ASTON MARTIN DB7 1997 Workshop Manual

Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 381 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide D-^?

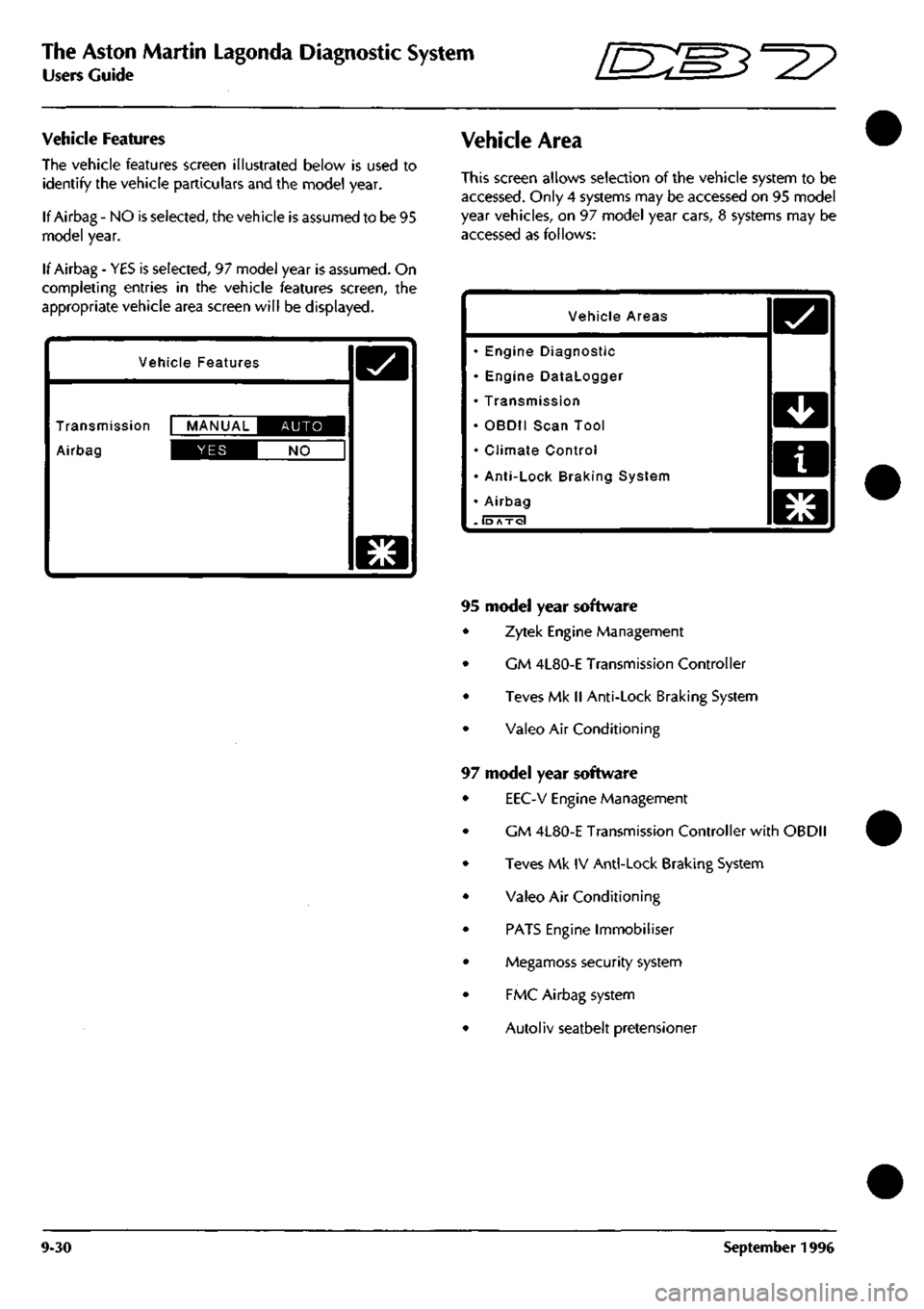

Vehicle Features

The vehicle features screen illustrated below is used to

identify the vehicle particulars and the model year.

If Airbag - NO is selected, the vehicle is assumed to be 95

model year.

If Airbag - YES is selected, 97 model year is assumed. On

completing entries in the vehicle features screen, the

appropriate vehicle area screen will be displayed.

Vehicle Features

Transmission MANUAL IIBIE^^I

Airbag IDS^I NO

D

Vehicle Area

This screen allows selection of the vehicle system to be

accessed.

Only 4 systems may be accessed on 95 model

year vehicles, on 97 model year cars, 8 systems may be

accessed as follows:

Vehicle Areas

• Engine Diagnostic

• Engine Datalogger

• Transmission

• OBDII Scan Tool

• Climate Control

• Anti-Lock Braking System

• Airbag

. lb Axol

o

PI

mLM

n

WLM

El

Ku^

95 model year software

Zytek Engine Management

GM 4L80-E Transmission Controller

Teves Mk II Anti-Lock Braking System

Valeo Air Conditioning

97 model year software

EEC-V Engine Management

CM 4L80-E Transmission Controller with OBDII

Teves Mk IV Anti-Lock Braking System

Valeo Air Conditioning

PATS Engine Immobiliser

Megamoss security system

FMC Airbag system

Autoliv seatbelt pretensioner

9-30 September 1996

Page 382 of 421

^?

The Aston Martin Lagonda Diagnostic System

Users Guide

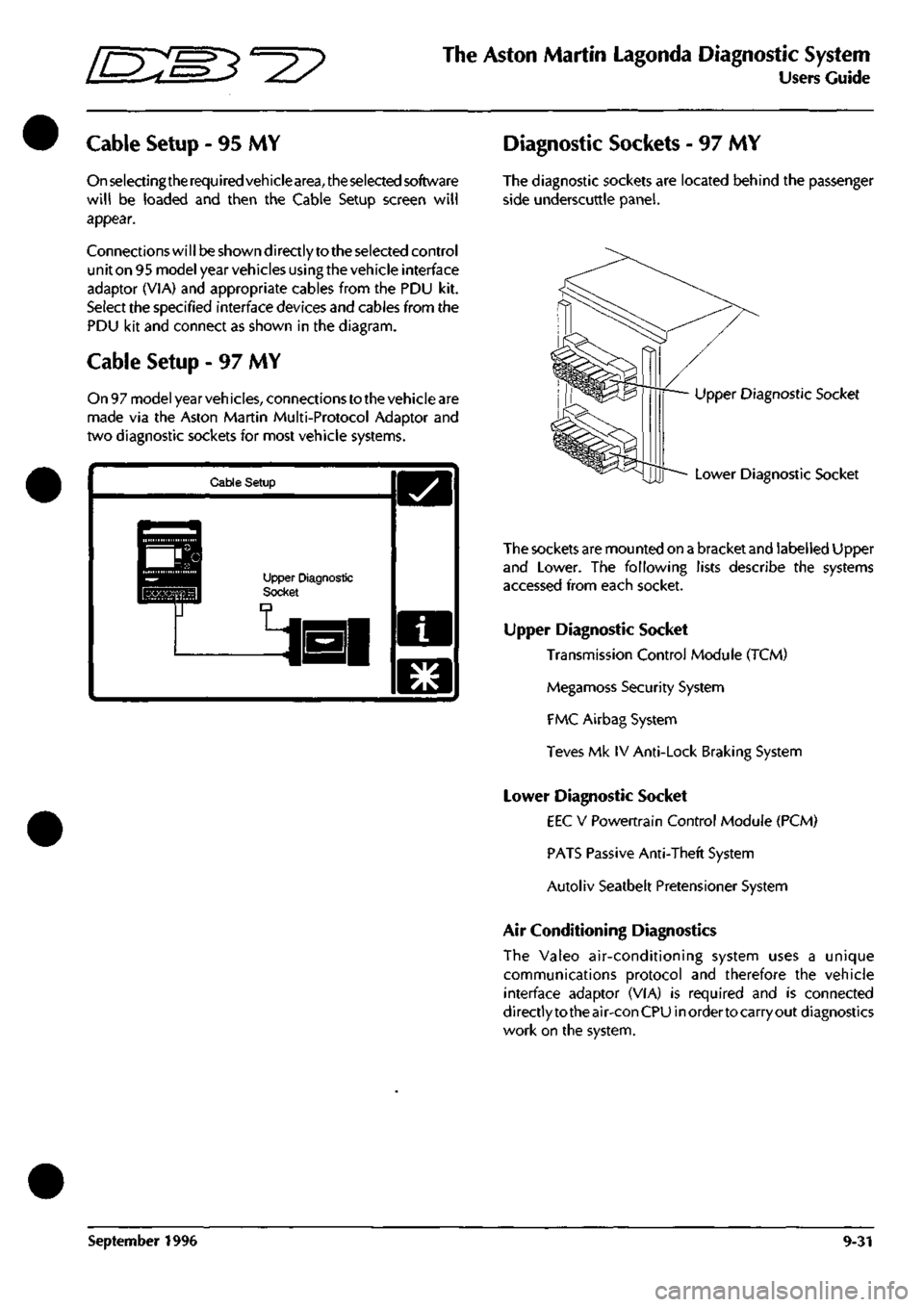

Cable Setup - 95 MY

On

selectingthe

required

vehiclearea,

the selected

software

will be loaded and then the Cable Setup screen will

appear.

Connections will

be

shown directly

to the selected

control

unit

on

95 nnodel year vehicles

using

the vehicle interface

adaptor (VIA) and appropriate cables from the PDU kit.

Select the specified interface devices and cables from the

PDU kit and connect as shown in the diagram.

Cable Setup - 97 MY

On 97 model year

vehicles,

connections

to the

vehicle are

made via the Aston Martin Multi-Protocol Adaptor and

two diagnostic sockets for most vehicle systems.

Cable Setup

Upper Diagnostic Socket

o

Diagnostic Sockets - 97 MY

The diagnostic sockets are located behind the passenger

side underscuttle panel.

Upper Diagnostic Socket

Lower Diagnostic Socket

The

sockets are

mounted on

a

bracket

and

labelled Upper

and Lower. The following lists describe the systems

accessed from each socket.

Upper Diagnostic Socket

Transmission Control Module (TCM)

Megamoss Security System

FMC Airbag System

Teves Mk IV Anti-Lock Braking System

Lower Diagnostic Socket

EEC V Powertrain Control Module (PCM)

PATS Passive Anti-Theft System

Autoliv Seatbelt Pretensioner System

Air Conditioning Diagnostics

The Valeo air-conditioning system uses a unique

communications protocol and therefore the vehicle

interface adaptor (VIA) is required and is connected

directlytotheair-conCPU inordertocarryout diagnostics

work on the system.

September 1996 9-31

Page 383 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide "^7

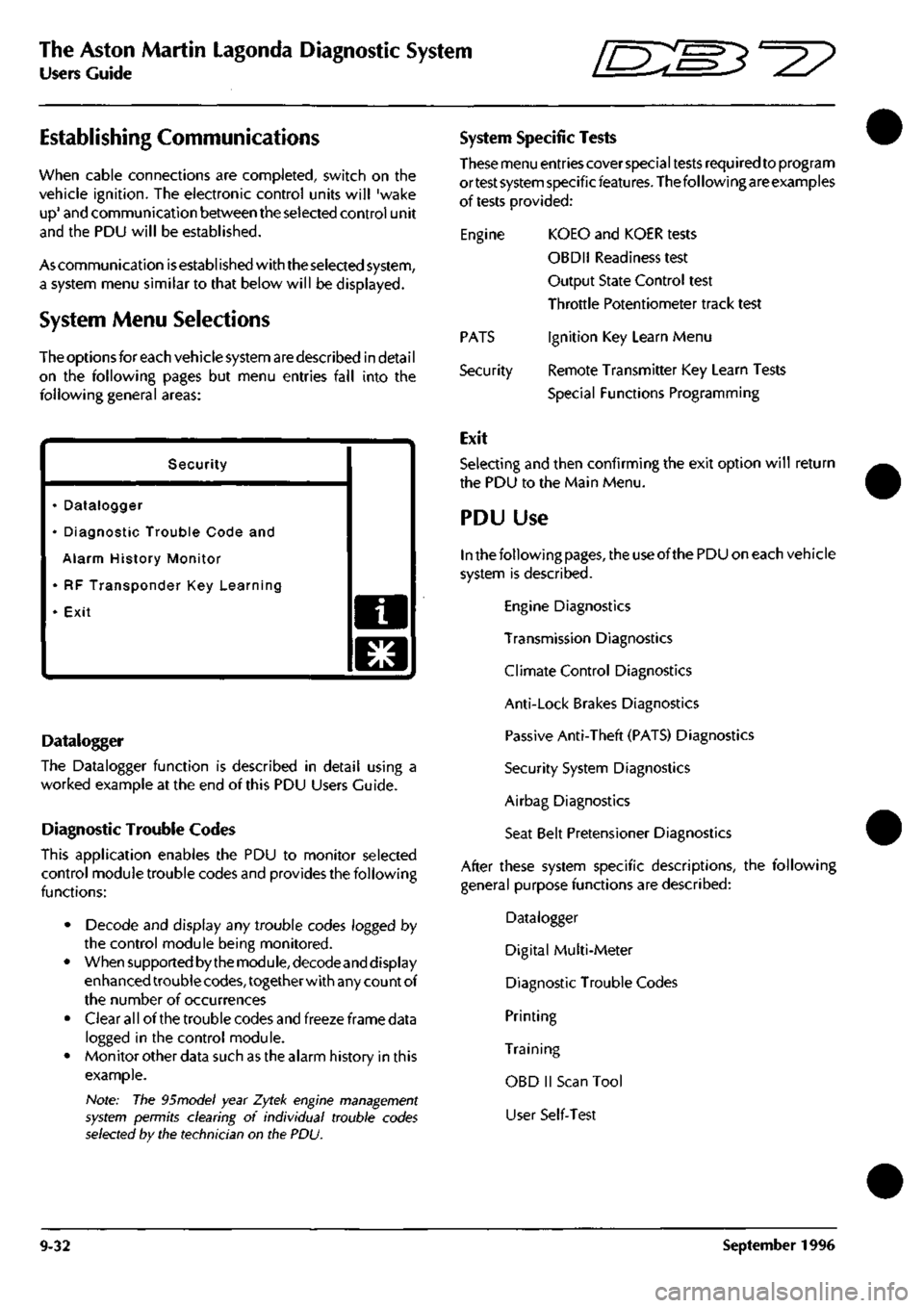

Establishing Communications

when cable connections are completed, switch on the

vehicle ignition. The electronic control units will 'wake

up'

and communication between the selected control unit

and the PDU will be established.

As communication

is

established with the selected system,

a system menu similar to that below will be displayed.

System Menu Selections

The options for each vehicle system are described in detai

I

on the following pages but menu entries fall into the

following general areas:

Security

• Datalogger

• Diagnostic Trouble Code and

Alarm History Monitor

• RF Transponder Key Learning

• Exit a

o

Datalogger

The Datalogger function is described in detail using a

worked example at the end of this PDU Users Guide.

Diagnostic Trouble Codes

This application enables the PDU to monitor selected

control module trouble codes and provides the following

functions:

• Decode and display any trouble codes logged by

the control module being monitored.

• When supported by the module, decodeand display

enhanced trouble

codes,

together with any count of

the number of occurrences

• Clear all of the trouble codes and freeze frame data

logged in the control module.

• Monitor other data such as the alarm history in this

example.

Note: The 95model year Zytek engine management

system permits clearing of individual trouble codes

selected by the technician on the PDU.

System Specific Tests

These menu entries cover special tests required to program

ortest system specificfeatures. The following are examples

of tests provided:

Engine KOEO and KOER tests

OBDII Readiness test

Output State Control test

Throttle Potentiometer track test

Ignition Key Learn Menu

Remote Transmitter Key Learn Tests

Special Functions Programming

PATS

Security

Exit

Selecting and then confirming the exit option will return

the PDU to the Main Menu.

PDU Use

In the following

pages,

the use of the PDU on each vehicle

system is described.

Engine Diagnostics

Transmission Diagnostics

Climate Control Diagnostics

Anti-Lock Brakes Diagnostics

Passive Anti-Theft (PATS) Diagnostics

Security System Diagnostics

Airbag Diagnostics

Seat Belt Pretensioner Diagnostics

After these system specific descriptions, the following

general purpose functions are described:

Datalogger

Digital Multi-Meter

Diagnostic Trouble Codes

Printing

Training

OBD II Scan Tool

User Self-Test

9-32 September 1996

Page 384 of 421

^27

The Aston Martin Lagonda Diagnostic System

Users Guide

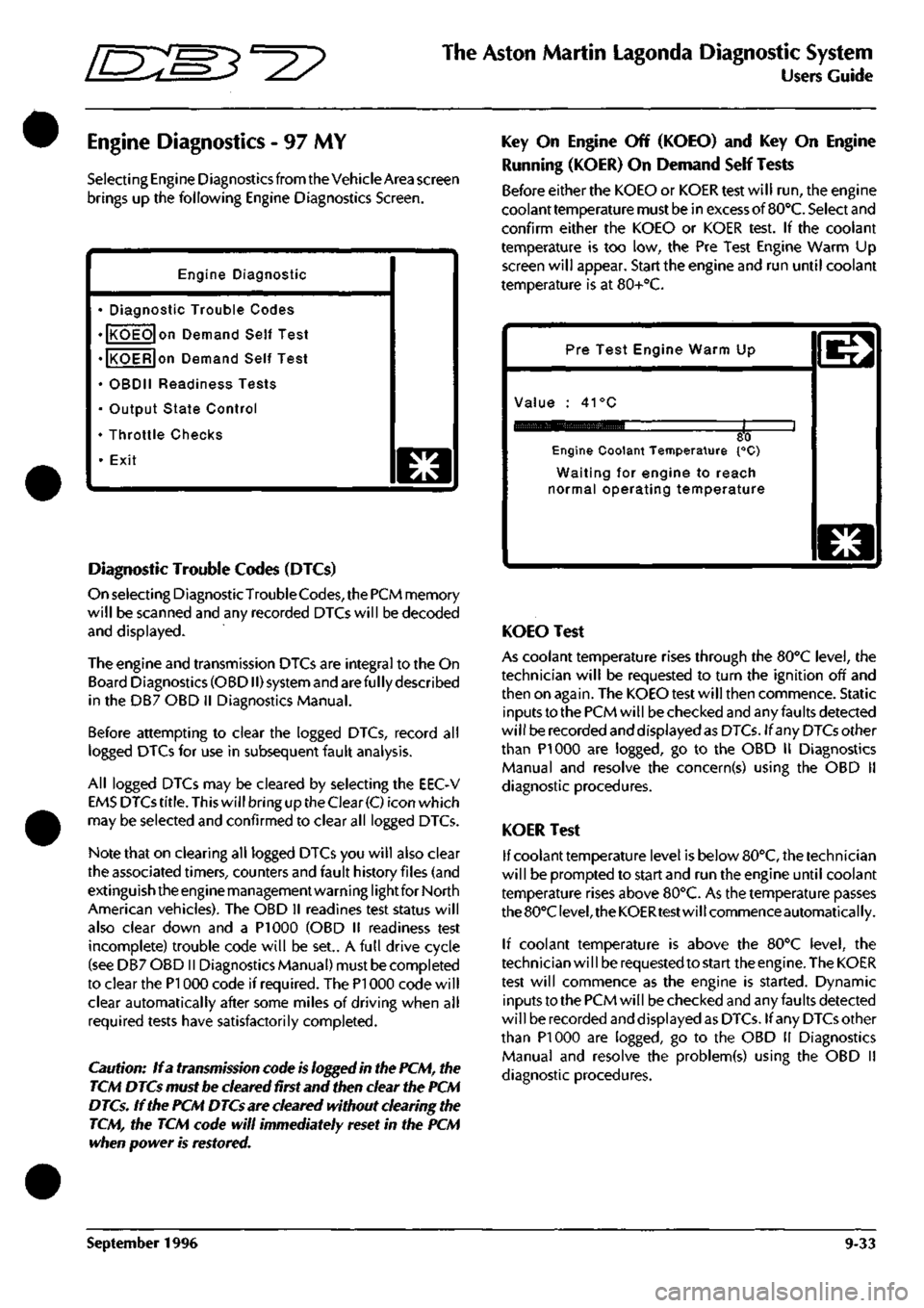

Engine Diagnostics - 97 MY

Selecting Engine Diagnostics from the Vehicle Area screen

brings up the following Engine Diagnostics Screen.

Engine Diagnostic

• Diagnostic Trouble Codes

• KOEO on Demand Self Test

• KOER on Demand Self Test

• OBDII Readiness Tests

• Output State Control

• Throttle Checks

• Exit

o

Diagnostic Trouble Codes (DTCs)

On selecting DiagnosticTrouble

Codes,

the PCM memory

will be scanned and any recorded DTCs will be decoded

and displayed.

The engine and transmission DTCs are integral to the On

Board Diagnostics (OBDII) system and are ful ly described

in the DB7 OBD II Diagnostics Manual.

Before attempting to clear the logged DTCs, record all

logged DTCs for use in subsequent fault analysis.

All logged DTCs may be cleared by selecting the EEC-V

EMS DTCs

title.

This will bring up the Clear

(C)

icon which

may be selected and confirmed to clear all logged DTCs.

Note that on clearing all logged DTCs you will also clear

the associated timers, counters and fault history files (and

extinguish the engine management warning lightfor North

American vehicles). The OBD II readines test status will

also clear down and a PI 000 (OBD II readiness test

incomplete) trouble code will be set.. A full drive cycle

(see DB7 OBD II Diagnostics Manual) must be completed

to clear the PI 000 code if required. The PI 000 code will

clear automatically after some miles of driving when all

required tests have satisfactorily completed.

Caution: If a transmission code is logged in the PCM, the

TCM DTCs must be cleared first and then clear the PCM

DTCs. If the PCM DTCs are cleared without clearing the

TCM, the TCM code will immediately reset in the PCM

when power is restored.

Key On Engine Off (KOEO) and Key On Engine

Running (KOER) On Demand Self Tests

Before either the KOEO or KOER test will run, the engine

coolant temperature must be in excess of

BO'C.

Select and

confirm either the KOEO or KOER test. If the coolant

temperature is too low, the Pre Test Engine Warm Up

screen will appear. Start the engine and run until coolant

temperature is at 80+°C.

Pre Test Engine Warm Up

Value : 41°C

80 Engine Coolant Temperature {°C)

Waiting for engine to reach

normal operating temperature

o

KOEO Test

As coolant temperature rises through the BO'C level, the

technician will be requested to turn the ignition off and

then on again. The KOEO test will then commence. Static

inputs to the PCM will be checked and any faults detected

will be recorded and displayed as DTCs. If any DTCs other

than PI 000 are logged, go to the OBD II Diagnostics

Manual and resolve the concern(s) using the OBD 11

diagnostic procedures.

KOER Test

If coolant temperature level is below 80°C, the technician

will be prompted to start and run the engine until coolant

temperature rises above 80°C. As the temperature passes

the 80°C

level,

the KOERtest will commence automatically.

If coolant temperature is above the 80°C level, the

technician wi

11

be requested to start the engine. The KOER

test will commence as the engine is started. Dynamic

inputs to the PCM will be checked and any faults detected

will be recorded and displayed as DTCs. If any DTCs other

than PI 000 are logged, go to the OBD 11 Diagnostics

Manual and resolve the problem(s) using the OBD II

diagnostic procedures.

September 1996 9-33

Page 385 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide ^-^z?

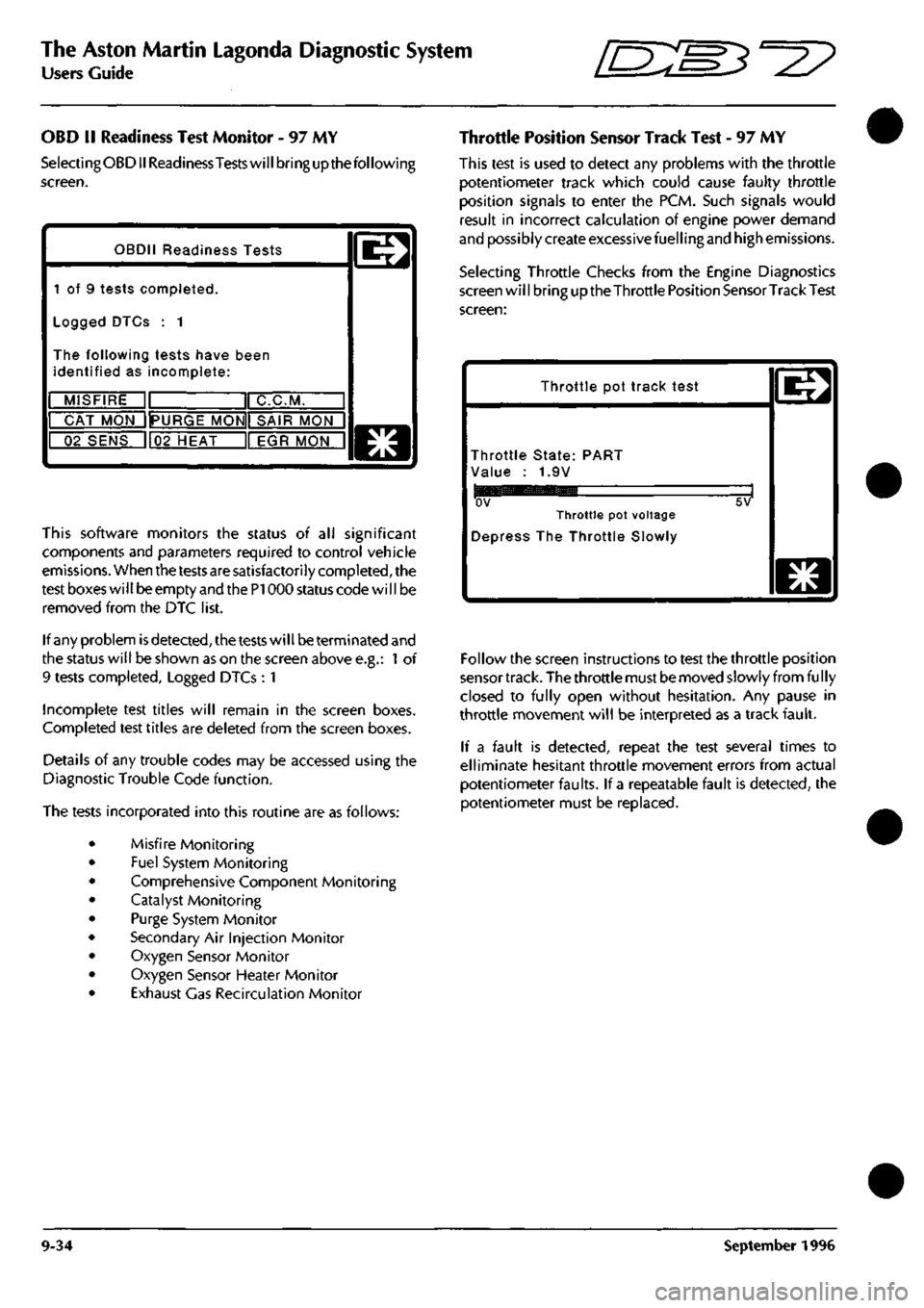

OBD

II

Readiness Test Monitor

- 97 MY

SelectingOBD II Readiness

Tests

will bring up the following

screen.

OBDII Readiness Tests

1

of 9

tests completed.

Logged DTCs

: 1

The following tests have been

identified

as

incomplete:

MISFIRE

ir

1 C.C.M.

CAT MON 1IPURGE

MONII SAIR

M"ONn

02 SENS

1l02

HEAT

II EGR

MONTI

@

This software monitors

the

status

of all

significant

components and parameters required

to

control vehicle

emissions. When the tests are satisfactorily completed, the

test boxes wi

11

be empty and the PI 000 status code wi

11

be

removed from

the DTC

list.

If any problem

is

detected,

the tests will be terminated and

the status will be shown as

on

the screen above e.g.:

1 of

9 tests completed. Logged DTCs

: 1

Incomplete test titles will remain

in the

screen boxes.

Completed test titles are deleted from

the

screen boxes.

Details

of any

trouble codes

may be

accessed using

the

Diagnostic Trouble Code function.

The tests incorporated into this routine are as follows:

Misfire Monitoring

Fuel System Monitoring

Comprehensive Component Monitoring

Catalyst Monitoring

Purge System Monitor

Secondary

Air

Injection Monitor

Oxygen Sensor Monitor

Oxygen Sensor Heater Monitor

Exhaust Gas Recirculation Monitor

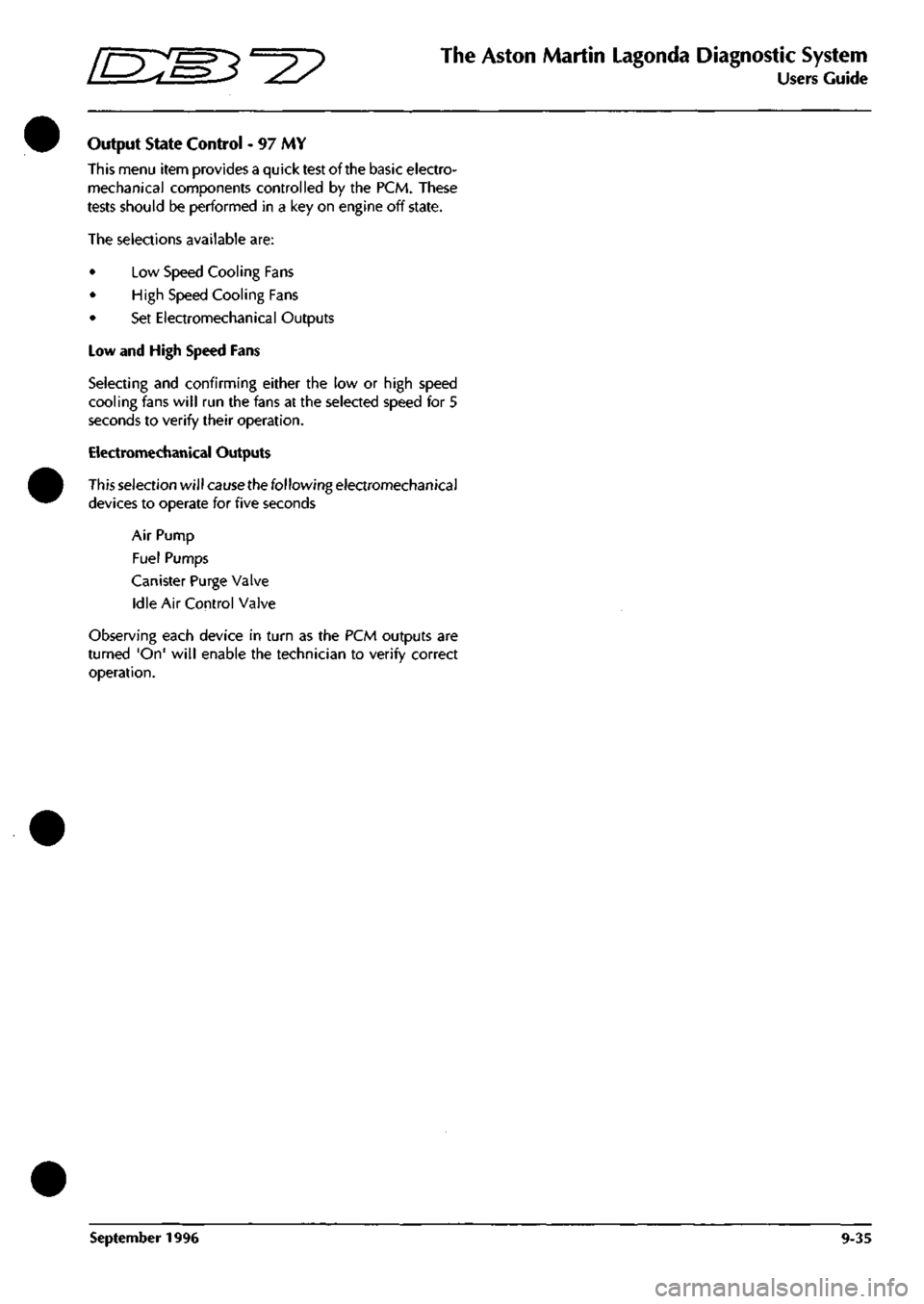

Throttle Position Sensor Track Test

- 97 MY

This test

is

used

to

detect

any

problems with

the

throttle

potentiometer track which could cause faulty throttle

position signals

to

enter

the

PCM. Such signals would

result

in

incorrect calculation

of

engine power demand

and possibly create excessive fuelling and high emissions.

Selecting Throttle Checks from

the

Engine Diagnostics

screen will bring uptheThrottle Position Sensor Track Test

screen:

Throttle

pot

track test

Throttle State: PART

Value

: 1.9V

ov

Throttle

pot

voltage

Depress

The

Throttle Slowly

5V

o

Follow the screen instructions

to

test the throttle position

sensor track. The throttle must be moved slowly from fu

I

ly

closed

to

fully open without hesitation.

Any

pause

in

throttle movement will

be

interpreted

as a

track fault.

If

a

fault

is

detected, repeat

the

test several times

to

elliminate hesitant throttle movement errors from actual

potentiometer faults.

If

a repeatable fault

is

detected,

the

potentiometer must

be

replaced.

9-34 September

1996

Page 386 of 421

^^2?

The Aston Martin Lagonda Diagnostic System

Users Guide

Output State Control - 97 MY

This menu item provides a quick test of the basic electro

mechanical components controlled by the PCM. These

tests should be performed in a key on engine off state.

The selections available are:

• Low Speed Cooling Fans

• High Speed Cooling Fans

• Set Electromechanical Outputs

Low and High Speed Fans

Selecting and confirming either the low or high speed

cooling fans will run the fans at the selected speed for 5

seconds to verify their operation.

Electromechanical Outputs

This selection will cause the following electromechanical

devices to operate for five seconds

Air Pump

Fuel Pumps

Canister Purge Valve

Idle Air Control Valve

Observing each device in turn as the PCM outputs are

turned 'On' will enable the technician to verify correct

operation.

September 1996 9-35

Page 387 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide ffi:S5'=2?

Engine Datalogger

The datalogger software is designed to aid the technician in identifying permanent or intermittent faults in the DB7's

electrical and electronic systems. It can provide a recorded view of selected signals over a chosen time period. This

recording may be captured in a static, rolling road or road test situation. Data recorded during such tests may then be

analysed on completion of the test or printed out for later analysis.

Datalogger operation is described using a fully worked example at the end of this PDU Users Guide.

The full list of datalogger signal names and descriptions is provided in the DB7 OBDII Diagnostic Manual and on the PDU

screen.

The following list is a summary of the PCM signals which may be monitored.

Signal Description

ACCS Air-Con Control Switch - 1 = A/C On

ACP Air-Con Pressure Sensor - 1 = A/C pressure high

ACT MAX Maximum Intake Air Temperature signal during normal running

Adap Fuel 1 Current Adaptive Fuel Correction - (% of range)

Adap Fuel 2 Current Adaptive Fuel Correction - (% of range)

ADPT1F Adaptive Fuel - Table 1 failure mode

ADPT2F Adaptive Fuel - Table 2 failure mode

AIR Air Pump On/Off - 1 = Pump On

AIRM Air Pump Monitor -1 =

high,

pump on

B+ Battery Positive - Volts

BARO Barometric Pressure

CID Cylinder Identification - Cam sensor status

CMP STAT Cam Position Sensor -1 = CID mis, not currently reliable

DRVCNT Number of OBDll Drive Cycles Completed

DSDRPM Desired engine speed (RPM)

DTCCNT Diagnostic Trouiale Codes Count (Fault codes + pending codes. MIL and non-MIL)

ECT MAX Maximum Engine Coolant Temperature signal during normal running

ECT STAT Engine Coolant Temperature - in or out of range

ECT-C Engine Coolant Temperature - "C or raw counts

ECT-V Engine Coolant Temperature - Volts or raw counts

EGR STAT EVP EGR sensor failure

ENGLOAD Engine Load (Ratio of air charge over standard)

ENGRPM Engine Speed - RPM

EPT DPFE Sensor feedback

EVAP DC Cannister Purge Duty Cycle (% on)

EVAPCVA Vapour Management Valve (VMV) fault detected

Evts HI Cumulative cylinder events total carried over from previous background logic executions

Evts LO Cumulative cylinder events total carried over from previous background logic executions

FPM Fuel Pump Monitor - 0 = pump off, 1 = pump on

FPUMP DC Desired Fuel Pump Duty Cycle - 0% or 100%

H02S12 Sensor Output - Volts

H02S21 Sensor Output - Volts

H02S22 Sensor Output - Volts

H02S1I Sensor Output - Volts

HFC High Speed Fan Status

Htrl

1

ret Highest number of retries seen on the H02S 11 heater

Htrl 2 ret Highest number of retries seen on the H02S 12 heater

Htr21 ret Highest number of retries seen on the H02S 21 heater

Htr22 ret Highest number of retries seen on the H02S 22 heater

HTRCM11 H02S n heater current

HTRCM12 H02S 12 heater current

HTRCM21 H02S 21 heater current

HTRCM22 H02S 22 heater current

9-36 September 1996

Page 388 of 421

^

The Aston Martin Lagonda Diagnostic System

Users Guide

Signal Description

lACDTCY Idle Air Control Duty Cycle (% open)

lAT Intake Air Temperature - °C or raw input counts

lAT STAT Air Temperature - Temperature sensor failure

lAT-V Intake Air Temperature - Volts or raw counts

IGN Desired Ignition Timing - ° BTDC

INDS Input from manual lever position sensor (counts)

IPWA Injector Pulse Width in mS- Bank A (Cylinders

1

-3)

IPWB Injector Pulse Width in mS- Bank B (Cylinders 4-6)

LAMSE1 Current Short Term Fuel Trim 1, adjustment from stoich - (% of range)

LAMSE2 Current Short Term Fuel Trim 2, adjustment from stoich - (% of range)

LFC Low Speed Fan Status

LOOP Fuel Control -1 = Open Loop, 0 = Closed Loop

MAF MAX Maximum Mass Air Flow signal during normal running

MAF Raw MAF sensor output (A/D counts)

MAF STAT Mass Air Flow Meter - MAF sensor failure

MIL Mali Indicator Lamp Status -1 = Lamp On

Mis HI Cumulative misfires detected by misfire test (Hi bit).

Mis LO Cumulative misfires detected by misfire test (Lo bit).

Mis nc HI Cumulative misfires detected by a misfire test (Hi bit).

Mis nc LO Cumulative misfires detected by a misfire test.

Misi HI Cumulative misfires detected by cylinder

1

misfire test (Hi bit).

Misi LO Cumulative misfires detected by cylinder

1

misfire test (Lo bit).

Mis2 HI Cumulative misfires detected by cylinder 2 misfire test (Hi bit).

Mis2 LO Cumulative misfires detected by cylinder 2 misfire test (Lo bit).

Mis3 HI Cumulative misfires detected by cylinder 3 misfire test (Hi bit).

Mis3 LO Cumulative misfires detected by cylinder 3 misfire test (Lo bit).

Mis4 HI Cumulative misfires detected by cylinder 4 misfire test (Hi bit).

Mis4 LO Cumulative misfires detected by cylinder 4 misfire test (Lo bit).

Mis5 HI Cumulative misfires detected by cylinder 5 misfire test (Hi bit).

Mis5 LO Cumulative misfires detected by cylinder 5 misfire test (Lo bit).

Mis6 HI Cumulative misfires detected by cylinder 6 misfire test (Hi bit).

Mis6 LO Cumulative misfires detected by cylinder 6 misfire test (Lo bit).

MISF Misfire Monitor - 1 = Currently misfiring

ODCODES Total number of on-demand codes currently stored.

PGM CVS DC Purge Management Duty Cycle (% on)

PIP Profile ignition Pick-Up - PIP input level

PNP Park Neutral Position Switch

R-BIAS1 Rear bias trim (Bank 1, cylinders

1

-3)

R-BIAS2 Rear bias trim (Bank 2, cylinders 4-6)

RATCH Lowest TP reading during driving

TP MAX Maximum Throttle Potentiometer signal during normal running

TP STAT Throttle Position Sensor - TP sensor failure

TP Throttle Potentiometer - Volts or counts

TPR-V Raw counts from sensor

TQ-NET Net torque into the torque convertor

TRIP OBDII Drive Cycle Complete (except cat monitor) - 1 = Trip completed

TRIPCNT Number of Completed OBDII Trips

VS MAX Maximum Vehicle Speed signal during normal running

VS STAT Vehicle Speed Sensor mode flag

VS Vehicle Speed - MPH

WAC Wide Open Throttle A/C Cut-Off -1 = High (WOT Relay)

September 1996 9-37

Page 389 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide ^?

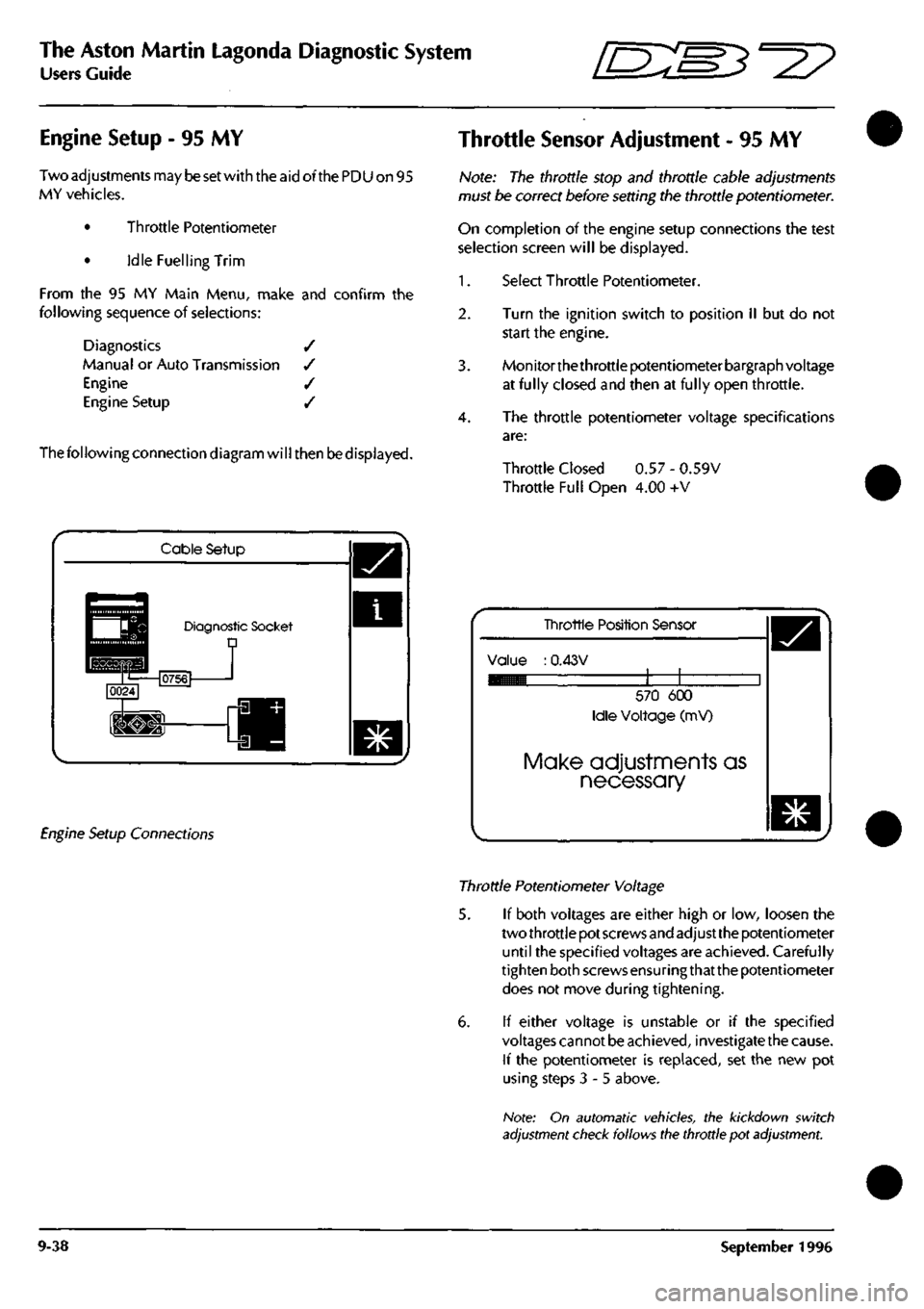

Engine Setup

- 95 MY

Two adjustments

may

beset with the aid of the PDU

on 95

MY vehicles.

• Throttle Potentiometer

• Idle Fuelling Trim

From

the 95 MY

Main Menu, make

and

confirm

the

following sequence

of

selections:

Diagnostics

/

Manual

or

Auto Transmission

/

Engine

/

Engine Setup

/

The following connection diagram will then be displayed.

Throttle Sensor Adjustment

- 95 MY

Note:

The

throttle stop

and

throttle cable adjustments

must

be

correct before setting

the

throttle potentiometer.

On completion

of the

engine setup connections

the

test

selection screen will

be

displayed.

1.

Select Throttle Potentiometer.

2.

Turn

the

ignition switch

to

position

II but do not

start

the

engine.

3. Monitorthethrottle potentiometer bargraph voltage

at fully closed

and

then

at

fully open throttle.

4.

The

throttle potentiometer voltage specifications

are:

Throttle Closed

0.57 -

0.59V

Throttle Full Open

4.00 +V

Cable Setup

Diagnostic Socket D

Engine Setup Connections

Tinrottle Position Sensor

Value

:

0.43V

570

600

Idle Voltage

(mV)

Make adjustments as

necessary

Throttle Potentiometer Voltage

5.

If

both voltages

are

either high

or low,

loosen

the

two throttle pot screws and adjust the potentiometer

until

the

specified voltages

are

achieved. Carefully

tighten both screws ensuringthat the potentiometer

does

not

move during tightening.

6.

If

either voltage

is

unstable

or if the

specified

voltages cannot

be

achieved, investigate the cause.

If

the

potentiometer

is

replaced,

set the new pot

using steps

3-5

above.

Note:

On

automatic vehicles,

the

kickdown switch

adjustment check follows the throttle

pot

adjustment.

9-38 September

1996

Page 390 of 421

ffi:

The Aston Martin Lagonda Diagnostic System

Users Guide

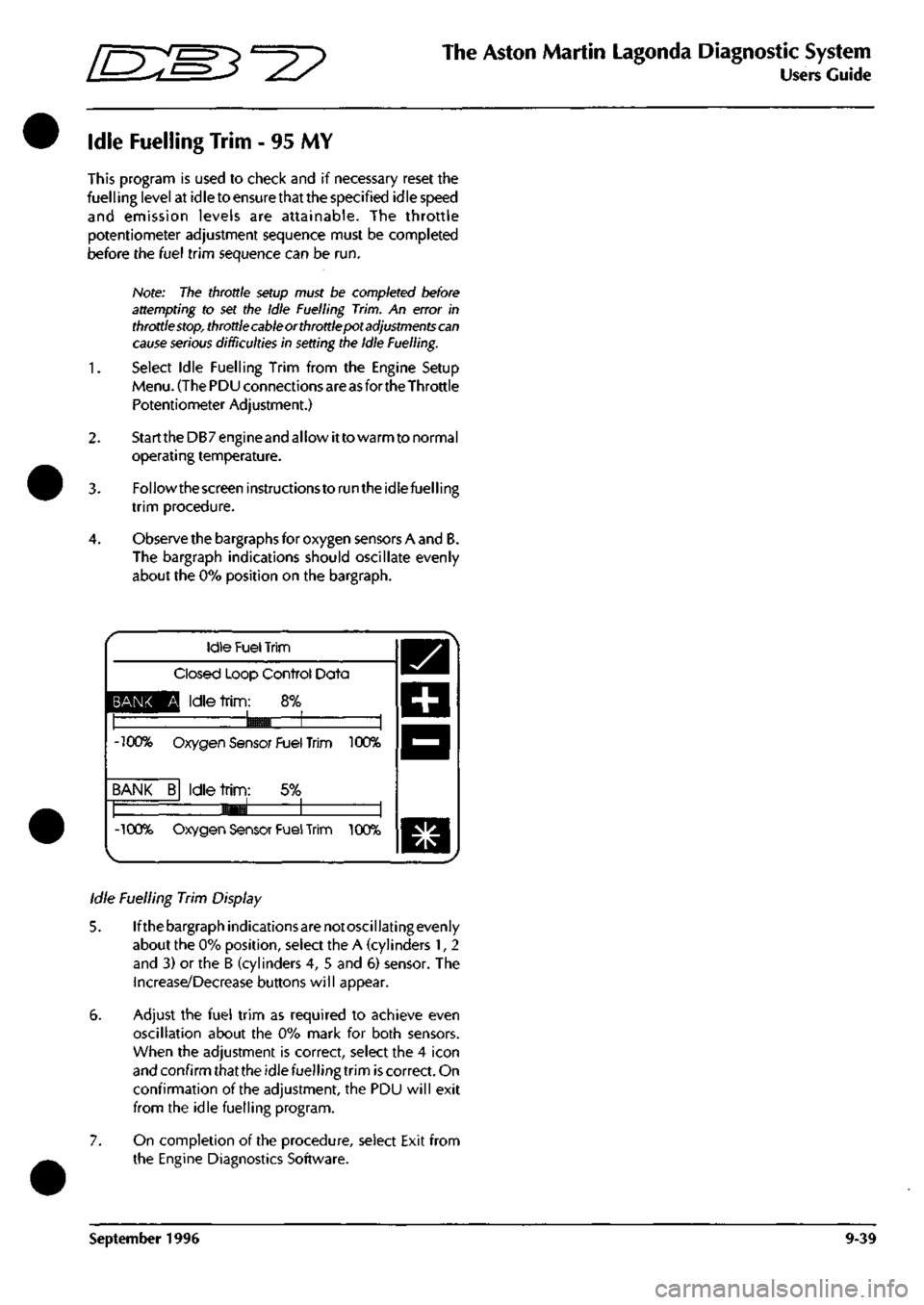

Idle Fuelling Trim - 95 MY

This program is used to check and if necessary reset the

fuelling level at idle to ensure that the specified idle speed

and emission levels are attainable. The throttle

potentiometer adjustment sequence must be completed

before the fuel trim sequence can be run.

Note: The throttle setup must be completed before

attempting to set the Idle Fuelling Trim. An error in

throttle

stop,

throttle cable or throttle pot

adjustments can

cause serious

difficulties in setting the Idle Fuelling.

Select Idle Fuelling Trim from the Engine Setup

Menu.

(The PDU connections are

as

fortheThrottle

Potentiometer Adjustment.)

1.

3.

StarttheDB7engineand allow itto warm to normal

operating temperature.

Followthescreeninstructionstorunthe idle fuelling

trim procedure.

Observe the bargraphs for oxygen sensors A and B.

The bargraph indications should oscillate evenly

about the 0% position on the bargraph.

BANK

-100%

BANK

-100%

Idle

Fuel

Trim

Closed Loop Control Data

Q Idle

trim:

8%

9^B 1 1

Oxygen Sensor Fuel Trim 100%

B Idle

trim:

5% —1 1 1

«^

1 1 Oxygen Sensor Fuel

Trim

100%

Idle Fuelling Trim Display

5. Ifthebargraphindicationsarenotoscillatingevenly

about the 0% position, select the A (cylinders 1, 2

and 3) or the B (cylinders 4, 5 and 5) sensor. The

Increase/Decrease buttons will appear.

6. Adjust the fuel trim as required to achieve even

oscillation about the 0% mark for both sensors.

When the adjustment is correct, select the 4 icon

and confirm that the idle fuelling trim is correct. On

confirmation of the adjustment, the PDU will exit

from the idle fuelling program.

7. On completion of the procedure, select Exit from

the Engine Diagnostics Software.

September 1996 9-39