ECO mode ASTON MARTIN V8 VANTAGE 2010 User Guide

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 826 of 947

Electronics Training Programme

Getting Help

If you require help while learning to use the system, or whenever a reminder is required when

prompted for a yes/no answer. Say ‘Help’ into t he microphone. The system includes help prompts in

every menu. Alternatively if you say ‘repea t’ the system will repeat the question.

Connecting A Phone

A connection between the vehicle Bluetooth syst em and a phone is called a ‘Paired Link’.

When a paired link is set up the Bluetooth system remembers the phone’s ID. Once the Bluetooth

system and the phone are paired, the Bluetooth system automatically connects to your phone every

time you start your vehicle or powe r up the vehicle’s Bluetooth system.

This system supports paired links with up to four phones.

Note: The process of initiating a Bluetooth connection with a phone varies per phone manufacturer.

For more information refer to the user’s guide for your mobile phone.

Use the following procedure only if there are no handsets paired to the system:

1. Press the button. When prompted say ‘Pair phone’. The system responds with ‘Set your

phone in scan mode and enter 1234 when prompted for the ‘passcode’.

2. When the phone displays ‘Aston Martin’ sele ct the device. The phone displays the passcode

entry screen.

3. Enter the passkey (1234). The phone displays ‘P IN verified’ and the system will say ‘Pairing

complete. Connection in progress’.

Note: Some phones will ask you to a ccept the BT link. Enter Yes.

Upon successful completion the system say’s ‘Co nnection is complete. Phone

To pair additional phones to the system:

1. Press the button. When prompted say ‘Set-up menu’. The system responds with ‘Set-up

menu. Please say a command’.

2. Say ‘Pair phone’. The system responds with ‘Set your phone in scan mode and enter 1234

when prompted for the passcode’.

3. When the phone displays ‘Aston Martin’, select the device. The phone will display the

passcode entry screen.

4. Enter the passkey value provided by the system . The phone confirms that the PIN is verified

and the system will say ‘Pairing complete. Connection in progress’.

Note: Some phones will ask you to a ccept the BT link. Enter Yes.

Upon successful completion the sy stem will say ‘Connection is complete. Phone

The Bluetooth system will not recognise a mobile p hone even if it is ‘paired’, if the mobile phone

does not have Bluetooth enabled. For more information refer to the user’s guide for your mobile

phone.

21

Page 834 of 947

Electronics Training Programme

The procedure to change the selected language is:

Warning: When changing the system’s language, all contac ts in the Bluetooth contacts list are deleted.

1. Press and hold the button while turning on the vehicle ignition. Continue holding the

button for at least 10 seconds.

The system enters language selection mode and re sponds with ‘Language Menu. Press volume up or

down to change language’.

2. Use the volume Up / Down button to scroll through the language choices. As a language appears, the system plays the prompt for that la nguage (For example: ‘English. To choose this

language, restart the vehicle’.).

When the desired language has been selected, turn t he vehicle ignition to 0 (off). Wait for 6 seconds,

then switch the ignition to II (on), the new language is then loaded.

29

Page 854 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 8 of 43

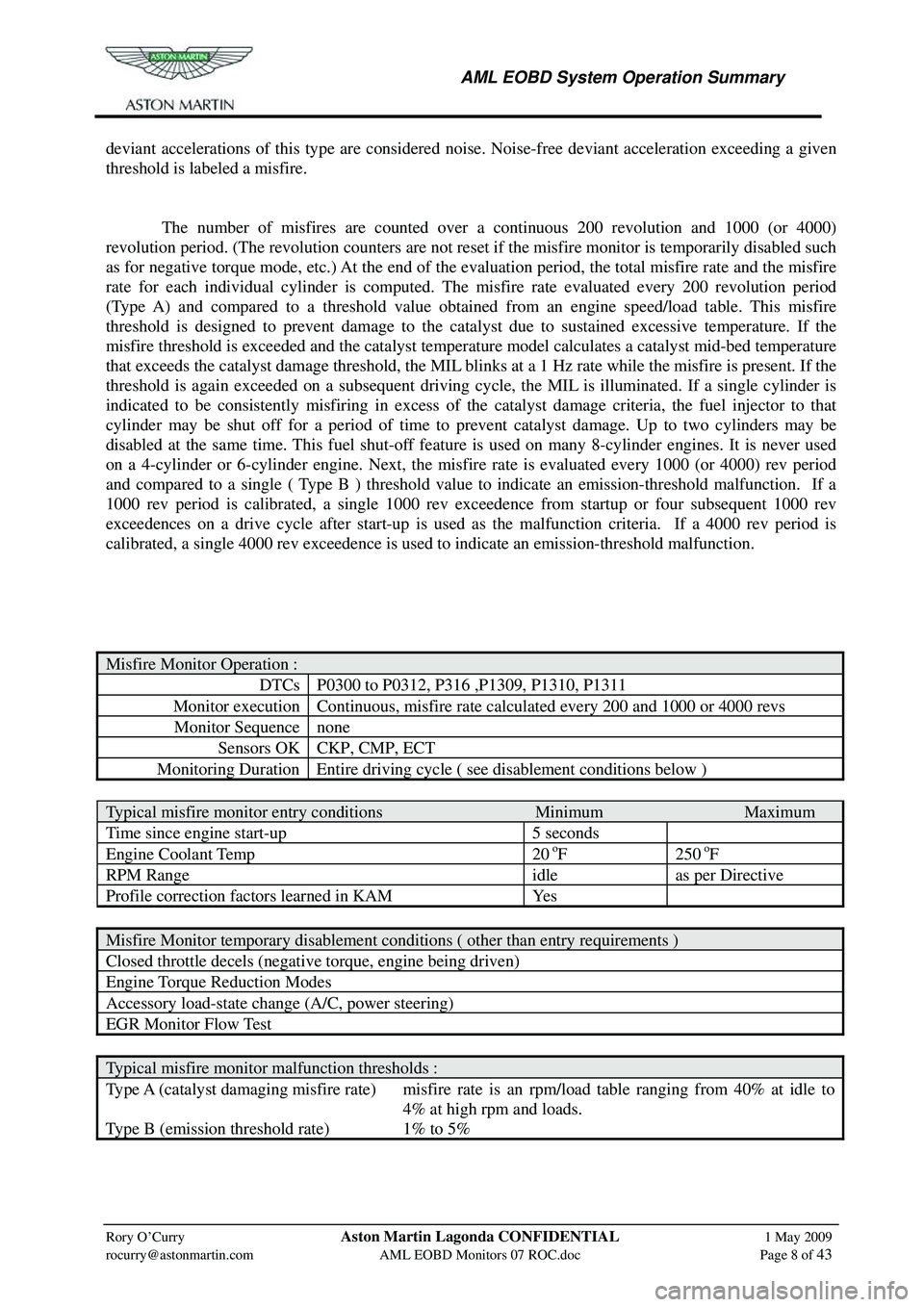

deviant accelerations of this type are considered noise. Noise-free deviant acceleration exceeding a given

threshold is labeled a misfire.

The number of misfires are counted over a continuous 200 revolution and 1000 (or 4000)

revolution period. (The revolution counters are not reset if the misfire monitor is temporarily disabled such

as for negative torque mode, etc.) At the end of the evaluation period, the total misfire rate and the misfire

rate for each individual cylinder is computed. The misfire rate evaluated every 200 revolution period

(Type A) and compared to a threshold value obtaine d from an engine speed/load table. This misfire

threshold is designed to prevent damage to the cat alyst due to sustained excessive temperature. If the

misfire threshold is exceeded and the catalyst temperature model calculates a catalyst mid-bed temperature

that exceeds the catalyst damage threshold, the MIL blinks at a 1 Hz rate while the misfire is present. If the

threshold is again exceeded on a subsequent driving cy cle, the MIL is illuminated. If a single cylinder is

indicated to be consistently misfiring in excess of the catalyst damage criteria, the fuel injector to that

cylinder may be shut off for a period of time to pr event catalyst damage. Up to two cylinders may be

disabled at the same time. This fuel shut-off feature is used on many 8-cylinder engines. It is never used

on a 4-cylinder or 6-cylinder engine. Next, the misf ire rate is evaluated every 1000 (or 4000) rev period

and compared to a single ( Type B ) threshold value to indicate an emission-threshold malfunction. If a

1000 rev period is calibrated, a single 1000 rev exceedence from startup or four subsequent 1000 rev

exceedences on a drive cycle after start-up is used as the malfunction criteria. If a 4000 rev period is

calibrated, a single 4000 rev exceedence is used to indicate an emission-threshold malfunction.

Misfire Monitor Operation :

DTCs P0300 to P0312, P316 ,P1309, P1310, P1311

Monitor execution Continuous, misfire rate calculated every 200 and 1000 or 4000 revs

Monitor Sequence none

Sensors OK CKP, CMP, ECT

Monitoring Duration Entire driving cycle ( see disablement conditions below )

Typical misfire monitor entry conditions Minimum Maximum

Time since engine start-up 5 seconds

Engine Coolant Temp 20 oF 250 oF

RPM Range idle as per Directive

Profile correction factors learned in KAM Yes

Misfire Monitor temporary disablement conditions ( other than entry requirements )

Closed throttle decels (negative torque, engine being driven)

Engine Torque Reduction Modes

Accessory load-state change (A/C, power steering)

EGR Monitor Flow Test

Typical misfire monitor malfunction thresholds :

Type A (catalyst damaging misfire rate) misfire rate is an rpm/load table ranging from 40% at idle to

4% at high rpm and loads.

Type B (emission threshold rate) 1% to 5%

Page 869 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 23 of 43

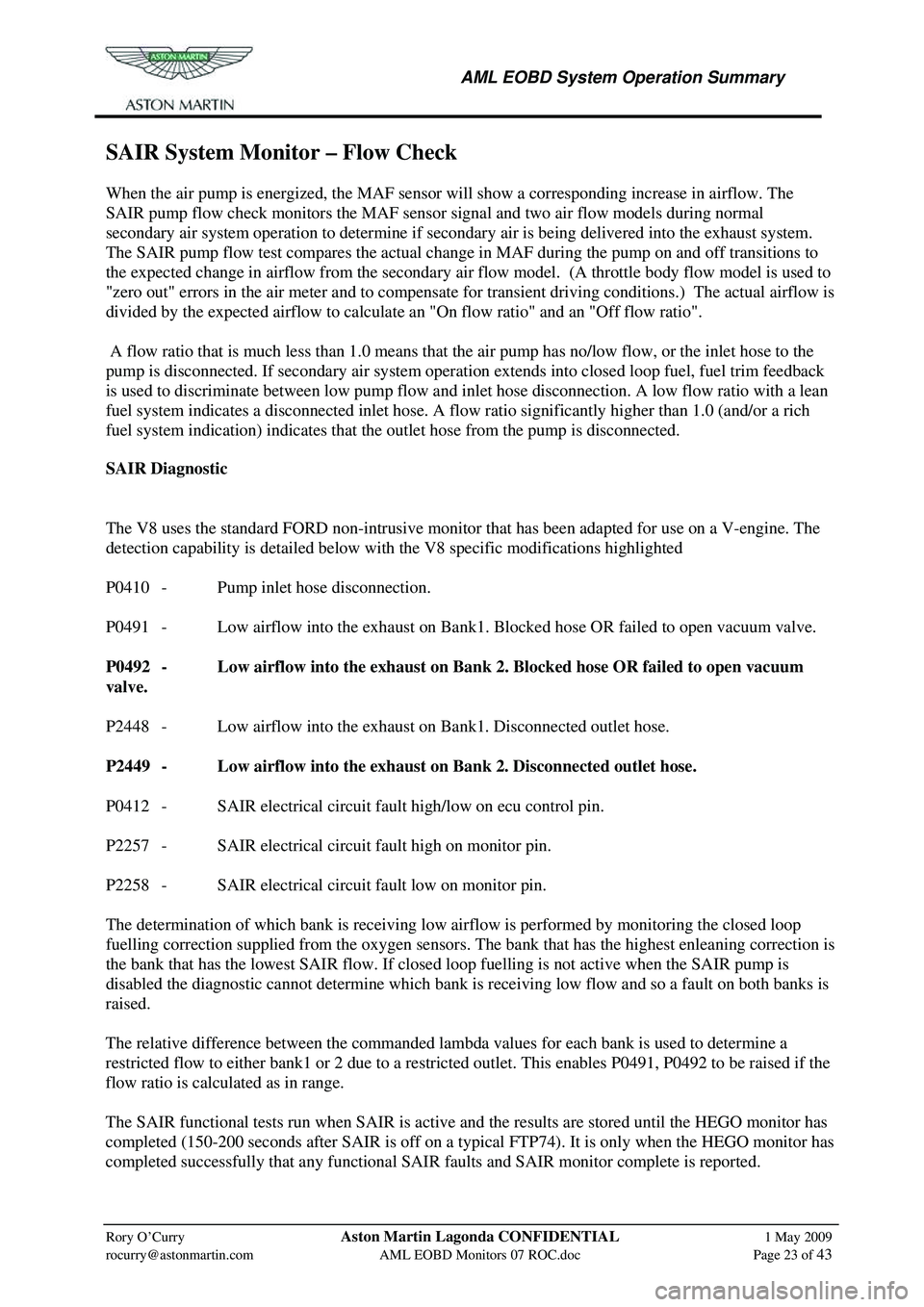

SAIR System Monitor – Flow Check

When the air pump is energized, the MAF sensor will show a corresponding increase in airflow. The

SAIR pump flow check monitors the MAF sensor signal and two air flow models during normal

secondary air system operation to determine if secondary air is being delivered into the exhaust system.

The SAIR pump flow test compares the actual change in MAF during the pump on and off transitions to

the expected change in airflow from the secondary air fl ow model. (A throttle body flow model is used to

"zero out" errors in the air meter and to compensate fo r transient driving conditions.) The actual airflow is

divided by the expected airflow to calculate an "On flow ratio" and an "Off flow ratio".

A flow ratio that is much less than 1.0 means that the air pump has no/low flow, or the inlet hose to the

pump is disconnected. If secondary air system operation ex tends into closed loop fuel, fuel trim feedback

is used to discriminate between low pump flow and in let hose disconnection. A low flow ratio with a lean

fuel system indicates a disconnected inlet hose. A flow ratio significantly higher than 1.0 (and/or a rich

fuel system indication) indicates that th e outlet hose from the pump is disconnected.

SAIR Diagnostic

The V8 uses the standard FORD non-intrusive monitor that has been adapted for use on a V-engine. The

detection capability is detailed below with the V8 specific modifications highlighted

P0410 - Pump inlet hose disconnection.

P0491 - Low airflow into the exhaust on Bank1. Blocked hose OR failed to open vacuum valve.

P0492 - Low airflow into the exhaust on Bank 2. Blocked hose OR failed to open vacuum

valve.

P2448 - Low airflow into the exhaust on Bank1. Disconnected outlet hose.

P2449 - Low airflow into the exhaust on Bank 2. Disconnected outlet hose.

P0412 - SAIR electrical circuit fault high/low on ecu control pin.

P2257 - SAIR electrical circuit fault high on monitor pin.

P2258 - SAIR electrical circuit fault low on monitor pin.

The determination of which bank is receiving low ai rflow is performed by monitoring the closed loop

fuelling correction supplied from the oxygen sensors. The bank that has the highest enleaning correction is

the bank that has the lowest SAIR flow. If closed loop fuelling is not active when the SAIR pump is

disabled the diagnostic cannot determ ine which bank is receiving low flow and so a fault on both banks is

raised.

The relative difference between the commanded lambda values for each bank is used to determine a

restricted flow to either bank1 or 2 due to a restricted outlet. This enables P0491, P0492 to be raised if the

flow ratio is calculated as in range.

The SAIR functional tests run when SAIR is active and the results are stored until the HEGO monitor has

completed (150-200 seconds after SAIR is off on a typical FTP74). It is only when the HEGO monitor has

completed successfully that any functional SAIR fa ults and SAIR monitor complete is reported.

Page 883 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 37 of 43

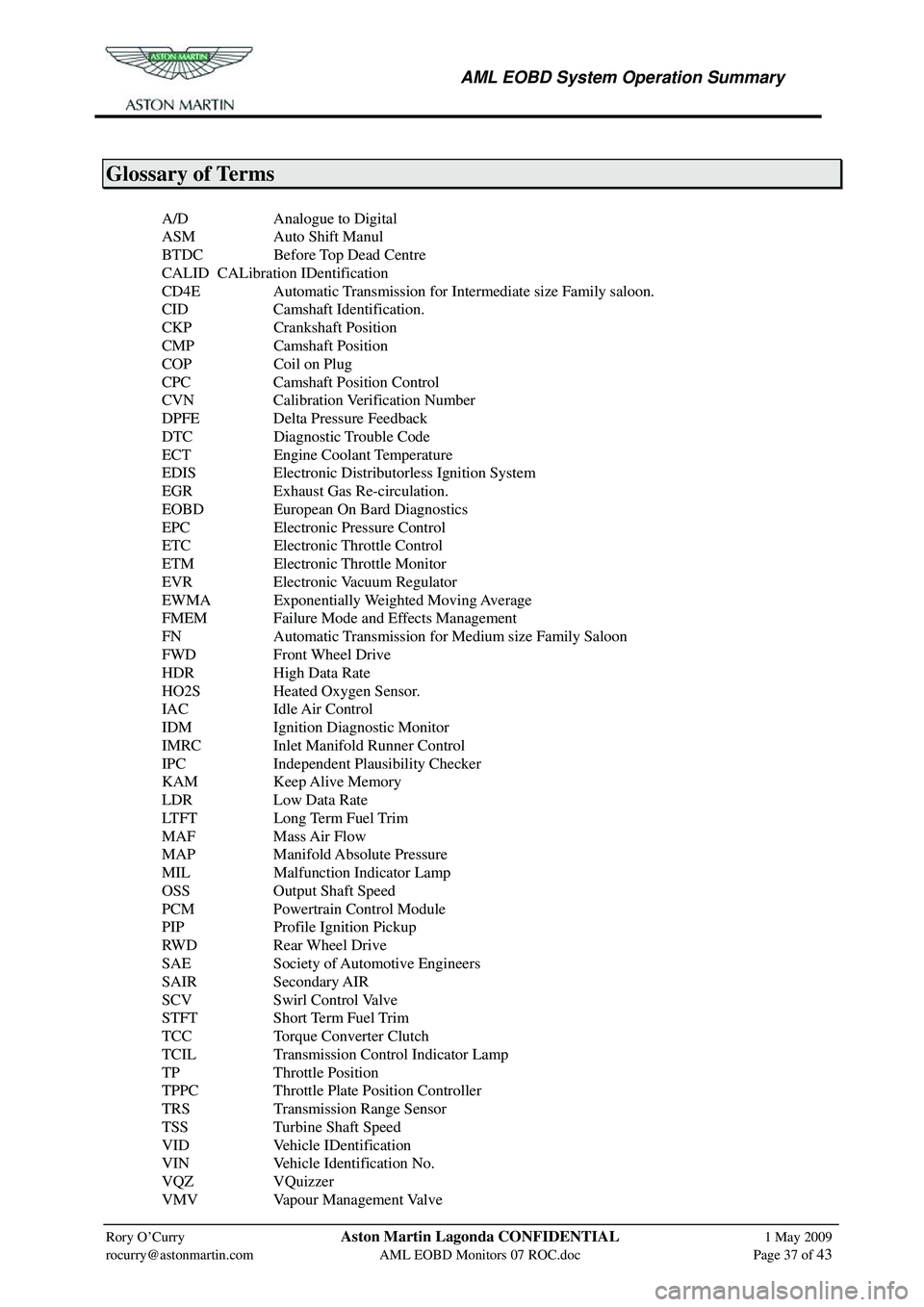

Glossary of Terms

A/D Analogue to Digital

ASM Auto Shift Manul

BTDC Before Top Dead Centre

CALID CALibration IDentification

CD4E Automatic Transmission for Intermediate size Family saloon.

CID Camshaft Identification.

CKP Crankshaft Position

CMP Camshaft Position

COP Coil on Plug

CPC Camshaft Position Control

CVN Calibration Verification Number

DPFE Delta Pressure Feedback

DTC Diagnostic Trouble Code

ECT Engine Coolant Temperature

EDIS Electronic Distributorless Ignition System

EGR Exhaust Gas Re-circulation.

EOBD European On Bard Diagnostics

EPC Electronic Pressure Control

ETC Electronic Throttle Control

ETM Electronic Throttle Monitor

EVR Electronic Vacuum Regulator

EWMA Exponentially Weighted Moving Average

FMEM Failure Mode and Effects Management

FN Automatic Transmission for Medium size Family Saloon

FWD Front Wheel Drive

HDR High Data Rate

HO2S Heated Oxygen Sensor.

IAC Idle Air Control

IDM Ignition Diagnostic Monitor

IMRC Inlet Manifold Runner Control

IPC Independent Plausibility Checker

KAM Keep Alive Memory

LDR Low Data Rate

LTFT Long Term Fuel Trim

MAF Mass Air Flow

MAP Manifold Absolute Pressure

MIL Malfunction Indicator Lamp

OSS Output Shaft Speed

PCM Powertrain Control Module

PIP Profile Ignition Pickup

RWD Rear Wheel Drive

SAE Society of Automotive Engineers

SAIR Secondary AIR

SCV Swirl Control Valve

STFT Short Term Fuel Trim

TCC Torque Converter Clutch

TCIL Transmission Control Indicator Lamp

TP Throttle Position

TPPC Throttle Plate Position Controller

TRS Transmission Range Sensor

TSS Turbine Shaft Speed

VID Vehicle IDentification

VIN Vehicle Identification No.

VQZ VQuizzer

VMV Vapour Management Valve

Page 890 of 947

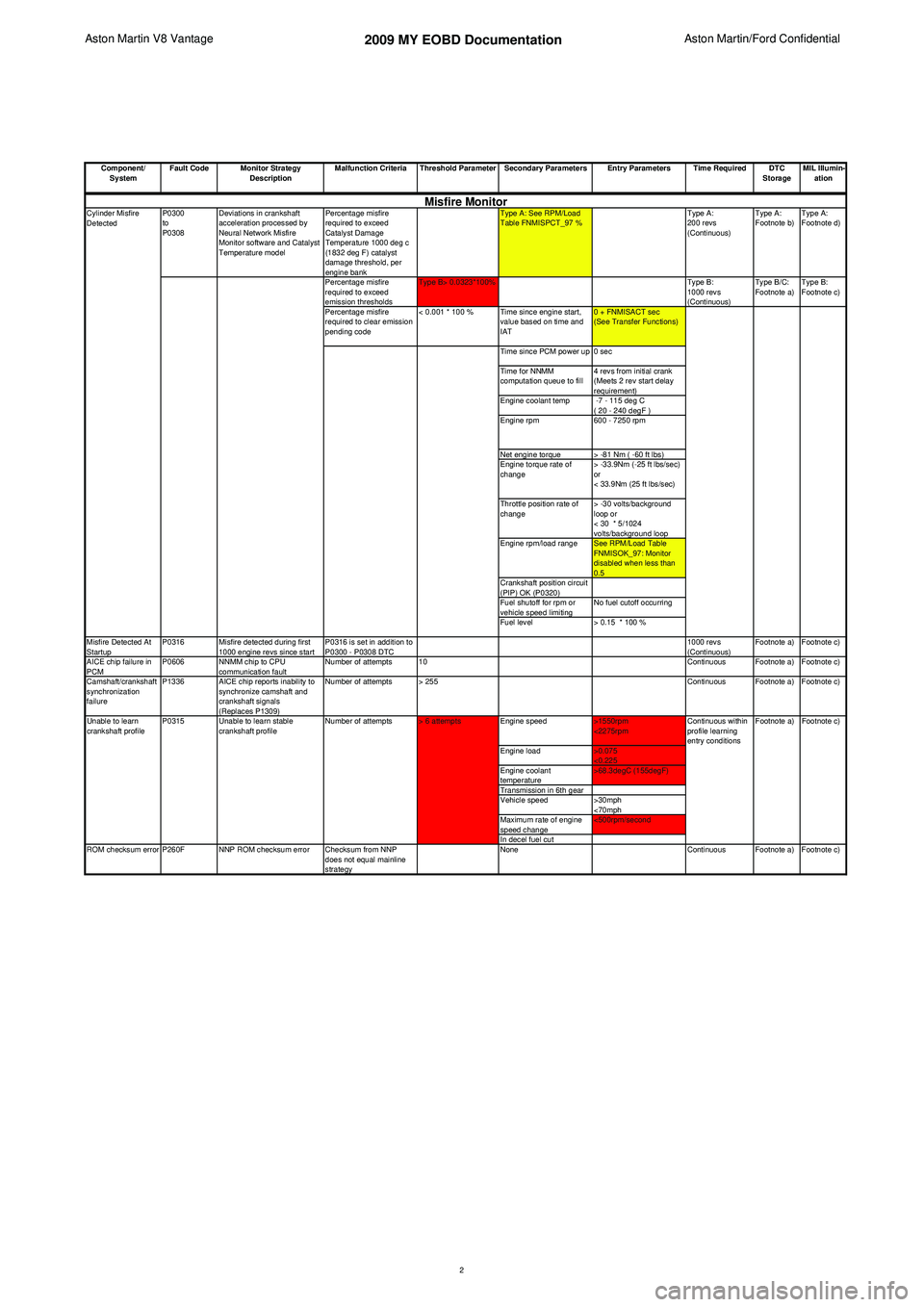

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

P0300

to

P0308 Deviations in crankshaft

acceleration processed by

Neural Network Misfire

Monitor software and Catalyst

Temperature model Percentage misfire

required to exceed

Catalyst Damage

Temperature 1000 deg c

(1832 deg F) catalyst

damage threshold, per

engine bank Type A: See RPM/Load

Table FNMISPCT_97 %

Type A:

200 revs

(Continuous)Type A:

Footnote b)

Type A:

Footnote d)

Percentage misfire

required to exceed

emission thresholds Type B> 0.0323*100% Type B:

1000 revs

(Continuous)Type B/C:

Footnote a)

Type B:

Footnote c)

Percentage misfire

required to clear emission

pending code < 0.001 * 100 % Time since engine start,

value based on time and

IAT 0 + FNMISACT sec

(See Transfer Functions)

Time since PCM power up 0 sec

Time for NNMM

computation queue to fill 4 revs from initial crank

(Meets 2 rev start delay

requirement)

Engine coolant temp -7 - 115 deg C ( 20 - 240 degF )

Engine rpm 600 - 7250 rpm

Net engine torque > -81 Nm ( -60 ft lbs)

Engine torque rate of

change > -33.9Nm (-25 ft lbs/sec)

or

< 33.9Nm (25 ft lbs/sec)

Throttle position rate of

change > -30 volts/background

loop or

< 30 * 5/1024

volts/background loop

Engine rpm/load range See RPM/Load Table FNMISOK_97: Monitor

disabled when less than

0.5

Crankshaft position circuit

(PIP) OK (P0320)

Fuel shutoff for rpm or

vehicle speed limiting No fuel cutoff occurring

Fuel level > 0.15 * 100 %

Misfire Detected At

Startup P0316 Misfire detected during first

1000 engine revs since start P0316 is set in addition to

P0300 - P0308 DTC 1000 revs

(Continuous)Footnote a) Footnote c)

AICE chip failure in

PCM P0606 NNMM chip to CPU

communication fault Number of attempts 10

Continuous Footnote a) Footnote c)

Camshaft/crankshaft

synchronization

failure P1336 AICE chip reports inability to

synchronize camshaft and

crankshaft signals

(Replaces P1309) Number of attempts > 255

Continuous Footnote a) Footnote c)

Engine speed >1550rpm

<2275rpm

Engine load >0.075

<0.225

Engine coolant

temperature >68.3degC (155degF)

Transmission in 6th gear

Vehicle speed >30mph

<70mph

Maximum rate of engine

speed change <500rpm/second

In decel fuel cut

ROM checksum error P260F NNP ROM checksum error Checksum from NNP does not equal mainline

strategyNone

Continuous Footnote a) Footnote c)

Cylinder Misfire

DetectedMisfire Monitor

Footnote c)

Unable to learn

crankshaft profile P0315 Unable to learn stable

crankshaft profile Number of attempts > 6 attempts Continuous within

profile learning

entry conditionsFootnote a)

2

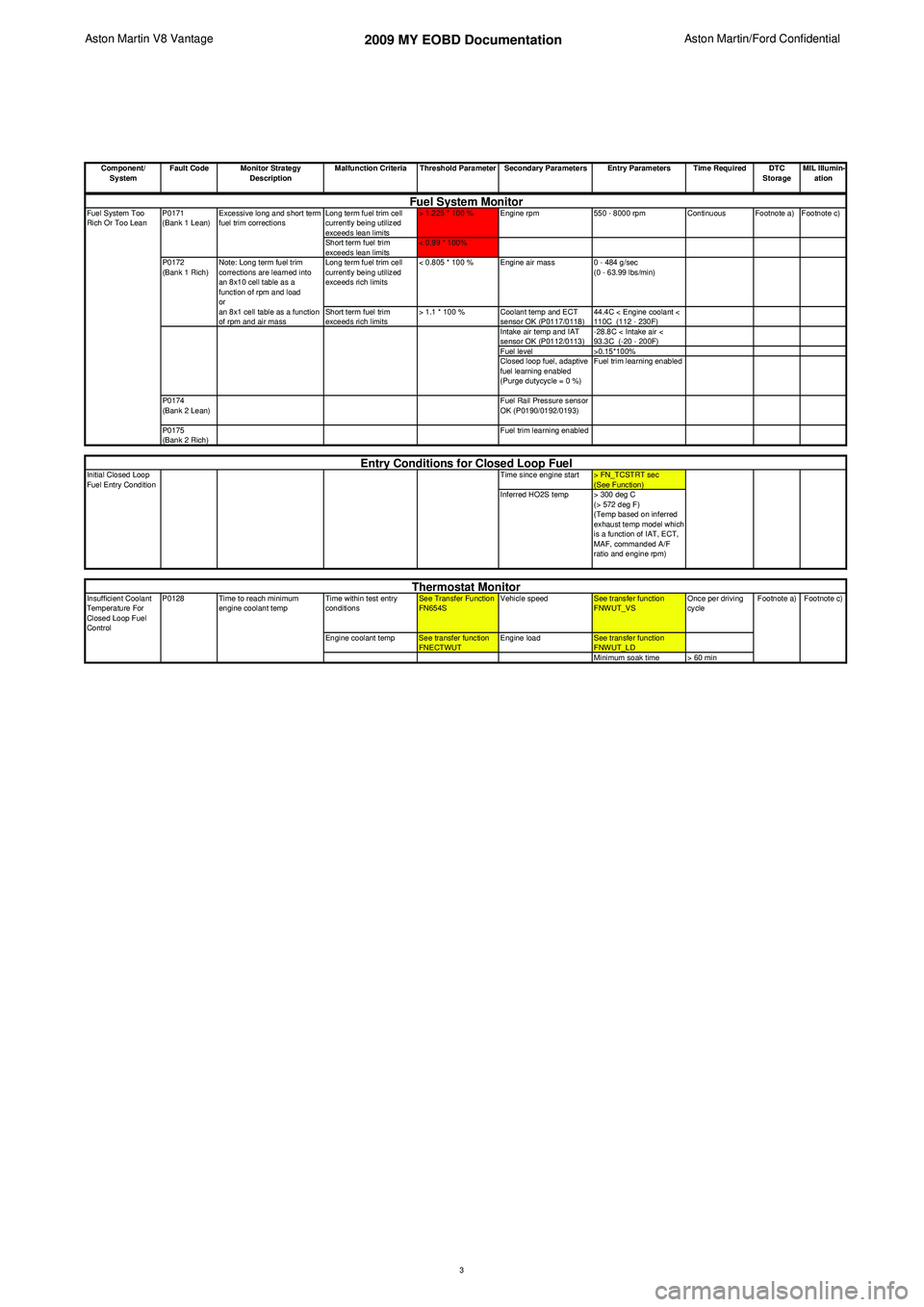

Page 891 of 947

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

Long term fuel trim cell

currently being utilized

exceeds lean limits > 1.225 * 100 % Engine rpm

550 - 8000 rpmContinuous Footnote a) Footnote c)

Short term fuel trim

exceeds lean limits < 0.99 * 100%

Long term fuel trim cell

currently being utilized

exceeds rich limits < 0.805 * 100 % Engine air mass

0 - 484 g/sec

(0 - 63.99 lbs/min)

Short term fuel trim

exceeds rich limits > 1.1 * 100 % Coolant temp and ECT

sensor OK (P0117/0118) 44.4C < Engine coolant <

110C (112 - 230F)

Intake air temp and IAT

sensor OK (P0112/0113) -28.8C < Intake air <

93.3C (-20 - 200F)

Fuel level >0.15*100%

Closed loop fuel, adaptive

fuel learning enabled

(Purge dutycycle = 0 %) Fuel trim learning enabled

P0174

(Bank 2 Lean) Fuel Rail Pressure sensor

OK (P0190/0192/0193)

P0175

(Bank 2 Rich) Fuel trim learning enabled

Time since engine start > FN_TCSTRT sec

(See Function)

Inferred HO2S temp > 300 deg C (> 572 deg F)

(Temp based on inferred

exhaust temp model which

is a function of IAT, ECT,

MAF, commanded A/F

ratio and engine rpm)

Time within test entry

conditions See Transfer Function

FN654SVehicle speed

See transfer function

FNWUT_VS Once per driving

cycle

Engine coolant temp See transfer function FNECTWUTEngine load

See transfer function

FNWUT_LD

Minimum soak time > 60 min

Entry Conditions for Closed Loop Fuel

Thermostat MonitorInitial Closed Loop

Fuel Entry Condition Note: Long term fuel trim

corrections are learned into

an 8x10 cell table as a

function of rpm and load

or

an 8x1 cell table as a function

of rpm and air mass

P0172

(Bank 1 Rich)

Fuel System MonitorFuel System Too

Rich Or Too Lean

P0171

(Bank 1 Lean)Excessive long and short term

fuel trim corrections

Footnote c)

Insufficient Coolant

Temperature For

Closed Loop Fuel

Control P0128 Time to reach minimum

engine coolant temp Footnote a)

3

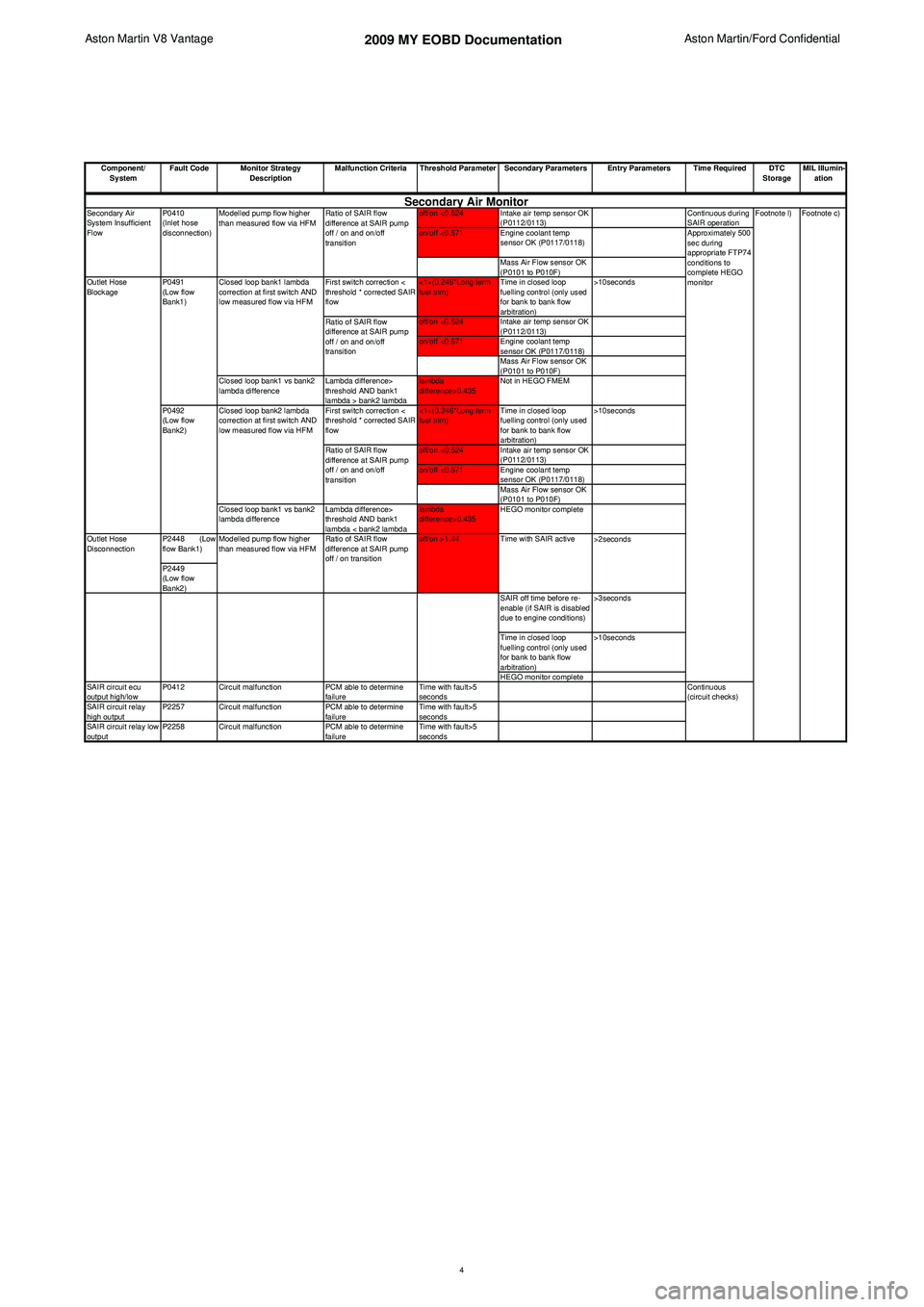

Page 892 of 947

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

off/on <0.524 Intake air temp sensor OK (P0112/0113) Continuous during

SAIR operation

on/off <0.671 Engine coolant temp sensor OK (P0117/0118)

Mass Air Flow sensor OK

(P0101 to P010F)

First switch correction <

threshold * corrected SAIR

flow <1+(0.246*Long term

fuel trim)

Time in closed loop

fuelling control (only used

for bank to bank flow

arbitration) >10seconds

off/on <0.524 Intake air temp sensor OK (P0112/0113)

on/off <0.671 Engine coolant temp sensor OK (P0117/0118)

Mass Air Flow sensor OK

(P0101 to P010F)

Closed loop bank1 vs bank2

lambda difference Lambda difference>

threshold AND bank1

lambda > bank2 lambdalambda

difference>0.435

Not in HEGO FMEM

First switch correction <

threshold * corrected SAIR

flow <1+(0.246*Long term

fuel trim)

Time in closed loop

fuelling control (only used

for bank to bank flow

arbitration) >10seconds

off/on <0.524 Intake air temp sensor OK (P0112/0113)

on/off <0.671 Engine coolant temp sensor OK (P0117/0118)

Mass Air Flow sensor OK

(P0101 to P010F)

Closed loop bank1 vs bank2

lambda difference Lambda difference>

threshold AND bank1

lambda < bank2 lambdalambda

difference>0.435

HEGO monitor complete

P2448 (Low

flow Bank1)

P2449

(Low flow

Bank2) SAIR off time before re-

enable (if SAIR is disabled

due to engine conditions)>3seconds

Time in closed loop

fuelling control (only used

for bank to bank flow

arbitration) >10seconds

HEGO monitor complete

SAIR circuit ecu

output high/low P0412 Circuit malfunction

PCM able to determine

failure Time with fault>5

seconds

SAIR circuit relay

high output P2257 Circuit malfunction

PCM able to determine

failure Time with fault>5

seconds

SAIR circuit relay low

output P2258 Circuit malfunction

PCM able to determine

failure Time with fault>5

seconds

Ratio of SAIR flow

difference at SAIR pump

off / on and on/off

transition

Modelled pump flow higher

than measured flow via HFM

Ratio of SAIR flow

difference at SAIR pump

off / on and on/off

transition

Ratio of SAIR flow

difference at SAIR pump

off / on and on/off

transition

>2secondsFootnote c)

Approximately 500

sec during

appropriate FTP74

conditions to

complete HEGO

monitorSecondary Air Monitor

Modelled pump flow higher

than measured flow via HFM Ratio of SAIR flow

difference at SAIR pump

off / on transitionoff/on >1.44

Outlet Hose

Disconnection Footnote l)

Continuous

(circuit checks)

Outlet Hose

Blockage

P0492

(Low flow

Bank2)

P0410

(Inlet hose

disconnection)

Secondary Air

System Insufficient

Flow

Closed loop bank1 lambda

correction at first switch AND

low measured flow via HFM

Closed loop bank2 lambda

correction at first switch AND

low measured flow via HFM

P0491

(Low flow

Bank1)

Time with SAIR active

4

Page 895 of 947

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

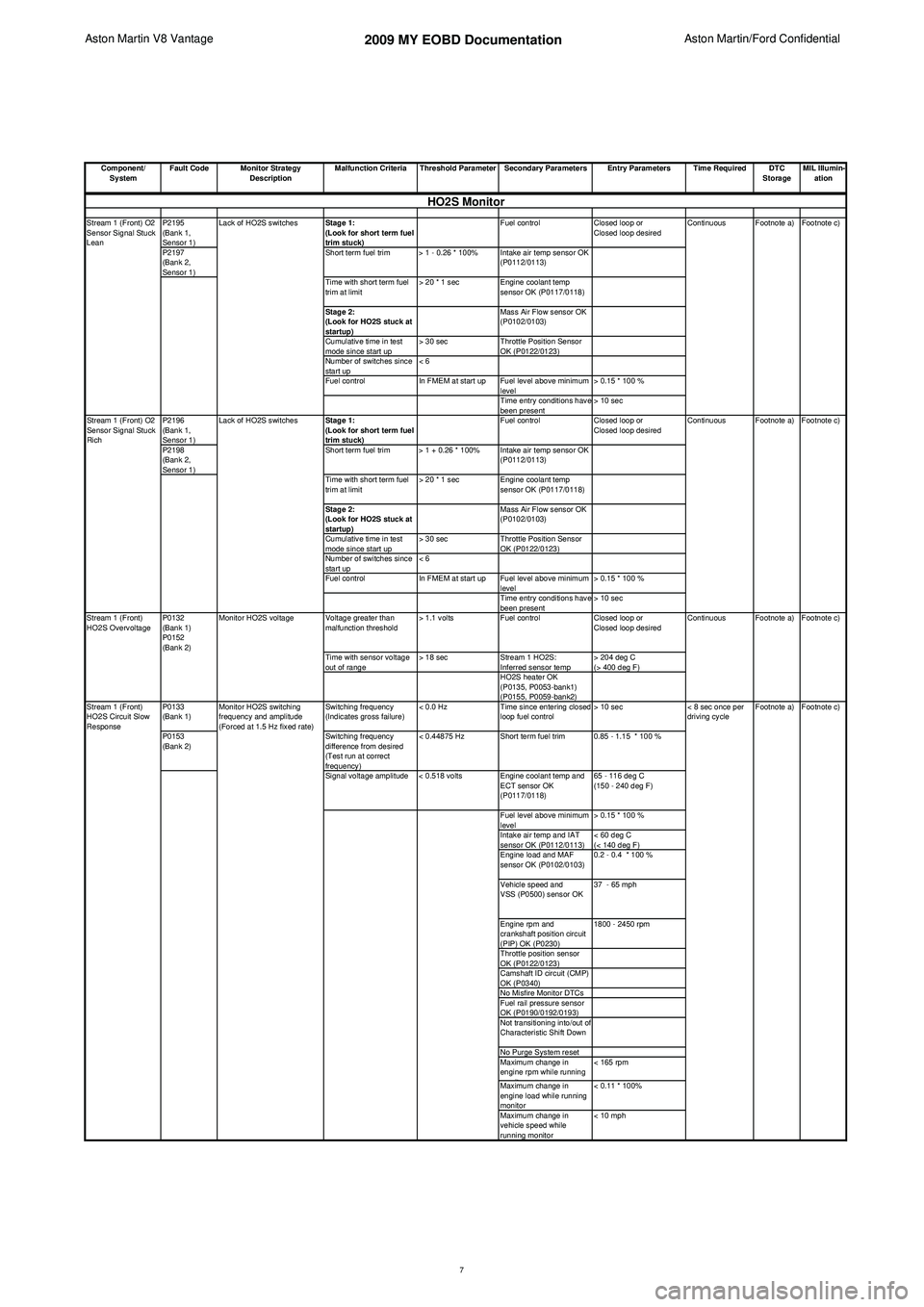

P2195

(Bank 1,

Sensor 1) Stage 1:

(Look for short term fuel

trim stuck) Fuel control Closed loop or

Closed loop desired

P2197

(Bank 2,

Sensor 1) Short term fuel trim > 1 - 0.26 * 100% Intake air temp sensor OK

(P0112/0113)

Time with short term fuel

trim at limit > 20 * 1 sec

Engine coolant temp

sensor OK (P0117/0118)

Stage 2:

(Look for HO2S stuck at

startup) Mass Air Flow sensor OK

(P0102/0103)

Cumulative time in test

mode since start up > 30 sec

Throttle Position Sensor

OK (P0122/0123)

Number of switches since

start up < 6

Fuel control In FMEM at start up Fuel level above minimum

level > 0.15 * 100 %

Time entry conditions have

been present > 10 sec

P2196

(Bank 1,

Sensor 1) Stage 1:

(Look for short term fuel

trim stuck) Fuel control

Closed loop or

Closed loop desired

P2198

(Bank 2,

Sensor 1) Short term fuel trim > 1 + 0.26 * 100% Intake air temp sensor OK

(P0112/0113)

Time with short term fuel

trim at limit > 20 * 1 sec

Engine coolant temp

sensor OK (P0117/0118)

Stage 2:

(Look for HO2S stuck at

startup) Mass Air Flow sensor OK

(P0102/0103)

Cumulative time in test

mode since start up > 30 sec

Throttle Position Sensor

OK (P0122/0123)

Number of switches since

start up < 6

Fuel control In FMEM at start up Fuel level above minimum

level > 0.15 * 100 %

Time entry conditions have

been present > 10 sec

Voltage greater than

malfunction threshold > 1.1 volts

Fuel control Closed loop or

Closed loop desired

Time with sensor voltage

out of range > 18 sec

Stream 1 HO2S:

Inferred sensor temp > 204 deg C

(> 400 deg F)

HO2S heater OK

(P0135, P0053-bank1)

(P0155, P0059-bank2)

P0133

(Bank 1) Switching frequency

(Indicates gross failure)< 0.0 Hz

Time since entering closed

loop fuel control > 10 sec

P0153

(Bank 2) Switching frequency

difference from desired

(Test run at correct

frequency)< 0.44875 Hz Short term fuel trim 0.85 - 1.15 * 100 %

Signal voltage amplitude < 0.518 volts Engine coolant temp and ECT sensor OK

(P0117/0118)65 - 116 deg C

(150 - 240 deg F)

Fuel level above minimum

level > 0.15 * 100 %

Intake air temp and IAT

sensor OK (P0112/0113) < 60 deg C

(< 140 deg F)

Engine load and MAF

sensor OK (P0102/0103) 0.2 - 0.4 * 100 %

Vehicle speed and

VSS (P0500) sensor OK 37 - 65 mph

Engine rpm and

crankshaft position circuit

(PIP) OK (P0230) 1800 - 2450 rpm

Throttle position sensor

OK (P0122/0123)

Camshaft ID circuit (CMP)

OK (P0340)

No Misfire Monitor DTCs

Fuel rail pressure sensor

OK (P0190/0192/0193)

Not transitioning into/out of

Characteristic Shift Down

No Purge System reset

Maximum change in

engine rpm while running

it

< 165 rpm

Maximum change in

engine load while running

monitor < 0.11 * 100%

Maximum change in

vehicle speed while

running monitor < 10 mphContinuous

Footnote a)

Footnote a)

Monitor HO2S voltage Footnote a) Footnote c)

Stream 1 (Front)

HO2S Overvoltage

< 8 sec once per

driving cycle

Stream 1 (Front)

HO2S Circuit Slow

Response Monitor HO2S switching

frequency and amplitude

(Forced at 1.5 Hz fixed rate)

P0132

(Bank 1)

P0152

(Bank 2)

Continuous Footnote a) Footnote c)Footnote c)

Continuous

Stream 1 (Front) O2

Sensor Signal Stuck

Lean

Lack of HO2S switches

Lack of HO2S switches

HO2S Monitor

Footnote c)

Stream 1 (Front) O2

Sensor Signal Stuck

Rich

7

Page 897 of 947

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

Vehicle speed VSS

(P0500) sensor OK

Throttle position sensor

TPS OK (P0122/0123)

Vehicle speed and TPS in

range VSS<30mph OR

TPS>5.27deg (60cnts)

Battery Voltage 11< Voltage <18

SAIR not commanded >3 seconds

Time with fault >5 seconds

MAF1+MAF2

(0.35*estimate) Vehicle speed VSS

(P0500) sensor OK

MAF1< 0.5*estimate -

max (0.5*30.23g/sec)

OR (0.35*

(0.5*estimate)) Throttle position sensor

TPS OK (P0122/0123)

Vehicle speed and TPS in

range

VSS<30mph OR

TPS>5.27deg (60cnts)

Battery Voltage 11< Voltage <18

SAIR not commanded >3 seconds

Time with fault >5 seconds

Sensor signal voltage < 0.024 volts (0g/sec) Time since last PIP signal (Engine not stalled)< 150 msec

Fault filter routine > 1 sec

Sensor signal voltage > 4.88 volts (293g/sec) Time since last PIP signal (Engine not stalled)< 150 msec

Fault filter routine > 1 sec MAF1+MAF2

(0.35*estimate)Vehicle speed VSS

(P0500) sensor OK

MAF1< 0.5*estimate -

max (0.5*30.23g/sec) Throttle position sensor

TPS OK (P0122/0123)

MAF2< 0.5*estimate -

max (0.5*30.23g/sec)

OR (0.35*

(0.5*estimate)) Vehicle speed and TPS in

range

VSS<30mph OR

TPS>5.27deg (60cnts)

Battery Voltage 11< Voltage <18

SAIR not commanded >3 seconds

Time with fault >5 seconds

Vehicle speed VSS

(P0500) sensor OK

Throttle position sensor

TPS OK (P0122/0123)

Vehicle speed and TPS in

range VSS<30mph OR

TPS>5.27deg (60cnts)

Battery Voltage 11< Voltage <18

SAIR not commanded >3 seconds

Time with fault >5 seconds

MAF1+MAF2

(0.35*estimate) Vehicle speed VSS

(P0500) sensor OK

MAF2< 0.5*estimate -

max (0.5*30.23g/sec)

OR (0.35*

(0.5*estimate)) Throttle position sensor

TPS OK (P0122/0123)

Vehicle speed and TPS in

range

VSS<30mph OR

TPS>5.27deg (60cnts)

Battery Voltage 11< Voltage <18

SAIR not commanded >3 seconds

Time with fault >5 seconds

Sensor signal voltage < 0.024 volts (0g/sec) Time since last PIP signal (Engine not stalled)< 150 msec

Fault filter routine > 1 sec

Sensor signal voltage > 4.88 volts (293g/sec) Time since last PIP signal (Engine not stalled)< 150 msec

Fault filter routine > 1 sec MAF1+MAF2

(0.35*estimate)Vehicle speed VSS

(P0500) sensor OK

MAF1< 0.5*estimate -

max (0.5*30.23g/sec)

OR (0.35*

(0.5*estimate)) Throttle position sensor

TPS OK (P0122/0123)

MAF2< 0.5*estimate -

max (0.5*30.23g/sec)

OR (0.35*

(0.5*estimate)) Vehicle speed and TPS in

range

VSS<30mph OR

TPS>5.27deg (60cnts)

Battery Voltage 11< Voltage <18

SAIR not commanded >3 seconds

Time with fault >5 seconds

P010F

(MAFA/B

Correlation) Rationality Check

MAF codes raised P0100,P0101,P0104,

P010A,P010B,P010ETime with fault

>5 secondsComprehensive Component Monitor

MAF2 voltage < 0.024

(0g/sec) Continuous

P0100 (MAF A

Airpath) Rationality Check - Compares

measured MAF vs modelled

airflow MAF1 vs MAF2 low airflow

Circuit Check

P0103 (High) MAF1< 0.5*estimate -

max (0.5*30.23g/sec)

OR (0.35*

(0.5*estimate))

MAF1+MAF2 not equal to

estimate AND MAF1 vs

MAF2 low airflow

MAF Sensor Input

Circuit Check

P0104

(Backflow) Rationality Check

P0101 (MAF A

Range)

Rationality Check - Compares

measured MAF vs modelled

airflow

P010E

Backflow) Rationality Check

P0102 (Low)

MAF1 voltage < 0.024

(0g/sec)

P010A (MAF B

Airpath)

P010B MAF B

Range) Rationality Check - Compares

measured MAF vs modelled

airflow

Rationality Check - Compares

measured MAF vs modelled

airflow

MAF1+MAF2 not equal to

estimate AND MAF2 vs

MAF1 low airflow

MAF2 vs MAF1 low airflow MAF2< 0.5*estimate -

max (0.5*30.23g/sec)

OR (0.35*

(0.5*estimate)) Footnote a)

MAF1+MAF2 not equal to

estimate AND MAF1 & 2

do not equal estimate.

MAF2 voltage low.

P010C (Low) Circuit Check

Circuit Check

P010D (High) MAF1+MAF2 not equal to

estimate AND MAF1 & 2

do not equal estimate.

MAF1 voltage low.

Footnote c)

9