ASTON MARTIN V8 VANTAGE 2010 Workshop Manual

Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 941 of 947

Service Bulletin SB-17-0298

February 2009 Page 4 of 5

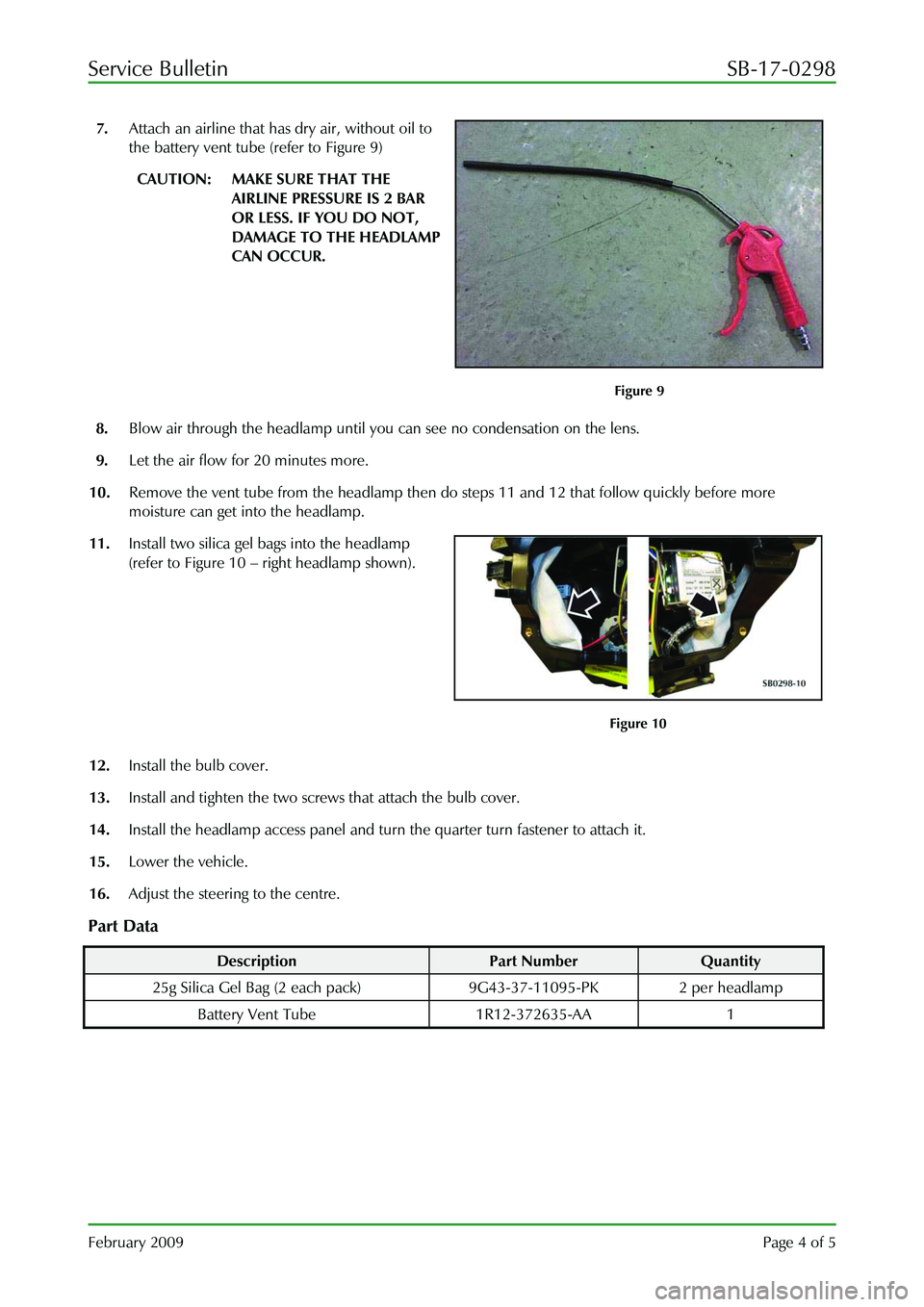

7. Attach an airline that has dry air, without oil to

the battery vent tube (refer to Figure 9)

CAUTION: MAKE SURE THAT THE

AIRLINE PRESSURE IS 2 BAR

OR LESS. IF YOU DO NOT,

DAMAGE TO THE HEADLAMP

CAN OCCUR.

Figure 9

8. Blow air through the headlamp until you can see no condensation on the lens.

9. Let the air flow for 20 minutes more.

10. Remove the vent tube from the headlamp then do steps 11 and 12 that follow quickly before more

moisture can get into the headlamp.

11. Install two silica gel bags into the headlamp

(refer to Figure 10 – right headlamp shown).

Figure 10

12. Install the bulb cover.

13. Install and tighten the two screws that attach the bulb cover.

14. Install the headlamp access panel and turn the quarter turn fastener to attach it.

15. Lower the vehicle.

16. Adjust the steering to the centre.

Part Data

Description Part Number Quantity

25g Silica Gel Bag (2 each pa ck) 9G43-37-11095-PK 2 per headlamp

Battery Vent Tube 1R12-372635-AA 1

Page 942 of 947

Service Bulletin SB-17-0298

February 2009 Page 5 of 5

Warranty Data

DBS and DB9, Coupe and Volante

Description Time Allowed Labour Code

Headlamp Condensation Drying Procedure – The

two sides 0.9 hrs. 17.01.BG

Headlamp Condensation Drying Procedure – One

Side 0.45 hrs. 17.01.BH

Vantage Coupe and Roadster

Description Time Allowed Labour Code

Headlamp Condensation Drying

Procedure – The two sides. 1.0 hrs. 17.01.BG

Headlamp Condensation Drying

Procedure – One Side 0.5 hrs. 17.01.BH

If you have any queries related to th

is Service Bulletin, please contact: Aston Martin Technical Services on:

+44 (0) 1926 644720 or facsimile: +44 (0) 1926 644733.

E-mail: [email protected]

. Or contact your After Sales Manager.

The English version of this Service Bulletin is written in Simplified Technical English to ASD STE-100™.

Page 943 of 947

SB0286V2

December 2009 Page 1 of 5

SERVICE BULLETIN

To: All Dealers

For the attention of: Service Manager/After Sales Manager

Please copy to: The Dealer Principal

Aston Martin Technician(s)

The Parts Manager

Reference

SB0286V2

Issued:

25 December 2009

Model: All Models

VIN Range: All

Subject: Rear Lamp Assembly Condensation Removal and

Repair Procedure Page 1 of 5

Reason for Version 2 of this Service Bulletin (SB0286)

Version 2 of this Service Bulletin has been issued to change the criteria for the quantity of water in the rear lamp,

before you change the lamp. Amendments to this document have a black line against them in the left-side

margin. Please destroy all copies of SB0286 that you have and replace them with this Service Bulletin SB0286V2.

Reason for this Service Bulletin

This Service Bulletin has been issued to give a procedure to dry out and repair a rear lamp assembly (lamp) that

has condensation inside. If a rear lamp has condensation inside, do the Workshop Procedure that follows:

Note: If there is moisture inside the lamp then there must be some damage.

Note: Before you do the Workshop Procedure you must make sure that the lamp unit operates correctly

because it is possible that water can have caused a shor t in the circuitry. It is also possible that if the

unit does not operate correctly, this drying out procedure can

repair the problem.

Workshop Procedure

1. Do a check of the operation of the lamp.

2. If two or more functions of the lamp do not operate correctly, install a new lamp.

3. Do a check for moisture in the rear lamp. If you can s ee water in the rear lamp that is not condensation on

the lens, install a new lamp.

CAUTION: WHEN YOU WORK ON THE LAMP MAKE SURE TH AT IT IS ON A PROTECTIVE SURFACE TO

PREVENT DAMAGE.

4. Remove the rear lamp assembly (Refer to the Workshop Manual procedure 17.02.AA (Left Side) or

17.02.AB (Right Side)).

5. If you do not replace the lamp because of the conditions in steps 2 or 3, do the procedure that follows to

dry the lamp.

Page 944 of 947

Service Bulletin SB0286V2

December 2009 Page 2 of 5

6. On the bottom of the lamp, make a mark for

the centre-point of the hole. The hole must be

40mm from the outside edge and at the centre

of the area shown in Figure 1.

Figure 1

CAUTION: WHEN YOU DRILL THE HOLE AT STEP 7, DO NOT DRILL THROUGH INTO THE LAMP

UNIT MORE THAN 10 MM. IF YOU DO, DAMAGE TO THE INTERNAL FITTINGS CAN

OCCUR.

7. Use a sharp 12 to 13 mm drill bit to drill a hole

at the position marked in Step 6. Drill slowly

and carefully to make sure that no swarf goes

into the lamp unit (Refer to Figure 2).

Figure 2

8 Turn the lamp unit to let the water drain out of the hole.

8. Find the location of the water leak (see the

example in Figure 3). Refer to ‘ Water Leak

Locations ’ after this Workshop Procedure for

the usual crack or split locations.

Figure 3

Page 945 of 947

Service Bulletin SB0286V2

December 2009 Page 3 of 5

Note: The location of the water leak can be difficult to find.

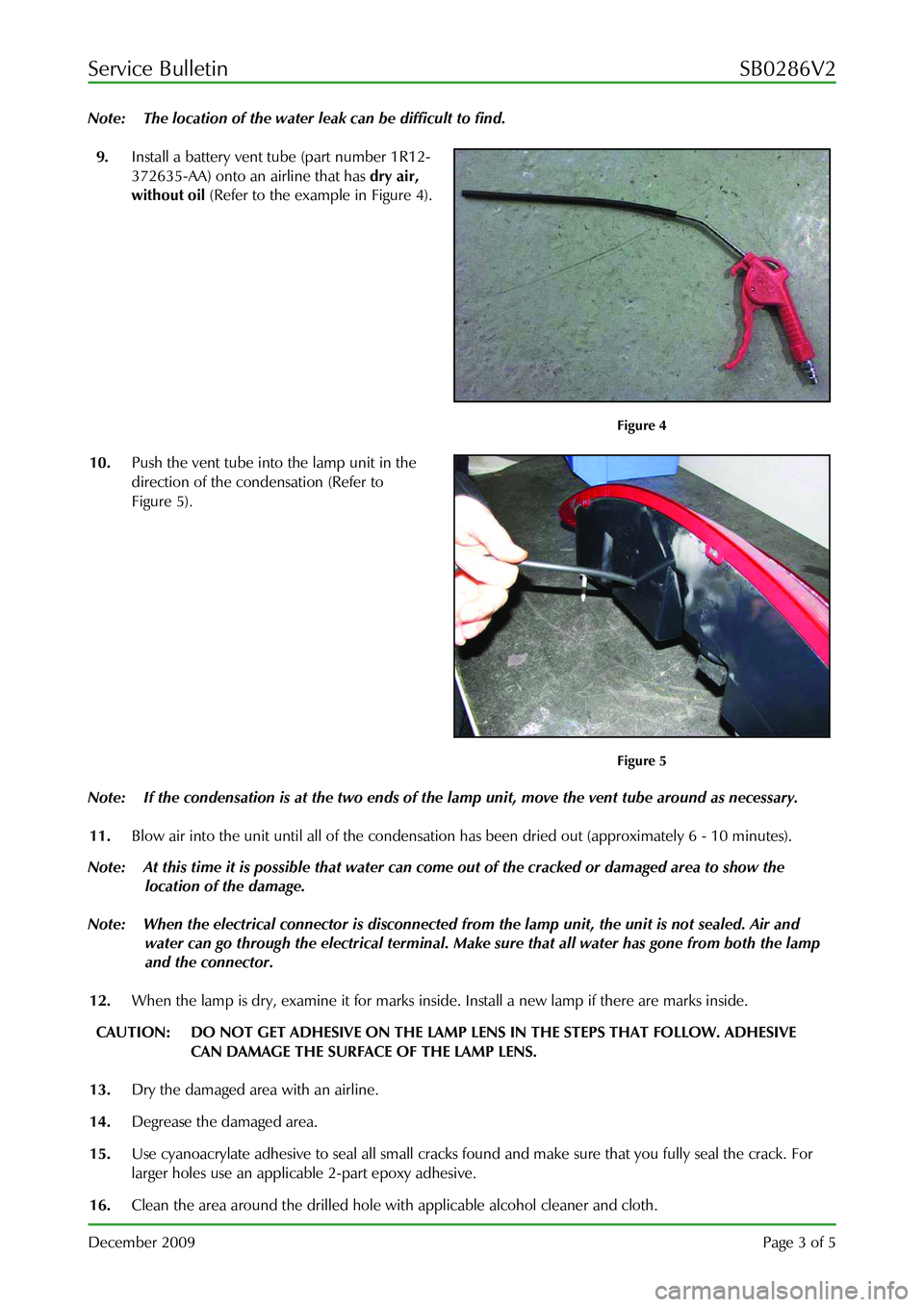

9. Install a battery vent tube (part number 1R12-

372635-AA) onto an airline that has dry air,

without oil (Refer to the example in Figure 4).

Figure 4

10. Push the vent tube into the lamp unit in the

direction of the condensation (Refer to

Figure 5).

Figure 5

Note: If the condensation is at the two ends of the la mp unit, move the vent tube around as necessary.

11. Blow air into the unit until all of the condensati on has been dried out (approximately 6 - 10 minutes).

Note: At this time it is possible that water can come out of the cracked or damaged area to show the

location of the damage.

Note: When the electrical connector is disconnected from the lamp unit, the unit is not sealed. Air and

water can go through the electrical terminal. Make sure that all water has gone from both the lamp

and the connector.

12. When the lamp is dry, examine it for marks inside. Install a new lamp if there are marks inside.

CAUTION: DO NOT GET ADHESIVE ON THE LAMP LENS IN THE STEPS THAT FOLLOW. ADHESIVE

CAN DAMAGE THE SURFACE OF THE LAMP LENS.

13. Dry the damaged area with an airline.

14. Degrease the damaged area.

15. Use cyanoacrylate adhesive to seal all small cracks fo und and make sure that you fully seal the crack. For

larger holes use an applicab le 2-part epoxy adhesive.

16. Clean the area around the drilled hole with applicable alcohol cleaner and cloth.

Page 946 of 947

Service Bulletin SB0286V2

December 2009 Page 4 of 5

17. Apply the adhesive patch (part number 4G43-

L20220-AA) to seal the hole (refer to Figure 6).

Figure 6

CAUTION: INSTALL NEW FOAM SEALS ON THE ATTACHMENT SCREWS WHEN YOU DO THE STEP

THAT FOLLOWS. IF YOU DO NOT, WATER CAN LEAK INTO THE VEHICLE.

18. Install the rear lamp assembly (Refer to the Work shop Manual procedure 17.02.AA (Left Side) or 17.02.AB

(Right Side).

Water Ingress Locations

Possible areas include:

• A crack in the lens under the infi ll panel (Figure 7 and Figure 8).

• Cracks in the housing around the mounting points (It em A, Figure 9), rub-through on the edge of the

lens (Item B, Figure 9) and lens /housing separation because of lo ad between the lens and the panel

(Figure 10).

Figure 7

Figure 8

Page 947 of 947

Service Bulletin SB0286V2

December 2009 Page 5 of 5

Figure 9

Figure 10

Parts Data

Description Part Number Quantity

Battery Vent Tube 1R12-372635-AA 1

Adhesive Sealing Patch 4G43-L20220-AA 1

Warranty Data

DB9 Coupe and Volante

Description Time Allowed Labour Code

Rear Lamp Unit – Left Side - Drying

Procedure 0.8 17.03.AC

Rear Lamp Unit – Right Side -

Drying Procedure 0.8 17.03.AD

V8 Vantage and Roadster

Description Time Allowed Labour Code

Rear Lamp Unit – Le

ft Side - Drying

Procedure 0.65 17.03.AC

Rear Lamp Unit – Right Side -

Drying Procedure 0.70 17.03.AD

DBS

Description Time Allowed Labour Code

Rear Lamp Unit – Le

ft Side - Drying

Procedure 0.8 17.03.AC

Rear Lamp Unit – Right Side -

Drying Procedure 0.8 17.03.AD

A

B

If you have any queries related to th

is Service Bulletin, please contact: Aston Martin Technical Services on:

+44 (0) 1926 644720 or facsimile: +44 (0) 1926 644733.

E-mail: [email protected]

. Or contact your After Sales Manager.

The English version of this Service Bulletin is written in Simplified Technical English to ASD STE-100™.