ASTON MARTIN DB7 1997 Workshop Manual

Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 391 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide ^=2?

Transmission Diagnostics

Automatic transmission DB7s are fitted with a GM4L80-

E gearbox electronically controlled by a Transmission

Control Unit (TCM)

The TCM is mounted on the rear left wheel

arch.

It may be

electronically accessed from the upper diagnostic socket.

The TCM continuously monitors requests made by the

driver via the gear selector, throttle pedal, mode switch,

etc. This data is used in conjunction with speed input from

the transmission unit to calculate the optimum shift points

undercurrentconditions.Shiftpressureand ignition retard

are also controlled from this data to enhance shift quality

and reduce transmission wear.

TheTCM also detects faults within the transmission system

and stores the relevant fault codes for later analysis.

Gearshifts are controlled by two solenoid valves and a

pressure regulator within the transmission valve block

assembly.

If a serious fault occurs, the TCM removes all electrical

power from these valves and the transmission defaults to

a 'limp home' condition. In this state, only mechanical

selection of either reverse or second gear is available.

Gearshift Timing

Inputs from the performance mode switch (Sport, Normal

or 1st Gear Inhibit) and the throttle position sensor are

used to modify transmission gearshift operation

as

required

by the driver.

Sport mode raises the roadspeed at which gearshifts occur

enabling higher acceleration rates for the vehicle.

1st gear inhibit prevents engagement of first gear to reduce

the risk of wheel slip in icy conditions.

The throttle position sensor signal is continuously

monitored by the TCM to detect a rapid throttle opening.

If the throttle position sensor signal rises rapidly to above

4.5 volts, a 'Kickdown' condition is initiated. In this

condition,

upshifts are delayed to higher road speeds to

provide the higher acceleration required for overtaking

etc.

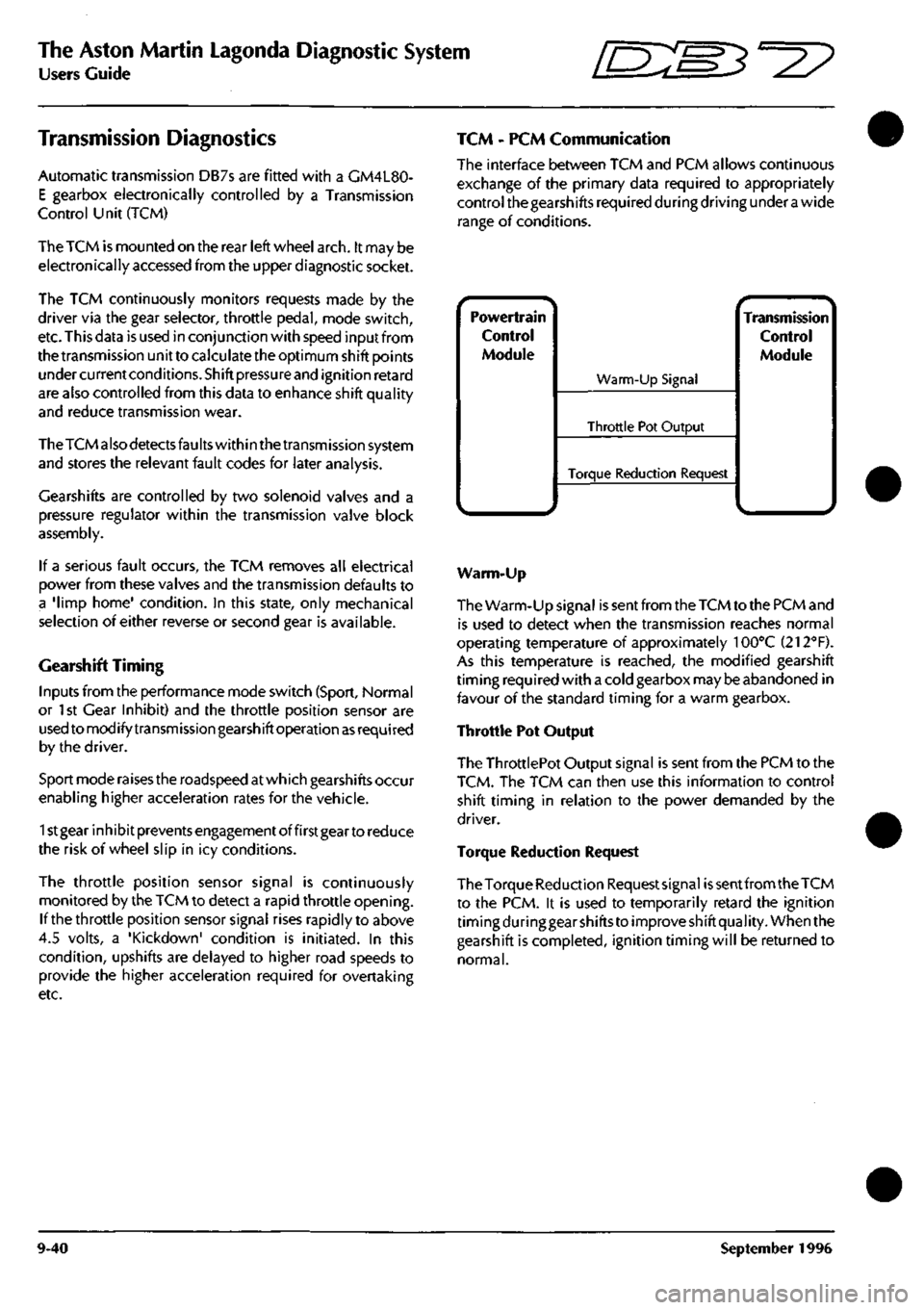

TCM - PCM Communication

The interface between TCM and PCM allows continuous

exchange of the primary data required to appropriately

control the gearshifts required during driving under

a

wide

range of conditions.

Powertrain

Control

Module

^.. ^

Warm-Up Signal

Throttle Pot Output

Torque Reduction Request

^ •- -^ Transmission

Control

Module

Warm-Up

The Warm-Up signal is sent from the TCM to the PCM and

is used to detect when the transmission reaches normal

operating temperature of approximately 100°C (212"'F).

As this temperature is reached, the modified gearshift

timing required with a cold gearbox may be abandoned in

favour of the standard timing for a warm gearbox.

Throttle Pot Output

The ThrottlePot Output signal is sent from the PCM to the

TCM.

The TCM can then use this information to control

shift timing in relation to the power demanded by the

driver.

Torque Reduction Request

The Torque Reduction Requestsignai

is

sent from the TCM

to the PCM. it is used to temporarily retard the ignition

timing during gear shifts to improve shift quality. When the

gearshift is completed, ignition timing will be returned to

normal.

9-40 September 1996

Page 392 of 421

^^?

The Aston Martin Lagonda Diagnostic System

Users Guide

Transmission Diagnostics

Selecting 'Transmission from the vehicle area menu will

present the technician with the following transmission

diagnostic tools menu:

Transmission Diagnostic

• Datalogger

• Diagnostic Trouble Codes

o

The Datalogger function is fully described in the worked

example at the rear of this PDU Users Guide.

Transmission Datalogger

The PDU datalogger function may be used to monitor the

following transmission controller signals

DIGS Number of DTCs Logged

The Diagnostics status manager (DSM) receives and

processes fault information and decides when a DTC

should be logged and the MIL turned on (if enabled). The

actual total stored is indicated by the parameter DTCS.

FBRAKE Brake Switch

The footbrake switch signal is input to the

TCM.

The input

is normally at ground potential and goes open circuit

when the brakes are applied. If the torque converter

clutch is applied it will disengage when this signal is

detected.

FMA Actual Force Motor Current

The force motor regulates the transmission fluid pressure.

It is a variable force solenoid whose coil current is

determined by the TCM. Range 0 -1.245 amps. A driver

circuit limits excessive current flow and performs a

ratiometric comparison of Desired (commanded) Force

Motor Current and Actual Force Motor current. The

parameter monitors the Actual Force Motor current 1 Bit

= l/204.8amps.

HOT Hot Mode

The signal from the transmission temperature sensor is

used to control TCC and line pressure. It is also used in

many diagnostic signals and is a critical component for

OBD II. Above 120°C the TCC is on in 2nd, 3rd and 4th

gears.

This reduces transmission temperature by decreasing

the heat generated by the torque converter. It also

provides maximum cooling by routing transmission fluid

directly to the transmission cooler in the radiator. When

the Hot Mode is ON the bit is set to 1.

IGN+ Ignition Feed Positive

The TCM receives ignition voltage through TCM pin 53.

MD Desired Force Motor Current

The force motor regulates the transmission fluid pressure.

It is a variable force solenoid whose coil current is

determined by the TCM. Range 0 -1.245 amps. A driver

circuit limits excessive current flow and performs a

ratiometric comparison of Desired (commanded) Force

Motor Current. The parameter mon itors the Desired Force

Motor current 1 Bit = 1/204.8amps.

RATIO Actual Gear Ratio

The diagnostic detects malfunction in the transmission

output components by monitoring the actual gear ratio.

The actual gear ratio is calculated using input (Ni) and

output speed (No): Ratio = Ni/No. This is compared with

the standard gear ratio for each gear. Malfunction can be

defined as: actual gear ratio is not equal to any of the

standard gear ratios.

RPM Engine Speed

The engine speed signal is input from the instrument pack.

The

signal

origi

nates

at the crankshaft

sensor.

The crankshaft

sensor signal is modified by the PCM and the instrument

pack before being input to the TCM.

SSA Shift Solenoid A

Shift solenoid A is attached to the valve body and its outlet

is open to exhaust when it is switched off. A OFF - outlet

open - 2nd and 3rd gears selected. The solenoid is

energised by the TCM providing an internal ground to

close the outlet. A ON - outlet closed -1 st and 4th gears

selected.

SSB Shift Solenoid B

Shift solenoid B is attached to the valve body and its outlet

is open to exhaust when it is switched off. B OFF - outlet

open - 1st and 2nd gears selected. The solenoid is

energised by the TCM providing an internal ground to

close the outlet. B ON - outlet closed - 3rd and 4th gears

selected.

September 1996 9-41

Page 393 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide ^7

TCCS Torque Convertor Clutch Solenoid

The torque converter clutch solenoid is mounted on the

valve body. The signal is Pulse Width Modulated at 32Hz

to provide closed loop control of the pressure across the

converter clutch plates. 1 bit = 0.39% Range 0 to 100%

TP Throttle Position

This is provided by the EECV Engine Management System

as a Pulse Width Modulated signal derived from the

throttle position signal read by that module from the

throttle position sensor.

TCS Torque Convertor Slip

Torque converter slip is defined

as

the difference between

the Input/turbine (ni) speed and the Engine speed (Ne):

Slip = Ne-Ni. The PWM duty cycle may increase from 0

to 100% when TCC is fully applied. In practice a 100%

duty cycle will be achieved only if

a

large slip is detected.

Normal ly only a 50 to 95% duty cycle will be required for

full application of the TCC. Slip is expressed in rpm. 1 Bit

- 1/8 rpm. Range -4096 to +4096 rpm.

TCSW Transmission Control Switch

A three position switch allows the driver to select Sport,

Normal or 1st Gear Inhibit mode. When 'Sport' is selected

gearshifts take place at higher engine revs. When '1st

Gear Inhibit' is selected, the transmission only operates in

the higher forward ratios to prevent wheel slip in icy

conditions.

TISSA Turbine Input Shaft Speed

Turbine speed is the speed of the input shaft of the

transmission measured by the input speed sensor mounted

on the transmission. An alternating waveform is induced

in the sensor by 31 serrations on the forward clutch

housing as it rotates. The waveform frequency and

amplitude is low at low speeds and high at high speeds.

The TCM changes this signal into a digital signal. 1 bit =

1/8 RPM. Range: 0 - 8192 RPM.

TOS+ Transmission Output Speed

The output speed sensor is mounted on the transmission

case and measures the speed of the output shaft. As the

shaft rotates an alternating waveform is induced in the

sensor which varies in frequency and voltage. The wave

form is converted into

a

digital signal by the TCM and used

to control TCC, line pressure, shift timing and torque

management. 1 bit = 1/8 RPM. Range 0-8192 RPM

TRX Transmission Control Switch X

TRY Transmission Control Switch Y

TRZ Transmission Control Switch Z

The transmission range is detected by the pressure switch

manifold (PSM) and input to the

TCM.

The signal consists

of three discrete lines X, Y, Z which transmit a 3 bit binary

code as shown in the table below.

0 = open circuit

1 = short circuit to ground

X Y Z

p

R

N

D

3

2

Error

0

1

0

1

0

0

1

0

0

0

0

1

1

1

0

1

0

0

1

0

1

VS Vehicle Speed

Veh icie speed

is

derived from

a pu Ised

wave form generated

by the speed sensor in the hypoid unit. There are 40 pulses

per shaft rotation and the TCM converts this to vehicle

speed and applies correction for axle ratio and road wheel

diameter. 1 bit -

1

kph. Range 0 - 255kph

Transmission Diagnostic Trouble Codes

The diagnostic trouble codes supported by the CM 4L80-

E

Transmission Control Module are covered indetail inthe

DB7 OBD II Diagnostics Manual.

TOT Transmission Oil Temperature

The transmission temperature sensor signal is used to

control TCC and line

pressure.

It

has a

negative temperature

coefficient so when the temperature is cold its resistance

is high and the TCM sees

a

high voltage. Asthe temperature

warms the volts drop across the sensor decreases and the

signal voltage becomes lower. The TCM converts this

analogue input into a digital signal.

1 bit =

1

°C Range -55°C to +200°C.

9-42 September 1996

Page 394 of 421

^?

The Aston Martin Lagonda Diagnostic System

Users Guide

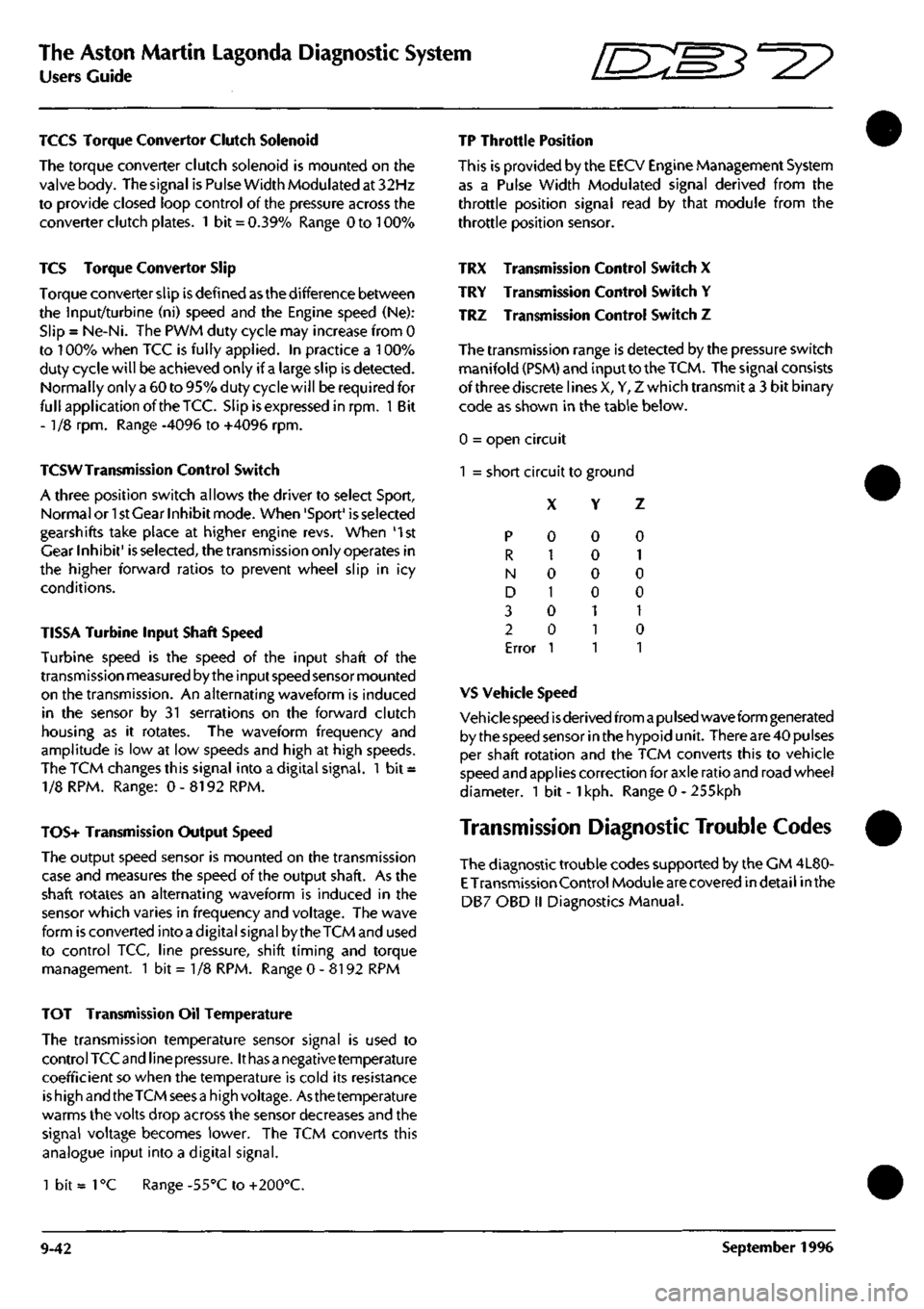

Climate Control Diagnostics

The air conditioning control module is located at the right

end of the air conditioning unit. Since this controller uses

a unique communications protocol, the PDU must be

connected directly to the unit via the Vehicle Inerface

Adaptor as shown in the following cable setup screen.

Cable Setup

Adigitalmicroprocessorwithin the control module receives

data signals from the operator controlled switches.

Comparison of these signals with those returned from

system temperature sensors and feedback devices results

in the appropriate output voltage changes needed to vary:

Blower motor speed, flap position and the solenoids

which respond to operator selected temperature demand.

The air from two blower motors is passed through the

evaporator matrix which, depending on the positions of

the humidity buttons, removes heat from the incoming air.

Dependingon the position of the two blend flaps, the cold

air either passes directly to the vehicle outlet vents, or is

passed through the heater matrix to be reheated and then

to the vehicle outlet vents.

The amount of air passing through the heater matrix is

infinitely variable depending on ambienttemperature and

the temperature selected within the vehicle.

Selecting 'Climate Control' from the vehicle area menu,

will presentthetechnician with the dataloggertool selection

screen.

Details of the signals which may be monitored in the

system may be found in the DB7 Workshop Manual -

Section 8 - Air Conditioning'

Anti-Lock Braking Diagnostics

The Teves Mk IV Braking System consists of two sub

systems, power braking and anti-lock braking.

The PDU software(DataLogger) only allows the monitoring

of the anti-lock braking system.

The ABS System consists of:

Four wheel speed sensors.

One control module.

Seven solenoid valves.

One pressure switch.

One fluid level switch.

The ABS System

is

controlled and continuously monitored

by the ABS control module, which automatically

switchesoffthesystemifafailure is identified, illuminating

a warning lamp and leaving

full,

boosted braking to all

wheels. A wheel speed sensor is installed at each wheel.

Their wheel speed related signals are processed by the

control module, which triggers the solenoid valves to

modulate hydraulic pressure, preventing the wheels from

locking.

The control module also monitors the fluid

level and will inhibit ABS operation should lowfluid level

be detected.

The Datalogger function will permit monitoring of the

complete system apart from the solenoid valves. The

control module transmits short duration test pulses of 25

to 100 microseconds to the solenoid valves. These

pulses are too fast for the PDU to monitor and as a result

would cause confusing waveforms.

Selecting 'Anti-Lock Braking' from the vehicle area menu,

will present the technician with the following menu of

diagnostic tools screen:

Anti-Lock Brakes Diagnostic

Datalogger

Diagnostic Trouble Codes

o

ABS Diagnostic Trouble Codes

The DTCs which are supported in the Teves Mk IV ABS

system are listed in the workshop manual - Section 5

Brakes Wheels and Tyres.

September 1996 9-43

Page 395 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide

Em^'^?

ABS Datalogger

The following signals in the Teves Mk IV ABS system may

be monitored using the datalogger function.

DTCs Number of DTCs Logged

The Diagnostic status manager (DSM) receives and

processes fault information and decides when a DTC

should be logged and the MIL turned on. The actual total

stored is indicated by the parameter.

FBRAKE Brake Switch

The signal from the brake switch is used by the CM to

ensure that traction control is inhibited when the brakes

are applied. The input circuitry within the CM is a

1

OK

pull-up to ignition voltage. When the switch is closed the

parameter is set to 1.

FLWS Front Left Wheel Speed Sensor

An indication sensor outputs a sinusoidal wave form 48

pulses per revolution. The output is processed by the CM

to control braking and traction. The sensor is continually

monitored for open and short failure and operating range.

If its output exceeds 330km/h it is deemed to be faulty and

the CM is disabled. The parameter tracks the sensor

weaveform through 255 steps.

FRWS Front Right Wheel Speed Sensor

An indication sensor outputs a sinusoidal wave form 48

pulses per revolution. The output is processed by the CM

to control braking and traction. The sensor is continually

monitored for open and short failure and operating range.

If its output exceeds 330km/h it

is

deemed to be faulty and

the CM is disabled. The parameter tracks the sensor

weaveform through 255 steps.

RLWS Rear Left Wheel Speed Sensor

An indication sensor outputs a sinusoidal wave form 48

pulses per revolution. The output is processed by the CM

to control braking and traction. The sensor is continually

monitored for open and short failure and operating range.

If its output exceeds 330km/h it

is

deemed to be faulty and

the CM is disabled. The parameter tracks the sensor

weaveform through 255 steps.

RRWS Rear Right Wheel Speed Sensor

An indication sensor outputs a sinusoidal wave form 48

pulses per revolution. The output is processed by the CM

to control braking and traction. The sensor is continually

monitored for open and short failure and operating range.

If its output exceeds 330km/h it is deemed to be faulty and

the CM is disabled. The parameter tracks the sensor

waveform through 255 steps.

Passive Anti Theft (PATS) Diagnostics

Security System Diagnostics

Becauseof the requirementto maintain vehicle security,

the PATS and Security System operating instructions

and diagnostics are covered in the Vehicle Security

supplement to section 6 of the workshop manual. This

supplement has restricted circulation and is only

available to Aston Martin Dealers.

9-44 September 1996

Page 396 of 421

^^2?

The Aston Martin Lagonda Diagnostic System

Users Guide

Airbag System Diagnostics

WARNING: Whilst it

is

completely safe to

access

and read the airbag diagnostic module memory at

the diagnostic socket, significant personal risks

exist in the performance of any other

tasks

on the

airbag system or components. Therefore all

workshop manual warnings must be read and all

safety procedures must be followed before, during

and on completion of any other practical work on

the airbag system.

System Description

The airbag system installation comprises:

Airbag Diagnostic Module

Driver and passenger airbag modules

Two front impact (crash) sensors

One 'safing' sensor

Dedicated wiring harness

SRS indicator/warning lamp

The system is designed to provide protection for both

driver and front seat passenger by automatically

deploying airbags in the event of a collision during

forward travel.

Intheeventof

a

collision, the crash and safing sensors

will operate, completing the firing circuit and causing

the airbags to inflate within 32 milliseconds. At least

one crash sensor and the safing sensor must operate to

fire the airbags.

Any faults in system components, installation or wiring

will be indicated by a flashing code on the SRS/

AIRBAG warning lamp. Fault code information may

also be monitored using the PDU or scan

tool.

A full description of the airbag system components is

included in the workshop manual.

Airbag Diagnostics

The Airbag Control Module indicates a fault by

transmitting a pulsed signal down the Airbag System

Failure line to flash the SRS/AIRBAC warning lamp.

The fault code is repeated continuously. If there are

two or more faults, the fault code with the highest

priority is transmitted first. The second fault code is

only transmitted when the first fault has been rectified.

TheSRS/AIRBAC warning lamp is also used to indicate

any problem in the seat belt pretensioner system (if

fitted). Flashing of the lamp indicates an airbag fault,

constant illumination of the lamp indicates a seat belt

pretensioner fault.

At the top left of the PDU screen there is a bullet mark

which indicates the current state of the Airbag System

Failure line. As a code is transmitted the bullet mark

can be seen to flash.The PDU reads the fault code, and

writes the code number and fault description to the

screen.

The PDU continues to monitor the transmitted

code.

If the transmitted code changes, the new code

number and description will appear below the first.

PMC Airbag

32 Drivers airbag circuit

shorted or open

o

when remedial action has been taken to correct a

fault, press the Clear Button to clear down the PDU

display. Then use the PDU to ensure that no faults are

reported.

A series of audible beeps, continuously transmitted by

the Airbag Diagnostic Module, indicates that there is

an Airbag System fault to report and that the Airbag

System Failure line

is

open circuit. The PDU is notable

to monitor the fault line in this situation as there is no

pull-up resistor, normally provided by a warning lamp

in the instrument pack.

Rapid continuous flashing of the Instrument Pack

Airbag Failure Lamp indicates that both front impact

sensors are disconnected. No fault code is reported on

the PDU, however on close inspection the bullet mark

can be seen to flicker.

September 1996 9-45

Page 397 of 421

The Aston Martin Lagonda Diagnostic System //~~^ ^?~?^ " ^ ^

Users Guide

Airbag Diagnostic Trouble Code Monitor

The following diagnostic trouble codes are supported by the Airbag Control Module:

12 Low battery voltage

13 Air bag circuit shorted to ground

14 Front inpact sensor circuit shorted to ground

21 Safing impact sensor incorrectly mounter to vehicle

22 Safing impact sensor output shorted to battery voltage

23 Safing impact sensor input feed / return open circuit

24 Safing impact sensor output feed / return open circuit

32 Driver side airbag circuit high resistance or open

33 Passenger side airbag circuit high resistance or open

34 Driver side airbag circuit low resistance or short circuit

41 Front right impact sensor feed / return open circuit

42 Front left impact sensor feed / return open circuit

44 Front right impact sensor incorrectly mounted to vehicle

45 Front left impact sensor incorrectly mounted to vehicle

51 Airbag CM internal thermal fuse - intermittent short to ground

52 Back up power supply - voltage boost fault

53 Front impact sensor circuits resistance to ground or internal Airbag CM failure

9-46 September 1996

Page 398 of 421

^^?

The Aston Martin Lagonda Diagnostic System

Users Guide

Seat Belt Pretensioner Diagnostics

(where fitted)

Description

The DB7 seat belt pretensioner system operates the

drivers seat belt pretensioner in conjunction with the

Airbag system. The seat belt pretensioner control

module is located underthe right hand seat, beside the

seat control module.

The pretensioner control module calculates changes

in vehicle speed using an input signal from an

accelerometer. When a collision is detected (Rapid

reduction in vehicle speed) the pretensioner charge is

fired using electrical energy stored in a capacitor

within the pretensioner control module. Firing of the

pretensioner charge applies additional tension to the

drivers seat belt.

The airbag and seat belt pretensioner systems share the

SRS (Airbag) warning lamp. Any fault detected by the

pretensioner control module is indicated by constant

illumination ofthe

SRS

(Airbag) warning

lamp.

Flashing

of the SRS warning lamp indicates a fault in the airbag

system.

Should both systems develop faults, the pretensioner

system will permanently illuminate the warning lamp.

This would mask the airbag system warning indication.

Therefore, rectify the pretensioner fault and then retest

for faults in the airbag system

The pretensioner control module can log up to 10

diagnostic trouble codes together with a time since

each fault was alerted to the driver. Each fault will be

identified as 'Permanent' or 'Intermittent' on the PDU

diagnostic trouble codes screen.

System Connections

The Autoliv RC5 Pretensioner Control Module has an

18 pin connector featuring six shorting bridges. The

mating halves ofthe connector may be securely locked

using a double mechanical locking system.

The following pins on the control module connector

are used in the Aston Martin seat belt pretensioner

system:

Pin 1

Pin 2

Pin n

Pin 12

Pin 14

Pin 15

Case

September 1996

Ground

SRS/Airbag Warning Lamp

Drivers airbag positive

Drivers airbag negative

Serial communications

12 volt positive feed

Ground

System Fault Strategy

No single fault may cause an unexpected deployment.

The controller will supervise the airbag/pretensioner

electrical system in order to warn the driver should a

fault occur. Any fault detected by the self diagnostics

shall cause the airbag warning lamp to be activated,

and in some cases the pretensioner control module to

enter shutdown mode. In shutdown mode, the energy

ofthe reserve capacitors shall be discharged to avoid

unintended deployment.

As the ignition is switched on, the pretensioner

controller will directly discharge theenergy capacitors.

When the start up procedure is completed without

detecting any faults, the converter will be activated

allowing the capacitors to be

charged.

The system shall

be fully active within 11 seconds after switching the

ignition on providing that no faults are detected.

All system faults monitored by the controller are filtered

in software to avoid fault warnings due to transient

electrical disturbances.

If a fault which could lead to inadvertent deployment

bedetectedbythemicroprocessor,asoftwareshutdown

will be generated. However, a leakage to an earth or

positive potential in the pretensioner output circuit

shall not cause the controller to enter shutdown mode.

If

a

permanent short of the ignition transistor occurs, a

shutdown shall be generated by the hardware circuit.

If a shutdown occurs, the system shall be unable to

deploy the pretensioner after a period of

3

seconds (i.e.

capacitors discharged to under minimum deployment

voltage).

WARNING: To avoid the possibility of personal

injury caused by accidental deployment of the

pretensioner, disconnect the vehicle battery and

wait at least 10 minutes for all voltages to fully

discharge before working on the pretensioner

system. This covers the possibility of the normal

capacitor discharge circuits being inopera tive and

failing to discharge the capacitor when instructed

to do so.

If the module enters shutdown mode, all diagnostic

functions are stopped, but the communications link

remains active. A fault code corresponding to the

cause of the problem may be read by the PDU.

9-47

Page 399 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide ^?

Seatbelt Pretensioner Diagnostic Trouble Codes

050A Pretensioner squib leak to battery positive

050B Pretensioner squib leak to ground

050C Pretensioner squib high resistance

050D Pretensioner squib low resistance

0D13 Capacitor voltage error

0D14 Capacitor capacitance

0D09 Energy reserve switch

0D1E Energy shutdown switch

050E Seatbelt pretensioner switch error

0109 Accelerometer function

01OA Acceleration out of range

01

OB Accelerometer offset

0209 Safing sensor error

030A Temperature sensor error

060C Warning lamp short circuit

060D Warning lamp open circuit

060E Warning lamp driver error

OAOC Analogue voltage error

0A09 Communications error

090A EEPROM not programmed

0909 EEPROM checksum

OAOA External watchdog error

OAOB External watchdog time out

020A Safing sensor not closed

090C RAM check error

9-48 September 1996

Page 400 of 421

^^

The Aston Martin Lagonda Diagnostic System

Users Guide

Print Facility

The print trace and print screen facilities provided on

DB7 CD2 will enable the Dealer to print directly to a

serial printer via an isolated RS 232 cable.

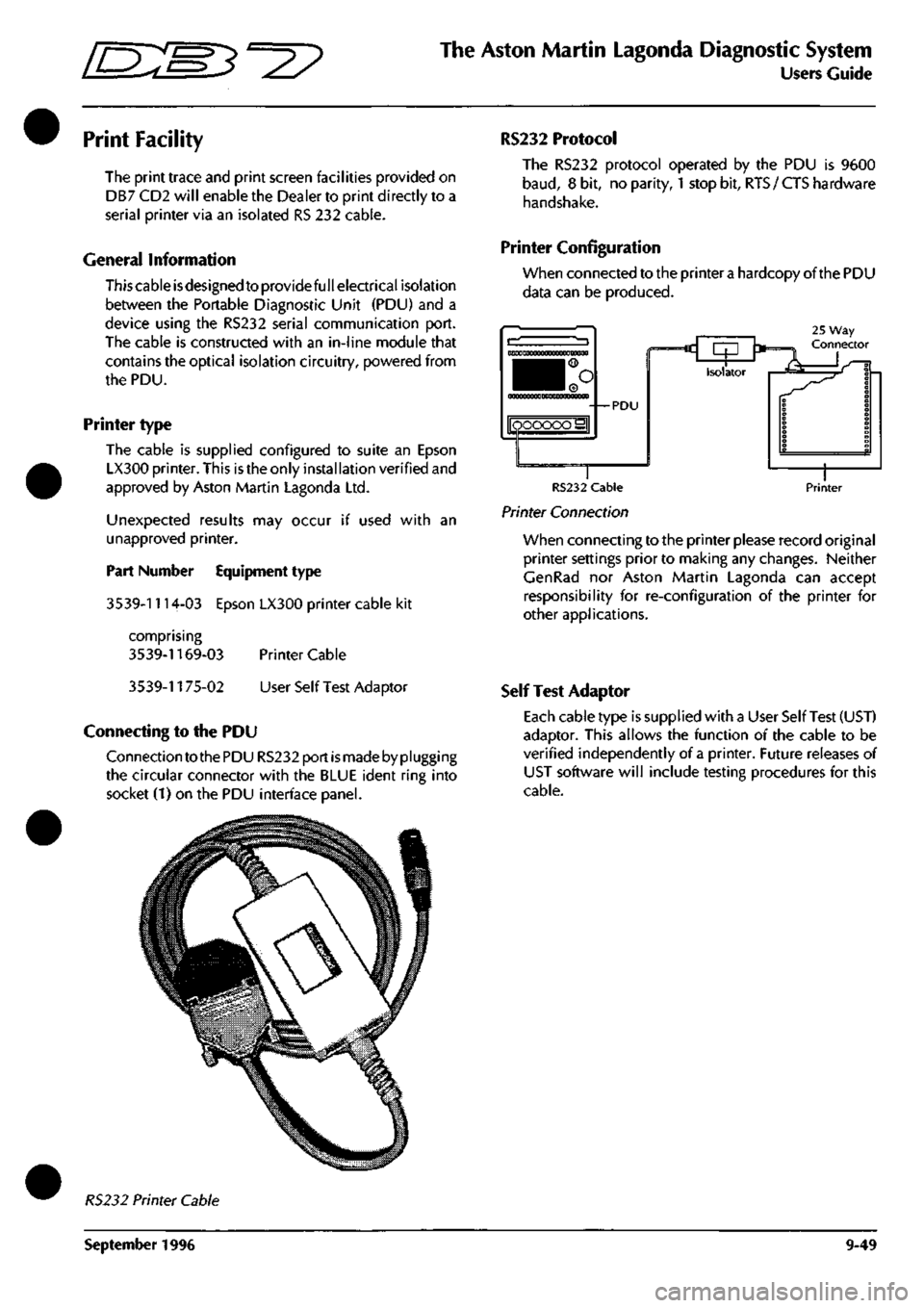

General Information

This cable isdesigned to provide full electrical isolation

between the Portable Diagnostic Unit (PDU) and a

device using the RS232 serial communication port.

The cable is constructed with an in-line module that

contains the optical isolation circuitry, powered from

the PDU.

Printer type

The cable is supplied configured to suite an Epson

LX300 printer. This is the only instal lation verified and

approved by Aston Martin Lagonda Ltd.

Unexpected results may occur if used with an

unapproved printer.

Part Number Equipment type

3539-1114-03 Epson LX300 printer cable kit

comprising

3539-1169-03 Printer Cable

3539-1175-02 User Self Test Adaptor

Connecting to the PDU

Connection to the PDU RS232 port

is

made by plugging

the circular connector with the BLUE ident ring into

socket (1) on the PDU interface panel.

RS232 Protocol

The RS232 protocol operated by the PDU is 9600

baud,

8 bit, no parity,

1

stop bit,

RTS

/ CTS hardware

handshake.

Printer Configuration

When connected to the printer

a

hardcopy of the PDU

data can be produced.

25 Way Connector c rp '*= Isolator •—*«

RS232 Cable

Printer Connection

Printer

When connecting to the printer please record original

printer settings prior to making any changes. Neither

CenRad nor Aston Martin Lagonda can accept

responsibility for re-configuration of the printer for

other applications.

Self Test Adaptor

Each cable type is supplied with a User Self Test (UST)

adaptor. This allows the function of the cable to be

verified independently of a printer. Future releases of

UST software will include testing procedures for this

cable.

RS232 Printer Cable

September 1996 9-49