ASTON MARTIN V8 VANTAGE 2010 Workshop Manual

Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 871 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 25 of 43

VCT Monitor

Variable Cam Timing System Monitor

VCT Hardware

Variable Cam Timing (VCT) enables rotation of the camshaft(s) relative to the crankshaft (phase-shifting)

as a function of engine operating conditions. Intake Only (phase-shifting only the intake cam) is used in

the AML application.

VCT is used primarily to increase internal residua l dilution at part throttle to reduce NOx, and to

improve fuel economy. With Intake Only VCT, the in take camshaft is advanced at part throttle and WOT

(at low to mid-range engine speeds) to open the in take valve earlier for increased residual dilution and

close the intake valve earlier in the compression stroke for increased power. When the engine is cold,

opening the intake valve earlier warms the charge which improves fuel vaporization for less HC

emissions; when the engine is warm, the residua l burned gasses limit peak combustion temperature to

reduce NOx formation.

The VCT system hardware consists of a contro l solenoid and a pulse ring on the camshaft. The PCM

calculates relative cam position using the CMP input to process variable reluctance sensor pulses coming

from the pulse ring mounted on the camshaft. Each pul se wheel has N + 1 teeth where N = the number of

cylinders per bank. The N equally spaced teeth are used for cam phasing; the remaining tooth is used to

determine cylinder # 1 position. Relative cam position is calculated by measuring the time between the

rising edge of profile ignition pickup (PIP ) and the falling edges of the VCT pulses.

VCT Diagnostic

The PCM continually calculates a cam position error value based on the difference between the desired

and actual position and uses this information to cal culate a commanded duty cycle for the VCT solenoid

valve. When energized, engine oil is allowed to flow to the VCT unit thereby advancing and retarding cam

timing. The VCT logic calculates the instantaneous va riance in actual cam position (the squared difference

between actual cam position and commanded cam position), then calculates the long term variance using a

rolling average filter (Exponentially Weighted Moving Average).

If the VCT system is stuck or operates with an consta nt error relative to the target position, the monitor

will detect a variance which will quickly accumulate. There are three variance indices that monitor cam

variance in the retard direction, the advance directi on, and for V engines, the difference between banks. If

any variance index is greater than the malfunction threshold, a VCT target error malfunction will be

indicated (P0011, P0012 Bank 1, P0021, P0022 Bank 2).

The VCT solenoid output driver in the PCM is check ed electrically for open circuit and shorts (P0010

Bank 1, P0020 Bank 2).

VCT Monitor Operation:

Page 872 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 26 of 43

Page 873 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 27 of 43

Comprehensive Component Monitor - Engine

General Inputs

Analog inputs such as Ambient Air Temperature (P0072, P0073), Intake Air Temperature (P0112, P0113),

Engine Coolant Temperature (P0117, P0118), Cylinder Head Temperature (P1289, P1290), Mass Air Flow

(P0102, P0103) and Manifold Absolute Pressure (P0107, P0108) are checked for opens, shorts, or out-of-

range values by monitoring the analog -to-digital (A/D) input voltage.

Analog Sensor Check Operation:

DTCs P0072, P0073, P0112, P0113, P0117, P0118, P0102, P0103, P0107, P0108,

P1289, P1290

Monitor execution continuous

Monitor Sequence none

Monitoring Duration 5 seconds to register a malfunction

Typical analog sensor check malfunction thresholds:

Voltage < 0.20 volts or voltage > 4.80 volts

On Vehicles fitted with Cylinder Head Temperature (CHT ) Sensors, 'Fail Safe Cooling' can be applied if

the cylinder head temperature is too high. The P1299 DTC will be set under these conditions.

Loss of Keep Alive Memory (KAM) power (a separate wire feeding the PCM) results in a P1633 DTC and

immediate MIL illumination.

Loss or corruption of the Vehicle Identification (VID) Block in the PCM results in a P1639 DTC and

immediate MIL illumination.

Ignition

Electronic Ignition systems (Electronic Distributorless Ignition System - EDIS or Coil on Plug - COP)

systems are used on all applications.

The EDIS system, located in the PCM, processes the 36 (or 40) tooth crankshaft position signal to

generate a low data rate PIP signal to control a 4 or 6 terminal 'double-ended' coil pack. The 'double ended'

coils fire a pair of spark plugs simultaneously - one is on its compression stroke, the other on its exhaust

stroke. The COP system also uses the EDIS system in the same way as described above, however each

sparkplug has it’s own coil which is fired only once on the compression stroke.

The ignition system is checked by monitoring three ignition signals during normal vehicle operation:

Profile Ignition Pickup (CKP, commonly known as PIP), the timing reference signal derived from the crankshaft 36-tooth wheel and processed by the EDIS system. PIP is a 50% duty cycle, square

wave signal that has a rising edge at 10 ° BTDC.

Camshaft IDentification (CMP, commonly known at CID), a signal derived from the camshaft to identify the #1 cylinder

Page 874 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 28 of 43

Ignition Diagnostic Monitor (IDM), a signal which indicates that the primary side of the coil has

fired. This signal is received as a digital pulsewidth signal from the EDIS system which process

the high voltage flyback signal from the primary side coil.

The relationship between successive PIP events is ev aluated to determine whether the PIP signal is

rational. Too large a change in 3 successive PIP indicates a missing or noisy PIP signal (P0320 or P0321).

Then the CMP edge count is compared to the PIP e dge count. If the proper ratio of CMP events to PIP

events is not being maintained (for example, 1 CMP e dge for every 8 PIP edges for an 8-cylinder engine),

it indicates a missing or noisy CMP signal (P0340). Finally, the relationship between IDM edges and PIP

edges is evaluated. If there is not an IDM edge (co il firing) for every PIP edge (commanded spark event),

the PCM will look for a pattern of failed IDM events to determine which ignition coil has failed circuit

continuity (P0351-56).

Ignition System Check Operation:

DTCs P0320 / P0321 (CKP), P0340 (CMP), P0351 - P0358 (Coil Primary)

Monitor execution continuous

Monitor Sequence none

Monitoring Duration < 5 seconds

Typical ignition check entry conditions : Minimum Maximum

Engine RPM for CKP, CMP 200 rpm

Engine RPM for coil primary 200 rpm

Typical ignition check malfunction thresholds:

For PIP : Time between PIP edges : > 350 milliseconds

Ratio of current PIP period to last two periods : < 0.75 > 1.75

For CMP : Ratio of PIP events to CMP events: 4:1, 6:1, 8:1 or 10:1 based on engine cyl.

For coils : Ratio of PIP events to IDM events: 1:1

General Outputs

The Fuel Injectors are checked electrically for open and short circuit (P0201 to P0208).

The Idle Air Control (IAC) solenoid is checked electrically for open and shorts (P1504).

The Purge Solenoid or Vapour Management Valve output circuit is checked for opens and shorts (P0443).

Purge Solenoid / VMV Check Operation:

DTCsP0443

Monitor execution continuous (5 seconds to identify malfunction/obtain smart driver status)

Monitor Sequencenone

Monitoring Duration 5 seconds for electrical malfunctions

Typical Purge Solenoid / VMV component malfunction thresholds:

P0443 open / shorted at 0 and 100% duty cycle

Page 875 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 29 of 43

The Intake Manifold Runner Control (IMRC) is a syst em which uses dual intake runners to supply air to

each cylinder. The secondary runners are normally closed, but the PCM opens them under high rpm

conditions when the driver is demanding additiona l power from the engine. The IMRC system can be

actuated using an electric motor or a vacuum moto r. The IMRC system is functionally checked by

monitoring the runner control plates using switches. If the actual position of the runner control plates does

not match the commanded position, a malfunction of the IMRC system is indicated (P1518, P1519).

The Swirl Control Valve (SCV) is a system which uses di fferent regions of the Intake plenum to influence

the pattern of the airflow into the combustion chamber.

It is important to note that this functional / rationality check may or may not be a MIL Code. This is

dependent on whether the EOBD Thresholds are exceeded.

IMRC / SCV System Check Operation:

DTCs P1520 (IMRC input switch electrical check)

P1518, P 1519 (IMRC stuck open functional check)

Monitor execution continuous

Monitor Sequence none

Monitoring Duration 5 seconds

Typical IMRC functional check malfunction thresholds

IMRC plates do not match commanded position (functional)

IMRC switches open/shorted (electrical)

Camshaft Position Control (also known as Variable Cam Ti ming) is a system which is able to advance and

retard camshaft timing relative to the crankshaft. Th is phasing is controlled by a duty-cycled output. The

output driver is checked electrically for opens and s horts (P1380). The system is checked functionally by

monitoring the closed loop phase control correction. If the proper phasing cannot be maintained and the

system has an advance or retard error greater than the malfunction threshold, a CPC control malfunction is

indicated (P1381, P1383).

It is important to note that the functional / rationality checks may or may not be a MIL Code. This is

dependent on whether the EOBD Thresholds are exceeded.

Camshaft Position Control System Check Operation:

DTCs P1380 (CPC output electrical check)

P1381 (CPC timing over-advanced functional check)

P1383 (CPC timing over-retarded functional check)

Monitor execution continuous

Monitor Sequence ECT > 150 oF

Monitoring Duration 5 seconds

Typical CPC functional check malfunction thresholds:

timing over-advanced/over-retard ed by > 10 crankshaft degrees

Engine CCM temporary disablement conditions ( other than entry requirements ) :

None, except CPC does not operate (and is therefore not checked) if ACT/IAT, ECT/CHT, MAF/MAP or

TP sensors are malfunctioning.

Page 876 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 30 of 43

Comprehensive Component Monitor - Manual Transmission.

General.

The MIL is illuminated for all emissions relate d electrical component malfunctions. A manual

transmission vehicle will have either a Vehicle Speed Sensor (VSS) or an Output Shaft Speed Sensor

(OSS). The MIL will illuminate if the speed signal is declared as zero when the vehicle is inferred to be

moving.

Transmission Inputs

Vehicle Speed Sensor Check Operation:

DTCs P0500

Monitor execution continuous

Monitor Sequence none

Monitoring Duration 30 seconds

Typical VSS check entry conditions : Minimum Maximum

Load 0.5

Engine rpm 1900 rpm 4500 rpm

Typical VSS malfunction thresholds:

Vehicle is inferred to be moving with positive driving torque for 5 seconds.

Output Shaft Speed Sensor Functional Check Operation:

DTCs P0720

Monitor execution continuous

Monitor Sequence none

Monitoring Duration 30 seconds

Typical OSS check entry conditions : Minimum Maximum

Load 0.5

Engine rpm 1900 rpm 4500 rpm

Output shaft rpm 100 rpm

Typical OSS functional check malfunction thresholds:

Vehicle is inferred to be moving with positive driving torque and OSS < 100 to 200 rpm for 5 seconds.

Manual Transmission CCM temporary disablement conditions (other than entry requirements) :

None.

Page 877 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 31 of 43

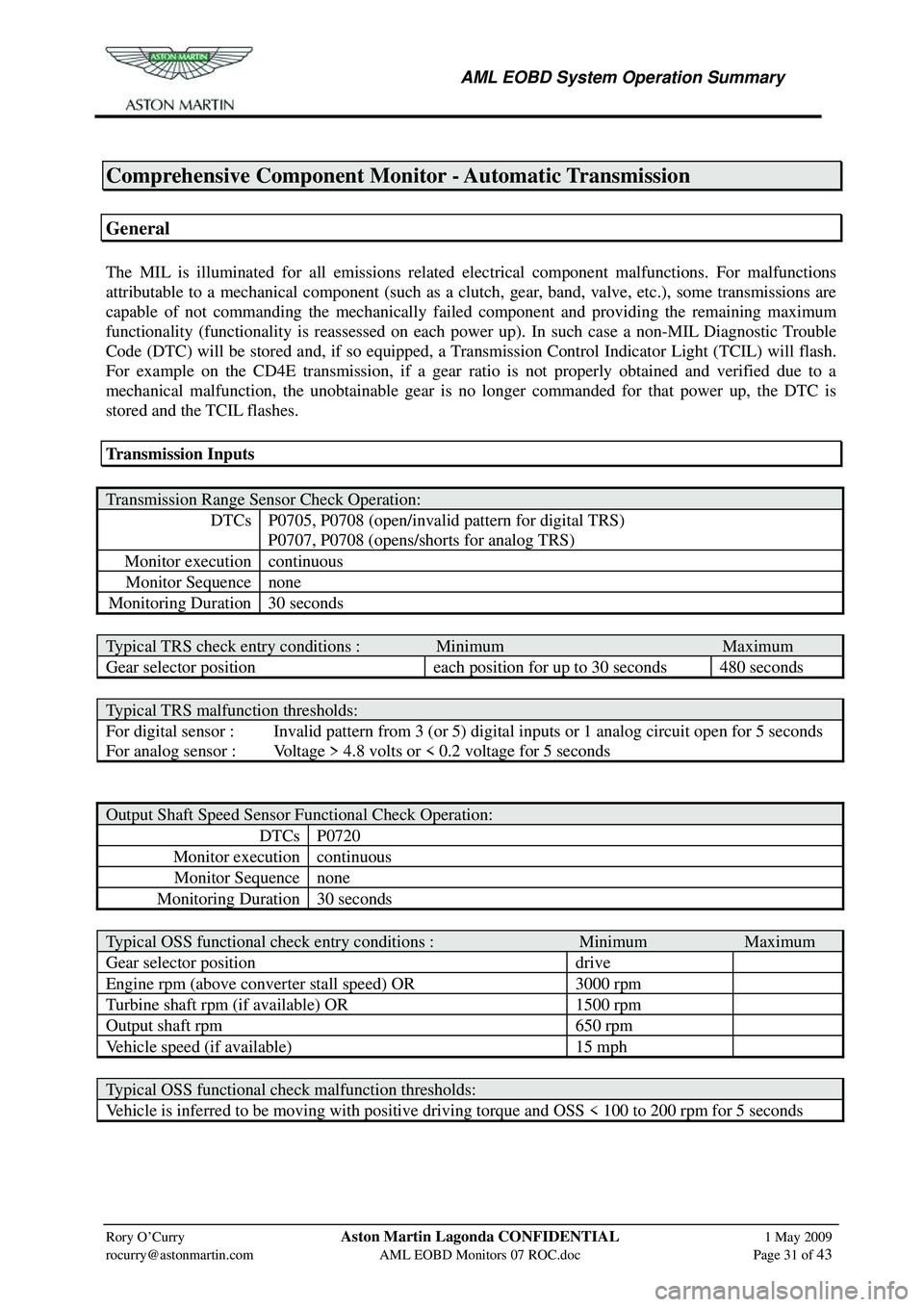

Comprehensive Component Monitor - Automatic Transmission

General

The MIL is illuminated for all emissions related electrical component malfunctions. For malfunctions

attributable to a mechanical component (such as a clutch, gear, band, valve, etc.), some transmissions are

capable of not commanding the mechanically faile d component and providing the remaining maximum

functionality (functionality is reassessed on each power up). In such case a non-MIL Diagnostic Trouble

Code (DTC) will be stored and, if so equipped, a Transmission Control Indicator Light (TCIL) will flash.

For example on the CD4E transmission, if a gear ratio is not properly obtained and verified due to a

mechanical malfunction, the unobtainable gear is no longer commanded for that power up, the DTC is

stored and the TCIL flashes.

Transmission Inputs

Transmission Range Sensor Check Operation:

DTCs P0705, P0708 (open/invalid pattern for digital TRS)

P0707, P0708 (opens/shorts for analog TRS)

Monitor execution continuous

Monitor Sequence none

Monitoring Duration 30 seconds

Typical TRS check entry conditions : Minimum Maximum

Gear selector position each position for up to 30 seconds 480 seconds

Typical TRS malfunction thresholds:

For digital sensor : Invalid pattern from 3 (or 5) digital inputs or 1 analog circuit open for 5 seconds

For analog sensor : Voltage > 4.8 volts or < 0.2 voltage for 5 seconds

Output Shaft Speed Sensor Functional Check Operation:

DTCs P0720

Monitor execution continuous

Monitor Sequence none

Monitoring Duration 30 seconds

Typical OSS functional check entry conditions : Minimum Maximum

Gear selector position drive

Engine rpm (above converter stall speed) OR 3000 rpm

Turbine shaft rpm (if available) OR 1500 rpm

Output shaft rpm 650 rpm

Vehicle speed (if available) 15 mph

Typical OSS functional check malfunction thresholds:

Vehicle is inferred to be moving with positive driving torque and OSS < 100 to 200 rpm for 5 seconds

Page 878 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 32 of 43

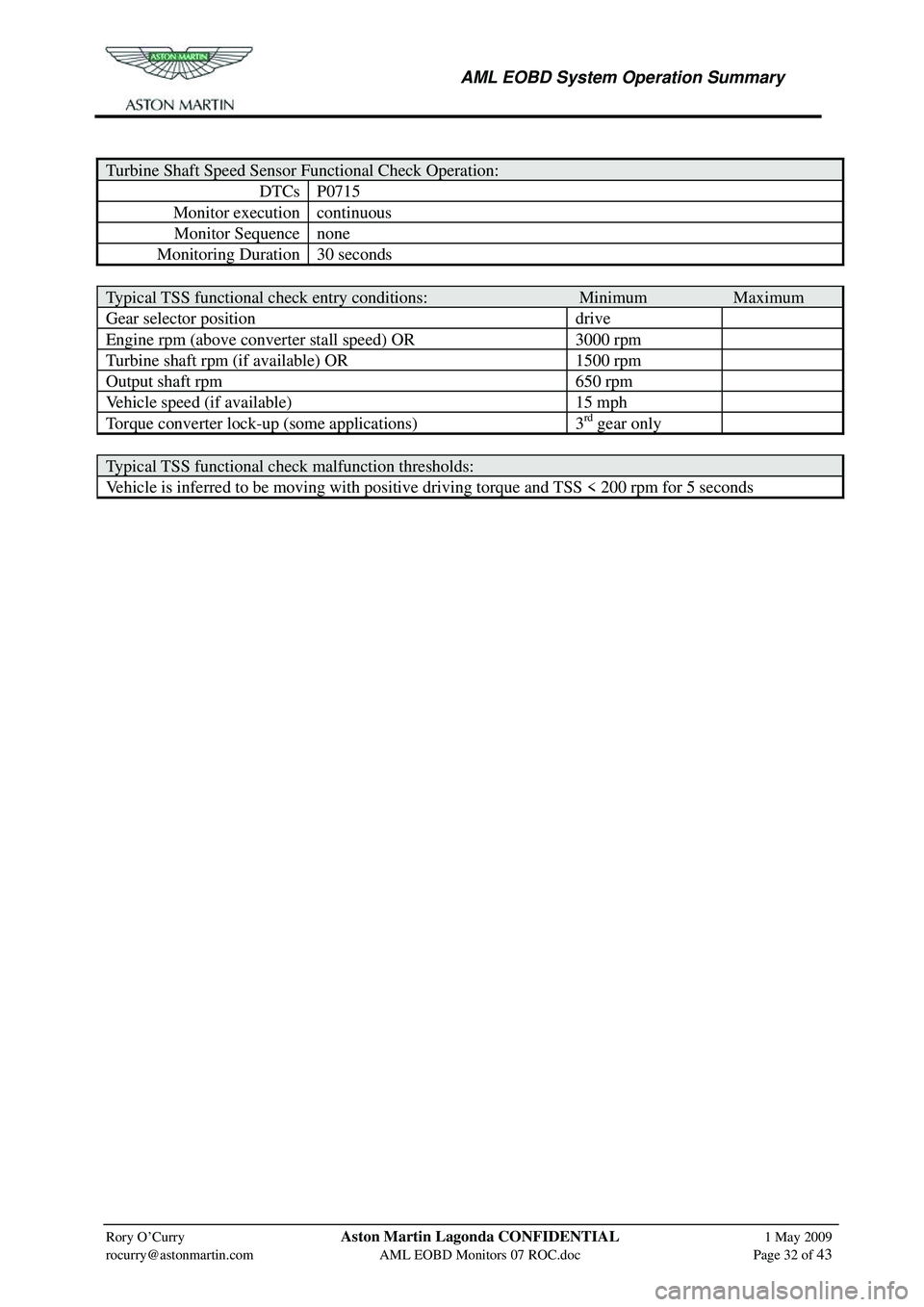

Turbine Shaft Speed Sensor Functional Check Operation:

DTCs P0715

Monitor execution continuous

Monitor Sequence none

Monitoring Duration 30 seconds

Typical TSS functional check entry conditions: Minimum Maximum

Gear selector position drive

Engine rpm (above converter stall speed) OR 3000 rpm

Turbine shaft rpm (if available) OR 1500 rpm

Output shaft rpm 650 rpm

Vehicle speed (if available) 15 mph

Torque converter lock-up (some applications) 3rd gear only

Typical TSS functional check malfunction thresholds:

Vehicle is inferred to be moving with positiv e driving torque and TSS < 200 rpm for 5 seconds

Page 879 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 33 of 43

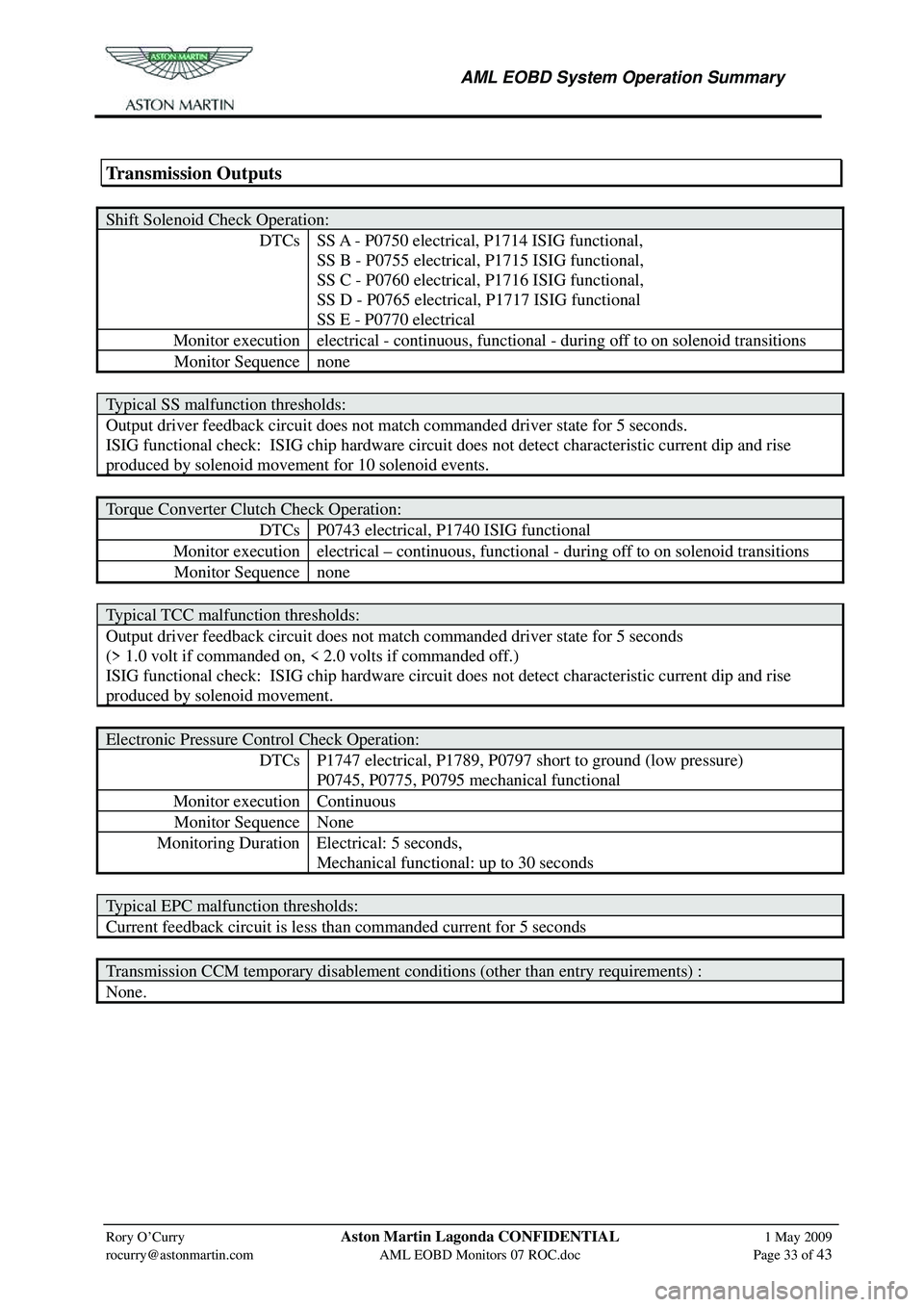

Transmission Outputs

Shift Solenoid Check Operation:

DTCs SS A - P0750 electrical, P1714 ISIG functional,

SS B - P0755 electrical, P1715 ISIG functional,

SS C - P0760 electrical, P1716 ISIG functional,

SS D - P0765 electrical, P1717 ISIG functional

SS E - P0770 electrical

Monitor execution electrical - continuous, functi onal - during off to on solenoid transitions

Monitor Sequence none

Typical SS malfunction thresholds:

Output driver feedback circuit does not match commanded driver state for 5 seconds.

ISIG functional check: ISIG chip hardware circu it does not detect characteristic current dip and rise

produced by solenoid movement for 10 solenoid events.

Torque Converter Clutch Check Operation:

DTCs P0743 electrical, P1740 ISIG functional

Monitor execution electrical – continuous, functi onal - during off to on solenoid transitions

Monitor Sequence none

Typical TCC malfunction thresholds:

Output driver feedback circuit does not match commanded driver state for 5 seconds

(> 1.0 volt if commanded on, < 2.0 volts if commanded off.)

ISIG functional check: ISIG chip hardware circu it does not detect characteristic current dip and rise

produced by solenoid movement.

Electronic Pressure Control Check Operation:

DTCs P1747 electrical, P1789, P0797 short to ground (low pressure)

P0745, P0775, P0795 mechanical functional

Monitor execution Continuous

Monitor Sequence None

Monitoring Duration Electrical: 5 seconds,

Mechanical functional: up to 30 seconds

Typical EPC malfunction thresholds:

Current feedback circuit is less than commanded current for 5 seconds

Transmission CCM temporary disablement conditions (other than entry requirements) :

None.

Page 880 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 34 of 43

6HP26 Automatic Transmission

This transmission is operated by a stand-alone transmission control module (TCM). The MIL related

Diagnostic Trouble Codes will be transmitted via CAN to the Engine Control Module (ECM), and the

MIL illuminated, for all emissions related electrical and mechanical component malfunctions. For

malfunctions attributable to a mechanical component, this transmission may be capable of not

commanding the mechanically failed component a nd providing the remaining maximum functionality

(functionality may be reassessed on each power up). The TCM may be interrogated for transmission

information attributable to setting either code. The TCM Diagnostic Trouble Codes are addressed via a

separate document enclosed.

Auto Shift Manual (ASM) Transmission

The ASM system is based around a standard manual transmission with a clutch and mechanical selection

of a set range of gear ratios (in this case 6 speeds). In this application both clutch and gear selection

operations are controlled via a Transmission Contro l Module (TCM) which commands hydraulic actuators

based on commands from a number of inputs.

The driver actions of depressing and releasing the clutch pedal to control clutch actuation and the shifting

of gears using a gear lever have, in essence, been re placed by a TCM, hydraulic actuators and electronic

switches.

With ASM the demand to shift gears can either be direct from the driver (as in a conventional manual

transmission), or controlled automatically by the system based on parameters such as road speed, current

gear selected and throttle demand.

The MIL is illuminated for all emissions related electrical component malfunctions. For malfunctions

attributable to a mechanical component (such as a cl utch, gear, actuator, etc.), functionality is reassessed

on each power up. In such case a non-MIL or MIL Diagnos tic Trouble Code (DTC) will be stored and, if

so equipped, a Transmission Control Indicator Light will activate and/or a message will be displayed. For

example on the ASM transmission, if a gear selection is not properly obtained and verified due to a

mechanical malfunction, then the amber Transmission Control Indicator Light will activate and the

message center will display 'GEARBOX FAULT'. In addition, the powertrain MIL will activate and a

DTC will be stored. The TCM Diagnostic Trouble Cod es are addressed via a separate document enclosed.