ASTON MARTIN DB7 1997 Workshop Manual

Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 401 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide ^=2?

Printer Use Digital Multimeter

Print Trace

The Trace Buffer is used to record technician use of the

PDU.As the diagnostics are executed, the following

information is written to trace:

Screen Title

Menu options selected

Operator questions selected

Operator actions

Control module information

Test limits and results

P codes detected by the DTC monitor

Snapshot data from the datalogger

OBD II freeze frame data

Set up the printer and load with paper. Select Print

Trace and confirm the selection. All recorded

information in the above list will be printed.

Printtrace is supported in English, French, German and

Italian.

Print Screen

The Print Screen function dumps a bitmap image of the

current screen display to the printer. This function is

particularly useful for recordingdata such as waveforms

captured by the datalogger application.

The print screen function is supported in English,

French,

German, Italian and Japanese.

Introduction

The Digital Multi-Meterprovidesthecapability to measure

voltage, current, resistance, frequency, pulse width, pulse

period and duty cycle using measurement probes or

vehicle interface adaptor channels.

WARNING: DMM measurements must not be taken

while the PDU

is

connected to the

base

station. The PDU

measurement system

becomes

referenced to earth when

connected to the base station. Serious measurement

errors may be present

because

of any voltage difference

between vehicle ground and base station earth. Operation

of the PDU in this mode has both functional and safety

implications and therefore must be

avoided.

A digital multimeter (DMM) is resident within the PDU

software toolbox.

The DMM application can be accessed from the main

menu.

On selection of "Digital Multimeter" from the main

menu,

the PDU will always display the same screen,

known as the DMM general screen.

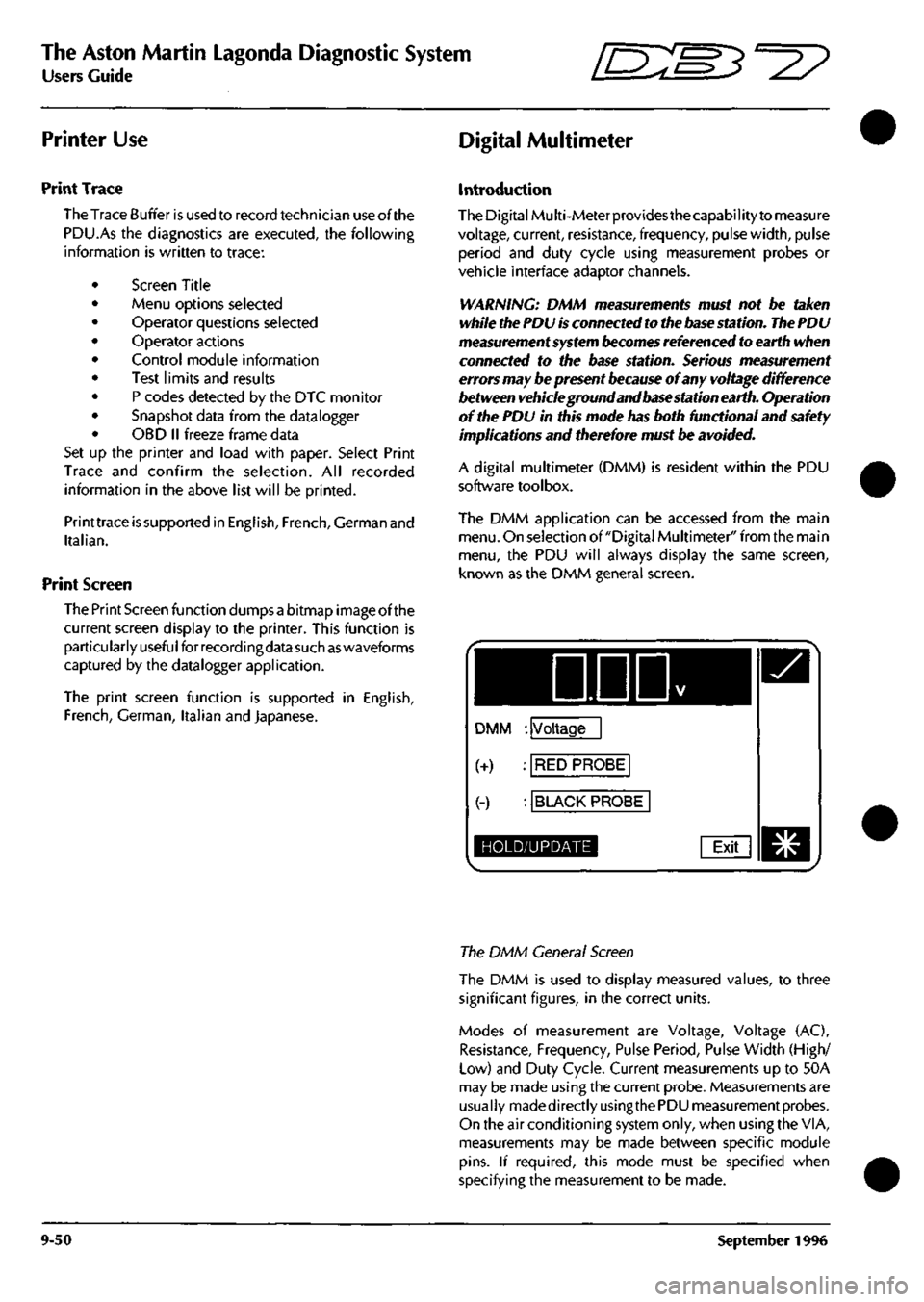

DDD

DMM : Voltage

(+) : RED PROBE

(-) : BLACK PROBE

HOLD/UPDATE Exit

The DMM General Screen

The DMM is used to display measured values, to three

significant figures, in the correct units.

Modes of measurement are Voltage, Voltage (AC),

Resistance, Frequency, Pulse Period, Pulse Width (High/

Low) and Duty Cycle. Current measurements up to 50A

may be made using the current probe. Measurements are

usually madedirectlyusingthe PDU measurement probes.

On the air conditioning system only, when using the VIA,

measurements may be made between specific module

pins.

If required, this mode must be specified when

specifying the measurement to be made.

9-50 September 1996

Page 402 of 421

^^?

The Aston Martin Lagonda Diagnostic System

Users Guide

Operation

On selection of DMM the general screen, as shown in Fig.

1,

will be displayed.

Voltage is the default selection for measurement, with red

and black probes selected

as

sources.

To choose alternatives

to these options, press the relevant description for change

followed by the 'tick' icon in the top, right-hand, corner.

If the measurement mode (Voltage) is selected for change,

followed by a confirming 'tick', a screen as show will be

displayed.

Select DMM Measurement

^Q^||[

Resistance

Pulse Period

Pulse Width

(low)

Voltage (AC)

Frequency

Pulse Width

(High)

Duty Cycle

DMM Measurement Selection

Selection of any option from this screen, followed by a

confirming 'tick', will return the operator to the general

screen but with the new mode displayed against DMM.

If 'Resistance' is selected an additional

icon,

showing an

audio symbol, will appear above the "EXIT" display. This

icon allows the enabling / disabling of an audible signal

which sounds when measured valuefal

Is

below 0.5 ohms.

Touch the icon to toggle the warning ON / OFF directly,

no confirming 'tick' is necessary. A 'cross' is displayed

over the icon when warning is turned OFF.

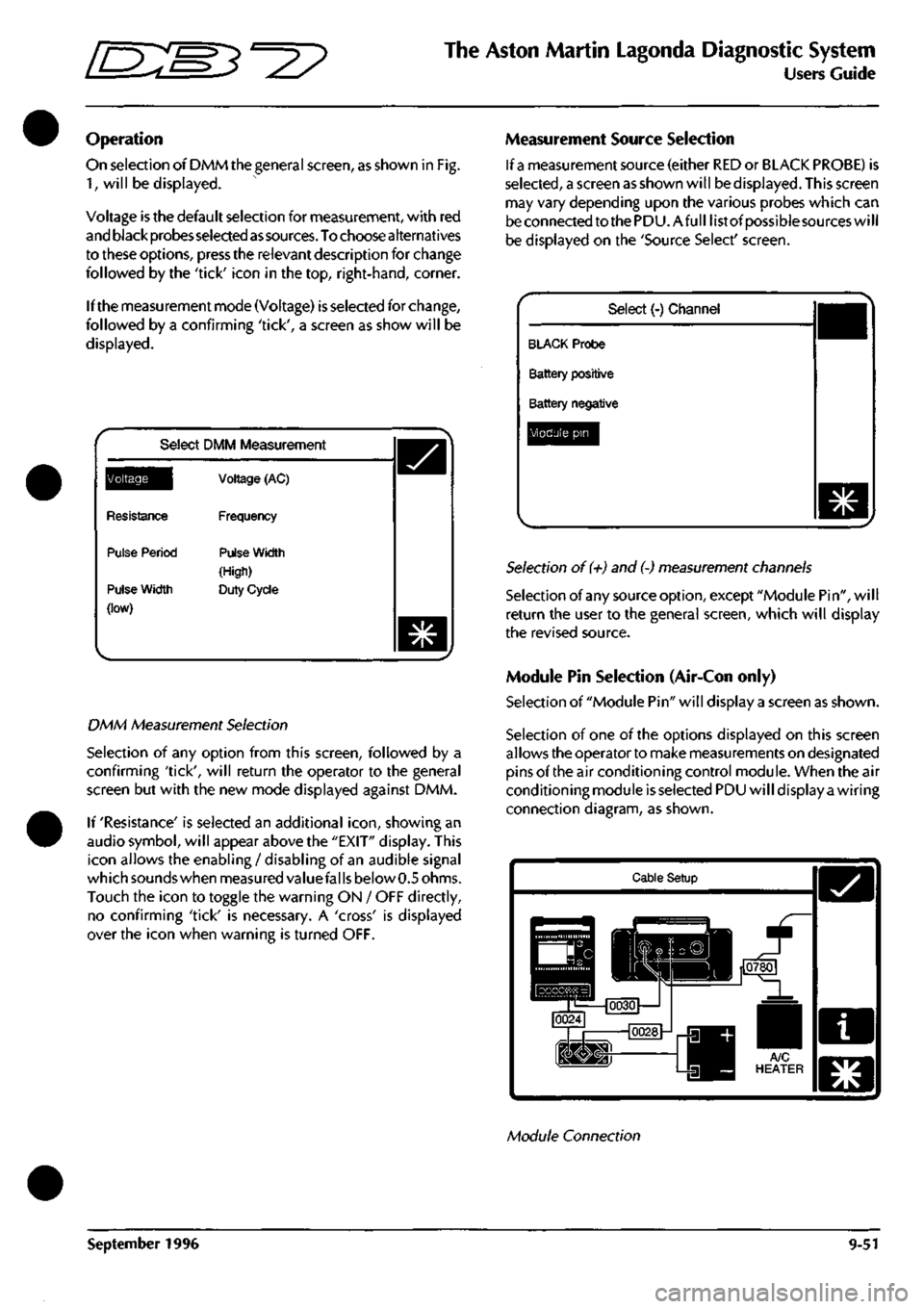

Measurement Source Selection

If

a

measurement source (either RED or BLACK PROBE) is

selected,

a screen as shown will be displayed. This screen

may vary depending upon the various probes which can

be connected to the PDU.Afull list of possiblesources will

be displayed on the 'Source Select' screen.

Select (-) Channel

BLACK Probe

Battery positive

Battery negative

Module pin

Selection of (+) and (-) measurement channels

Selection of any source option, except "Module Pin", will

return the user to the general screen, which will display

the revised source.

Module Pin Selection (Air-Con only)

Selection of "Module Pin" will display a screen as shown.

Selection of one of the options displayed on this screen

allows the operator to make measurements on designated

pins of the air conditioning control module. When the air

conditioning module is selected PDU will display a wiring

connection diagram, as shown.

Cable Setup

Module Connection

September 1996 9-51

Page 403 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide [S:S3^2?

The PDU will then check the cable connections. Until all

connections are correct, the PDU will not allow progression

beyond this

screen.

Pressingthe'asterisk'icon and selecting

abort returns the operator to the general screen if an

incorrect system has been chosen.

If selection and wiring are correct a numeric keypad will

be displayed. The operator can nowenterapin numberto

be tested, using this keypad.

Pin

Numeric Keypad

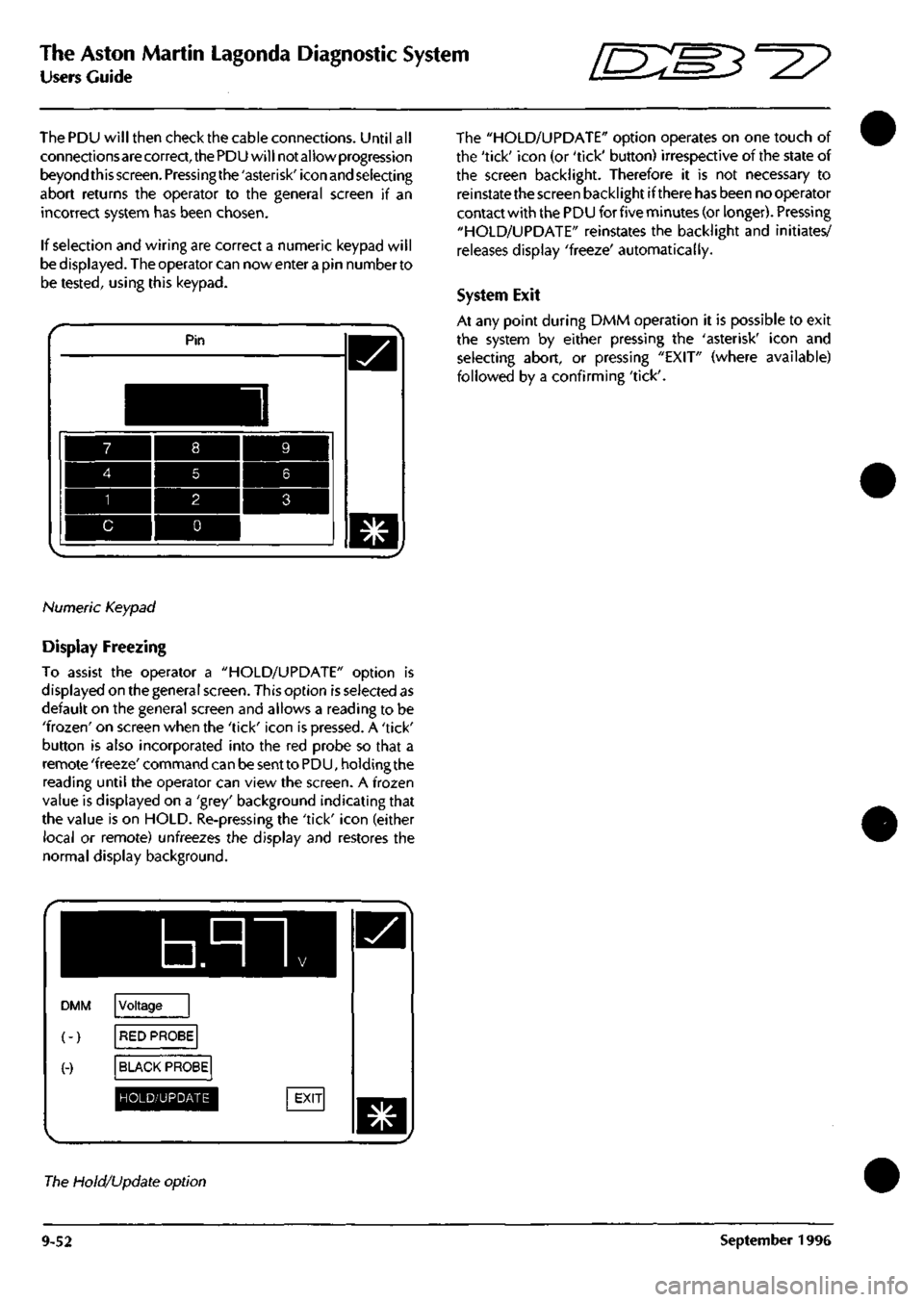

Display Freezing

To assist the operator a "HOLD/UPDATE" option is

displayed on the general screen. This option is selected as

default on the general screen and allows a reading to be

'frozen'

on screen when the 'tick' icon is pressed. A 'tick'

button is also incorporated into the red probe so that a

remote 'freeze' command can be sent to PDU, holding the

reading until the operator can view the screen. A frozen

value is displayed on a 'grey' background indicating that

the value is on HOLD. Re-pressing the 'tick' icon (either

local or remote) unfreezes the display and restores the

normal display background.

b.nn

DMM

(-)

(-)

Voltage

RED PROBE

BLACK PROBE

HOLD/UPDATE

The "HOLD/UPDATE" option operates on one touch of

the 'tick' icon (or 'tick' button) irrespective of the state of

the screen backlight. Therefore it is not necessary to

reinstate the screen backlight if there has been no operator

contact with the PDU for five minutes (or longer). Pressing

"HOLD/UPDATE" reinstates the backlight and initiates/

releases display 'freeze' automatically.

System Exit

At any point during DMM operation it is possible to exit

the system by either pressing the 'asterisk' icon and

selecting abort, or pressing "EXIT" (where available)

followed by a confirming 'tick'.

The Hold/Update option

9-52 September 1996

Page 404 of 421

^7

The Aston Martin Lagonda Diagnostic System

Users Guide

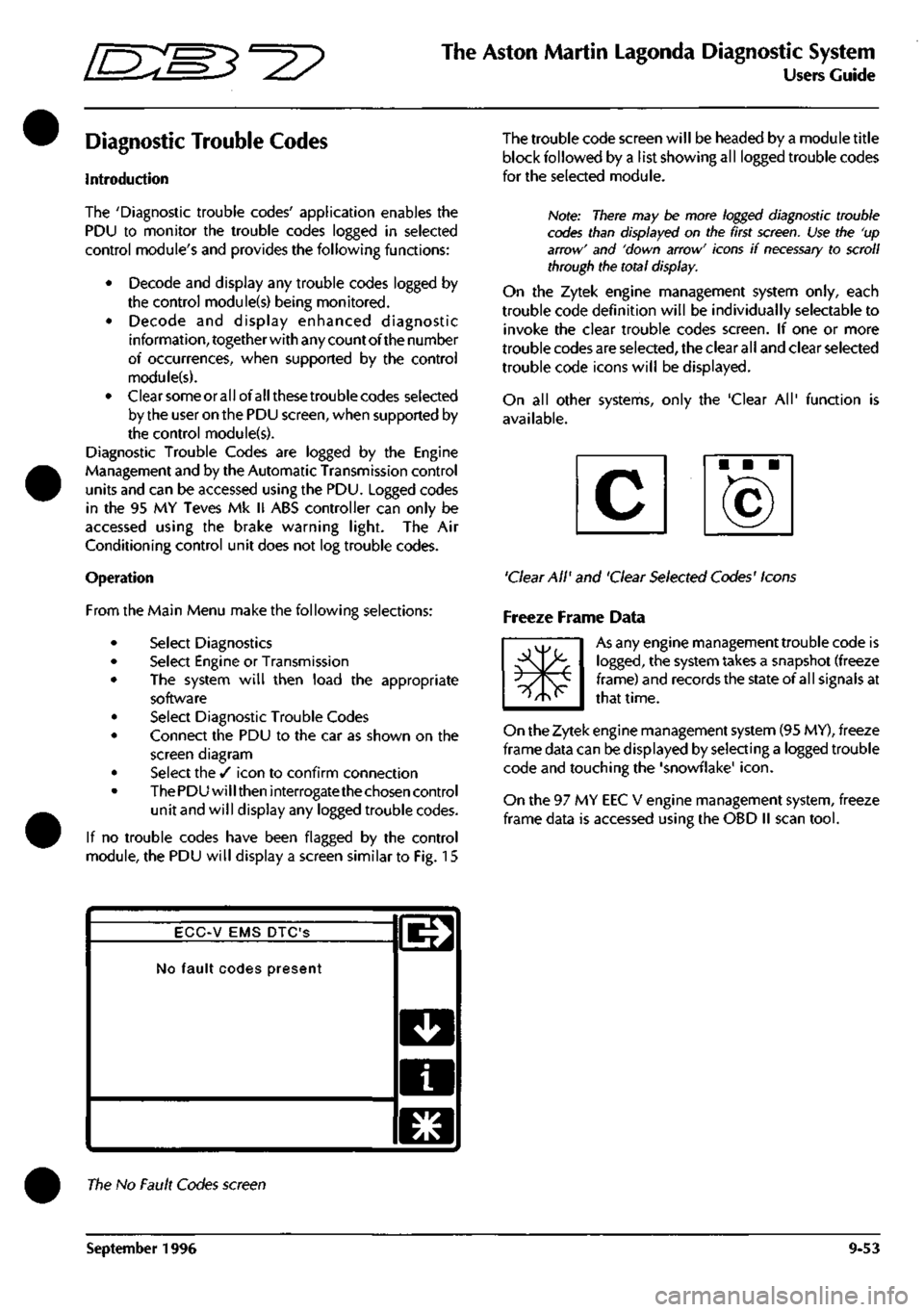

Diagnostic Trouble Codes

Introduction

The 'Diagnostic trouble codes' application enables the

PDU to monitor the trouble codes logged in selected

control module's and provides the following functions:

• Decode and display any trouble codes logged by

the control module(s) being monitored.

• Decode and display enhanced diagnostic

information, together with any count of the number

of occurrences, when supported by the control

module(s).

• Clearsomeorallofallthesetroublecodes selected

by the user on the PDU screen, when supported by

the control module(s).

Diagnostic Trouble Codes are logged by the Engine

Management and by the Automatic Transmission control

units and can be accessed using the PDU. Logged codes

in the 95 MY Teves Mk II ABS controller can only be

accessed using the brake warning light. The Air

Conditioning control unit does not log trouble codes.

Operation

From the Main Menu make the following selections:

Select Diagnostics

Select Engine or Transmission

The system will then load the appropriate

software

Select Diagnostic Trouble Codes

Connect the PDU to the car as shown on the

screen diagram

Select the / icon to confirm connection

The PDU will then interrogate the chosen control

unit and will display any logged trouble codes.

If no trouble codes have been flagged by the control

module, the PDU will display a screen similar to Fig. 15

The trouble code screen will be headed by a module title

block followed by a list showing all logged trouble codes

for the seleaed module.

Note: There may be more logged diagnostic trouble

codes than displayed on the first

screen.

Use the 'up

arrow' and 'down arrow' icons if

necessary

to scroll

through the total display.

On the Zytek engine management system only, each

trouble code definition will be individually selectable to

invoke the clear trouble codes screen. If one or more

trouble codes are selected, the clear all and clear selected

trouble code icons will be displayed.

On all other systems, only the 'Clear All' function is

available.

'Clear All' and 'Clear Selected Codes' Icons

Freeze Frame Data

m*

As any engine management trouble code is

logged,

the system takes a snapshot (freeze

frame) and records the state of all signals at

that time.

On the Zytek engine management system (95 MY), freeze

frame data can be displayed by selecting a logged trouble

code and touching the 'snowflake'

icon.

On the 97 MY EEC V engine management system, freeze

frame data is accessed using the OBD II scan

tool.

ECC-V EMS DTC'S

No fault codes present

l^

D

a

El

The No Fault Codes screen

September 1996 9-53

Page 405 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide

•=2?

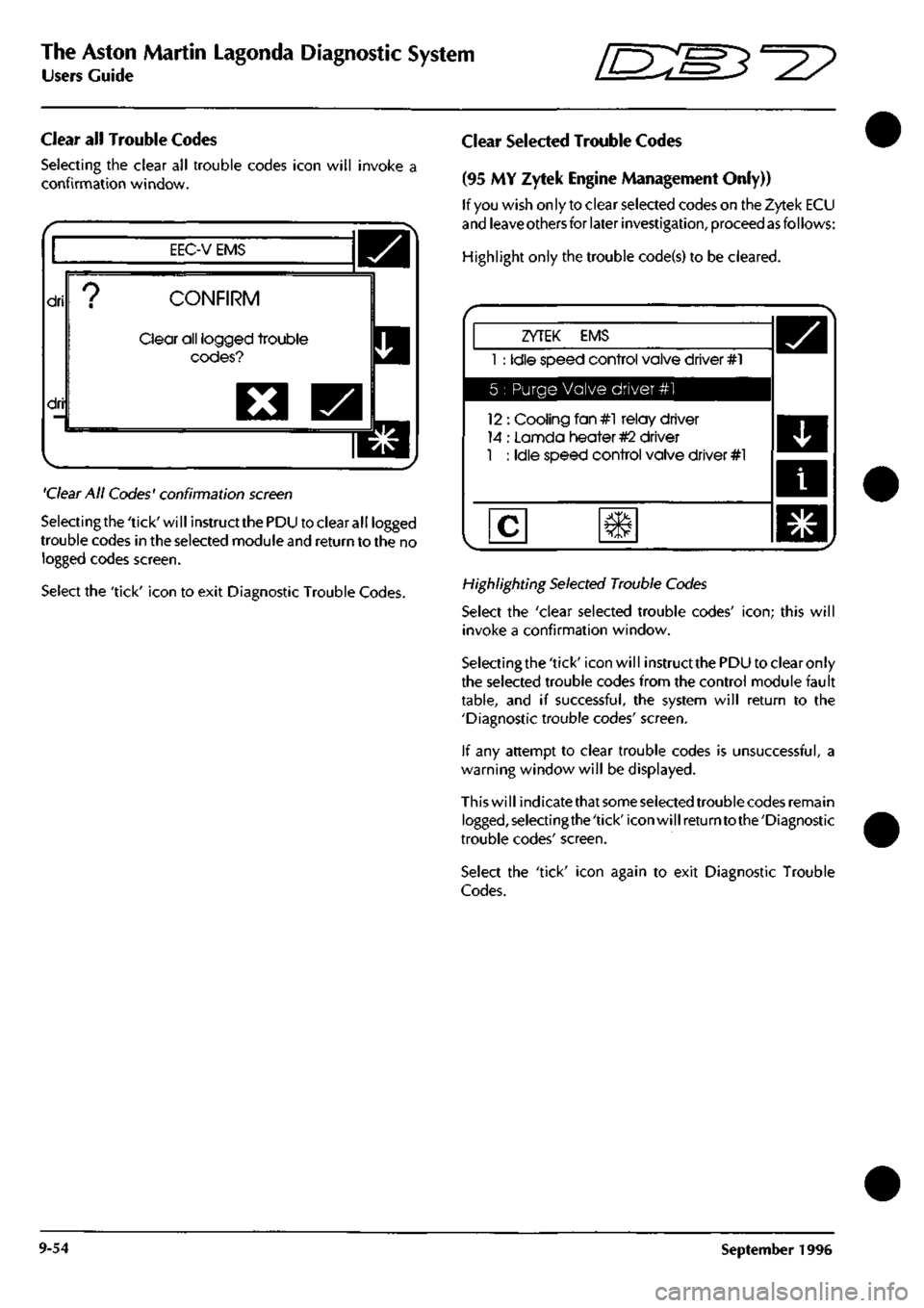

Clear all Trouble Codes

Selecting the clear all trouble codes icon will invoke a

confirmation window.

EEC-V EMS

dri

dri

CONFIRM

Clear all logged trouble

codes?

O

'Clear

All Codes' confirmation

screen

Selectingthe'tick'will instructthePDU to clear all logged

trouble codes in the selected module

and

return to the no

logged codes screen.

Select the 'tick' icon to exit Diagnostic Trouble Codes.

Clear Selected Trouble Codes

(95 MY Zytek Engine Management Only))

If

you

wish only to clear selected codes on the Zytek ECU

and

leave others

for later

investigation,

proceed

as

follows:

Highlight only the trouble code(s) to be cleared.

ZYTEK EMS

1 : Idle speed control valve driver #1

5 : Purge Valve driver #1

12 : Cooling fan#l relay driver

14 : Lannda heater

#2

driver

1 : Idle speed control valve driver #1

Highlighting

Selected

Trouble

Codes

Select the 'clear selected trouble codes'

icon;

this will

invoke a confirmation window.

Selectingthe 'tick' icon will instruct

the

PDU to clear only

the selected trouble codes from the control module fault

table,

and if successful, the system will return to the

'Diagnostic trouble codes' screen.

If any attempt to clear trouble codes is unsuccessful, a

warning window will be displayed.

This will indicatethat

some selected

trouble codes remain

logged,selectingthe'tick'iconwillreturntothe'Diagnostic

trouble codes' screen.

Select the 'tick' icon again to exit Diagnostic Trouble

Codes.

9-54 September 1996

Page 406 of 421

"^I?

The Aston Martin Lagonda Diagnostic System

Users Guide

Datalogger

Introduction

Datalogger is software produced to identify permanent or

intermittent faults on vehicle electronics. The objective of

Datalogger is to provide a view of the vehicle's electrical

behaviour, such that intermittent activity can be recorded

and interpreted quickly and accurately. Running on the

Portable Diagnostic Unit (PDU), the Datalogger

appi ication can captu

re

vehicle information in three ways.

• Serial communications direct from the control unit.

• Parallel communications using the Interface Adaptor.

• Direct signal monitoringusingthemeasurementprobes.

Serial Communication

Serial Communication is a two-wire communication link

between the PDU and most vehicle control modules

providingdigital measurements forconnected components.

The serial communication link allows the tester to

determine the current condition of components connected

to the control module, and to identify any history of faults.

On later vehicles, the PDU is connected to the vehicle

diagnostic sockets via the mu

Iti

Protocol Adaptor (MPA) to

gather serial data from the control modules.

Parallel Communication

The Vehicle Interface Adapter (VIA) provides an interface

between the PDU and the vehicle harnesses for the

acquisition of multiple analogue measurements. The VIA

is

connected between the relevantvehicle control module

and it'sharness connector. Thisallows the PDU to captu re

information from a multitude of channels entering the

control module. This vehicle interface is used with control

modules not equipped with a serial communication link

(Teves Mk II braking system and the air conditioning

system).

Measurement Probes

The measurement probes permit readings to be taken

directly from any connector on the vehicle.

Datalogger Applications

Datalogger may be used to interrogate the following DB7

systems:

• ABS braking system controller

• Engine Management Controller

• Air Conditioning Controller

• Automatic Transmission Controller

• Passive Anti Theft (97 MY)

• Security System (97 MY)

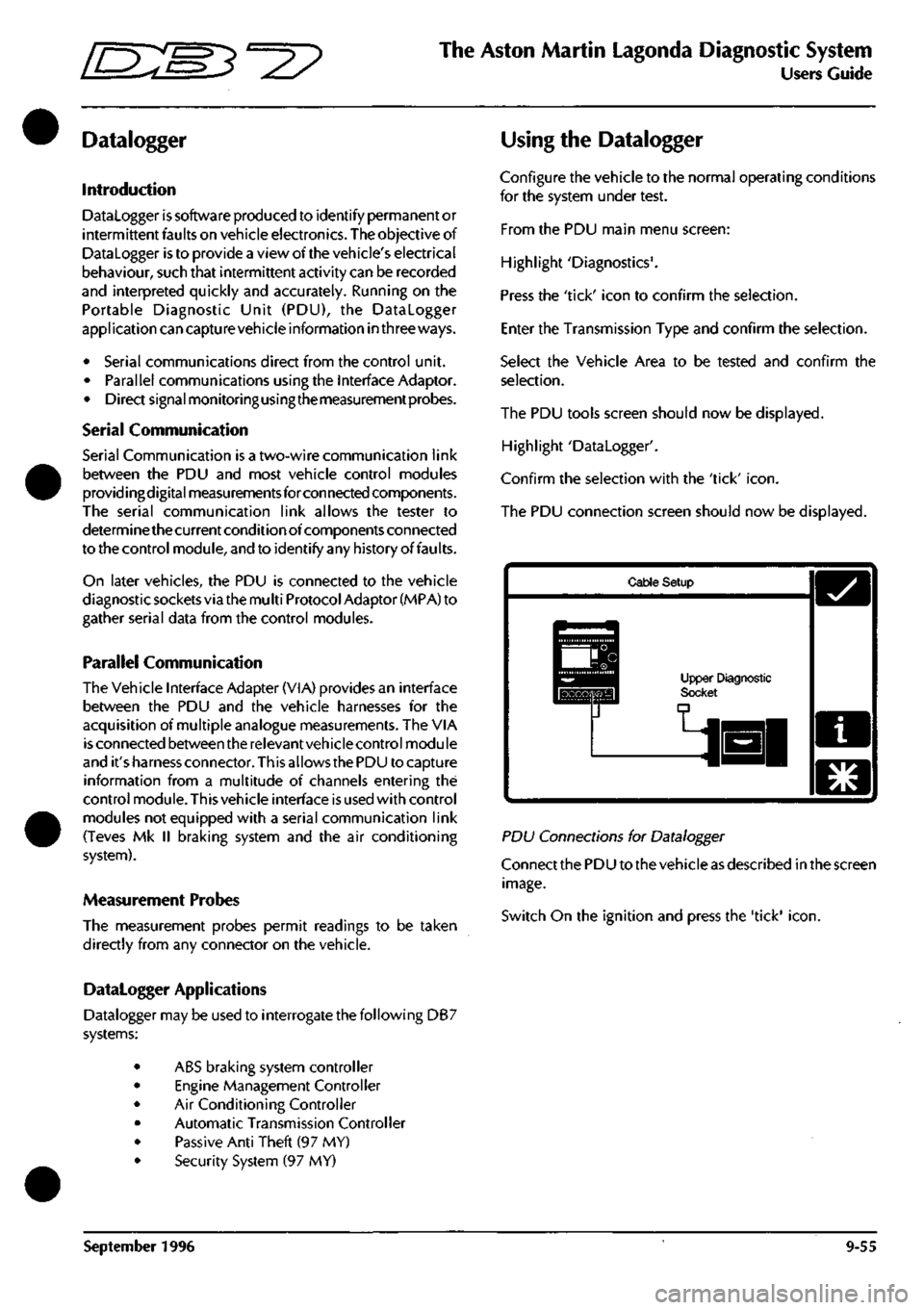

Using the Datalogger

Configure the vehicle to the normal operating conditions

for the system under test.

From the PDU main menu screen:

Highlight 'Diagnostics'.

Press the 'tick' icon to confirm the selection.

Enter the Transmission Type and confirm the selection.

Select the Vehicle Area to be tested and confirm the

selection.

The PDU tools screen should now be displayed.

Highlight 'Datalogger'.

Confirm the selection with the 'tick'

icon.

The PDU connection screen should now be displayed.

Cable Setup

Upper Diagnostic Socl

PD\J Connections for Datalogger

Connect the PDU to the vehicle as described in the screen

image.

Switch On the ignition and press the 'tick'

icon.

September 1996 9-55

Page 407 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide •^^

'Establishing connection to control module' should now

be displayed on the screen.

If for any reason the PDU cannot communicate with the

relevantvehiclecontrol modulea 'communicationsfailure

screen'

will be displayed with a retry option.

Check all connections before retrying.

Once commu nications are successfu

I

'Starti ng Datalogger'

will appear on the screen momentarily.

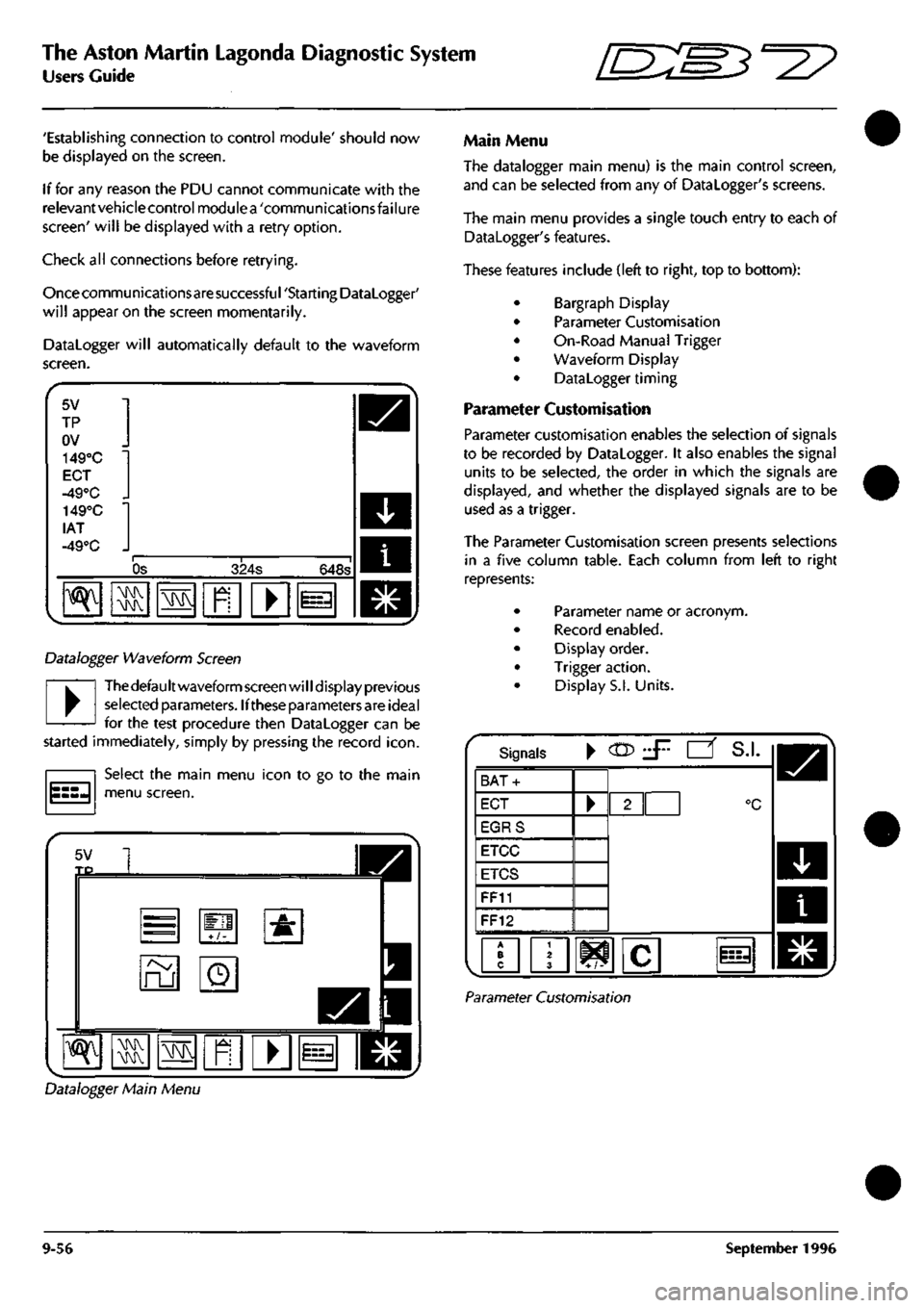

Datalogger will automatically default to the waveform

screen.

5V

TP

ov

149°C

EOT

-49°C _

lAT

-49°C _

"^

Os 324s 648s

•\N

M\^

\!M

n

• i=-i

Datalogger Waveform Screen

•

Thedefaultwaveform screen will display previous

selected parameters. Ifthese parameters are ideal

for the test procedure then Datalogger can be

started immediately, simply by pressing the record

icon.

Select the main menu icon to go to the main

menu screen.

5V TP

=

ru

+/-

o

•&

^ M\K ras

1

I

Main Menu

The datalogger main menu) is the main control screen,

and can be selected from any of Datalogger's screens.

The main menu provides a single touch entry to each of

Datalogger's features.

These features include (left to right, top to bottom):

Bargraph Display

Parameter Customisation

On-Road Manual Trigger

Waveform Display

Datalogger timing

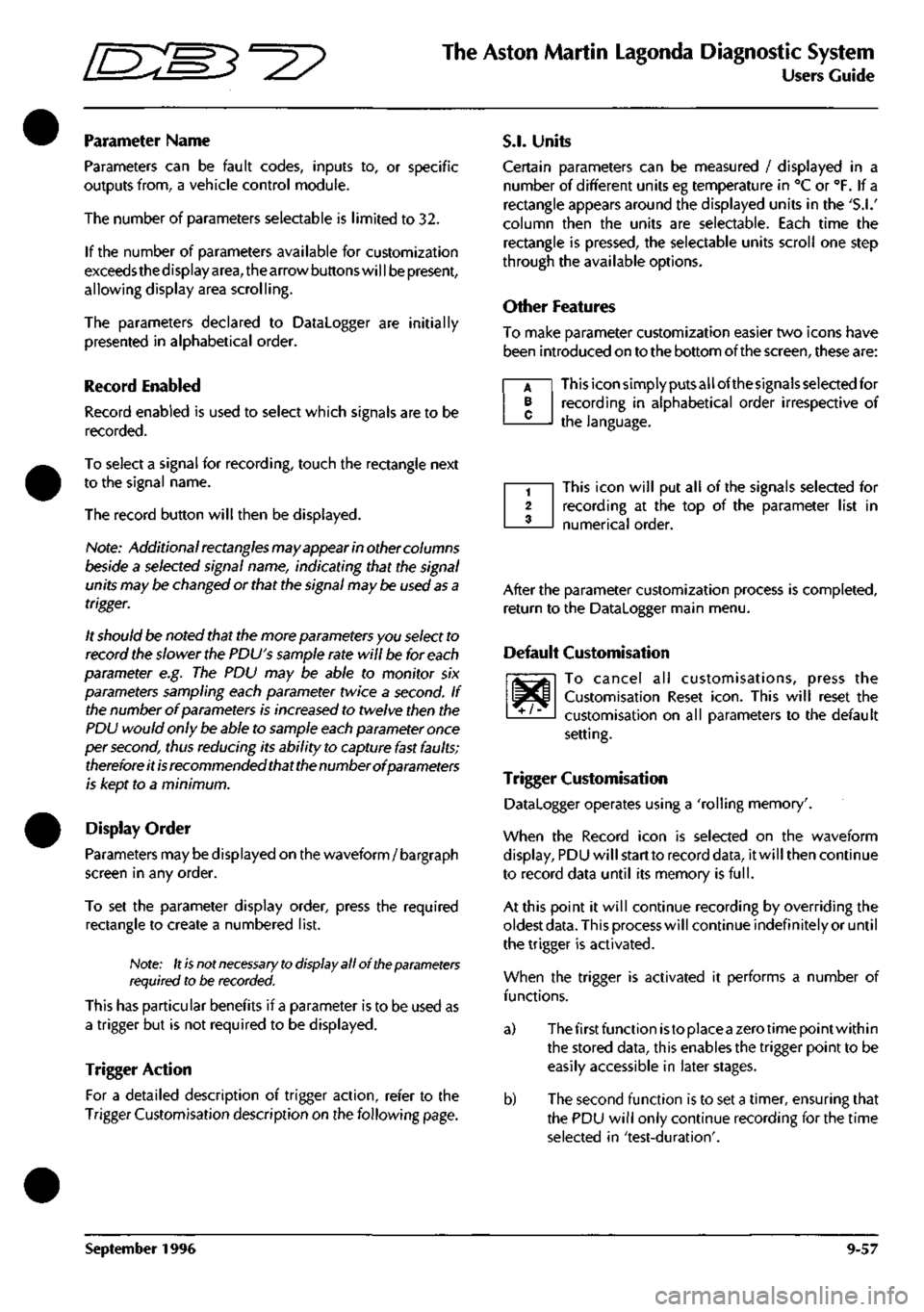

Parameter Customisation

Parameter customisation enables the selection of signals

to be recorded by Datalogger. It also enables the signal

units to be selected, the order in which the signals are

displayed,

and whether the displayed signals are to be

used as a trigger.

The Parameter Customisation screen presents selections

in a five column table. Each column from left to right

represents:

Parameter name or acronym.

Record enabled.

Display order.

Trigger action.

Display S.I. Units.

Signals •

CO?

J^ •' S.I.

BAT-

ECT

EGRS

ETCC

ETCS

FF11

FF12

/•? 103

Parameter Customisation

Datalogger Main Menu

9-56 September 1996

Page 408 of 421

^

The Aston Martin Lagonda Diagnostic System

Users Guide

Parameter Name

Parameters can be fault codes, inputs to, or specific

outputs from, a vehicle control module.

The number of parameters selectable is limited to 32.

If the number of parameters available for customization

exceeds the d isplay

area,

the arrow buttons wi

11

be present,

allowing display area scrolling.

The parameters declared to Datalogger are initially

presented in alphabetical order.

Record Enabled

Record enabled is used to select which signals are to be

recorded.

To select a signal for recording, touch the rectangle next

to the signal name.

The record button will then be displayed.

Nofe:

Additional rectangles may appear in other columns

beside a selected signal name, indicating that the signal

units may be changed or that the signal may be used

as

a

trigger.

It should be noted that the more parameters you select to

record the slower the PDU's sample rate will be for each

parameter e.g. The PDU may be able to monitor six

parameters sampling each parameter twice a second. If

the number of parameters is increased to twelve then the

PDU would only be able to sample each parameter once

per second, thus reducing its ability to capture fast faults;

therefore it

is

recommended that the number of parameters

is kept to a minimum.

Display Order

Parameters may be displayed on the waveform/ bargraph

screen in any order.

To set the parameter display order, press the required

rectangle to create a numbered list.

Note: It

is

not

necessary to

display all of the parameters

required to be recorded.

This has particular benefits if a parameter is to be used as

a trigger but is not required to be displayed.

Trigger Action

For a detailed description of trigger action, refer to the

Trigger Customisation description on the following page.

S.I.

Units

Certain parameters can be measured / displayed in a

number of different units eg temperature in °C or °F. If a

rectangle appears around the displayed units in the

'S.I.'

column then the units are selectable. Each time the

rectangle is pressed, the selectable units scroll one step

through the available options.

Other Features

To make parameter customization easier two icons have

been introduced on to the bottom of the screen, these are:

This icon simply puts all ofthesignals selected for

recording in alphabetical order irrespective of

the language.

A B C

This icon will put all of the signals selected for

recording at the top of the parameter list in

numerical order.

^T/^

After the parameter customization process is completed,

return to the Datalogger main menu.

Default Customisation

To cancel all customisations, press the

Customisation Reset

icon.

This will reset the

customisation on all parameters to the default

setting.

Trigger Customisation

Datalogger operates using a 'rolling memory'.

When the Record icon is selected on the waveform

display, PDU will start to record data, it will then continue

to record data until its memory is

full.

At this point it will continue recording by overriding the

oldest

data.

This process will continue indefinitely or until

the trigger is activated.

When the trigger is activated it performs a number of

functions.

a) The first function istoplaceazerotimepointwithin

the stored data, this enables the trigger point to be

easily accessible in later stages.

b) The second function is to set a timer, ensuring that

the PDU wil

I

only continue recording for the time

selected in 'test-duration'.

September 1996 9-57

Page 409 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide 5^^?

Only the data within the selected time period will be

stored.

A trigger is used to define the zero time point on

any waveform display. This is used to make it easier to

locate the actual point at which the fault occurred on the

waveform display. Triggers may take three forms.

1.

Manual Trigger

A manual trigger would be used in circumstances where

the technician can clearly identify the point when the fault

occurs and has access to the PDU at this point.

The trigger icon should be pressed on the waveform /

bargraph display (ortheon-road trigger icon) at the instant

the fault occurs. This will then become the zero point for

the waveform/bargraph display. The waveform/bargraph

display up to this point would have a negative form.

2.

Fault Code Trigger

The fault code trigger is used when the first indication of

a fault is normally by the appearance of a warning lamp

within the instrument pack. For some vehicle systems

Datalogger can trigger on specific fault codes, this type of

triggering is more precise than simply triggering on the

warning lamp.

This trigger

is

selected during the parameter customisation

process. To select a fault code to trigger 'on', set the fault

code (parameter) to record.

Asign the display order by touching the rectangle below

the Eye icon repeatedly until the desired display order

number is shown.

Press the rectangle in the trigger column.

Highlight the fault code parameter again and select the

magnifying glass

icon.

The trigger customisation screen

will be displayed.

Select the appropriate trigger style icon and select the tick

icon to confirm.

Press the Tick icon again to return to the main Datalogger

screen.

Select the Record icon to start data capture.

The unit will trigger when the fault code appears and will

set the zero time point of the waveform / bargraph display.

3. Specific Signal Trigger

It is possible to select a specific parameter or signal to

trigger Datalogger.

Triggering on specific signals is likely to be used when the

vehicle system has no on-board diagnostics or when

diagnostic information is not readily available at the time

the fault occurs, e.g. air-conditioning.

Thistypeoftriggershouldonly be used when it is known

that a particular signal has certain characteristics at the

time the fault occurs, e.g. one signal will always go from

12 Volts to ground, bringing on a warning lamp when a

particular fault occurs,

as

this is a known event, this signal

may be used to trigger the PDU.

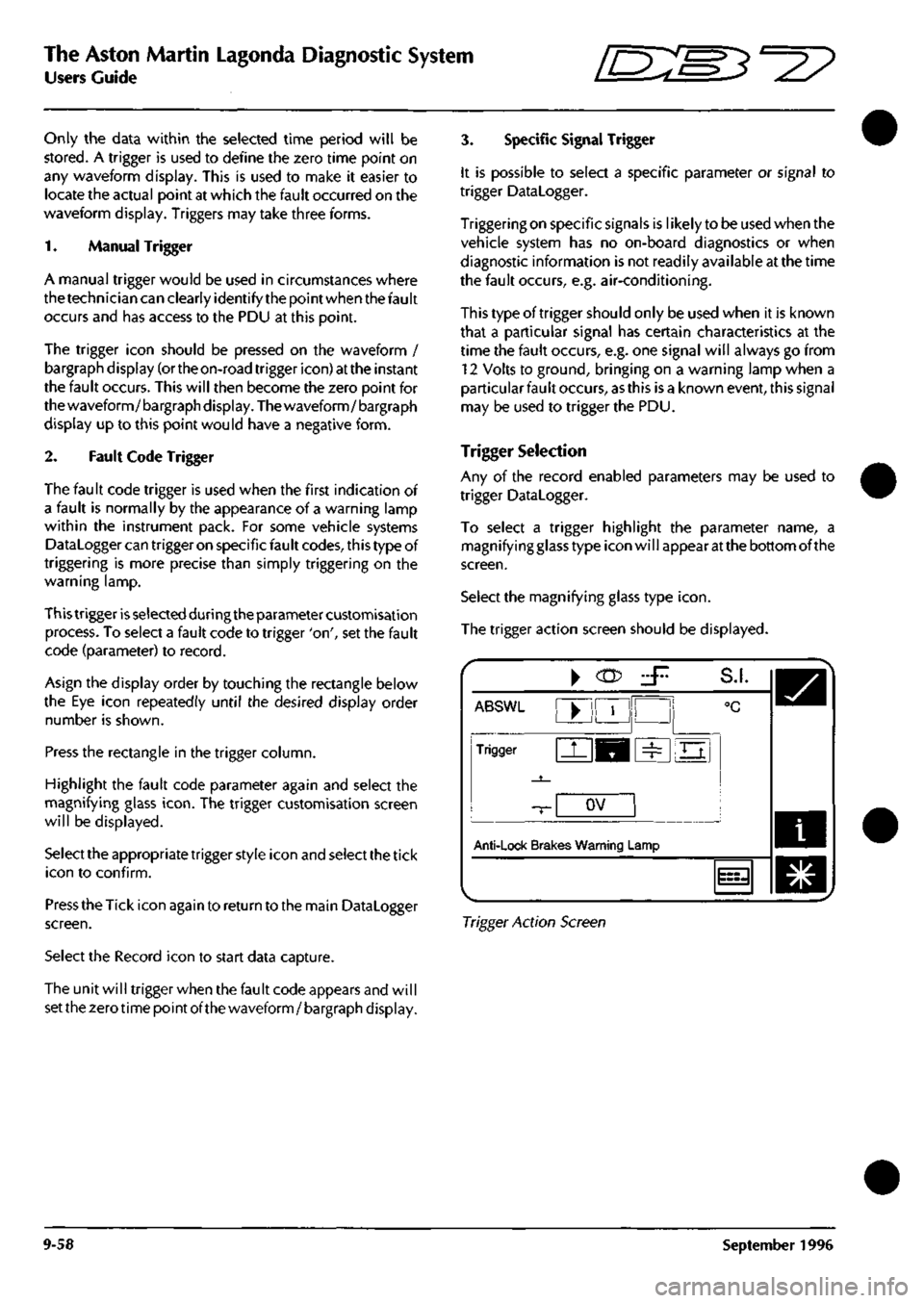

Trigger Selection

Any of the record enabled parameters may be used to

trigger Datalogger.

To select a trigger highlight the parameter name, a

magnifying glass type icon will appear at the bottom of the

screen.

Select the magnifying glass type

icon.

The trigger action screen should be displayed.

ABSWl

Trigger

-T-

Anti-lock Brak

^

^M

ov

es Warning

L

zF

!

=^

S.I.

°C

Ei

.amp

i

m,

Trigger Action Screen

9-58 September 1996

Page 410 of 421

^^?

The Aston Martin Lagonda Diagnostic System

Users Guide

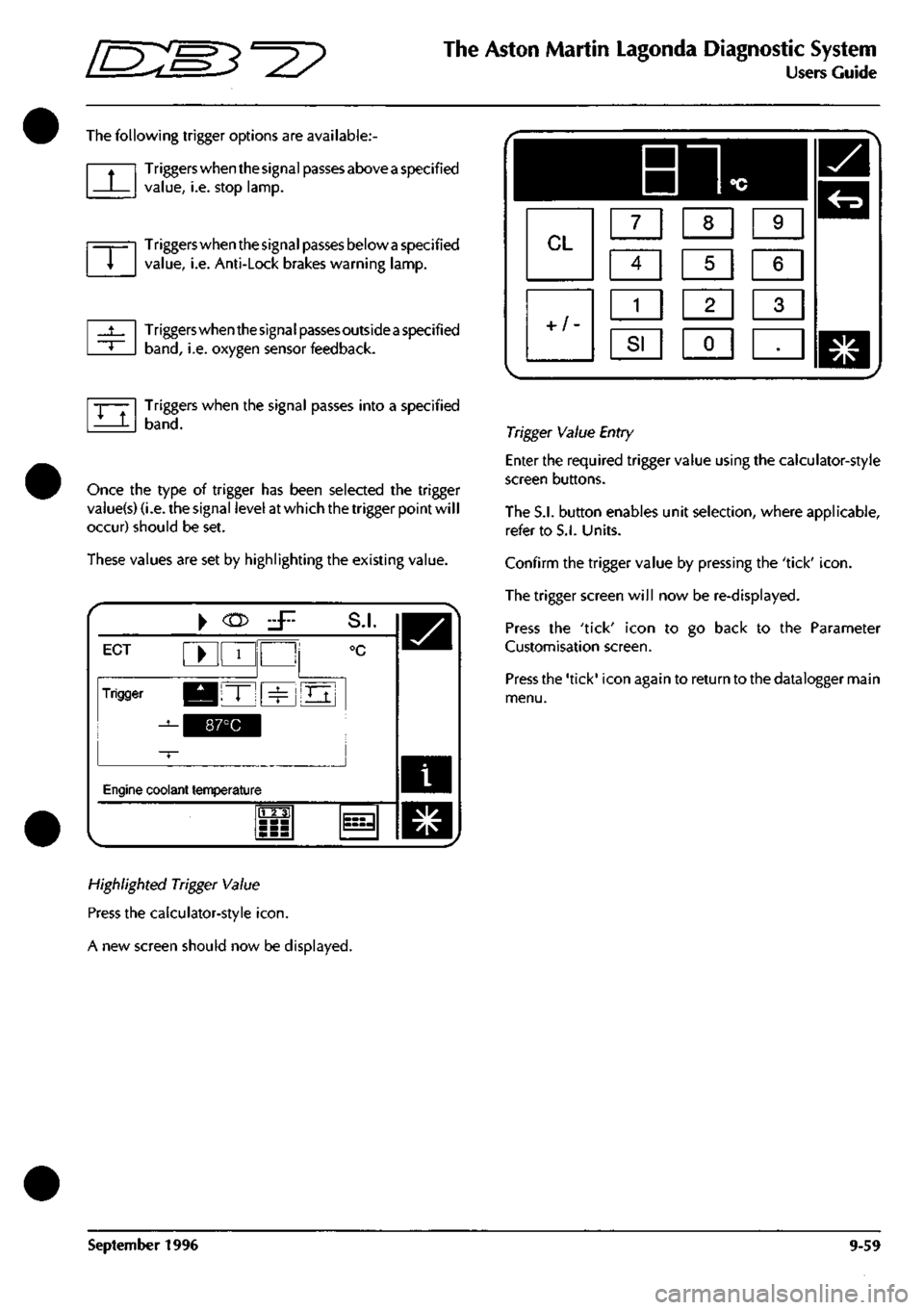

The following trigger options are available:

Triggers when the signal passes above

a

specified

value,

i.e. stop lamp.

Triggers when the signal passes below

a

specified

value,

i.e. Anti-Lock brakes warning lamp.

Triggers when the signa

I

passes outside

a

specified

band,

i.e. oxygen sensor feedback.

Triggers when the signal passes into a specified

band.

Once the type of trigger has been selected the trigger

vaiue(s) (i.e. the signal level at which the trigger point wil

I

occur) should be set.

These values are set by highlighting the existing value.

i

ECT ^ 1

Trigger KBIT" ^

^^^^1

S.I.

°c

Oj

Engine coolant temperature

m

^

Highlighted Trigger Value

Press the calculator-style

icon.

A new screen should now be displayed.

Trigger Value Entry

Enter the required trigger value using the calculator-style

screen buttons.

The S.I. button enables unit selection, where applicable,

refer to S.I. Units.

Confirm the trigger value by pressing the 'tick'

icon.

The trigger screen will now be re-displayed.

Press the 'tick' icon to go back to the Parameter

Customisation screen.

Press the 'tick' icon again to return to the datalogger main

menu.

September 1996 9-59