ASTON MARTIN V8 VANTAGE 2010 Workshop Manual

Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 911 of 947

V12 Family EOBD

Documentation

Data Table

Aston Martin Lagonda Ltd.

Page 912 of 947

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

P0420

(Bank 1) HC efficiency inferred from

oxygen storage capacity Rear/Front HO2S switch

ratio> 0.76 (Unitless) Engine coolant temp and

ECT sensor OK

(P0117/0118) 65C < Engine coolant

< 110C (150 - 230F)

Once per driving

cycleFootnote a) Footnote c)

P0430

(Bank 2) HC efficiency inferred from

oxygen storage capacity Rear/Front HO2S switch

ratio>0.76 (Unitless) Intake air temp and IAT

sensor OK (P0112/0113) -7C < Inlet Air Tmp

< 82C (20-180F) Approximately 900

sec

Minimum time since start

to run Catalyst Monitor 60 sec

Air mass range cell 1 HO2S11 switches : 200 HO2S21 switches: 200 3.78 - 11.3 g/s

(0.5-1.5 lb/min)

Air mass range cell 2 HO2S11 switches : 200 HO2S21 switches: 200 11.3 - 18.9 g/sec

(1.5-2.5 lb/min)

Air mass range cell 3 HO2S11 switches : 200 HO2S21 switches:

FEGO2_MX_CT3 18.9 - 26.5 g/s

(2.5-3.5 lb/min)

Maximum number of

HO2S11 (Bank 1 front)

switches to allow monitor

completion 300

Maximum number of

HO2S21 (Bank 2 front)

switches to allow monitor

completion 300

Load range for air

mass cell 1 HO2S11 switches : 200

HO2S21 switches: 200 0.1 * 100 % - 1.0 * 100 %

Load range for air

mass cell 2 HO2S11 switches : 200

HO2S21 switches: 200 0.1 * 100 % - 1.0 * 100 %

Load range for air

mass cell 3 HO2S11 switches : 200

HO2S21 switches: 200 0.1 * 100 % - 1.0 * 100 %

Rpm range for air

mass cell 1 HO2S11 switches : 200

HO2S21 switches: 200 0 - 4000 rpmCatalyst Efficiency MonitorCatalyst System

Efficiency Below

Threshold

(Index Monitor)

1

Page 913 of 947

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

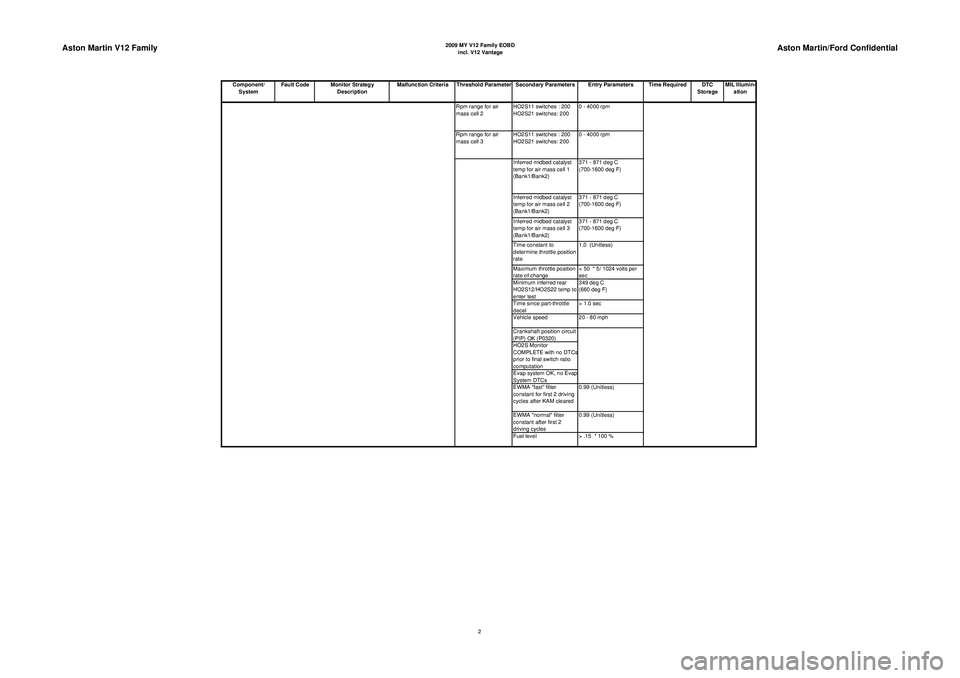

Rpm range for air

mass cell 2 HO2S11 switches : 200

HO2S21 switches: 200 0 - 4000 rpm

Rpm range for air

mass cell 3 HO2S11 switches : 200

HO2S21 switches: 200 0 - 4000 rpm

Inferred midbed catalyst

temp for air mass cell 1

(Bank1/Bank2) 371 - 871 deg C

(700-1600 deg F)

Inferred midbed catalyst

temp for air mass cell 2

(Bank1/Bank2) 371 - 871 deg C

(700-1600 deg F)

Inferred midbed catalyst

temp for air mass cell 3

(Bank1/Bank2) 371 - 871 deg C

(700-1600 deg F)

Time constant to

determine throttle position

rate 1.0 (Unitless)

Maximum throttle position

rate of change < 50 * 5/ 1024 volts per

sec

Minimum inferred rear

HO2S12/HO2S22 temp to

enter test 349 deg C

(660 deg F)

Time since part-throttle

decel > 1.0 sec

Vehicle speed 20 - 80 mph

Crankshaft position circuit

(PIP) OK (P0320)

HO2S Monitor

COMPLETE with no DTC

s

prior to final switch ratio

computation

Evap system OK, no Evap

System DTCs

EWMA "fast" filter

constant for first 2 driving

cycles after KAM cleared 0.99 (Unitless)

EWMA "normal" filter

constant after first 2

driving cycles 0.99 (Unitless)

Fuel level > .15 * 100 %

2

Page 914 of 947

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

P0300

to

P0312 Deviations in crankshaft

acceleration processed by

Neural Network Misfire

Monitor software and Catalyst

Temperature model Percentage misfire

required to exceed

Catalyst Damage

Temperature 900 deg c

(1650 deg F) catalyst

damage threshold, per

engine bank Type A: See RPM/Load

Table FNMISPCT_97 %

Type A:

200 revs

(Continuous)Type A:

Footnote b)

Type A:

Footnote d)

Full-range misfire capability Percentage misfire required to exceed

emission thresholdsType B: > 0.01 * 100

%

Type B:

1000 revs

(Continuous)Type B/C:

Footnote a)

Type B:

Footnote c)

Percentage misfire

required to clear emission

pending code < 0.001 * 100 % Time since engine start,

value based on time and

IAT 0 + FNMISACT sec

(See Transfer Functions)

Full-range misfire redline:

6900 rpm Time since PCM power up 0 sec

Time for NNMM

computation queue to fill4 revs from initial crank

(Meets 2 rev start delay

requirement)

Engine coolant temp -7 - 121 deg C ( 20 - 250 deg )

Engine rpm 500 - 4000rpm

Engine rpm in neutral

(Auto trans. only) < 3100 rpm

Net engine torque > -68 Nm ( -50 ft lbs)

Engine torque rate of

change > -34 Nm/s or < 41 Nm/s

(> -25 ft lbs/sec or

< 30 ft lbs/sec)

Throttle position rate of

change > -20 volts/background

loop or

< 30 * 5/1024

volts/background loop

Closed throttle

deceleration

(Dashpot mode) Closed throttle,

vehicle speed < 4 mph,

dashpot airflow adder

present

Engine rpm/load range See RPM/Load Table FNMISOK_97: Monitor

disabled when less than

0.5

Crankshaft position circuit

(PIP) OK (P0320)

Fuel shutoff for rpm or

vehicle speed limiting No fuel cutoff occurring

Fuel level > 0.15 * 100 %

Cylinder Misfire

Detected

Misfire Monitor

3

Page 915 of 947

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ationMisfire Detected At

Startup P0316 Misfire detected during first

1000 engine revs since start P0316 is set in addition to

P0300 - P0310 DTC 1000 revs

(Continuous)Footnote a) Footnote c)

AICE chip failure in

PCM P0606 NNMM chip to CPU

communication fault Number of attempts 10

Continuous Footnote a) Footnote c)

Camshaft/crankshaft

synchronization

failure P1336 AICE chip reports inability to

synchronize camshaft and

crankshaft signals

(Replaces P1309) Number of attempts > 255

Continuous Footnote a) Footnote c)

Unable to learn

crankshaft profile P0315 Unable to learn stable

crankshaft profile Number of attempts > 6 attempts

Continuous within

profile learning

entry conditionsFootnote a) Footnote c)

ROM checksum error P260F NNP ROM checksum error Checksum from NNP does not equal mainline

strategyNone

Continuous Footnote a) Footnote c)

Fuel System Too

Rich Or Too Lean P0171

(Bank 1 Lean)Excessive long and short term

fuel trim corrections Long term fuel trim cell

currently being utilized

exceeds lean limits> 1.24 * 100 % Engine rpm

600 - 4000 rpmContinuous Footnote a) Footnote c)

Short term fuel trim

exceeds lean limits < 0.96 * 100%

P0172

(Bank 1 Rich) Note: Long term fuel trim

corrections are learned into

an 8x10 cell table as a

function of rpm and load

or

an 8x1 cell table as a function

of rpm and air mass Long term fuel trim cell

currently being utilized

exceeds rich limits

< 0.76 * 100 % Engine air mass 3.4 - 484 g/sec

(0.45 - 63.99 lbs/min)

Short term fuel trim

exceeds rich limits > 1.1 * 100 %

P0174

(Bank 2 Lean) Closed loop fuel, adaptive

fuel learning enabled

(Purge dutycycle = 0 %)Fuel trim learning enabled Fuel trim learning

enabled

P0175

(Bank 2 Rich) Fuel Rail Pressure sensor

OK (P0190/0192/0193)Fuel S

ystem Monitor

4

Page 916 of 947

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ationStream 1 (Front) O2

Sensor Signal Stuck

Lean P2195

(Bank 1,

Sensor 1)Lack of HO2S switches

Stage 1:

(Look for short term fuel

trim stuck) Fuel control Closed loop or

Closed loop desiredContinuous Footnote a) Footnote c)

P2197

(Bank 2,

Sensor 1) Short term fuel trim > 1 + 0.3 * 100% Intake air temp sensor OK

(P0112/0113)

Time with short term fuel

trim at limit > 22 * 2 sec Engine coolant temp

sensor OK (P0117/0118)

Stage 2:

(Look for HO2S stuck at

startu

p)

Mass Air Flow sensor OK

(P0102/0103)

Cumulative time in test

mode since start up > 30 sec Throttle Position Sensor

OK (P0122/0123)

Number of switches since

start up < 4

Fuel tank pressure low

enough and sensor OK

(P0451, P0452, P0453) < 2,491 Pa

(< 10 in H2O)

Fuel control In FMEM at start up Fuel level above minimum

level > 0.15 * 100 %

Stuck sensor recovery

efforts failed

Time entry conditions hav

e

been present > 10 sec

Stream 1 (Front) O2

Sensor Signal Stuck

Rich P2196

(Bank 1,

Sensor 1)Lack of HO2S switches

Stage 1:

(Look for short term fuel

trim stuck) Fuel control

Closed loop or

Closed loop desired Continuous Footnote a) Footnote c)

P2198

(Bank 2,

Sensor 1) Short term fuel trim < 1 - 0.3 * 100% Intake air temp sensor OK

(P0112/0113)

Time with short term fuel

trim at limit > 22 * 2 sec. Engine coolant temp

sensor OK (P0117/0118)

Stage 2:

(Look for HO2S stuck at

startu

p)

Mass Air Flow sensor OK

(P0102/0103)

Cumulative time in test

mode since start up > 30 sec Throttle Position Sensor

OK (P0122/0123)

Number of switches since

start up < 4

Fuel tank pressure low

enough and sensor OK

(P0451, P0452, P0453) < 2,491 Pa

(< 10 in H2O)

Fuel control In FMEM at start up Fuel level above minimum

level > 0.15 * 100 %

Stuck sensor recovery efforts failedTime entry conditions hav

e

been present > 10 sec

HO2S Monitor

5

Page 917 of 947

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ationStream 1 (Front)

HO2S Circuit Slow

Response P0133

(Bank 1)

Monitor HO2S switching

frequency and amplitude

(Forced at 1.5 Hz fixed rate) Switching frequency

(Indicates gross failure)

< 0.0 Hz Time since entering close

d

loop fuel control> 10 sec < 4 sec once per

driving cycleFootnote a) Footnote c)

P0153

(Bank 2) Switching frequency

difference from desired

(Test run at correct

frequency)< 0.19 Hz

Short term fuel trim 0.9 - 1.1 * 100 %

Signal voltage amplitude < 0.55 volts Engine coolant temp and

ECT sensor OK

(P0117/0118) 55 - 116 deg C

(130 - 240 deg F)

Fuel level above minimum

level > 0.15 * 100 %

Intake air temp and IAT

sensor OK (P0112/0113) < 71 deg C

(< 160 deg F)

Engine load and MAF

sensor OK (P0102/0103) 0.15 - 0.4 * 100 %

Vehicle speed and

VSS (P0500) or

OSS (P0720) sensor OK 30 - 60 mph

Engine rpm and

crankshaft position circuit

(PIP) OK (P0230) 1000 - 2200 rpm

Throttle position sensor

OK (P0122/0123)

Camshaft ID circuit (CMP)

OK (P0340)

No Misfire Monitor DTCs

Fuel rail pressure sensor

OK (P0190/0192/0193)

Flex fuel composition not

changing

Not transitioning into/out o

f

Characteristic Shift Down

Not in Phase 0 of Evap

Monitor

No Purge System reset

Maximum change in

engine rpm while running

monitor < 160 rpm

Maximum change in

engine load while running

monitor < 0.13 * 100%

Maximum change in

vehicle speed while

running monitor < 2.0 mph

Maximum change in short

term fuel trim while

running monitor (PTEC

only) < 0.1

6

Page 918 of 947

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ationStream 1 (Front)

HO2S Overvoltage P0132

(Bank 1)

P0152

(Bank 2)Monitor HO2S voltage Voltage greater than

malfunction threshold> 1.1 volts

Fuel control Closed loop or

Closed loop desired Continuous Footnote a) Footnote c)

Time with sensor voltage

out of range > 25 sec

Stream 1 HO2S:

Inferred sensor temp > 204 deg C

(> 400 deg F)

HO2S heater OK

(P0135, P0053-bank1)

(P0155, P0059-bank2)

Rear HO2S Circuit

Malfunction P0136

(Bank 1)Monitor normal signal voltage

envelope; forced A/F

excursion if required for green

catalyst

(Rationality check) HO2S min and max signal

voltages

Rich- < 0.48 volts

Lean- > 0.42 voltsInferred exhaust temp 149 - 760 deg C

(300 - 1400 deg F)Once per driving

cycleFootnote a) Footnote c)

P0156

(Bank 2) Downstream heater on

time> 90 sec

Throttle position Part throttle

Engine rpm - for forced

excursion only > 1000 rpm

Inferred exhaust temp - fo

r

forced excursion only < 871 deg C

(< 1600 deg F)

Flex fuel composition not

changing

Upstream sensor(s) tested

7

Page 919 of 947

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ationStream 2 (CMS) O2

Sensor signal Stuck

Lean P2270

(Bank 1)

Monitor normal signal voltage

envelope; forced A/F

excursion if required for green

catalyst

(Rationality check) HO2S maximum signal

voltage

< 0.42 volts Inferred exhaust temp 149 - 760 deg C

(300 - 1400 deg F)Once per driving

cycleFootnote a) Footnote c)

P2272

(Bank 2) Stream 2 heater on time > 90 sec

Fuel level above minimum

level> 0.15 * 100 %

Throttle position Part throttle

Engine rpm - for forced

excursion only > 1000 rpm

Inferred exhaust temp - fo

r

forced excursion only < 871 deg C

(< 1600 deg F)

Flex fuel composition not

changing

Upstream sensor(s) tested

Stream 2 (CMS) O2

Sensor signal Stuck

Rich P2271

(Bank 1)

HO2S minimum signal

voltage> 0.48 volts Inferred exhaust temp 149 - 760 deg C

(300 - 1400 deg F)Once per driving

cycleFootnote a) Footnote c)

P2273

(Bank 2) Stream 2 heater on time > 90 sec

Fuel level above minimum

level> 0.15 * 100 %

Throttle position Part throttle

Engine rpm - for forced

excursion only > 1000 rpm

Inferred exhaust temp - fo

r

forced excursion only < 871 deg C

(< 1600 deg F)

Flex fuel composition not

changing

Upstream sensor(s) tested

Stream 2 (CMS)

HO2S Overvoltage Monitor HO2S voltage Voltage greater than

malfunction threshold> 1.1 volts

Stream 2 HO2S heater on

time > 90 sec

Continuous Footnote a) Footnote c)

Time with sensor voltage

out of range > 25 sec

Stream 2 HO2S:

Inferred sensor temp > 204 deg C

(> 400 deg F)

HO2S heater OK

(P0141, P0054-bank1)

(P0161, P0060-bank2)

P0138

(Bank 1)

P0158

(Bank 2) Monitor normal signal voltage

envelope; forced A/F

excursion if required for green

catalyst

(Rationality check)

8

Page 920 of 947

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ationHO2S Heater Circuit

Malfunction P0135

(HO2S11)Circuit continuity check,

monitor voltage for opens and

shorts Feedback circuit state

matches commanded

output state

(Digital signal)Feedback circuit high

or low

Stream 1 HO2S:

Inferred sensor temp 19 - 649 deg C

(67 - 1200 deg F)Continuous

Footnote c)

P0155

(HO2S21) Monitor retries allowed for

malfunction

(Background loops)RETRY_ALLOW

P0053

(HO2S11) Functional check, monitor min

.

and max. heater current Heater circuit current < 0.465 amps or

> 3.0 ampsStream 1 HO2S:

Inferred sensor temp 121 - 593 deg C

(250 - 1100 deg F)Once per driving

cycle Footnote c)

P0059

(HO2S21) Stream 1 HO2S heater on

time> 30 sec

Stream 1 sensor(s) tested

(P0133/P0153 tests

completed)

Stream 2 sensor(s) tested

(P2270, P2271, 2272, and

P2273 tests completed)

P0141

(HO2S12) Circuit continuity check,

monitor voltage for opens and

shorts Feedback circuit state

matches commanded

output state

(Digital signal)Feedback circuit high

or low

Stream 2 HO2S:

Inferred sensor temp 149 - 760 deg C

(300 - 1400 deg F)Continuous

Footnote c)

P0161

(HO2S22) Monitor retries allowed for

malfunction

(Background loops)RETRY_ALLOW

P0054

(HO2S12) Functional check, monitor min

.

and max. heater current Heater circuit current < 0.22 amps Stream 2 HO2S:

Inferred sensor temp121 - 732 deg C

(250 - 1350 deg F)Once per driving

cycle Footnote c)

P0060

(HO2S22) > 3.0 amps

Stream 2 HO2S heater on

time > 30 sec

Stream 1 sensor(s) tested

(P0133/P0153 tests

completed)

Stream 2 sensor(s) tested

(P2270, P2271, 2272, and

P2273 tests completed)

Stream 3 sensor(s) tested

(P2274, P2275, 2276, and

P2277 tests completed) Footnote a)

Footnote a)

9