ASTON MARTIN DB7 1997 Workshop Manual

Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 201 of 421

^^?

Electrics

Airbag System

Airbag DM Fault Code 12

Low battery voltage

Normal Operation

The airbag diagnostic module (DM) monitors the

voltage at pin 1-7 which should be equal to the

battery voltage. If a voltage lower than 9 volts is

detected at pin 1-7, the airbag warning lamp will be

illuminated and fault code 12 will be flashed.

Possible Causes

Drop in battery voltage to DM pin 1-7 caused by:

• Open circuit to pin

1

-7 from the battery

• Short circuit to ground on the battery feed

circuit

• Safing sensor feed shorted to ground

• Safing sensor internal short to ground

• Faulty charge system draining the battery

Fault Analysis

WARNING: Read and adhere to all warnings and

safety procedures at the start of

this

section when

working on the airbag system.

1.

Complete a battery voltage test as follows:

a) Measure the battery voltage at the battery under

KOEO and KOER conditions.

If the battery voltage is below 10.5 volts during

KOEO or below 12.5 volts during the KOER tests,

service the battery

and

charging system

as

necessary.

Retest for airbag system fau

It

code 12 and go to step

2 if the fault recurs.

2.

Complete a 12 volts supply check at the diagnostic

module:

a) Disarm the airbag system and fit airbag simulators

(6.4.21.4)

b) Disconnect the airbag diagnostic module.

c) Switch on the ignition.

d) Measurethevoltagebetween DM hamessconnector

pin 1-7 (+) and harness connector pin 1-3 (-).

e) If battery voltage is not present, go to step 3.

If battery voltage is present at pin 1-7, renew the

diagnostic module. Rearm and verify the airbag

system.

3. Check the supply fuse as follows:

a) Check fuse F16 in the passenger side fusebox RHD

(or F18 in passenger fusebox LHD).

If the fuse has not blown, check for an open circuit

between battery positive and diagnostic module

connector pin

1

-7.

If the fuse has blown. Renew the fuse and/or repair

the wiring and go to step 4.

4.

Check for a short circuit as follows:

a) Switch off the ignition. With the airbag diagnostic

module disconnected, measure the continuity to

earth from diagnostic module connector pin

1

-7 to

ground.

If no short circuit is detected, go to step 5.

Ifashortto ground isdetected, service the wiring as

necessary. Reconnect the diagnostic module and

retest to ensure that code 12 is cleared.

5. Check for a short circuit to ground on the safing

sensor wiring as follows:

a) Check for a short circuit to ground at diagnostic

module pin 1-9.

b) If a short is detected, disconnect the safing sensor

and repeat the check at diagnostic module pin

1

-9.

If a short is still detected, service the wiring from

diagnostic module pin

1

-9 to safing sensor pin 7.

c) If no short circuit is detected, change the airbag

diagnostic module. Reconnect the diagnostic

module and retest to ensure that code 12 does not

recur.

6. Rearm the airbags (6.4.21.4)

September 1996 6-85

Page 202 of 421

Electrics

Airbag System ^2?

Airbag DM Fault Code 13

Airbag circuit short to ground

Normal Operation

The diagnostic modu

le

measures the voltage at pins

2-5 and 2-6. The voltage at these pins is dependant

on charging system voltage as shown in the table

belovi-.

'in 2-5

2.3V

2.4 V

2.5V

2.7V

2.8V

3.0V

3.1V

3.2V

3.4V

3.5V

3.7V

3.8V

4.0V

4.1V

4.3V

Pin 2-6

2.3V

2.4V

2.5V

2.7V

2.8V

3.0V

3.1V

3.2V

3.4V

3.5V

3.7V

3.8V

4.0V

4.1V

4.3V

Charge Volts

9.0V

9.5V

lO.OV

10.5V

11.OV

11.5V

12.0V

12.5V

13.0V

13.5V

14.0V

14.5V

15.0V

15.5V

16.0V

If the diagnostic monitor measures a voltage of 2.0

volts or less on pins 2-5 and 2-6, a fau It code 13 will

be generated and flashed to the instrument pack to

be signalled on the airbag warning lamp. Voltages

as low as 2.0 volts indicate a possible short to

ground in these circuits.

When generating a code 13 the diagnostic module

also generates a signal to blow its own internal

thermal fuse. This action disables the airbag

deployment circuit. The airbag diagnostic module

fuse is non-repairable and the module must be

replaced after repairing the short circuit, if the

voltage at pins 2-5 and 2-6 returns to normal, fault

code 51 (blown thermal fuse) will be stored in

memory.

6.

Fault Analysis

WARNING: Read and adhere to all warnings and

safety procedures at the start of this section when

working on the airbag

system.

Disarm the airbag system and fit airbag simulators

(6.4.21.4)

Disconnect the airbag diagnostic module. Switch

on the ignition.

Measure the continuity to ground at the following

pins on the diagnostic module harness connector:

2-2 Passenger airbag feed

2-3 Passenger airbag return

2-4 Drivers airbag return

2-5 Drivers airbag feed

2-11 Safing sensor feed

If no short circuit is detected, go to step 4.

If

a

short circuit is detected, disconnect the relevant

airbag simulator or the safing sensor and repeat the

continuity measurement to isolate the circuit fault.

Service the wiring or replace the safing sensor as

necessary. Fit a new airbag diagnostic module and

rearm the airbags (6.4.21.4).

Check for intermittent short circuits in the cable

reel cassette. Monitor the continuity to ground at

pins 2-4 and 2-5 whilst rotating the steering from

lock to lock in both directions.

If no short circuit is detected, go to step 5.

If a short circuit is detected, replace the column

switchgear assembly. Fit a new airbag diagnostic

module and rearm the airbags (6.4.21.4).

WARNING: Do not attempt to make any electrical

measurements on the airbag

modules.

Any induced

voltage can

cause

the airbag

to

deploy with the

risk

of personal

injury.

Fit a replacement diagnostic module and

replacement airbag modules.

Caution: Do not refit

the

old

airbag

modules.

They may

be faulty and would

damage the

new diagnostic module.

Rearm the airbag system (6.4.21.4).

6-86 September 1996

Page 203 of 421

mxm^^^?

Electrics

Airbag System

Airbag DM Fault Code 14

Primary crash sensor circuit short to ground

Airbag DM Fault Code 21

Safing sensor insecure mounting.

Normal Operation

The diagnostic module measuresthevoltage at pins

1

-2 and

1

-6. The normal voltage at these pins is 10

volts (±1 volt) with the ignition on, and battery

voltage with the ignition off.

If the voltage at the airbag diagnostic module

connector pins

1

-2 or

1

-6 drops below 5 volts, fault

code 14 will be generated and the airbag warning

lamp will be switched on. When generating a code

14 the diagnostic module also generates a signal to

blow its own internal thermal fuse. This action

disables the airbag deployment circuit. The airbag

diagnostic module fuse is non-repairable and the

module must be replaced after removing the short

circuit. If the voltage at pins 1-2 and 1-6 returns to

normal,

fault code 51 (blown thermal fuse) will be

logged.

Fault Analysis

WARNING: Read and adhere to all warnings and

safety procedures at the start of

this

section when

working on the airbag system.

1.

Disarm the airbag system and fit airbag simulators

(6.4.21.4)

2.

Disconnect the airbag diagnostic module and

remove the plastic wedge from plug

1

(slate).

Note:

The

plastic wedge contains a shorting bar which

would

short

together pins

1-3

(gnd),

1-11

and 1-2 when

the plug is disconnected.

3 Measure the continuity to ground at the following

pins on the diagnostic module harness connector:

1-2 RH crash sensor monitor

1-11 LH crash sensor feed

1

-6 LH crash sensor monitor

1-12 RH crash sensor feed

If no short circuit is detected, go to step 4.

If a short circuit

is

detected, disconnect the relevant

crash sensorandrepeatthecontinuity measurement

to isolate the circuit fault. Service the wiring or

replace the crash sensor as necessary. Refit the

plastic wedge to the diagnostic module connector.

Fit a new airbag diagnostic module and rearm the

airbags (6.4.21.4).

Normal Operation

The diagnostic module measures the resistance

between pins

1

-10 (safing sensor case ground) and

1-3 (monitor reference ground) at the diagnostic

module connector. If the resistance is greater than

2Q

a

fault code

21

will be generated and the airbag

warning lamp will be switched on.

Note:

a

good ground connection is vital.

The

wire from

pin

1-1

is riveted to the safing

sensor case

and the

case

must

be securely

grounded to the vehicle

body.

Fault Analysis

WARNING: Read and adhere to all warnings and

safety procedures at the start of this section when

working on the airbag system.

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

Disconnect the diagnostic connector and check for

continuity from pin 1-3 to chassis ground.

If continuity is good, go to step 3.

If the resistance reading is 2Q or more, service the

diagnostic module ground circuit to pin 1-3 as

necessary. Confirm a good ground path between

pins 1-10 and 1-3.Clearthecode21 and rearm the

airbags (6.4.21.4).

Check for continuity between pins

1

-10 and chassis

ground at the safing sensor.

If the resistance is above 2Q, check for continuity

from the safing sensor connector pin 5 to chassis

ground.

Also check the safing sensor mounting for

corrosion,

dirt or loose fixings. Service the wiring

and/or clean and secure the sensor mounting as

necessary, if a satisfactory ground is not achieved,

replace the safing sensor.

Make

a

final continuity test from diagnostic module

connector pin

1

-3 to

1

-10 to ensure a satisfactory

ground

path.

Reconnect the diagnostic module.

Clear the code

21.

Rearm the airbags (6.4.21.4).

September 1996 6-87

Page 204 of 421

Electrics

Airbag System [D:B3-2?

Airbag DM Fault Code 22

Safing sensor output circuit shorted to battery

voltage.

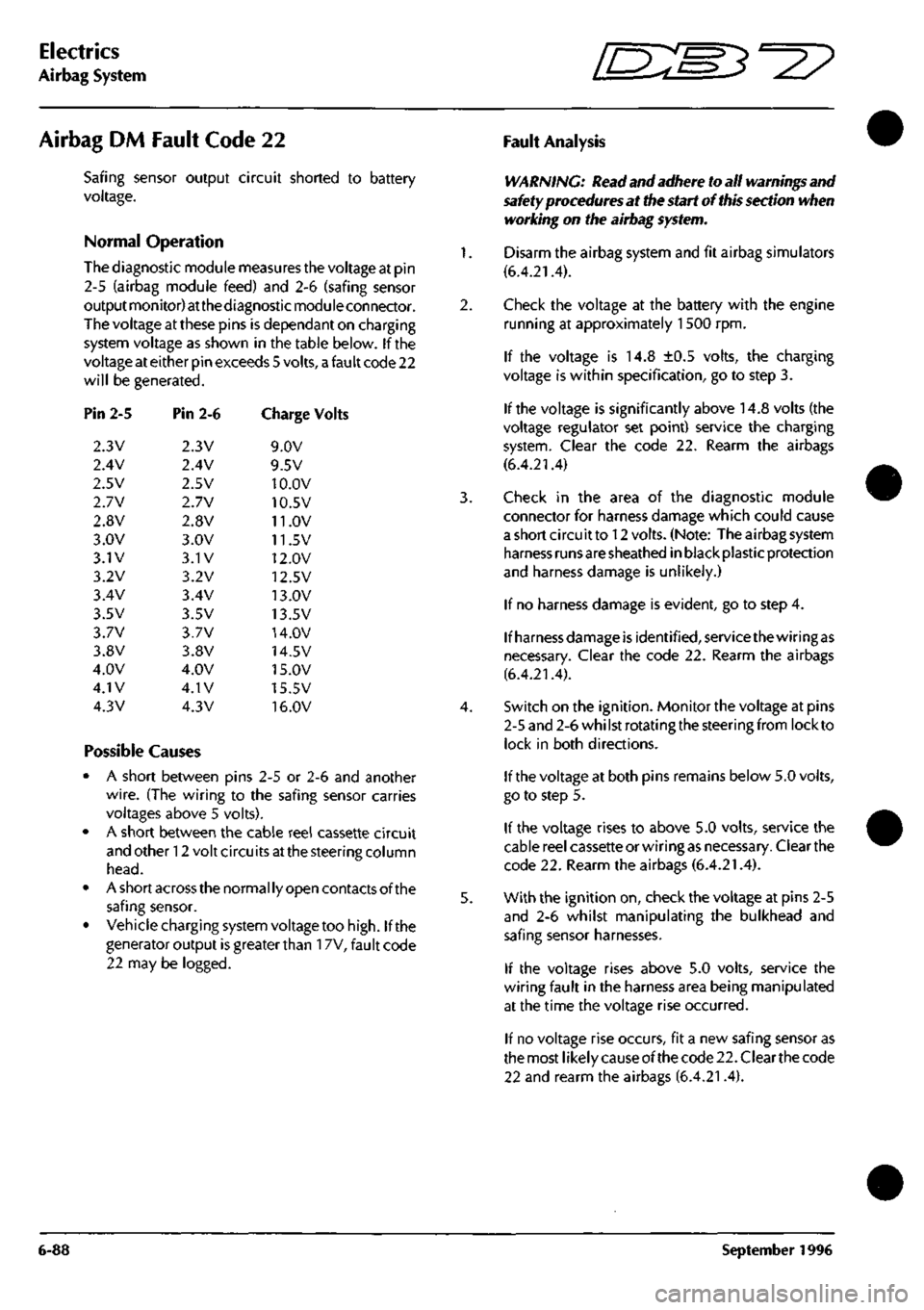

Normal Operation

The diagnostic module measures the voltage at pin

2-5 (airbag module feed) and 2-5 (safing sensor

output monitor) at thediagnosticmoduleconnector.

The voltage at these pins is dependant on charging

system voltage as shown in the table below. If the

voltage at either pin exceeds 5 volts,

a

fault code 22

will be generated.

in 2-5

2.3V

2.4V

2.5V

2.7V

2.8V

3.0V

3.1V

3.2V

3.4 V

3.5V

3.7V

3.8V

4.0V

4.1V

4.3V

Pin 2-6

2.3V

2.4V

2.5V

2.7V

2.8V

3.0V

3.1V

3.2 V

3.4 V

3.5V

3.7V

3.8V

4.0V

4.1V

4.3V

Charge Volts

9.0V

9.5V

10.0V

10.5V

11.0V

11.5V

12.0V

12.5V

13.0V

13.5V

14.0V

14.5V

15.0V

15.5V

16.0V

Possible Causes

• A short between pins 2-5 or 2-6 and another

wire.

(The wiring to the safing sensor carries

voltages above 5 volts).

• A short between the cable reel cassette circuit

and other 12 volt circu its at the steering column

head.

• A short across the normal ly open contacts of the

safmg sensor.

• Vehiclechargingsystem voltage too

high.

If the

generator output is greater than 17V, fault code

22 may be logged.

Fault Analysis

WARNING: Read and adhere to all warnings and

safety procedures at the start of this section when

working on the airbag system.

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

Check the voltage at the battery with the engine

running at approximately 1500 rpm.

If the voltage is 14.8 ±0.5 volts, the charging

voltage is within specification, go to step 3.

If the voltage is significantly above 14.8 volts (the

voltage regulator set point) service the charging

system.

Clear the code 22. Rearm the airbags

(6.4.21.4)

Check in the area of the diagnostic module

connector for harness damage which could cause

a short circu it to 12 volts. (Note: The airbag system

harness runs are sheathed in black plastic protection

and harness damage is unlikely.)

If no harness damage is evident, go to step 4.

If harness damage is identified, service the wiring as

necessary. Clear the code 22. Rearm the airbags

(6.4.21.4).

Switch on the ignition. Monitor the voltage at pins

2-5 and 2-6 whilst rotatingthe steering from lock to

lock in both directions.

If the voltage at both pins remains below 5.0 volts,

go to step 5.

If the voltage rises to above 5.0 volts, service the

cable reel cassette or wiring as necessary. Clear the

code 22. Rearm the airbags (6.4.21.4).

With the ignition on, check the voltage at pins 2-5

and 2-6 whilst manipulating the bulkhead and

safing sensor harnesses.

If the voltage rises above 5.0 volts, service the

wiring fault in the harness area being manipulated

at the time the voltage rise occurred.

If no voltage rise occurs, fit a new safing sensor as

the most likely cause of the code 22. Clear the code

22 and rearm the airbags (6.4.21.4).

6-88 September 1996

Page 205 of 421

>^ '—-y ^ Electrics

-^ ^ ^ Airbag System

Airbag DM Fault Code 23

Safing sensor input- battery feed/return open circuit.

Normal Operation

The diagnostic module measures the voltage on

diagnostic module pin

1

-9 at all times. The voltage

can be as high as 25 volts when the backup power

supply is fully charged.

Pin

1

-9 is connected to pin 2-11 inside the safing

sensor and the voltage on both these pins shou

Id

be

the same. If the voltage on pin 2-11 fails below the

voltage on pin

1

-9, a code 23 is generated.

Possible Causes

• Open circuit in the wiring to diagnostic module

pin 1-9.

• Open circuit in the wiring to diagnostic module

pin2-n.

Fault Analysis

WARNING: Read and adhere to all

warnings

and

safety procedures at the start of

this

section when

working on the airbag

system.

1.

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

2.

Disconnect the diagnostic connector and thesafing

sensor connector. Check for continuity from DM

pi n 1

-9 to safing sensor harness connector

pi n

7 and

from DMpin 1-11 to

safing

sensor harness connector

pin 6.

If the continuity of both leads is good, go to step 3.

If a continuity fault is detected, repair the wiring as

necessary. Reconnect ail components. Clear the

code 23. Rearm the airbags (6.4.21.4).

3. Check the continuity between pins 6 and 7 of the

safing sensor.

If the continuity is good, replace the diagnostic

module. Rearm the airbags (6.4.21.4).

If a continuity fault is detected, replace the safing

sensor. Reset the code 23. Rearm the airbags

(6.4.21.4).

September 1996 6-89

Page 206 of 421

Electrics

Airbag System =2?

Airbag DM Fault Code 24

Safing sensor output - battery feed/return open

circuit.

Normal Operation

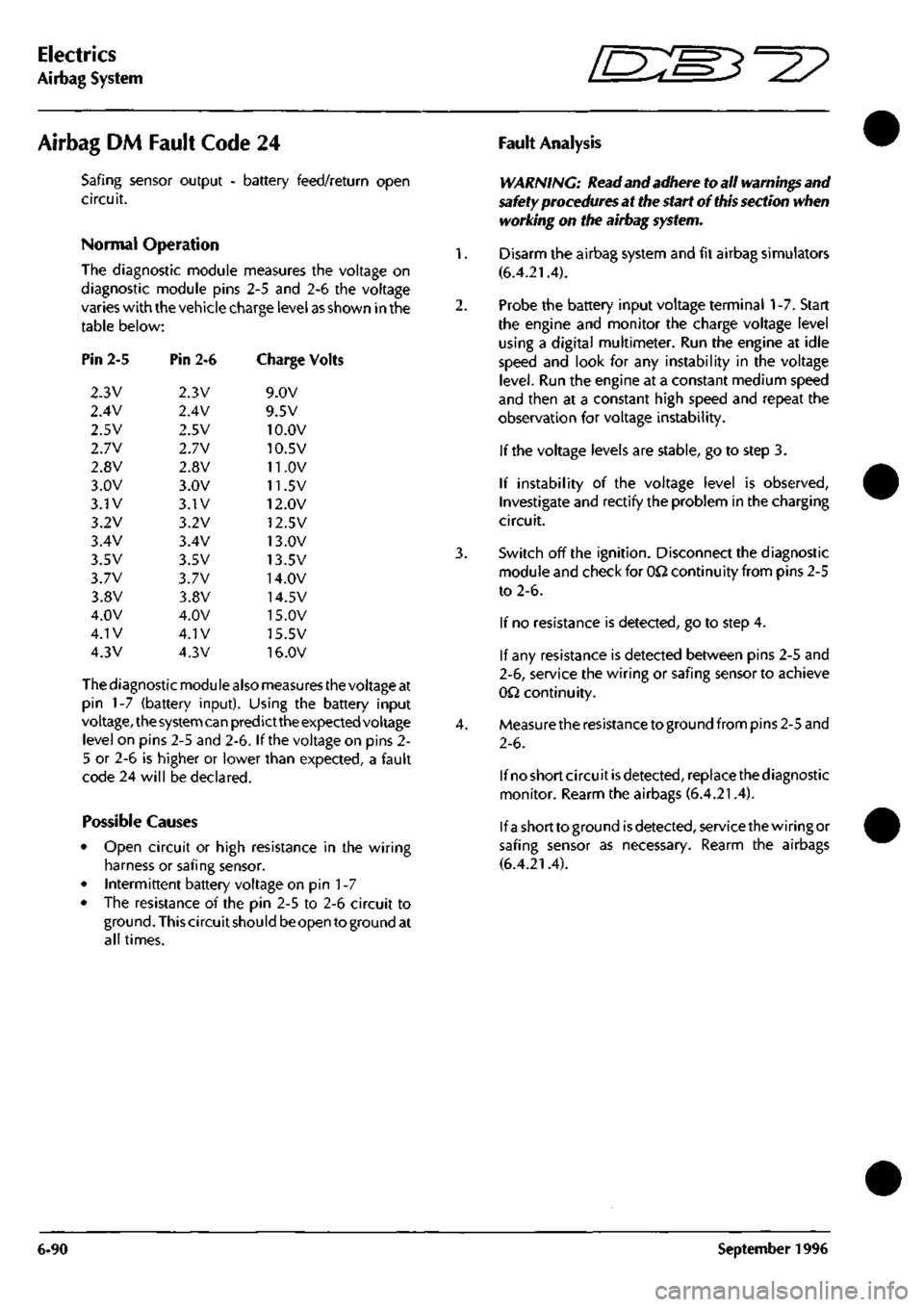

The diagnostic module measures the voltage on

diagnostic module pins 2-5 and 2-6 the voltage

varies with the vehicle charge level

as

shown in the

table below:

in 2-5

2.3V

2.4 V

2.5V

2.7V

2.8V

3.0V

3.1V

3.2V

3.4V

3.5V

3.7V

3.8V

4.0V

4.1V

4.3V

Pin 2-6

2.3V

2.4V

2.5V

2.7V

2.8V

3.0V

3.1V

3.2V

3.4V

3.5V

3.7V

3.8V

4.0V

4.1V

4.3V

Cliarge Volts

9.0V

9.5V

10.0V

10.5V

11.0V

11.5V

12.0V

12.5V

13.0V

13.5V

14.0V

14.5V

15.0V

15.5V

16.0V

The diagnostic module also measures the voltage at

pin 1-7 (battery input). Using the battery input

voltage, the system can predict the expected voltage

level on pins 2-5 and 2-6. If the voltage on pins 2-

5 or 2-6 is higher or lower than expected, a fault

code 24 will be declared.

Possible Causes

• Open circuit or high resistance in the wiring

harness or safing sensor.

• Intermittent battery voltage on pin 1-7

• The resistance of the pin 2-5 to 2-6 circuit to

ground.

This circuit should be open to ground at

all times.

Fault Analysis

WARNING: Read and adhere to all warnings and

safety procedures at the start of

this

section when

working on the airbag system.

1.

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

2.

Probe the battery input voltage terminal

1

-7. Start

the engine and monitor the charge voltage level

using a digital multimeter. Run the engine at idle

speed and look for any instability in the voltage

level.

Run the engine at a constant medium speed

and then at a constant high speed and repeat the

observation for voltage instability.

If the voltage levels are stable, go to step 3.

If instability of the voltage level is observed,

Investigate and rectify the problem in the charging

circuit.

3. Switch off the ignition. Disconnect the diagnostic

module and check for OQ continuity from pins 2-5

to 2-6.

If no resistance is detected, go to step 4.

If any resistance is detected between pins 2-5 and

2-6,

service the wiring or safing sensor to achieve

Ofi continuity.

4.

Measure the resistance to ground from pins 2-5 and

2-6.

If no short circuit is detected, replace the diagnostic

monitor. Rearm the airbags (6.4.21.4).

If

a

short to grou

nd

is detected, service the wiring or

safing sensor as necessary. Rearm the airbags

(6.4.21.4).

6-90 September 1996

Page 207 of 421

o; D^?

Electrics

Airbag System

Airbag DM Fault Code 32

Drivers airbagcircuit high resistance or open circuit.

Normal Operation

The diagnostic module measures the resistance

across pins 2-4 and 2-5 every time the ignition is

switched on. The resistance should be 1.6 to

1.8£2.

This value is made up of the airbag

1

.OQ and the

cable reel cassette windings 0.3-0.4Q per winding.

If the total resistance in the drivers airbag circuit

exceeds 4.0^, fault code 32 will be declared and

the airbag lamp will be illuminated.

Note: The

resistance

of

the airbag simulator is

2.5Q,

therefore expect total resistance readings

of 2.8 - 2.9Q

with

the simulator

fitted.

Caution: The drivers airbag and the cable reel

cassette connectors contains shorting bars which

short circuit pins 1 and 3 of the connectors when

disconnected.

DO NOT REMOVE THE AIRBAG SHORTING

BAR

UNDER ANY CIRCUMSTANCES.

The harness shorting bars may be temporarily

removed during the following resistance checks.

Possible Causes

• Excessive resistance in the cable reel cassette

connections.

• Open circuitor high resistance in the cable reel

cassette windings.

• Open circuit or high resistance in the wiring

harness

• Open circuit or high resistance in the drivers

airbag module.

• Defective diagnostic module.

WARNING: Do not attempt a direct resistance

check on the airbag module. Accidental

deployment can occur due to the induced voltage

from the measuring equipment.

3.

Fault Analysis

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

Disconnect the diagnostic module and remove the

plastic wedge from connector 2 (black). Measure

the resistance between pins 2-4 and 2-5. The

resistance should be 2.8 - 2.9Q.

If the resistance is 2.8 - 2.9Q, go to step 3.

if the resistance is not in the range 2.8 - 2.9D, isolate

the continuity problem noting the following:

a) Pin 2-4 is shorted to pin 2-5 by a shorting link

. when plug 2 of the diagnostic connector is

removed.

Removal of the plastic wedge from

the plug will remove the short circuit.

b) Both halves of the cable reel conneaor have

shorting links which will short pin 1 to pin 3

when the connection is removed. Removal of

the plastic wedge horn either half will remove

the short circuit in that part of the wiring.

c) A shorting link is fitted in the airbag module

connector. Do not attempt to remove this

shorting link or the plastic wedge. Do not

attempt to measure the resistance of the airbag

module.

d) Carefully replace all plastic wedges on

completion of the circuit checks.

The fault is therefore in either the airbag module or

in the airbag diagnostic module.

Substitute a known good diagnostic module. If

code 32 recurs with the airbag simulator fitted,

there is a fault in the wiring.

If the fau

It

code 32 does not recur, rearm the airbags

(6.4.21.4) and retest.

If fau

It

code 32 recu

rs

with the ai rbag modu

le

fitted,

the airbag module is faulty. Replace the drivers

airbag module (4.5.01.3).

September 1996 6-91

Page 208 of 421

Electrics

Airbag System ^^2?

Airbag DM Fault Code 33

Passengers airbag circuit high resistance or open

circuit.

Normal Operation

The diagnostic module measures the resistance

across pins 2-2 and 2-3 every time the ignition is

switched on. The resistance should be 0.9 to 1.1Q.

If the total resistance in the passengers airbag

circuit exceeds 4.0Q, fault code 33 will be declared

and the airbag lamp will be illuminated.

Note:

The

nominal

resistance

of the airbag simulator

is

2.5£2,

therefore

expect

a

total circuitresistancereadingof

2.4 - 2.6Q with the simulator

fitted.

Caution: The passenger airbag connector contains

shorting bars which short circuit pins 1 and 3 of

both sides of the connector when disconnected.

DO NOT REMOVE THE AIRBAG SHORTING

BAR

UNDER ANY CIRCUMSTANCES.

The harness shorting bar may be temporarily

removed during the following resistance checks.

Possible Causes

• Open circuit or high resistance in the wiring

harness

• Open circuit or high resistance in the passenger

airbag module.

• Defective diagnostic module

WARNING: Do not attempt a direct resistance

check on the airbag module. Accidental

deployment can occur due to the induced voltage

from the measuring equipment.

Fault Analysis

1.

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

2.

Disconnectthediagnostic module and remove the

plastic wedge from connector 2 (black). Measure

the resistance between pins 2-2 and 2-3. The

resistance should be 2.4 - 2.6Q.

if the resistance is 2.4 - 2.6Q, go to step 3.

Ifthe resistance is not in the range 2.4-2.6S2, isolate

the continuity problem noting the following:

a) In the diagnostic module connector, pin 2-2 is

shorted to pin 2-3 by a shorting link when plug

2 of the diagnostic connector is removed.

Removal of the plastic wedge from the plug wi

11

remove this short circuit.

b) At the airbag module harness connector, pin 1

is shorted to pin 3 when the airbag is

disconnected. Removal of the plastic wedge

from the plug will remove this short circuit.

c) The shorting link fitted in the airbag module

connector will short pin 1 to pin 3 when the

airbag is disconnected. Do not attempt to

remove

this

shorting link or the plastic wedge.

Do not attempt

to

measure the resistance of the

airbag module.

c) Carefully replace all plastic wedges on

completion of the circuit checks.

3. The fault is therefore in either the airbag module or

in the airbag diagnostic module.

Substitute a known good diagnostic module. If

code 33 recurs with the airbag simulator fitted,

there is still a fault in the wiring or the simulator.

Ifthe fault code 33 does not recur, rearm the airbags

(6.4.21.4) and retest.

If fault code 33 recurs with the airbag module fitted,

the airbag module is faulty. Replace the passengers

airbag module (7.8.02.6).

6-92 September 1996

Page 209 of 421

in:m3'^?

Electrics

Airbag System

Airbag DM Fault Code 34

Drivers airbag circuit low resistance or short circuit.

Normal Operation

The diagnostic module measures the resistance

across pins 2-5 and 2-4 every time the ignition is

switched on. The resistance should be 1.6 to 1.8Q.

This value is made up of the airbag

1

.OQ and the

cable reel cassette windings 0.3-0.4£2 per winding.

If the total resistance in the passengers airbag

circuit falls below 0.7Q, fault code 34 will be

declared and the airbag lamp will be illuminated.

Note: The nominal

resistance

of the airbag simulator is

2.5Q, therefore expect

a

total circuit resistance readingof

3.1 -

3.3£2

with the simulator

fitted.

Caution: The drivers airbag connector contains

shorting bars which short circuit pins 1 and 3 of

both sides of the connector when disconnected.

DO NOT REMOVE THE AIRBAC CONNECTOR

SHORTING BAR UNDER ANY CIRCUMSTANCES.

The airbag harness shorting bar may be temporarily

disabled during the following resistance checks.

Possible Causes

• Poorly mated cable reel cassette connector. If

the connector is poorly mated, the shorting bars

may not be fully retracted.

• Faulty shorting bar may short circuit 2-4 and 2-

5 together.

• Short circuit in the cable reel cassette windings.

• A short across the airbag terminals in the airbag

module.

Fault Analysis

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

Disconnect the diagnostic module and remove the

plastic wedge from connector 2 (black). Measure

the resistance between pins 2-5 and 2-4. The

resistance should be 3.1 - 3.3Q.

If the resistance is 3.1 to 3.3Q, go to step 4.

If the resistance is below 3.1 - 3.3Q, go to step 3.

Disconnect the cable reel cassette connector at the

steering column and remove the plastic wedge.

Measure the resistance from pins 2-4 and 2-5 at the

diagnostic module connector.

If the resistance is infinity, check the cable reel

cassette for short circuits. Replace the column

switchgear assembly if necessary. Refit the plastic

wedges. Reconnect the diagnostic module. Clear

the code 34. Rearm the airbags (6.4.21.4).

If the resistance is less than infinity, replace the

main airbag harness. Refit the plastic wedges.

Reconnect the diagnostic module. Clear the code

34.

Rearm the airbags (6.4.21.4).

Since the circuit resistance is in specification, the

fault must lie in the diagnostic module or in the

airbag module.

Substitute a known good diagnostic module. If

code 34 recurs with the airbag simulator fitted,

there is still a fault in the wiring or the simulator.

If the fault code 34 does not recur, rearm the airbags

(6.4.21.4) and retest.

If fault code 34 recurs with the airbag modulefitted,

the airbag module is faulty. Replace the drivers

airbag module (4.5.01.3).

September 1996 6-93

Page 210 of 421

Electrics

Airbag System ^^?

Airbag DM Fault Code 35

Passengers airbag circuit low resistance or short

circuit.

Normal Operation

The diagnostic module measures the resistance

across pins 2-2 and 2-3 every time the ignition is

switched on. The resistance should be 0.9 to

1.1Q..

If the total resistance in the passengers airbag

circuit falls below 0.7S2, fault code 35 will be

declared and the airbag lamp will be illuminated.

f^ote:

The

nominal

resistance

of the airbag simulator

is

2.5£2,

therefore expect

a

total circuit

resistance

reading of

2.4 - 2.6Q with the simulator fitted.

Caution: The passengers airbag connector contains

shorting bars which short circuit pins 1 and 3 of

both sides of the connector when disconnected.

DO NOT REMOVE OR DISABLE THE AIRBAG

CONNECTOR SHORTING BAR UNDER ANY

CIRCUMSTANCES.

The airbag harness shorting bar may be temporarily

disabled during the following resistance checks.

Possible Causes

• Poorly mated airbag harness connector. If the

connector is poorly mated, the shorting bars

may not be fully retracted.

• Faulty shorting bar may short circuit 2-2 and 2-

3 together.

• A short across the airbag terminals in the

passengers airbag module.

Fault Analysis

1.

Disarm the airbag system and check the security of

the passengers airbag module connector before

disconnecting.

If the connector is secure, complete the disarming

procedure, fit the airbag simulators (6.4.21.4). Go

to step 2

If the connector is insecure, service as necessary,

clear the code 35, rearm the airbags. Check that

code 35 does not recur.

2.

Disconnectthediagnostic module and removethe

plastic wedge from connector 2 (black). Measure

the resistance between pins 2-2 and 2-3. The

resistance should be 2.4 - 2.6Q.

If the resistance is 2.4 - 2.6Q, go to step 4.

If the resistance is below 2.4 - 2.6fl, go to step 3.

3. Disconnect the airbag simulator at the passengers

airbag module and remove the plastic wedge from

the harness connector. Measure the resistance

between pins 2-2 and 2-3 at the diagnostic module

connector.

If the resistance is infinity, the airbag harness is

good at this time. Swap the airbag simulators at the

drivers and passengers airbag connectors. Repeat

the resistance check. If the resistance is less than

infinity, there is a fault in the passengers airbag

harness connector. Service the connector or replace

the harness as necessary. Refit the plastic wedges.

Reconnect the diagnostic module. Clear the code

35.

Rearm the airbags.

If the resistance is less than infinity, service the

bulkhead harness as necessary. Refit the plastic

wedges. Reconnect the diagnostic module. Clear

the code 35. Rearm the airbags (6.4.21.4).

4.

Since the circuit resistance is in specification, the

fault must lie in the diagnostic module or in the

airbag module.

Substitute a known good diagnostic module. If

code 35 recurs with the airbag simulator fitted,

there is still a fault in the wiring or the simulator.

If the fault code 35 does not recur, rearm the airbags

(6.4.21.4) and retest.

If fault code 35 recurs with the airbag module fitted,

the airbag module is faulty. Replace the passengers

airbag module (7.8.02.6).

6-94 September 1996