ASTON MARTIN V8 VANTAGE 2010 Workshop Manual

Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 901 of 947

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

TPPC chip failure in

PCM P0606 TPPC chip to CPU

communication fault Number of attempts > 1

Continuous Footnote a) Footnote c)

Engine rpm > 1000 rpmEngine coolant temp > 15 deg C

(> 60 deg F)Continuous Footnote a) Footnote c)

Sensor signal voltage < 1.22 volts or > 3.42 volts

Engine load > 0.7 * 100% or < 0.2 *

100%

Time with sensor out of

range > 3.0 sec

Time with low throttle

voltage at TPPC or PCM >= 0.176 seconds

Sensor signal voltage < 0.2 volts

Time with high throttle

voltage at TPPC or PCM >= 0.176 seconds

Sensor signal voltage > 4.87 volts

Time with low throttle

voltage at TPPC or PCM >= 0.176 seconds

Sensor signal voltage < 0.08 volts

Time with high throttle

voltage at TPPC or PCM >= 0.176 seconds

Sensor signal voltage > 4.80 volts

Time with correlation

failure from the TPPC or

PCM or Equizzer >= 240 sec

Magnitude of the

difference of the relative

readings of the sensor

signal voltage > 0.073 volts

(6.533deg)

P2104 ETC FMEM – forced idle Two or three pedal sensors failed, throttle

plate stuck>= 100 to 400 msec None

N/AContinuous Footnote a) Footnote c)

P2105 ETC FMEM – forced engine shutdown Equizzer detected fault >= 16 to 960 msec None

N/AContinuous Footnote a) Footnote c)

P2106 ETC FMEM – pedal-follower mode Sensor fault: MAF, one

TP, CKP, TSS, OSS, stuck

throttle, throttle actuator

circuit fault>= 16 to 960 msec None

N/AContinuous Footnote a) Footnote c)

P2110 ETC FMEM – default throttle angle Two TPs failed; TPPC

detected fault>= 600 to 800 msec None

N/AContinuous Footnote a) Footnote c)

P2111

(Stuck Open) Functional test

Desired throttle angle vs.

actual throttle angle

measured in a rolling

average routine during

throttle tip-in> 3.5 degrees None

N/AContinuous Footnote a) Footnote c)

P2112

(Stuck Closed) Functional test

Desired throttle angle vs.

actual throttle angle

measured in a rolling

average routine during

throttle tip-out> 3.5 degrees None

N/AContinuous Footnote a) Footnote c)

P2107 TPPC processor check Internal processor test, lost communication with

main CPU>= 60 msec None N/A Continuous Footnote a) Footnote c)

P2100 Circuit check Throttle actuator circuit open>= 1750 msec None N/A Continuous Footnote a) Footnote c)

P2101 Range check Throttle actuator range/performance test,

throttle plate angle does

not followed commanded

angle>= 500 msec None N/A Continuous Footnote a) Footnote c)Electronic Throttle Control

Rationality check

None

TP Sensor

Inconsistent With

MAF Sensor

TP Sensor A/B

Correlation

TP Sensor 'B' Input

Out Of Range P0122 (Low)

P0123 (High)

Range check

Rationality check vs. MAF

input

Throttle Actuator

Control System

Throttle Plate

Position Controller

(TPPC)

Throttle Actuator

Control Motor P2135

N/AContinuous Footnote a) Footnote c) Footnote c)

None

P0222 (Low) Range check N/AContinuous Footnote a)

P0223 (High)

TP Sensor 'A' Input

Out Of Range

None

N/A Continuous Footnote a) Footnote c)

P0068

13

Page 902 of 947

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

At 98% DC:

At 0% DC:

FNMISPCT_97

Load RPM700 950 1500 2000 2500 3000 4000 5000 6000 7500

0.10.20 0.20 0.20 0.20 0.20 0.20 0.17 0.12 0.12 0.100.150.20 0.20 0.20 0.20 0.20 0.20 0.17 0.12 0.12 0.100.20.20 0.20 0.20 0.20 0.20 0.20 0.17 0.12 0.12 0.100.30.20 0.20 0.20 0.20 0.20 0.16 0.15 0.11 0.12 0.090.40.20 0.20 0.20 0.20 0.16 0.14 0.12 0.10 0.10 0.090.50.20 0.20 0.20 0.16 0.16 0.14 0.12 0.09 0.09 0.080.70.20 0.20 0.20 0.16 0.14 0.13 0.12 0.08 0.08 0.080.90.20 0.20 0.20 0.16 0.14 0.13 0.12 0.08 0.08 0.08

Misfire Monitor Time Delay Since Engine Start Up = 0 seconds + FNMISACT valu

eFNMISACTACT ( degC )-40 -29 -7 60 66 93

output_axis [s]180 180 0 0 0 0

FNMISOK_97

Load RPM 700 950 1500 2000 2500 3000 4000 5000 6000 7500 0.10.043 0.043 0.001 0.043 0000000.150.614 0.614 0.833 0.614 1 0.444 0 0 0 00.21 1 1 1 1 1 0.474 0.029 0 00.31 1 1 1 1 1 1 0.885 0.474 0.0430.4111111111 0.6140.511111111110.711111111110.91111111111

FN_TCSTRT (sec)

TCSTRT [degC] -28.8 -17.7 -6.6 10 26.6 37.7 46.1 82.2 93.3 output_axis [s] 12093581086555

FN384 (RPM)ECT [degC] -160 -17.7 10 15.5 32.2 123.3

output_axis [RPM] 200 200 250 250 250 250

FN202 ("H20)SYS DELPR (kPa)29.09 33.86 40.63 54.18 67.72 88.04

output_axis [kPa]6.77 6.97 9.41 16.52 26.71 47.74

FN654S (sec)

TCSTRT [degC] -160 -34.4 -23.3 -15 -6.6 10 48.8 123.3

output_axis [s] 1400 1400 1150 990 870 670

340 340

FNECTWUT (degF)TCSTRT [degC] -160 -9.4 -6.6 123.3

output_axis [degC] 71.1 71.1 77.2 77.2

FNWUT_LDTCSTRT [degC] -160 -17.7 -6.6 123.3

output_axis 0.3 0.3 0.3 0.3

FNWUT_VS (mph)TCSTRT [degC] -160 -17.7 10 26.6 123.3

output_axis [mph] 20 20 25 30 30

FNCAM_ACT_FKDEG CRK0 0.2 2 2.8 60

output_axis [mph] 0.01 0.04 0.4 1 1

CAM_RANGE_SENSDEG CRK -50 -30 -15 0 20

output_axis 22222

DMTL total small leak threshold = TDMKLGTF+TDMKLGTF

DMTL total small leak threshold = TDMKLGTF+TDMKLGTF+FN_KFTDSTAB

TDMKLGTF

GVTAF0.15 0.25 0.5 0.75 0.85

output_axis [s] 115 125 150 188 210

TDMGLGTFGVTAF0.15 0.25 0.5 0.75 0.85

output_axis [s] 0.1 0.1 0.1 0.1 0.1

FIPTGLRIPTGH [A]01234

5678

output_axis [s] 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5

FIPTGLRIPTGH [A]01234

5678

output_axis [s] 11111

1111

FN_KFTDSTABGVTAF/IPTGH01234

5678

0.15 76 76 76 76 76 76 76 76 76

0.25 105 105 105 105 105 105 105 105 105

0.35 135 135 135 135 135 135 135 135 135

0.45 167 167 167 167 167 167 167 167 167

0.55 205 205 205 205 205 205 205 205 205

0.65 262 262 262 262 262 262 262 262 262

0.75 318 318 318 318 318 318 318 318 318

0.85 380 380 380 380 380 380 380 380 380

Signal circuit voltage threshold calculation for DTC P0443

[(42 x Battery voltage) - 150] x 5.0/1024 volts

[(32 x Battery voltage) - 200] x 5.0/1024 volts

14

Page 903 of 947

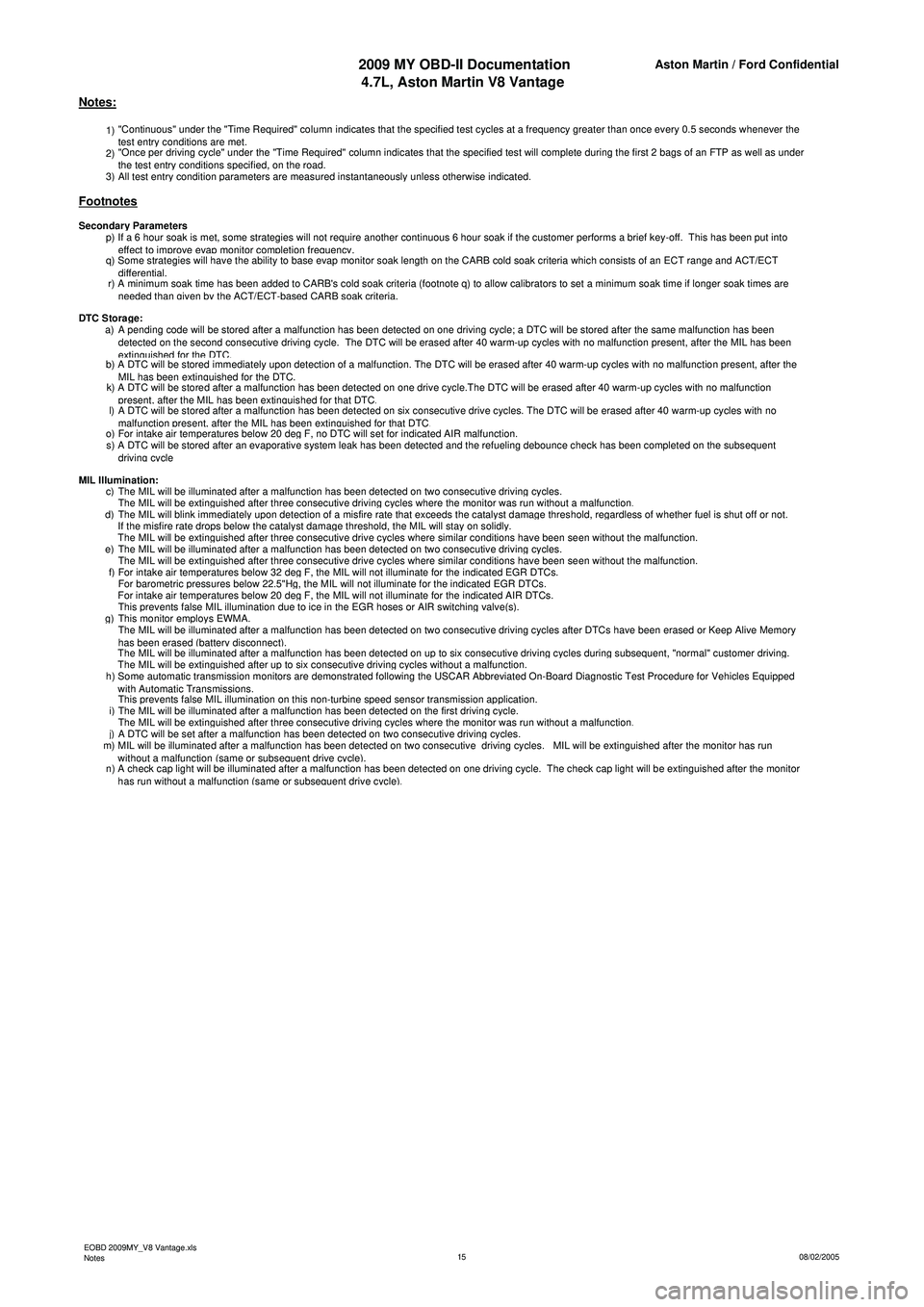

2009 MY OBD-II Documentation4.7L, Aston Martin V8 VantageAston Martin / Ford Confidential

1) "Continuous" under the "Time Required" column indicates that the specified test cycles at a frequency greater than once every 0.5 seconds whenever the

test entry conditions are met.

2) "Once per driving cycle" under the "Time Required" column indicates that the specified test will complete during the first 2 bags of an FTP as well as under

the test entr

y conditions specified, on the road.

3)All test entry condition parameters are measured instantaneously unless otherwise indicated.

p) If a 6 hour soak is met, some strategies will not require another continuous 6 hour soak if the customer performs a brief key-off. This has been put into

effect to improve evap monitor completion frequency.

q) Some strategies will have the ability to base evap monitor soak length on the CARB cold soak criteria which consists of an ECT range and ACT/ECT

differential.

r) A minimum soak time has been added to CARB's cold soak criteria (footnote q) to allow calibrators to set a minimum soak time if longer soak times are

n

eeded than given by the ACT/ECT-based CARB soak criteria.

a) A pending code will be stored after a malfunction has been detected on one driving cycle; a DTC will be stored after the same malfunction has been detected on the second consecutive driving cycle. The DTC will be erased after 40 warm-up cycles with no malfunction present, after the MIL has been

extinguished for the DTC.b) A DTC will be stored immediately upon detection of a malfunction. The DTC will be erased after 40 warm-up cycles with no malfunction present, after the MIL has been extinguished for the DTC.k) A DTC will be stored after a malfunction has been detected on one drive cycle.The DTC will be erased after 40 warm-up cycles with no malfunction present, after the MIL has been extinguished for that DTC.l) A DTC will be stored after a malfunction has been detected on six consecutive drive cycles. The DTC will be erased after 40 warm-up cycles with no malfunction present, after the MIL has been extinguished for that DTC.o)For intake air temperatures below 20 deg F, no DTC will set for indicated AIR malfunction.

s) A DTC will be stored after an evaporative system leak has been detected and the refueling debounce check has been completed on the subsequent

driving cycle

c)The MIL will be illuminated after a malfunction has been detected on two consecutive driving cycles.

The MIL will be extinguished after three consecutive driving cycles where the monitor was run without a malfunction.d)The MIL will blink immediately upon detection of a misfire rate that exceeds the catalyst damage threshold, regardless of whether fuel is shut off or not.

If the misfire rate drops below the catalyst damage threshold, the MIL will stay on solidly.

The MIL will be extinguished after three consecutive drive cycles where similar conditions have been seen without the malfunction.e)The MIL will be illuminated after a malfunction has been detected on two consecutive driving cycles.

The MIL will be extinguished after three consecutive drive cycles where similar conditions have been seen without the malfunction.f)For intake air temperatures below 32 deg F, the MIL will not illuminate for the indicated EGR DTCs.

For barometric pressures below 22.5"Hg, the MIL will not illuminate for the indicated EGR DTCs.

For intake air temperatures below 20 deg F, the MIL will not illuminate for the indicated AIR DTCs.

This prevents false MIL illumination due to ice in the EGR hoses or AIR switching valve(s).g)This monitor employs EWMA.

The MIL will be illuminated after a malfunction has been detected on two consecutive driving cycles after DTCs have been erased or Keep Alive Memory

h

as been erased (battery disconnect).

The MIL will be illuminated after a malfunction has been detected on up to six consecutive driving cycles during subsequent, "normal" customer driving.

The MIL will be extinguished after up to six consecutive driving cycles without a malfunction.

h) Some automatic transmission monitors are demonstrated following the USCAR Abbreviated On-Board Diagnostic Test Procedure for Vehicles Equipped

wi

th Automatic Transmissions.

This prevents false MIL illumination on this non-turbine speed sensor transmission application.

i)The MIL will be illuminated after a malfunction has been detected on the first driving cycle.

The MIL will be extinguished after three consecutive driving cycles where the monitor was run without a malfunction.j)A DTC will be set after a malfunction has been detected on two consecutive driving cycles.

m) MIL will be illuminated after a malfunction has been detected on two consecutive driving cycles. MIL will be extinguished after the monitor has run

wi

thout a malfunction (same or subsequent drive cycle).

n) A check cap light will be illuminated after a malfunction has been detected on one driving cycle. The check cap light will be extinguished after the monitor

h

as run without a malfunction (same or subsequent drive cycle).

MIL Illumination:

Notes:

Footnotes

Secondary Parameters

DTC Stora

ge:

EOBD 2009MY_V8 Vantage.xls

Notes 08/02/2005

15

Page 904 of 947

V8 4.7L EOBD Documentation

ASM Gearbox Tables

Page 905 of 947

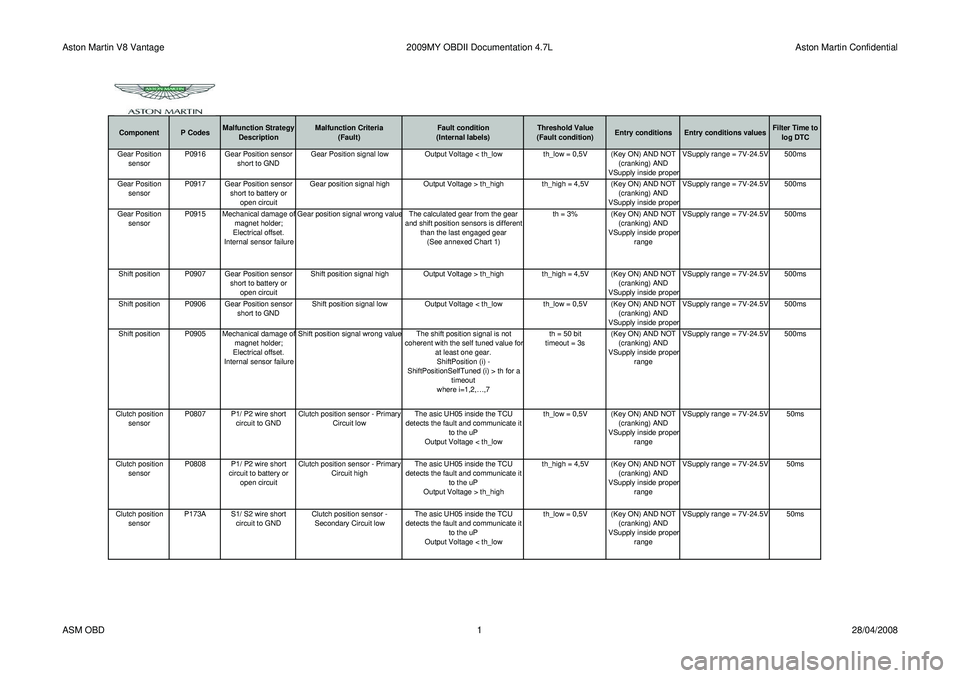

Aston Martin V8 Vantage2009MY OBDII Documentation 4.7L Aston Martin Confidential

Component P CodesMalfunction Strategy

Description Malfunction Criteria

(Fault) Fault condition

(Internal labels) Threshold Value

(Fault condition) Entry conditions Entry conditions values Filter Time to

log DTC

Gear Position sensor P0916 Gear Position sensor

short to GND Gear Position signal low Output Voltage < th_low th_low = 0,5V (Key ON) AND NOT

(cranking) AND

VSupply inside prope

r VSupply range = 7V-24.5V 500ms

Gear Position sensor P0917 Gear Position sensor

short to battery or open circuit Gear position signal high Output Voltage > th_high

th_high = 4,5V (Key ON) AND NOT

(cranking) AND

VSupply inside proper VSupply range = 7V-24.5V 500ms

Gear Position sensor P0915 Mechanical damage o

f

magnet holder;

Electrical offset.

Internal sensor failure Gear position signal wrong value The calculated gear from the gear

and shift position sensors is different than the last engaged gear(See annexed Chart 1) th = 3% (Key ON) AND NOT

(cranking) AND

VSupply inside prope

r

range VSupply range = 7V-24.5V 500ms

Shift position P0907 Gear Position sensor short to battery or open circuit Shift position signal high Output Voltage > th_high

th_high = 4,5V (Key ON) AND NOT

(cranking) AND

VSupply inside proper VSupply range = 7V-24.5V 500ms

Shift position P0906 Gear Position sensor short to GNDShift position signal low

Output Voltage < th_low th_low = 0,5V (Key ON) AND NOT

(cranking) AND

VSupply inside proper VSupply range = 7V-24.5V 500ms

Shift position P0905 Mechanical damage o

f

magnet holder;

Electrical offset.

Internal sensor failure Shift position signal wrong value The shift position signal is not

coherent with the self tuned value fo

r

at least one gear.ShiftPosition (i) -

ShiftPositionSelfTuned (i) > th for a timeout

where i=1,2,…,7 th = 50 bit

timeout = 3s (Key ON) AND NOT

(cranking) AND

VSupply inside prope

r

range VSupply range = 7V-24.5V 500ms

Clutch position sensor P0807 P1/ P2 wire short

circuit to GND Clutch position sensor - Primary

Circuit low The asic UH05 inside the TCU

detects the fault and communicate it to the uP

Output Voltage < th_low th_low = 0,5V (Key ON) AND NOT

(cranking) AND

VSupply inside proper

range VSupply range = 7V-24.5V 50ms

Clutch position sensor P0808 P1/ P2 wire short

circuit to battery or open circuit Clutch position sensor - Primary

Circuit high The asic UH05 inside the TCU

detects the fault and communicate it to the uP

Output Voltage > th_high th_high = 4,5V (Key ON) AND NOT

(cranking) AND

VSupply inside proper

range VSupply range = 7V-24.5V 50ms

Clutch position sensor P173A S1/ S2 wire short

circuit to GND Clutch position sensor -

Secondary Circuit low The asic UH05 inside the TCU

detects the fault and communicate it to the uP

Output Voltage < th_low th_low = 0,5V (Key ON) AND NOT

(cranking) AND

VSupply inside proper

range VSupply range = 7V-24.5V 50ms

ASM OBD

128/04/2008

Page 906 of 947

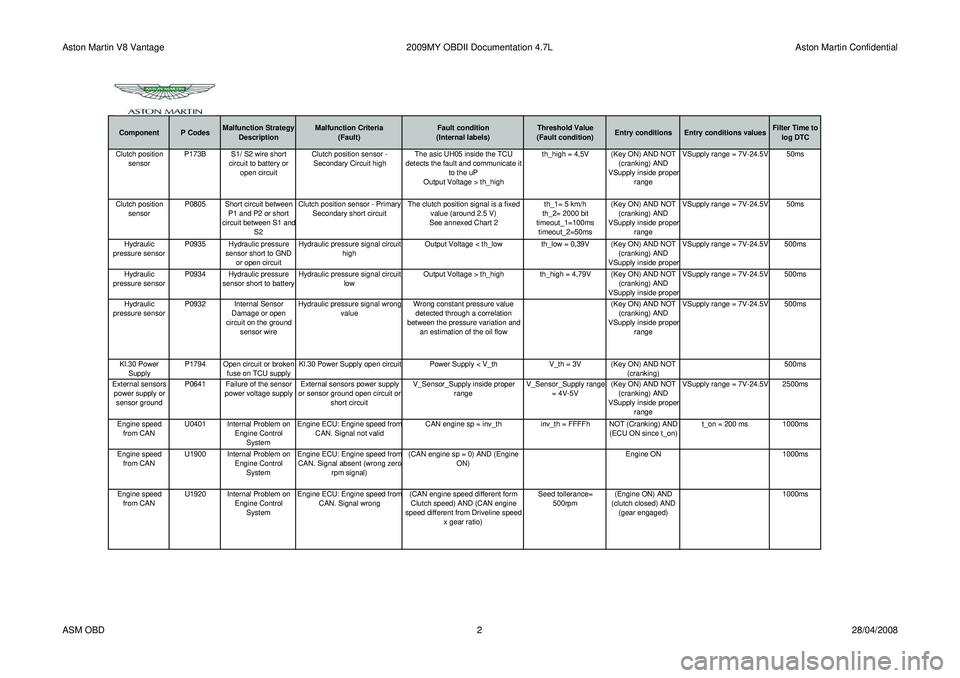

Aston Martin V8 Vantage2009MY OBDII Documentation 4.7L Aston Martin Confidential

Component P CodesMalfunction Strategy

Description Malfunction Criteria

(Fault) Fault condition

(Internal labels) Threshold Value

(Fault condition) Entry conditions Entry conditions values Filter Time to

log DTCClutch position sensor P173B S1/ S2 wire short

circuit to battery or open circuit Clutch position sensor -

Secondary Circuit high The asic UH05 inside the TCU

detects the fault and communicate it to the uP

Output Voltage > th_high th_high = 4,5V (Key ON) AND NOT

(cranking) AND

VSupply inside prope

r

range VSupply range = 7V-24.5V 50ms

Clutch position sensor P0805 Short circuit between

P1 and P2 or short

circuit between S1 and S2 Clutch position sensor - Primary

Secondary short circuit The clutch position signal is a fixed

value (around 2.5 V)

See annexed Chart 2 th_1= 5 km/h

th_2= 2000 bit

timeout_1=100ms timeout_2=50ms (Key ON) AND NOT

(cranking) AND

VSupply inside proper

range VSupply range = 7V-24.5V 50ms

Hydraulic

pressure sensor P0935 Hydraulic pressure

sensor short to GND or open circuit Hydraulic pressure signal circuit

high Output Voltage < th_low th_low = 0,39V (Key ON) AND NOT

(cranking) AND

VSupply inside proper VSupply range = 7V-24.5V 500ms

Hydraulic

pressure sensor P0934 Hydraulic pressure

sensor short to battery Hydraulic pressure signal circuit

low Output Voltage > th_high th_high = 4,79V (Key ON) AND NOT

(cranking) AND

VSupply inside proper VSupply range = 7V-24.5V 500ms

Hydraulic

pressure sensor P0932 Internal Sensor

Damage or open

circuit on the ground sensor wire Hydraulic pressure signal wrong

value Wrong constant pressure value

detected through a correlation

between the pressure variation and an estimation of the oil flow (Key ON) AND NOT

(cranking) AND

VSupply inside proper

range VSupply range = 7V-24.5V 500ms

Kl.30 Power Supply P1794 Open circuit or broken

fuse on TCU supply Kl.30 Power Supply open circuit Power Supply < V_th

V_th = 3V (Key ON) AND NOT

(cranking) 500ms

External sensors power supply or sensor ground P0641 Failure of the sensor

power voltage supply External sensors power supply

or sensor ground open circuit or short circuit V_Sensor_Supply inside proper

range V_Sensor_Supply range

= 4V-5V (Key ON) AND NOT

(cranking) AND

VSupply inside proper

range VSupply range = 7V-24.5V 2500ms

Engine speed from CAN U0401 Internal Problem on

Engine Control System Engine ECU: Engine speed fro

m

CAN. Signal not valid

CAN engine sp = inv_th inv_th = FFFFh NOT (Cranking) AND

(ECU ON since t_on)t_on = 200 ms 1000ms

Engine speed from CAN U1900 Internal Problem on

Engine Control System Engine ECU: Engine speed fro

m

CAN. Signal absent (wrong zero

rpm signal) (CAN engine sp = 0) AND (Engine

ON) Engine ON 1000ms

Engine speed from CAN U1920 Internal Problem on

Engine Control System Engine ECU: Engine speed fro

m

CAN. Signal wrong

(CAN engine speed different form

Clutch speed) AND (CAN engine

speed different from Driveline speed x gear ratio) Seed tollerance=

500rpm (Engine ON) AND

(clutch closed) AND (gear engaged) 1000ms

ASM OBD

228/04/2008

Page 907 of 947

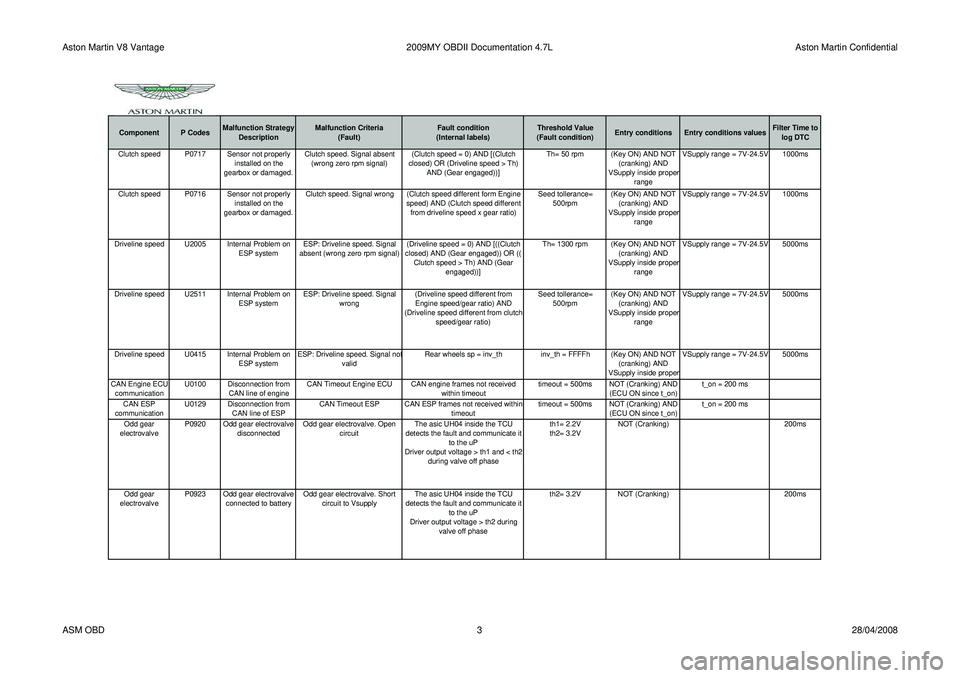

Aston Martin V8 Vantage2009MY OBDII Documentation 4.7L Aston Martin Confidential

Component P CodesMalfunction Strategy

Description Malfunction Criteria

(Fault) Fault condition

(Internal labels) Threshold Value

(Fault condition) Entry conditions Entry conditions values Filter Time to

log DTCClutch speed P0717 Sensor not properly installed on the

gearbox or damaged. Clutch speed. Signal absent

(wrong zero rpm signal) (Clutch speed = 0) AND [(Clutch

closed) OR (Driveline speed > Th) AND (Gear engaged))] Th= 50 rpm (Key ON) AND NOT

(cranking) AND

VSupply inside prope

r

range VSupply range = 7V-24.5V 1000ms

Clutch speed P0716 Sensor not properly installed on the

gearbox or damaged. Clutch speed. Signal wrong (Clutch speed different form Engine

speed) AND (Clutch speed different from driveline speed x gear ratio) Seed tollerance=

500rpm (Key ON) AND NOT

(cranking) AND

VSupply inside proper

range VSupply range = 7V-24.5V 1000ms

Driveline speed U2005 Internal Problem on ESP systemESP: Driveline speed. Signal

absent (wrong zero rpm signal) (Driveline speed = 0) AND [((Clutch

closed) AND (Gear engaged)) OR (( Clutch speed > Th) AND (Gear engaged))] Th= 1300 rpm (Key ON) AND NOT

(cranking) AND

VSupply inside proper

range VSupply range = 7V-24.5V 5000ms

Driveline speed U2511 Internal Problem on ESP systemESP: Driveline speed. Signal

wrong (Driveline speed different from

Engine speed/gear ratio) AND

(Driveline speed different from clutch speed/gear ratio) Seed tollerance=

500rpm (Key ON) AND NOT

(cranking) AND

VSupply inside proper

range VSupply range = 7V-24.5V 5000ms

Driveline speed U0415 Internal Problem on ESP systemESP: Driveline speed. Signal no

t

valid Rear wheels sp = inv_th

inv_th = FFFFh (Key ON) AND NOT

(cranking) AND

VSupply inside prope

r VSupply range = 7V-24.5V 5000ms

CAN Engine ECU communication U0100 Disconnection from

CAN line of engine CAN Timeout Engine ECU CAN engine frames not received

within timeouttimeout = 500ms NOT (Cranking) AND

(ECU ON since t_on) t_on = 200 ms

CAN ESP

communication U0129 Disconnection from

CAN line of ESP CAN Timeout ESP CAN ESP frames not received within

timeouttimeout = 500ms NOT (Cranking) AND

(ECU ON since t_on) t_on = 200 ms

Odd gear

electrovalve P0920 Odd gear electrovalve

disconnected Odd gear electrovalve. Open

circuit The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output voltage > th1 and < th2 during valve off phase th1= 2.2V

th2= 3.2V

NOT (Cranking)

200ms

Odd gear

electrovalve P0923 Odd gear electrovalve

connected to battery Odd gear electrovalve. Short

circuit to Vsupply The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output voltage > th2 during valve off phase th2= 3.2V

NOT (Cranking) 200ms

ASM OBD 328/04/2008

Page 908 of 947

Aston Martin V8 Vantage2009MY OBDII Documentation 4.7L Aston Martin Confidential

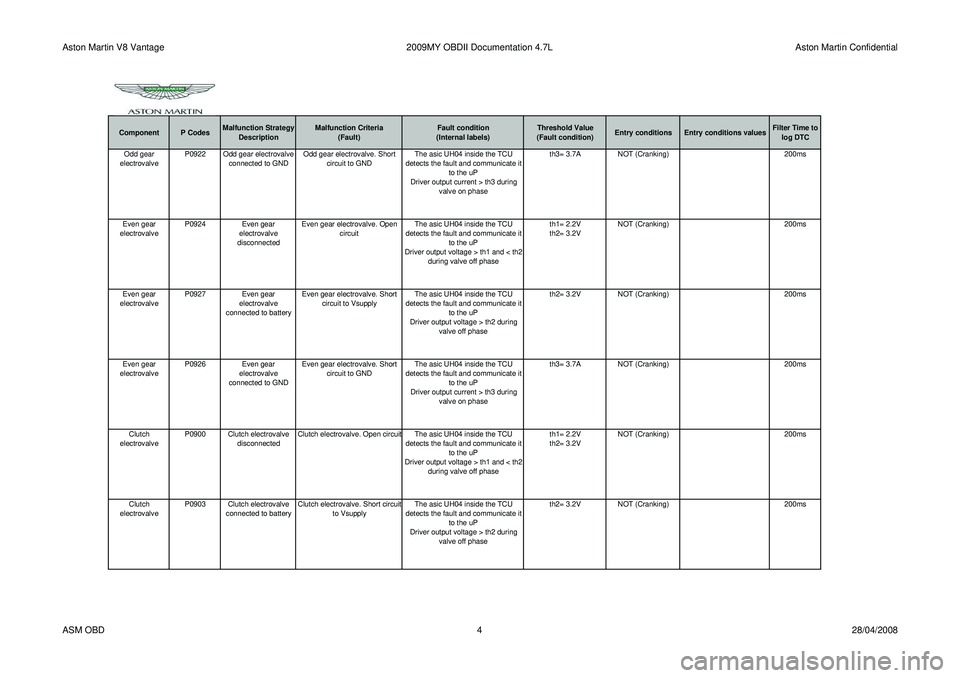

Component P CodesMalfunction Strategy

Description Malfunction Criteria

(Fault) Fault condition

(Internal labels) Threshold Value

(Fault condition) Entry conditions Entry conditions values Filter Time to

log DTCOdd gear

electrovalve P0922 Odd gear electrovalve

connected to GND Odd gear electrovalve. Short

circuit to GND The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output current > th3 during valve on phase th3= 3.7A

NOT (Cranking) 200ms

Even gear

electrovalve P0924 Even gear

electrovalve

disconnected Even gear electrovalve. Open

circuit The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output voltage > th1 and < th2 during valve off phase th1= 2.2V

th2= 3.2V

NOT (Cranking)

200ms

Even gear

electrovalve P0927

Even gear

electrovalve

connected to battery Even gear electrovalve. Short

circuit to Vsupply The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output voltage > th2 during valve off phase th2= 3.2V

NOT (Cranking) 200ms

Even gear

electrovalve P0926 Even gear

electrovalve

connected to GND Even gear electrovalve. Short

circuit to GND The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output current > th3 during valve on phase th3= 3.7A

NOT (Cranking) 200ms

Clutch

electrovalve P0900 Clutch electrovalve

disconnected Clutch electrovalve. Open circuit The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output voltage > th1 and < th2 during valve off phase th1= 2.2V

th2= 3.2V

NOT (Cranking)

200ms

Clutch

electrovalve P0903 Clutch electrovalve

connected to battery Clutch electrovalve. Short circuit

to Vsupply The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output voltage > th2 during valve off phase th2= 3.2V

NOT (Cranking) 200ms

ASM OBD 428/04/2008

Page 909 of 947

Aston Martin V8 Vantage2009MY OBDII Documentation 4.7L Aston Martin Confidential

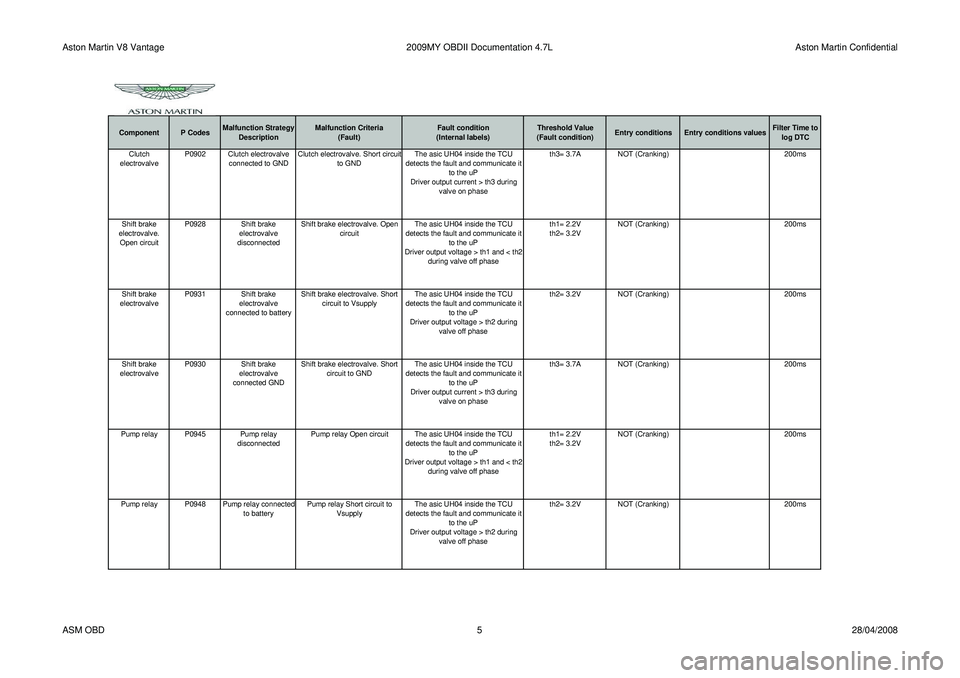

Component P CodesMalfunction Strategy

Description Malfunction Criteria

(Fault) Fault condition

(Internal labels) Threshold Value

(Fault condition) Entry conditions Entry conditions values Filter Time to

log DTCClutch

electrovalve P0902 Clutch electrovalve

connected to GND Clutch electrovalve. Short circuit

to GND The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output current > th3 during valve on phase th3= 3.7A

NOT (Cranking) 200ms

Shift brake

electrovalve. Open circuit P0928 Shift brake

electrovalve

disconnected Shift brake electrovalve. Open

circuit The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output voltage > th1 and < th2 during valve off phase th1= 2.2V

th2= 3.2V

NOT (Cranking)

200ms

Shift brake

electrovalve P0931 Shift brake

electrovalve

connected to battery Shift brake electrovalve. Short

circuit to Vsupply The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output voltage > th2 during valve off phase th2= 3.2V

NOT (Cranking) 200ms

Shift brake

electrovalve P0930 Shift brake

electrovalve

connected GND Shift brake electrovalve. Short

circuit to GND The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output current > th3 during valve on phase th3= 3.7A

NOT (Cranking) 200ms

Pump relay P0945 Pump relay disconnectedPump relay Open circuit The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output voltage > th1 and < th2 during valve off phase th1= 2.2V

th2= 3.2V

NOT (Cranking)

200ms

Pump relay P0948 Pump relay connected to batteryPump relay Short circuit to

Vsupply The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output voltage > th2 during valve off phase th2= 3.2V

NOT (Cranking) 200ms

ASM OBD 528/04/2008

Page 910 of 947

Aston Martin V8 Vantage2009MY OBDII Documentation 4.7L Aston Martin Confidential

Component P CodesMalfunction Strategy

Description Malfunction Criteria

(Fault) Fault condition

(Internal labels) Threshold Value

(Fault condition) Entry conditions Entry conditions values Filter Time to

log DTCPump relay P0947 Pump relay connected GNDPump relay Short circuit to GND The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output current > th3 during valve on phase th3= 3.7A

NOT (Cranking) 200ms

Clutch system P186D Clutch or actuator or valve damagedClutch not opening before gear

shifting Clutch not open in a timeout timeout = 500ms (Gear shifting in

progress) AND

(Clutch opening

Gear Box system P1734 Mechanical or hydraulic problemGear Box. Disengage failed

(mechanical causes) Gear not disengaged in a timeout timeout = 500ms (Gear shifting phase)

AND (disengage phase)

Gear Box system P1701 Mechanical or hydraulic problemGear Box. Wrong gear

engagement The gear which is going to be

engaged is not the requested one (Gear shifting phase)

Hydraulic circuit P0868 Hydraulic leakage Hydraulic circuit. Pressure low Comparison between sensor pressure signal and threshold = f(oil temperature)

pressure < th Th= 25 bar @ -30°C

Th= 40 bar @120°C linear interpolation (Engine ON) AND

NOT (cranking) 200ms

Power grounds P1710 Power grounds. Disconnection both ground pins Power grounds. Disconnection

both ground pins The diagnosis is based on the batter

y

voltage modification during the

activation of the clutch electrovalve. Ubatt < Ubatt0 - DltUbatt Ubatt0 = Ubatt before

starting the testDltUbatt = 2,5V Wake-up phase

ASM OBD

628/04/2008