Alfa Romeo 4C Spider 2019 Owner's Manual

Manufacturer: ALFA ROMEO, Model Year: 2019, Model line: 4C Spider, Model: Alfa Romeo 4C Spider 2019Pages: 292, PDF Size: 3.25 MB

Page 201 of 292

Maintenance Plan

Required Maintenance Intervals

Refer to the maintenance plan on the following page for

the required maintenance intervals.

At Every Oil Change Interval As Indicated By OilChange Indicator System:

Change oil and filter.

Inspect battery and clean and tighten terminals as required.

At Every Oil Change Interval As Indicated By OilChange Indicator System:

Inspect brake pads, shoes, rotors, drums, and hoses. Inspect engine cooling system protection and hoses. Check and adjust hand brake.Inspect exhaust system.

Inspect engine air cleaner filter if using in dusty or off-road conditions.

Mileage or time passed

(whichever comes first)

12,000

24,000

36,000

48,000

60,000

72,000

84,000

96,000

108,000

120,000

132,000

144,000

156,000

Or Months: 12 24 36 48 60 72 84 96 108 120 132 144 156

Or Kilometers:

20,000

40,000

60,000

80,000

100,000

120,000

140,000

160,000

180,000

200,000

220,000

240,000

260,000

Check battery charge status and possibly

recharge # XXXXXXXXXXXXX

Check tire condition/wear and adjust pres-

sure if required XXXXXXXXXXXXX

8

SERVICING AND MAINTENANCE 199

Page 202 of 292

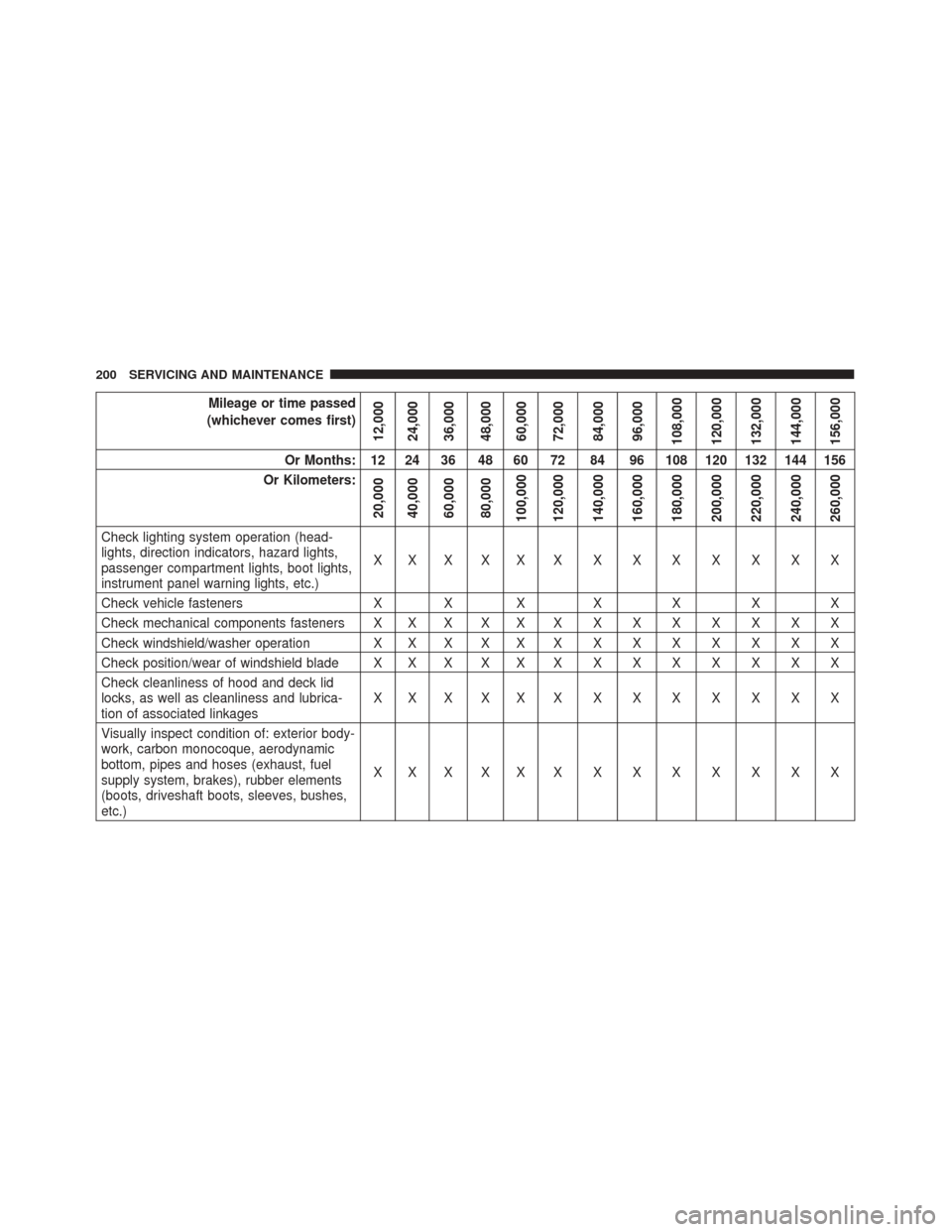

Mileage or time passed

(whichever comes first)

12,000

24,000

36,000

48,000

60,000

72,000

84,000

96,000

108,000

120,000

132,000

144,000

156,000

Or Months: 12 24 36 48 60 72 84 96 108 120 132 144 156

Or Kilometers:

20,000

40,000

60,000

80,000

100,000

120,000

140,000

160,000

180,000

200,000

220,000

240,000

260,000

Check lighting system operation (head-

lights, direction indicators, hazard lights,

passenger compartment lights, boot lights,

instrument panel warning lights, etc.) XXXXXXXXXXXXX

Check vehicle fasteners X X X X X X X

Check mechanical components fasteners X X X X X X X X XXXXX

Check windshield/washer operation X X X X X X X X XXXXX

Check position/wear of windshield blade X X X X X X X X XXXXX

Check cleanliness of hood and deck lid

locks, as well as cleanliness and lubrica-

tion of associated linkages XXXXXXXXXXXXX

Visually inspect condition of: exterior body-

work, carbon monocoque, aerodynamic

bottom, pipes and hoses (exhaust, fuel

supply system, brakes), rubber elements

(boots, driveshaft boots, sleeves, bushes,

etc.) XXXXXXXXXXXXX

200 SERVICING AND MAINTENANCE

Page 203 of 292

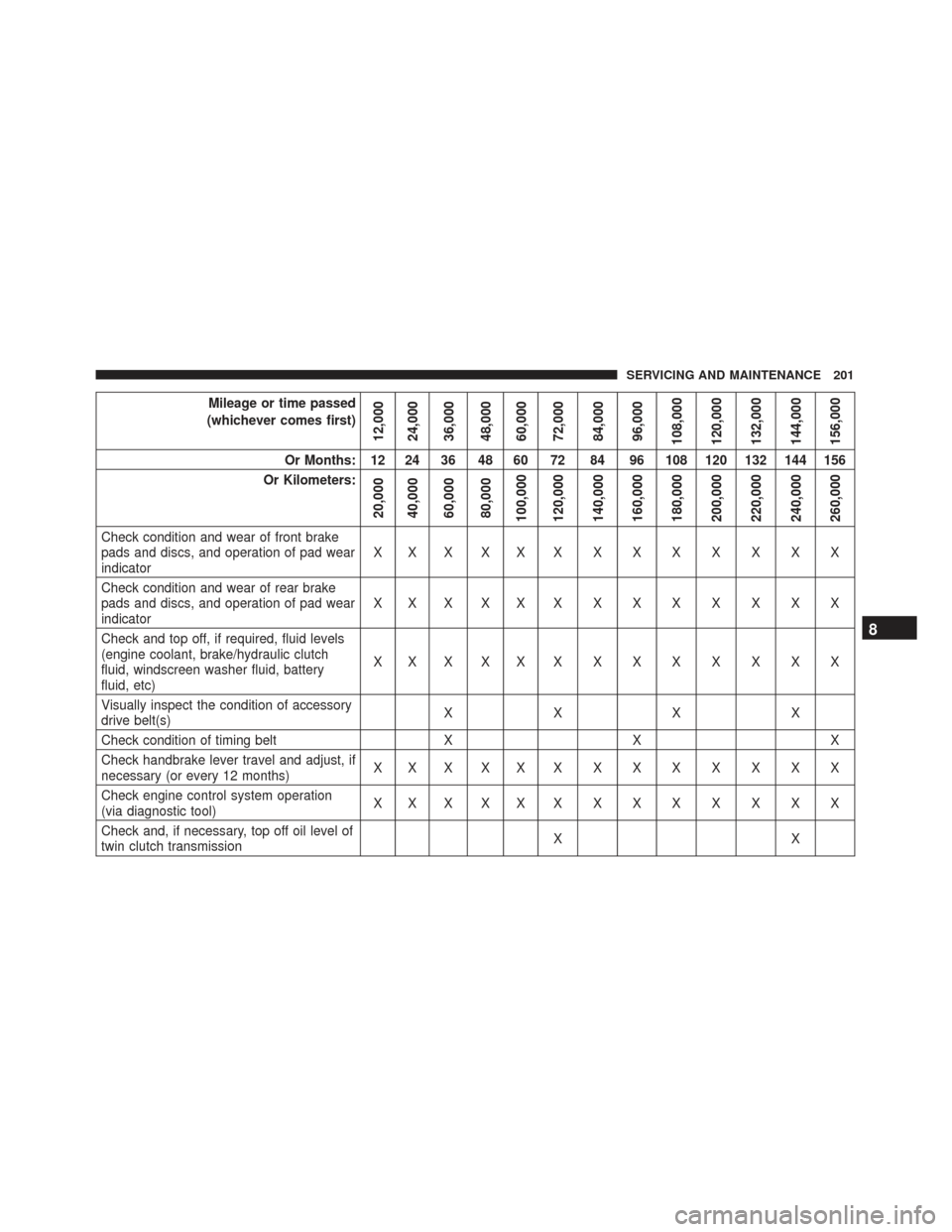

Mileage or time passed

(whichever comes first)

12,000

24,000

36,000

48,000

60,000

72,000

84,000

96,000

108,000

120,000

132,000

144,000

156,000

Or Months: 12 24 36 48 60 72 84 96 108 120 132 144 156

Or Kilometers:

20,000

40,000

60,000

80,000

100,000

120,000

140,000

160,000

180,000

200,000

220,000

240,000

260,000

Check condition and wear of front brake

pads and discs, and operation of pad wear

indicator XXXXXXXXXXXXX

Check condition and wear of rear brake

pads and discs, and operation of pad wear

indicator XXXXXXXXXXXXX

Check and top off, if required, fluid levels

(engine coolant, brake/hydraulic clutch

fluid, windscreen washer fluid, battery

fluid, etc) XXXXXXXXXXXXX

Visually inspect the condition of accessory

drive belt(s) XX X X

Check condition of timing belt X X X

Check handbrake lever travel and adjust, if

necessary (or every 12 months) XXXXXXXXXXXXX

Check engine control system operation

(via diagnostic tool) XXXXXXXXXXXXX

Check and, if necessary, top off oil level of

twin clutch transmission XX

8

SERVICING AND MAINTENANCE 201

Page 204 of 292

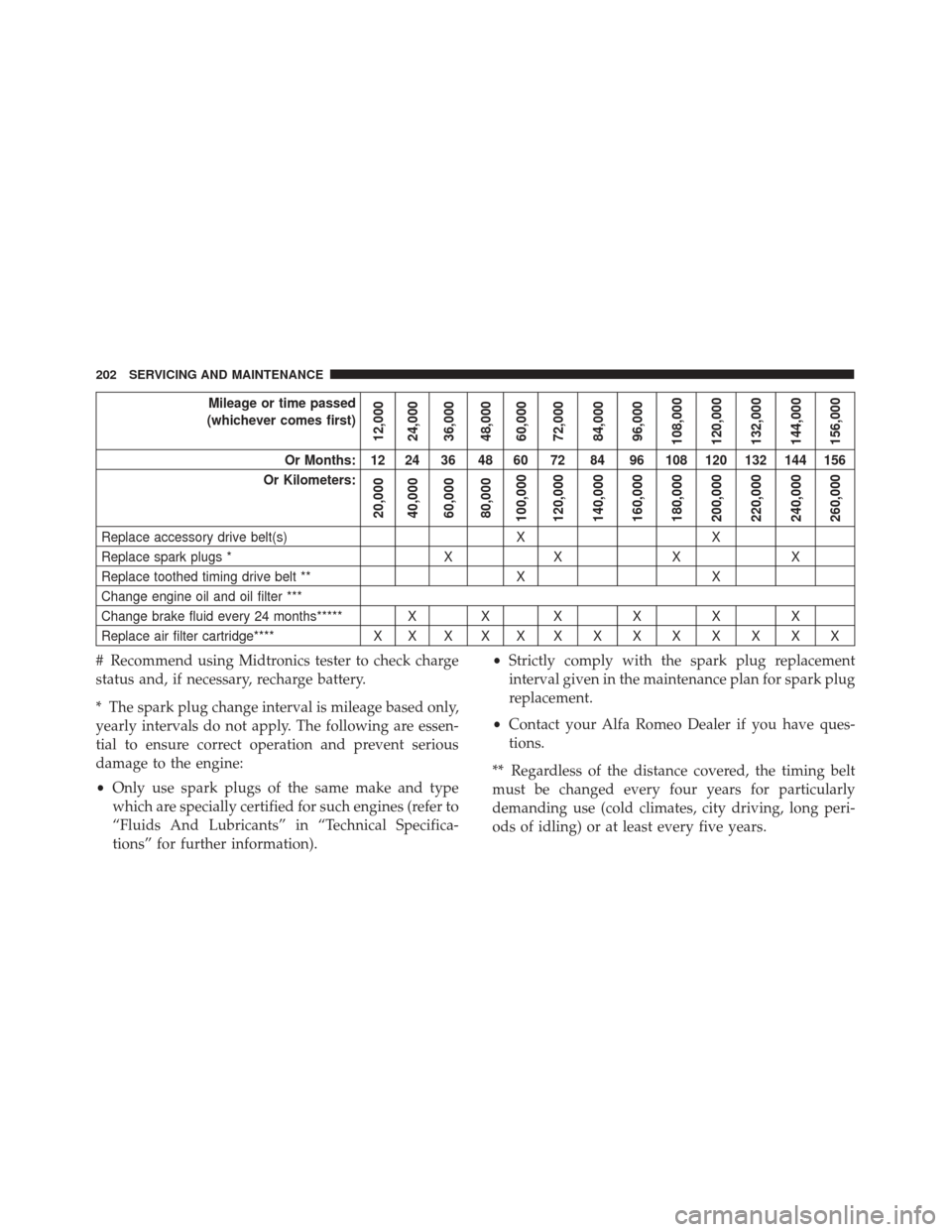

Mileage or time passed

(whichever comes first)

12,000

24,000

36,000

48,000

60,000

72,000

84,000

96,000

108,000

120,000

132,000

144,000

156,000

Or Months: 12 24 36 48 60 72 84 96 108 120 132 144 156

Or Kilometers:

20,000

40,000

60,000

80,000

100,000

120,000

140,000

160,000

180,000

200,000

220,000

240,000

260,000

Replace accessory drive belt(s) XX

Replace spark plugs * XX X X

Replace toothed timing drive belt ** XX

Change engine oil and oil filter ***

Change brake fluid every 24 months***** X X X XX X

Replace air filter cartridge**** X X X X X X X X XXXXX

# Recommend using Midtronics tester to check charge

status and, if necessary, recharge battery.

* The spark plug change interval is mileage based only,

yearly intervals do not apply. The following are essen-

tial to ensure correct operation and prevent serious

damage to the engine:

•Only use spark plugs of the same make and type

which are specially certified for such engines (refer to

“Fluids And Lubricants” in “Technical Specifica-

tions” for further information). •

Strictly comply with the spark plug replacement

interval given in the maintenance plan for spark plug

replacement.

• Contact your Alfa Romeo Dealer if you have ques-

tions.

** Regardless of the distance covered, the timing belt

must be changed every four years for particularly

demanding use (cold climates, city driving, long peri-

ods of idling) or at least every five years.

202 SERVICING AND MAINTENANCE

Page 205 of 292

*** The actual interval for changing the oil and replac-

ing the engine oil filter depends on the vehicle usage

conditions and is signalled by the warning light or

message (if present) on the instrument panel or every 12

months.

**** If the vehicle is operated in a dusty or dirty

environment the engine air filter has to be changed

every 6,500 miles (10,000 km).

***** DOT 4 brake fluid must be changed every two

years regardless of mileage.WARNING!

•You can be badly injured working on or around a

motor vehicle. Do only service work for which

you have the knowledge and the right equipment.

If you have any doubt about your ability to

perform a service job, take your vehicle to a

competent mechanic.

• Failure to properly inspect and maintain your

vehicle could result in a component malfunction

and effect vehicle handling and performance.

This could cause an accident.

8

SERVICING AND MAINTENANCE 203

Page 206 of 292

ENGINE COMPARTMENT

1750 Turbo Engine

1 — Fuse Box3 — Engine Oil Dip Stick5 — Coolant Reservoir

2 — Battery 4 — Engine Oil Fill

204 SERVICING AND MAINTENANCE

Page 207 of 292

Checking Oil Level

To assure proper engine lubrication, the engine oil must be

maintained at the correct level. Check the oil level at

regular intervals. The best time to check the engine oil level

is before starting the engine after it has sat overnight.

Do not check oil level when the engine is warm.

Checking engine oil level when the engine is warm will

give you an incorrect reading.

Checking the oil while the vehicle is on level ground,

and has sat overnight, will improve the accuracy of the

oil level readings. Maintain the oil level between the

range markings on the dipstick. The safe range is

indicated by a crosshatch zone. Adding 1 quart of oil

when the reading is at the low end of the indicated

range will result in the oil level at the full end of the

indicator range.

CAUTION!

Do not overfill the engine with oil. Overfilling the

engine with oil will cause oil aeration, which can

lead to loss of oil pressure and an increase in oil

temperature. This loss of oil pressure and increased

oil temperature could damage your engine.

Adding Washer Solvent

To check the windshield washer solvent level, proceed

as follows:

1. To avoid any interference during the procedure, liftthe windshield wiper blade.

2. Loosen the four screws using the supplied screw- driver. Remove the washer solvent protection panel.

1 — Brake Fluid Access Panel

2 — Washer Solvent Access Panel

8

SERVICING AND MAINTENANCE 205

Page 208 of 292

3. Release the plug from the opening.

4. Leaving the plug close to the opening, put a finger onthe central hole in the plug and remove it: the level

can be seen on the control pipe due to capillarity.

1 — Screw LocationsWasher Solvent Plug

Washer Solvent Dip Stick

206 SERVICING AND MAINTENANCE

Page 209 of 292

5. After the check, reinsert the plug with the controlpipe in the initial position.

6. Reposition the washer solvent protection panel and tighten the four self-tapping screws.

If the level is not sufficient, namely if there is no washer

solvent inside the pipe, proceed as follows:

1. To avoid any interference during the procedure, lift the windshield wiper blade.

2. Loosen the four screws using the supplied screw- driver. Remove the washer solvent protection panel.

3. Take the black funnel for topping up the windshield washer solvent and its extension pipe from the

service kit in the luggage compartment.

4. Take out the plug with the solvent control pipe through the washer solvent protection panel.

5. Introduce the funnel and its extension pipe in the reservoir neck and top up. 6. After topping up, remove the funnel with the exten-

sion pipe.

7. Refit the plug with the dipstick.

8. Reposition the washer solvent protection panel and tighten the four self-tapping screws.

Washer Solvent Fill Funnel

8

SERVICING AND MAINTENANCE 207

Page 210 of 292

WARNING!

Commercially available windshield washer sol-

vents are flammable. They could ignite and burn

you. Care must be exercised when filling or work-

ing around the washer solution.

Maintenance-Free Battery

Your vehicle is equipped with a maintenance-free bat-

tery. You will never have to add water, nor is periodic

maintenance required.

WARNING!

•Battery fluid is a corrosive acid solution and can

burn or even blind you. Do not allow battery

fluid to contact your eyes, skin, or clothing. Do

not lean over a battery when attaching clamps. If

acid splashes in eyes or on skin, flush the area

immediately with large amounts of water. Refer

to “Jump Starting Procedure” in “In Case Of

Emergency” for further information.

• Battery gas is flammable and explosive. Keep

flame or sparks away from the battery. Do not use

(Continued)

WARNING! (Continued)

a booster battery or any other booster source with

an output greater than 12 Volts. Do not allow

cable clamps to touch each other.

• Battery posts, terminals, and related accessories

contain lead and lead compounds. Wash hands

after handling.

• The battery in this vehicle has a vent hose that

should not be disconnected and should only be

replaced with a battery of the same type (vented).

CAUTION!

• It is essential when replacing the cables on the

battery that the positive cable is attached to the

positive post and the negative cable is attached to

the negative post. Battery posts are marked posi-

tive (+) and negative (-) and are identified on the

battery case. Cable clamps should be tight on the

terminal posts and free of corrosion.

•

If a “fast charger” is used while the battery is in the

vehicle, disconnect both vehicle battery cables be-

fore connecting the charger to the battery. Do not

use a “fast charger” to provide starting voltage.

208 SERVICING AND MAINTENANCE