ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 771 of 1771

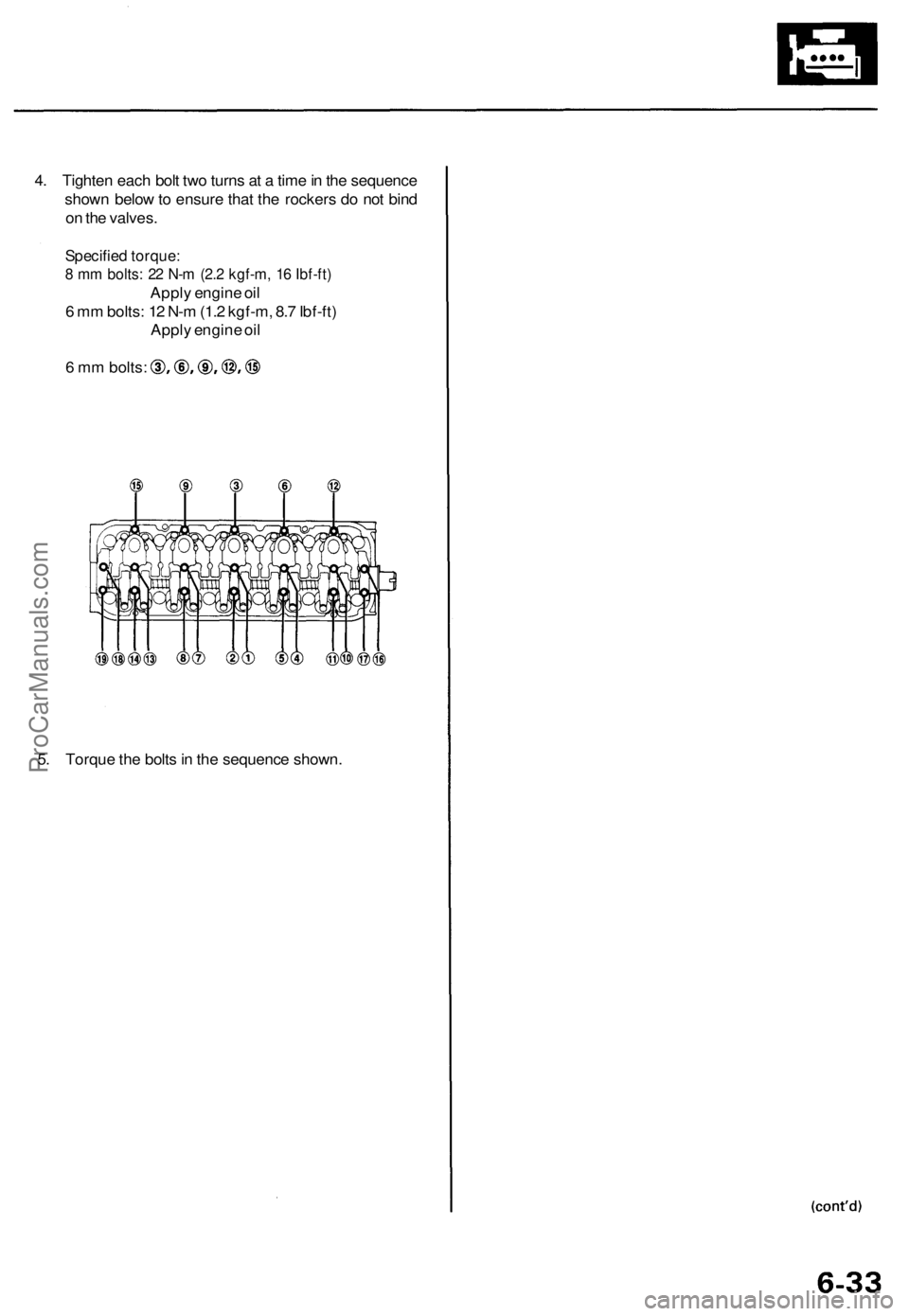

4. Tighten each bolt two turns at a time in the sequence

shown below to ensure that the rockers do not bind

on the valves.

Specified torque:

8 mm bolts: 22 N-m (2.2 kgf-m, 16 Ibf-ft)

Apply engine oil

6 mm bolts: 12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

Apply engine oil

6 mm bolts:

5. Torque the bolts in the sequence shown.ProCarManuals.com

Page 772 of 1771

Cylinder Hea d

Installatio n

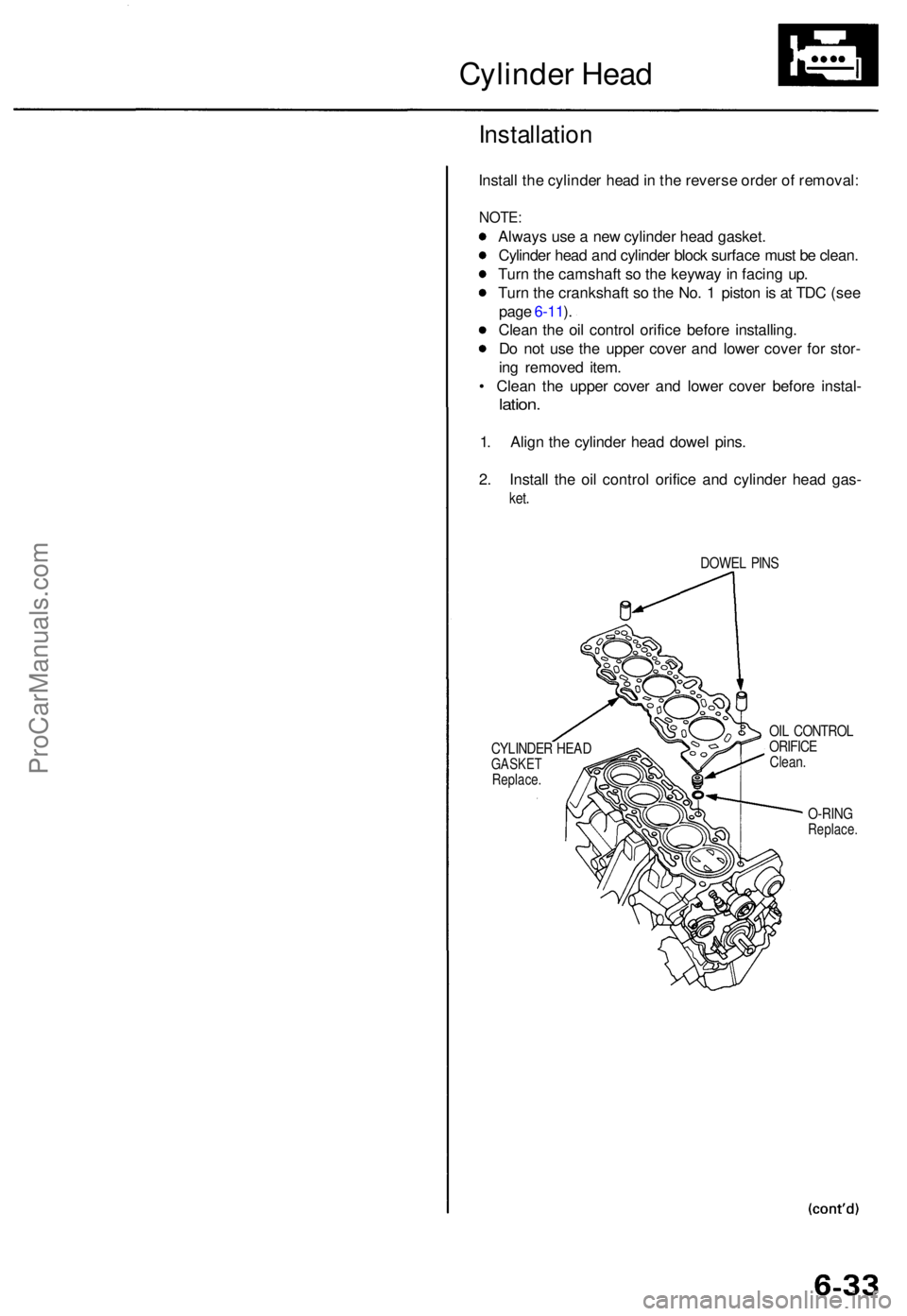

Install th e cylinde r hea d in th e revers e orde r o f removal :

NOTE:

Alway s us e a ne w cylinde r hea d gasket .

Cylinde r hea d an d cylinde r bloc k surfac e mus t b e clean .

Tur n th e camshaf t s o th e keywa y i n facin g up .

Tur n th e crankshaft so th e No . 1 pisto n is a t TD C (se e

pag e 6-11 ).

Clea n th e oi l contro l orific e befor e installing .

D o no t us e th e uppe r cove r an d lowe r cove r fo r stor -

in g remove d item .

• Clea n th e uppe r cove r an d lowe r cove r befor e instal -

lation.

1. Alig n th e cylinde r hea d dowe l pins .

2 . Instal l th e oi l contro l orific e an d cylinde r hea d gas -

ket.

DOWE L PIN S

CYLINDE R HEA D

GASKE TReplace .

OIL CONTRO L

ORIFIC E

Clean .

O-RIN GReplace .

ProCarManuals.com

Page 773 of 1771

Cylinder Hea d

Installatio n (cont'd )

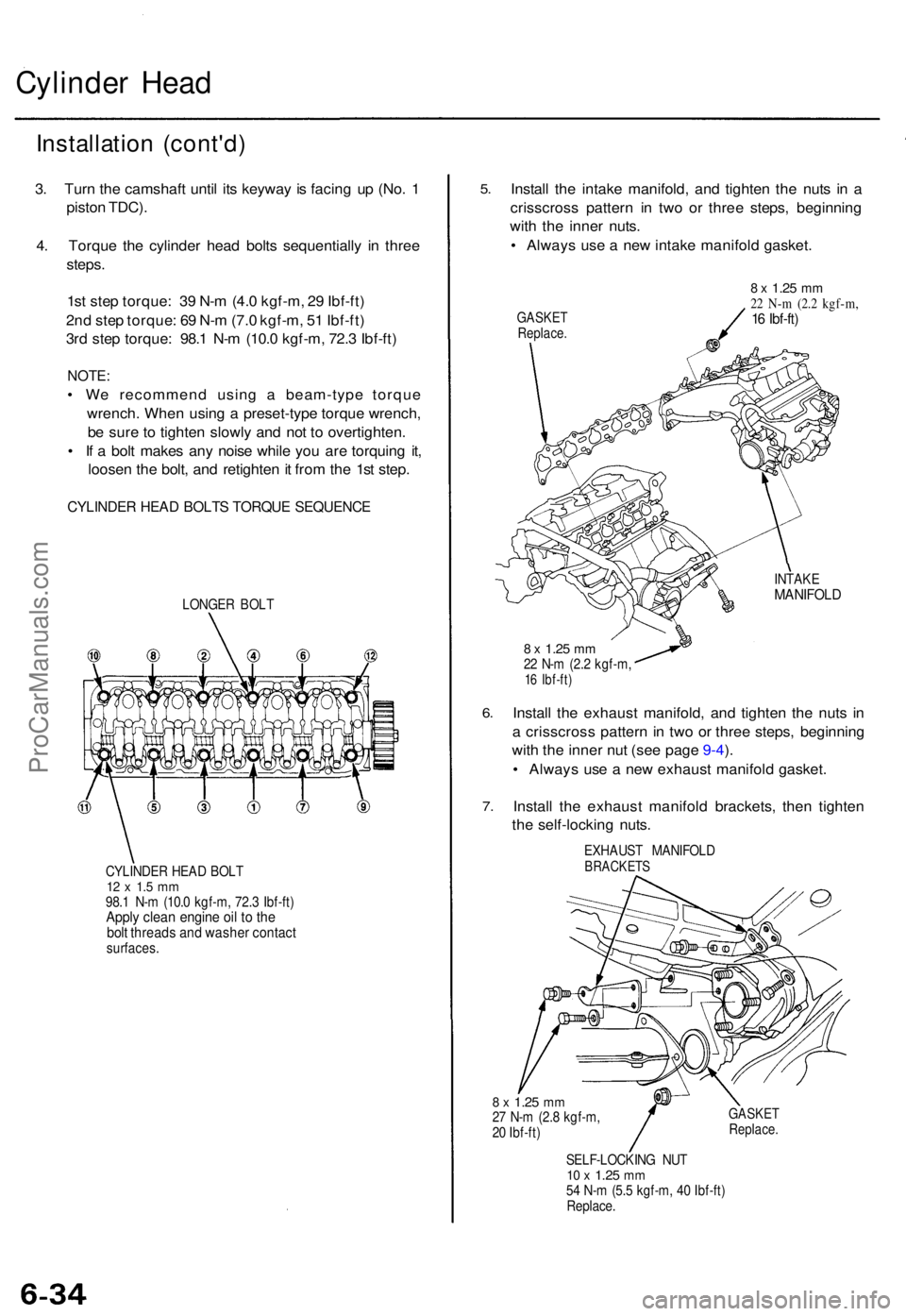

3. Tur n th e camshaf t unti l it s keywa y i s facin g u p (No . 1

pisto n TDC) .

4 . Torqu e th e cylinde r hea d bolt s sequentiall y i n thre e

steps .

1s t ste p torque : 3 9 N- m (4. 0 kgf-m , 2 9 Ibf-ft )

2n d ste p torque : 6 9 N- m (7. 0 kgf-m , 5 1 Ibf-ft )

3r d ste p torque : 98. 1 N- m (10. 0 kgf-m , 72. 3 Ibf-ft )

NOTE :

• W e recommen d usin g a beam-typ e torqu e

wrench . Whe n usin g a preset-typ e torqu e wrench ,

b e sur e t o tighte n slowl y an d no t t o overtighten .

• I f a bol t make s an y nois e whil e yo u ar e torquin g it ,

loose n th e bolt , an d retighte n it fro m th e 1s t step .

CYLINDE R HEA D BOLT S TORQU E SEQUENC E

LONGER BOL T

CYLINDE R HEA D BOL T

12 x 1. 5 m m98. 1 N- m (10. 0 kgf-m , 72. 3 Ibf-ft )Apply clea n engin e oi l t o th ebol t thread s an d washe r contac tsurfaces .

5.

6.

7 .

Instal l th e intak e manifold , an d tighte n th e nut s i n a

crisscros s patter n i n tw o o r thre e steps , beginnin g

wit h th e inne r nuts .

• Alway s us e a ne w intak e manifol d gasket .

GASKE TReplace .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,16 Ibf-ft )

INTAK EMANIFOL D

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,16 Ibf-ft )

Install th e exhaus t manifold , an d tighte n th e nut s i n

a crisscros s patter n in tw o o r thre e steps , beginnin g

wit h th e inne r nu t (se e pag e 9-4 ).

• Alway s us e a ne w exhaus t manifol d gasket .

Instal l th e exhaus t manifol d brackets , the n tighte n

th e self-lockin g nuts .

EXHAUS T MANIFOL DBRACKETS

8 x 1.2 5 mm27 N- m (2. 8 kgf-m ,

2 0 Ibf-ft )GASKE TReplace .

SELF-LOCKIN G NU T10 x 1.2 5 mm54 N- m (5. 5 kgf-m , 4 0 Ibf-ft )

Replace .

ProCarManuals.com

Page 774 of 1771

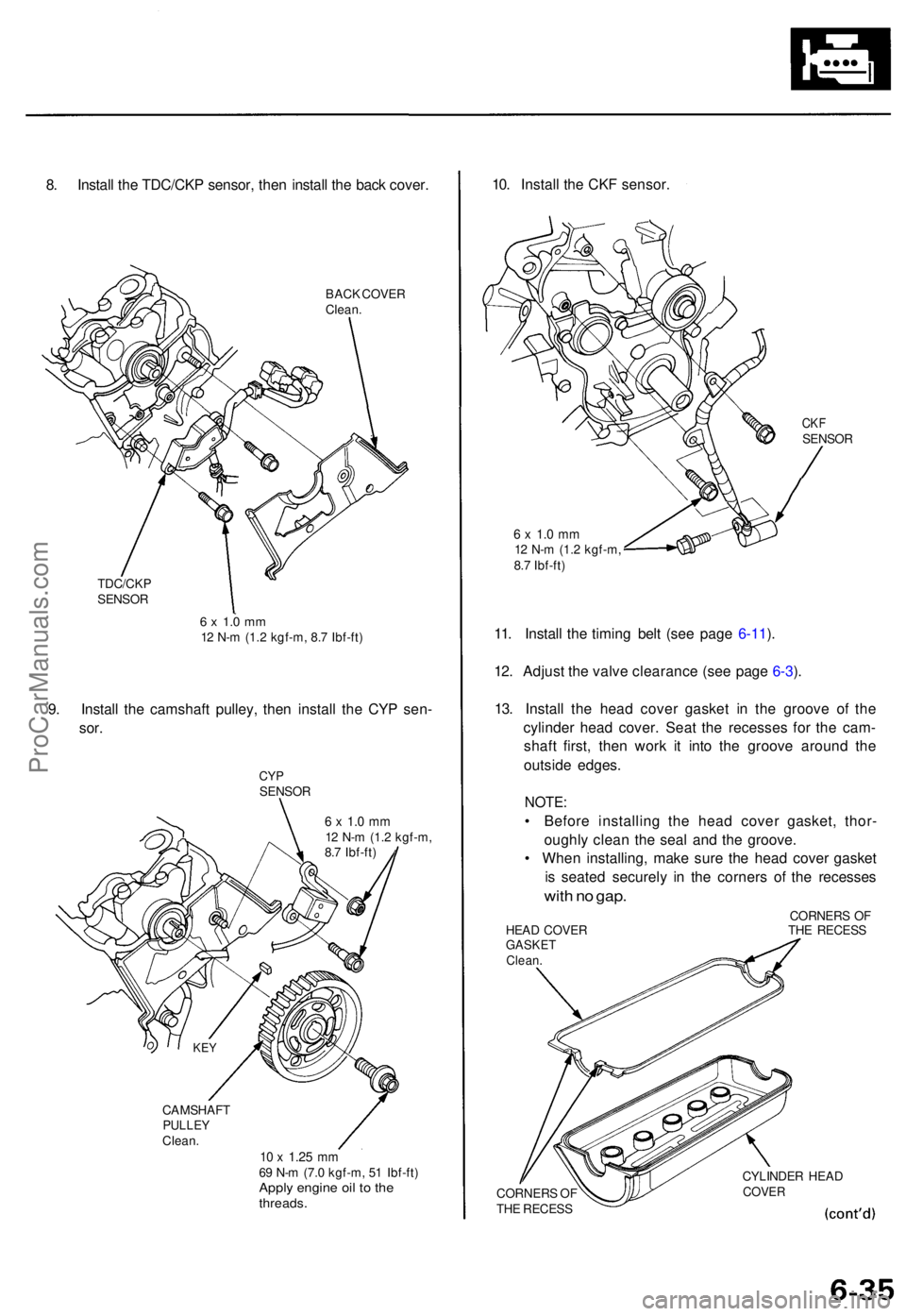

8. Instal l th e TDC/CK P sensor , the n instal l th e bac k cover .

BACK COVE R

Clean .

TDC/CK P

SENSO R

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

9. Instal l th e camshaf t pulley , the n instal l th e CY P sen -

sor.

CY PSENSO R

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

CAMSHAF T

PULLEYClean.10 x 1.2 5 mm69 N- m (7. 0 kgf-m , 5 1 Ibf-ft )Apply engin e oi l t o th ethreads .

10. Instal l th e CK F sensor .

CKFSENSO R

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

11. Instal l th e timin g bel t (se e pag e 6-11 ).

12 . Adjus t th e valv e clearanc e (se e pag e 6-3 ).

13 . Instal l th e hea d cove r gaske t i n th e groov e o f th e

cylinde r hea d cover . Sea t th e recesse s fo r th e cam -

shaf t first , the n wor k i t int o th e groov e aroun d th e

outsid e edges .

NOTE:

• Befor e installin g th e hea d cove r gasket , thor -

oughl y clea n th e sea l an d th e groove .

• Whe n installing , mak e sur e th e hea d cove r gaske t

i s seate d securel y i n th e corner s o f th e recesse s

with n o gap .

CORNER S O F

HEA D COVE R TH E RECES S

GASKETClean.

CORNER S O F

TH E RECES S CYLINDE

R HEA DCOVE R

KEY

ProCarManuals.com

Page 775 of 1771

Cylinder Head

Installation (cont'd)

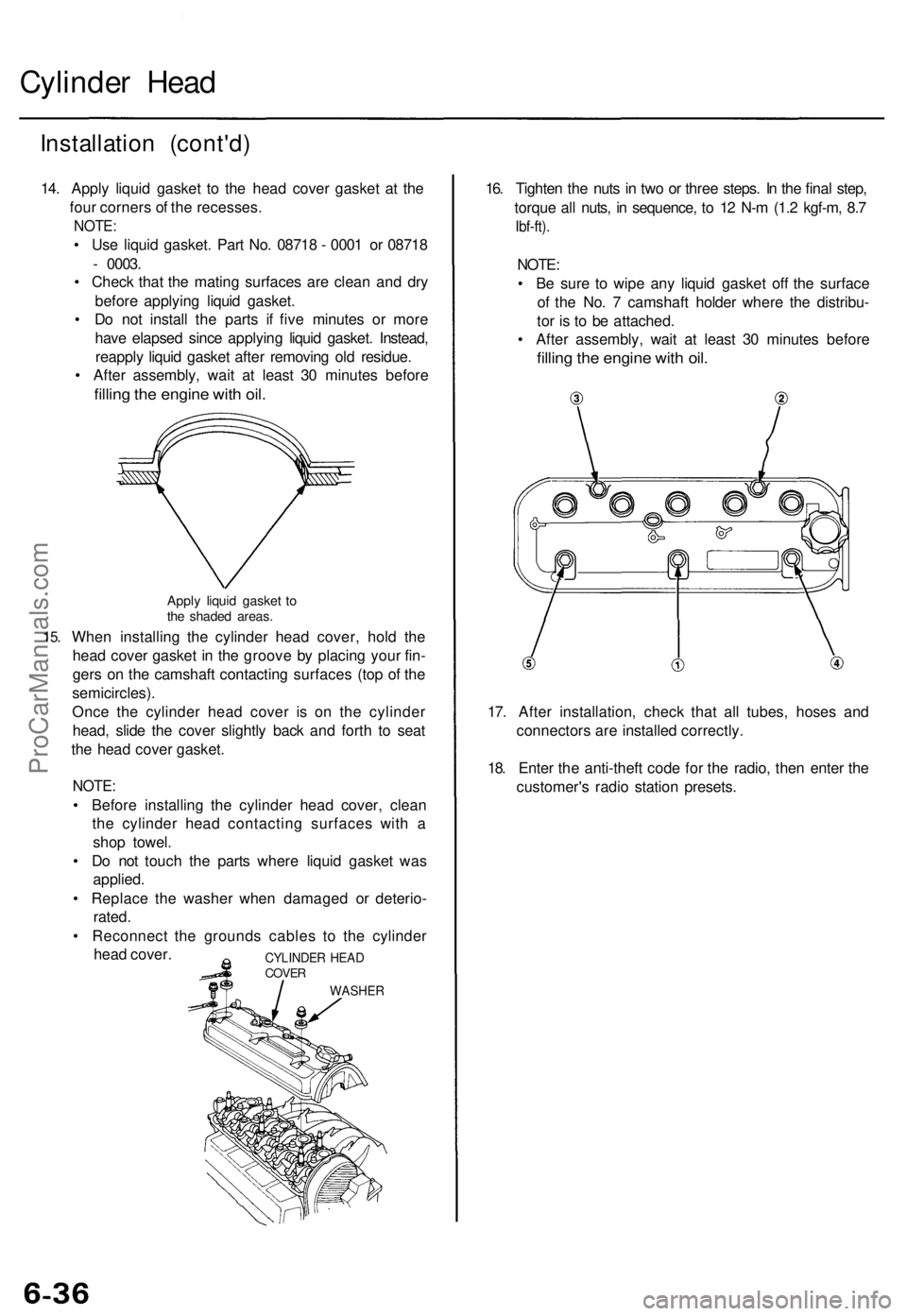

14. Apply liquid gasket to the head cover gasket at the

four corners of the recesses.

NOTE:

• Use liquid gasket. Part No. 08718 - 0001 or 08718

- 0003.

• Check that the mating surfaces are clean and dry

before applying liquid gasket.

• Do not install the parts if five minutes or more

have elapsed since applying liquid gasket. Instead,

reapply liquid gasket after removing old residue.

• After assembly, wait at least 30 minutes before

filling the engine with oil.

15.

Apply liquid gasket to

the shaded areas.

When installing the cylinder head cover, hold the

head cover gasket in the groove by placing your fin-

gers on the camshaft contacting surfaces (top of the

semicircles).

Once the cylinder head cover is on the cylinder

head, slide the cover slightly back and forth to seat

the head cover gasket.

NOTE:

• Before installing the cylinder head cover, clean

the cylinder head contacting surfaces with a

shop towel.

• Do not touch the parts where liquid gasket was

applied.

• Replace the washer when damaged or deterio-

rated.

• Reconnect the grounds cables to the cylinder

head cover.

16. Tighten the nuts in two or three steps. In the final step,

torque all nuts, in sequence, to 12 N-m (1.2 kgf-m, 8.7

Ibf-ft).

NOTE:

• Be sure to wipe any liquid gasket off the surface

of the No. 7 camshaft holder where the distribu-

tor is to be attached.

• After assembly, wait at least 30 minutes before

filling the engine with oil.

17. After installation, check that all tubes, hoses and

connectors are installed correctly.

18. Enter the anti-theft code for the radio, then enter the

customer's radio station presets.

CYLINDER HEAD

COVER

WASHERProCarManuals.com

Page 776 of 1771

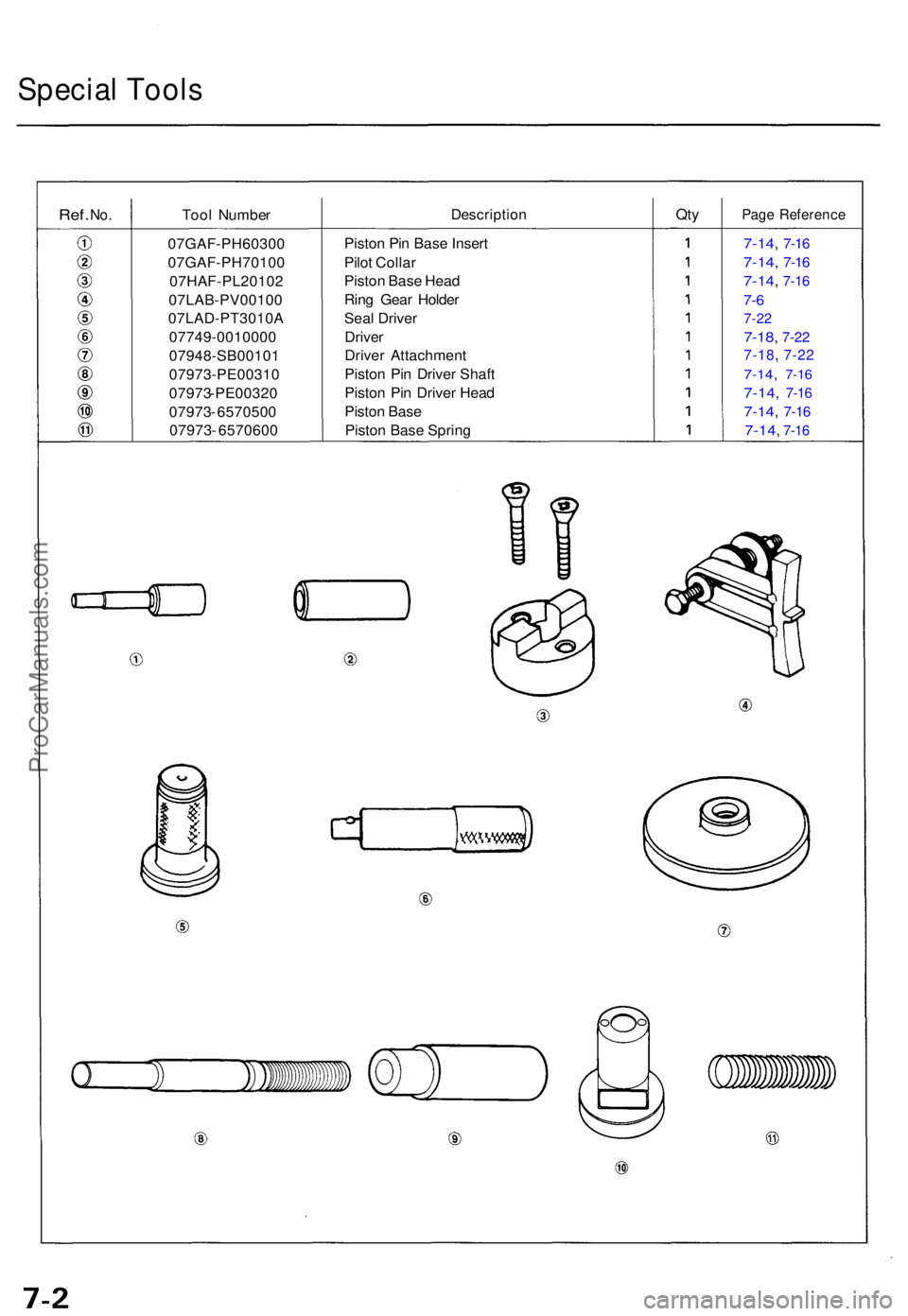

Special Tool s

Ref. No.Too l Numbe rDescriptio nQtyPag e Referenc e

Piston Pi n Bas e Inser t

Pilo t Colla r

Pisto n Bas e Hea d

Rin g Gea r Holde r

Sea l Drive r

Drive r

Drive r Attachmen t

Pisto n Pi n Drive r Shaf t

Pisto n Pi n Drive r Hea d

Pisto n Bas e

Pisto n Bas e Sprin g7-14, 7-1 6

7-14 , 7-1 6

7-14 , 7-1 6

7-6

7-2 2

7-18 , 7-2 2

7-18 , 7-2 2

7-14 , 7-1 6

7-14 , 7-1 6

7-14 , 7-1 6

7-14 , 7-1 6

07GAF -PH60300

07GAF-PH70100 07HAF-PL20102

07LAB-PV00100

07LAD-PT3010A

07749-0010000

07948-SB00101

07973-PE00310

07973 - PE00320

07973 - 6570500

07973 - 6570600

ProCarManuals.com

Page 777 of 1771

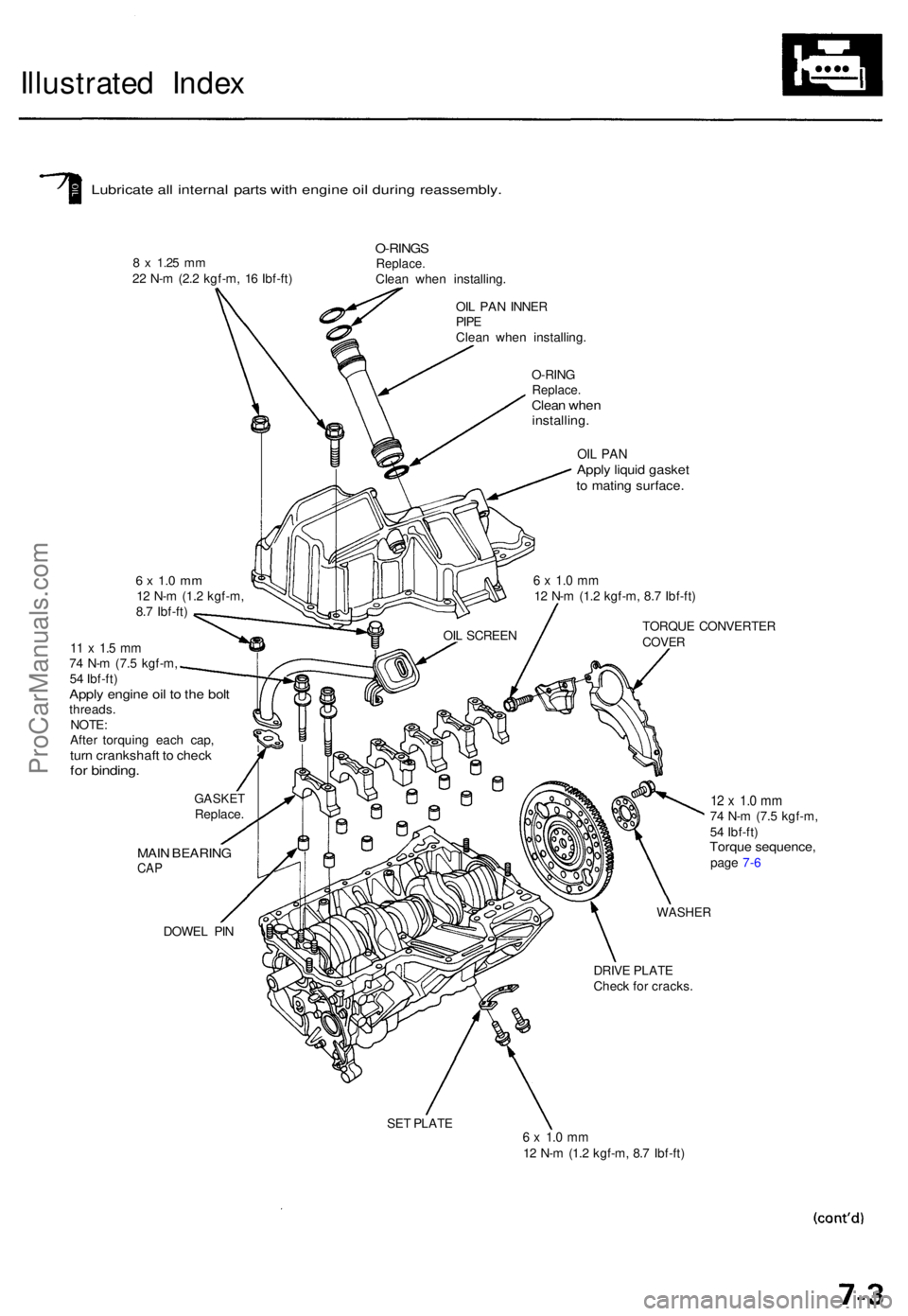

Illustrated Inde x

Lubricat e al l interna l part s wit h engin e oi l durin g reassembly .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

O-RING SReplace .Clean whe n installing .

OI L PA N INNE R

PIPEClea n whe n installing .

O-RIN G

Replace .Clean whe ninstalling .

DOWEL PI N

OIL PA NAppl y liqui d gaske tto matin g surface .

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

TORQU E CONVERTE R

COVER

12 x 1. 0 m m74 N- m (7. 5 kgf-m ,

5 4 Ibf-ft )

Torqu e sequence ,page 7- 6

WASHE R

DRIVE PLAT E

Chec k fo r cracks .

SE T PLAT E

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

11 x 1. 5 m m74 N- m (7. 5 kgf-m ,

5 4 Ibf-ft )

Apply engin e oi l t o th e bol tthreads .

NOTE :

Afte r torquin g eac h cap ,

turn crankshaf t t o chec kfor binding .

GASKE TReplace .

MAIN BEARIN GCAP

OIL SCREE N

ProCarManuals.com

Page 778 of 1771

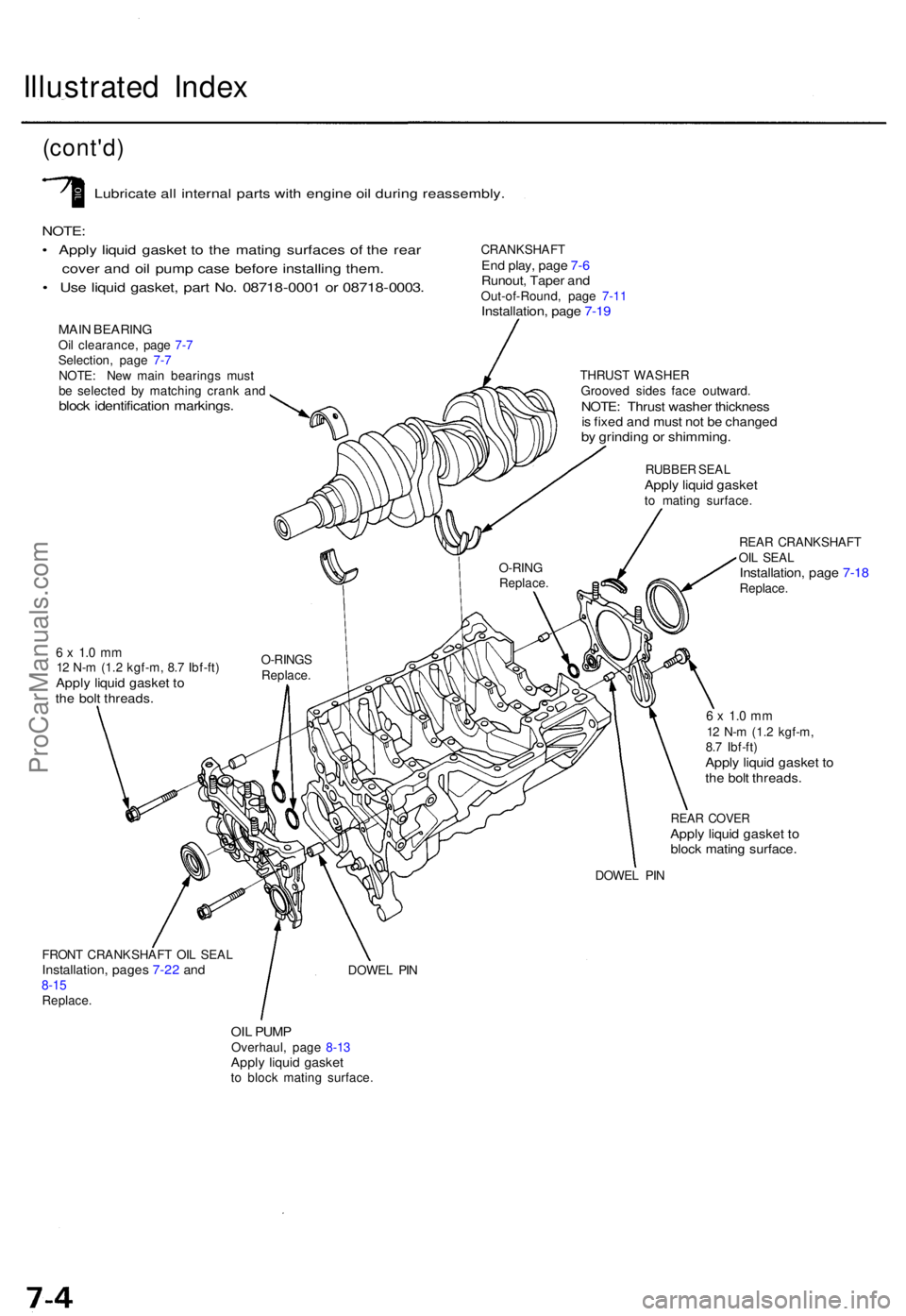

Illustrated Inde x

(cont'd )

Lubricat e al l interna l part s wit h engin e oi l durin g reassembly .

NOTE:

• Appl y liqui d gaske t t o th e matin g surface s o f th e rea r

cove r an d oi l pum p cas e befor e installin g them .

• Us e liqui d gasket , par t No . 0871 8-000 1 o r 0871 8-0003 .

MAIN BEARIN GOil clearance , pag e 7- 7

Selection , pag e 7- 7

NOTE : Ne w mai n bearing s mus t

b e selecte d b y matchin g cran k an d

bloc k identificatio n markings .

CRANKSHAF TEnd play , pag e 7- 6Runout , Tape r an dOut-of-Round , pag e 7-1 1Installation , pag e 7-1 9

THRUS T WASHE R

Groove d side s fac e outward .

NOTE: Thrus t washe r thicknes sis fixe d an d mus t no t b e change dby grindin g o r shimming .

RUBBER SEA LApply liqui d gaske tto matin g surface .

REA R CRANKSHAF T

OI L SEA L

Installation , pag e 7-1 8Replace .

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )Apply liqui d gaske t t oth e bol t threads .

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

Apply liqui d gaske t t oth e bol t threads .

REAR COVE RApply liqui d gaske t t obloc k matin g surface .

DOWEL PI N

FRON T CRANKSHAF T OI L SEA L

Installation , page s 7-2 2 an d8-1 5Replace .

DOWEL PI N

OIL PUM POverhaul , pag e 8-1 3Appl y liqui d gaske tto bloc k matin g surface . O-RIN

G

Replace .

O-RINGS

Replace .

ProCarManuals.com

Page 779 of 1771

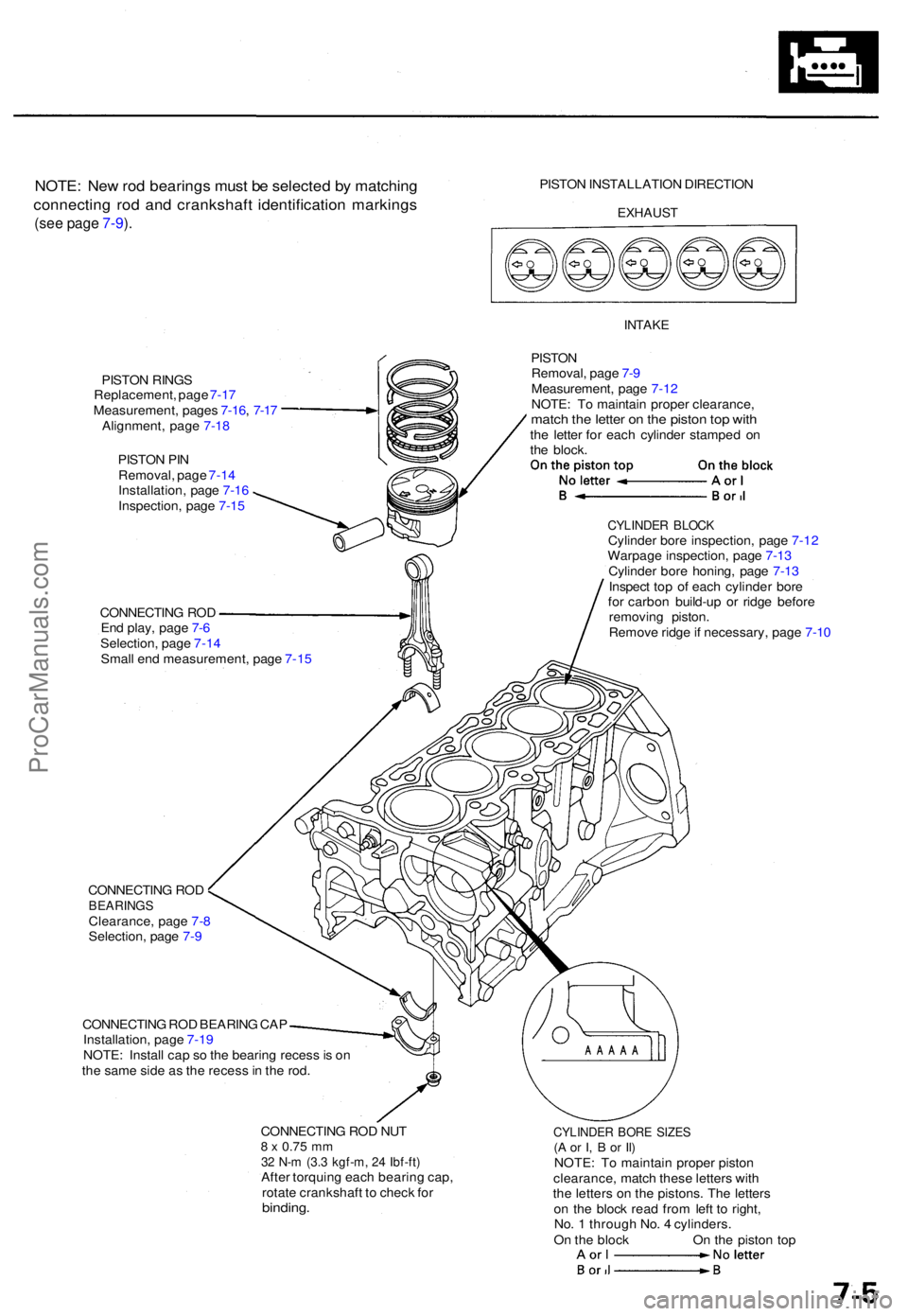

NOTE: Ne w ro d bearing s mus t b e selecte d b y matchin g

connectin g ro d an d crankshaf t identificatio n marking s

(see pag e 7-9 ).

PISTO N INSTALLATIO N DIRECTIO N

EXHAUST

PISTON RING S

Replacement , pag e 7-1 7

Measurement , page s 7-16 , 7-1 7

Alignment , pag e 7-1 8

PISTO N PI N

Removal , pag e 7-1 4

Installation , pag e 7-1 6

Inspection , pag e 7-1 5

INTAK E

PISTON

Removal , pag e 7- 9

Measurement , pag e 7-1 2

NOTE : T o maintai n prope r clearance ,

match th e lette r o n th e pisto n to p wit hthe lette r fo r eac h cylinde r stampe d o n

th e block .

CONNECTIN G RO D

En d play , pag e 7- 6

Selection , pag e 7-1 4

Smal l en d measurement , pag e 7-1 5

CYLINDE R BLOC KCylinde r bor e inspection , pag e 7-1 2

Warpag e inspection , pag e 7-1 3

Cylinde r bor e honing , pag e 7-1 3

Inspec t to p o f eac h cylinde r bor e

fo r carbo n build-u p o r ridg e befor e

removin g piston .

Remov e ridg e if necessary , pag e 7-1 0

CONNECTIN G RO D

BEARING SClearance , pag e 7- 8

Selection , pag e 7-9

CONNECTIN G RO D BEARIN G CA P

Installation , pag e 7-1 9

NOTE : Instal l ca p s o th e bearin g reces s is o n

th e sam e sid e a s th e reces s in th e rod .

CONNECTIN G RO D NU T

8 x 0.7 5 mm32 N- m (3. 3 kgf-m , 2 4 Ibf-ft )After torquin g eac h bearin g cap ,

rotat e crankshaf t t o chec k fo r

binding .

CYLINDE R BOR E SIZE S(A o r I , B or Il )NOTE : T o maintai n prope r pisto n

clearance , matc h thes e letter s wit h

th e letter s o n th e pistons . Th e letter s

o n th e bloc k rea d fro m lef t t o right ,

No . 1 throug h No . 4 cylinders .

O n th e bloc k O n th e pisto n to p

ProCarManuals.com

Page 780 of 1771

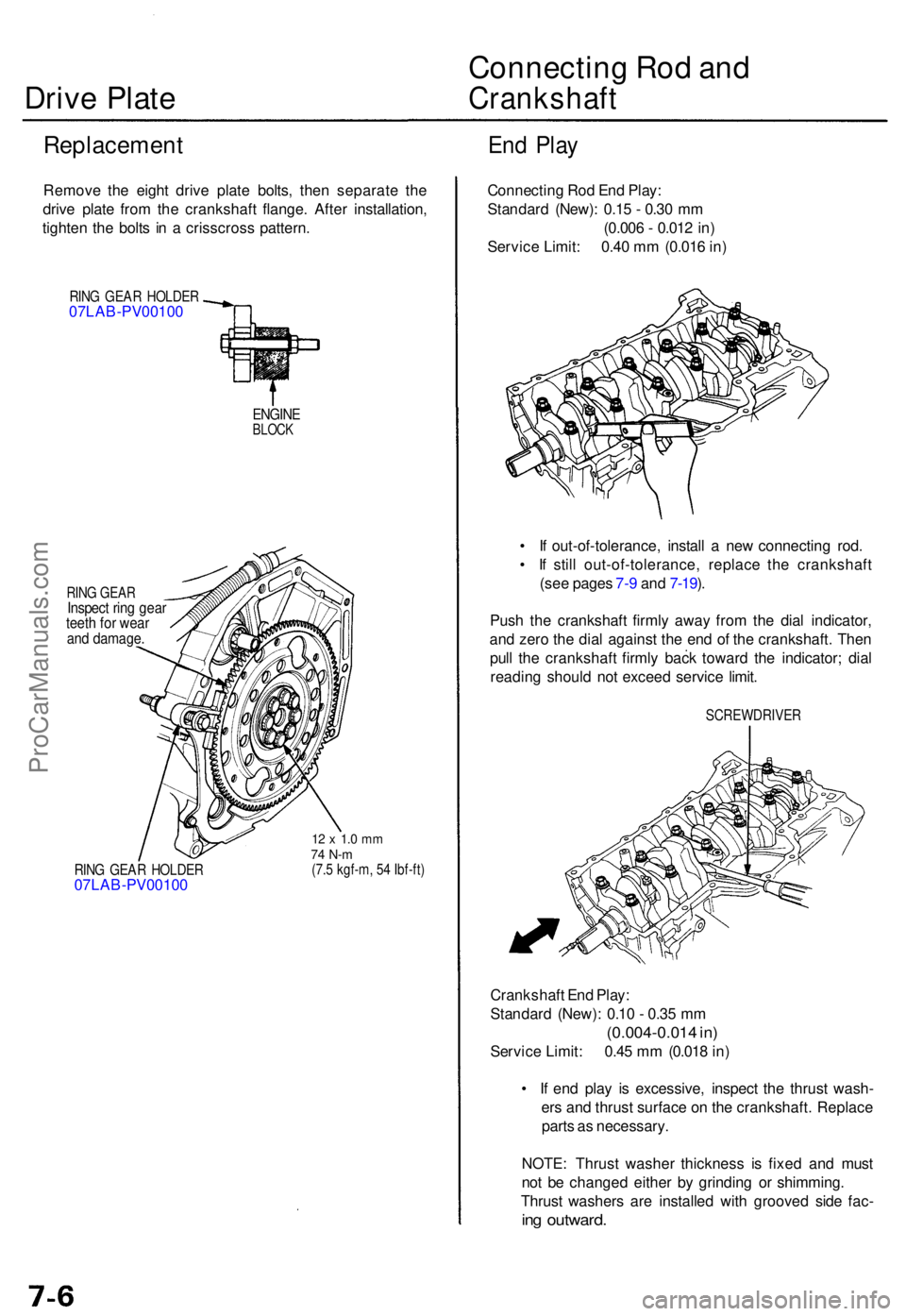

Drive Plat e Connectin

g Ro d an dCrankshaf t

Replacemen tEnd Pla y

Remov e th e eigh t driv e plat e bolts , the n separat e th e

driv e plat e fro m th e crankshaf t flange . Afte r installation ,

tighte n th e bolt s i n a crisscros s pattern .

RING GEA R HOLDE R07LAB-PV00100

ENGINEBLOCK

RING GEA RInspec t rin g gea rteeth fo r wea rand damage .

RING GEA R HOLDE R07LAB-PV0010 0

12 x 1. 0 m m74 N- m(7.5 kgf-m , 5 4 Ibf-ft )

Connectin g Ro d En d Play :

Standar d (New) : 0.1 5 - 0.3 0 m m

(0.00 6 - 0.01 2 in )

Servic e Limit : 0.4 0 m m (0.01 6 in )

• I f out-of-tolerance , instal l a ne w connectin g rod .

• I f stil l out-of-tolerance , replac e th e crankshaf t

(se e page s 7- 9 an d 7-19 ).

Pus h th e crankshaf t firml y awa y fro m th e dia l indicator ,

an d zer o th e dia l agains t th e en d o f th e crankshaft . The n

pul l th e crankshaf t firml y bac k towar d th e indicator ; dia l

readin g shoul d no t excee d servic e limit .

SCREWDRIVE R

Crankshaft En d Play :

Standar d (New) : 0.1 0 - 0.3 5 m m

(0.004-0.01 4 in )

Servic e Limit : 0.4 5 m m (0.01 8 in )

• I f en d pla y i s excessive , inspec t th e thrus t wash -

er s an d thrus t surfac e o n th e crankshaft . Replac e

part s a s necessary .

NOTE : Thrus t washe r thicknes s i s fixe d an d mus t

no t b e change d eithe r b y grindin g o r shimming .

Thrus t washer s ar e installe d wit h groove d sid e fac -

ing outward .

ProCarManuals.com