window ASTON MARTIN DB7 1997 Owner's Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 193 of 421

^7

Electrics

Airbag System

6.4.21.2

Airbag 'Safing' Sensor Renew

Read and adhere to all warnings and safety

procedures quoted at the start of this section when

working on the airbag system.

1.

Disconnect the battery and wait for at least one

minute before working on the airbag system.

Note:

The

vehicle battery must be disconnected within

12 secondsofswitchingoffthe ignition to avoid the alarm

siren sounding.

^h

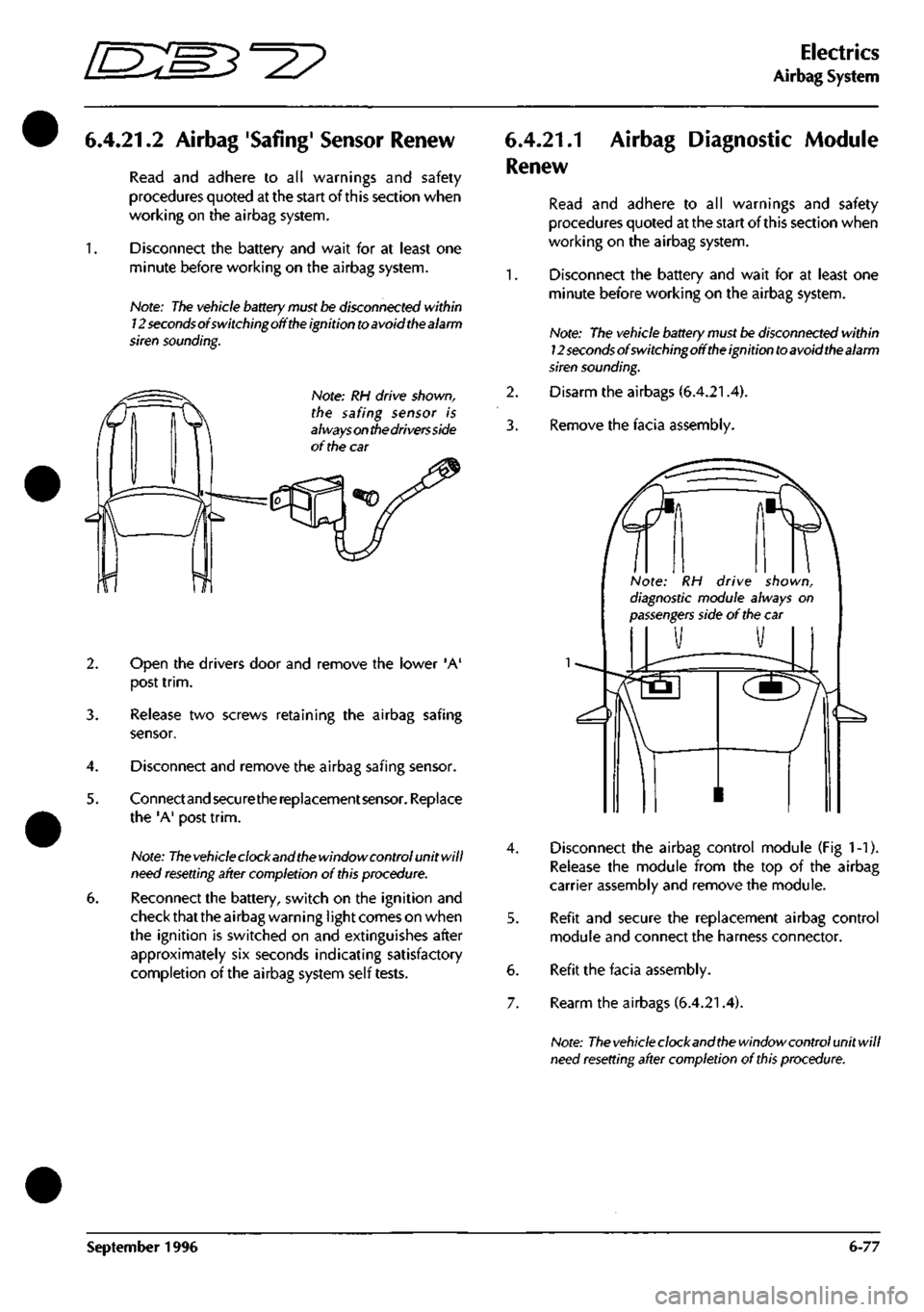

Note: RH drive shown,

the safing sensor is

always

on

the drivers side

of the car

2. Open the drivers door and remove the lower 'A'

post

trim.

3. Release two screws retaining the airbag safing

sensor.

4.

Disconnect and remove the airbag safing sensor.

5. Connectand securethe replacement sensor. Replace

the 'A' post

trim.

Note:

The

vehicle clock and

the

window control unit will

need

resetting

after completion of

this

procedure.

6. Reconnect the battery, switch on the ignition and

check that the airbag warning

I

ight comes on when

the ignition is switched on and extinguishes after

approximately six seconds indicating satisfactory

completion of the airbag system self tests.

6.4.21.1

Renew

Airbag Diagnostic Module

1.

2.

3.

4.

6.

7.

Read and adhere to all warnings and safety

procedures quoted at the start of this section when

working on the airbag system.

Disconnect the battery and wait for at least one

minute before working on the airbag system.

Note: The vehicle battery must

be

disconnected within

l2secondsofswitchingofftheignitiontoavoidthealarm

siren

sounding.

Disarm the airbags (6.4.21.4).

Remove the facia assembly.

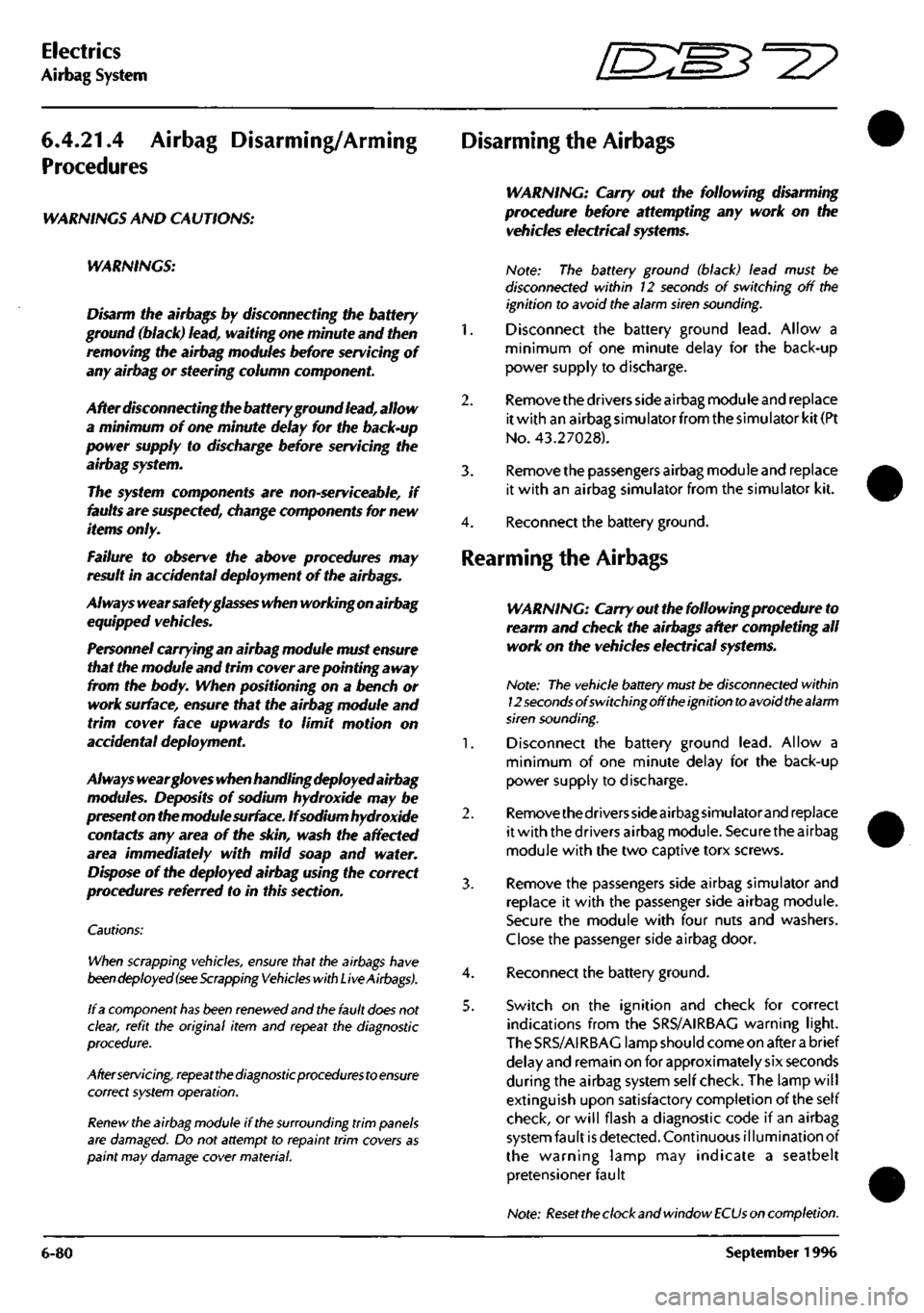

Note: RH drive shown,

diagnostic module always on

passengers

side of

the

car

Disconnect the airbag control module (Fig 1-1).

Release the module from the top of the airbag

carrier assembly and remove the module.

Refit and secure the replacement airbag control

module and connect the harness connector.

Refit the facia assembly.

Rearm the airbags (6.4.21.4).

Note:

The

vehicle clock and

the

window control unit will

need

resetting

after completion of this procedure.

September 1996 6-77

Page 196 of 421

Electrics

Airbag System ^2?

6.4.21.4

Airbag Disarming/Arming

Procedures

WARNINGS AND CAUTIONS:

WARNINGS:

Disarm the airbags by disconnecting the battery

ground (black)

lead,

waiting one minute and then

removing the airbag modules before servicing of

any airbag or steering column component.

After disconnecting the battery ground

lead,

allow

a minimum of one minute delay for the back-up

power supply to discharge before servicing the

airbag system.

The system components are non-serviceable, if

faults are

suspected,

change components for new

items

only.

Failure to observe the above procedures may

result in accidental deployment of the airbags.

Always wear safety

glasses

when working on airbag

equipped vehicles.

Personnel carrying an airbag module must ensure

that the module and trim cover are pointing away

from the

body.

When positioning on a bench or

work surface, ensure that the airbag module and

trim cover face upwards to limit motion on

accidental deployment.

Always wear

gloves

when handling deployed airbag

modules. Deposits of sodium hydroxide may be

presenton the module surface. If sodium hydroxide

contacts any area of the skin, wash the affected

area immediately with mild soap and

water.

Dispose of the deployed airbag using the correct

procedures referred to in this section.

Cautions:

When scrapping vehicles,

ensure

that the

airbags

have

been deployed (see

Scrapping Vehicles

with Live

Airbags).

If a component

has been

renewed and the fault

does

not

clear,

refit the original item and repeat the diagnostic

procedure.

After

servicing,

repeatthe diagnostic

procedures

to ensure

correct

system

operation.

Renew

the airbag module if the surrounding trim

panels

are

damaged.

Do not attempt to repaint trim covers as

paint may

damage

cover material.

Disarming the Airbags

3.

4.

WARNING: Carry out the following disarming

procedure before attempting any work on the

vehicles electrical

systems.

Note: The battery ground (black) lead must be

disconnected within 12 seconds of switching off the

ignition to avoid the alarm siren sounding.

Disconnect the battery ground

lead.

Allow a

minimum of one minute delay for the back-up

power supply to discharge.

Remove the drivers side airbag module and replace

it with an airbag simulatorfrom the simulator kit (Pt

No.

43.27028).

Remove the passengers airbag module and replace

it with an airbag simulator from the simulator kit.

Reconnect the battery ground.

Rearming the Airbags

WARNING: Carry out the following procedure to

rearm and check the airbags after completing all

work on the vehicles electrical

systems.

Note: The vehicle battery

must be

disconnected within

12

seconds

of switching off

the

ignition

to

avoid the alarm

siren sounding.

^. Disconnect the battery ground

lead.

Allow a

minimum of one minute delay for the back-up

power supply to discharge.

2.

Removethedriverssideairbagsimulatorand replace

it with the drivers airbag module. Secure the airbag

module with the two captive torx screws.

3. Remove the passengers side airbag simulator and

replace it with the passenger side airbag module.

Secure the module with four nuts and washers.

Close the passenger side airbag door.

4.

Reconnect the battery ground.

5. Switch on the ignition and check for correct

indications from the SRS/AIRBAG warning light.

TheSRS/AIRBAC lamp should come on after

a

brief

delay and remain on for approximately six seconds

during the airbag system self check. The lamp will

extinguish upon satisfactory completion of the self

check, or will flash a diagnostic code if an airbag

system fault is detected. Continuous illumination of

the warning lamp may indicate a seatbelt

pretensioner fault

Note:

Reset the

clock and window

ECUs

on completion.

6-80 September 1996

Page 219 of 421

'^^

Electrics

Seat Belt Pretensioner

6.6.26.1

Pretensioner Control Module -

Renew

Read the warnings given in system fault strategy

and service instructions on the previous page before

starting the following procedure.

Procedure

1.

Disconnect the battery ground (black) lead and

wait at least 10 minutes for the pretensioner power

supply to fully discharge before working on the

pretensioner system.

Note:

The

vehicle battery must

be

disconnected within

12

seconds

of switching off

the

ignition to avoid the alarm

siren sounding.

2. Motor the right front seat to its rearmost position.

3. Remove the floor carpet and the ECU cover.

4.

Disconnect the pretensioner control module

connector (orange connector with black safety

clip).

5. Remove 3 flange screws securing the module,

noting the position of the earth strap.

6. Fit the new pretensioner control module with the

connector facing to the rear and secure with 3

flange screwsensuringthatthe earth strap is secured

with the outboard rear screw.

7. Connect the orange connector to the control

module.

8. RefitandsecuretheECU cover and the floor carpet.

9. Reconnect the battery ground (black)

lead.

Note:

The

vehicle clock and the window control unit will

need

resetting

after completion of this procedure.

10.

Switch on the ignition and check that the airbag

warni ng I ight comes on when the ign ition

is

switched

on and extinguishesafterapproximately sixseconds

indicating satisfactory completion of the

pretensioner and airbag system self tests.

6.6.24.1

Pretensioner Assembly Renew

Read the warnings given in system fault strategy

and service i nstruaions on the previous page before

starting the following procedure.

1.

2.

4.

Procedure

Motor the drivers seat to its rearmost position.

Disconnect the battery ground (black) lead and

wait at least 10 minutes for the pretensioner power

supply to fully discharge before working on the

pretensioner system.

Note: Disconnect the battery within 12 seconds of

switchingoffthe ignition to avoid the alarm siren sounding.

Remove the pretensioner trim cover. Unbolt the

drivers seat. Tip the seat rearwards and disconnect

the seat and pretensioner squib connectors.

Release one bolt at the

base

of the seat belt

stal k

and

remove the pretensioner assembly.

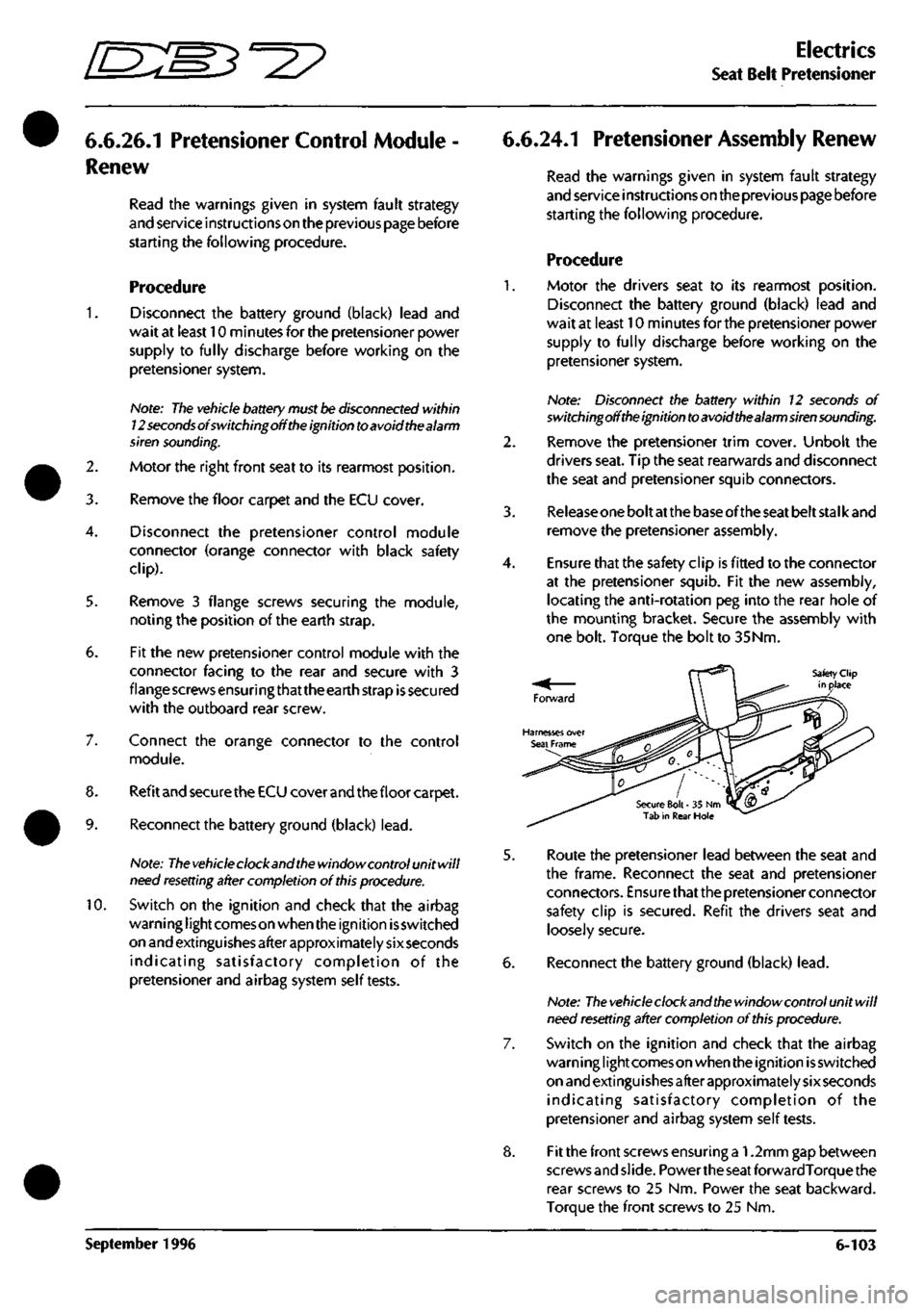

Ensure that the safety clip is fitted to the connector

at the pretensioner squib. Fit the new assembly,

locating the anti-rotation peg into the rear hole of

the mounting bracket. Secure the assembly with

one bolt. Torque the bolt to 35Nm.

Safety Clip in place

5. Route the pretensioner lead between the seat and

the frame. Reconnect the seat and pretensioner

connectors. Ensure that the pretensioner connector

safety clip is secured. Refit the drivers seat and

loosely secure.

6. Reconnect the battery ground (black)

lead.

Note:

The

vehicle clock and

the

window control unit will

need

resetting

after completion of this procedure.

7. Switch on the ignition and check that the airbag

warn i ng I ight comes on when the ignition

is

switched

on and extingu

ishes

after approximately six seconds

indicating satisfactory completion of the

pretensioner and airbag system self tests.

8. Fit the front screws ensuring a 1.2mm gap between

screws and slide. Power the seat forwardTorque the

rear screws to 25 Nm. Power the seat backward.

Torque the front screws to 25 Nm.

September 1996 6-103

Page 227 of 421

3-^?

Electrics

Seat Removal/Replacement 97.5 MY

6.6.03

Seat Removal 97.5 MY

Description

The 97.5 MY front seats are common to the DB7

Coupe

and

Volante

models.

Seat

switch

assembi ies

are located on the outboard side of both driver and

passenger

seats.

The front switch controls fore and

aft movement and the seat height adjustment. The

centre switch controls the recline adjustment. The

rear switch

controls

the

lumbar support adjustment.

The seat

heater switches are mounted on the centre

console, forward of the gear selector

lever.

Only one of

the

slide,

recline or height motors can

be driven under manual control at any one time.

Each seat switch pack is hard wired to the relevant

Seat Control

Module

beneath each

seat.

The

module

outputs are hard wired to the seat motors.

Removal

WARNING -

Seat

belt

Pretensioners

(if fitted):

To avoid the possibility

of

personal

injury

caused

by accidental deployment of the seat belt

pretensioner,

disconnect

the

vehicle battery and

wait at

least

10

minutes

for all

voltages

to fully

discharge

before working on the

pretensioner

system.

This covers the possibility

of

the normal

capacitor

discharge

circuits being inoperative and

failing to discharge the detonator capacitor when

instructed

to

do

so.

Procedure

1.

Motortheseatto

its

maximum forward position and

remove the fixings at the rear of the slides.

2.

Motor the seat to its maximum rearward position

and remove the front seat slide fixings.

3. Disconnect the battery

ground

(black)

lead.

Wait at

least 10 minutes for the pretensioner power supply

to fully discharge before working on the seat if a

pretensioner is fitted.

Note: Disconnect the battery within 12 seconds of

switching off the ignition to avoid the alarm siren sounding.

4.

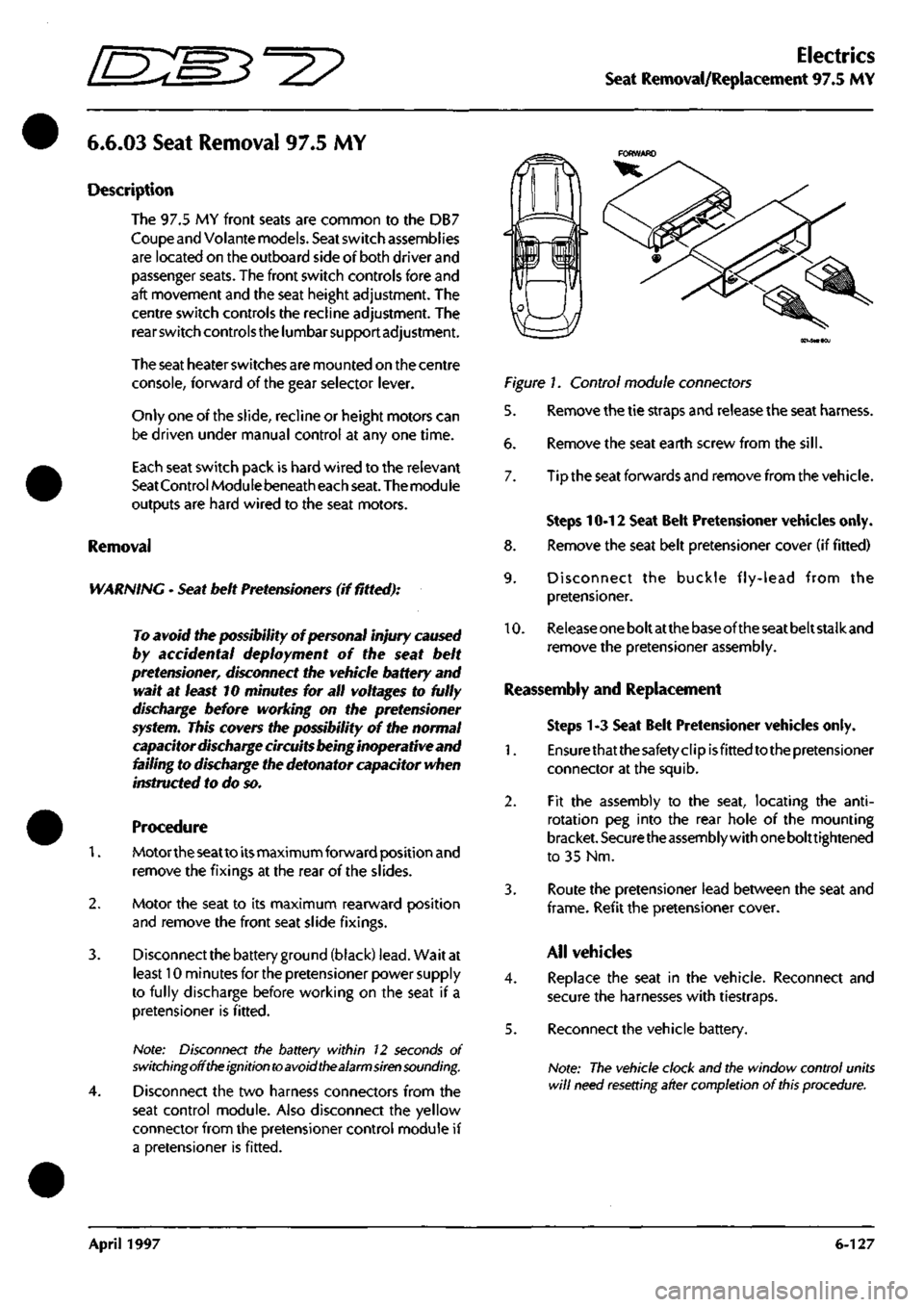

Disconnect the two harness connectors from the

seat control module. Also disconnect the yellow

connector from the pretensioner control module if

a pretensioner is fitted.

Figure 1. Control module connectors

5. Remove the tie straps and release the seat harness.

6. Remove the seat earth screw from the

sill.

7. Tip the seat forwards and remove from the vehicle.

Steps 10-12 Seat Belt Pretensioner vehicles only.

8. Remove the seat belt pretensioner cover (if fitted)

9. Disconnect the buckle fly-lead from the

pretensioner.

10.

Release

one

bolt at

the

base of the

seat

belt stalk and

remove the pretensioner assembly.

Reassembly and Replacement

Steps 1-3 Seat Belt Pretensioner vehicles only.

1.

Ensurethatthesafetyclipisfittedtothepretensioner

connector at the squib.

2.

Fit the assembly to the seat, locating the

anti-

rotation peg into the rear hole of the mounting

bracket.

Securethe

assembly with

one

bolttightened

to 35 Nm.

3. Route the pretensioner lead between the seat and

frame.

Refit the pretensioner

cover.

All vehicles

4.

Replace the seat in the vehicle. Reconnect and

secure the harnesses with tiestraps.

5. Reconnect the vehicle battery.

Note:

The vehicle clock and the window control units

will

need resetting after completion

of

this

procedure.

April 1997 6-127

Page 228 of 421

Electrics

Seat Control Module Removal/Replacement 97.5 MY 'O "3^2?

Switch on the ignition and checi< that the airbag

warning lamp comes on when the ignition is

switched on and extinguishes after approximately

six seconds indicating satisfactory completion of

the pretensioner and airbag system self

tests.

Fit

the front

seat

retaining screws ensuring

a

1.2mm

gap between the screw heads

and

the

slides.

Power

the seat forward and refit the rear screws.

Caution:

Centralise the

rear

fixing holes

with the

body weld

nuts

prior to

inserting the

bolts.

Torque the rear screws to 25 Nm. Power the seat

backwards. Torque the front screws to 25 Nm.

Motor the seat through its full range of movement

to ensure correct

operation.

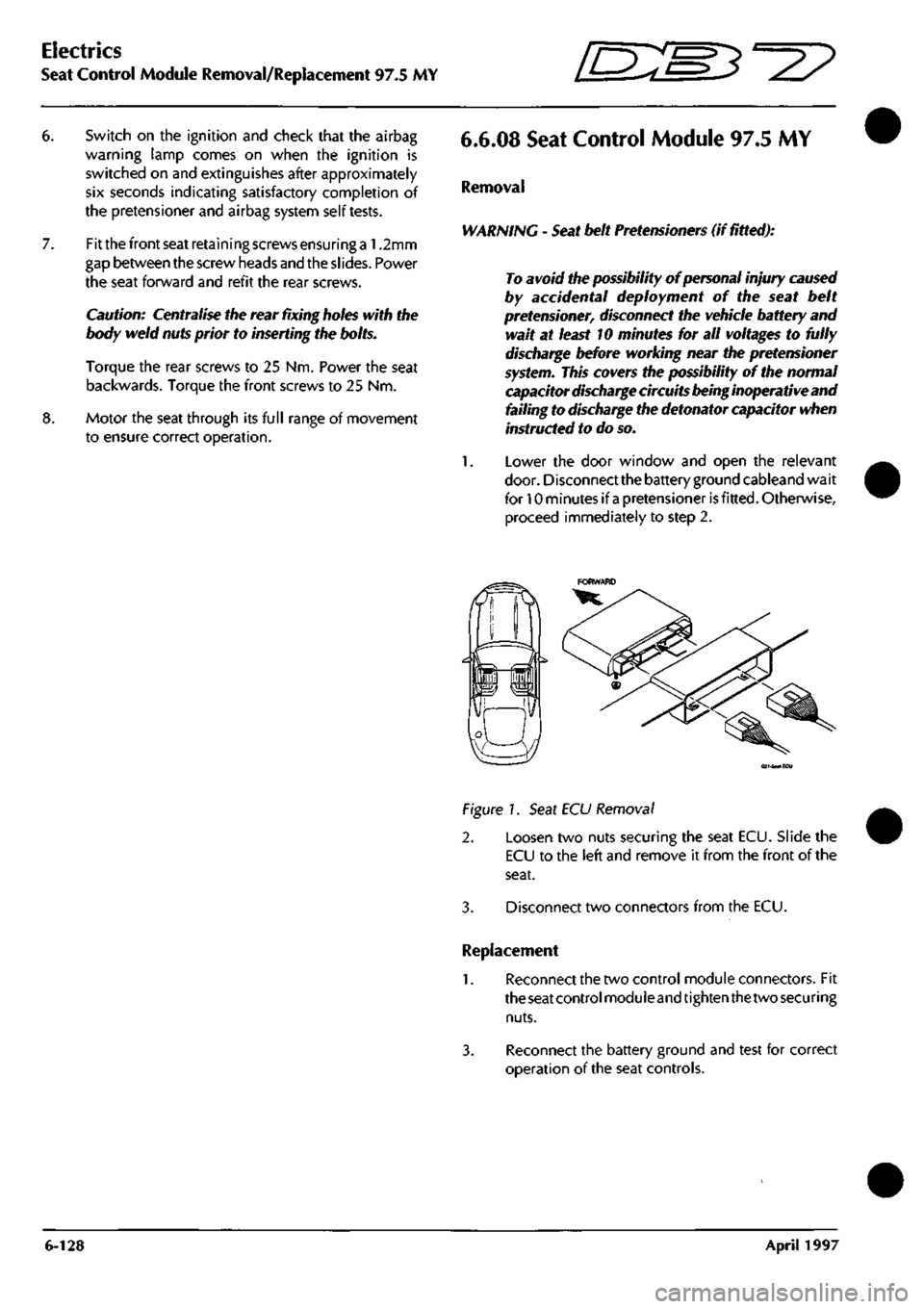

6.6.08

Seat Control Module 97.5 MY

Removal

WARNING -

Seat

belt

Pretensioners

(if

fitted):

To avoid the possibility

of

personal injury caused

by accidental deployment of the seat belt

pretensioner,

disconnect

the

vehicle battery and

wait at

least

10

minutes

for all

voltages

to fully

discharge

before

working

near the

pretensioner

system.

This covers

the

possibility

of

the

normal

capacitor

discharge circuits

being

inoperative and

failing to discharge the detonator capacitor when

instructed

to

do

so.

1.

Lower the door window and open the relevant

door. Disconnect

the

battery ground cableand wait

for 10 minutes if

a

pretensioner

is

fitted.

Otherwise,

proceed immediately to step 2.

(ei-SMiECu

Figure!.

Seat ECU Removal

2. Loosen two nuts securing the seat ECU. Slide the

ECU to the left and remove it from the front of the

seat.

3. Disconnect two connectors from the ECU.

Replacement

1.

Reconnect the two control module connectors. Fit

the seat control

moduleand

tighten

thetwo securing

nuts.

3. Reconnect the battery ground and test for correct

operation of the seat controls.

6-128 April 1997

Page 229 of 421

O" D^?

Body and Trim

Contents

Contents

Body and Trim

Body Repair

Potential Risks

Precautions

General Repair Notes

Steel Body Parts - Repair, Remove and Replace

RTM Body Parts

Body Panel and Trim Removal

Front Apron

Front Undertray

Wheel Arch Liners

Side Sills (top fixings)

Side Sills (bottom fixings)

Rear Bumper

Doors

Door Liners

Door Liner (components)

Steering Wheel

Column Switches

Instrument Panel (surround)

Instrument Panel

Facia Underscuttles

Glove Box

Facia Mountings (1)

Facia Mountings (2)

Console Instruments

Radio

Front Seats

Ashtray

Centre Console

Seat ECU Covers

Rear Console

Rear Seats and C Post Trim

Quarter Panels, B Post Panels, Parcel Shelf

Headlining

Roof System Description and Repair Procedures

Vol ante Roof

Roof and Rear Quarter Light Control

Roof Component Location

Roof Control System

9.0.02.1

Roof Removal/Replacement

9.0.02.3

Roof Hydrailic Control System

9.0.02.5

Bleeding the Roof Hydraulic System

9.1.01.1

Rear Quarter Window Renewal

9.1.01.2

Rear Quarter Glass Adjustment

9.1.01.4

Rear Quarter Window Lift Motor - LH

9.1.01.5

Rear Quarter Window Lift Motor - RH

Roof Sealing and Wind Noise

9.2.01.5

'A' Post/Header Sealing and Lock Adj

9.2.01.6

Roof Seals - Adjustment

9.2.01.7

Cheater Plate Seals - Adjust/Renew

9.2.01.8

Door Glass Adjustment

Alcantara Cleaning

7-1

7-2

7-2

7-3

7-3

7-4

7-5

7-6

Sheet 1

Sheet 2

Sheet 3

Sheet 4

Sheet 5

Sheet 6

Sheet 7

Sheet 8

Sheet 9

Sheet 10

Sheet 11

Sheet 12

Sheet 13

Sheet 14

Sheet 15

Sheet 16

Sheet 17

Sheet 18

Sheet 19

Sheet 20

Sheet 21

Sheet 22

Sheet 23

Sheet 24

Sheet 25

Sheet 26

Sheet 27

7-7

7-7

7-8

7-9

7-10

7-11

7-12

7-13

7-14

7-15

7-16

7-17

7-17

7-18

7-19

7-20

7-21

May 1996 7-1

Page 262 of 421

y/--^^^^3^

'—-p "^ Body and Trim

Roof Description

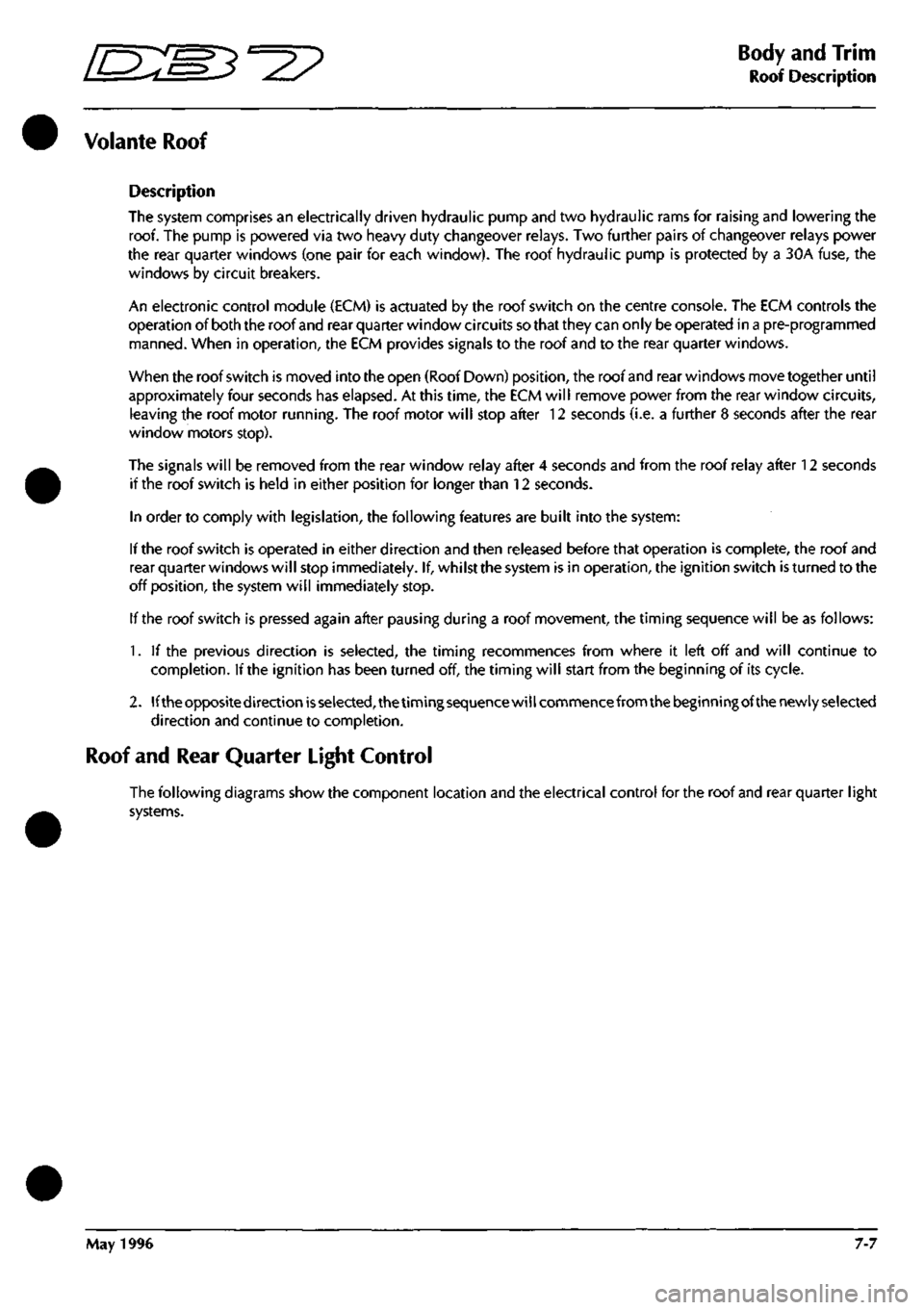

Volante Roof

Description

The system comprises an electrically driven hydraulic pump and two hydraulic rams for raising and lowering the

roof.

The pump is powered via two heavy duty changeover relays. Two further pairs of changeover relays power

the rear quarter windows (one pair for each window). The roof hydraulic pump is protected by a 30A fuse, the

windows by circuit breakers.

An electronic control module (ECM) is actuated by the roof switch on the centre console. The ECM controls the

operation of

both

the roof

and

rear quarter window circuits

so

that they can only be operated in

a

pre-programmed

manned.

When in operation, the ECM provides signals to the roof and to the rear quarter windows.

When the roof

switch

is moved into the open (Roof Down) position, the roof

and

rear windows move together until

approximately four seconds has elapsed. At this time, the ECM will remove power from the rear window circuits,

leaving the roof motor running. The roof motor will stop after 12 seconds (i.e. a further 8 seconds after the rear

window motors stop).

The signals will be removed from the rear window relay after 4 seconds and from the roof relay after 12 seconds

if the roof switch is held in either position for longer than 12 seconds.

In order to comply with legislation, the following features are built into the system:

If the roof switch is operated in either direction and then released before that operation is complete, the roof and

rear quarter windows will stop immediately. If, whilst the system is in operation, the ignition switch

is

turned to the

off position, the system will immediately stop.

If the roof switch is pressed again after pausing during a roof movement, the timing sequence will be as follows:

1.

If the previous direction is selected, the timing recommences from where it left off and will continue to

completion. If the ignition has been turned off, the timing will start from the beginning of its cycle.

2.

If theoppositedirection

is

selected,

the timing sequence will commence

from the beginning

of the newly selected

direction and continue to completion.

Roof and Rear Quarter Light Control

The following diagrams show the component location and the electrical control for the roof and rear quarter light

systems.

May 1996 7-7

Page 263 of 421

Body and Trim >/—^

^^^^5^

' ^ ^

Roof Components I -^' ^—^ -^-^

Roof Component Location

Roof Switch

Hydraulic Pump

ECM

Roof Up Relay

Roof Down Relay

LH Q Light Up Relay

LH Q Light Down Relay

RH Q Light Up Relay

RH Q Light Down Relay

Fuse and Circuit Breakers

Hydraulic Rams

Heated Rear Window Overide Switch

Figure 7. Roof

System

Component Location

7-8 May 1996

Page 264 of 421

5^^

Body and Trim

Roof Control System

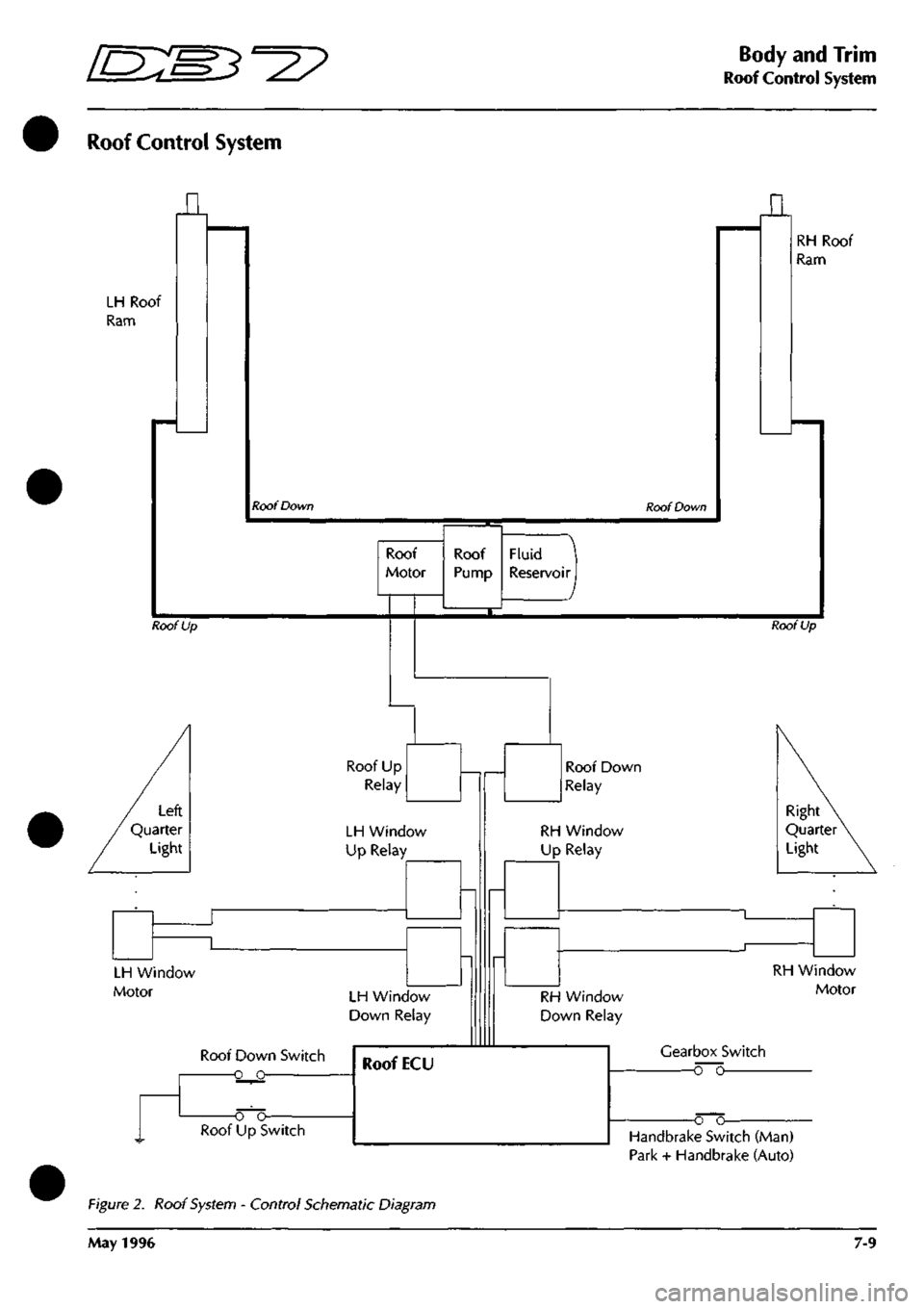

Roof Control System

LH Roof

Ram

n

Roof Down Roof Down

n

RH Roof

Ram

Roof

Motor

Roof Up

Fluid

Reservoir I

Roof Up

Roof Up

Relay

LH Window

Up Relay

LH Window

Motor LH Window

Down Relay

Roof Down Switch

-o o-

Roof Down

Relay

RH Window

Up Relay

Right

Quarter

Light

RH Window

Down Relay

RH Window

Motor

Gearbox Switch

o~o

o o-Handbrake Switch (Man)

Park + Handbrake (Auto)

Figure 2. Roof System - Control Schematic Diagram

May 1996 7-9

Page 265 of 421

Body and Trim

Roof Removal/Replacement [D::M^=2?

9.0.02.1 - Roof Removal/Replacement

1.

2.

3.

4.

5.

6.

7.

8.

Move the front seats fully forward for access.

Remove the rear seat squab and cushion. Remove

the rear quarter trim panel.

Release the roof side curtain clips.

Release the rear window support bracket securing

bolts (Fig 1-2).

Remove the side curtain clips (2 per side).

Release the side curtain rods and move the curtains

aside.

Disconnect the heated rear window connector.

Release the rear window support bracket from the

body.

Figure 1. Rear Window Support Bracket

9. Release the roof catches.

10.

Select Manual on the roof motor control switch.

Lower the roof to the midway position. Select

Electric on the roof motor control switch - the roof

will remain in a raised position.

11.

Raise the trim and remove the cable securing nuts.

12.

Release the roof outer finisher securing screws and

remove the finisher.

13.

Release the cable and roof material from the body

channel.

cqD

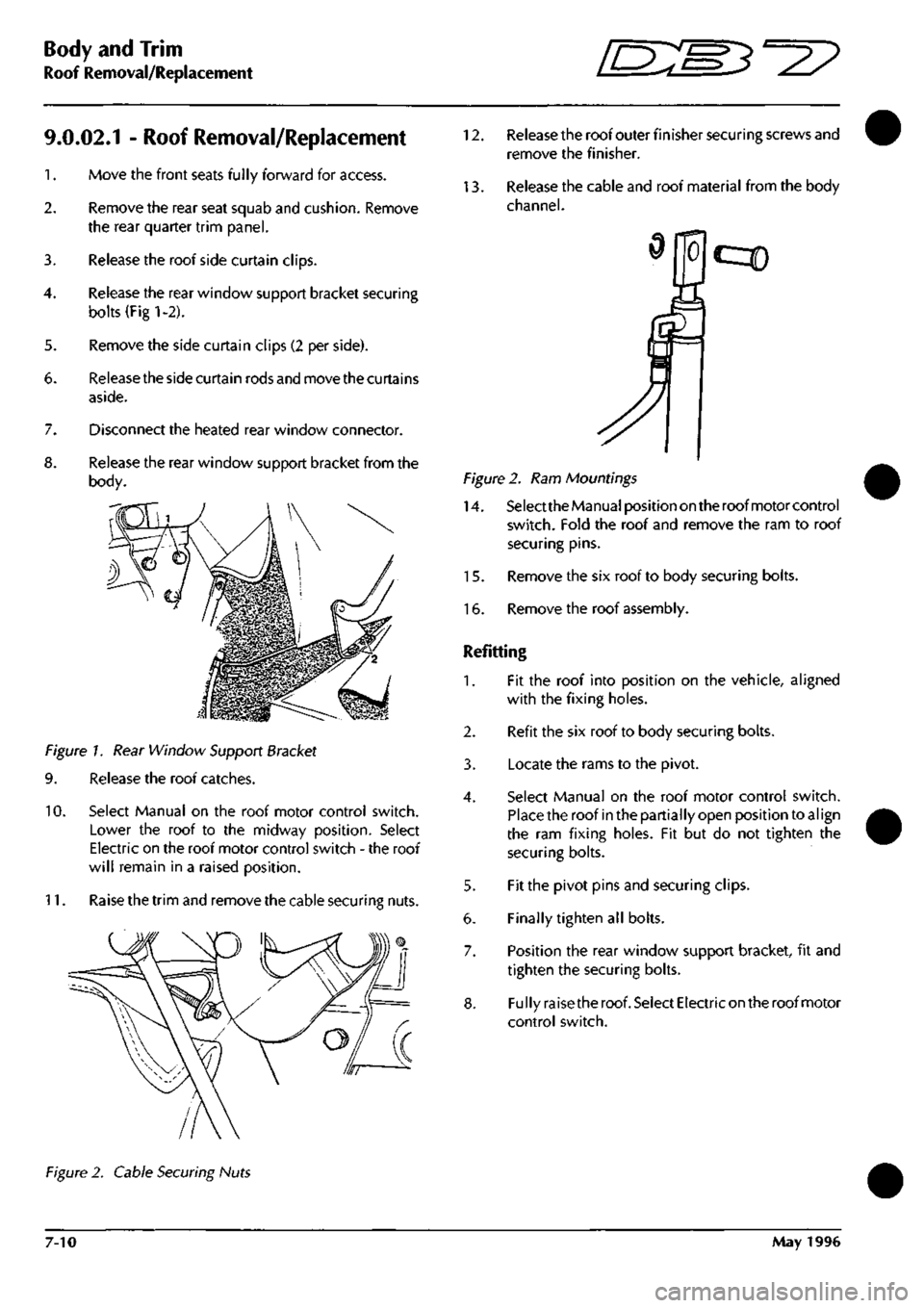

Figure 2. Ram Mountings

14.

Select the Manual position on the roof motor control

switch.

Fold the roof and remove the ram to roof

securing pins.

15.

Remove the six roof to body securing bolts.

16.

Remove the roof assembly.

Refitting

1.

Fit the roof into position on the vehicle, aligned

with the fixing holes.

2.

Refit the six roof to body securing bolts.

3. Locate the rams to the pivot.

4.

Select Manual on the roof motor control switch.

Place the roof in the partially open position to

al

ign

the ram fixing holes. Fit but do not tighten the

securing bolts.

5. Fit the pivot pins and securing clips.

6. Finally tighten all bolts.

7. Position the rear window support bracket, fit and

tighten the securing bolts.

8. Fully raise the roof. Select Electric on the roof motor

control switch.

Figure 2. Cable Securing Nuts

7-10 May 1996