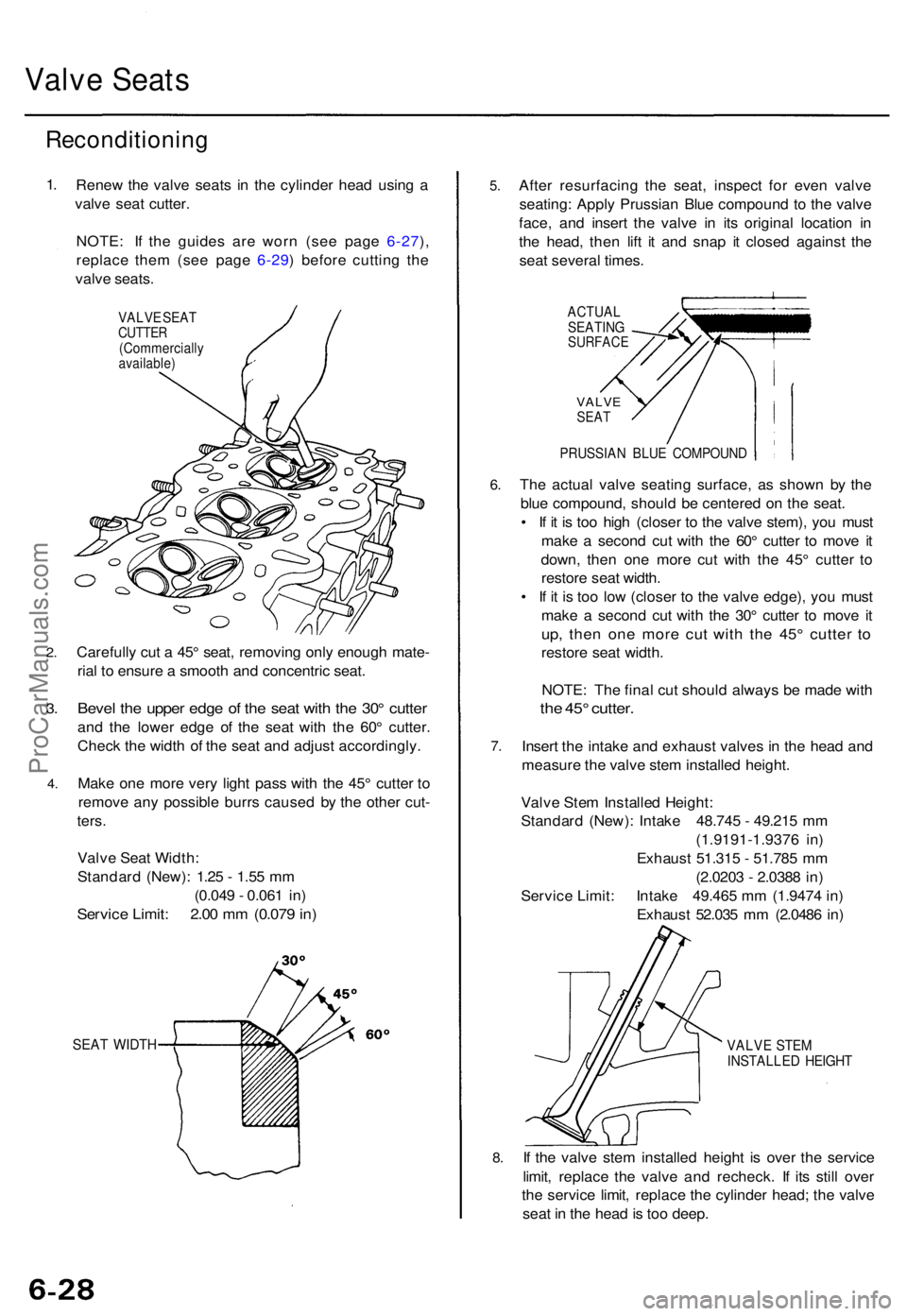

Valve Seat s

Reconditionin g

1.

2 .

3.

4 .

Rene w th e valv e seat s i n th e cylinde r hea d usin g a

valv e sea t cutter .

NOTE : I f th e guide s ar e wor n (se e pag e 6-27 ),

replac e the m (se e pag e 6-29 ) befor e cuttin g th e

valv e seats .

VALV E SEA TCUTTE R(Commerciall yavailable)

Carefully cu t a 45 ° seat , removin g onl y enoug h mate -

ria l t o ensur e a smoot h an d concentri c seat .

Beve l th e uppe r edg e o f th e sea t wit h th e 30 ° cutte r

and th e lowe r edg e o f th e sea t wit h th e 60 ° cutter .

Chec k th e widt h o f th e sea t an d adjus t accordingly .

Mak e on e mor e ver y ligh t pas s wit h th e 45 ° cutte r t o

remov e an y possibl e burr s cause d b y th e othe r cut -

ters .

Valv e Sea t Width :

Standar d (New) : 1.2 5 - 1.5 5 m m

(0.04 9 - 0.06 1 in )

Servic e Limit : 2.0 0 m m (0.07 9 in )

SEA T WIDT H

5.

6.

7 .

8.

Afte r resurfacin g th e seat , inspec t fo r eve n valv e

seating : Appl y Prussia n Blu e compoun d t o th e valv e

face , an d inser t th e valv e i n it s origina l locatio n i n

th e head , the n lif t i t an d sna p i t close d agains t th e

sea t severa l times .

ACTUA L

SEATIN G

SURFAC E

VALVESEAT

PRUSSIA N BLU E COMPOUN D

The actua l valv e seatin g surface , a s show n b y th e

blu e compound , shoul d b e centere d o n th e seat .

• I f i t i s to o hig h (close r t o th e valv e stem) , yo u mus t

mak e a secon d cu t wit h th e 60 ° cutte r t o mov e i t

down , the n on e mor e cu t wit h th e 45 ° cutte r t o

restor e sea t width .

• I f i t i s to o lo w (close r t o th e valv e edge) , yo u mus t

mak e a secon d cu t wit h th e 30 ° cutte r t o mov e i t

up , the n on e mor e cu t wit h th e 45 ° cutte r t o

restor e sea t width .

NOTE : Th e fina l cu t shoul d alway s b e mad e wit h

the 45 ° cutter .

Insert th e intak e an d exhaus t valve s i n th e hea d an d

measur e th e valv e ste m installe d height .

Valv e Ste m Installe d Height :

Standar d (New) : Intak e 48.74 5 - 49.21 5 m m

(1.9191-1.937 6 in )

Exhaus t 51.31 5 - 51.78 5 m m

(2.020 3 - 2.038 8 in )

Servic e Limit : Intak e 49.46 5 m m (1.947 4 in )

Exhaus t 52.03 5 m m (2.048 6 in )

VALV E STE M

INSTALLE D HEIGH T

If th e valv e ste m installe d heigh t i s ove r th e servic e

limit , replac e th e valv e an d recheck . I f it s stil l ove r

th e servic e limit , replac e th e cylinde r head ; th e valv e

sea t i n th e hea d is to o deep .

ProCarManuals.com

Page 765 of 1771

Valve Guide s

Replacemen t

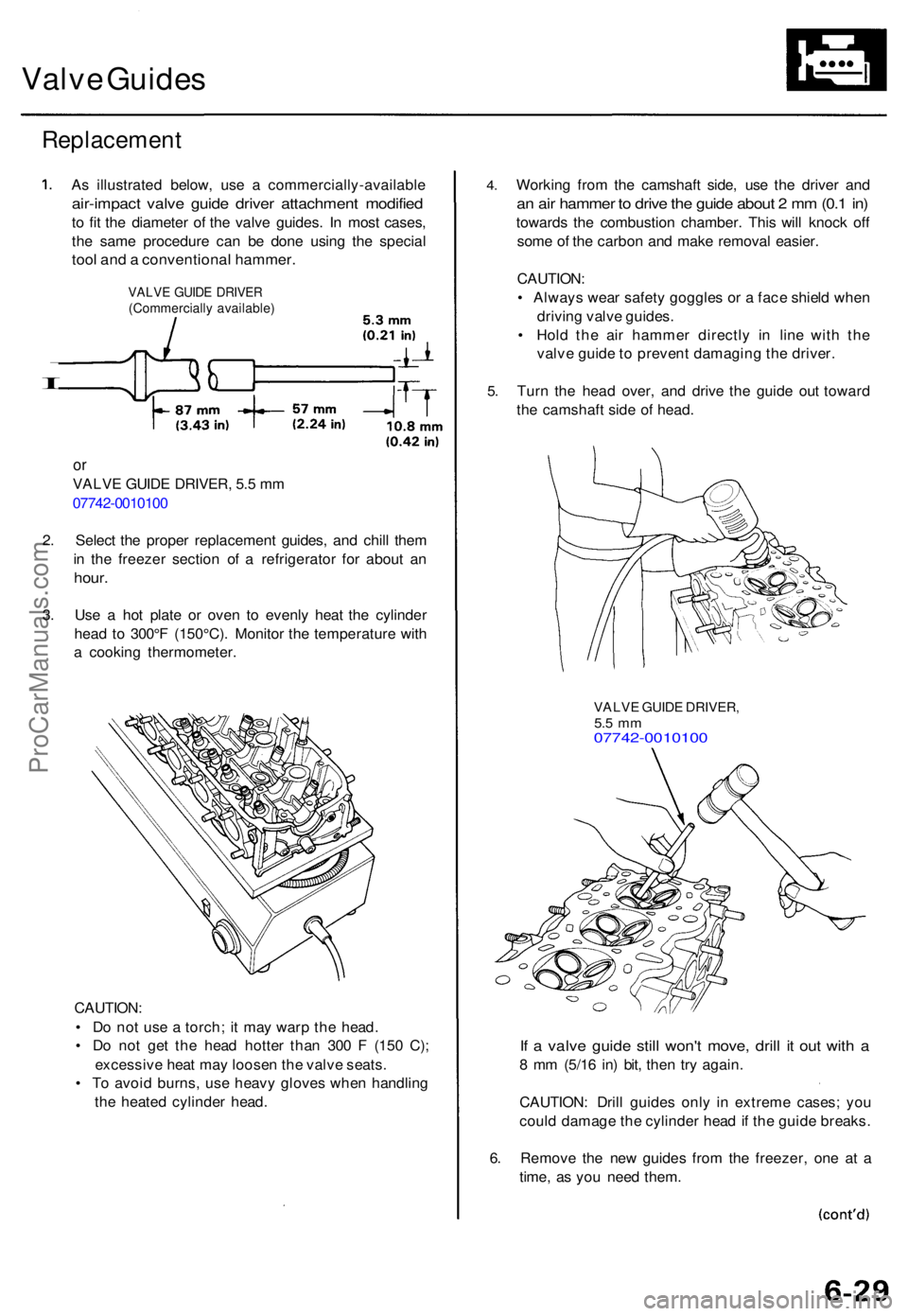

I

As illustrate d below , us e a commercially-availabl e

air-impact valv e guid e drive r attachmen t modifie d

to fi t th e diamete r o f th e valv e guides . I n mos t cases ,

th e sam e procedur e ca n b e don e usin g th e specia l

tool an d a conventiona l hammer .

VALVE GUID E DRIVE R(Commerciall y available )

or

VALV E GUID E DRIVER , 5. 5 m m

07742-001010 0

2 . Selec t th e prope r replacemen t guides , an d chil l the m

i n th e freeze r sectio n o f a refrigerato r fo r abou t a n

hour .

3. Us e a ho t plat e o r ove n t o evenl y hea t th e cylinde r

hea d t o 300° F (150°C) . Monito r th e temperatur e wit h

a cookin g thermometer .

CAUTION :

• D o no t us e a torch ; i t ma y war p th e head .

• D o no t ge t th e hea d hotte r tha n 30 0 F (15 0 C) ;

excessiv e hea t ma y loose n th e valv e seats .

• T o avoi d burns , us e heav y glove s whe n handlin g

th e heate d cylinde r head .

4.

5.

Workin g fro m th e camshaf t side , us e th e drive r an d

an ai r hamme r t o driv e th e guid e abou t 2 m m (0. 1 in )

towards the combustio n chamber . Thi s wil l knoc k of f

som e o f th e carbo n an d mak e remova l easier .

CAUTION :

• Alway s wea r safet y goggle s o r a fac e shiel d whe n

drivin g valv e guides .

• Hol d th e ai r hamme r directl y i n lin e wit h th e

valv e guid e t o preven t damagin g th e driver .

Tur n th e hea d over , an d driv e th e guid e ou t towar d

th e camshaf t sid e o f head .

VALV E GUID E DRIVER ,5.5 m m07742-001010 0

If a valv e guid e stil l won' t move , dril l i t ou t wit h a

8 m m (5/1 6 in ) bit , the n tr y again .

CAUTION : Dril l guide s onl y i n extrem e cases ; yo u

coul d damag e th e cylinde r hea d if th e guid e breaks .

6 . Remov e th e ne w guide s fro m th e freezer , on e a t a

time , a s yo u nee d them .

ProCarManuals.com

Page 766 of 1771

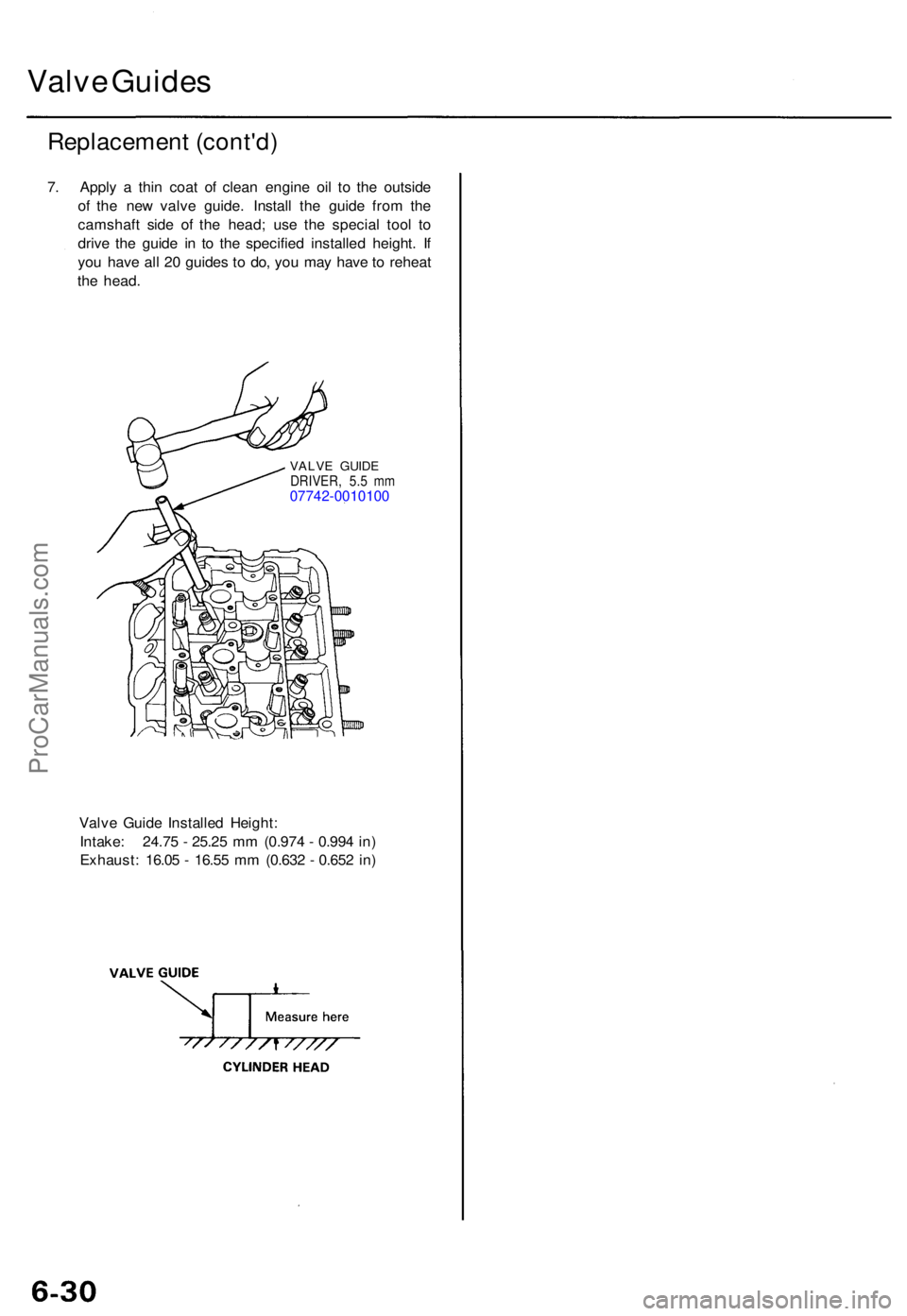

Valve Guide s

Replacemen t (cont'd )

7. Appl y a thi n coa t o f clea n engin e oi l t o th e outsid e

of th e ne w valv e guide . Instal l th e guid e fro m th e

camshaf t sid e o f th e head ; us e th e specia l too l t o

driv e th e guid e i n t o th e specifie d installe d height . I f

yo u hav e al l 2 0 guide s t o do , yo u ma y hav e to rehea t

th e head .

VALV E GUID EDRIVER , 5. 5 m m07742-001010 0

Valve Guid e Installe d Height :

Intake : 24.7 5 - 25.2 5 m m (0.97 4 - 0.99 4 in )

Exhaust : 16.0 5 - 16.5 5 m m (0.63 2 - 0.65 2 in )

ProCarManuals.com

Page 767 of 1771

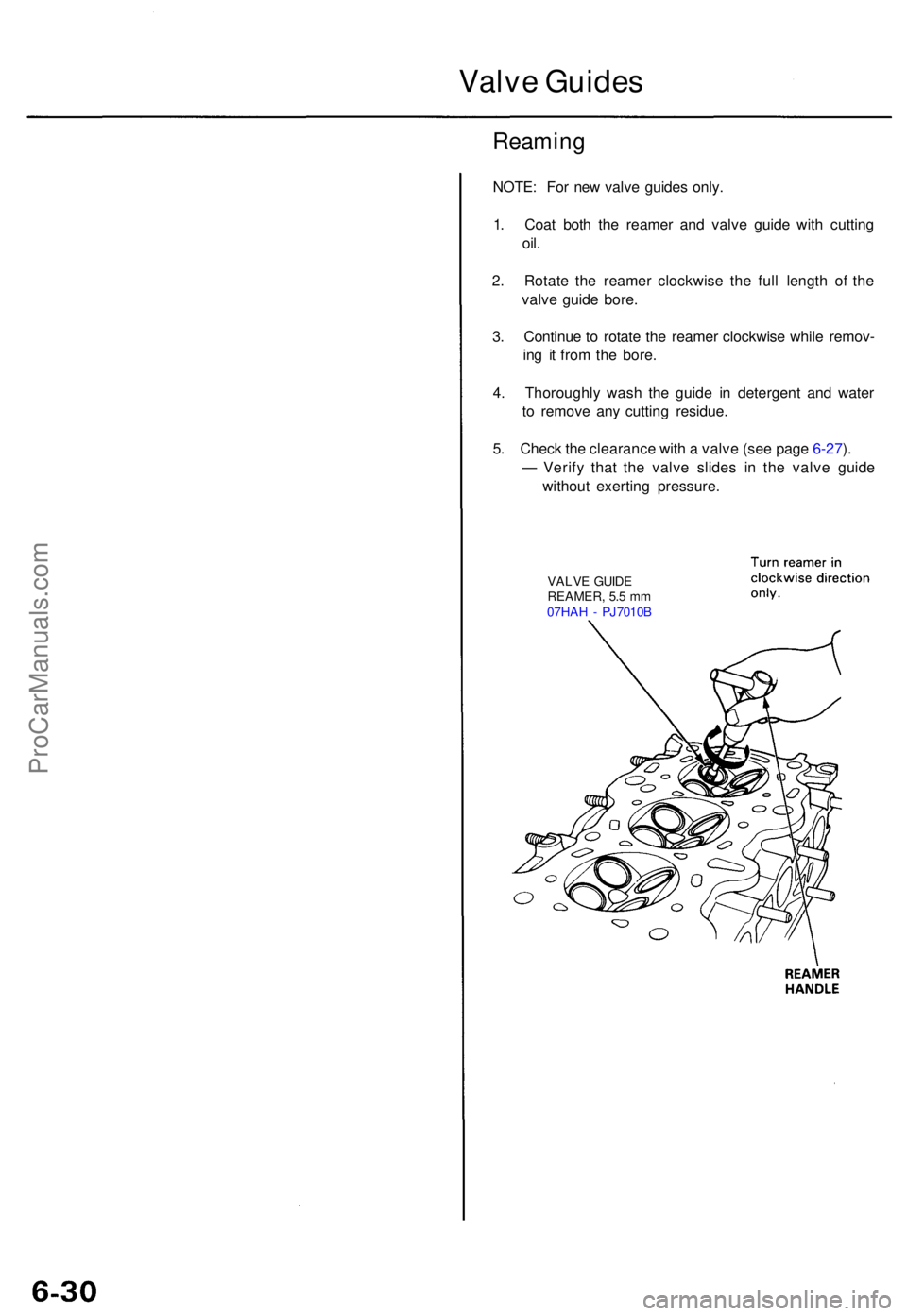

Valve Guide s

Reamin g

NOTE: Fo r ne w valv e guide s only .

1 . Coa t bot h th e reame r an d valv e guid e wit h cuttin g

oil.

2. Rotat e th e reame r clockwis e th e ful l lengt h o f th e

valv e guid e bore .

3 . Continu e t o rotat e th e reame r clockwis e whil e remov -

in g i t fro m th e bore .

4 . Thoroughl y was h th e guid e i n detergen t an d wate r

t o remov e an y cuttin g residue .

5 . Chec k th e clearanc e wit h a valv e (se e pag e 6-27 ).

— Verif y tha t th e valv e slide s i n th e valv e guid e

withou t exertin g pressure .

VALVE GUID E

REAMER , 5. 5 m m

07HA H - PJ7010 B

ProCarManuals.com

Page 768 of 1771

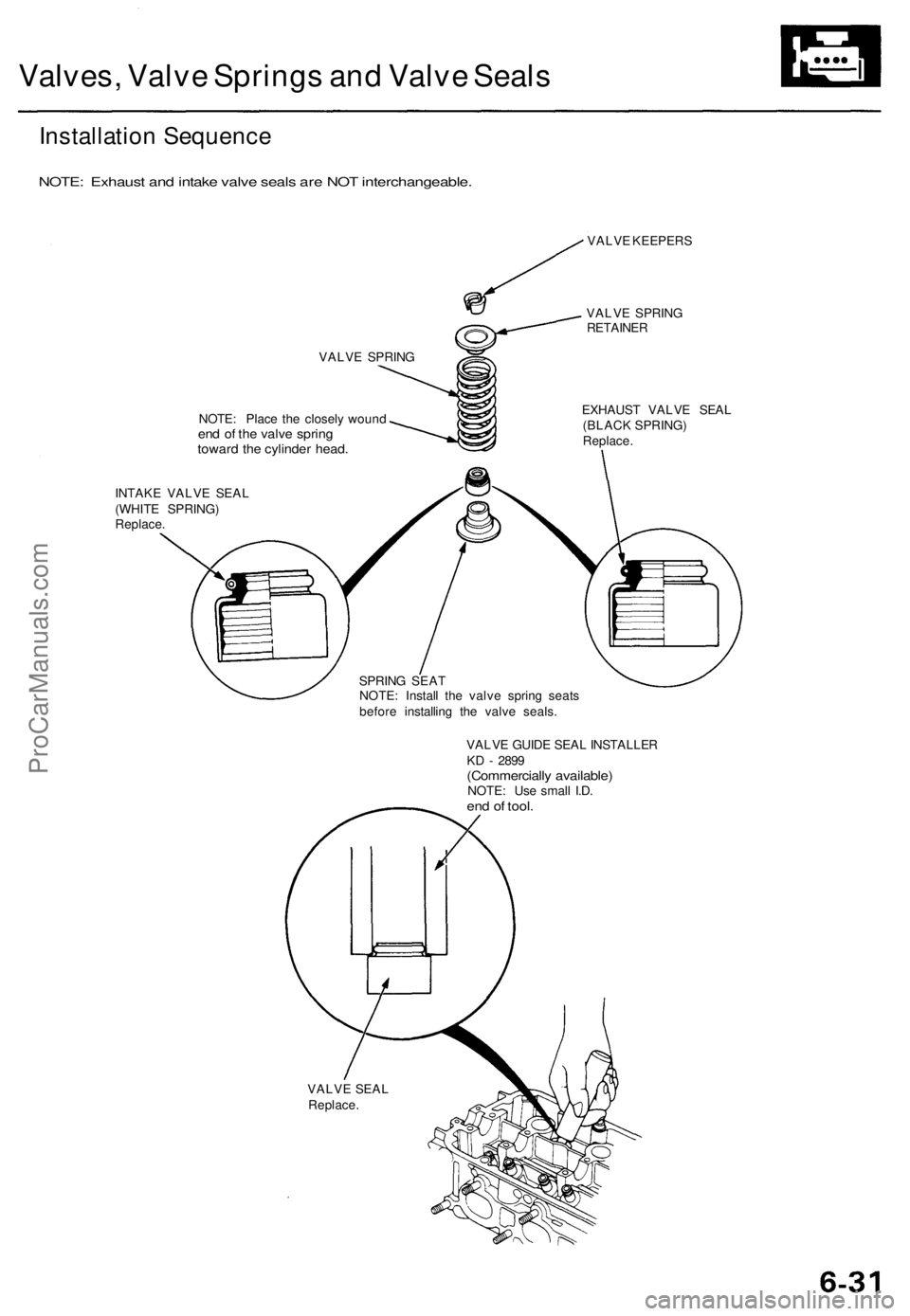

Valves, Valve Springs and Valve Seals

Installation Sequence

NOTE: Exhaust and intake valve seals are NOT interchangeable.

VALVE SPRING

NOTE: Place the closely wound

end of the valve spring

toward the cylinder head.

VALVE KEEPERS

VALVE SPRING

RETAINER

EXHAUST VALVE SEAL

(BLACK SPRING)

Replace.

INTAKE VALVE SEAL

(WHITE SPRING)

Replace.

SPRING SEAT

NOTE: Install the valve spring seats

before installing the valve seals.

VALVE GUIDE SEAL INSTALLER

KD - 2899

(Commercially available)

NOTE: Use small I.D.

end of tool.

VALVE SEAL

Replace.ProCarManuals.com

Page 769 of 1771

Valves, Valv e Spring s an d

Valv e Seal s

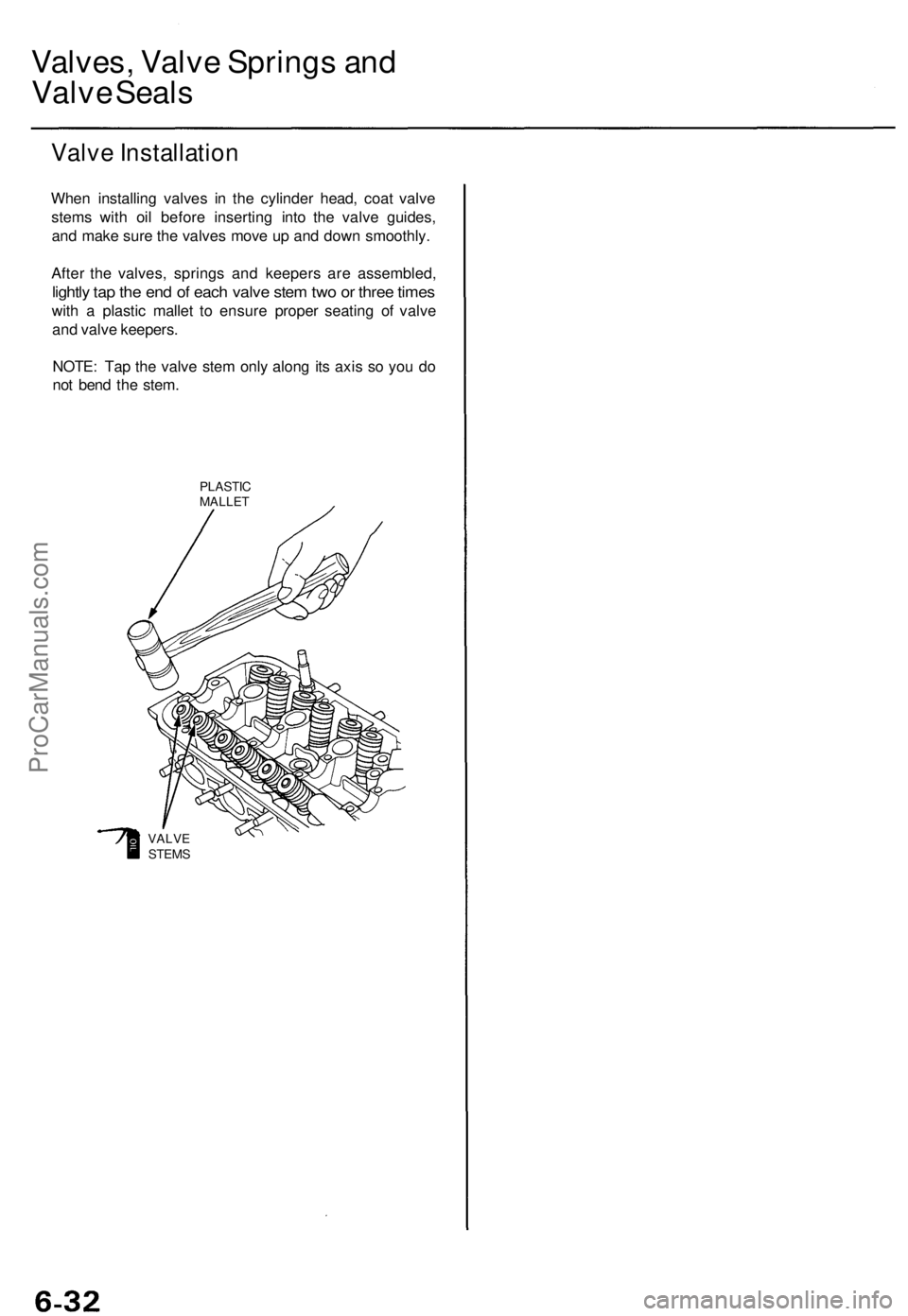

Valv e Installatio n

When installin g valve s i n th e cylinde r head , coa t valv e

stem s wit h oi l befor e insertin g int o th e valv e guides ,

an d mak e sur e th e valve s mov e u p an d dow n smoothly .

Afte r th e valves , spring s an d keeper s ar e assembled ,

lightly ta p th e en d o f eac h valv e ste m tw o o r thre e time s

with a plasti c malle t t o ensur e prope r seatin g o f valv e

an d valv e keepers .

NOTE : Ta p th e valv e ste m onl y alon g it s axi s s o yo u d o

no t ben d th e stem .

PLASTI CMALLET

VALVESTEMS

ProCarManuals.com

Page 770 of 1771

Camshaft/Rocker Arms and

Camshaft Seal

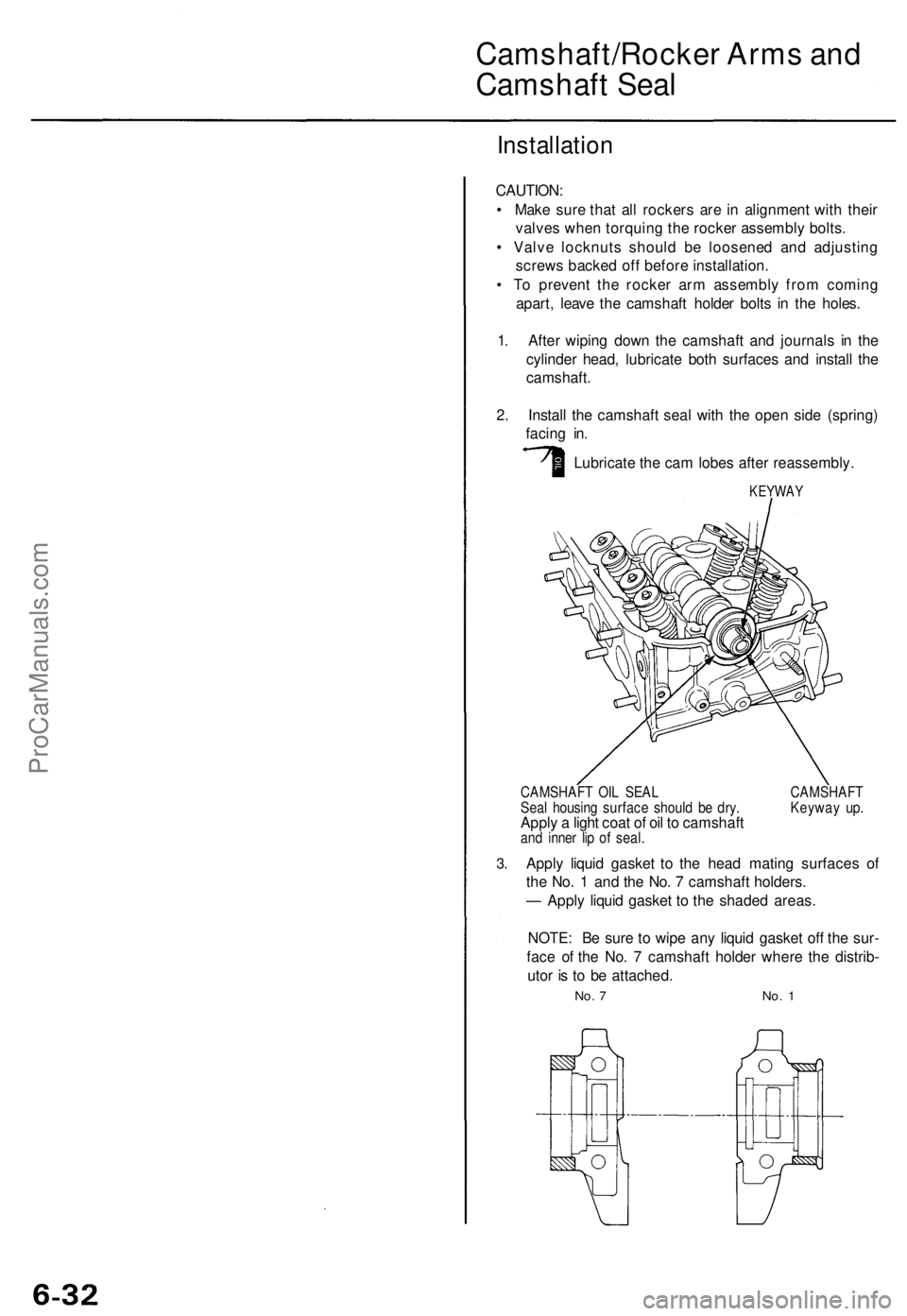

Installation

CAUTION:

• Make sure that all rockers are in alignment with their

valves when torquing the rocker assembly bolts.

• Valve locknuts should be loosened and adjusting

screws backed off before installation.

• To prevent the rocker arm assembly from coming

apart, leave the camshaft holder bolts in the holes.

1. After wiping down the camshaft and journals in the

cylinder head, lubricate both surfaces and install the

camshaft.

2. Install the camshaft seal with the open side (spring)

facing in.

Lubricate the cam lobes after reassembly.

KEYWAY

3.

CAMSHAFT OIL SEAL CAMSHAFT

Seal housing surface should be dry. Keyway up.

Apply a light coat of oil to camshaft

and inner lip of seal.

Apply liquid gasket to the head mating surfaces of

the No. 1 and the No. 7 camshaft holders.

— Apply liquid gasket to the shaded areas.

NOTE: Be sure to wipe any liquid gasket off the sur-

face of the No. 7 camshaft holder where the distrib-

utor is to be attached.

No. 7 No. 1ProCarManuals.com