ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 741 of 1771

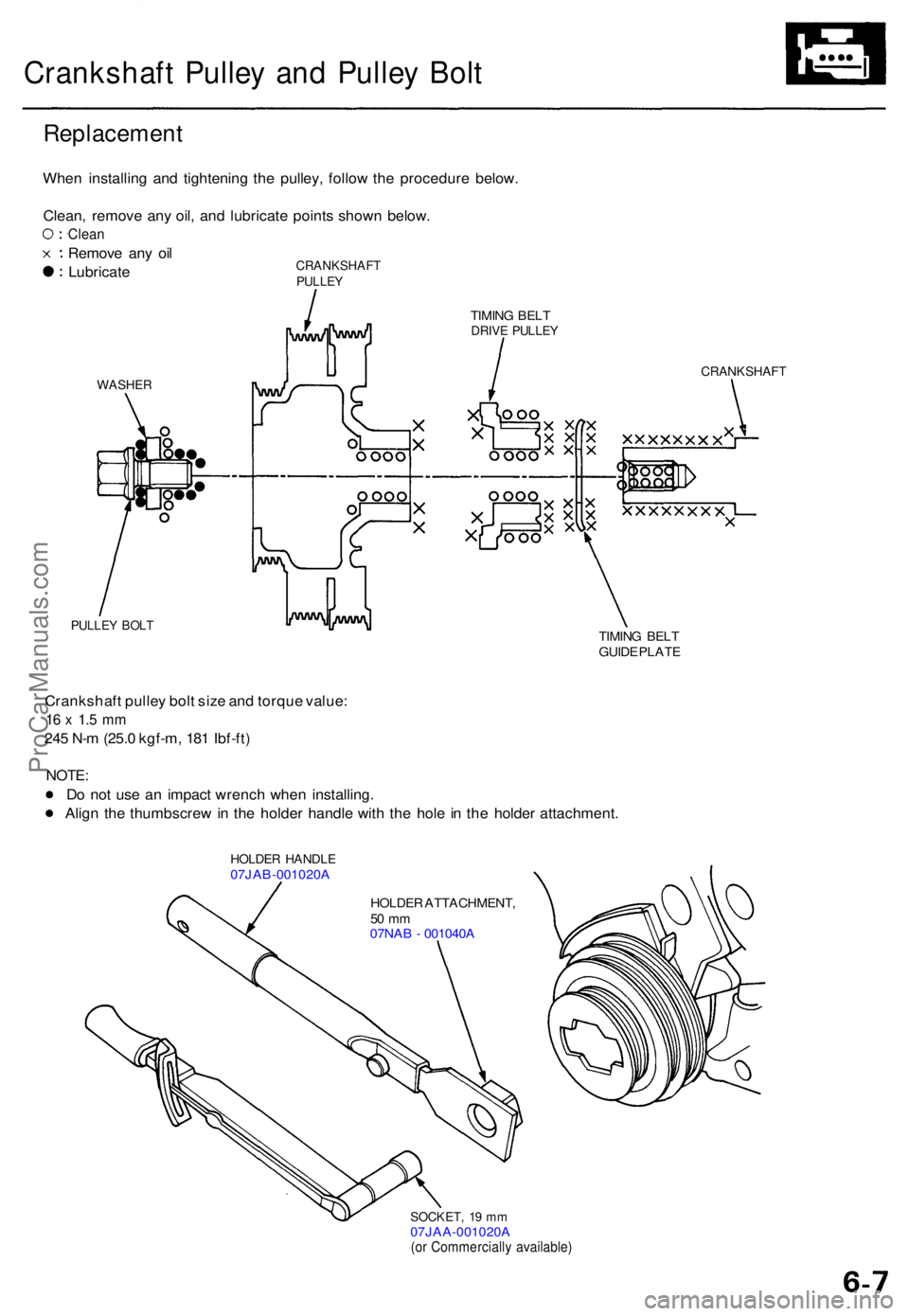

Crankshaft Pulle y an d Pulle y Bol t

Replacemen t

When installin g an d tightenin g th e pulley , follo w th e procedur e below .

Clean , remov e an y oil , an d lubricat e point s show n below .

Clean

Remov e an y oi l

Lubricat eCRANKSHAF TPULLEY

WASHE R

PULLEY BOL T

TIMIN G BEL TDRIV E PULLE Y

CRANKSHAF T

TIMING BEL T

GUID E PLAT E

Crankshaf t pulle y bol t siz e an d torqu e value :

16 x 1. 5 m m

245 N- m (25. 0 kgf-m , 18 1 Ibf-ft )

NOTE :

Do no t us e a n impac t wrenc h whe n installing .

Alig n th e thumbscre w in th e holde r handl e wit h th e hol e in th e holde r attachment .

HOLDER HANDL E07JAB-001020 A

HOLDER ATTACHMENT ,

50 m m07NA B - 001040 A

SOCKET , 1 9 m m07JAA-001020 A(or Commerciall y available )

ProCarManuals.com

Page 742 of 1771

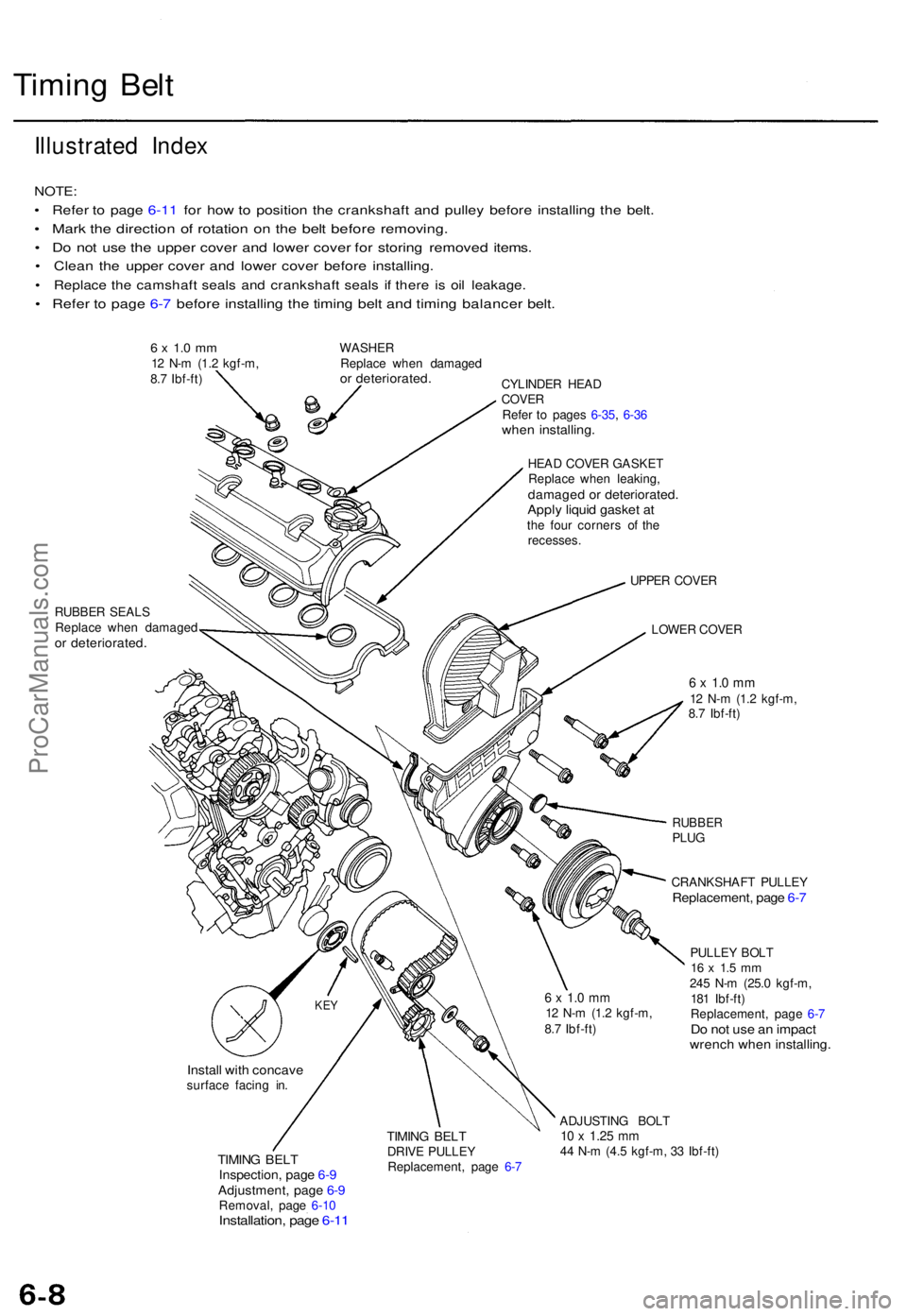

Timing Bel t

Illustrate d Inde x

NOTE :

• Refe r t o pag e 6-1 1 fo r ho w to positio n th e crankshaf t an d pulle y befor e installin g th e belt .

• Mar k th e directio n o f rotatio n o n th e bel t befor e removing .

• D o no t us e th e uppe r cove r an d lowe r cove r fo r storin g remove d items .

• Clea n th e uppe r cove r an d lowe r cove r befor e installing .

• Replac e th e camshaf t seal s an d crankshaf t seal s i f ther e i s oi l leakage .

• Refe r t o pag e 6- 7 befor e installin g th e timin g bel t an d timin g balance r belt .

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft ) WASHE

R

Replac e whe n damage dor deteriorated .CYLINDER HEA DCOVE RRefer t o page s 6-35 , 6-3 6whe n installing .

HEAD COVE R GASKE T

Replac e whe n leaking ,

damage d o r deteriorated .Apply liqui d gaske t a tth e fou r corner s o f th e

recesses .

RUBBE R SEAL S

Replac e whe n damage d

or deteriorated .

UPPER COVE R

LOWE R COVE R

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

RUBBE RPLUG

CRANKSHAF T PULLE Y

Replacement , pag e 6- 7

PULLE Y BOL T16 x 1. 5 m m245 N- m (25. 0 kgf-m ,

18 1 Ibf-ft )

Replacement , pag e 6- 7

Do no t us e a n impac twrench whe n installing .

Install wit h concav esurface facin g in .

TIMIN G BEL TInspection , pag e 6- 9Adjustment , pag e 6- 9Removal , pag e 6-1 0Installation , pag e 6-1 1

TIMIN G BEL TDRIV E PULLE Y

Replacement , pag e 6- 7 ADJUSTIN

G BOL T10 x 1.2 5 mm44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

KEY6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

ProCarManuals.com

Page 743 of 1771

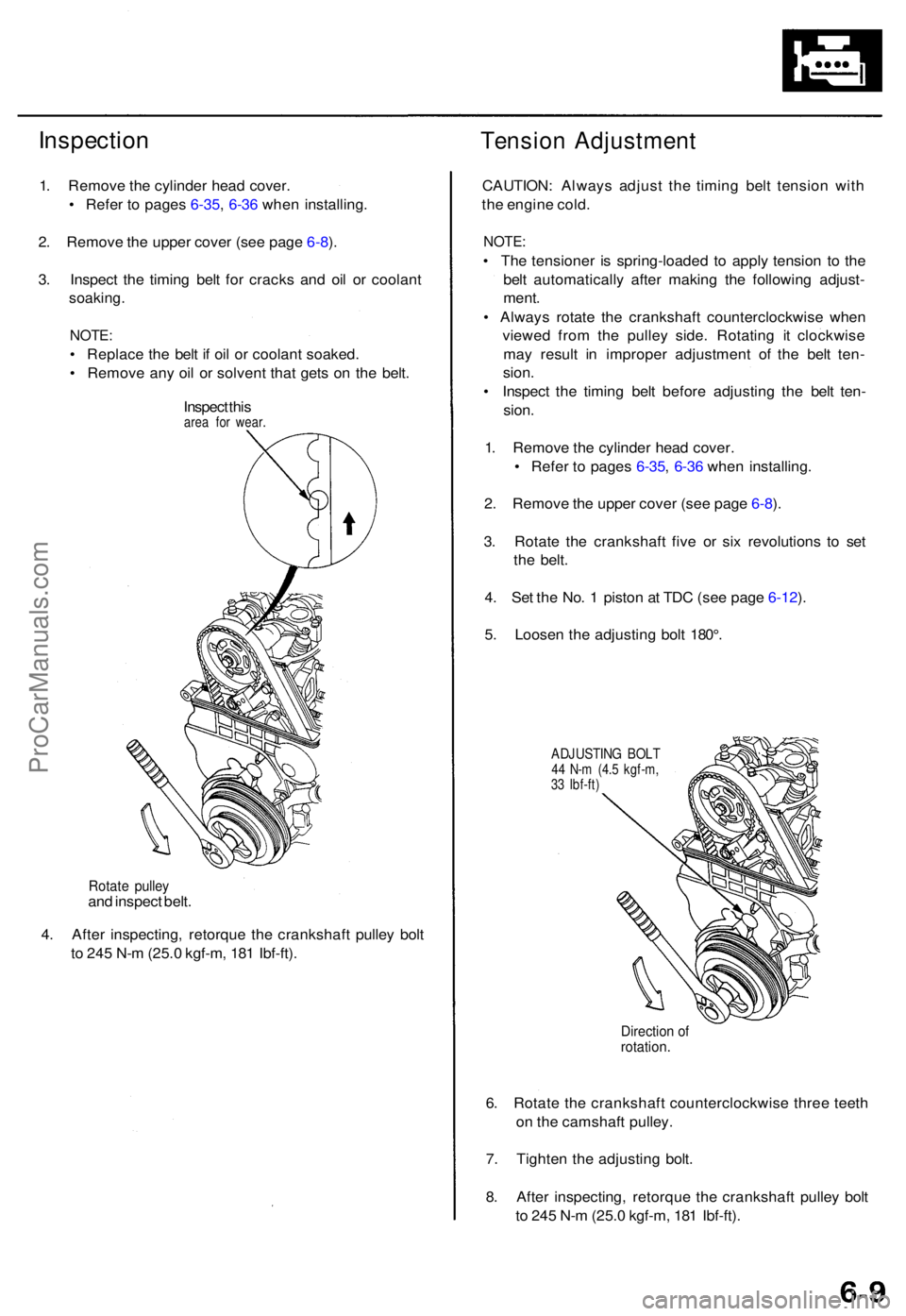

Inspection

1. Remov e th e cylinde r hea d cover .

• Refe r t o page s 6-35 , 6-3 6 whe n installing .

2 . Remov e th e uppe r cove r (se e pag e 6-8 ).

3 . Inspec t th e timin g bel t fo r crack s an d oi l o r coolan t

soaking .

NOTE:

• Replac e th e bel t i f oi l o r coolan t soaked .

• Remov e an y oi l o r solven t tha t get s o n th e belt .

Inspec t thi s

are a fo r wear .

Tensio n Adjustmen t

Rotate pulle yand inspec t belt .

4 . Afte r inspecting , retorqu e th e crankshaf t pulle y bol t

t o 24 5 N- m (25. 0 kgf-m , 18 1 Ibf-ft) . CAUTION

: Alway s adjus t th e timin g bel t tensio n wit h

th e engin e cold .

NOTE :

• Th e tensione r i s spring-loade d t o appl y tensio n t o th e

bel t automaticall y afte r makin g th e followin g adjust -

ment .

• Alway s rotat e th e crankshaf t counterclockwis e whe n

viewe d fro m th e pulle y side . Rotatin g i t clockwis e

ma y resul t i n imprope r adjustmen t of the bel t ten -

sion .

• Inspec t th e timin g bel t befor e adjustin g th e bel t ten -

sion .

1 . Remov e th e cylinde r hea d cover .

• Refe r t o page s 6-35 , 6-3 6 whe n installing .

2 . Remov e th e uppe r cove r (se e pag e 6-8 ).

3 . Rotat e th e crankshaf t fiv e o r si x revolution s t o se t

th e belt .

4 . Se t th e No . 1 pisto n a t TD C (se e pag e 6-12 ).

5 . Loose n th e adjustin g bol t 180° .

ADJUSTIN G BOL T44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

Directio n o frotation .

6. Rotat e th e crankshaf t counterclockwis e thre e teet h

o n th e camshaf t pulley .

7 . Tighte n th e adjustin g bolt .

8 . Afte r inspecting , retorqu e th e crankshaf t pulle y bol t

t o 24 5 N- m (25. 0 kgf-m , 18 1 Ibf-ft) .

ProCarManuals.com

Page 744 of 1771

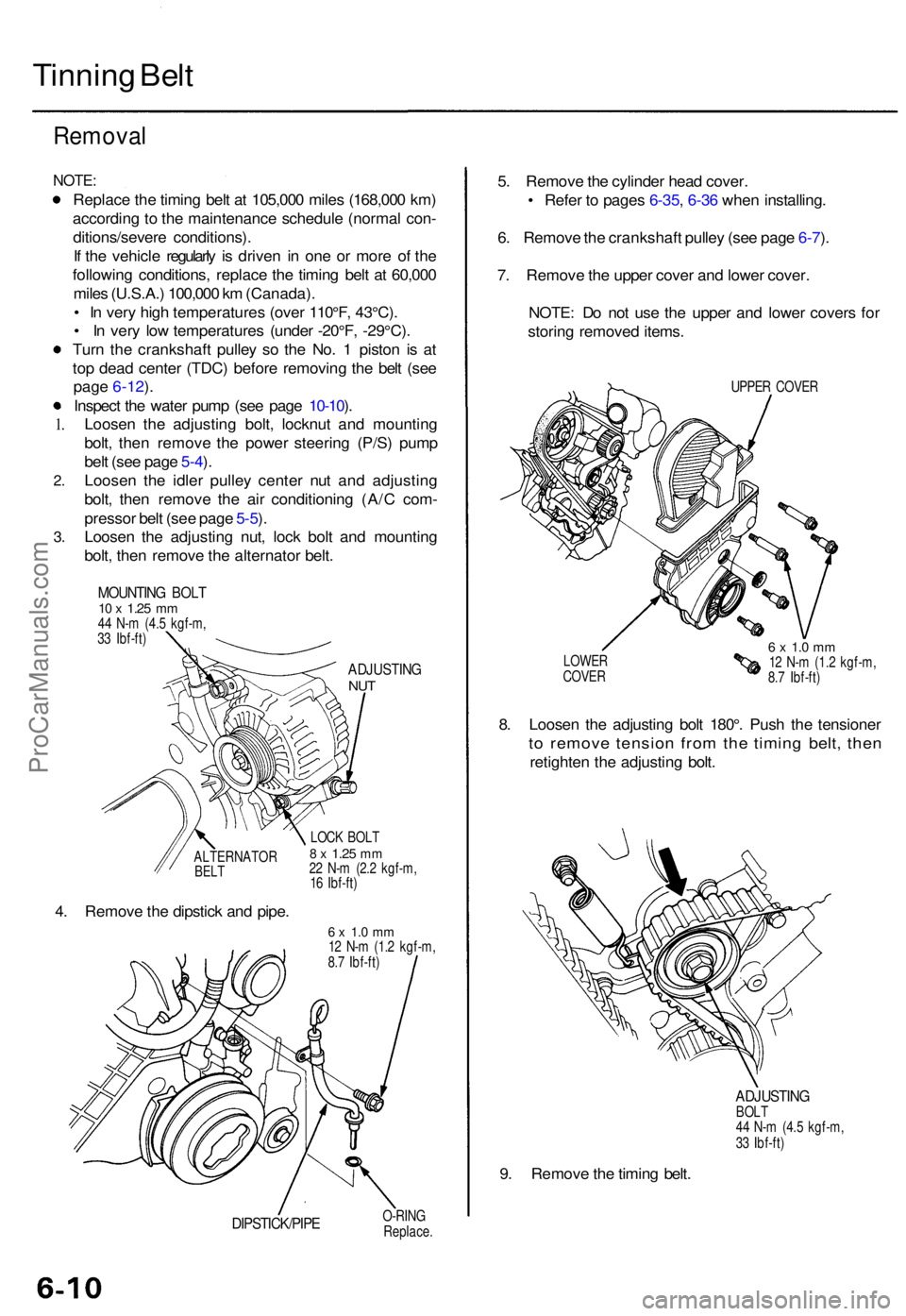

Tinning Bel t

Remova l

NOTE:

2.

3.

Replac e th e timin g bel t a t 105,00 0 mile s (168,00 0 km )

accordin g t o th e maintenanc e schedul e (norma l con -

ditions/sever e conditions) .

I f th e vehicl e regularl y i s drive n i n on e o r mor e o f th e

followin g conditions , replac e th e timin g bel t a t 60,00 0

mile s (U.S.A. ) 100,00 0 k m (Canada) .

• I n ver y hig h temperature s (ove r 110°F , 43°C) .

• I n ver y lo w temperature s (unde r -20°F , -29°C) .

Tur n th e crankshaf t pulle y s o th e No . 1 pisto n i s a t

to p dea d cente r (TDC ) befor e removin g th e bel t (se e

page 6-12).

Inspec t th e wate r pum p (se e pag e 10-10 ).

Loose n th e adjustin g bolt , locknu t an d mountin g

bolt , the n remov e th e powe r steerin g (P/S ) pum p

bel t (se e pag e 5-4 ).

Loose n th e idle r pulle y cente r nu t an d adjustin g

bolt , the n remov e th e ai r conditionin g (A/ C com -

presso r bel t (se e pag e 5-5 ).

Loose n th e adjustin g nut , loc k bol t an d mountin g

bolt , the n remov e th e alternato r belt .

MOUNTIN G BOL T10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

ADJUSTIN GNUT

ALTERNATO RBELT

4. Remov e th e dipstic k an d pipe .

LOCK BOL T8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

DIPSTICK/PIP EO-RINGReplace .

5. Remov e th e cylinde r hea d cover .

• Refe r t o page s 6-35 , 6-3 6 whe n installing .

6 . Remov e th e crankshaf t pulle y (se e pag e 6-7 ).

7 . Remov e th e uppe r cove r an d lowe r cover .

NOTE : D o no t us e th e uppe r an d lowe r cover s fo r

storin g remove d items .

UPPER COVE R

LOWE R

COVE R

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

8. Loose n th e adjustin g bol t 180° . Pus h th e tensione r

to remov e tensio n fro m th e timin g belt , the n

retighte n th e adjustin g bolt .

ADJUSTIN GBOLT

4 4 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

9. Remov e th e timin g belt .

1.

ProCarManuals.com

Page 745 of 1771

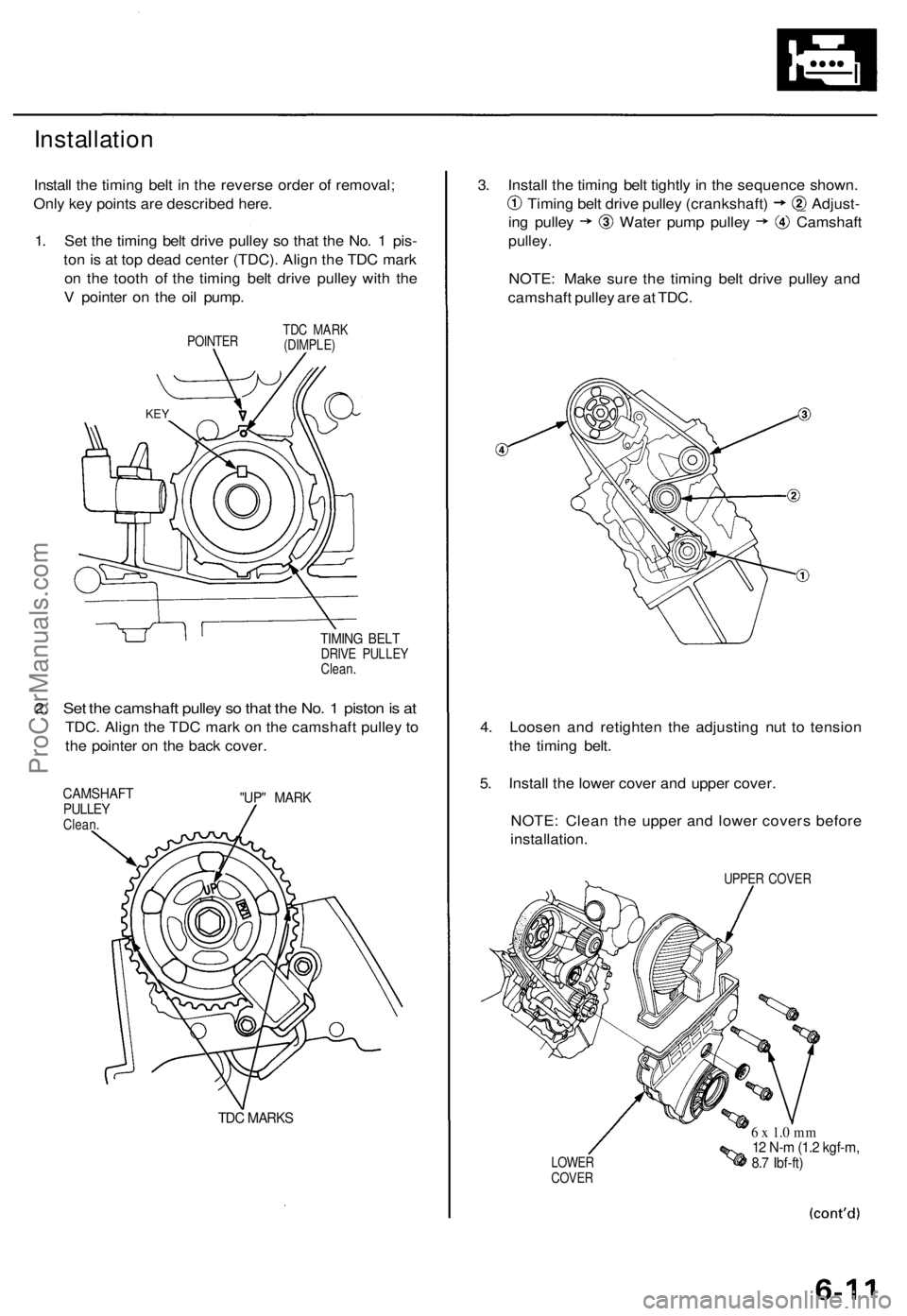

Installation

Install the timing belt in the reverse order of removal;

Only key points are described here.

1. Set the timing belt drive pulley so that the No. 1 pis-

ton is at top dead center (TDC). Align the TDC mark

on the tooth of the timing belt drive pulley with the

V pointer on the oil pump.

POINTER

TDC MARK

(DIMPLE)

TIMING BELT

DRIVE PULLEY

Clean.

2. Set the camshaft pulley so that the No. 1 piston is at

TDC. Align the TDC mark on the camshaft pulley to

the pointer on the back cover.

CAMSHAFT

PULLEY

Clean.

"UP" MARK

TDC MARKS

3. Install the timing belt tightly in the sequence shown.

Timing belt drive pulley (crankshaft) _ Adjust-

ing pulley Water pump pulley Camshaft

pulley.

NOTE: Make sure the timing belt drive pulley and

camshaft pulley are at TDC.

4. Loosen and retighten the adjusting nut to tension

the timing belt.

5. Install the lower cover and upper cover.

NOTE: Clean the upper and lower covers before

installation.

UPPER COVER

LOWER

COVER

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

KEYProCarManuals.com

Page 746 of 1771

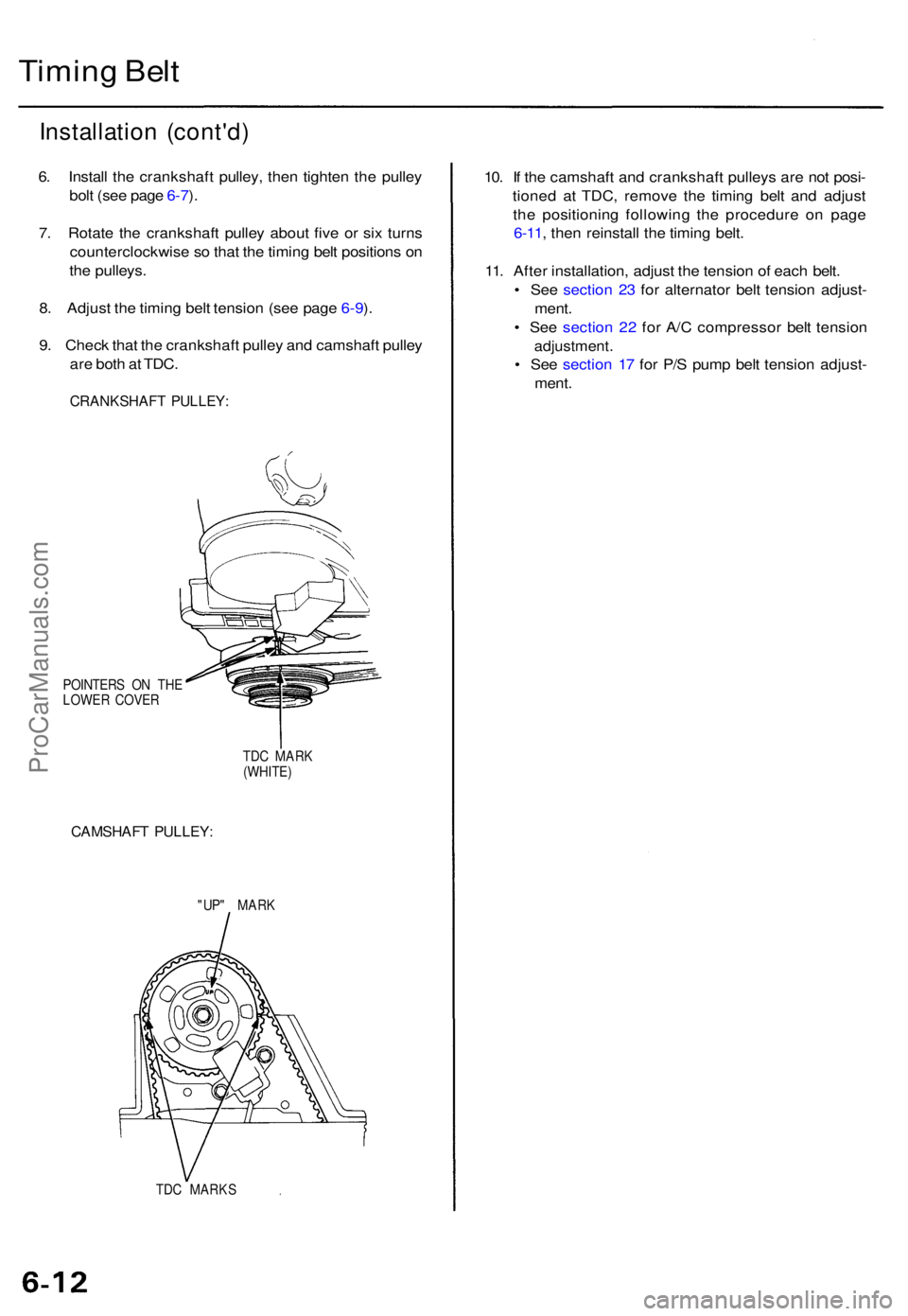

Timing Bel t

Installatio n (cont'd )

6. Instal l th e crankshaf t pulley , the n tighte n th e pulle y

bol t (se e pag e 6-7 ).

7 . Rotat e th e crankshaf t pulle y abou t fiv e o r si x turn s

counterclockwis e s o tha t th e timin g bel t position s o n

th e pulleys .

8 . Adjus t th e timin g bel t tensio n (se e pag e 6-9 ).

9 . Chec k tha t th e crankshaf t pulle y an d camshaf t pulle y

ar e bot h a t TDC .

CRANKSHAF T PULLEY :

POINTER S O N TH E

LOWE R COVE R

TDC MAR K

(WHITE )

CAMSHAF T PULLEY :

"UP" MAR K

TD C MARK S

10. I f th e camshaf t an d crankshaf t pulley s ar e no t posi -

tione d a t TDC , remov e th e timin g bel t an d adjus t

th e positionin g followin g th e procedur e o n pag e

6-11 , the n reinstal l th e timin g belt .

11 . Afte r installation , adjus t th e tensio n o f eac h belt .

• Se e sectio n 2 3 fo r alternato r bel t tensio n adjust -

ment .

• Se e sectio n 2 2 fo r A/ C compresso r bel t tensio n

adjustment .

• Se e sectio n 1 7 fo r P/ S pum p bel t tensio n adjust -

ment .

ProCarManuals.com

Page 747 of 1771

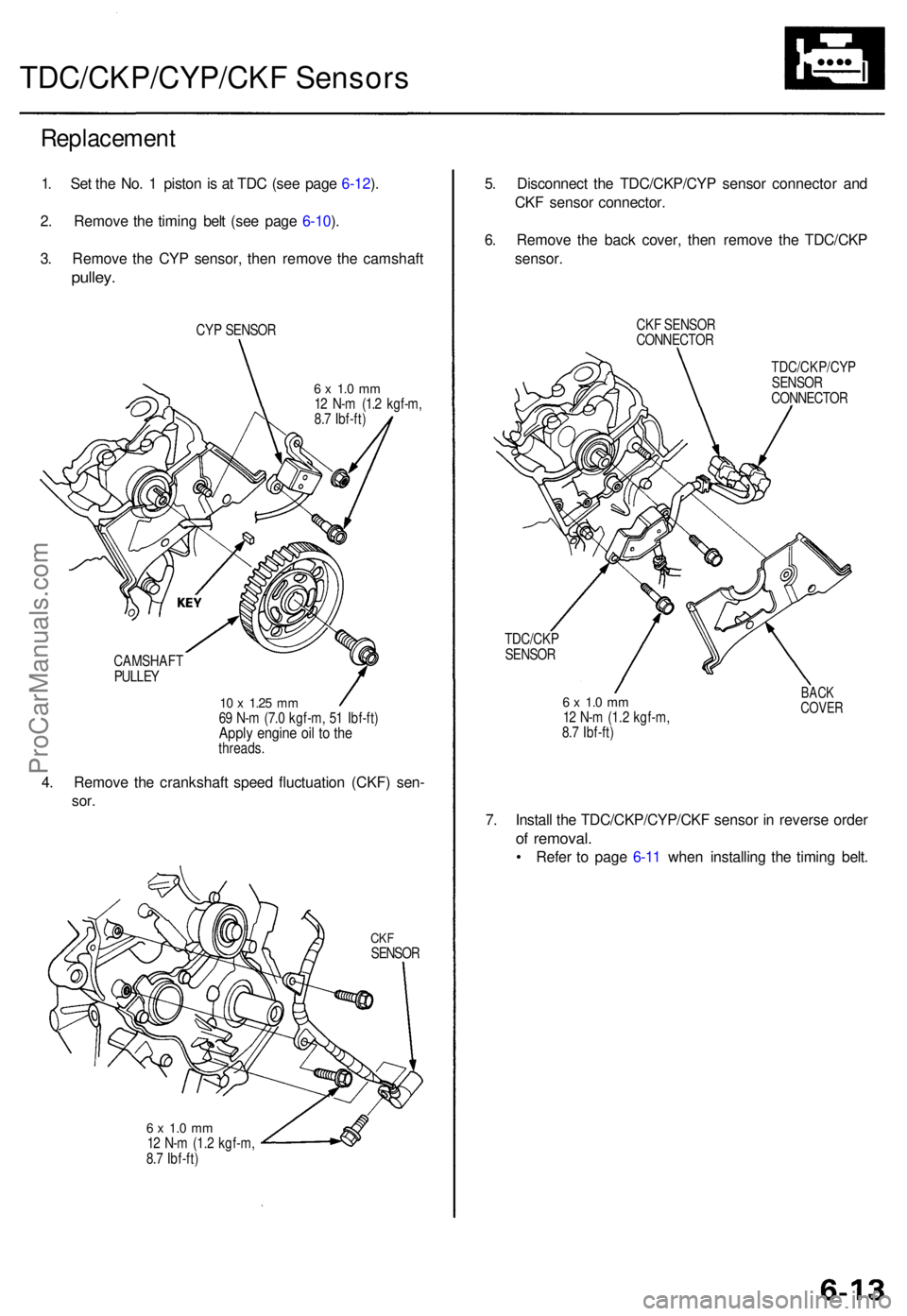

TDC/CKP/CYP/CKF Sensor s

Replacemen t

1. Se t th e No . 1 pisto n is a t TD C (se e pag e 6-12 ).

2 . Remov e th e timin g bel t (se e pag e 6-10 ).

3 . Remov e th e CY P sensor , the n remov e th e camshaf t

pulley.

CYP SENSO R

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

CAMSHAF T

PULLE Y

10 x 1.2 5 mm69 N- m (7. 0 kgf-m , 5 1 Ibf-ft )Apply engin e oi l t o th ethreads .

4. Remov e th e crankshaf t spee d fluctuatio n (CKF ) sen -

sor.

CKFSENSO R

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

5. Disconnec t th e TDC/CKP/CY P senso r connecto r an d

CK F senso r connector .

6 . Remov e th e bac k cover , the n remov e th e TDC/CK P

sensor .

CKF SENSO R

CONNECTO R

TDC/CKP/CY P

SENSO R

CONNECTO R

TDC/CK P

SENSO R

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

BACKCOVE R

7. Instal l th e TDC/CKP/CYP/CK F senso r i n revers e orde r

of removal .

• Refe r t o pag e 6-1 1 whe n installin g th e timin g belt .

ProCarManuals.com

Page 748 of 1771

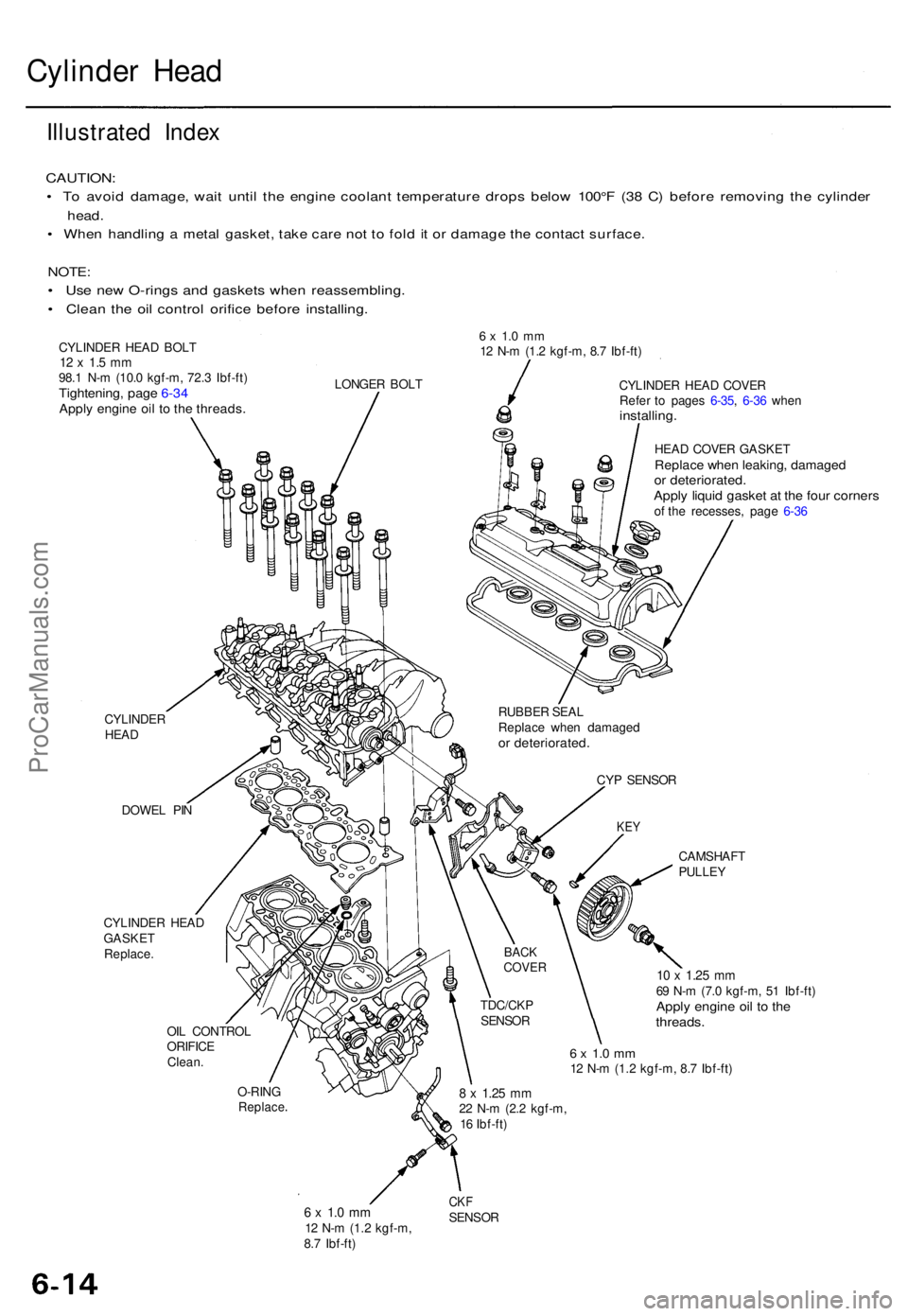

Cylinder Hea d

Illustrate d Inde x

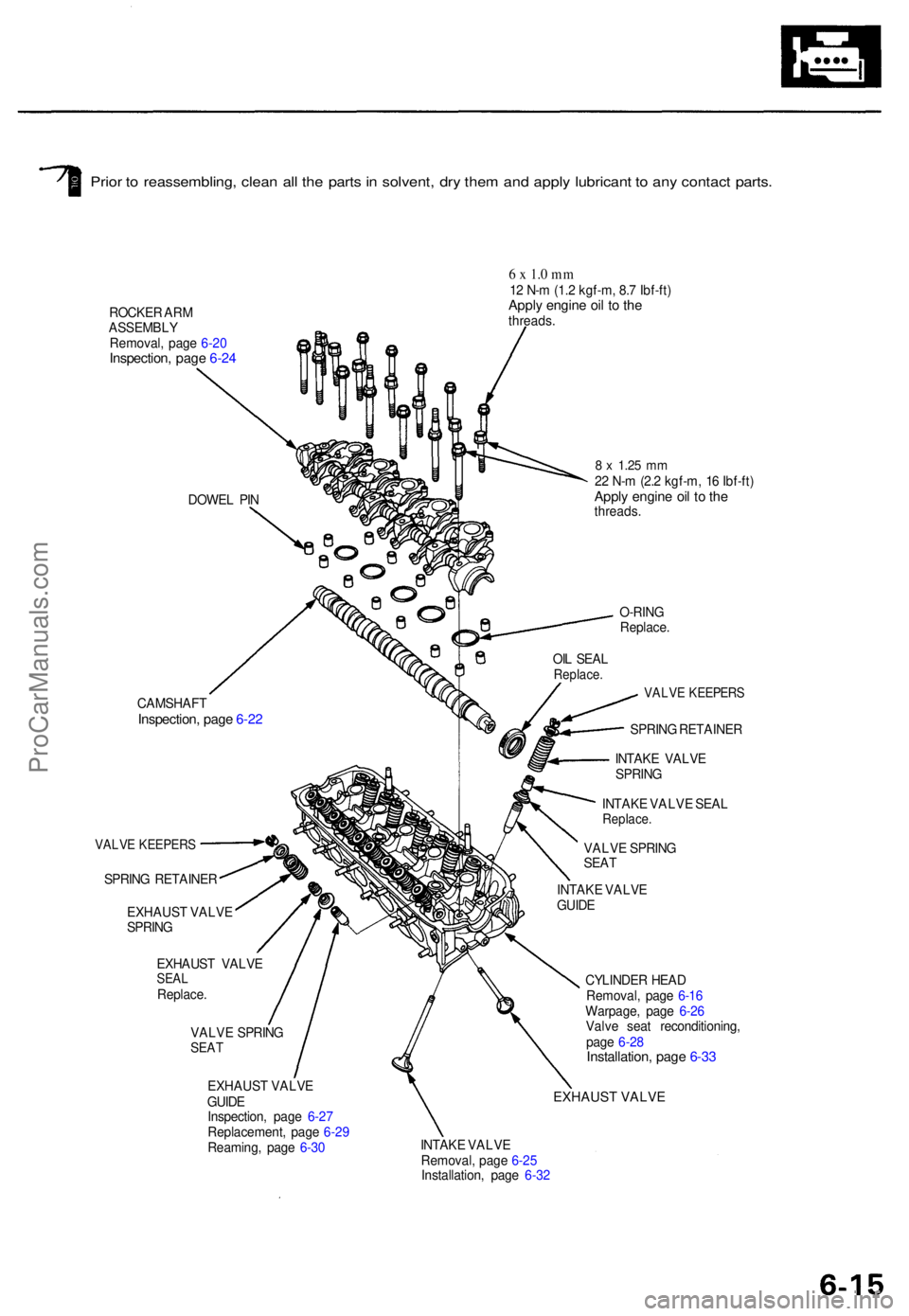

CAUTION :

• T o avoi d damage , wai t unti l th e engin e coolan t temperatur e drop s belo w 100° F (3 8 C ) befor e removin g th e cylinde r

head.

• Whe n handlin g a meta l gasket , tak e car e no t t o fol d it o r damag e th e contac t surface .

NOTE:

• Us e ne w O-ring s an d gasket s whe n reassembling .

• Clea n th e oi l contro l orific e befor e installing .

CYLINDER HEA D BOL T12 x 1. 5 m m98. 1 N- m (10. 0 kgf-m , 72. 3 Ibf-ft )Tightening , pag e 6-3 4Appl y engin e oi l t o th e threads .

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

LONGE R BOL T

CYLINDE R

HEA D

DOWE L PI N

CYLINDE R HEA D

GASKE T

Replace . CYLINDE

R HEA D COVE R

Refe r t o page s 6-35 , 6-3 6 whe n

installing .

HEAD COVE R GASKE TReplace whe n leaking , damage dor deteriorated .Apply liqui d gaske t a t th e fou r corner sof th e recesses , pag e 6-3 6

CAMSHAF T

PULLEY

OIL CONTRO L

ORIFIC E

Clean .

10 x 1.2 5 mm69 N- m (7. 0 kgf-m , 5 1 Ibf-ft )Apply engin e oi l t o th ethreads .

6 x 1. 0 m m12 N- m (1.2 kgf-m , 8. 7 Ibf-ft )

O-RIN G

Replac e

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

CKFSENSO R

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

TDC/CK

P

SENSO R

BACKCOVE R

CYP SENSO R

KEY

RUBBE R SEA L

Replac e whe n damage d

or deteriorated .

ProCarManuals.com

Page 749 of 1771

Prior t o reassembling , clea n al l th e part s in solvent , dr y the m an d appl y lubrican t t o an y contac t parts .

ROCKE R AR M

ASSEMBL Y

Removal , pag e 6-2 0

Inspection , pag e 6-2 4

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )Apply engin e oi l t o th ethreads .

DOWE L PI N

O-RING

Replace .

CAMSHAF TInspection, pag e 6-2 2

VALV E KEEPER S

SPRING RETAINE R

EXHAUS T VALV E

SPRIN G

EXHAUS T VALV E

SEALReplace .

VALVE SPRIN GSEAT

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )Apply engin e oi l t o th ethreads .

VALVE KEEPER S

SPRING RETAINE R

INTAK E VALV E

SPRIN G

INTAK E VALV E SEA L

Replace .

VALVE SPRIN G

SEA T

EXHAUS T VALV E

GUID E

Inspection , pag e 6-2 7

Replacement , pag e 6-2 9

Reaming , pag e 6-3 0 CYLINDE

R HEA D

Removal , pag e 6-1 6

Warpage , pag e 6-2 6

Valv e sea t reconditioning ,

pag e 6-2 8

Installation , pag e 6-3 3

EXHAUST VALVE

INTAK E VALV E

Removal , pag e 6-2 5

Installation , pag e 6-3 2OI

L SEA L

Replace .

INTAKE VALV E

GUID E

ProCarManuals.com

Page 750 of 1771

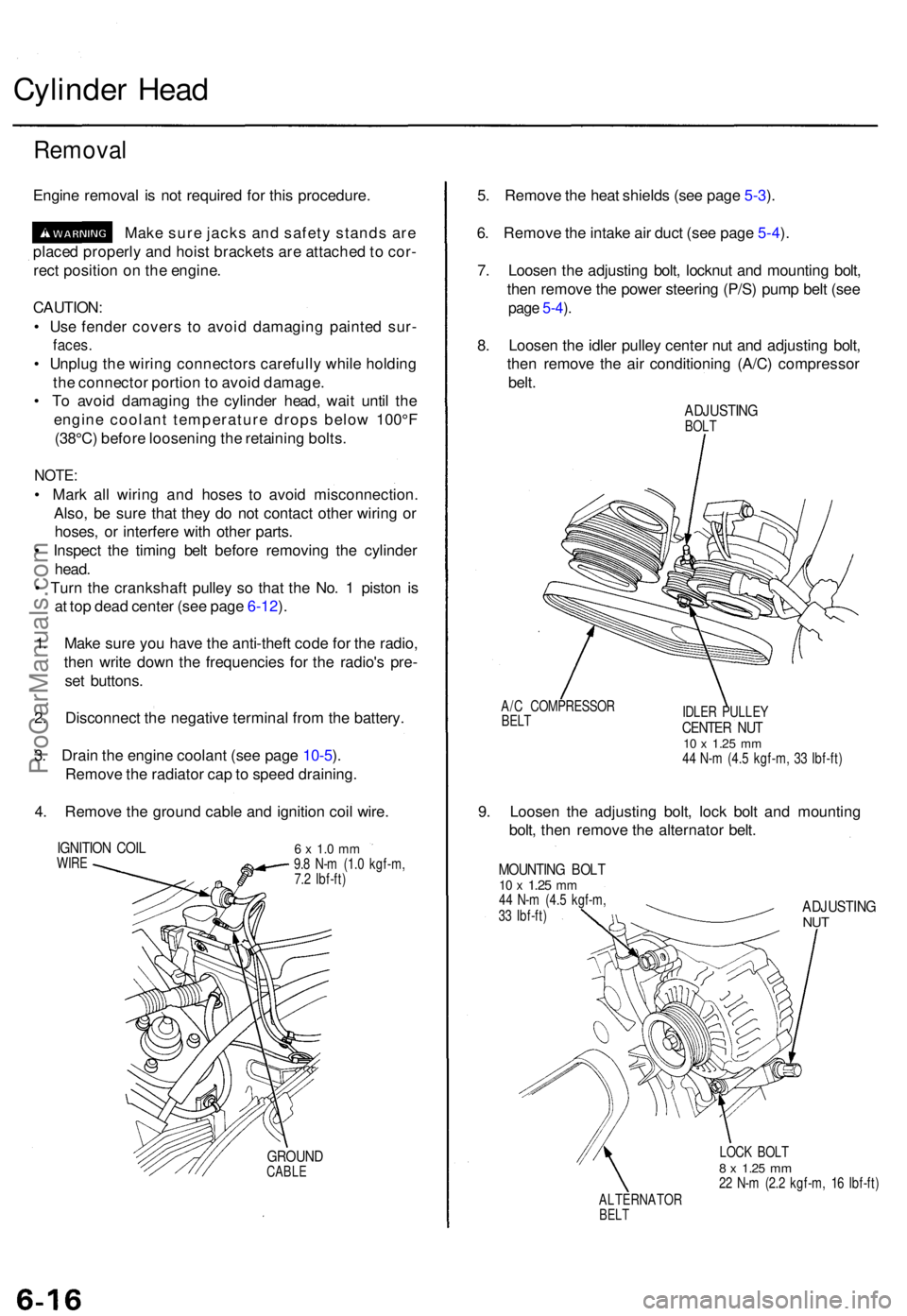

Cylinder Hea d

Remova l

Engine remova l i s no t require d fo r thi s procedure .

Mak e sur e jack s an d safet y stand s ar e

place d properl y an d hois t bracket s ar e attache d to cor -

rec t positio n o n th e engine .

CAUTION :

• Us e fende r cover s t o avoi d damagin g painte d sur -

faces .

• Unplu g th e wirin g connector s carefull y whil e holdin g

th e connecto r portio n to avoi d damage .

• T o avoi d damagin g th e cylinde r head , wai t unti l th e

engin e coolan t temperatur e drop s belo w 100° F

(38°C ) befor e loosenin g th e retainin g bolts .

NOTE :

• Mar k al l wirin g an d hose s t o avoi d misconnection .

Also , b e sur e tha t the y d o no t contac t othe r wirin g o r

hoses , o r interfer e wit h othe r parts .

• Inspec t th e timin g bel t befor e removin g th e cylinde r

head .

• Tur n th e crankshaf t pulle y s o tha t th e No . 1 pisto n i s

a t to p dea d cente r (se e pag e 6-12 ).

1 . Mak e sur e yo u hav e th e anti-thef t cod e fo r th e radio ,

the n writ e dow n th e frequencie s fo r th e radio' s pre -

se t buttons .

2 . Disconnec t th e negativ e termina l fro m th e battery .

3 . Drai n th e engin e coolan t (se e pag e 10-5 ).

Remov e th e radiato r cap to spee d draining .

4 . Remov e th e groun d cabl e an d ignitio n coi l wire .

IGNITIO N COI LWIRE6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

GROUN DCABLE

5. Remov e th e hea t shield s (se e pag e 5-3 ).

6 . Remov e th e intak e ai r duc t (se e pag e 5-4 ).

7 . Loose n th e adjustin g bolt , locknu t an d mountin g bolt ,

the n remov e th e powe r steerin g (P/S ) pum p bel t (se e

page 5-4 ).

8 . Loose n th e idle r pulle y cente r nu t an d adjustin g bolt ,

the n remov e th e ai r conditionin g (A/C ) compresso r

belt .

ADJUSTIN GBOLT

A/ C COMPRESSO R

BELTIDLE R PULLE YCENTER NU T10 x 1.2 5 mm44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

9. Loose n th e adjustin g bolt , loc k bol t an d mountin g

bolt , the n remov e th e alternato r belt .

MOUNTIN G BOL T10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )ADJUSTIN GNUT

LOC K BOL T8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

ALTERNATO R

BELT

ProCarManuals.com